ECO mode NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1460 of 2898

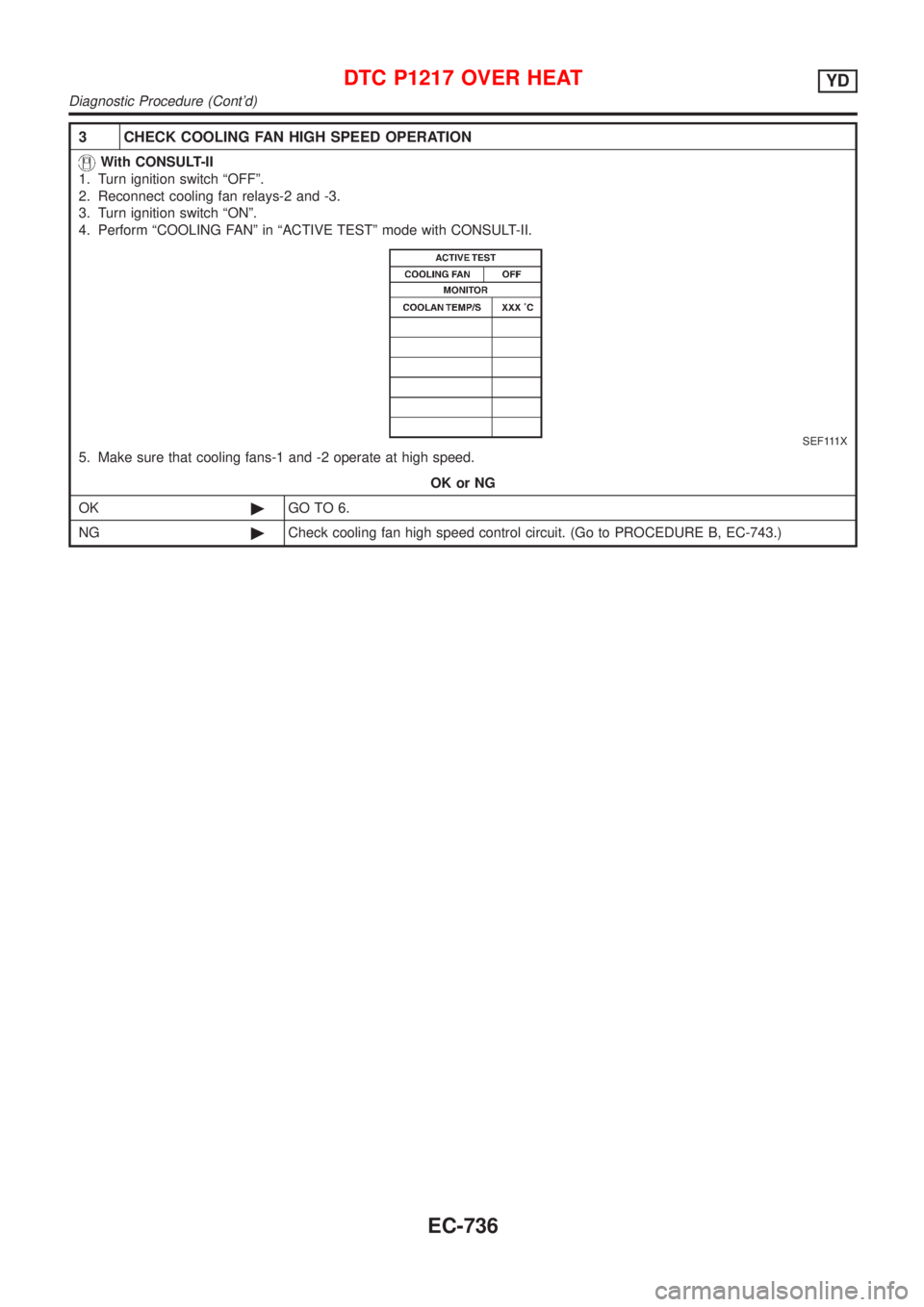

3 CHECK COOLING FAN HIGH SPEED OPERATION

With CONSULT-II

1. Turn ignition switch ªOFFº.

2. Reconnect cooling fan relays-2 and -3.

3. Turn ignition switch ªONº.

4. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

SEF111X

5. Make sure that cooling fans-1 and -2 operate at high speed.

OK or NG

OK©GO TO 6.

NG©Check cooling fan high speed control circuit. (Go to PROCEDURE B, EC-743.)

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont'd)

EC-736

Page 1470 of 2898

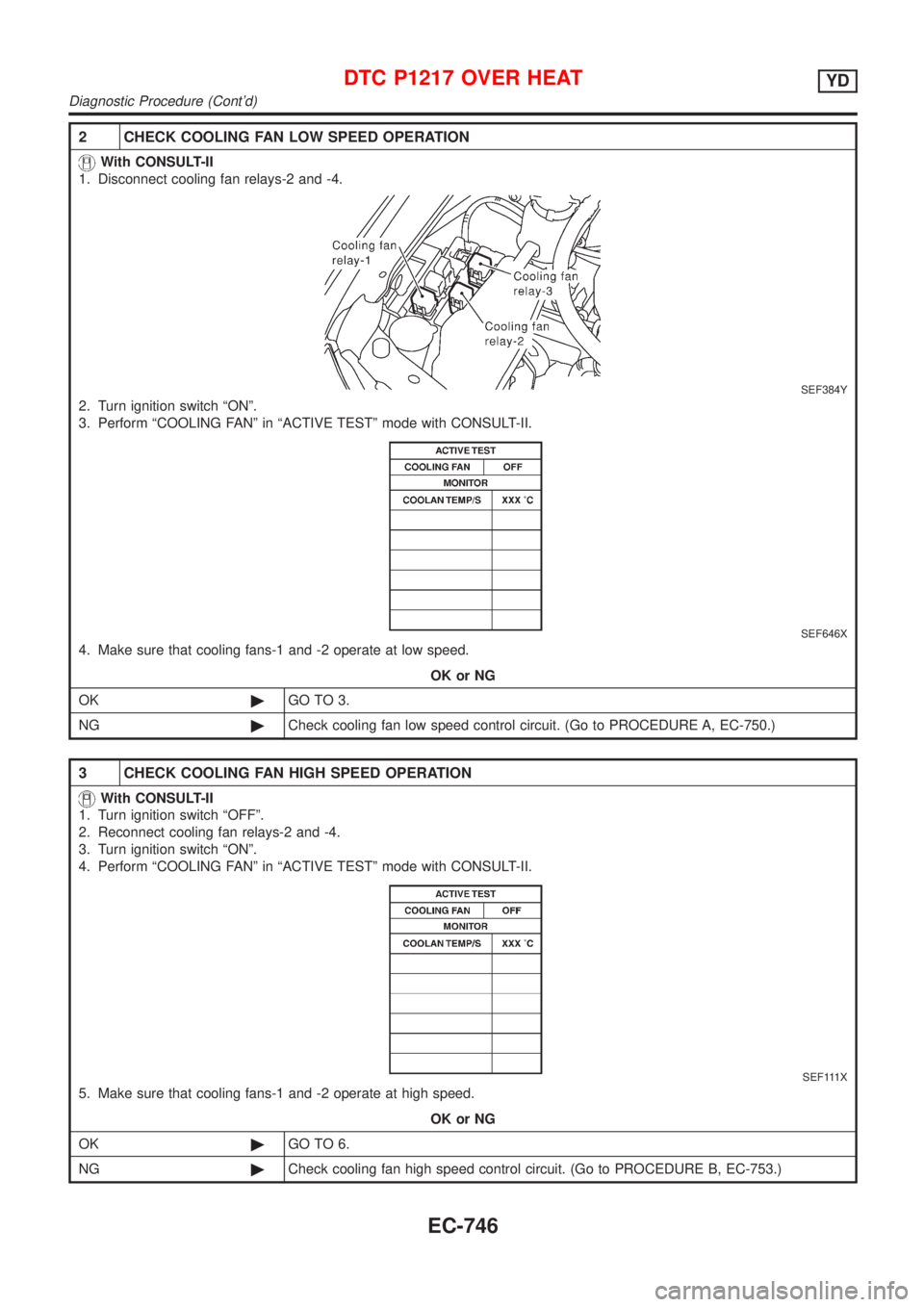

2 CHECK COOLING FAN LOW SPEED OPERATION

With CONSULT-II

1. Disconnect cooling fan relays-2 and -4.

SEF384Y

2. Turn ignition switch ªONº.

3. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

SEF646X

4. Make sure that cooling fans-1 and -2 operate at low speed.

OK or NG

OK©GO TO 3.

NG©Check cooling fan low speed control circuit. (Go to PROCEDURE A, EC-750.)

3 CHECK COOLING FAN HIGH SPEED OPERATION

With CONSULT-II

1. Turn ignition switch ªOFFº.

2. Reconnect cooling fan relays-2 and -4.

3. Turn ignition switch ªONº.

4. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

SEF111X

5. Make sure that cooling fans-1 and -2 operate at high speed.

OK or NG

OK©GO TO 6.

NG©Check cooling fan high speed control circuit. (Go to PROCEDURE B, EC-753.)

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont'd)

EC-746

Page 1482 of 2898

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0729Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

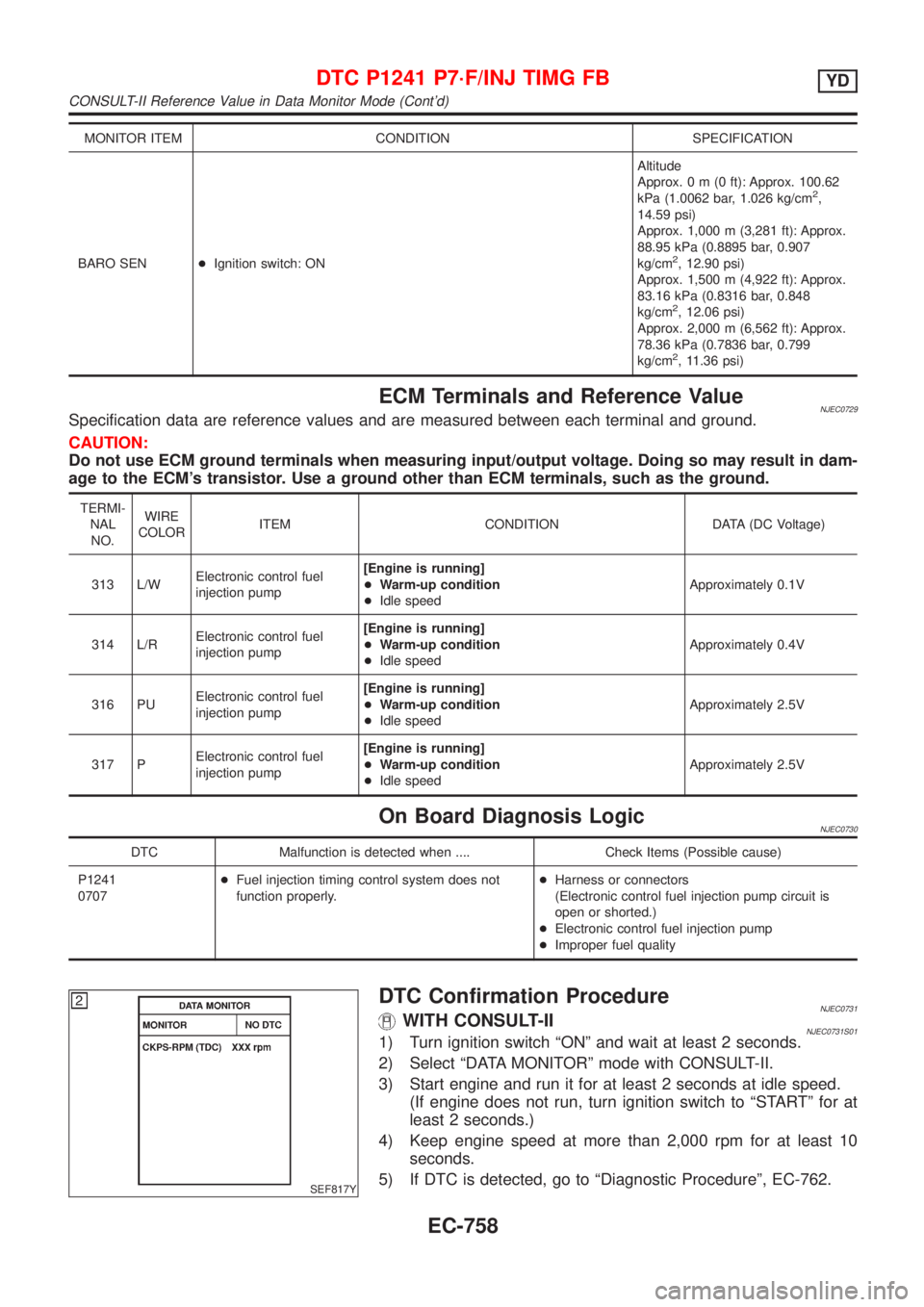

On Board Diagnosis LogicNJEC0730

DTC Malfunction is detected when .... Check Items (Possible cause)

P1241

0707+Fuel injection timing control system does not

function properly.+Harness or connectors

(Electronic control fuel injection pump circuit is

open or shorted.)

+Electronic control fuel injection pump

+Improper fuel quality

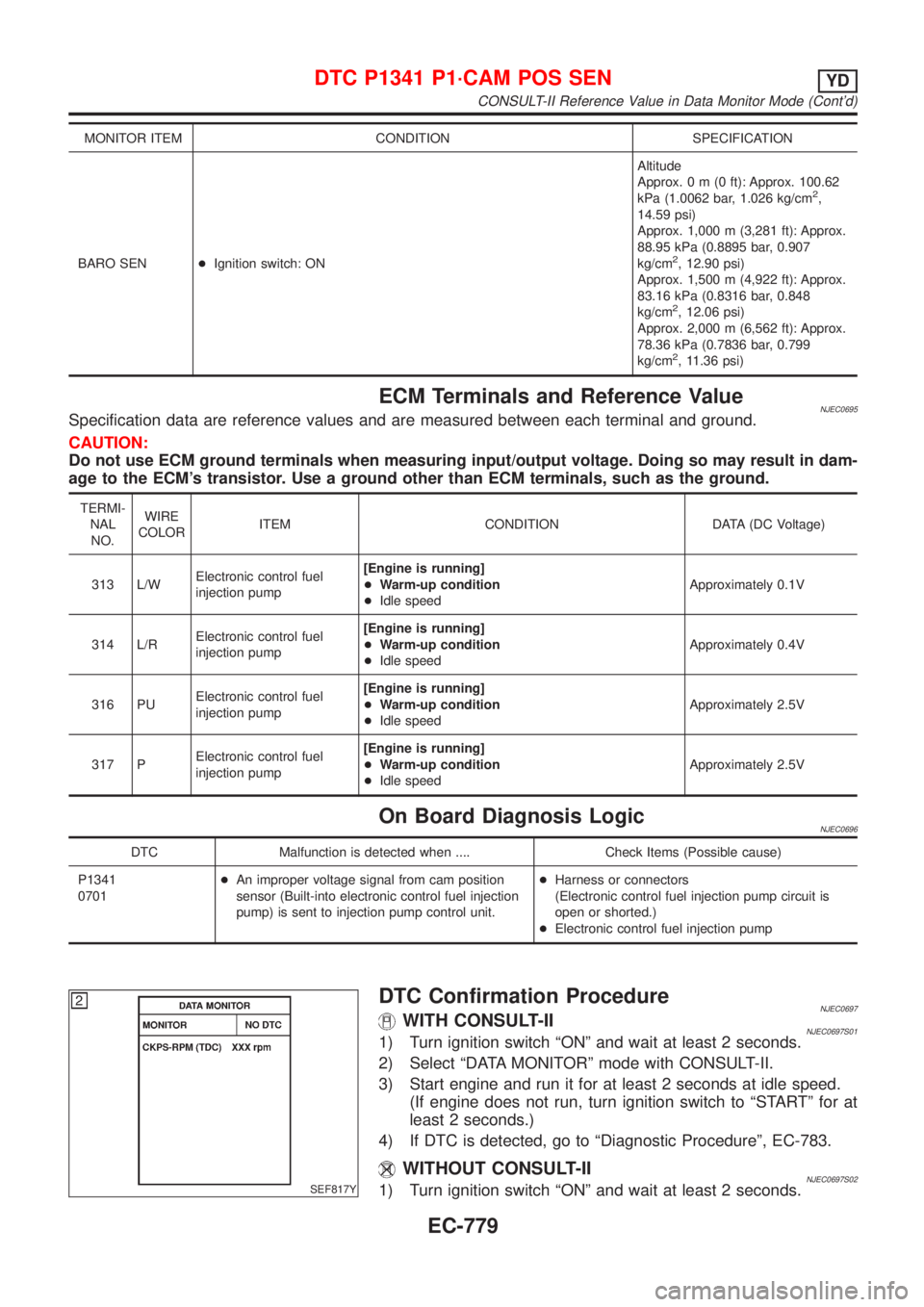

SEF817Y

DTC Confirmation ProcedureNJEC0731WITH CONSULT-IINJEC0731S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) Keep engine speed at more than 2,000 rpm for at least 10

seconds.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-762.

DTC P1241 P7´F/INJ TIMG FBYD

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-758

Page 1483 of 2898

WITHOUT CONSULT-IINJEC0731S021) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Keep engine speed at more than 2,000 rpm for at least 10

seconds.

4) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

5) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-762.

DTC P1241 P7´F/INJ TIMG FBYD

DTC Confirmation Procedure (Cont'd)

EC-759

Page 1489 of 2898

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0716Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNJEC0717

DTC Malfunction is detected when .... Check Items (Possible cause)

P1251

0704+Spill valve (Built-into electronic control fuel injec-

tion pump) does not function properly.+Harness or connectors

(Electronic control fuel injection pump circuit is

open or shorted.)

+Electronic control fuel injection pump

SEF817Y

DTC Confirmation ProcedureNJEC0718WITH CONSULT-IINJEC0718S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-769.

WITHOUT CONSULT-IINJEC0718S021) Turn ignition switch ªONº and wait at least 2 seconds.

DTC P1251 P4´SPILL/V CIRCYD

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-765

Page 1490 of 2898

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-769.

DTC P1251 P4´SPILL/V CIRCYD

DTC Confirmation Procedure (Cont'd)

EC-766

Page 1496 of 2898

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0702Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNJEC0703

DTC Malfunction is detected when .... Check Items (Possible cause)

P1337

0702+Injection pump control unit input signal [Crank-

shaft position sensor (TDC) signal] processing

function is malfunctioning.+Harness or connectors

(Electronic control fuel injection pump circuit is

open or shorted.)

+Electronic control fuel injection pump

SEF817Y

DTC Confirmation ProcedureNJEC0704WITH CONSULT-IINJEC0704S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC P0335 is detected, go to ªDiagnostic procedureº,

EC-698.

If DTC P1337 is detected, go to ªDiagnostic Procedureº,

EC-776.

DTC P1337 P2´DTC PULSE SIGYD

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-772

Page 1497 of 2898

WITHOUT CONSULT-IINJEC0704S021) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC P0335 is detected, go to ªDiagnostic Procedureº,

EC-698.

If DTC P1337 is detected, go to ªDiagnostic Procedureº,

EC-776.

DTC P1337 P2´DTC PULSE SIGYD

DTC Confirmation Procedure (Cont'd)

EC-773

Page 1503 of 2898

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0695Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNJEC0696

DTC Malfunction is detected when .... Check Items (Possible cause)

P1341

0701+An improper voltage signal from cam position

sensor (Built-into electronic control fuel injection

pump) is sent to injection pump control unit.+Harness or connectors

(Electronic control fuel injection pump circuit is

open or shorted.)

+Electronic control fuel injection pump

SEF817Y

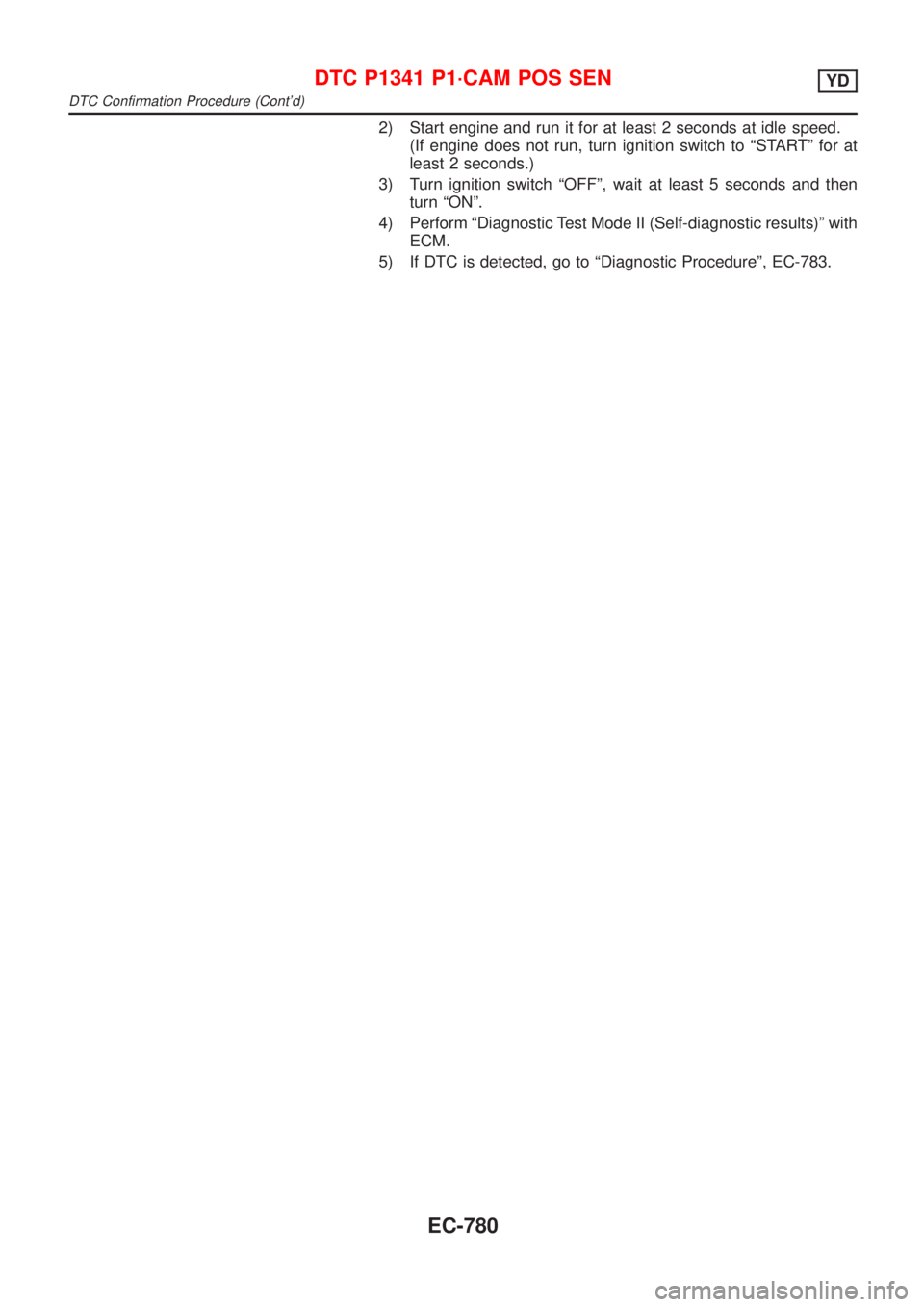

DTC Confirmation ProcedureNJEC0697WITH CONSULT-IINJEC0697S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-783.

WITHOUT CONSULT-IINJEC0697S021) Turn ignition switch ªONº and wait at least 2 seconds.

DTC P1341 P1´CAM POS SENYD

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-779

Page 1504 of 2898

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-783.

DTC P1341 P1´CAM POS SENYD

DTC Confirmation Procedure (Cont'd)

EC-780