ECO mode NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1404 of 2898

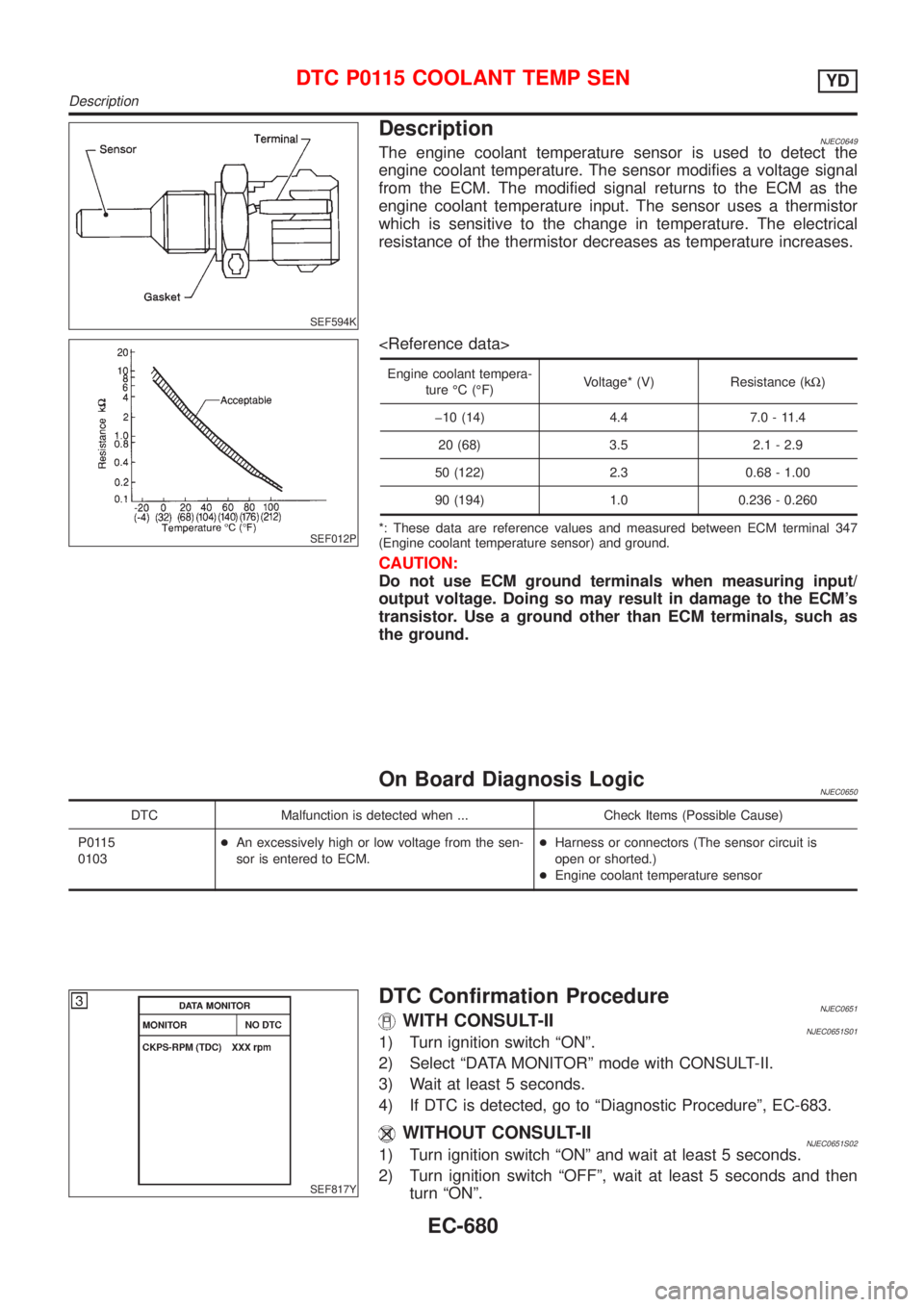

SEF594K

DescriptionNJEC0649The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature increases.

SEF012P

Engine coolant tempera-

ture ÉC (ÉF)Voltage* (V) Resistance (kW)

þ10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

*: These data are reference values and measured between ECM terminal 347

(Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis LogicNJEC0650

DTC Malfunction is detected when ... Check Items (Possible Cause)

P0115

0103+An excessively high or low voltage from the sen-

sor is entered to ECM.+Harness or connectors (The sensor circuit is

open or shorted.)

+Engine coolant temperature sensor

SEF817Y

DTC Confirmation ProcedureNJEC0651WITH CONSULT-IINJEC0651S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-683.

WITHOUT CONSULT-IINJEC0651S021) Turn ignition switch ªONº and wait at least 5 seconds.

2) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

DTC P0115 COOLANT TEMP SENYD

Description

EC-680

Page 1410 of 2898

![NISSAN ALMERA 2001 Service Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

434 W Accelerator position sensor[Ignition switch ªONº]

+Accelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

+Accelerator pe NISSAN ALMERA 2001 Service Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

434 W Accelerator position sensor[Ignition switch ªONº]

+Accelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

+Accelerator pe](/img/5/57348/w960_57348-1409.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

434 W Accelerator position sensor[Ignition switch ªONº]

+Accelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

+Accelerator pedal fully depressed3.0 - 4.3V

435 W/GAccelerator position switch

(Idle)[Ignition switch ªONº]

+Accelerator pedal fully releasedApproximately 0V

[Ignition switch ªONº]

+Accelerator pedal depressedBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNJEC0682

DTC Malfunction is detected when ... Check Items (Possible Cause)

P0120

0403+The relation between sensor and switch signals

is not in the nomal range during the specified

accelerator positions.+Harness or connectors

(The sensor circuit is open or shorted.)

+Accelerator position sensor

+Accelerator position switch

SEF817Y

DTC Confirmation ProcedureNJEC0683WITH CONSULT-IINJEC0683S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Depress and release fully accelerator pedal slowly.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-688.

WITHOUT CONSULT-IINJEC0683S021) Turn ignition switch ªONº.

2) Depress and release fully accelerator pedal slowly.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-688.

DTC P0120 ACCEL POS SENSORYD

ECM Terminals and Reference Value (Cont'd)

EC-686

Page 1416 of 2898

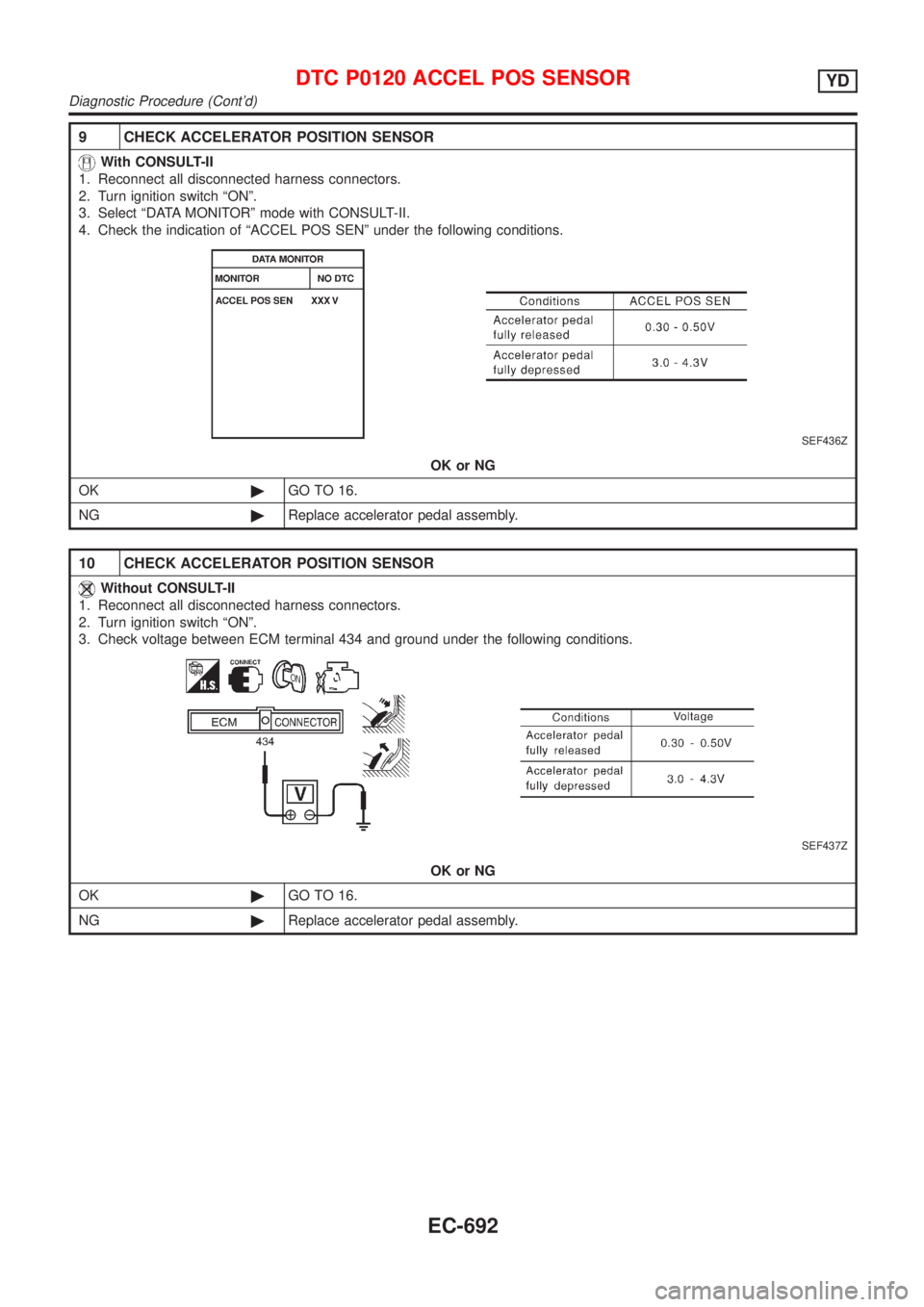

9 CHECK ACCELERATOR POSITION SENSOR

With CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Select ªDATA MONITORº mode with CONSULT-II.

4. Check the indication of ªACCEL POS SENº under the following conditions.

SEF436Z

OK or NG

OK©GO TO 16.

NG©Replace accelerator pedal assembly.

10 CHECK ACCELERATOR POSITION SENSOR

Without CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Check voltage between ECM terminal 434 and ground under the following conditions.

SEF437Z

OK or NG

OK©GO TO 16.

NG©Replace accelerator pedal assembly.

DTC P0120 ACCEL POS SENSORYD

Diagnostic Procedure (Cont'd)

EC-692

Page 1420 of 2898

SEF817Y

DTC Confirmation ProcedureNJEC0690Before performing the following procedure, confirm that bat-

tery voltage is more than 10V.

WITH CONSULT-IINJEC0690S011) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-698.

WITHOUT CONSULT-IINJEC0690S021) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle speed.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-698.

DTC P0335 CRANK POS SEN (TDC)YD

DTC Confirmation Procedure

EC-696

Page 1431 of 2898

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-710.

DTC P0571 BRAKE SWYD

DTC Confirmation Procedure (Cont'd)

EC-707

Page 1438 of 2898

SEC220B

DescriptionNJEC0734The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis LogicNJEC0735

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1107

0802+An excessively high or low voltage from the

absolute pressure sensor (built-into ECM) is sent

to ECM.+ECM

(ECCS-D control module)

SEF817Y

DTC Confirmation ProcedureNJEC0736WITH CONSULT-IINJEC0736S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-715.

WITHOUT CONSULT-IINJEC0736S021) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-715.

DTC P1107 ECM 10YD

Description

EC-714

Page 1441 of 2898

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0674Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNJEC0675

DTC Malfunction is detected when .... Check Items (Possible cause)

P1180

0402+An improper voltage signal from fuel temperature

sensor (Built-into electronic control fuel injection

pump) is sent to injection pump control unit.+Harness or connectors

(Electronic control fuel injection pump circuit is

open or shorted.)

+Electronic control fuel injection pump

SEF817Y

DTC Confirmation ProcedureNJEC0676WITH CONSULT-IINJEC0676S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-721.

WITHOUT CONSULT-IINJEC0676S021) Turn ignition switch ªONº and wait at least 2 seconds.

DTC P1180 P9´FUEL TEMP SENYD

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-717

Page 1442 of 2898

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-721.

DTC P1180 P9´FUEL TEMP SENYD

DTC Confirmation Procedure (Cont'd)

EC-718

Page 1448 of 2898

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0755Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNJEC0756

DTC Malfunction is detected when .... Check Items (Possible cause)

P1202

1002+Fuel cut control system does not function properly.+Harness or connectors

(Electronic control fuel circuit is open or shorted.)

+Electronic control fuel

SEF817Y

DTC Confirmation ProcedureNJEC0757WITH CONSULT-IINJEC0757S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-728.

DTC P1202 FUEL CUT SYSTEM2YD

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-724

Page 1449 of 2898

WITHOUT CONSULT-IINJEC0757S021) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-728.

DTC P1202 FUEL CUT SYSTEM2YD

DTC Confirmation Procedure (Cont'd)

EC-725