torque NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2247 of 2898

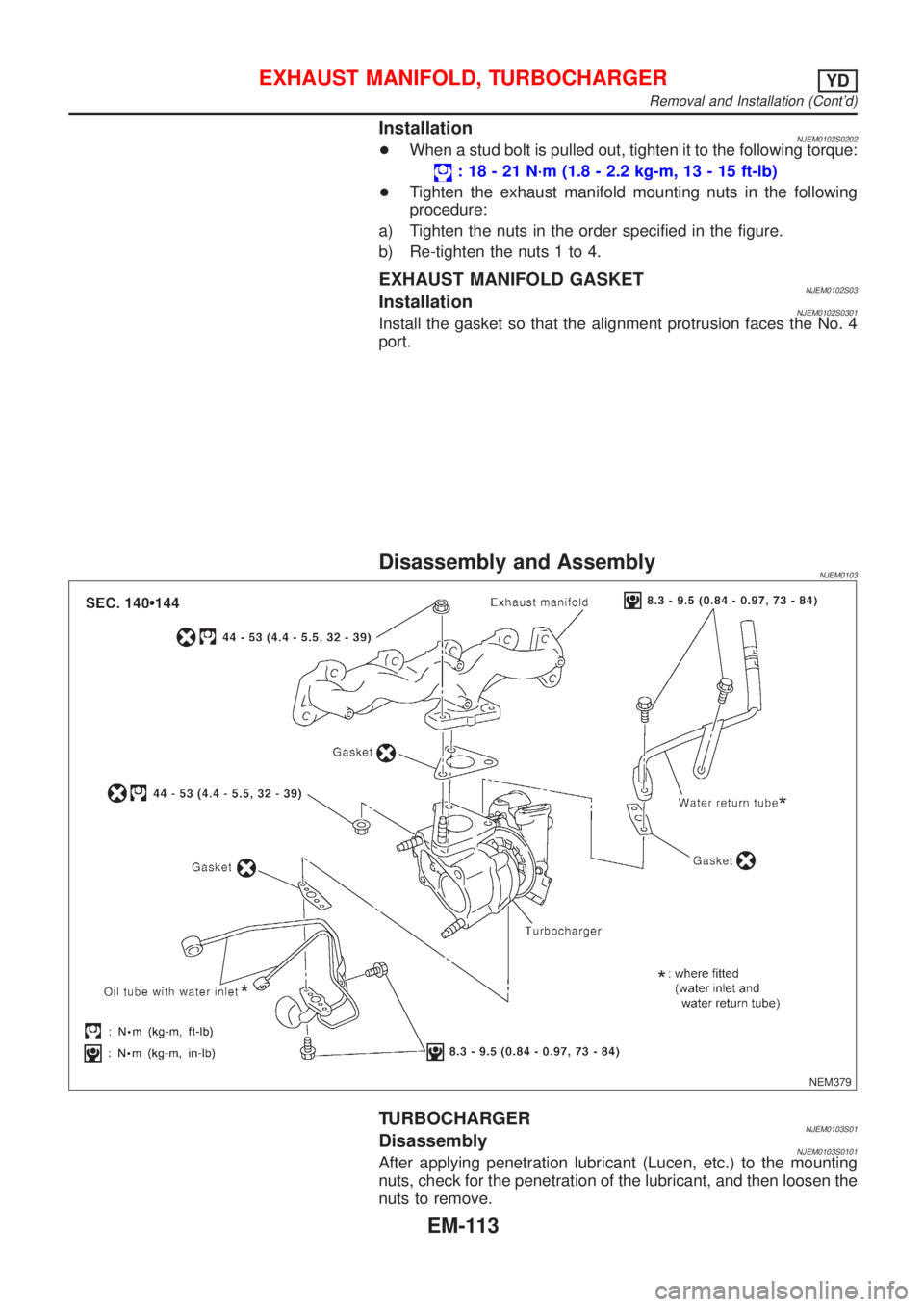

InstallationNJEM0102S0202+When a stud bolt is pulled out, tighten it to the following torque:

: 18 - 21 N´m (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

+Tighten the exhaust manifold mounting nuts in the following

procedure:

a) Tighten the nuts in the order specified in the figure.

b) Re-tighten the nuts 1 to 4.

EXHAUST MANIFOLD GASKETNJEM0102S03InstallationNJEM0102S0301Install the gasket so that the alignment protrusion faces the No. 4

port.

Disassembly and AssemblyNJEM0103

NEM379

TURBOCHARGERNJEM0103S01DisassemblyNJEM0103S0101After applying penetration lubricant (Lucen, etc.) to the mounting

nuts, check for the penetration of the lubricant, and then loosen the

nuts to remove.

EXHAUST MANIFOLD, TURBOCHARGERYD

Removal and Installation (Cont'd)

EM-113

Page 2248 of 2898

CAUTION:

Do not disassemble or adjust the turbocharger body.

AssemblyNJEM0103S0102When a stud bolt is pulled out, tighten it to the following torque:

: 24 - 27 N´m (2.4 - 2.8 kg-m, 18 - 20 ft-lb)

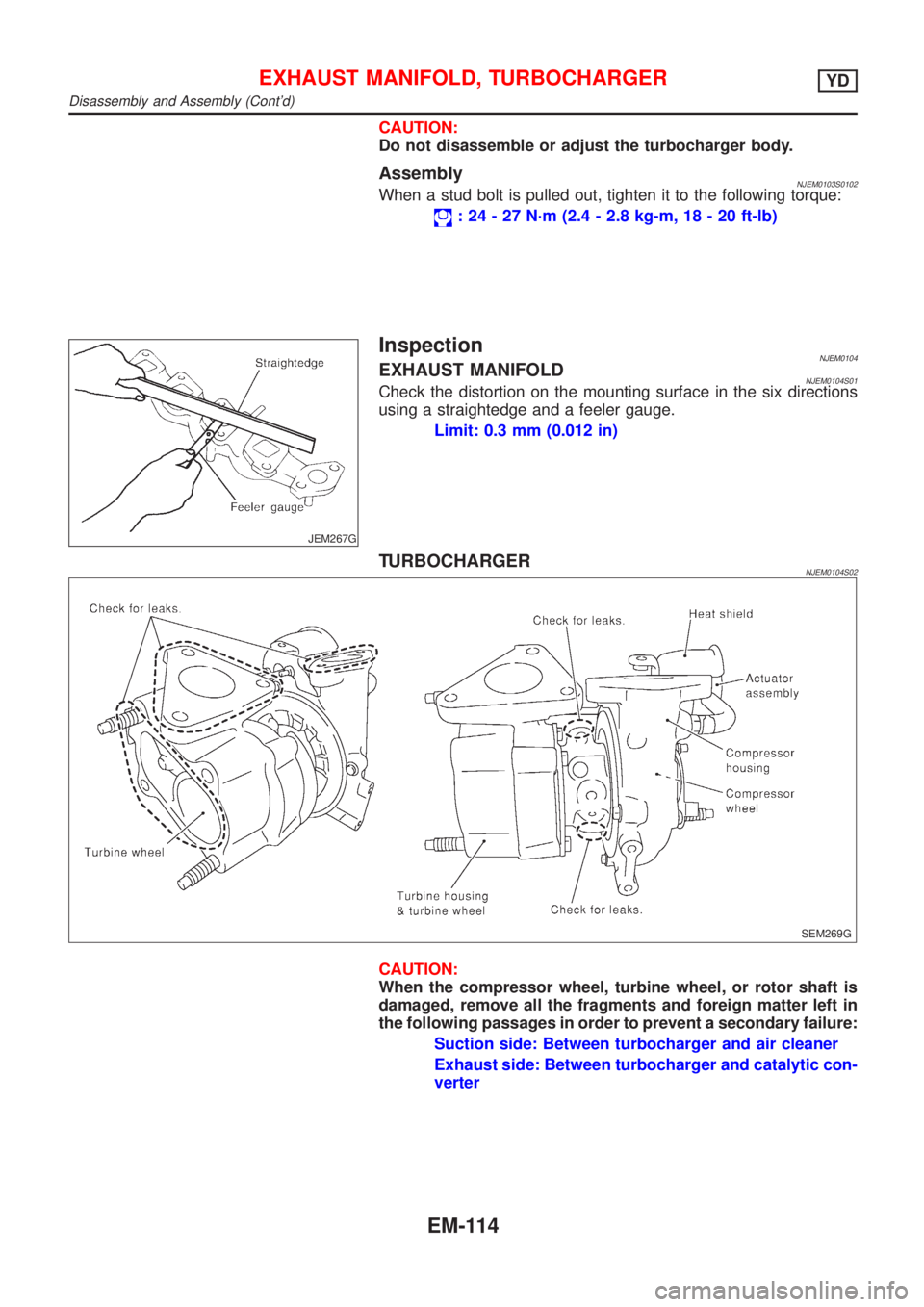

JEM267G

InspectionNJEM0104EXHAUST MANIFOLDNJEM0104S01Check the distortion on the mounting surface in the six directions

using a straightedge and a feeler gauge.

Limit: 0.3 mm (0.012 in)

TURBOCHARGERNJEM0104S02

SEM269G

CAUTION:

When the compressor wheel, turbine wheel, or rotor shaft is

damaged, remove all the fragments and foreign matter left in

the following passages in order to prevent a secondary failure:

Suction side: Between turbocharger and air cleaner

Exhaust side: Between turbocharger and catalytic con-

verter

EXHAUST MANIFOLD, TURBOCHARGERYD

Disassembly and Assembly (Cont'd)

EM-114

Page 2251 of 2898

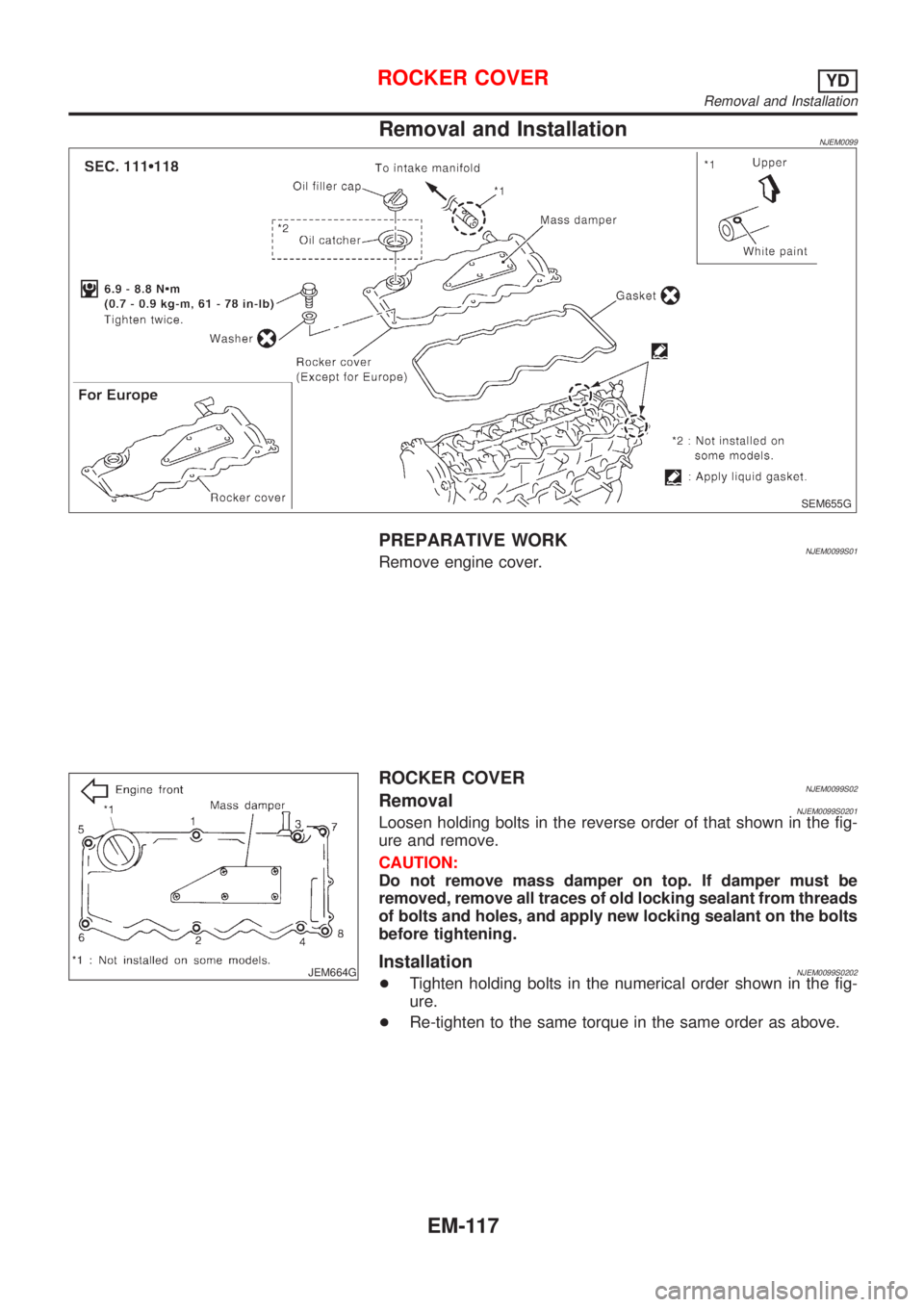

Removal and InstallationNJEM0099

SEM655G

PREPARATIVE WORKNJEM0099S01Remove engine cover.

JEM664G

ROCKER COVERNJEM0099S02RemovalNJEM0099S0201Loosen holding bolts in the reverse order of that shown in the fig-

ure and remove.

CAUTION:

Do not remove mass damper on top. If damper must be

removed, remove all traces of old locking sealant from threads

of bolts and holes, and apply new locking sealant on the bolts

before tightening.

InstallationNJEM0099S0202+Tighten holding bolts in the numerical order shown in the fig-

ure.

+Re-tighten to the same torque in the same order as above.

ROCKER COVERYD

Removal and Installation

EM-117

Page 2257 of 2898

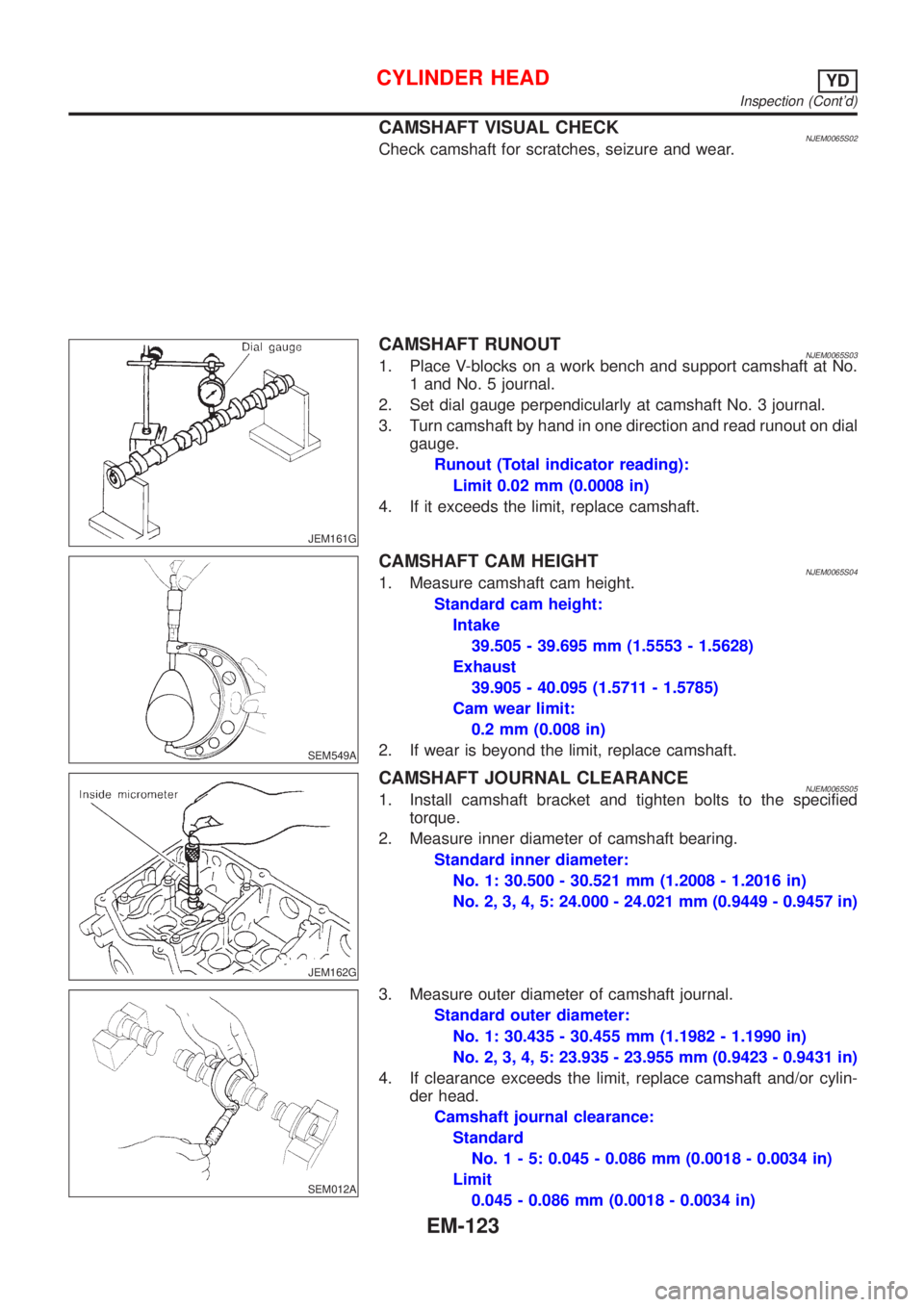

CAMSHAFT VISUAL CHECKNJEM0065S02Check camshaft for scratches, seizure and wear.

JEM161G

CAMSHAFT RUNOUTNJEM0065S031. Place V-blocks on a work bench and support camshaft at No.

1 and No. 5 journal.

2. Set dial gauge perpendicularly at camshaft No. 3 journal.

3. Turn camshaft by hand in one direction and read runout on dial

gauge.

Runout (Total indicator reading):

Limit 0.02 mm (0.0008 in)

4. If it exceeds the limit, replace camshaft.

SEM549A

CAMSHAFT CAM HEIGHTNJEM0065S041. Measure camshaft cam height.

Standard cam height:

Intake

39.505 - 39.695 mm (1.5553 - 1.5628)

Exhaust

39.905 - 40.095 (1.5711 - 1.5785)

Cam wear limit:

0.2 mm (0.008 in)

2. If wear is beyond the limit, replace camshaft.

JEM162G

CAMSHAFT JOURNAL CLEARANCENJEM0065S051. Install camshaft bracket and tighten bolts to the specified

torque.

2. Measure inner diameter of camshaft bearing.

Standard inner diameter:

No. 1: 30.500 - 30.521 mm (1.2008 - 1.2016 in)

No. 2, 3, 4, 5: 24.000 - 24.021 mm (0.9449 - 0.9457 in)

SEM012A

3. Measure outer diameter of camshaft journal.

Standard outer diameter:

No. 1: 30.435 - 30.455 mm (1.1982 - 1.1990 in)

No. 2, 3, 4, 5: 23.935 - 23.955 mm (0.9423 - 0.9431 in)

4. If clearance exceeds the limit, replace camshaft and/or cylin-

der head.

Camshaft journal clearance:

Standard

No.1-5:0.045 - 0.086 mm (0.0018 - 0.0034 in)

Limit

0.045 - 0.086 mm (0.0018 - 0.0034 in)

CYLINDER HEADYD

Inspection (Cont'd)

EM-123

Page 2283 of 2898

Standard

0.003 mm (0.0001 in)

Limit

0.005 mm (0.0002 in)

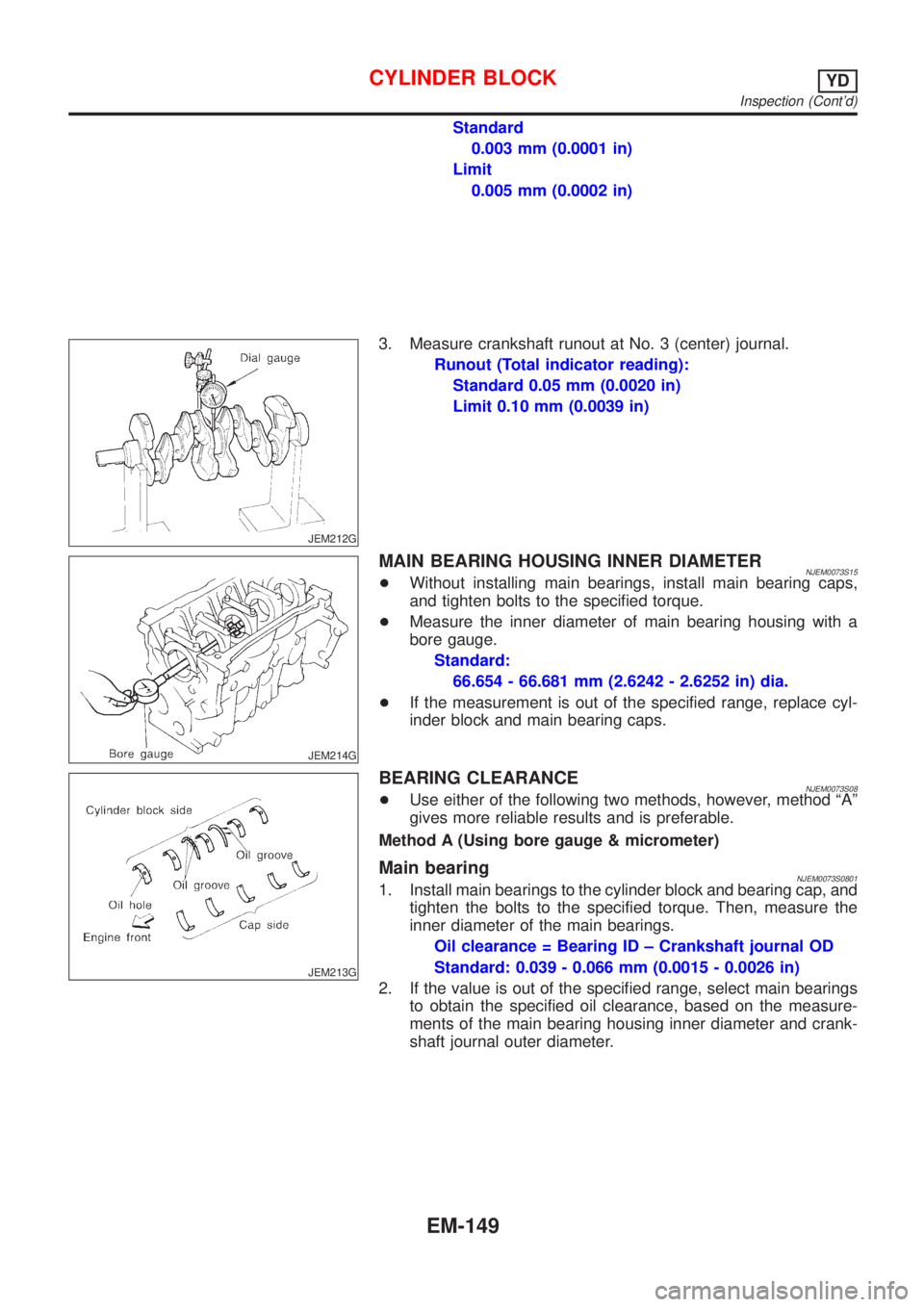

JEM212G

3. Measure crankshaft runout at No. 3 (center) journal.

Runout (Total indicator reading):

Standard 0.05 mm (0.0020 in)

Limit 0.10 mm (0.0039 in)

JEM214G

MAIN BEARING HOUSING INNER DIAMETERNJEM0073S15+Without installing main bearings, install main bearing caps,

and tighten bolts to the specified torque.

+Measure the inner diameter of main bearing housing with a

bore gauge.

Standard:

66.654 - 66.681 mm (2.6242 - 2.6252 in) dia.

+If the measurement is out of the specified range, replace cyl-

inder block and main bearing caps.

JEM213G

BEARING CLEARANCENJEM0073S08+Use either of the following two methods, however, method ªAº

gives more reliable results and is preferable.

Method A (Using bore gauge & micrometer)

Main bearingNJEM0073S08011. Install main bearings to the cylinder block and bearing cap, and

tighten the bolts to the specified torque. Then, measure the

inner diameter of the main bearings.

Oil clearance = Bearing ID ± Crankshaft journal OD

Standard: 0.039 - 0.066 mm (0.0015 - 0.0026 in)

2. If the value is out of the specified range, select main bearings

to obtain the specified oil clearance, based on the measure-

ments of the main bearing housing inner diameter and crank-

shaft journal outer diameter.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-149

Page 2285 of 2898

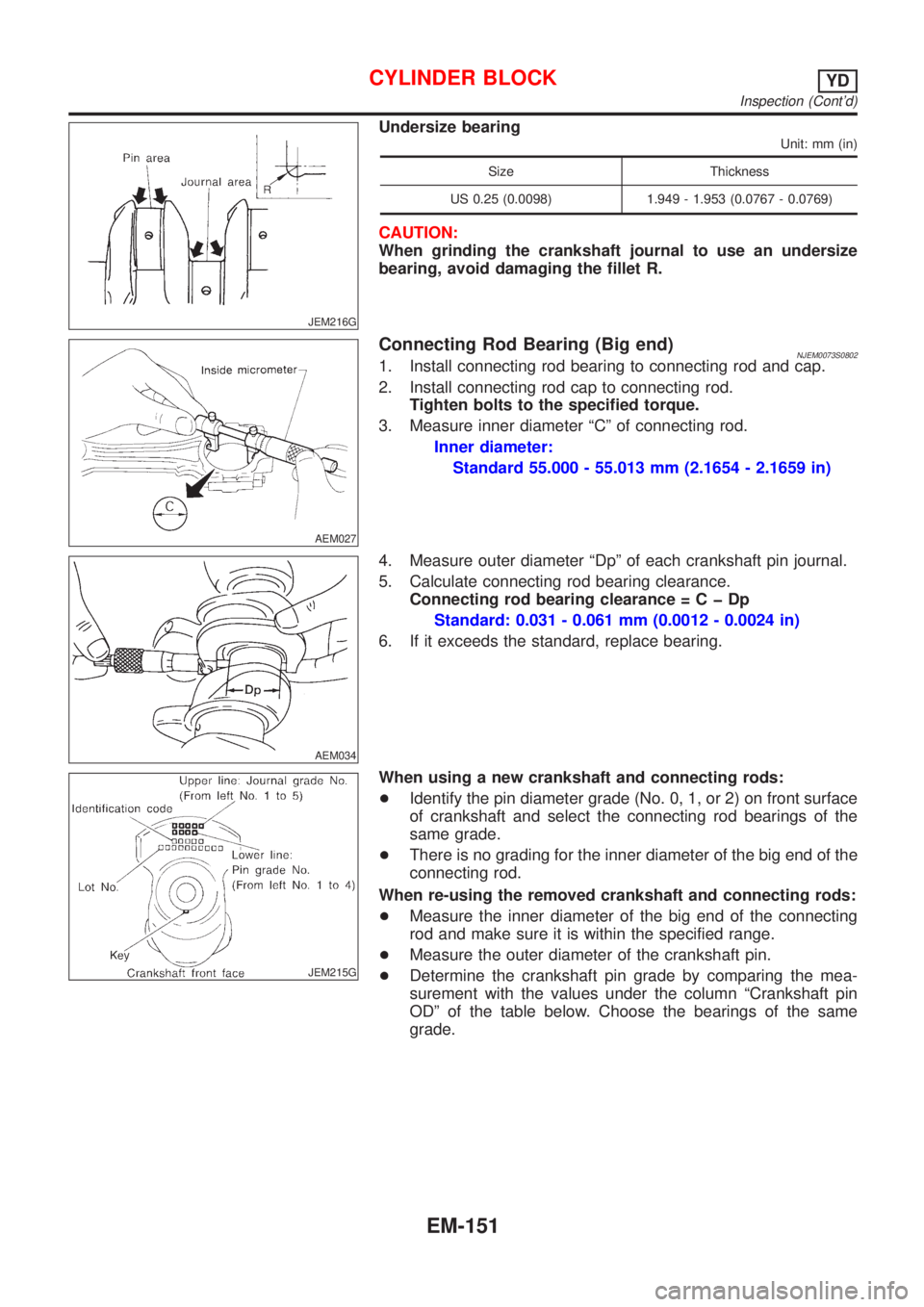

JEM216G

Undersize bearing

Unit: mm (in)

Size Thickness

US 0.25 (0.0098) 1.949 - 1.953 (0.0767 - 0.0769)

CAUTION:

When grinding the crankshaft journal to use an undersize

bearing, avoid damaging the fillet R.

AEM027

Connecting Rod Bearing (Big end)NJEM0073S08021. Install connecting rod bearing to connecting rod and cap.

2. Install connecting rod cap to connecting rod.

Tighten bolts to the specified torque.

3. Measure inner diameter ªCº of connecting rod.

Inner diameter:

Standard 55.000 - 55.013 mm (2.1654 - 2.1659 in)

AEM034

4. Measure outer diameter ªDpº of each crankshaft pin journal.

5. Calculate connecting rod bearing clearance.

Connecting rod bearing clearance=CþDp

Standard: 0.031 - 0.061 mm (0.0012 - 0.0024 in)

6. If it exceeds the standard, replace bearing.

JEM215G

When using a new crankshaft and connecting rods:

+Identify the pin diameter grade (No. 0, 1, or 2) on front surface

of crankshaft and select the connecting rod bearings of the

same grade.

+There is no grading for the inner diameter of the big end of the

connecting rod.

When re-using the removed crankshaft and connecting rods:

+Measure the inner diameter of the big end of the connecting

rod and make sure it is within the specified range.

+Measure the outer diameter of the crankshaft pin.

+Determine the crankshaft pin grade by comparing the mea-

surement with the values under the column ªCrankshaft pin

ODº of the table below. Choose the bearings of the same

grade.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-151

Page 2287 of 2898

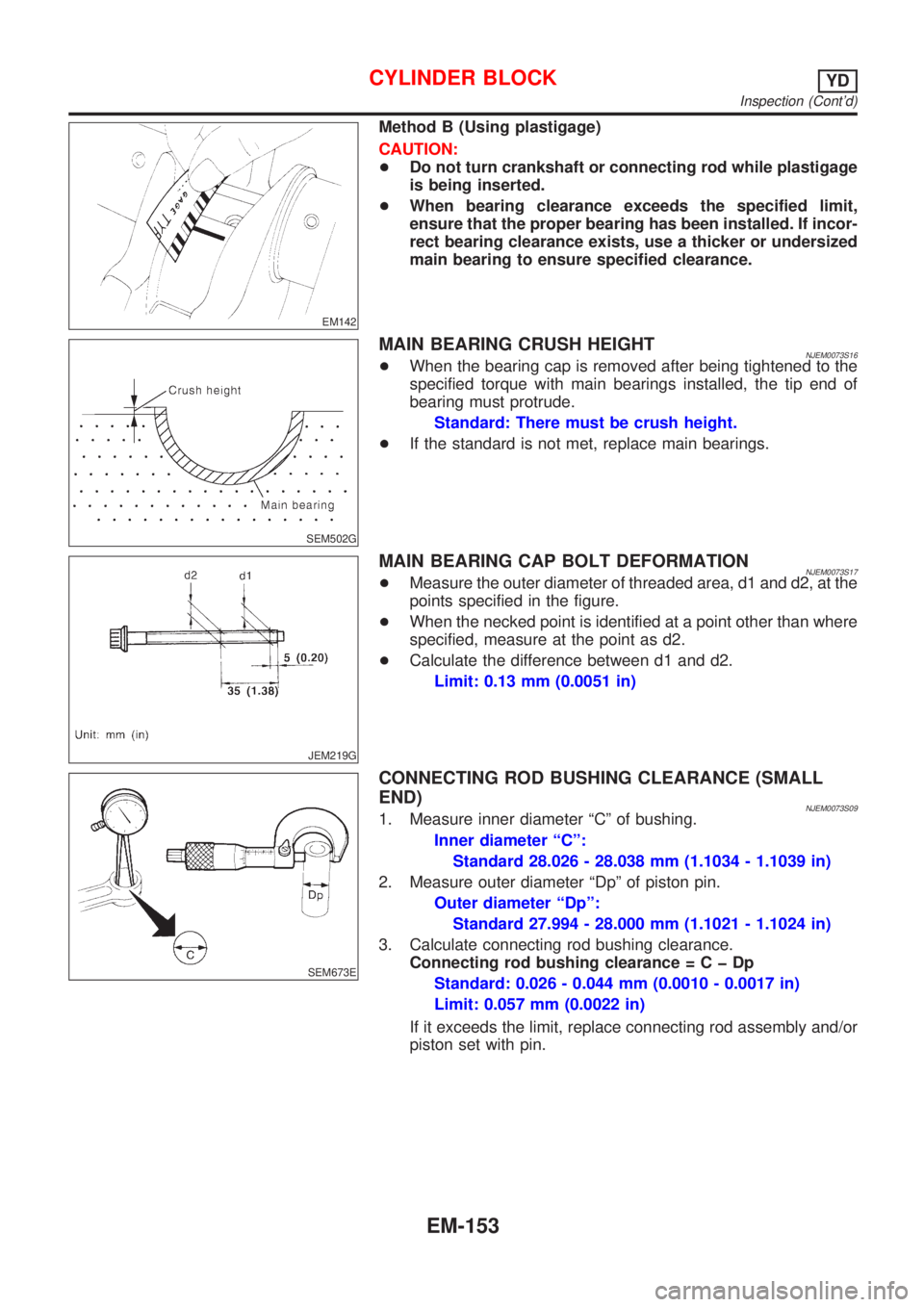

EM142

Method B (Using plastigage)

CAUTION:

+Do not turn crankshaft or connecting rod while plastigage

is being inserted.

+When bearing clearance exceeds the specified limit,

ensure that the proper bearing has been installed. If incor-

rect bearing clearance exists, use a thicker or undersized

main bearing to ensure specified clearance.

SEM502G

MAIN BEARING CRUSH HEIGHTNJEM0073S16+When the bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of

bearing must protrude.

Standard: There must be crush height.

+If the standard is not met, replace main bearings.

JEM219G

MAIN BEARING CAP BOLT DEFORMATIONNJEM0073S17+Measure the outer diameter of threaded area, d1 and d2, at the

points specified in the figure.

+When the necked point is identified at a point other than where

specified, measure at the point as d2.

+Calculate the difference between d1 and d2.

Limit: 0.13 mm (0.0051 in)

SEM673E

CONNECTING ROD BUSHING CLEARANCE (SMALL

END)

NJEM0073S091. Measure inner diameter ªCº of bushing.

Inner diameter ªCº:

Standard 28.026 - 28.038 mm (1.1034 - 1.1039 in)

2. Measure outer diameter ªDpº of piston pin.

Outer diameter ªDpº:

Standard 27.994 - 28.000 mm (1.1021 - 1.1024 in)

3. Calculate connecting rod bushing clearance.

Connecting rod bushing clearance=CþDp

Standard: 0.026 - 0.044 mm (0.0010 - 0.0017 in)

Limit: 0.057 mm (0.0022 in)

If it exceeds the limit, replace connecting rod assembly and/or

piston set with pin.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-153

Page 2290 of 2898

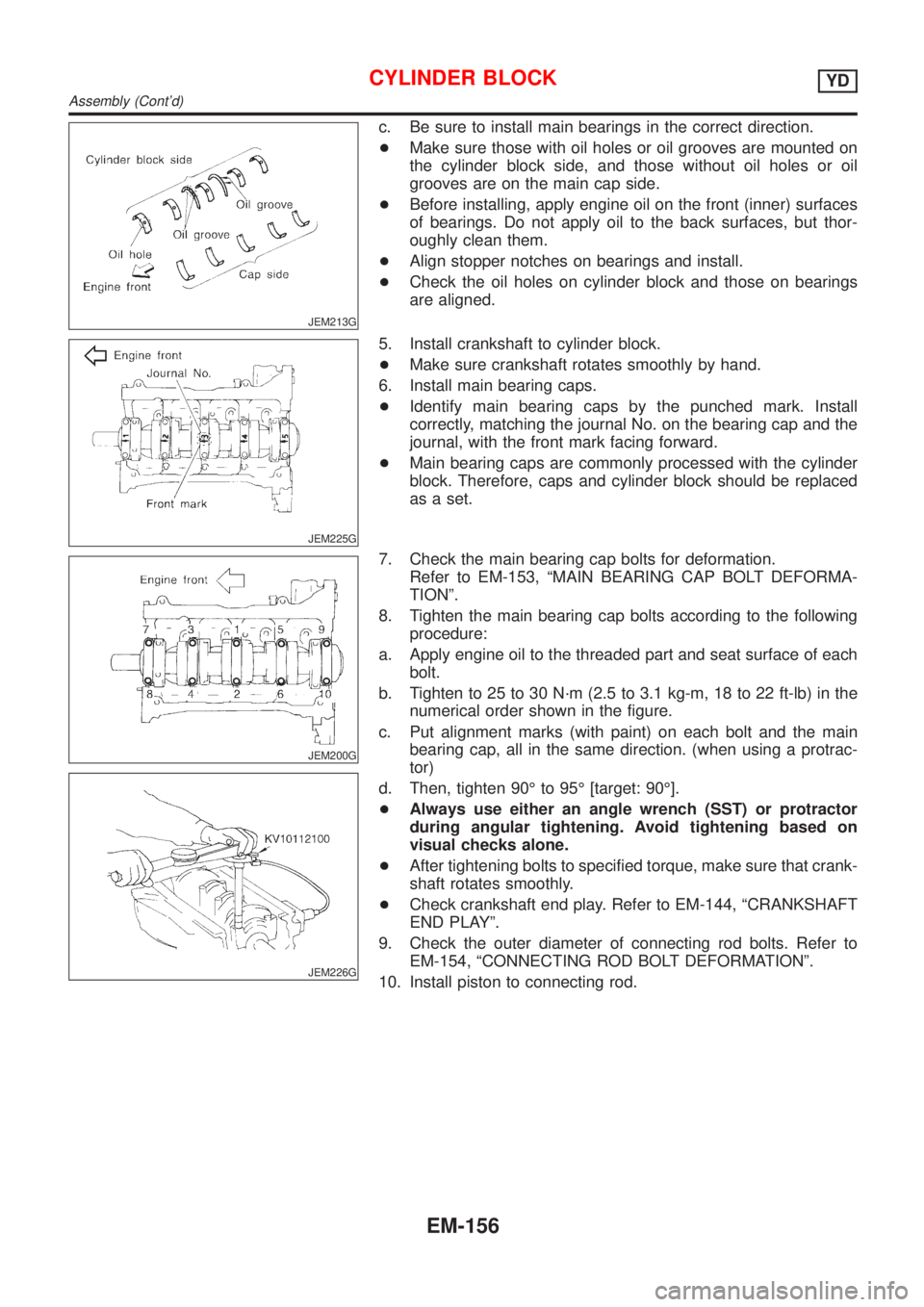

JEM213G

c. Be sure to install main bearings in the correct direction.

+Make sure those with oil holes or oil grooves are mounted on

the cylinder block side, and those without oil holes or oil

grooves are on the main cap side.

+Before installing, apply engine oil on the front (inner) surfaces

of bearings. Do not apply oil to the back surfaces, but thor-

oughly clean them.

+Align stopper notches on bearings and install.

+Check the oil holes on cylinder block and those on bearings

are aligned.

JEM225G

5. Install crankshaft to cylinder block.

+Make sure crankshaft rotates smoothly by hand.

6. Install main bearing caps.

+Identify main bearing caps by the punched mark. Install

correctly, matching the journal No. on the bearing cap and the

journal, with the front mark facing forward.

+Main bearing caps are commonly processed with the cylinder

block. Therefore, caps and cylinder block should be replaced

as a set.

JEM200G

JEM226G

7. Check the main bearing cap bolts for deformation.

Refer to EM-153, ªMAIN BEARING CAP BOLT DEFORMA-

TIONº.

8. Tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and seat surface of each

bolt.

b. Tighten to 25 to 30 N´m (2.5 to 3.1 kg-m, 18 to 22 ft-lb) in the

numerical order shown in the figure.

c. Put alignment marks (with paint) on each bolt and the main

bearing cap, all in the same direction. (when using a protrac-

tor)

d. Then, tighten 90É to 95É [target: 90É].

+Always use either an angle wrench (SST) or protractor

during angular tightening. Avoid tightening based on

visual checks alone.

+After tightening bolts to specified torque, make sure that crank-

shaft rotates smoothly.

+Check crankshaft end play. Refer to EM-144, ªCRANKSHAFT

END PLAYº.

9. Check the outer diameter of connecting rod bolts. Refer to

EM-154, ªCONNECTING ROD BOLT DEFORMATIONº.

10. Install piston to connecting rod.

CYLINDER BLOCKYD

Assembly (Cont'd)

EM-156

Page 2292 of 2898

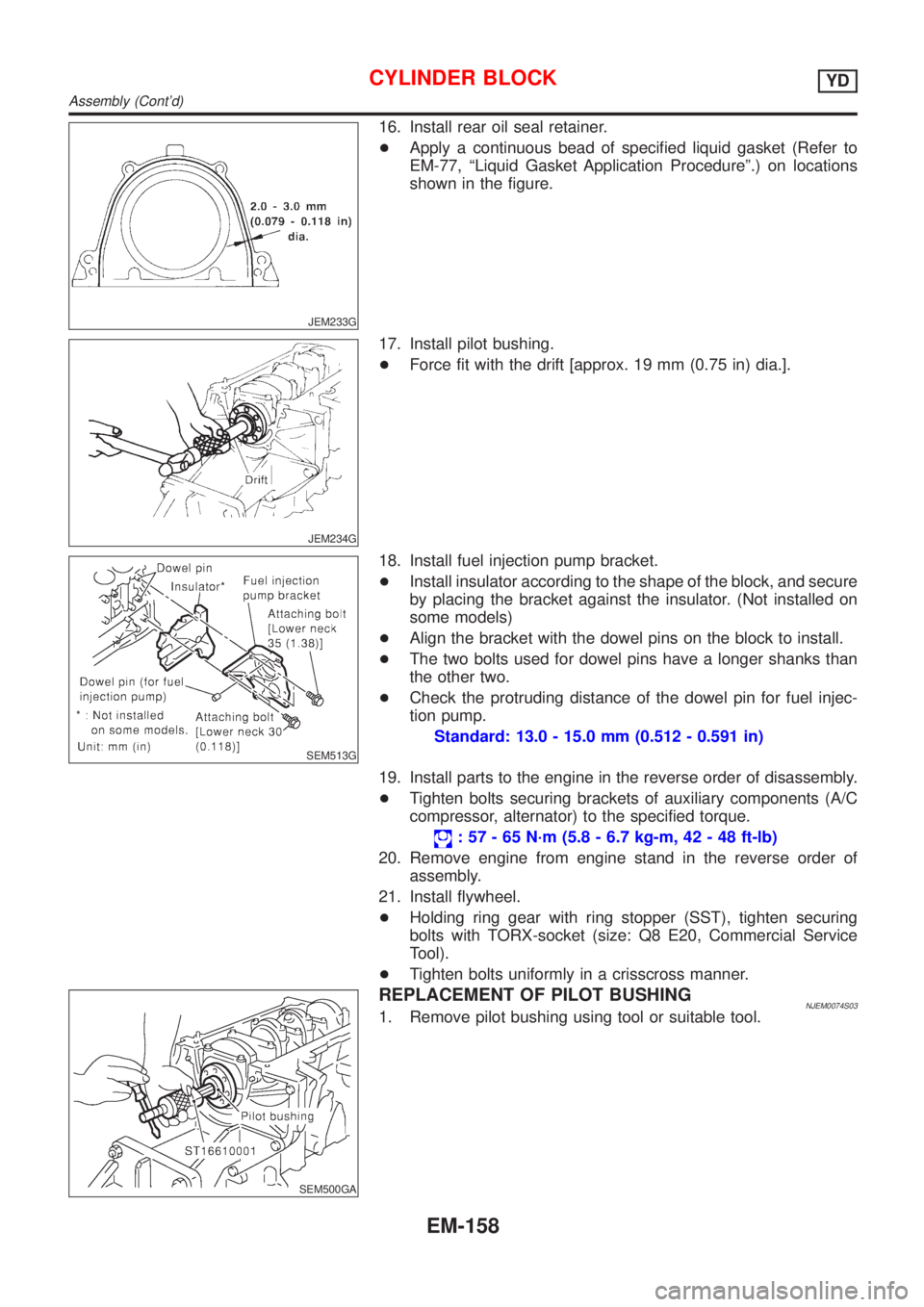

JEM233G

16. Install rear oil seal retainer.

+Apply a continuous bead of specified liquid gasket (Refer to

EM-77, ªLiquid Gasket Application Procedureº.) on locations

shown in the figure.

JEM234G

17. Install pilot bushing.

+Force fit with the drift [approx. 19 mm (0.75 in) dia.].

SEM513G

18. Install fuel injection pump bracket.

+Install insulator according to the shape of the block, and secure

by placing the bracket against the insulator. (Not installed on

some models)

+Align the bracket with the dowel pins on the block to install.

+The two bolts used for dowel pins have a longer shanks than

the other two.

+Check the protruding distance of the dowel pin for fuel injec-

tion pump.

Standard: 13.0 - 15.0 mm (0.512 - 0.591 in)

19. Install parts to the engine in the reverse order of disassembly.

+Tighten bolts securing brackets of auxiliary components (A/C

compressor, alternator) to the specified torque.

: 57 - 65 N´m (5.8 - 6.7 kg-m, 42 - 48 ft-lb)

20. Remove engine from engine stand in the reverse order of

assembly.

21. Install flywheel.

+Holding ring gear with ring stopper (SST), tighten securing

bolts with TORX-socket (size: Q8 E20, Commercial Service

Tool).

+Tighten bolts uniformly in a crisscross manner.

SEM500GA

REPLACEMENT OF PILOT BUSHINGNJEM0074S031. Remove pilot bushing using tool or suitable tool.

CYLINDER BLOCKYD

Assembly (Cont'd)

EM-158

Page 2309 of 2898

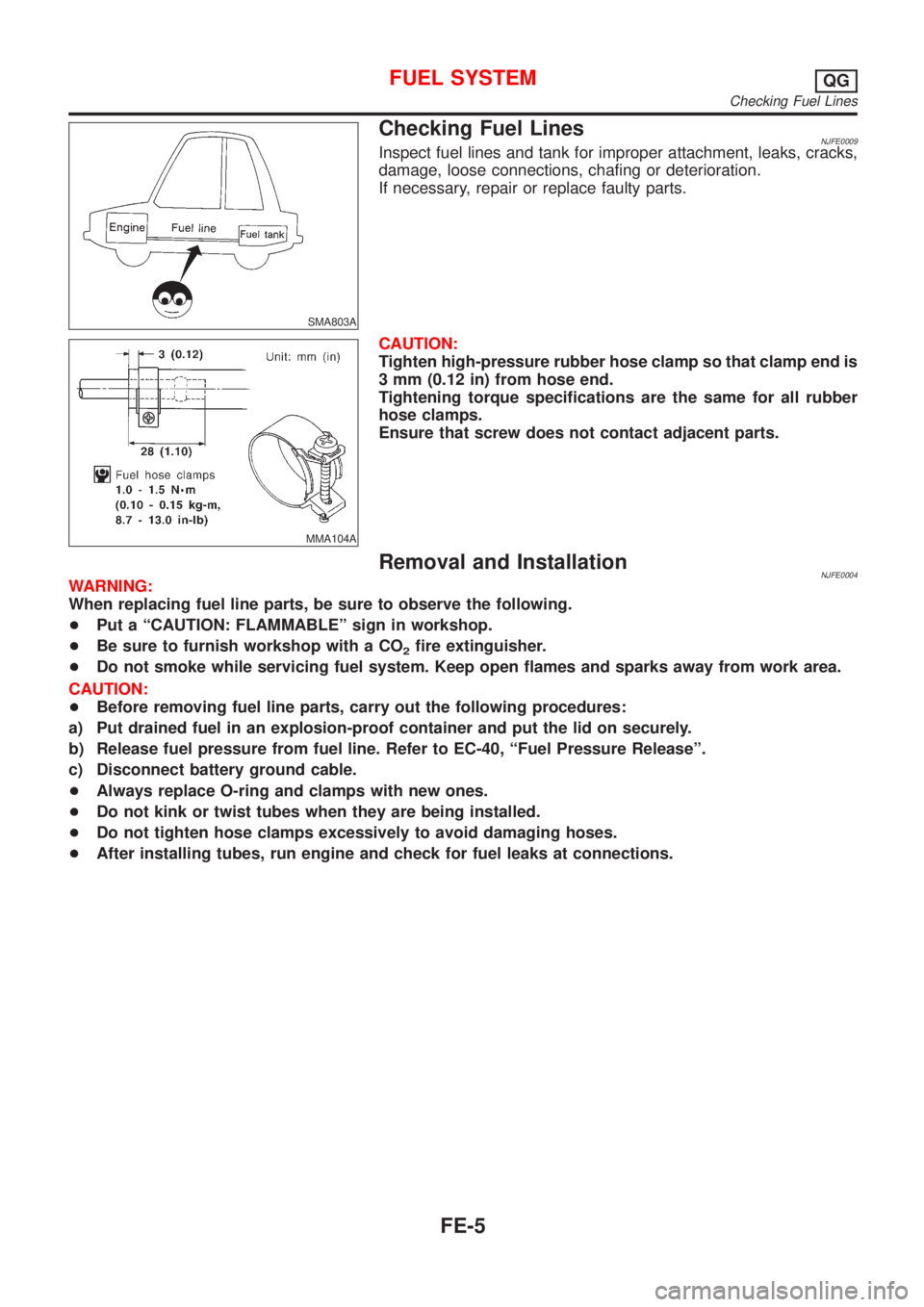

SMA803A

Checking Fuel LinesNJFE0009Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

MMA104A

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

Removal and InstallationNJFE0004WARNING:

When replacing fuel line parts, be sure to observe the following.

+Put a ªCAUTION: FLAMMABLEº sign in workshop.

+Be sure to furnish workshop with a CO

2fire extinguisher.

+Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

CAUTION:

+Before removing fuel line parts, carry out the following procedures:

a) Put drained fuel in an explosion-proof container and put the lid on securely.

b) Release fuel pressure from fuel line. Refer to EC-40, ªFuel Pressure Releaseº.

c) Disconnect battery ground cable.

+Always replace O-ring and clamps with new ones.

+Do not kink or twist tubes when they are being installed.

+Do not tighten hose clamps excessively to avoid damaging hoses.

+After installing tubes, run engine and check for fuel leaks at connections.

FUEL SYSTEMQG

Checking Fuel Lines

FE-5