torque NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 973 of 2898

Diagnostic ProcedureNJEC0134

1 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

Loosen and retighten heated oxygen sensor 1 (front).

Tightening torque:

40 - 60 N´m (4.1 - 6.1 kg-m, 30 - 44 ft-lb)

©GO TO 2.

2 CHECK INPUT SIGNAL CIRCUIT

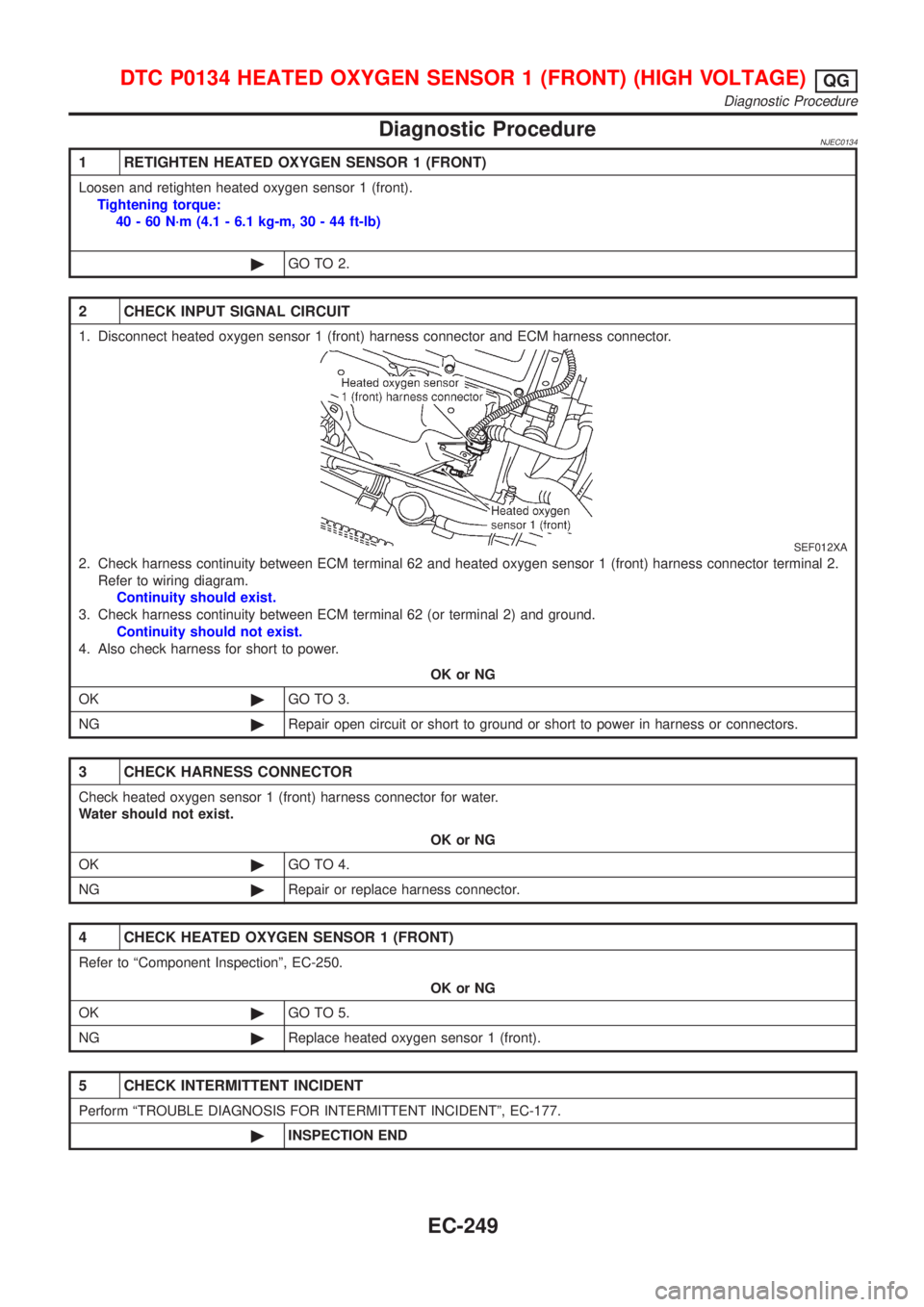

1. Disconnect heated oxygen sensor 1 (front) harness connector and ECM harness connector.

SEF012XA

2. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK HARNESS CONNECTOR

Check heated oxygen sensor 1 (front) harness connector for water.

Water should not exist.

OK or NG

OK©GO TO 4.

NG©Repair or replace harness connector.

4 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

Refer to ªComponent Inspectionº, EC-250.

OK or NG

OK©GO TO 5.

NG©Replace heated oxygen sensor 1 (front).

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

DTC P0134 HEATED OXYGEN SENSOR 1 (FRONT) (HIGH VOLTAGE)QG

Diagnostic Procedure

EC-249

Page 1178 of 2898

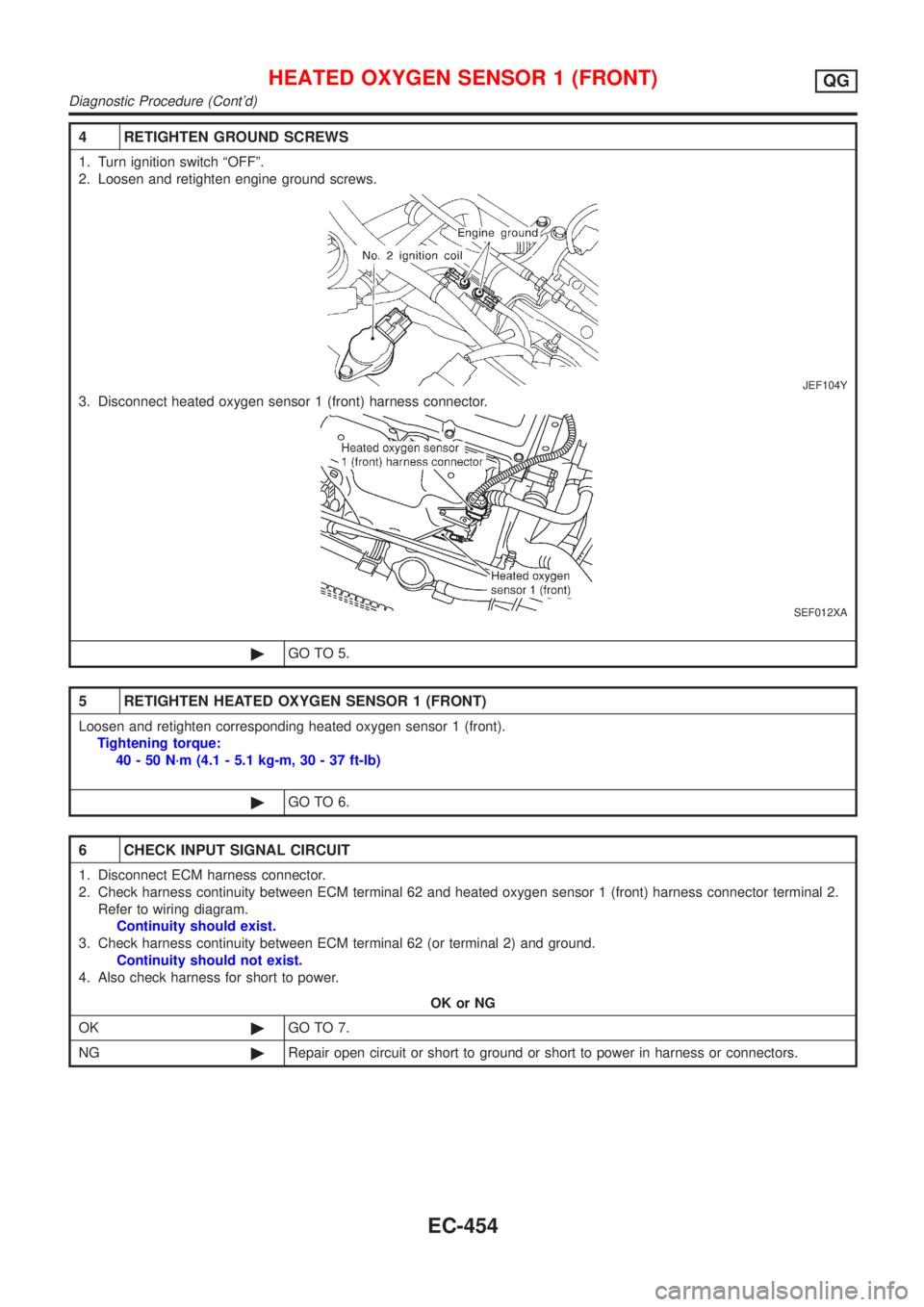

4 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

JEF104Y

3. Disconnect heated oxygen sensor 1 (front) harness connector.

SEF012XA

©GO TO 5.

5 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

Loosen and retighten corresponding heated oxygen sensor 1 (front).

Tightening torque:

40 - 50 N´m (4.1 - 5.1 kg-m, 30 - 37 ft-lb)

©GO TO 6.

6 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

HEATED OXYGEN SENSOR 1 (FRONT)QG

Diagnostic Procedure (Cont'd)

EC-454

Page 1537 of 2898

15 CHECK HARNESS CONTINUITY BETWEEN GLOW RELAY AND GLOW PLUG FOR OPEN AND SHORT

1. Disconnect glow plug harness connector.

2. Check harness continuity between glow relay terminal 3 and glow plug harness connector. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

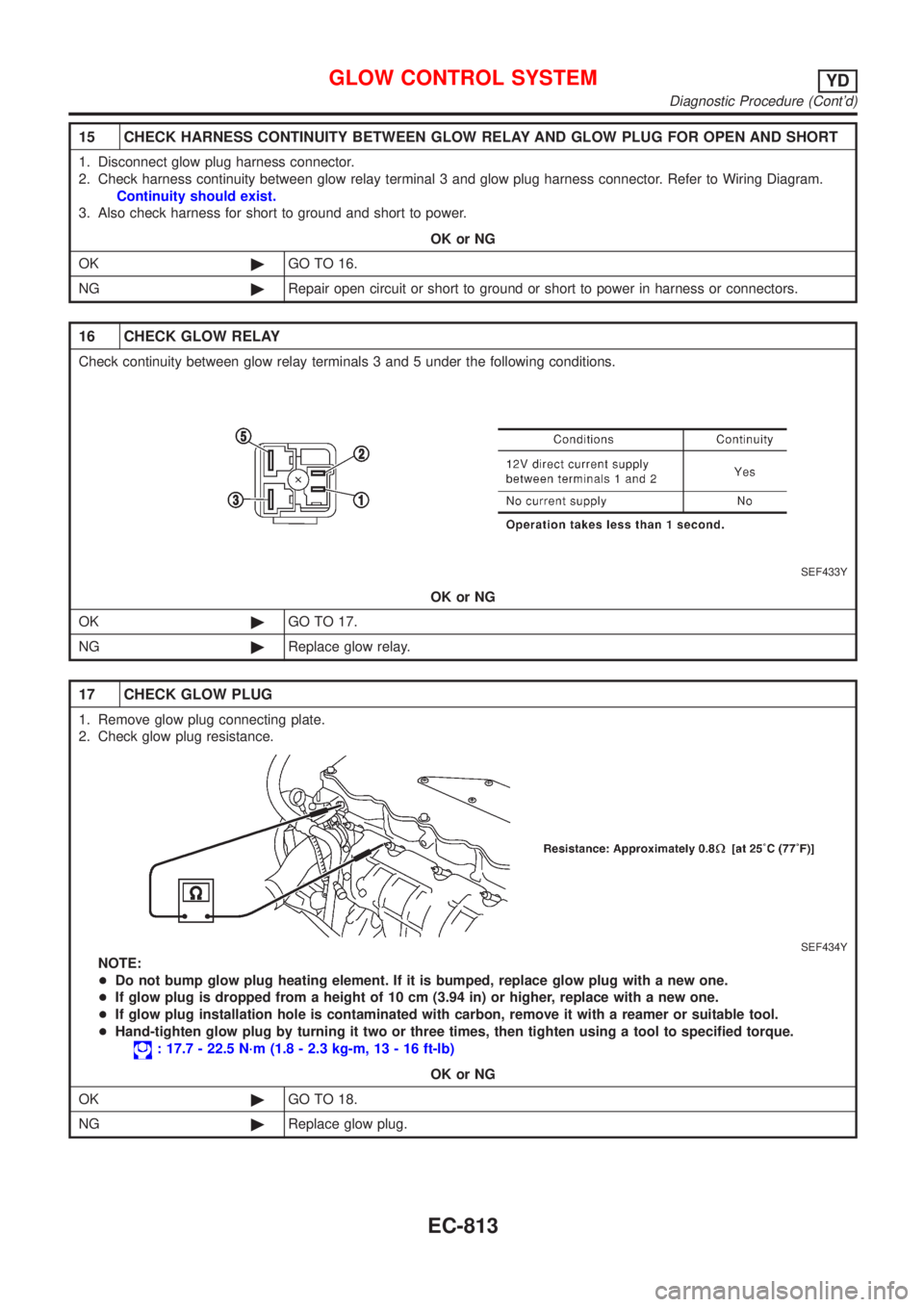

16 CHECK GLOW RELAY

Check continuity between glow relay terminals 3 and 5 under the following conditions.

SEF433Y

OK or NG

OK©GO TO 17.

NG©Replace glow relay.

17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

SEF434Y

NOTE:

+Do not bump glow plug heating element. If it is bumped, replace glow plug with a new one.

+If glow plug is dropped from a height of 10 cm (3.94 in) or higher, replace with a new one.

+If glow plug installation hole is contaminated with carbon, remove it with a reamer or suitable tool.

+Hand-tighten glow plug by turning it two or three times, then tighten using a tool to specified torque.

: 17.7 - 22.5 N´m (1.8 - 2.3 kg-m, 13 - 16 ft-lb)

OK or NG

OK©GO TO 18.

NG©Replace glow plug.

GLOW CONTROL SYSTEMYD

Diagnostic Procedure (Cont'd)

EC-813

Page 1780 of 2898

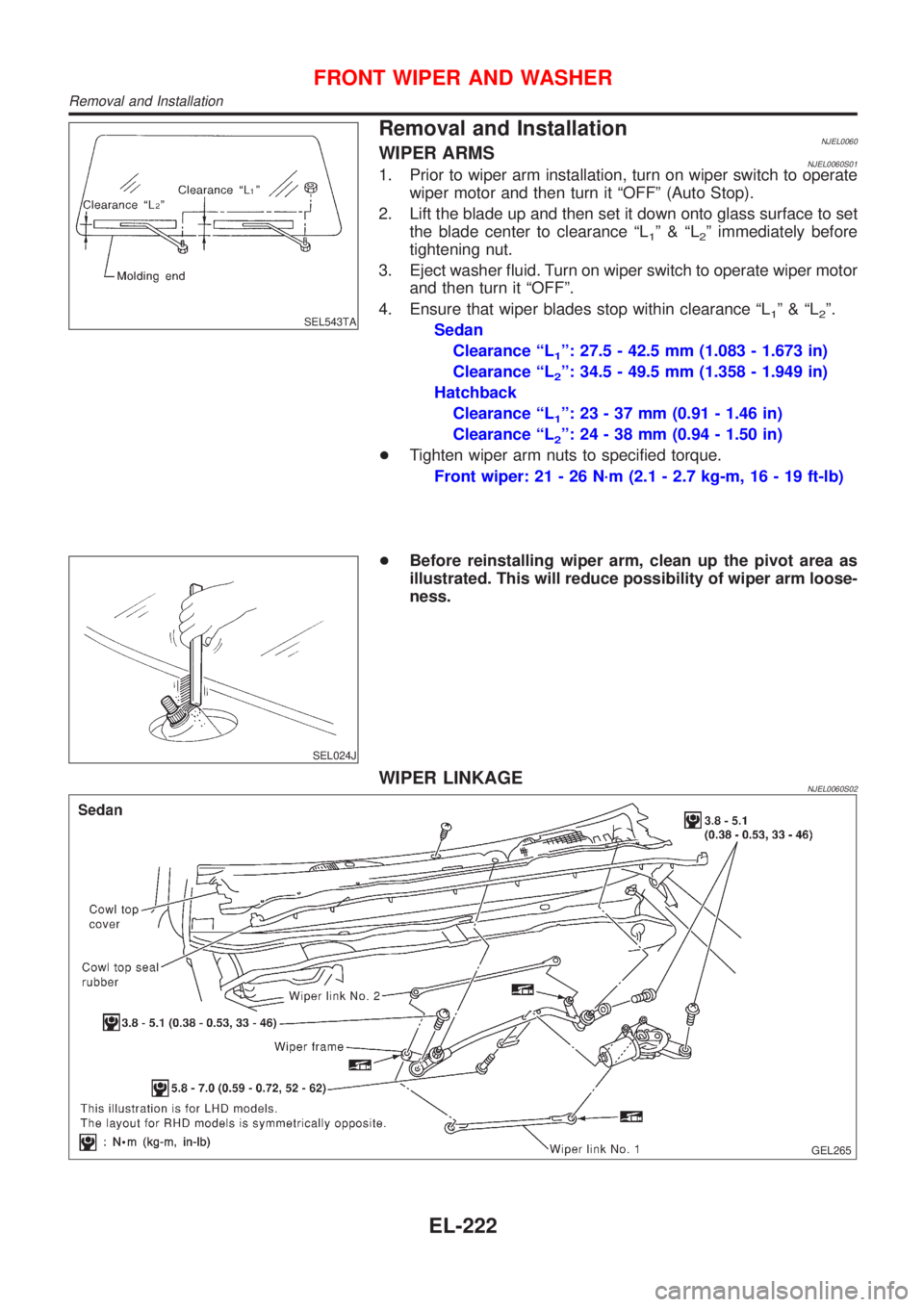

SEL543TA

Removal and InstallationNJEL0060WIPER ARMSNJEL0060S011. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it ªOFFº (Auto Stop).

2. Lift the blade up and then set it down onto glass surface to set

the blade center to clearance ªL

1º&ªL2º immediately before

tightening nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it ªOFFº.

4. Ensure that wiper blades stop within clearance ªL

1º&ªL2º.

Sedan

Clearance ªL

1º: 27.5 - 42.5 mm (1.083 - 1.673 in)

Clearance ªL

2º: 34.5 - 49.5 mm (1.358 - 1.949 in)

Hatchback

Clearance ªL

1º: 23 - 37 mm (0.91 - 1.46 in)

Clearance ªL

2º: 24 - 38 mm (0.94 - 1.50 in)

+Tighten wiper arm nuts to specified torque.

Front wiper: 21 - 26 N´m (2.1 - 2.7 kg-m, 16 - 19 ft-lb)

SEL024J

+Before reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm loose-

ness.

WIPER LINKAGENJEL0060S02

GEL265

FRONT WIPER AND WASHER

Removal and Installation

EL-222

Page 1787 of 2898

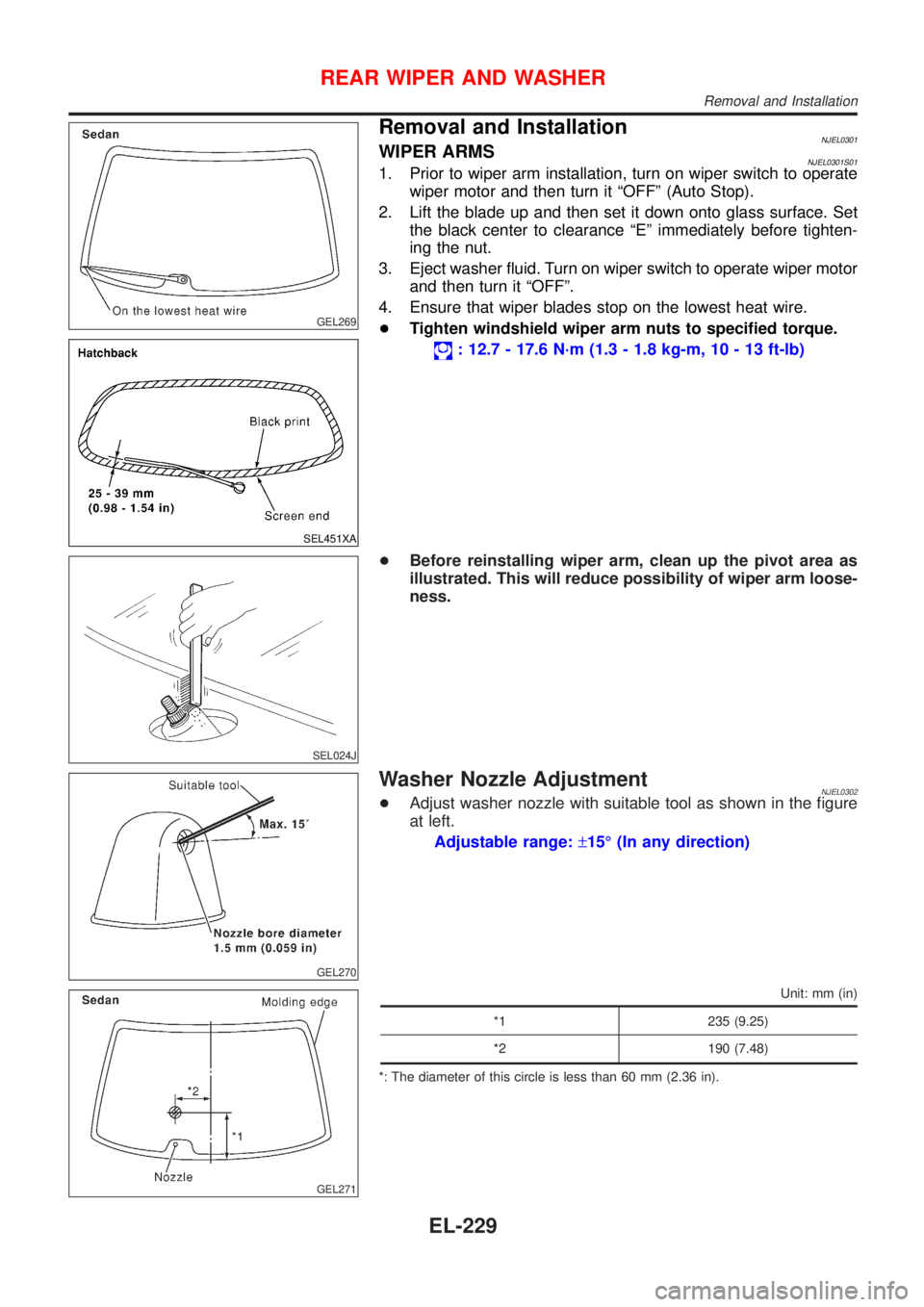

GEL269

SEL451XA

Removal and InstallationNJEL0301WIPER ARMSNJEL0301S011. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it ªOFFº (Auto Stop).

2. Lift the blade up and then set it down onto glass surface. Set

the black center to clearance ªEº immediately before tighten-

ing the nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it ªOFFº.

4. Ensure that wiper blades stop on the lowest heat wire.

+Tighten windshield wiper arm nuts to specified torque.

: 12.7 - 17.6 N´m (1.3 - 1.8 kg-m, 10 - 13 ft-lb)

SEL024J

+Before reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm loose-

ness.

GEL270

Washer Nozzle AdjustmentNJEL0302+Adjust washer nozzle with suitable tool as shown in the figure

at left.

Adjustable range:±15É (In any direction)

GEL271

Unit: mm (in)

*1 235 (9.25)

*2 190 (7.48)

*: The diameter of this circle is less than 60 mm (2.36 in).

REAR WIPER AND WASHER

Removal and Installation

EL-229

Page 2134 of 2898

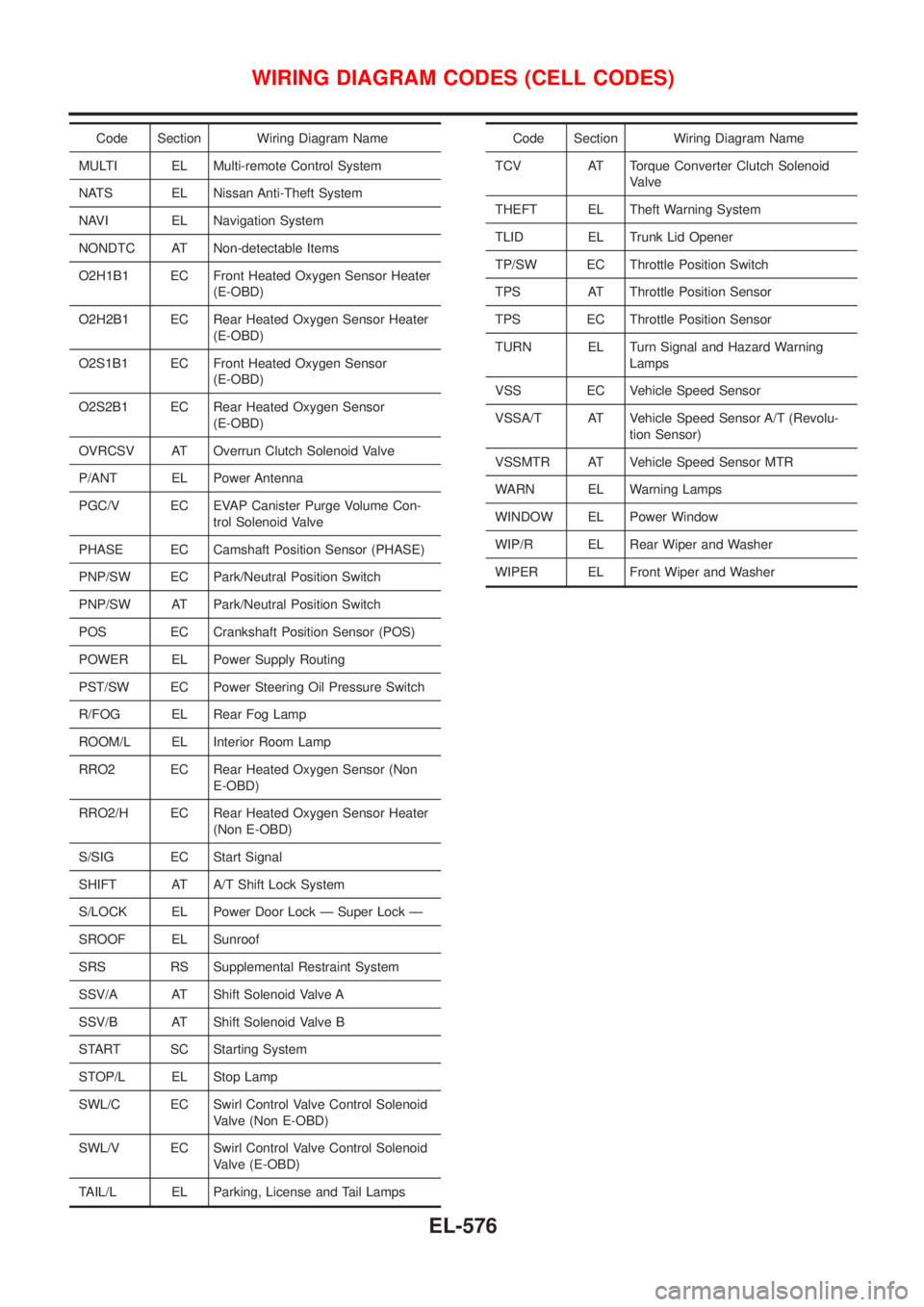

Code Section Wiring Diagram Name

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Front Heated Oxygen Sensor Heater

(E-OBD)

O2H2B1 EC Rear Heated Oxygen Sensor Heater

(E-OBD)

O2S1B1 EC Front Heated Oxygen Sensor

(E-OBD)

O2S2B1 EC Rear Heated Oxygen Sensor

(E-OBD)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume Con-

trol Solenoid Valve

PHASE EC Camshaft Position Sensor (PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (POS)

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

ROOM/L EL Interior Room Lamp

RRO2 EC Rear Heated Oxygen Sensor (Non

E-OBD)

RRO2/H EC Rear Heated Oxygen Sensor Heater

(Non E-OBD)

S/SIG EC Start Signal

SHIFT AT A/T Shift Lock System

S/LOCK EL Power Door Lock Ð Super Lock Ð

SROOF EL Sunroof

SRS RS Supplemental Restraint System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop Lamp

SWL/C EC Swirl Control Valve Control Solenoid

Valve (Non E-OBD)

SWL/V EC Swirl Control Valve Control Solenoid

Valve (E-OBD)

TAIL/L EL Parking, License and Tail LampsCode Section Wiring Diagram Name

TCV AT Torque Converter Clutch Solenoid

Valve

THEFT EL Theft Warning System

TLID EL Trunk Lid Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revolu-

tion Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-576

Page 2138 of 2898

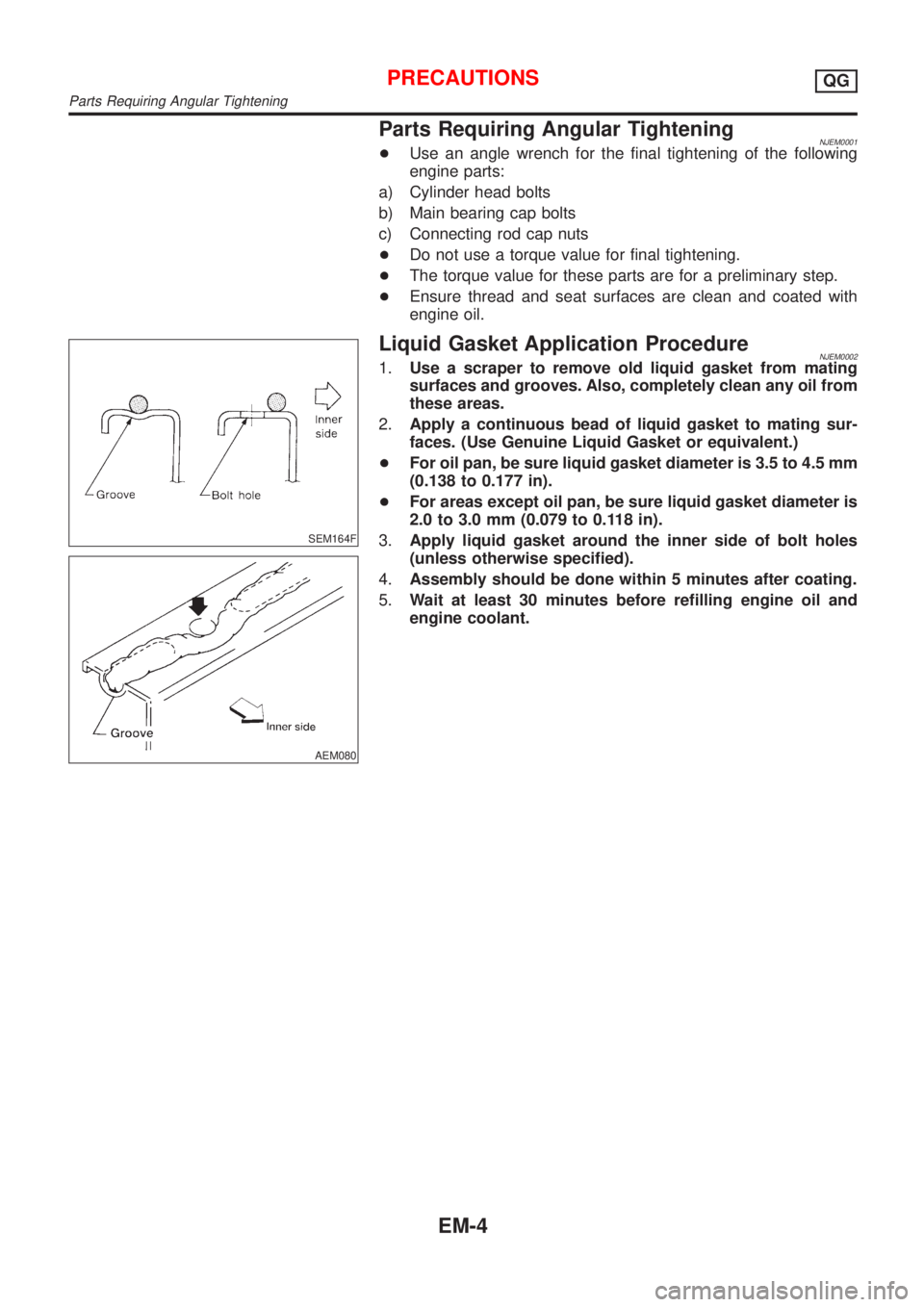

Parts Requiring Angular TighteningNJEM0001+Use an angle wrench for the final tightening of the following

engine parts:

a) Cylinder head bolts

b) Main bearing cap bolts

c) Connecting rod cap nuts

+Do not use a torque value for final tightening.

+The torque value for these parts are for a preliminary step.

+Ensure thread and seat surfaces are clean and coated with

engine oil.

SEM164F

AEM080

Liquid Gasket Application ProcedureNJEM00021.Use a scraper to remove old liquid gasket from mating

surfaces and grooves. Also, completely clean any oil from

these areas.

2.Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

+For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

+For areas except oil pan, be sure liquid gasket diameter is

2.0 to 3.0 mm (0.079 to 0.118 in).

3.Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

4.Assembly should be done within 5 minutes after coating.

5.Wait at least 30 minutes before refilling engine oil and

engine coolant.

PRECAUTIONSQG

Parts Requiring Angular Tightening

EM-4

Page 2163 of 2898

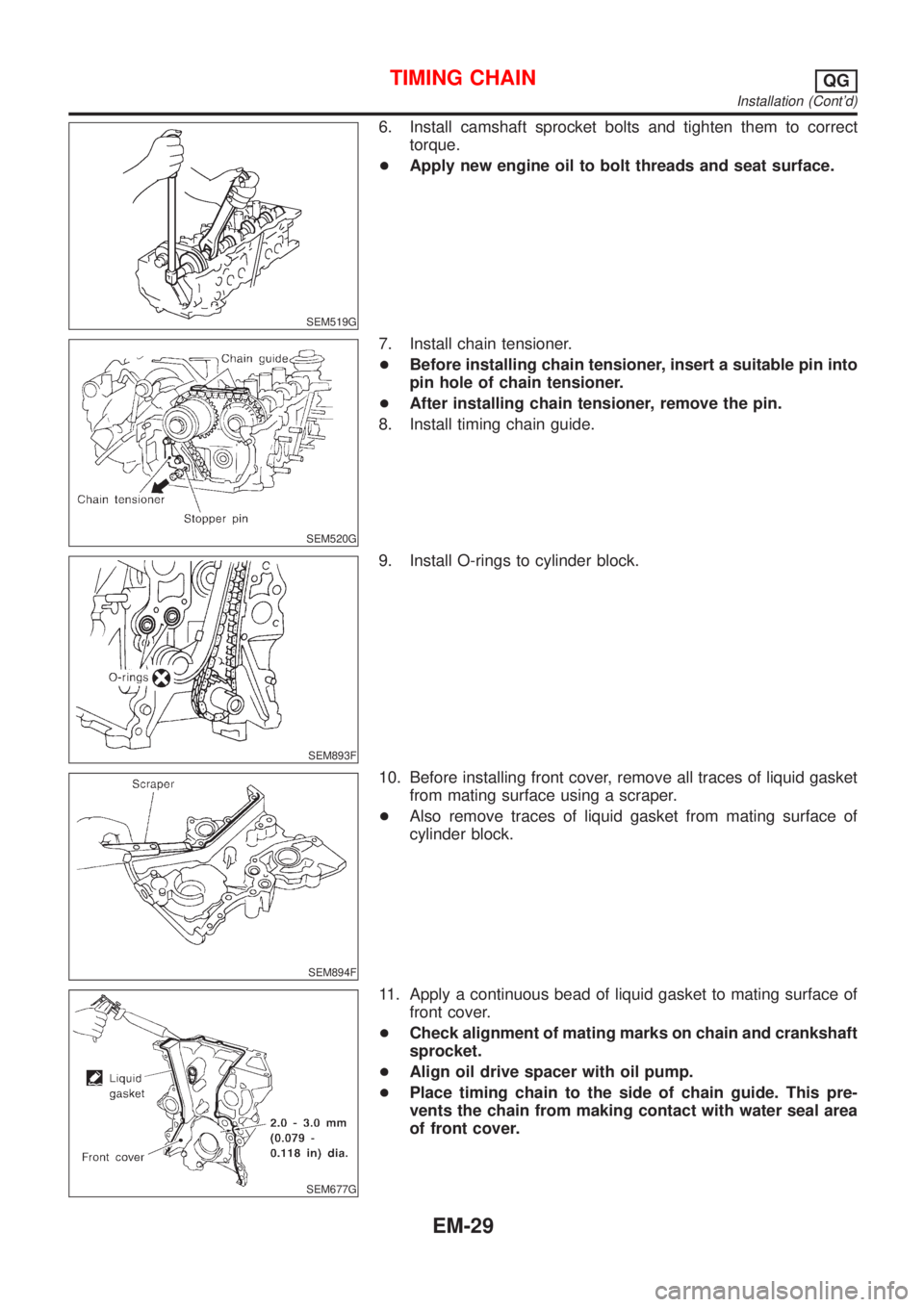

SEM519G

6. Install camshaft sprocket bolts and tighten them to correct

torque.

+Apply new engine oil to bolt threads and seat surface.

SEM520G

7. Install chain tensioner.

+Before installing chain tensioner, insert a suitable pin into

pin hole of chain tensioner.

+After installing chain tensioner, remove the pin.

8. Install timing chain guide.

SEM893F

9. Install O-rings to cylinder block.

SEM894F

10. Before installing front cover, remove all traces of liquid gasket

from mating surface using a scraper.

+Also remove traces of liquid gasket from mating surface of

cylinder block.

SEM677G

11. Apply a continuous bead of liquid gasket to mating surface of

front cover.

+Check alignment of mating marks on chain and crankshaft

sprocket.

+Align oil drive spacer with oil pump.

+Place timing chain to the side of chain guide. This pre-

vents the chain from making contact with water seal area

of front cover.

TIMING CHAINQG

Installation (Cont'd)

EM-29

Page 2164 of 2898

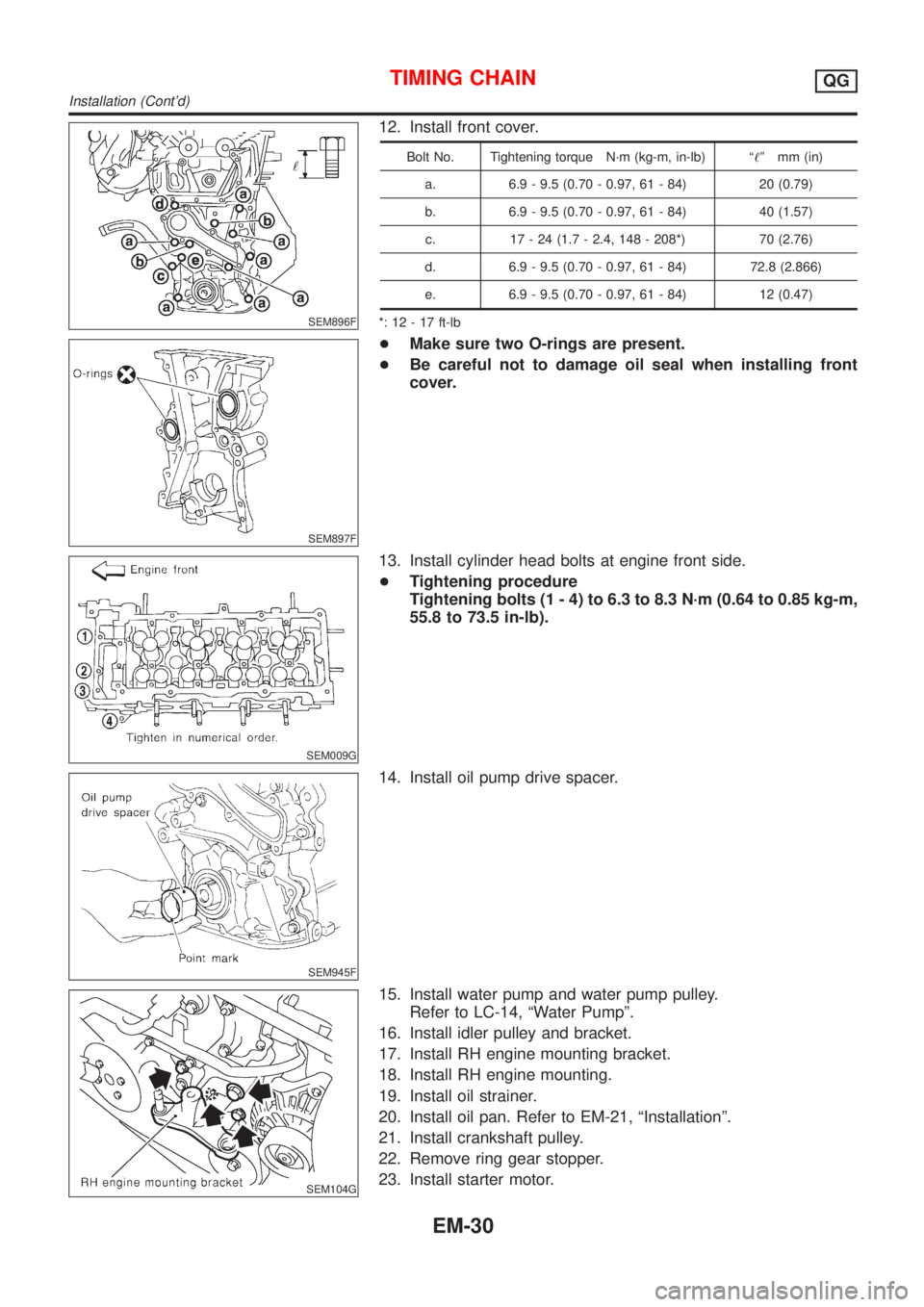

SEM896F

12. Install front cover.

Bolt No. Tightening torque N´m (kg-m, in-lb) ª!º mm (in)

a. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 20 (0.79)

b. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 40 (1.57)

c. 17 - 24 (1.7 - 2.4, 148 - 208*) 70 (2.76)

d. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 72.8 (2.866)

e. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 12 (0.47)

*: 12 - 17 ft-lb

SEM897F

+Make sure two O-rings are present.

+Be careful not to damage oil seal when installing front

cover.

SEM009G

13. Install cylinder head bolts at engine front side.

+Tightening procedure

Tightening bolts (1 - 4) to 6.3 to 8.3 N´m (0.64 to 0.85 kg-m,

55.8 to 73.5 in-lb).

SEM945F

14. Install oil pump drive spacer.

SEM104G

15. Install water pump and water pump pulley.

Refer to LC-14, ªWater Pumpº.

16. Install idler pulley and bracket.

17. Install RH engine mounting bracket.

18. Install RH engine mounting.

19. Install oil strainer.

20. Install oil pan. Refer to EM-21, ªInstallationº.

21. Install crankshaft pulley.

22. Remove ring gear stopper.

23. Install starter motor.

TIMING CHAINQG

Installation (Cont'd)

EM-30

Page 2172 of 2898

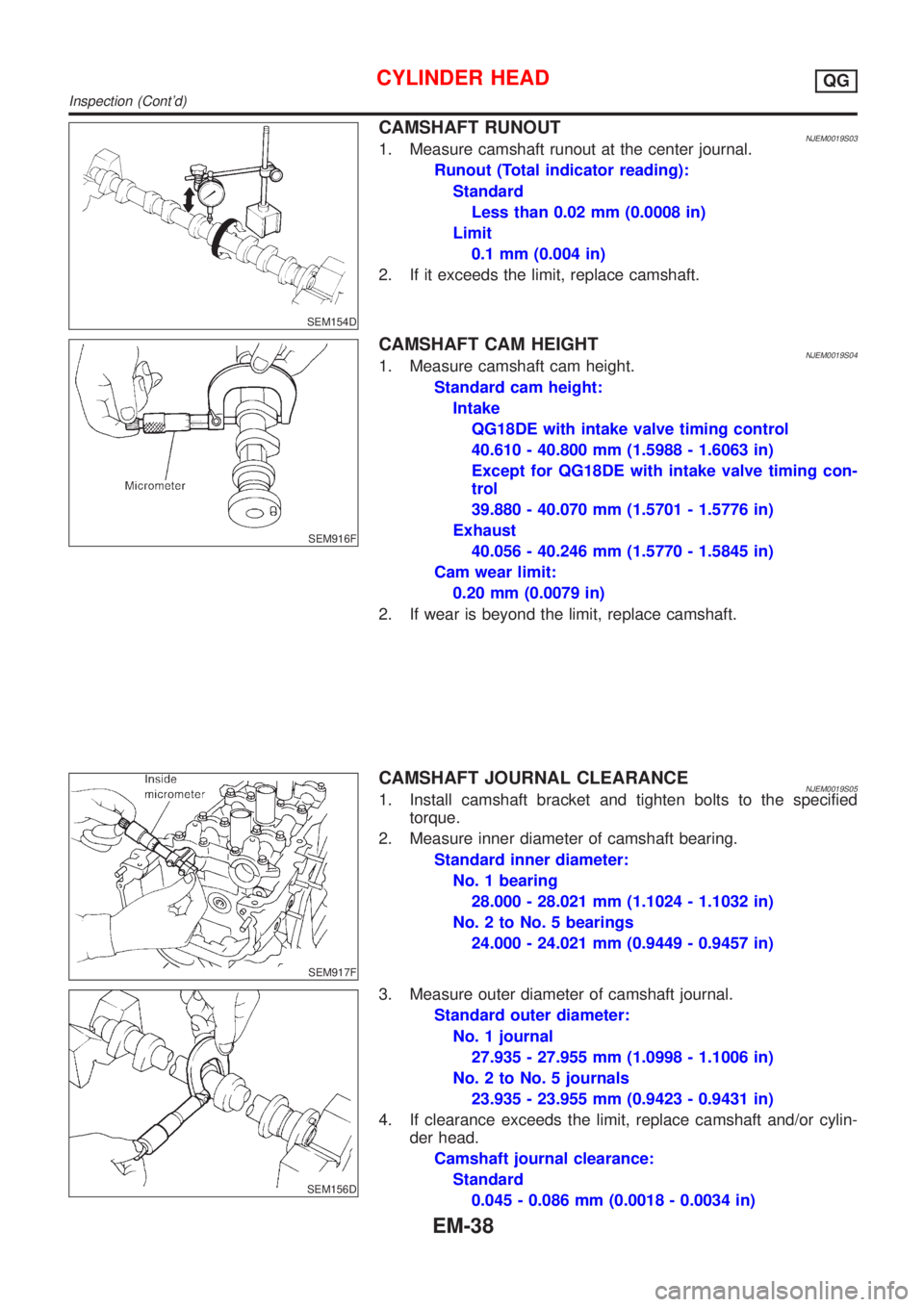

SEM154D

CAMSHAFT RUNOUTNJEM0019S031. Measure camshaft runout at the center journal.

Runout (Total indicator reading):

Standard

Less than 0.02 mm (0.0008 in)

Limit

0.1 mm (0.004 in)

2. If it exceeds the limit, replace camshaft.

SEM916F

CAMSHAFT CAM HEIGHTNJEM0019S041. Measure camshaft cam height.

Standard cam height:

Intake

QG18DE with intake valve timing control

40.610 - 40.800 mm (1.5988 - 1.6063 in)

Except for QG18DE with intake valve timing con-

trol

39.880 - 40.070 mm (1.5701 - 1.5776 in)

Exhaust

40.056 - 40.246 mm (1.5770 - 1.5845 in)

Cam wear limit:

0.20 mm (0.0079 in)

2. If wear is beyond the limit, replace camshaft.

SEM917F

CAMSHAFT JOURNAL CLEARANCENJEM0019S051. Install camshaft bracket and tighten bolts to the specified

torque.

2. Measure inner diameter of camshaft bearing.

Standard inner diameter:

No. 1 bearing

28.000 - 28.021 mm (1.1024 - 1.1032 in)

No. 2 to No. 5 bearings

24.000 - 24.021 mm (0.9449 - 0.9457 in)

SEM156D

3. Measure outer diameter of camshaft journal.

Standard outer diameter:

No. 1 journal

27.935 - 27.955 mm (1.0998 - 1.1006 in)

No. 2 to No. 5 journals

23.935 - 23.955 mm (0.9423 - 0.9431 in)

4. If clearance exceeds the limit, replace camshaft and/or cylin-

der head.

Camshaft journal clearance:

Standard

0.045 - 0.086 mm (0.0018 - 0.0034 in)

CYLINDER HEADQG

Inspection (Cont'd)

EM-38