ECO mode NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1510 of 2898

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0709Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNJEC0710

DTC Malfunction is detected when .... Check Items (Possible cause)

P1600

0703+Injection pump control unit receives incorrect

voltage signal from ECM continuously.+Harness or connectors

(Electronic control fuel injection pump circuit is

open or shorted.)

+Electronic control fuel injection pump

SEF817Y

DTC Confirmation ProcedureNJEC0711WITH CONSULT-IINJEC0711S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-790.

WITHOUT CONSULT-IINJEC0711S021) Turn ignition switch ªONº and wait at least 2 seconds.

DTC P1600 P3´PUMP COMM LINEYD

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-786

Page 1511 of 2898

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-790.

DTC P1600 P3´PUMP COMM LINEYD

DTC Confirmation Procedure (Cont'd)

EC-787

Page 1516 of 2898

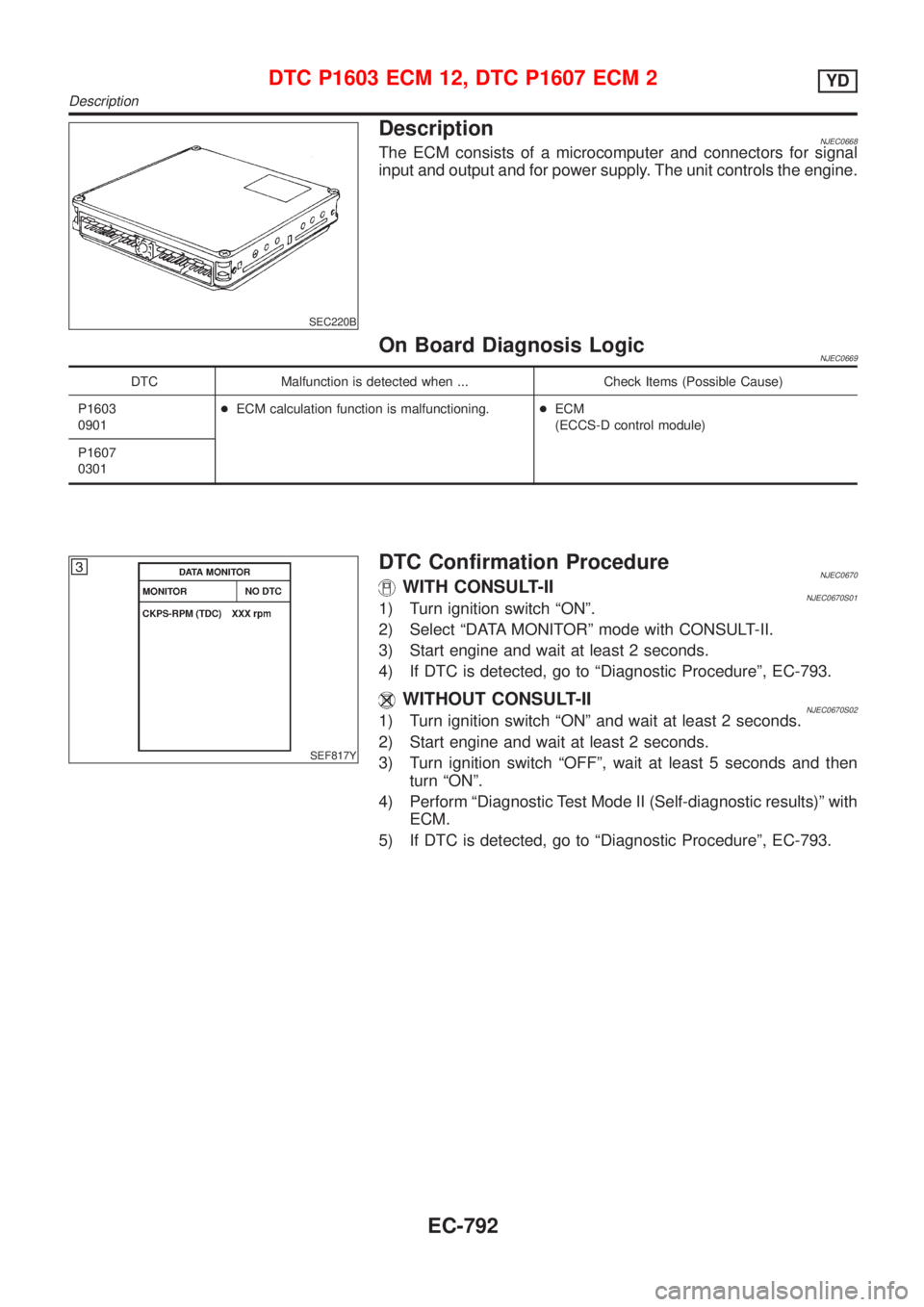

SEC220B

DescriptionNJEC0668The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis LogicNJEC0669

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1603

0901+ECM calculation function is malfunctioning.+ECM

(ECCS-D control module)

P1607

0301

SEF817Y

DTC Confirmation ProcedureNJEC0670WITH CONSULT-IINJEC0670S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-793.

WITHOUT CONSULT-IINJEC0670S021) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-793.

DTC P1603 ECM 12, DTC P1607 ECM 2YD

Description

EC-792

Page 1518 of 2898

ECM Terminals and Reference ValueNJEC0744Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

107

108

109R

R

RPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

325 G ECM relay (Self-shutoff)[Ignition switch ªONº]

[Ignition switch ªOFFº]

+For a few seconds after turning ignition switch

ªOFFº0-1V

[Ignition switch ªOFFº]

+A few seconds passed after turning ignition

switch ªOFFºBATTERY VOLTAGE

(11 - 14V)

507 W/R Ignition switch[Ignition switch ªOFFº]0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNJEC0745

DTC Malfunction is detected when .... Check Items (Possible Cause)

P1620

0902+An irregular voltage signal from the ECM relay is

sent to ECM.+Harness or connectors

(ECM relay circuit is open or shorted.)

+ECM relay

SEF817Y

DTC Confirmation ProcedureNJEC0746WITH CONSULT-IINJEC0746S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-797.

WITHOUT CONSULT-IINJEC0746S021) Turn ignition switch ªONº.

2) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-797.

DTC P1620 ECM RLYYD

ECM Terminals and Reference Value

EC-794

Page 1523 of 2898

SEC220B

DescriptionNJEC0749The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis LogicNJEC0750

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1621

0903+ECM input signal processing function is malfunc-

tioning.+ECM

(ECCS-D control module)

SEF817Y

DTC Confirmation ProcedureNJEC0751WITH CONSULT-IINJEC0751S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-800.

WITHOUT CONSULT-IINJEC0751S021) Turn ignition switch ªONº and wait at least 2 seconds.

2) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-800.

DTC P1621 ECM 15YD

Description

EC-799

Page 1525 of 2898

On Board Diagnosis LogicNJEC1258The ECM checks if battery voltage is within the tolerance range for the engine control system.

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1660

0502+An abnormally high or low voltage from the battery

is sent to ECM.+Incorrect jump starting

+Battery

+Alternator

+ECM

DTC Confirmation ProcedureNJEC1259With CONSULT-II

1) Check the following.

+Jumper cables are connected for jump starting.

+Battery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-801.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to SC-30, ªTrouble Diagnosisº.

4) Turn ignition switch ªONº and select ªDATA MONITORº mode with CONSULT-II.

5) Wait one minute.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-801.

If DTC is not detected, go to next step.

7) Start engine and wait one minute at idle.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-801.

Without CONSULT-II

1) Check the following.

+Jumper cables are connected for jump starting.

+Battery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-801.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to SC-30, ªTrouble Diagnosisº.

4) Turn ignition switch ªONº and wait one minute.

5) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-801.

If DTC is not detected, go to next step.

8) Start engine and wait one minute at idle.

9) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

10) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

11) If DTC is detected, go to ªDiagnostic Procedureº, EC-801.

Diagnostic ProcedureNJEC1260

1 INSPECTION START

Are jumper cables connected for the jump starting?

YesorNo

Ye s©GO TO 3.

No©GO TO 2.

DTC P1660 BATTERY VOLTAGEYD

On Board Diagnosis Logic

EC-801

Page 1528 of 2898

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,218 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0723Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNJEC0724

DTC Malfunction is detected when .... Check Items (Possible cause)

P1690

0705+Injection pump control unit does not function

properly.+Electronic control fuel injection pump

SEF817Y

DTC Confirmation ProcedureNJEC0725WITH CONSULT-IINJEC0725S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-805.

WITHOUT CONSULT-IINJEC0725S021) Turn ignition switch ªONº and wait at least 2 seconds.

DTC P1690 P5´PUMP C/MODULEYD

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-804

Page 1529 of 2898

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-805.

Diagnostic ProcedureNJEC0726

1 INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº, EC-804, again.

5. Is the DTC P1690 displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº, EC-804, again.

4. Perform ªDiagnostic Test Mode II (Self-diagnostic results)º.

5. Is the DTC 0705 displayed again?

YesorNo

Ye s©Replace electronic control fuel injection pump.

No©INSPECTION END

DTC P1690 P5´PUMP C/MODULEYD

DTC Confirmation Procedure (Cont'd)

EC-805

Page 1533 of 2898

Diagnostic ProcedureNJEC0763

1 INSPECTION START

Check fuel level, fuel supplying system, starter motor, etc.

OK or NG

OK©GO TO 2.

NG©Correct.

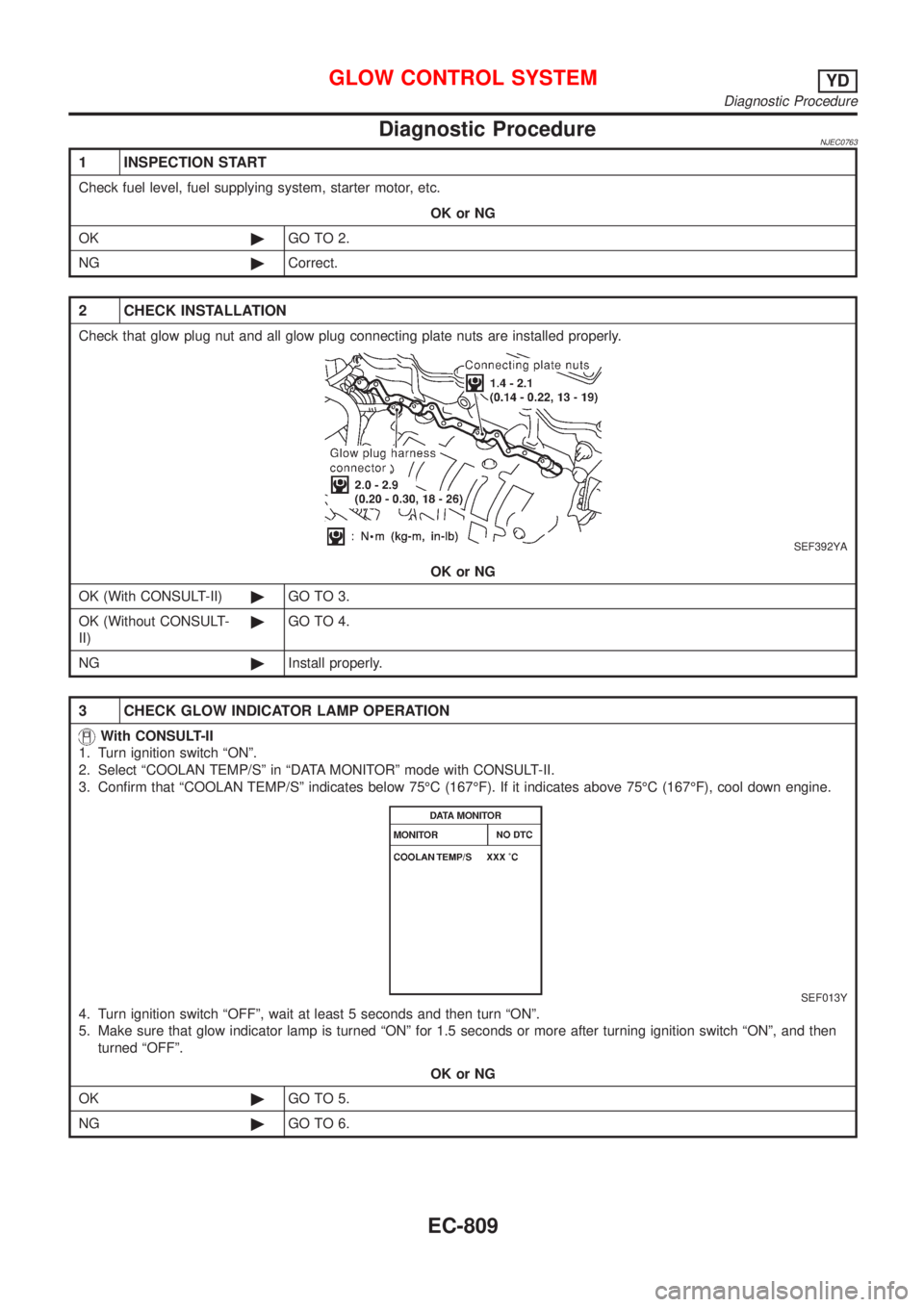

2 CHECK INSTALLATION

Check that glow plug nut and all glow plug connecting plate nuts are installed properly.

SEF392YA

OK or NG

OK (With CONSULT-II)©GO TO 3.

OK (Without CONSULT-

II)©GO TO 4.

NG©Install properly.

3 CHECK GLOW INDICATOR LAMP OPERATION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªCOOLAN TEMP/Sº in ªDATA MONITORº mode with CONSULT-II.

3. Confirm that ªCOOLAN TEMP/Sº indicates below 75ÉC (167ÉF). If it indicates above 75ÉC (167ÉF), cool down engine.

SEF013Y

4. Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

5. Make sure that glow indicator lamp is turned ªONº for 1.5 seconds or more after turning ignition switch ªONº, and then

turned ªOFFº.

OK or NG

OK©GO TO 5.

NG©GO TO 6.

GLOW CONTROL SYSTEMYD

Diagnostic Procedure

EC-809

Page 1546 of 2898

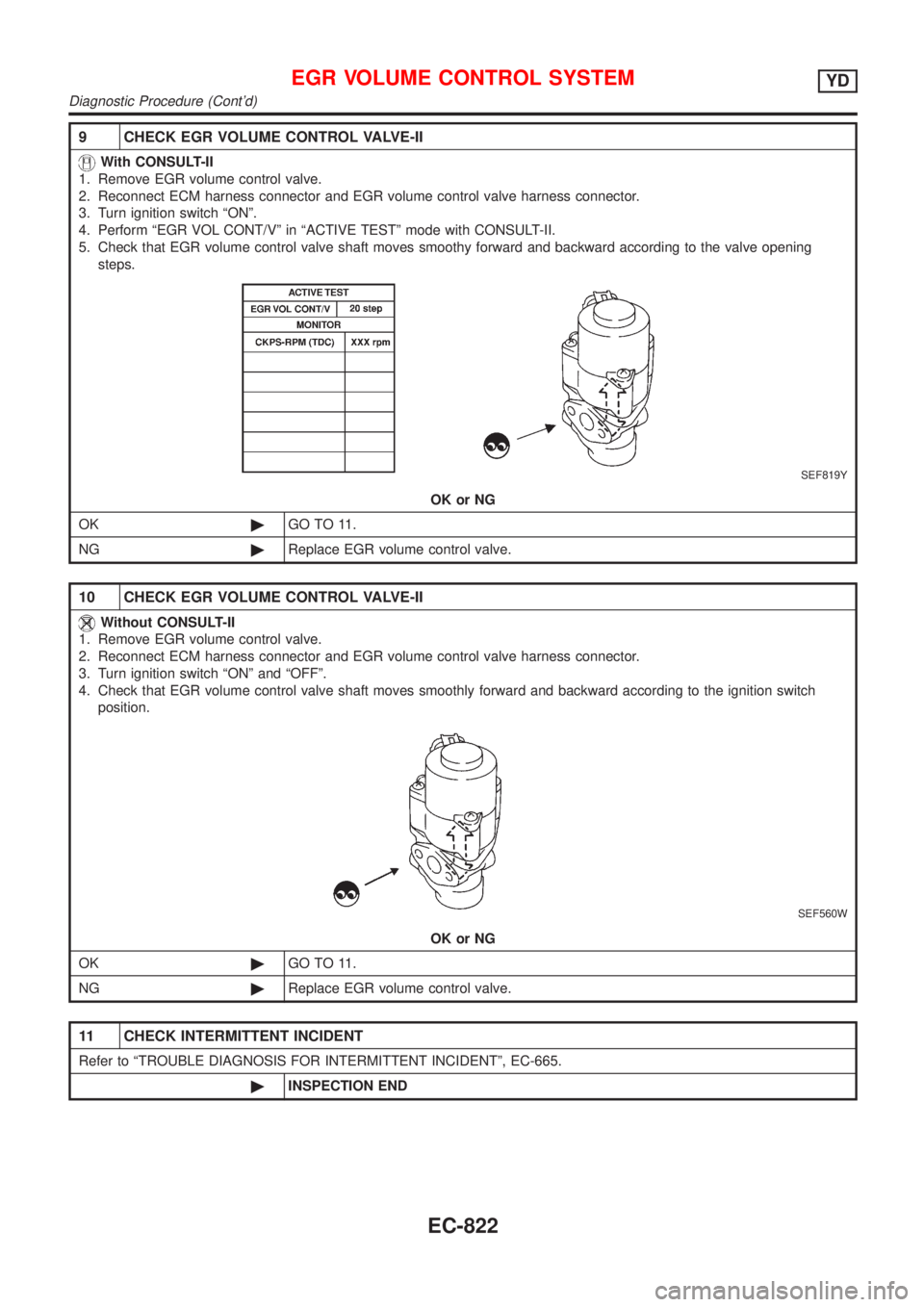

9 CHECK EGR VOLUME CONTROL VALVE-II

With CONSULT-II

1. Remove EGR volume control valve.

2. Reconnect ECM harness connector and EGR volume control valve harness connector.

3. Turn ignition switch ªONº.

4. Perform ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with CONSULT-II.

5. Check that EGR volume control valve shaft moves smoothy forward and backward according to the valve opening

steps.

SEF819Y

OK or NG

OK©GO TO 11.

NG©Replace EGR volume control valve.

10 CHECK EGR VOLUME CONTROL VALVE-II

Without CONSULT-II

1. Remove EGR volume control valve.

2. Reconnect ECM harness connector and EGR volume control valve harness connector.

3. Turn ignition switch ªONº and ªOFFº.

4. Check that EGR volume control valve shaft moves smoothly forward and backward according to the ignition switch

position.

SEF560W

OK or NG

OK©GO TO 11.

NG©Replace EGR volume control valve.

11 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-665.

©INSPECTION END

EGR VOLUME CONTROL SYSTEMYD

Diagnostic Procedure (Cont'd)

EC-822