NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2491 of 2898

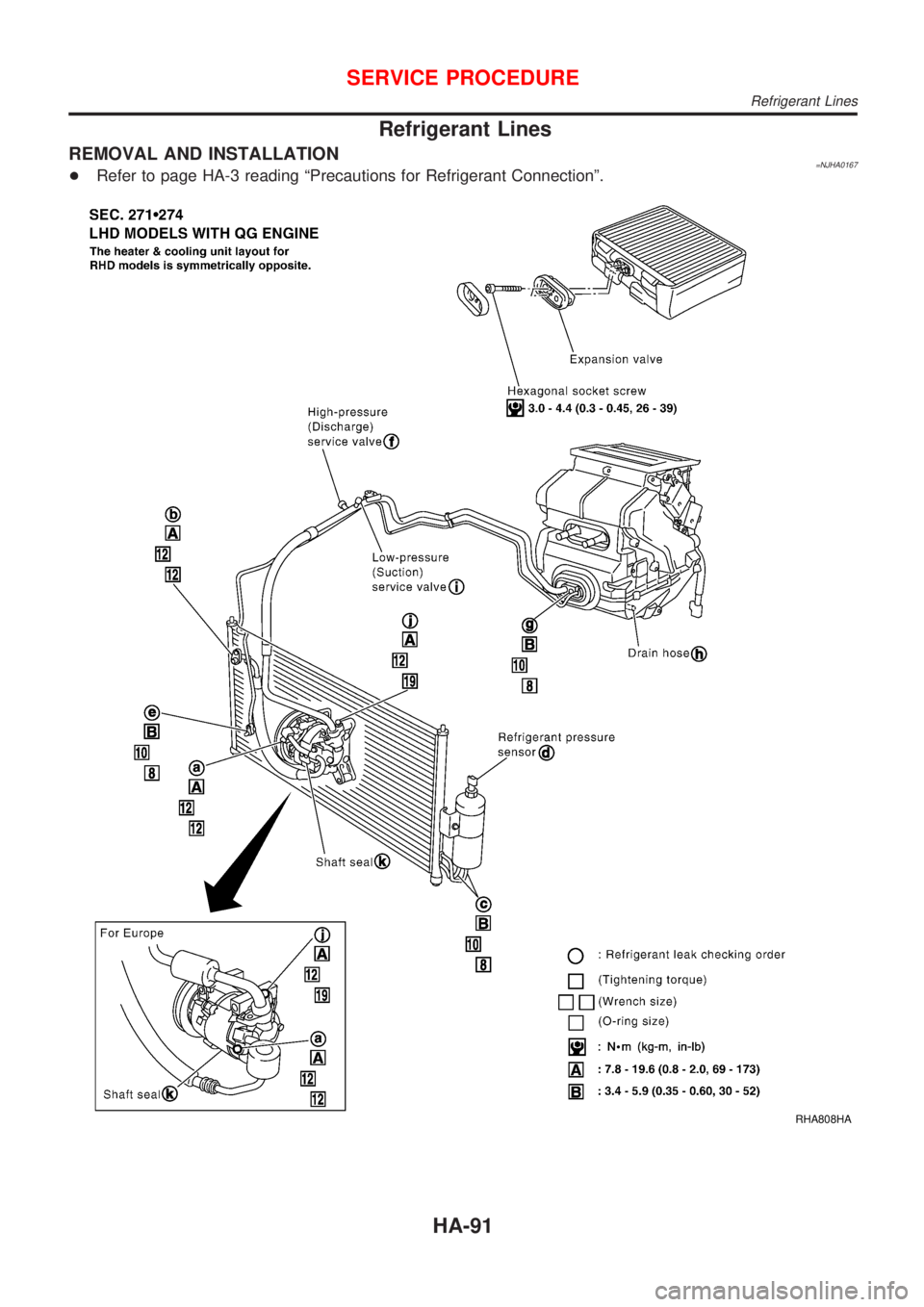

Refrigerant Lines

REMOVAL AND INSTALLATION=NJHA0167+Refer to page HA-3 reading ªPrecautions for Refrigerant Connectionº.

RHA808HA

SERVICE PROCEDURE

Refrigerant Lines

HA-91

Page 2492 of 2898

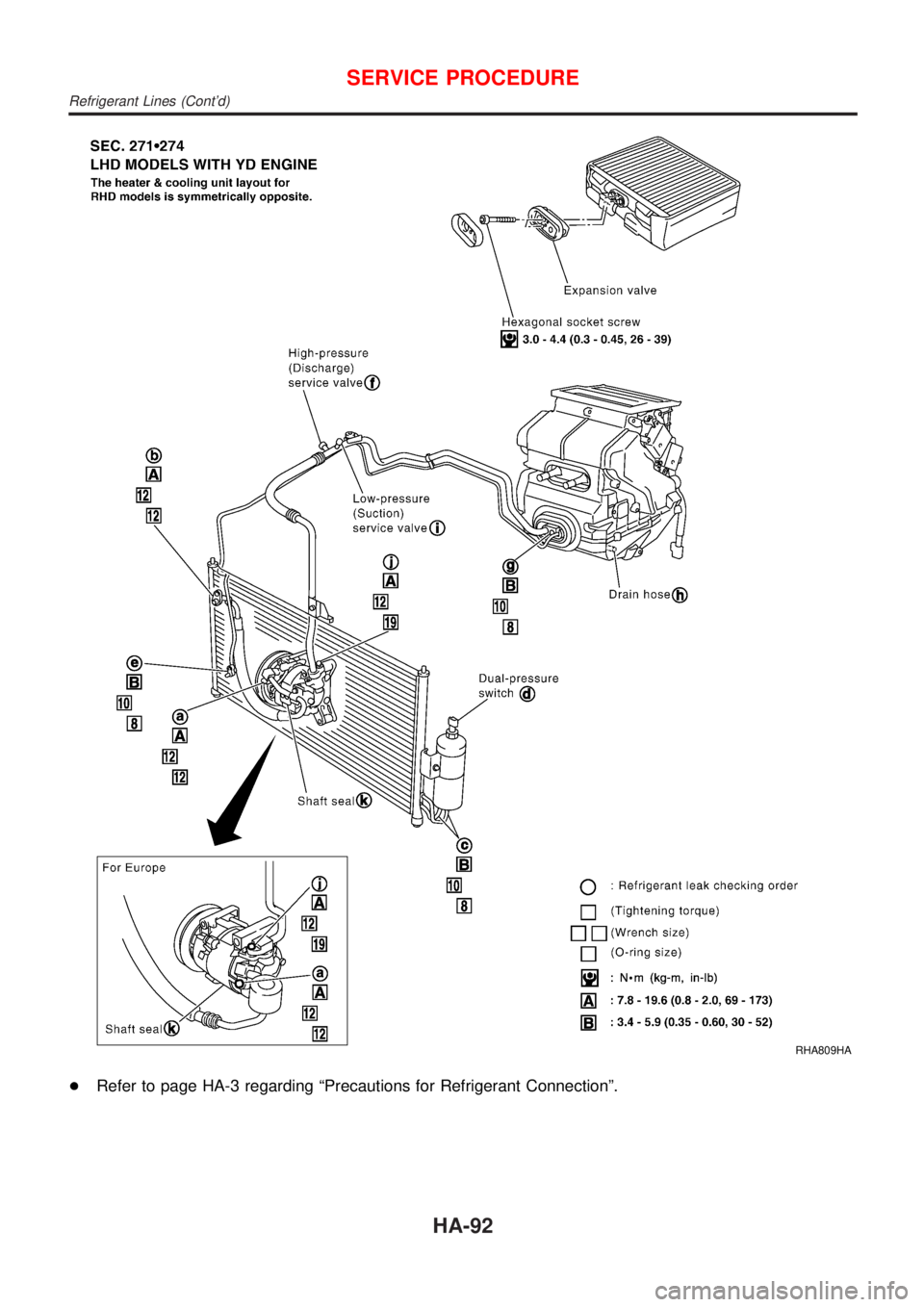

RHA809HA

+Refer to page HA-3 regarding ªPrecautions for Refrigerant Connectionº.

SERVICE PROCEDURE

Refrigerant Lines (Cont'd)

HA-92

Page 2493 of 2898

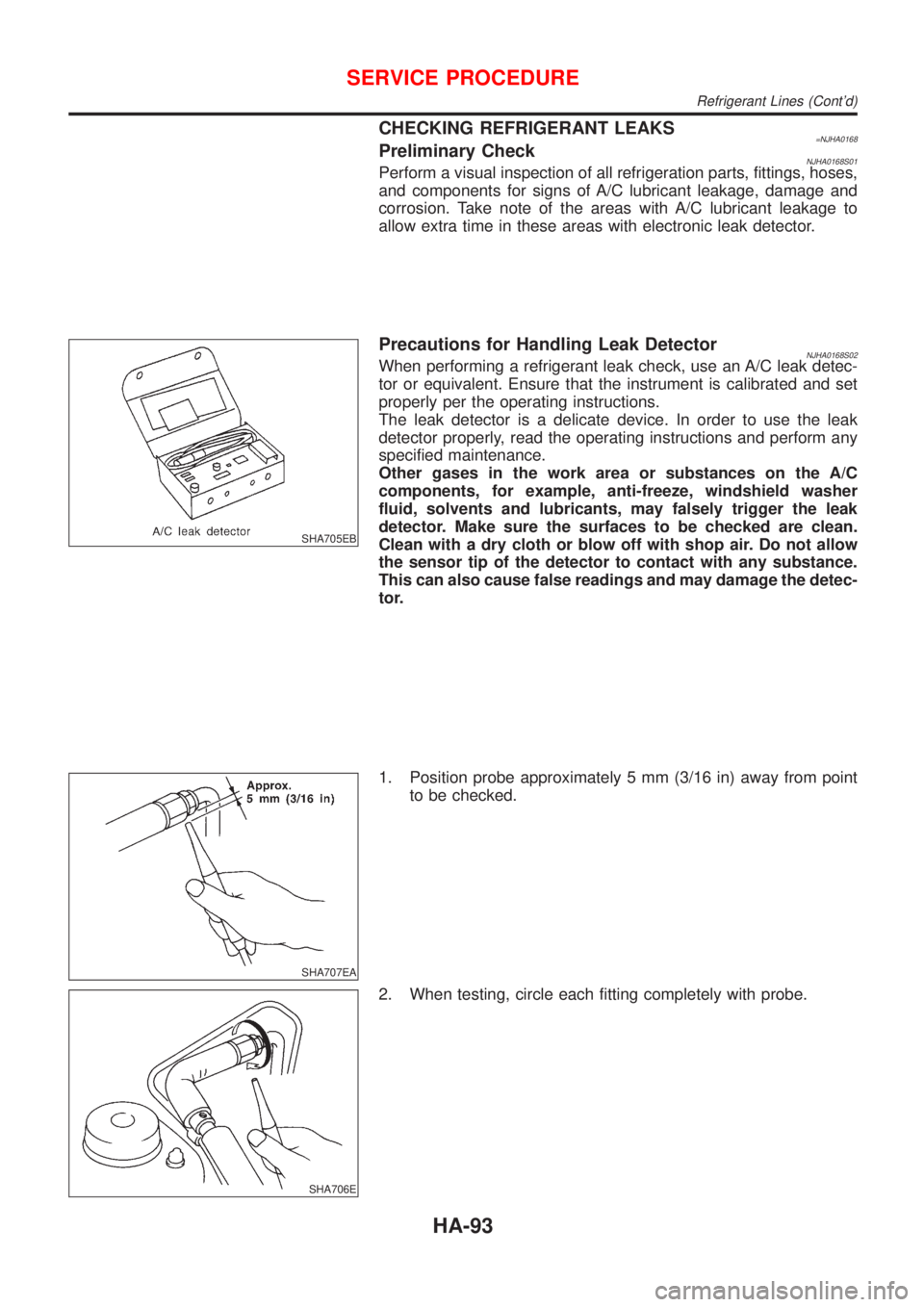

CHECKING REFRIGERANT LEAKS=NJHA0168Preliminary CheckNJHA0168S01Perform a visual inspection of all refrigeration parts, fittings, hoses,

and components for signs of A/C lubricant leakage, damage and

corrosion. Take note of the areas with A/C lubricant leakage to

allow extra time in these areas with electronic leak detector.

SHA705EB

Precautions for Handling Leak DetectorNJHA0168S02When performing a refrigerant leak check, use an A/C leak detec-

tor or equivalent. Ensure that the instrument is calibrated and set

properly per the operating instructions.

The leak detector is a delicate device. In order to use the leak

detector properly, read the operating instructions and perform any

specified maintenance.

Other gases in the work area or substances on the A/C

components, for example, anti-freeze, windshield washer

fluid, solvents and lubricants, may falsely trigger the leak

detector. Make sure the surfaces to be checked are clean.

Clean with a dry cloth or blow off with shop air. Do not allow

the sensor tip of the detector to contact with any substance.

This can also cause false readings and may damage the detec-

tor.

SHA707EA

1. Position probe approximately 5 mm (3/16 in) away from point

to be checked.

SHA706E

2. When testing, circle each fitting completely with probe.

SERVICE PROCEDURE

Refrigerant Lines (Cont'd)

HA-93

Page 2494 of 2898

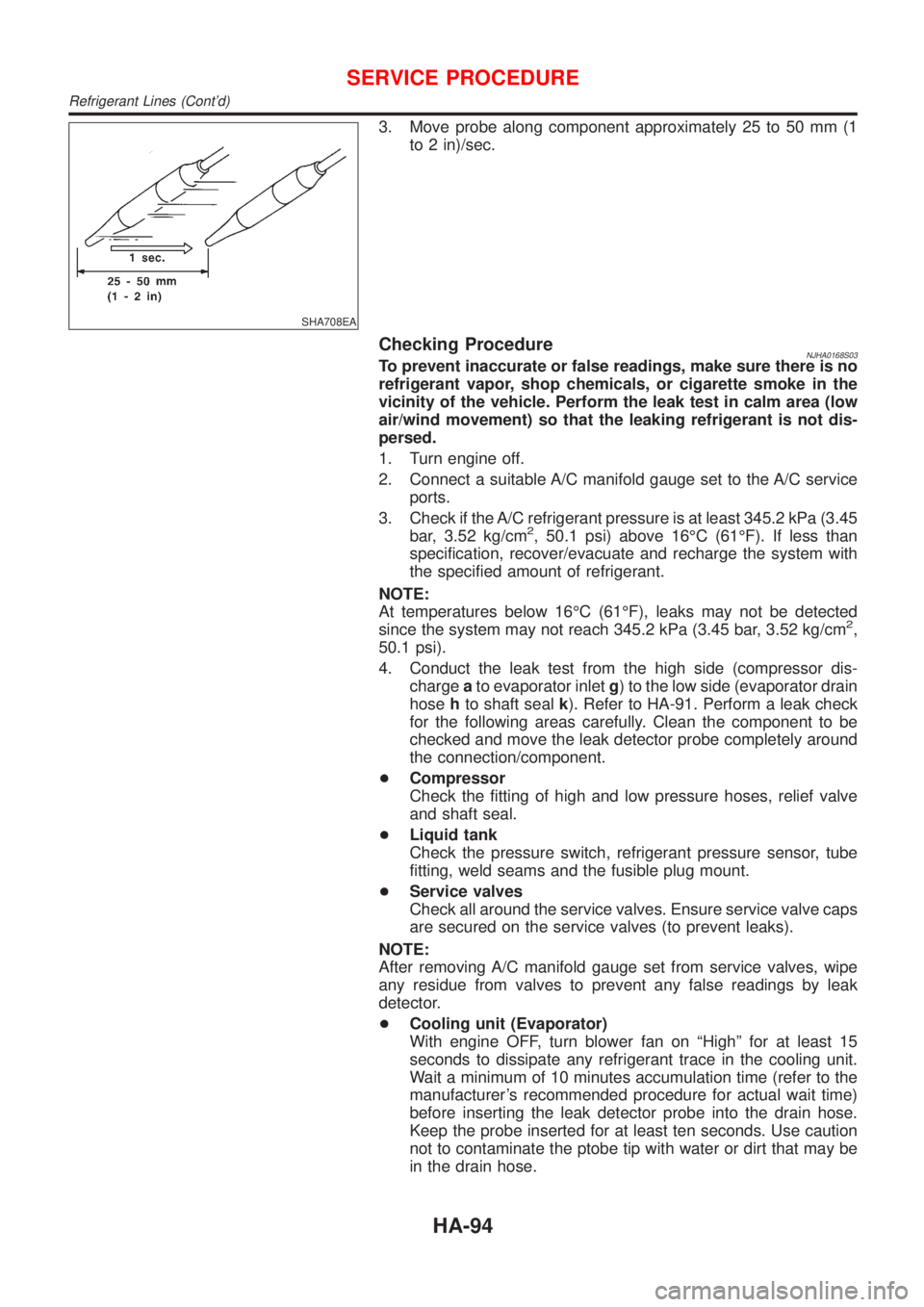

SHA708EA

3. Move probe along component approximately 25 to 50 mm (1

to 2 in)/sec.

Checking ProcedureNJHA0168S03To prevent inaccurate or false readings, make sure there is no

refrigerant vapor, shop chemicals, or cigarette smoke in the

vicinity of the vehicle. Perform the leak test in calm area (low

air/wind movement) so that the leaking refrigerant is not dis-

persed.

1. Turn engine off.

2. Connect a suitable A/C manifold gauge set to the A/C service

ports.

3. Check if the A/C refrigerant pressure is at least 345.2 kPa (3.45

bar, 3.52 kg/cm

2, 50.1 psi) above 16ÉC (61ÉF). If less than

specification, recover/evacuate and recharge the system with

the specified amount of refrigerant.

NOTE:

At temperatures below 16ÉC (61ÉF), leaks may not be detected

since the system may not reach 345.2 kPa (3.45 bar, 3.52 kg/cm

2,

50.1 psi).

4. Conduct the leak test from the high side (compressor dis-

chargeato evaporator inletg) to the low side (evaporator drain

hosehto shaft sealk). Refer to HA-91. Perform a leak check

for the following areas carefully. Clean the component to be

checked and move the leak detector probe completely around

the connection/component.

+Compressor

Check the fitting of high and low pressure hoses, relief valve

and shaft seal.

+Liquid tank

Check the pressure switch, refrigerant pressure sensor, tube

fitting, weld seams and the fusible plug mount.

+Service valves

Check all around the service valves. Ensure service valve caps

are secured on the service valves (to prevent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe

any residue from valves to prevent any false readings by leak

detector.

+Cooling unit (Evaporator)

With engine OFF, turn blower fan on ªHighº for at least 15

seconds to dissipate any refrigerant trace in the cooling unit.

Wait a minimum of 10 minutes accumulation time (refer to the

manufacturer's recommended procedure for actual wait time)

before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least ten seconds. Use caution

not to contaminate the ptobe tip with water or dirt that may be

in the drain hose.

SERVICE PROCEDURE

Refrigerant Lines (Cont'd)

HA-94

Page 2495 of 2898

5. If a leak detector detects a leak, verify at least once by blow-

ing compressed air into area of suspected leak, then repeat

check as outlined above.

6. Do not stop when one leak is found. Continue to check for

additional leaks at all system components.

If no leaks are found, perform steps7-10.

7. Start engine.

8. Set the heater A/C control as follows:

1) A/C switch ON.

2) Face mode

3) Recirculation position

4) Max cold temperature

5) Fan speed high

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps

4 through 6 above.

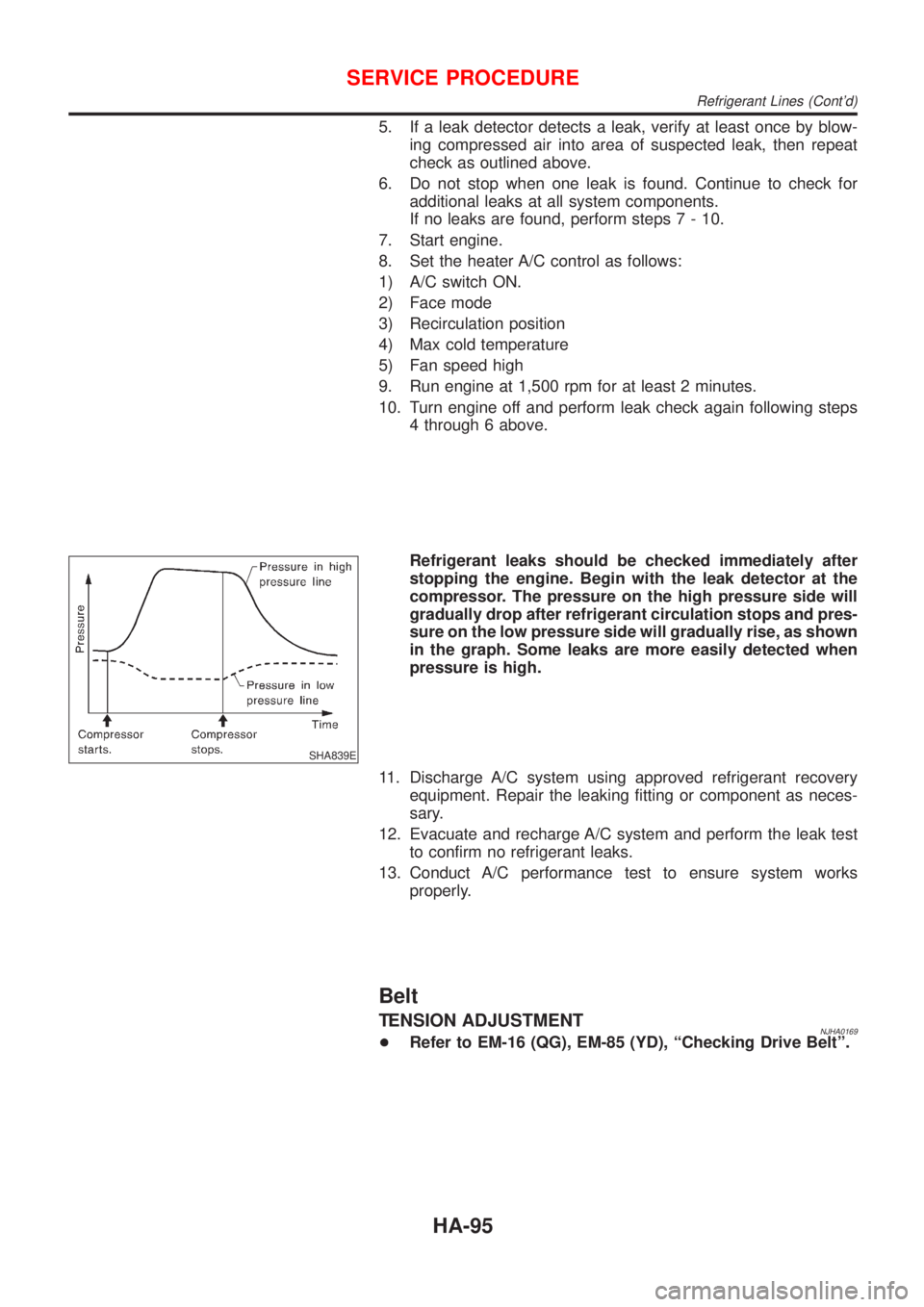

SHA839E

Refrigerant leaks should be checked immediately after

stopping the engine. Begin with the leak detector at the

compressor. The pressure on the high pressure side will

gradually drop after refrigerant circulation stops and pres-

sure on the low pressure side will gradually rise, as shown

in the graph. Some leaks are more easily detected when

pressure is high.

11. Discharge A/C system using approved refrigerant recovery

equipment. Repair the leaking fitting or component as neces-

sary.

12. Evacuate and recharge A/C system and perform the leak test

to confirm no refrigerant leaks.

13. Conduct A/C performance test to ensure system works

properly.

Belt

TENSION ADJUSTMENTNJHA0169+Refer to EM-16 (QG), EM-85 (YD), ªChecking Drive Beltº.

SERVICE PROCEDURE

Refrigerant Lines (Cont'd)

HA-95

Page 2496 of 2898

Idle Air Control Valve (IACV) Ð Auxiliary Air

Control (AAC) Valve

INSPECTIONNJHA0199+Refer to EC-376 (QG), ªSystem Descriptionº.

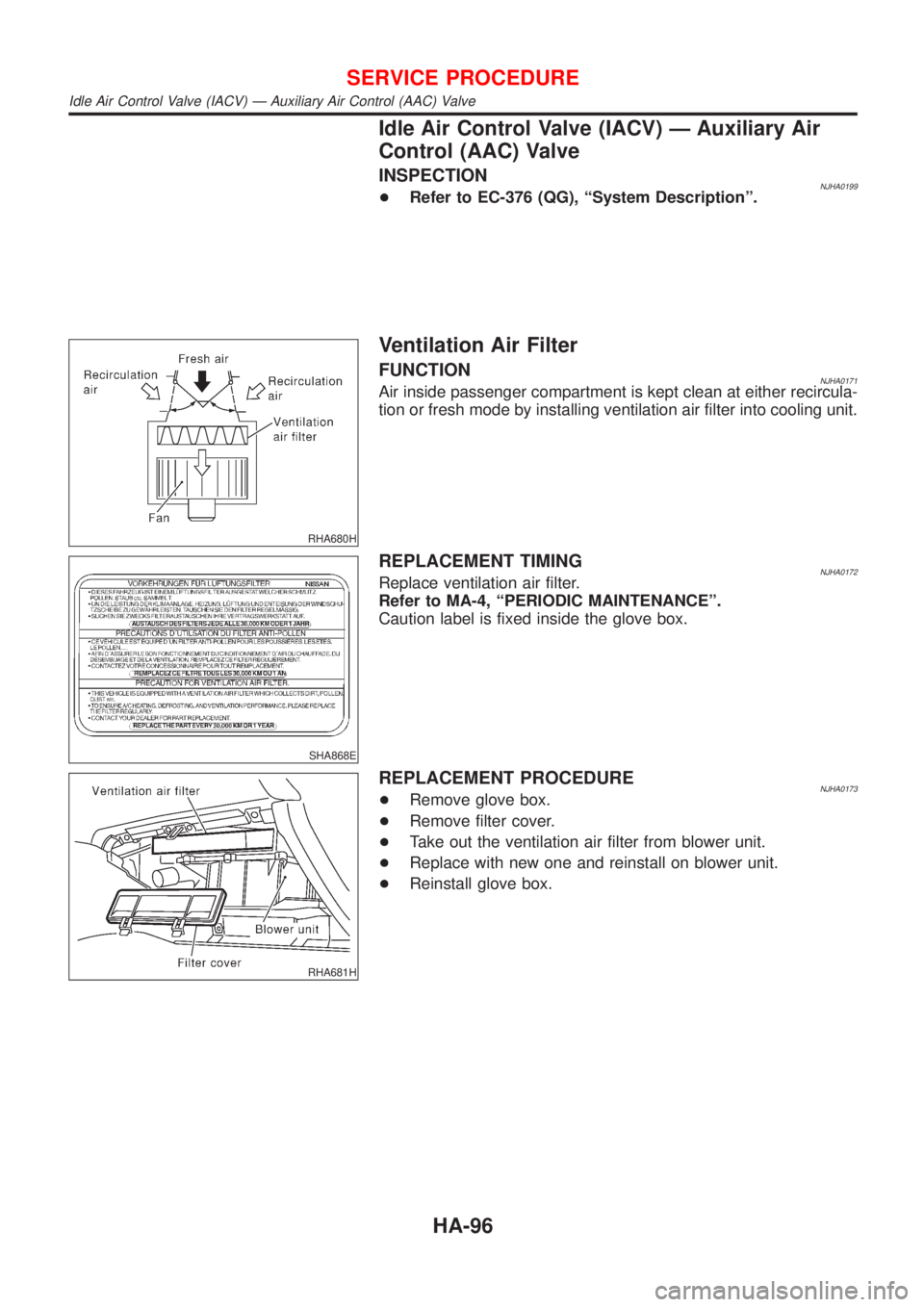

RHA680H

Ventilation Air Filter

FUNCTIONNJHA0171Air inside passenger compartment is kept clean at either recircula-

tion or fresh mode by installing ventilation air filter into cooling unit.

SHA868E

REPLACEMENT TIMINGNJHA0172Replace ventilation air filter.

Refer to MA-4, ªPERIODIC MAINTENANCEº.

Caution label is fixed inside the glove box.

RHA681H

REPLACEMENT PROCEDURENJHA0173+Remove glove box.

+Remove filter cover.

+Take out the ventilation air filter from blower unit.

+Replace with new one and reinstall on blower unit.

+Reinstall glove box.

SERVICE PROCEDURE

Idle Air Control Valve (IACV) Ð Auxiliary Air Control (AAC) Valve

HA-96

Page 2497 of 2898

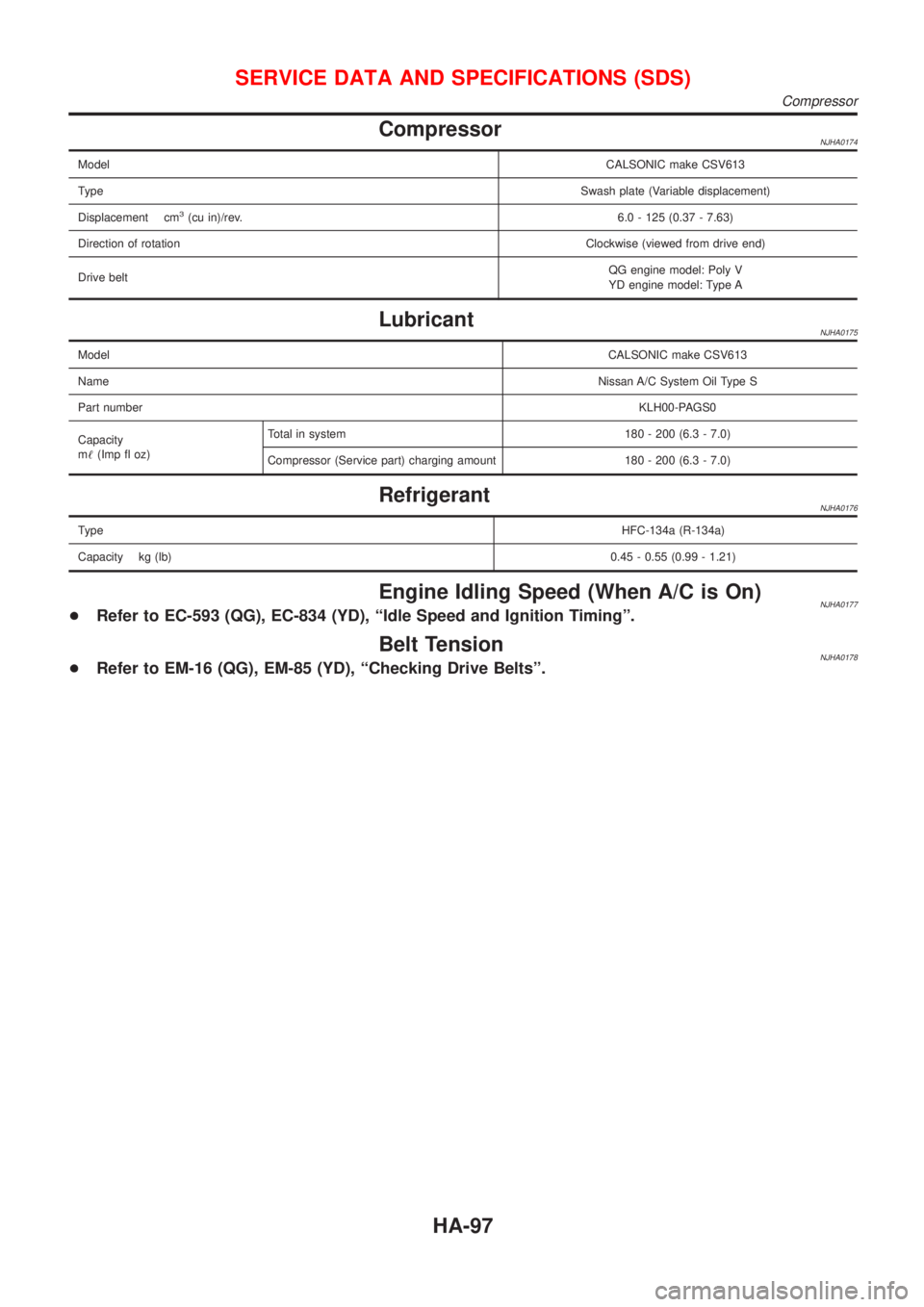

CompressorNJHA0174

ModelCALSONIC make CSV613

TypeSwash plate (Variable displacement)

Displacement cm

3(cu in)/rev.6.0 - 125 (0.37 - 7.63)

Direction of rotationClockwise (viewed from drive end)

Drive beltQG engine model: Poly V

YD engine model: Type A

LubricantNJHA0175

ModelCALSONIC make CSV613

NameNissan A/C System Oil Type S

Part numberKLH00-PAGS0

Capacity

m!(Imp fl oz)Total in system 180 - 200 (6.3 - 7.0)

Compressor (Service part) charging amount 180 - 200 (6.3 - 7.0)

RefrigerantNJHA0176

TypeHFC-134a (R-134a)

Capacity kg (lb)0.45 - 0.55 (0.99 - 1.21)

Engine Idling Speed (When A/C is On)NJHA0177+Refer to EC-593 (QG), EC-834 (YD), ªIdle Speed and Ignition Timingº.

Belt TensionNJHA0178+Refer to EM-16 (QG), EM-85 (YD), ªChecking Drive Beltsº.

SERVICE DATA AND SPECIFICATIONS (SDS)

Compressor

HA-97

Page 2498 of 2898

SERVICE DATA AND SPECIFICATIONS (SDS)

Belt Tension (Cont'd)

HA-98

Page 2499 of 2898

ALPHABETICAL INDEX

SECTION

IDX

Page 2500 of 2898

A

A/C HFC134a (R134a) system precaution . HA-2

A/C HFC134a (R134a) system service

procedure .............................................. HA-78

A/C HFC134a (R134a) system service

tools ....................................................... HA-11

A/C HFC134a system service equip-

ment precaution ....................................... HA-6

A/C air flow ............................................... HA-20

A/C component layout .............................. HA-18

A/C compressor clutch removal and

installation .............................................. HA-83

A/C compressor precaution ........................ HA-5

A/C compressor special service tool .......... HA-9

A/C control linkage adjustment

(manual A/C) ......................................... HA-41

A/C control operation (manual A/C) .......... HA-19

A/C diagnostic work flow

(manual A/C) ........................................ HA-33

A/C harness layout (manual A/C) ............. HA-22

A/C lubricant (R134a) ............................... HA-80

A/C operational check ............................... HA-34

A/C performance chart .............................. HA-71

A/C performance test diagnoses .............. HA-69

A/C relay ................................................... HA-66

A/C service data specification .................. HA-97

A/C switch ................................................. HA-67

A/C, M - Wiring diagram ........................... HA-27

A/CCUT - Wiring diagram ....................... EC-830

A/T - Wiring diagram - AT - 1ST .............. AT-207

A/T - Wiring diagram - AT - 2ND ............. AT-214

A/T - Wiring diagram - AT - 3RD ............. AT-220

A/T - Wiring diagram - AT - 4TH .............. AT-227

A/T - Wiring diagram - AT - BA/FTS ....... AT-167,

276

A/T - Wiring diagram - AT - ENG SS ...... AT-173,

201

A/T - Wiring diagram - AT - FTS .............. AT-191

A/T - Wiring diagram - AT - LPSV ... AT-178, 241

A/T - Wiring diagram - AT - MAIN ........... AT-123

A/T - Wiring diagram - AT -

NONDTC .............................................. AT-292

A/T - Wiring diagram - AT -

OVRCSV ...................................... AT-155, 270

A/T - Wiring diagram - AT - PNP/SW ...... AT-185

A/T - Wiring diagram - AT - SSV/A .. AT-144, 248

A/T - Wiring diagram - AT - SSV/B .. AT-150, 254

A/T - Wiring diagram - AT - TCV ..... AT-161, 235

A/T - Wiring diagram - AT - TPS ..... AT-136, 261

A/T - Wiring diagram - AT - VSS/AT ....... AT-128,

197

A/T - Wiring diagram - AT -

VSSMTR ...................................... AT-132, 283

A/T IND - Wiring diagram ........................ EL-195

A/T control ............................................... EC-532

A/T diagnosis communication line .......... EC-434

A/T fluid temperature sensor ................... AT-194A/T shift lock system - Wiring

diagram ................................................ AT-344

A/T shift lock system ................................ AT-343

A/T trouble diagnoses .......................... AT-69, 74

AAC/V - Wiring diagram ................. EC-378, 513

ABS (anti-lock brake system) ................... BR-49

ABS - Wiring diagram ............................... BR-54

ABS sensor rotor ....................................... AX-24

APS - Wiring diagram ............................. EC-685

ATDIAG - Wiring diagram ............... EC-435, 533

Accelerator control system .................... FE-3, 19

Accelerator position sensor .................... EC-685

Air bag disposal ........................................ RS-40

Air bag precautions ...................................... GI-3

Air bag ....................................................... RS-20

Air bleeding (hydraulic clutch) ................... CL-10

Air bleeding for brake system ..................... BR-9

Air conditioner cut control ................. EC-35, 612

Air flow meter - See Mass air flow

sensor .......................................... EC-187, 673

Air mix door control linkage

adjustment ............................................. HA-43

Air spoiler, rear .......................................... BT-47

Alternator ................................................... SC-31

Angular tightening application .............. EM-4, 77

Antenna - See Power antenna ................ EL-282

Anti-lock brake system - Wiring

diagram .................................................. BR-54

Audio and A/C control removal and

installation - See Instrument panel ........ BT-25

Audio ........................................................ EL-258

Automatic transaxle number ...................... GI-41

Auxiliary air control (AAC) valve ..... EC-376, 511

B

Back-up lamp switch (M/T) ....................... MT-21

Back-up lamp ............................................. EL-87

Ball joint (front) .......................................... SU-13

Basic inspection ...................... EC-100, 128, 641

Battery ......................................................... SC-3

Baulk ring (M/T) ............................ MT-31, 55, 93

Blower motor ............................................. HA-54

Blower resistor .......................................... HA-54

Board-on lift ................................................ GI-44

Body alignment .......................................... BT-77

Brake booster ............................................ BR-20

Brake fluid change ...................................... BR-8

Brake fluid level and line check .................. BR-8

Brake hydraulic line .................................. BR-10

Brake master cylinder ............................... BR-14

Brake pedal ............................................... BR-12

Bulb specifications ................................... EL-574

Bumper, front .............................................. BT-7

Bumper, rear .............................................. BT-10

ALPHABETICAL INDEX

IDX-2