ESP NISSAN ALMERA 2001 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 254 of 2898

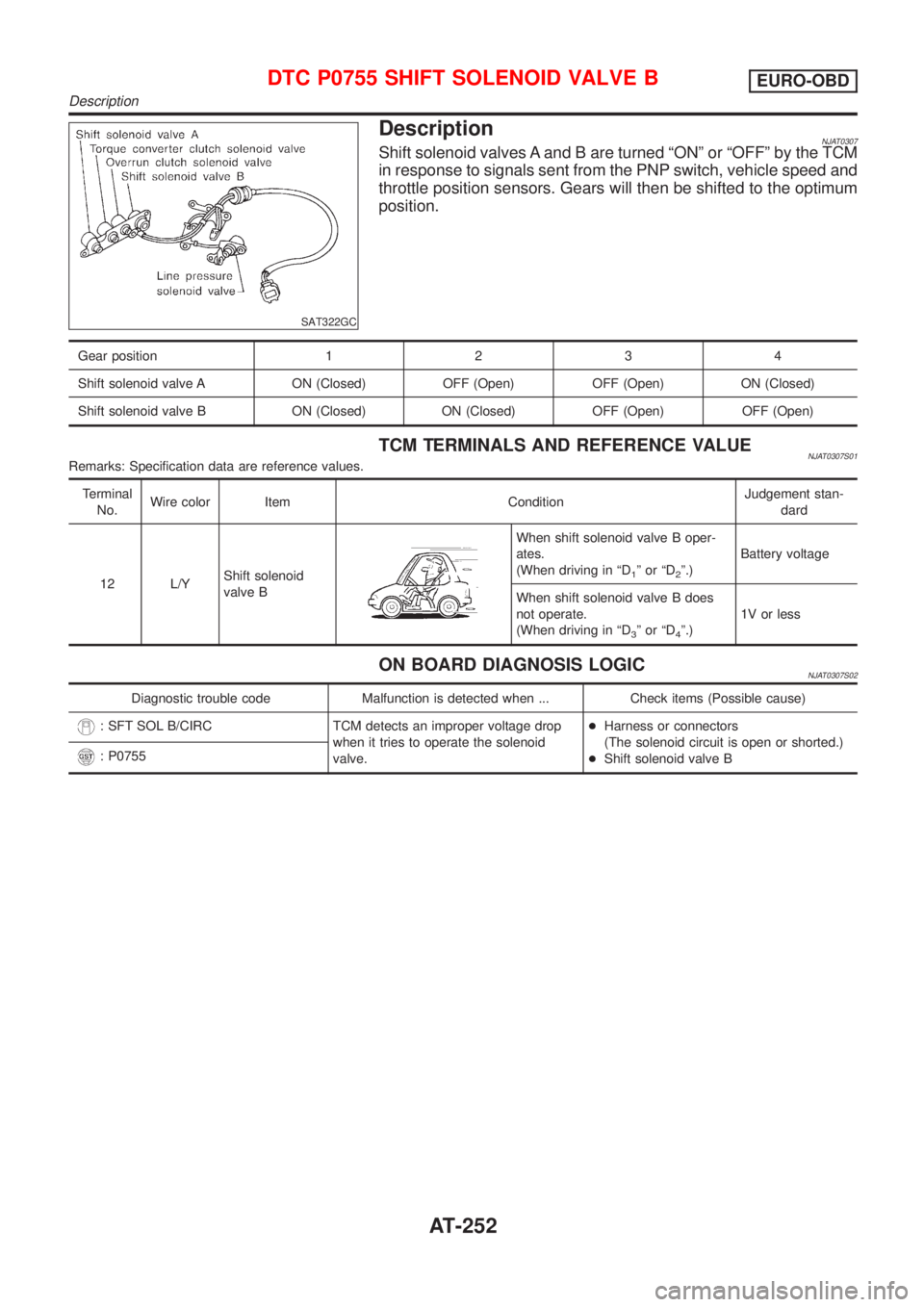

SAT322GC

DescriptionNJAT0307Shift solenoid valves A and B are turned ªONº or ªOFFº by the TCM

in response to signals sent from the PNP switch, vehicle speed and

throttle position sensors. Gears will then be shifted to the optimum

position.

Gear position1234

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

TCM TERMINALS AND REFERENCE VALUENJAT0307S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

12 L/YShift solenoid

valve B

When shift solenoid valve B oper-

ates.

(When driving in ªD

1ºorªD2º.)Battery voltage

When shift solenoid valve B does

not operate.

(When driving in ªD

3ºorªD4º.)1V or less

ON BOARD DIAGNOSIS LOGICNJAT0307S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: SFT SOL B/CIRC TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+Shift solenoid valve B

: P0755

DTC P0755 SHIFT SOLENOID VALVE BEURO-OBD

Description

AT-252

Page 260 of 2898

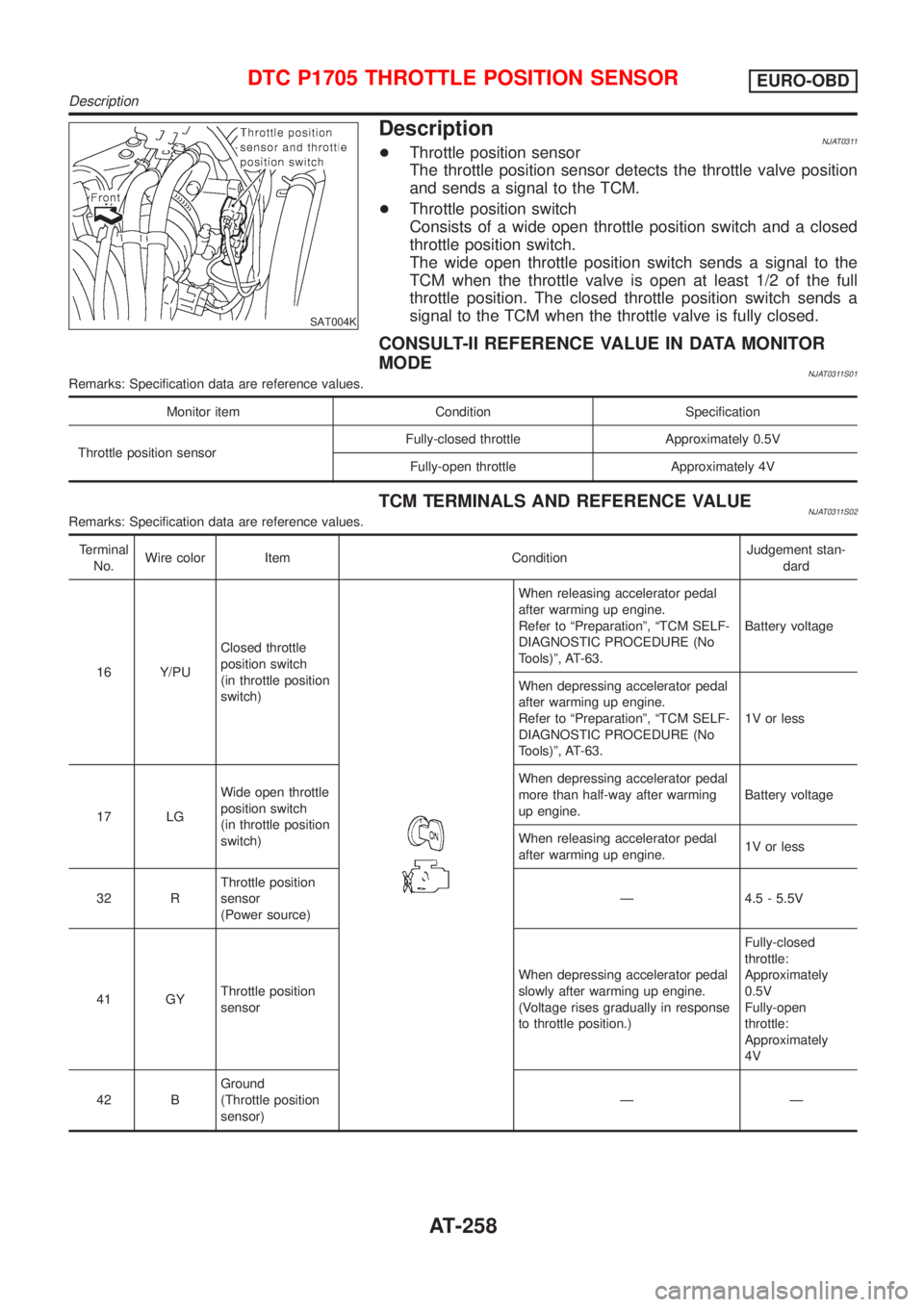

SAT004K

DescriptionNJAT0311+Throttle position sensor

The throttle position sensor detects the throttle valve position

and sends a signal to the TCM.

+Throttle position switch

Consists of a wide open throttle position switch and a closed

throttle position switch.

The wide open throttle position switch sends a signal to the

TCM when the throttle valve is open at least 1/2 of the full

throttle position. The closed throttle position switch sends a

signal to the TCM when the throttle valve is fully closed.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NJAT0311S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Throttle position sensorFully-closed throttle Approximately 0.5V

Fully-open throttle Approximately 4V

TCM TERMINALS AND REFERENCE VALUENJAT0311S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

16 Y/PUClosed throttle

position switch

(in throttle position

switch)

When releasing accelerator pedal

after warming up engine.

Refer to ªPreparationº, ªTCM SELF-

DIAGNOSTIC PROCEDURE (No

Tools)º, AT-63.Battery voltage

When depressing accelerator pedal

after warming up engine.

Refer to ªPreparationº, ªTCM SELF-

DIAGNOSTIC PROCEDURE (No

Tools)º, AT-63.1V or less

17 LGWide open throttle

position switch

(in throttle position

switch)When depressing accelerator pedal

more than half-way after warming

up engine.Battery voltage

When releasing accelerator pedal

after warming up engine.1V or less

32 RThrottle position

sensor

(Power source)Ð 4.5 - 5.5V

41 GYThrottle position

sensorWhen depressing accelerator pedal

slowly after warming up engine.

(Voltage rises gradually in response

to throttle position.)Fully-closed

throttle:

Approximately

0.5V

Fully-open

throttle:

Approximately

4V

42 BGround

(Throttle position

sensor)ÐÐ

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Description

AT-258

Page 266 of 2898

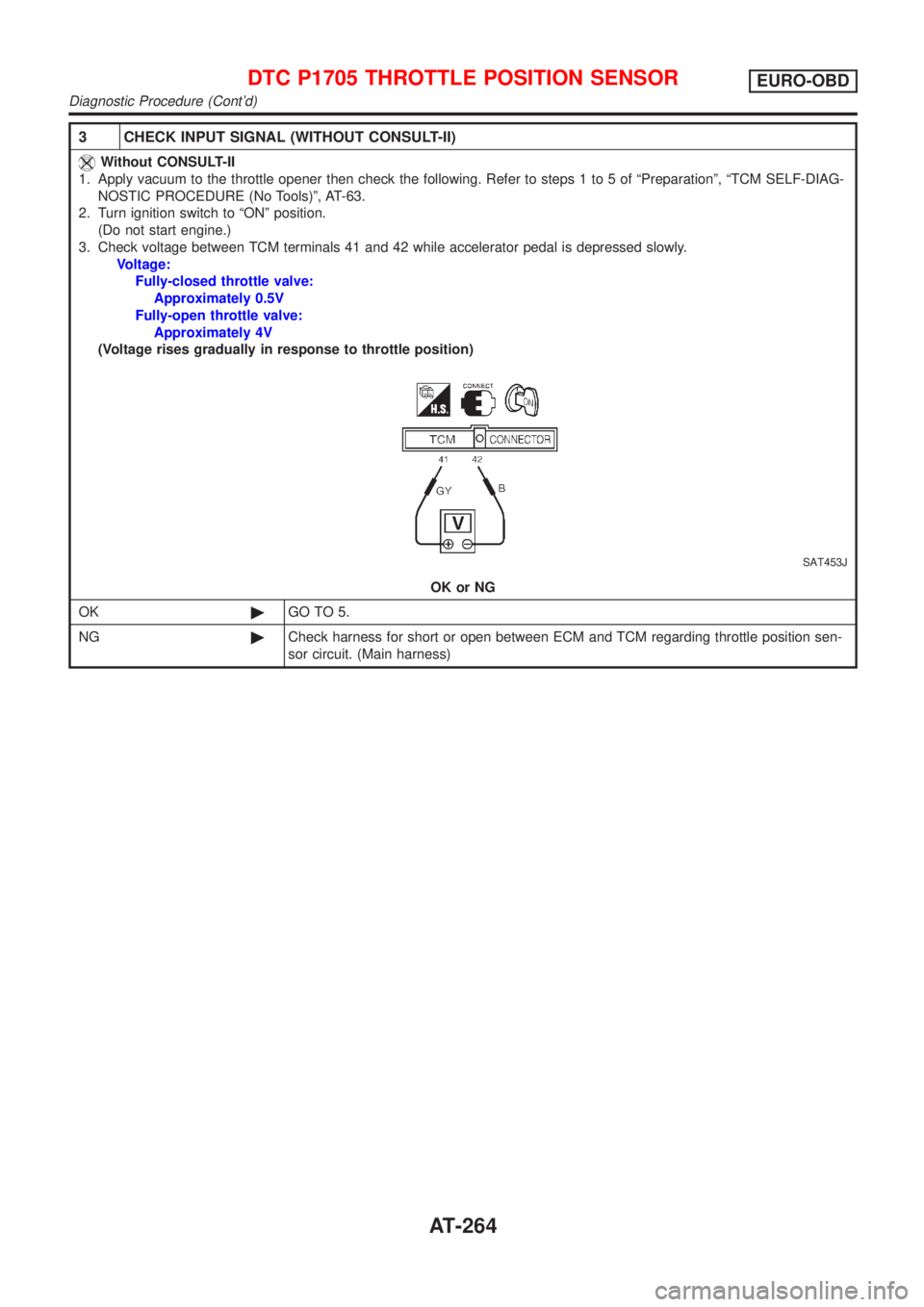

3 CHECK INPUT SIGNAL (WITHOUT CONSULT-II)

Without CONSULT-II

1. Apply vacuum to the throttle opener then check the following. Refer to steps 1 to 5 of ªPreparationº, ªTCM SELF-DIAG-

NOSTIC PROCEDURE (No Tools)º, AT-63.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Check voltage between TCM terminals 41 and 42 while accelerator pedal is depressed slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.5V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in response to throttle position)

SAT453J

OK or NG

OK©GO TO 5.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Diagnostic Procedure (Cont'd)

AT-264

Page 270 of 2898

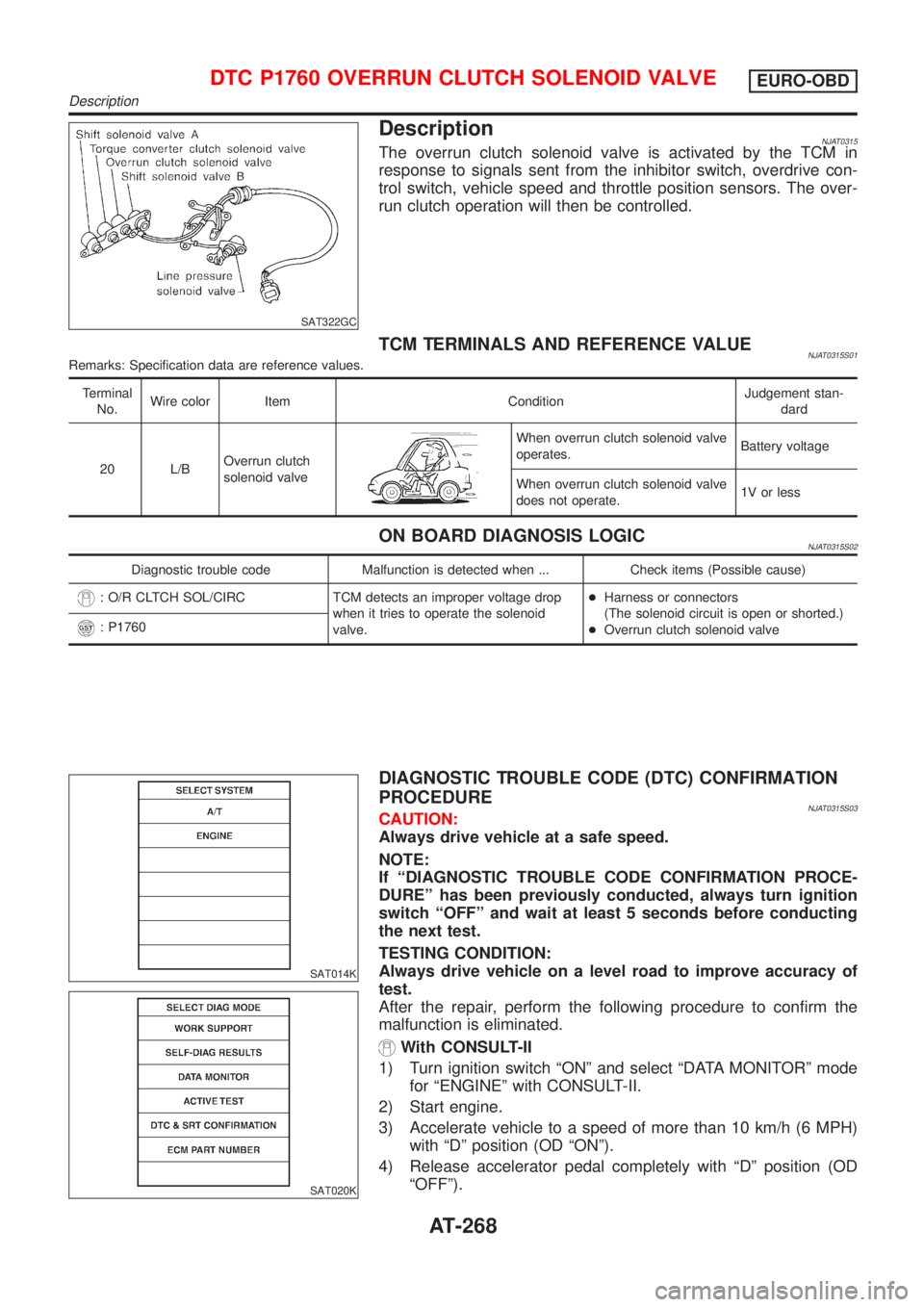

SAT322GC

DescriptionNJAT0315The overrun clutch solenoid valve is activated by the TCM in

response to signals sent from the inhibitor switch, overdrive con-

trol switch, vehicle speed and throttle position sensors. The over-

run clutch operation will then be controlled.

TCM TERMINALS AND REFERENCE VALUENJAT0315S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

20 L/BOverrun clutch

solenoid valve

When overrun clutch solenoid valve

operates.Battery voltage

When overrun clutch solenoid valve

does not operate.1V or less

ON BOARD DIAGNOSIS LOGICNJAT0315S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: O/R CLTCH SOL/CIRC TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+Overrun clutch solenoid valve

: P1760

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0315S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve accuracy of

test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine.

3) Accelerate vehicle to a speed of more than 10 km/h (6 MPH)

with ªDº position (OD ªONº).

4) Release accelerator pedal completely with ªDº position (OD

ªOFFº).

DTC P1760 OVERRUN CLUTCH SOLENOID VALVEEURO-OBD

Description

AT-268

Page 399 of 2898

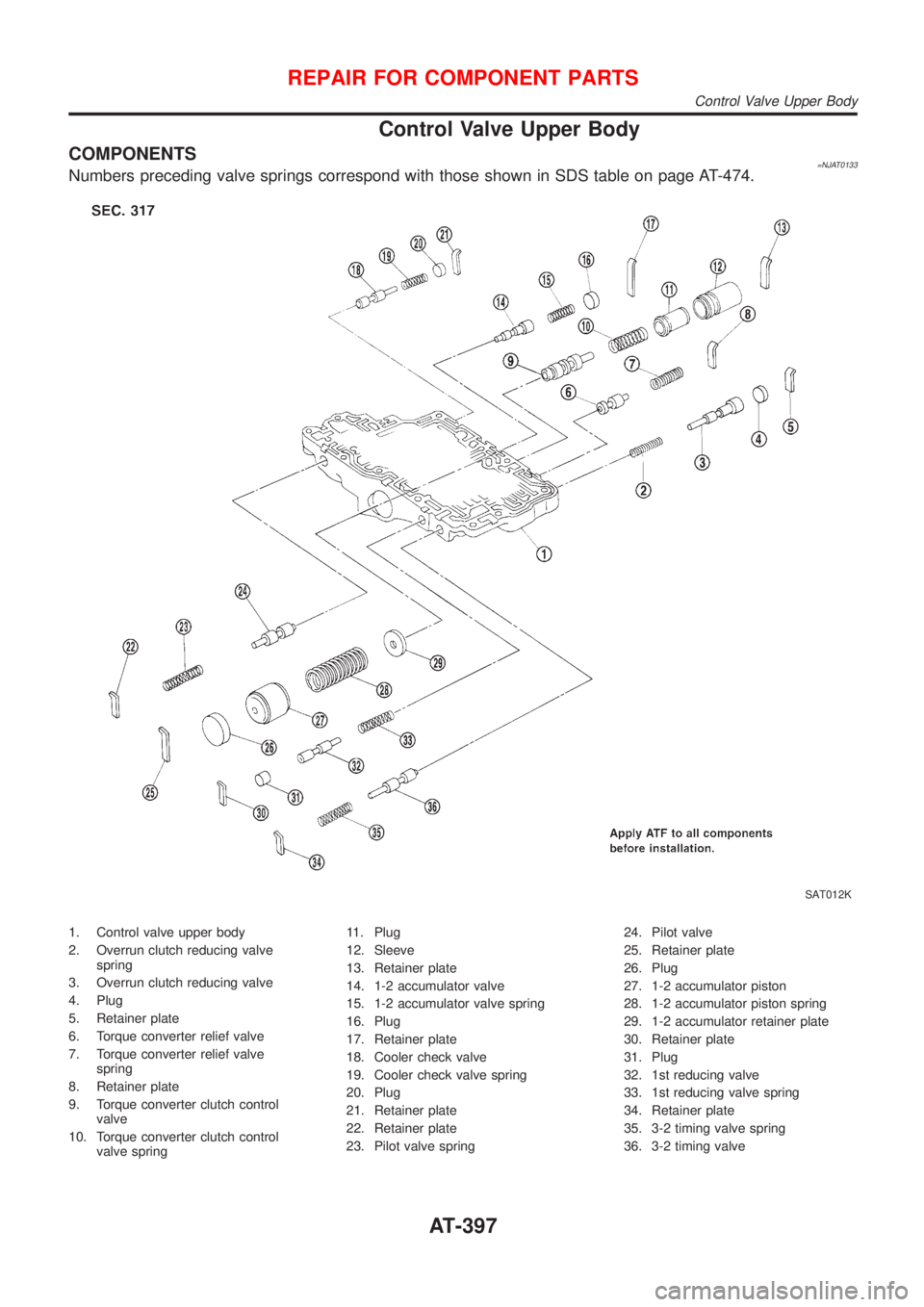

Control Valve Upper Body

COMPONENTS=NJAT0133Numbers preceding valve springs correspond with those shown in SDS table on page AT-474.

SAT012K

1. Control valve upper body

2. Overrun clutch reducing valve

spring

3. Overrun clutch reducing valve

4. Plug

5. Retainer plate

6. Torque converter relief valve

7. Torque converter relief valve

spring

8. Retainer plate

9. Torque converter clutch control

valve

10. Torque converter clutch control

valve spring11. Plug

12. Sleeve

13. Retainer plate

14. 1-2 accumulator valve

15. 1-2 accumulator valve spring

16. Plug

17. Retainer plate

18. Cooler check valve

19. Cooler check valve spring

20. Plug

21. Retainer plate

22. Retainer plate

23. Pilot valve spring24. Pilot valve

25. Retainer plate

26. Plug

27. 1-2 accumulator piston

28. 1-2 accumulator piston spring

29. 1-2 accumulator retainer plate

30. Retainer plate

31. Plug

32. 1st reducing valve

33. 1st reducing valve spring

34. Retainer plate

35. 3-2 timing valve spring

36. 3-2 timing valve

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body

AT-397

Page 403 of 2898

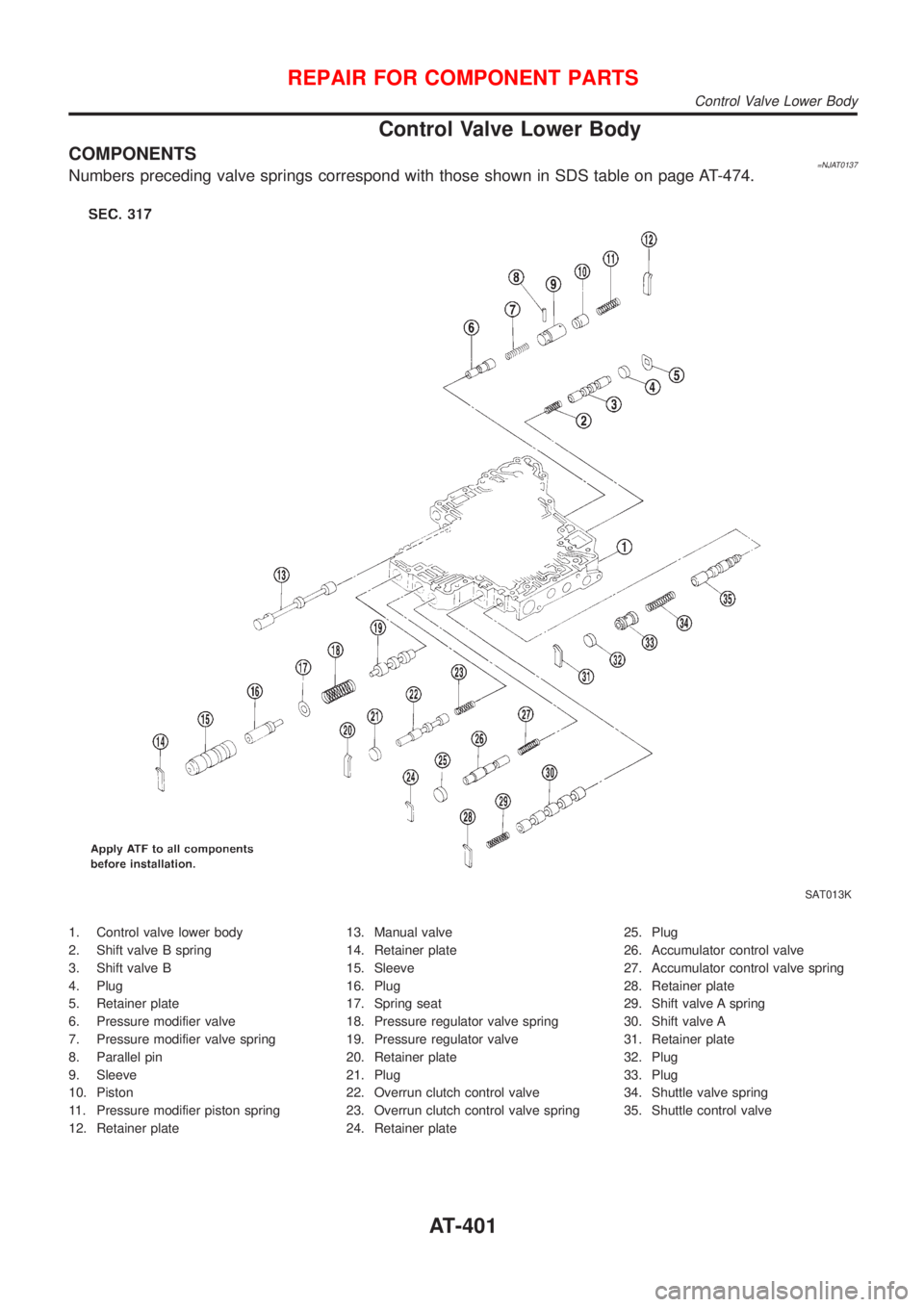

Control Valve Lower Body

COMPONENTS=NJAT0137Numbers preceding valve springs correspond with those shown in SDS table on page AT-474.

SAT013K

1. Control valve lower body

2. Shift valve B spring

3. Shift valve B

4. Plug

5. Retainer plate

6. Pressure modifier valve

7. Pressure modifier valve spring

8. Parallel pin

9. Sleeve

10. Piston

11. Pressure modifier piston spring

12. Retainer plate13. Manual valve

14. Retainer plate

15. Sleeve

16. Plug

17. Spring seat

18. Pressure regulator valve spring

19. Pressure regulator valve

20. Retainer plate

21. Plug

22. Overrun clutch control valve

23. Overrun clutch control valve spring

24. Retainer plate25. Plug

26. Accumulator control valve

27. Accumulator control valve spring

28. Retainer plate

29. Shift valve A spring

30. Shift valve A

31. Retainer plate

32. Plug

33. Plug

34. Shuttle valve spring

35. Shuttle control valve

REPAIR FOR COMPONENT PARTS

Control Valve Lower Body

AT-401

Page 539 of 2898

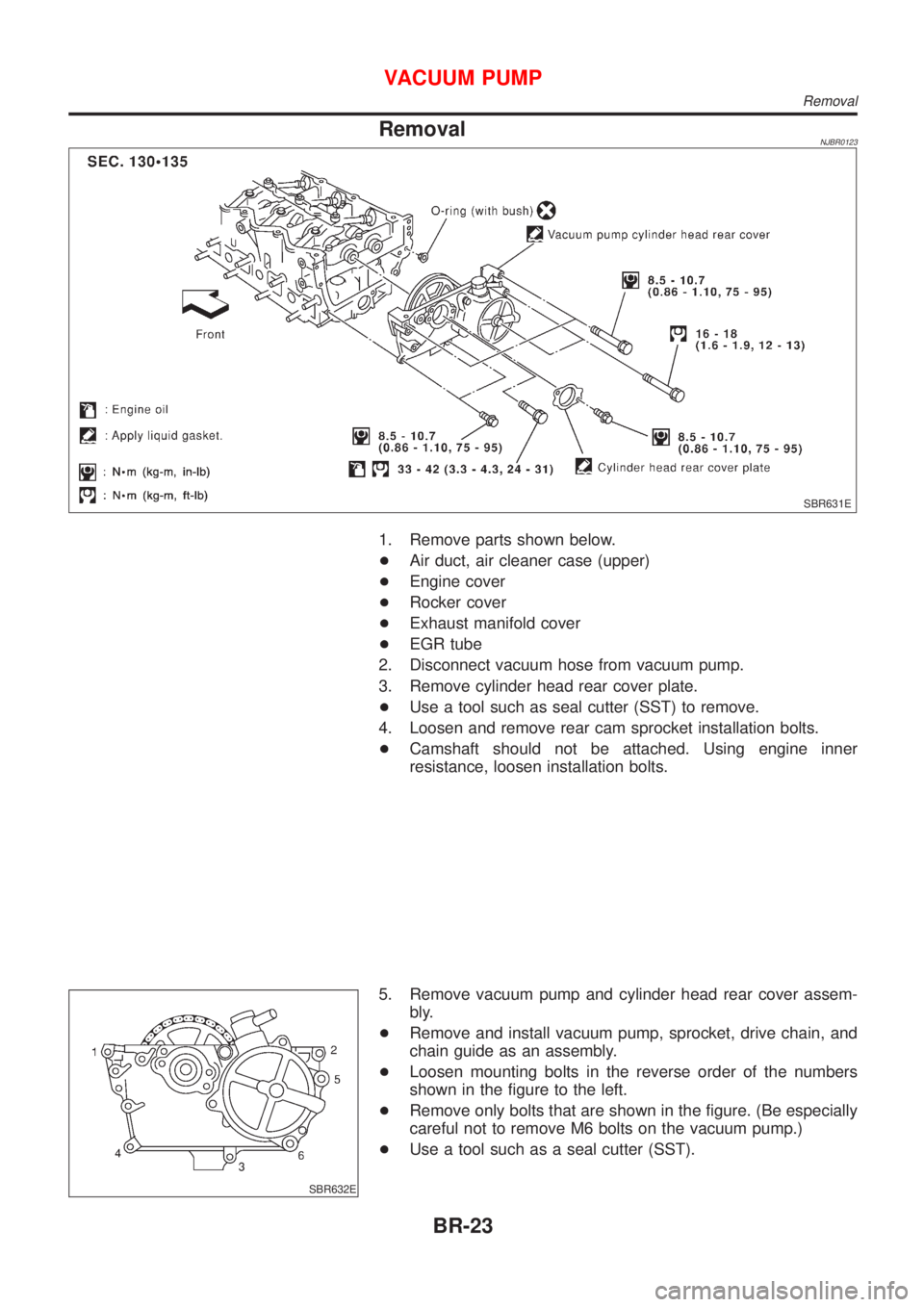

RemovalNJBR0123

SBR631E

1. Remove parts shown below.

+Air duct, air cleaner case (upper)

+Engine cover

+Rocker cover

+Exhaust manifold cover

+EGR tube

2. Disconnect vacuum hose from vacuum pump.

3. Remove cylinder head rear cover plate.

+Use a tool such as seal cutter (SST) to remove.

4. Loosen and remove rear cam sprocket installation bolts.

+Camshaft should not be attached. Using engine inner

resistance, loosen installation bolts.

SBR632E

5. Remove vacuum pump and cylinder head rear cover assem-

bly.

+Remove and install vacuum pump, sprocket, drive chain, and

chain guide as an assembly.

+Loosen mounting bolts in the reverse order of the numbers

shown in the figure to the left.

+Remove only bolts that are shown in the figure. (Be especially

careful not to remove M6 bolts on the vacuum pump.)

+Use a tool such as a seal cutter (SST).

VACUUM PUMP

Removal

BR-23

Page 587 of 2898

SEF233G

SEF234G

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

NJBR0094INTRODUCTIONNJBR0094S01The ABS system has an electronic control unit to control major

functions. The control unit accepts input signals from sensors and

instantly drives actuator. It is essential that both kinds of signals are

proper and stable. It is also important to check for conventional

problems: such as air leaks in the booster or lines, lack of brake

fluid, or other problems with the brake system.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or faulty wiring. In this case,

careful checking of suspicious circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems, so a

road test should be performed.

Before undertaking actual checks, take just a few minutes to talk

with a customer who approaches with a ABS complaint. The cus-

tomer is a very good source of information on such problems;

especially intermittent ones. Through the talks with the customer,

find out what symptoms are present and under what conditions

they occur.

Start your diagnosis by looking for ªconventionalº problems first.

This is one of the best ways to troubleshoot brake problems on an

ABS controlled vehicle. Also check related Service Bulletins for

information.

TROUBLE DIAGNOSIS Ð INTRODUCTIONABS

How to Perform Trouble Diagnoses for Quick and Accurate Repair

BR-71

Page 622 of 2898

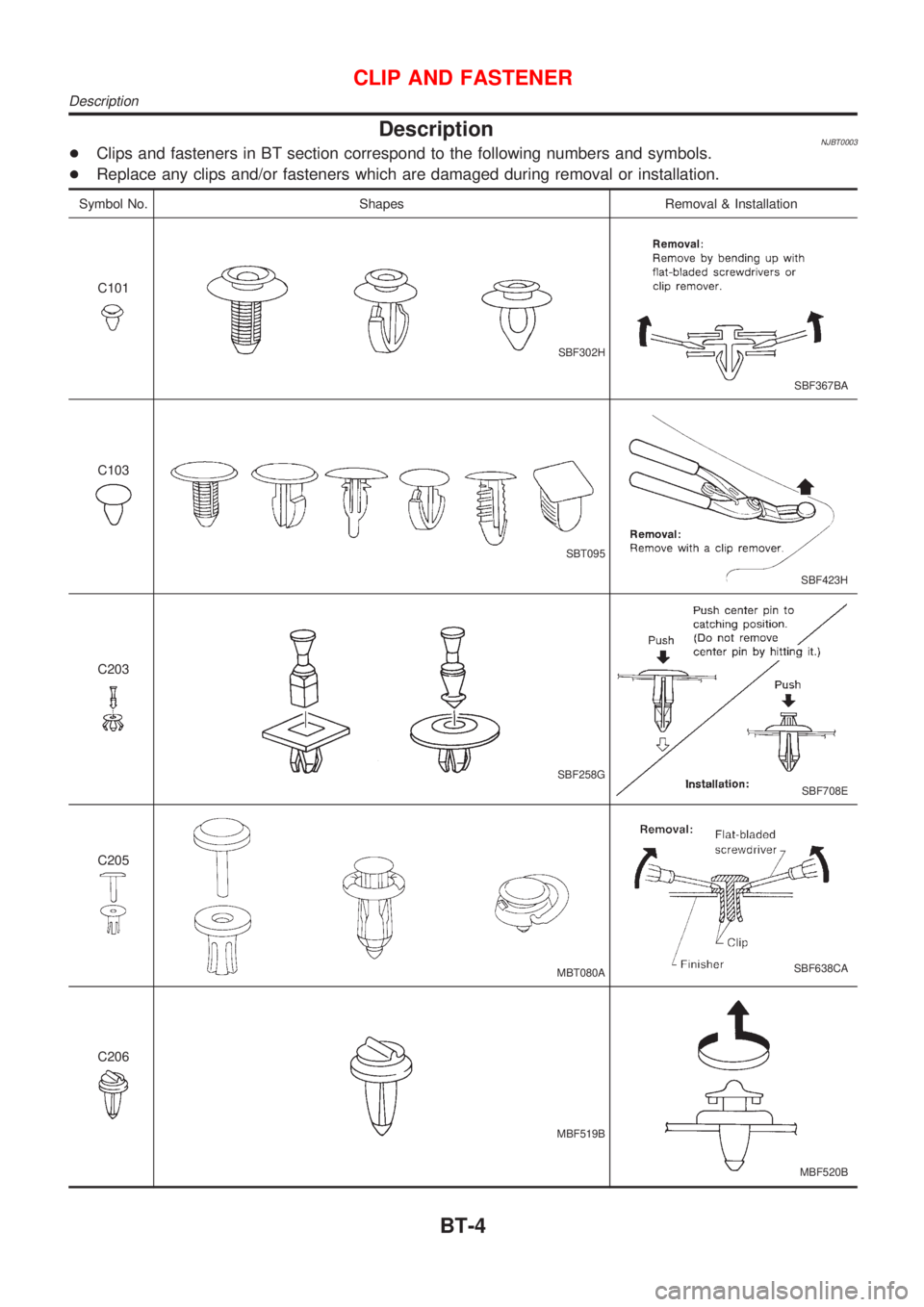

DescriptionNJBT0003+Clips and fasteners in BT section correspond to the following numbers and symbols.

+Replace any clips and/or fasteners which are damaged during removal or installation.

Symbol No. Shapes Removal & Installation

C101

SBF302H

SBF367BA

C103

SBT095

SBF423H

C203

SBF258G

SBF708E

C205

MBT080ASBF638CA

C206

MBF519B

MBF520B

CLIP AND FASTENER

Description

BT-4

Page 740 of 2898

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJEC0002The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnoses sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnoses sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harness can be identified by yellow harness connector.

Precautions for On Board Diagnostic (OBD)

System of Engine and A/T

NJEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

+Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission Control Module) before returning the vehicle to the customer.

PRECAUTIONSQG

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-16