power steering NISSAN ALMERA 2001 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2393 of 2898

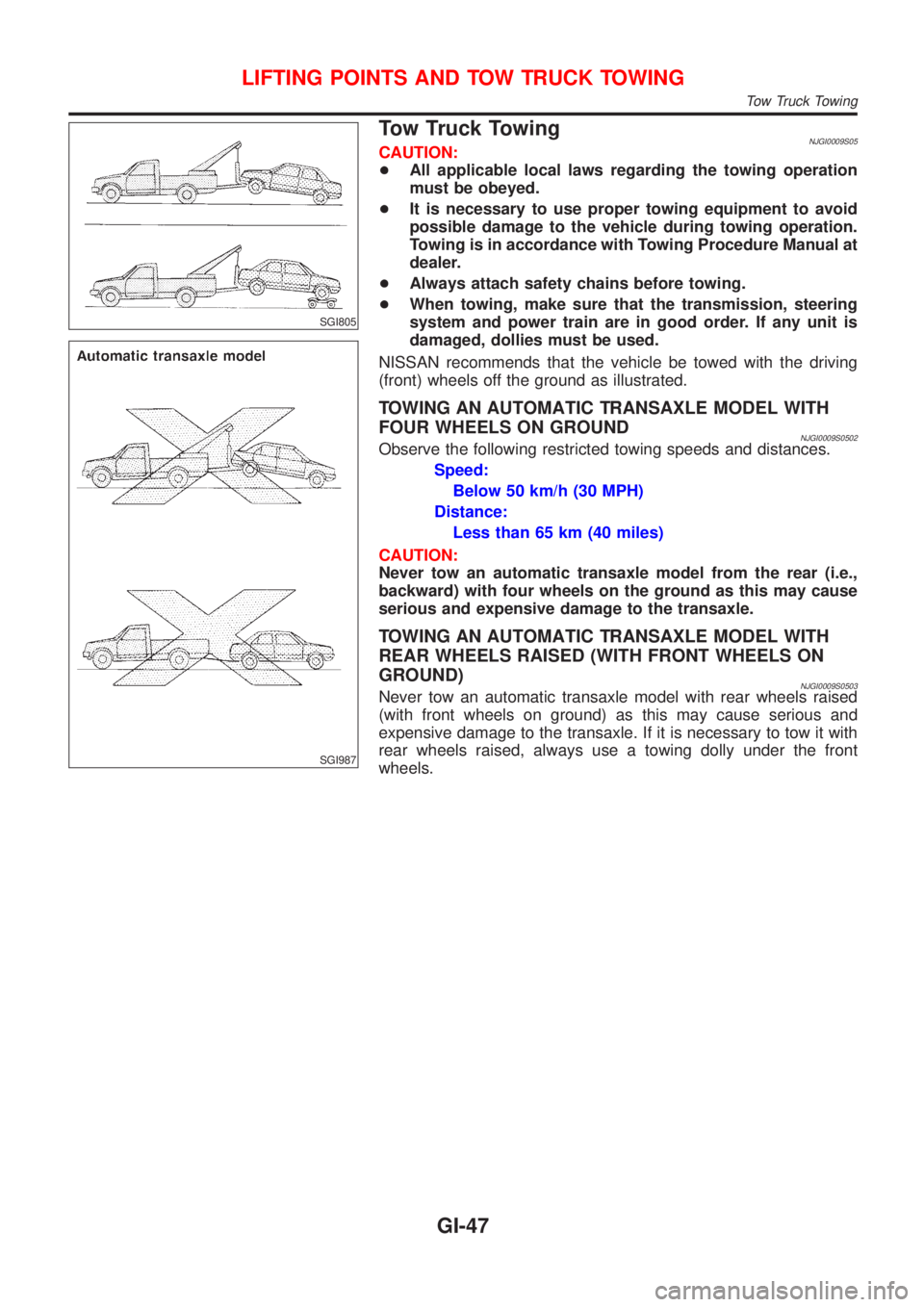

SGI805

SGI987

Tow Truck TowingNJGI0009S05CAUTION:

+All applicable local laws regarding the towing operation

must be obeyed.

+It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during towing operation.

Towing is in accordance with Towing Procedure Manual at

dealer.

+Always attach safety chains before towing.

+When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, dollies must be used.

NISSAN recommends that the vehicle be towed with the driving

(front) wheels off the ground as illustrated.

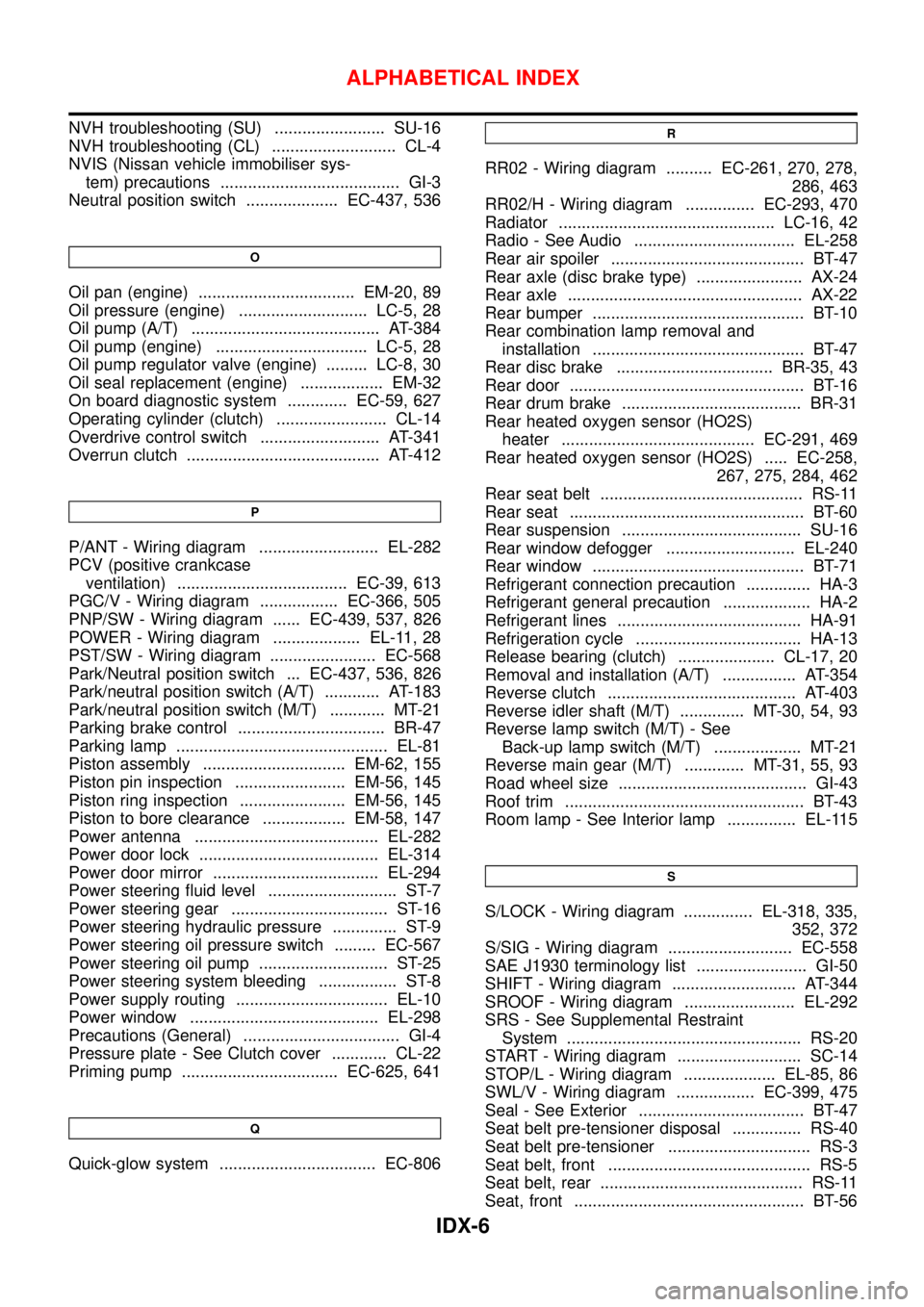

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH

FOUR WHEELS ON GROUND

NJGI0009S0502Observe the following restricted towing speeds and distances.

Speed:

Below 50 km/h (30 MPH)

Distance:

Less than 65 km (40 miles)

CAUTION:

Never tow an automatic transaxle model from the rear (i.e.,

backward) with four wheels on the ground as this may cause

serious and expensive damage to the transaxle.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH

REAR WHEELS RAISED (WITH FRONT WHEELS ON

GROUND)

NJGI0009S0503Never tow an automatic transaxle model with rear wheels raised

(with front wheels on ground) as this may cause serious and

expensive damage to the transaxle. If it is necessary to tow it with

rear wheels raised, always use a towing dolly under the front

wheels.

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing

GI-47

Page 2504 of 2898

NVH troubleshooting (SU) ........................ SU-16

NVH troubleshooting (CL) ........................... CL-4

NVIS (Nissan vehicle immobiliser sys-

tem) precautions ....................................... GI-3

Neutral position switch .................... EC-437, 536

O

Oil pan (engine) .................................. EM-20, 89

Oil pressure (engine) ............................ LC-5, 28

Oil pump (A/T) ......................................... AT-384

Oil pump (engine) ................................. LC-5, 28

Oil pump regulator valve (engine) ......... LC-8, 30

Oil seal replacement (engine) .................. EM-32

On board diagnostic system ............. EC-59, 627

Operating cylinder (clutch) ........................ CL-14

Overdrive control switch .......................... AT-341

Overrun clutch .......................................... AT-412

P

P/ANT - Wiring diagram .......................... EL-282

PCV (positive crankcase

ventilation) ..................................... EC-39, 613

PGC/V - Wiring diagram ................. EC-366, 505

PNP/SW - Wiring diagram ...... EC-439, 537, 826

POWER - Wiring diagram ................... EL-11, 28

PST/SW - Wiring diagram ....................... EC-568

Park/Neutral position switch ... EC-437, 536, 826

Park/neutral position switch (A/T) ............ AT-183

Park/neutral position switch (M/T) ............ MT-21

Parking brake control ................................ BR-47

Parking lamp .............................................. EL-81

Piston assembly ............................... EM-62, 155

Piston pin inspection ........................ EM-56, 145

Piston ring inspection ....................... EM-56, 145

Piston to bore clearance .................. EM-58, 147

Power antenna ........................................ EL-282

Power door lock ....................................... EL-314

Power door mirror .................................... EL-294

Power steering fluid level ............................ ST-7

Power steering gear .................................. ST-16

Power steering hydraulic pressure .............. ST-9

Power steering oil pressure switch ......... EC-567

Power steering oil pump ............................ ST-25

Power steering system bleeding ................. ST-8

Power supply routing ................................. EL-10

Power window ......................................... EL-298

Precautions (General) .................................. GI-4

Pressure plate - See Clutch cover ............ CL-22

Priming pump .................................. EC-625, 641

Q

Quick-glow system .................................. EC-806

R

RR02 - Wiring diagram .......... EC-261, 270, 278,

286, 463

RR02/H - Wiring diagram ............... EC-293, 470

Radiator ............................................... LC-16, 42

Radio - See Audio ................................... EL-258

Rear air spoiler .......................................... BT-47

Rear axle (disc brake type) ....................... AX-24

Rear axle ................................................... AX-22

Rear bumper .............................................. BT-10

Rear combination lamp removal and

installation .............................................. BT-47

Rear disc brake .................................. BR-35, 43

Rear door ................................................... BT-16

Rear drum brake ....................................... BR-31

Rear heated oxygen sensor (HO2S)

heater .......................................... EC-291, 469

Rear heated oxygen sensor (HO2S) ..... EC-258,

267, 275, 284, 462

Rear seat belt ............................................ RS-11

Rear seat ................................................... BT-60

Rear suspension ....................................... SU-16

Rear window defogger ............................ EL-240

Rear window .............................................. BT-71

Refrigerant connection precaution .............. HA-3

Refrigerant general precaution ................... HA-2

Refrigerant lines ........................................ HA-91

Refrigeration cycle .................................... HA-13

Release bearing (clutch) ..................... CL-17, 20

Removal and installation (A/T) ................ AT-354

Reverse clutch ......................................... AT-403

Reverse idler shaft (M/T) .............. MT-30, 54, 93

Reverse lamp switch (M/T) - See

Back-up lamp switch (M/T) ................... MT-21

Reverse main gear (M/T) ............. MT-31, 55, 93

Road wheel size ......................................... GI-43

Roof trim .................................................... BT-43

Room lamp - See Interior lamp ............... EL-115

S

S/LOCK - Wiring diagram ............... EL-318, 335,

352, 372

S/SIG - Wiring diagram ........................... EC-558

SAE J1930 terminology list ........................ GI-50

SHIFT - Wiring diagram ........................... AT-344

SROOF - Wiring diagram ........................ EL-292

SRS - See Supplemental Restraint

System ................................................... RS-20

START - Wiring diagram ........................... SC-14

STOP/L - Wiring diagram .................... EL-85, 86

SWL/V - Wiring diagram ................. EC-399, 475

Seal - See Exterior .................................... BT-47

Seat belt pre-tensioner disposal ............... RS-40

Seat belt pre-tensioner ............................... RS-3

Seat belt, front ............................................ RS-5

Seat belt, rear ............................................ RS-11

Seat, front .................................................. BT-56

ALPHABETICAL INDEX

IDX-6

Page 2556 of 2898

NJMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 2559 of 2898

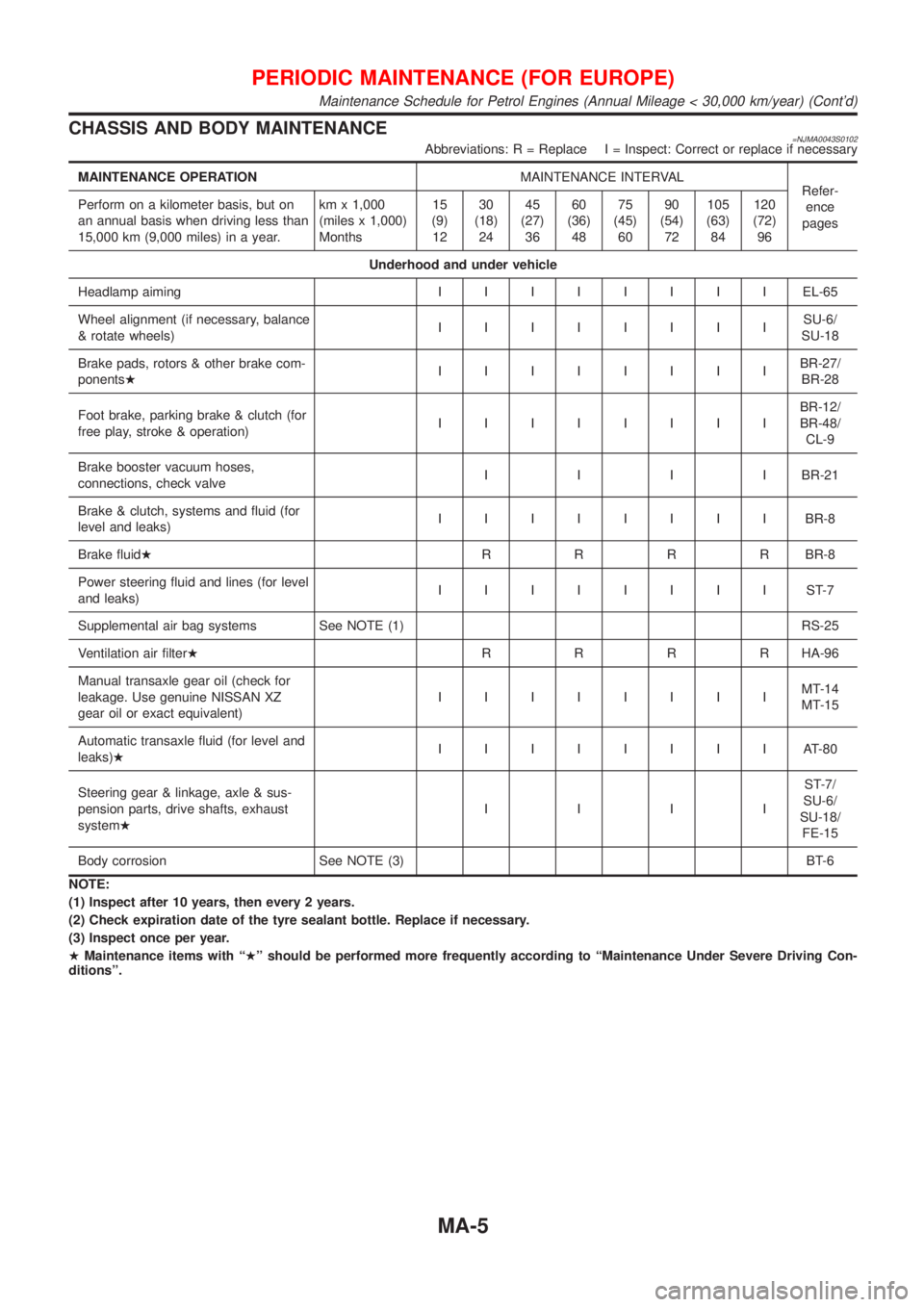

CHASSIS AND BODY MAINTENANCE=NJMA0043S0102Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis, but on

an annual basis when driving less than

15,000 km (9,000 miles) in a year.km x 1,000

(miles x 1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Underhood and under vehicle

Headlamp aimingIIIIIIIIEL-65

Wheel alignment (if necessary, balance

& rotate wheels)IIIIIIIISU-6/

SU-18

Brake pads, rotors & other brake com-

ponentsHIIIIIIIIBR-27/

BR-28

Foot brake, parking brake & clutch (for

free play, stroke & operation)IIIIIIIIBR-12/

BR-48/

CL-9

Brake booster vacuum hoses,

connections, check valveIIIIBR-21

Brake & clutch, systems and fluid (for

level and leaks)IIIIIIIIBR-8

Brake fluidHRRRRBR-8

Power steering fluid and lines (for level

and leaks)IIIIIIIIST-7

Supplemental air bag systems See NOTE (1) RS-25

Ventilation air filterHRRRRHA-96

Manual transaxle gear oil (check for

leakage. Use genuine NISSAN XZ

gear oil or exact equivalent)IIIIIIIIMT-14

MT-15

Automatic transaxle fluid (for level and

leaks)HIIIIIIIIAT-80

Steering gear & linkage, axle & sus-

pension parts, drive shafts, exhaust

systemHIIIIST-7/

SU-6/

SU-18/

FE-15

Body corrosion See NOTE (3) BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance Under Severe Driving Con-

ditionsº.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage < 30,000 km/year) (Cont'd)

MA-5

Page 2561 of 2898

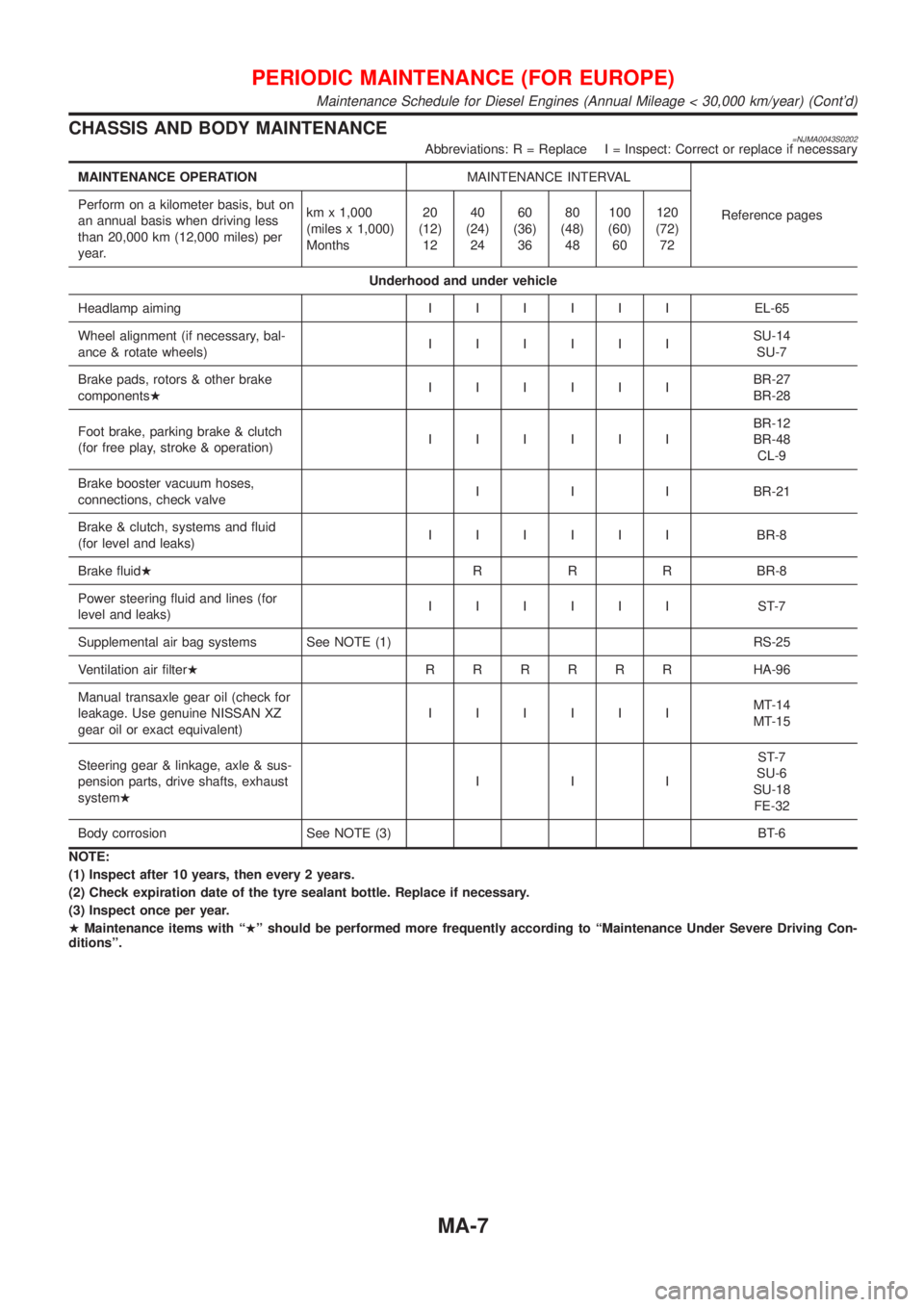

CHASSIS AND BODY MAINTENANCE=NJMA0043S0202Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference pages Perform on a kilometer basis, but on

an annual basis when driving less

than 20,000 km (12,000 miles) per

year.km x 1,000

(miles x 1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Underhood and under vehicle

Headlamp aimingIIIIIIEL-65

Wheel alignment (if necessary, bal-

ance & rotate wheels)IIIIIISU-14

SU-7

Brake pads, rotors & other brake

componentsHIIIIIIBR-27

BR-28

Foot brake, parking brake & clutch

(for free play, stroke & operation)IIIIIIBR-12

BR-48

CL-9

Brake booster vacuum hoses,

connections, check valveI I I BR-21

Brake & clutch, systems and fluid

(for level and leaks)IIIIIIBR-8

Brake fluidHR R R BR-8

Power steering fluid and lines (for

level and leaks)IIIIII ST-7

Supplemental air bag systems See NOTE (1) RS-25

Ventilation air filterHRRRRRRHA-96

Manual transaxle gear oil (check for

leakage. Use genuine NISSAN XZ

gear oil or exact equivalent)IIIIIIMT-14

MT-15

Steering gear & linkage, axle & sus-

pension parts, drive shafts, exhaust

systemHIIIST-7

SU-6

SU-18

FE-32

Body corrosion See NOTE (3) BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance Under Severe Driving Con-

ditionsº.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Diesel Engines (Annual Mileage < 30,000 km/year) (Cont'd)

MA-7

Page 2565 of 2898

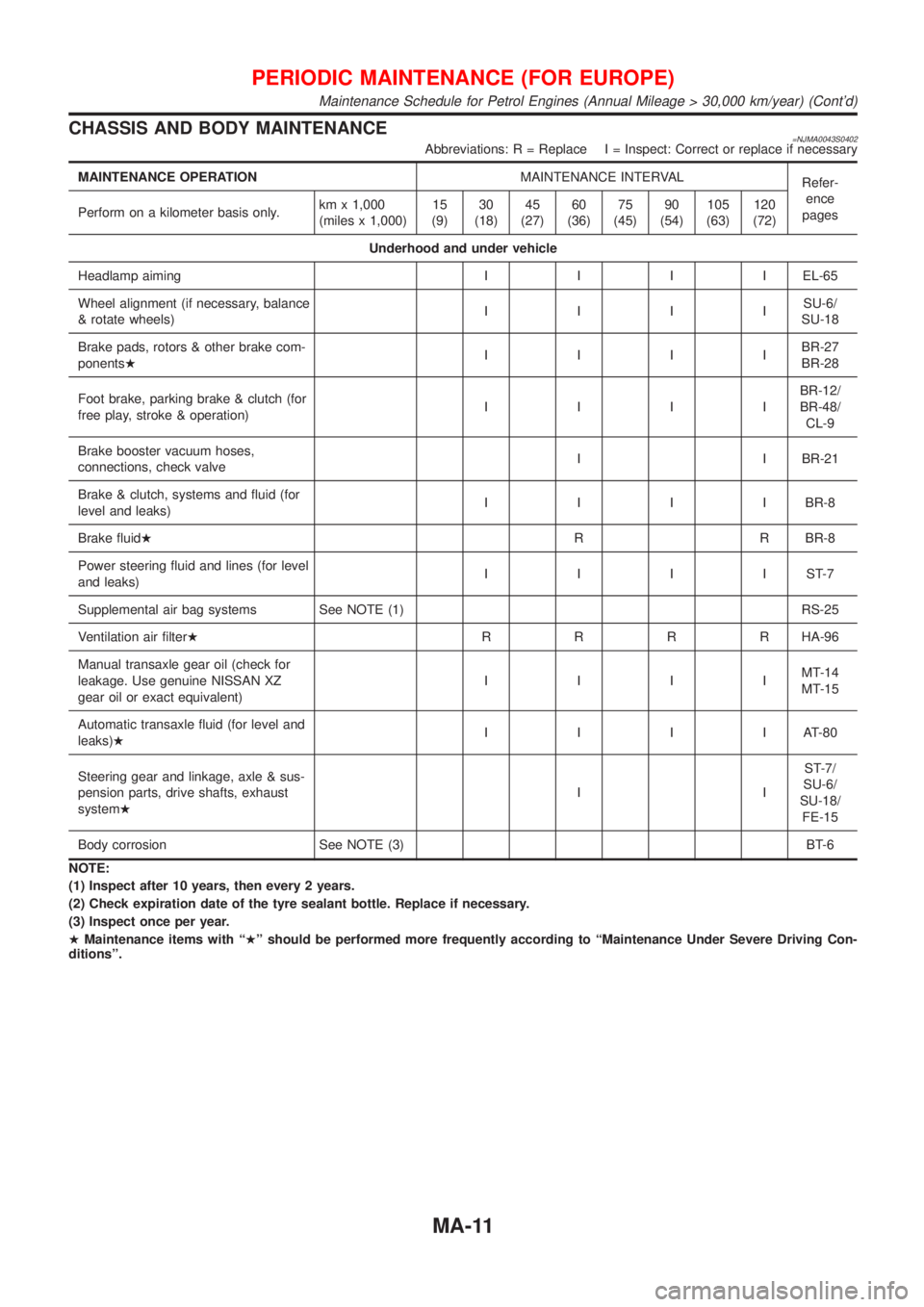

CHASSIS AND BODY MAINTENANCE=NJMA0043S0402Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis only.km x 1,000

(miles x 1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Underhood and under vehicle

Headlamp aimingIIIIEL-65

Wheel alignment (if necessary, balance

& rotate wheels)IIIISU-6/

SU-18

Brake pads, rotors & other brake com-

ponentsHIIIIBR-27

BR-28

Foot brake, parking brake & clutch (for

free play, stroke & operation)IIIIBR-12/

BR-48/

CL-9

Brake booster vacuum hoses,

connections, check valveI I BR-21

Brake & clutch, systems and fluid (for

level and leaks)IIIIBR-8

Brake fluidHR R BR-8

Power steering fluid and lines (for level

and leaks)IIIIST-7

Supplemental air bag systems See NOTE (1) RS-25

Ventilation air filterHRRRRHA-96

Manual transaxle gear oil (check for

leakage. Use genuine NISSAN XZ

gear oil or exact equivalent)IIIIMT-14

MT-15

Automatic transaxle fluid (for level and

leaks)HIIIIAT-80

Steering gear and linkage, axle & sus-

pension parts, drive shafts, exhaust

systemHIIST-7/

SU-6/

SU-18/

FE-15

Body corrosion See NOTE (3) BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance Under Severe Driving Con-

ditionsº.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage > 30,000 km/year) (Cont'd)

MA-11

Page 2567 of 2898

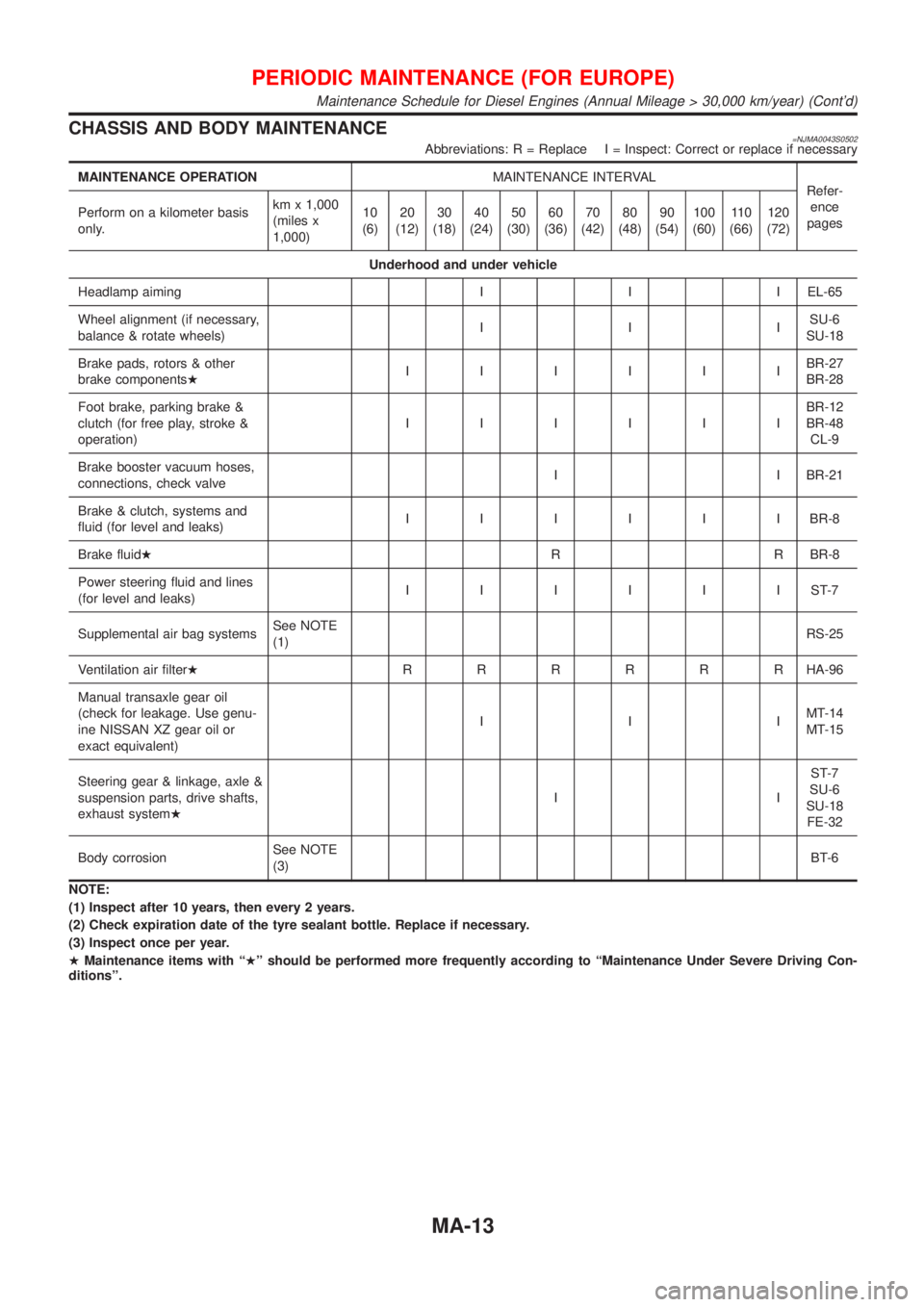

CHASSIS AND BODY MAINTENANCE=NJMA0043S0502Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis

only.km x 1,000

(miles x

1,000)10

(6)20

(12)30

(18)40

(24)50

(30)60

(36)70

(42)80

(48)90

(54)100

(60)11 0

(66)120

(72)

Underhood and under vehicle

Headlamp aiming I I I EL-65

Wheel alignment (if necessary,

balance & rotate wheels)IIISU-6

SU-18

Brake pads, rotors & other

brake componentsHIIIIIIBR-27

BR-28

Foot brake, parking brake &

clutch (for free play, stroke &

operation)IIIIIIBR-12

BR-48

CL-9

Brake booster vacuum hoses,

connections, check valveI I BR-21

Brake & clutch, systems and

fluid (for level and leaks)IIIIIIBR-8

Brake fluidHR R BR-8

Power steering fluid and lines

(for level and leaks)IIIIIIST-7

Supplemental air bag systemsSee NOTE

(1)RS-25

Ventilation air filterHRRRRRRHA-96

Manual transaxle gear oil

(check for leakage. Use genu-

ine NISSAN XZ gear oil or

exact equivalent)IIIMT-14

MT-15

Steering gear & linkage, axle &

suspension parts, drive shafts,

exhaust systemHIIST-7

SU-6

SU-18

FE-32

Body corrosionSee NOTE

(3)BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance Under Severe Driving Con-

ditionsº.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Diesel Engines (Annual Mileage > 30,000 km/year) (Cont'd)

MA-13

Page 2570 of 2898

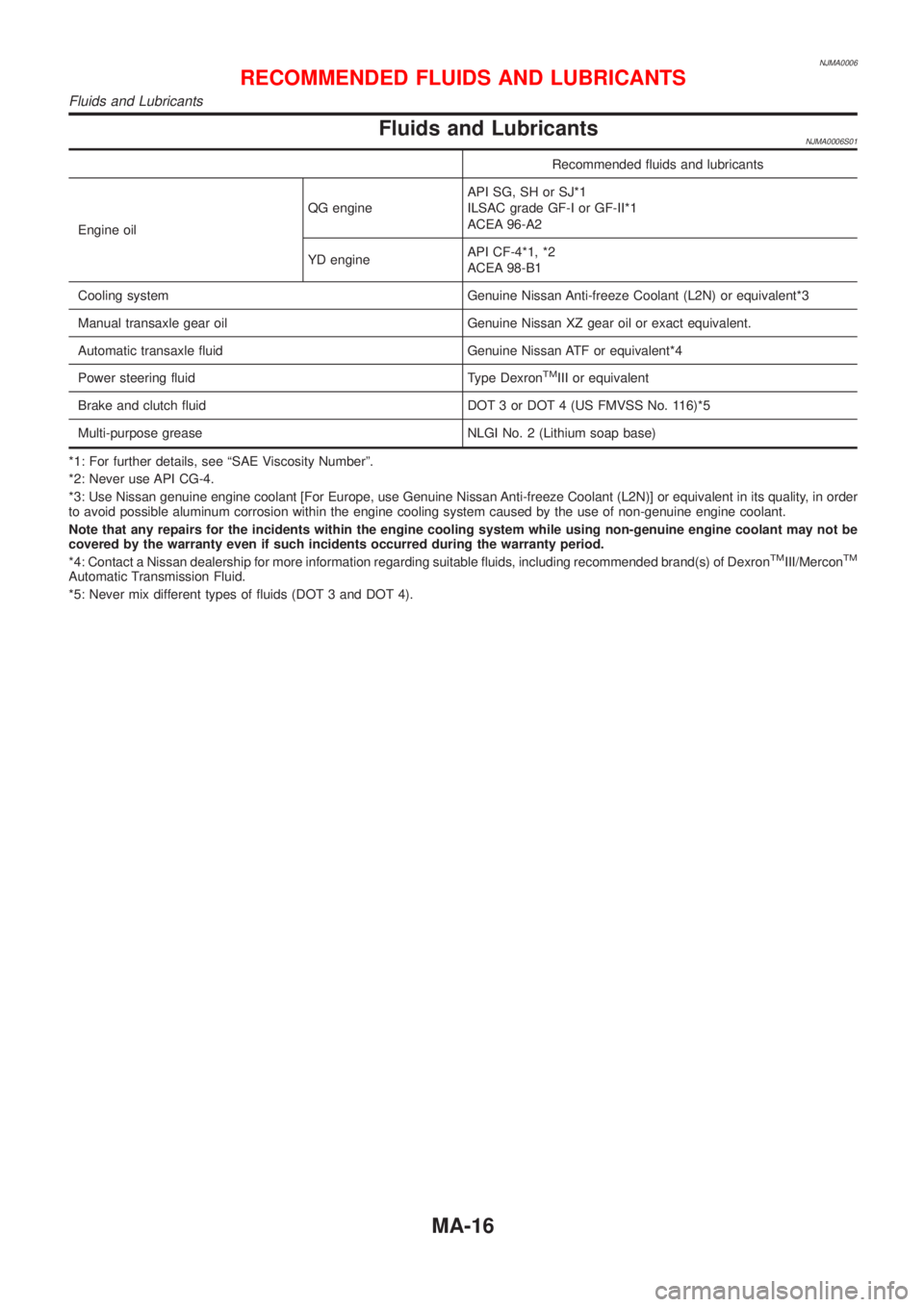

NJMA0006

Fluids and LubricantsNJMA0006S01

Recommended fluids and lubricants

Engine oilQG engineAPI SG, SH or SJ*1

ILSAC grade GF-I or GF-II*1

ACEA 96-A2

YD engineAPI CF-4*1, *2

ACEA 98-B1

Cooling system Genuine Nissan Anti-freeze Coolant (L2N) or equivalent*3

Manual transaxle gear oil Genuine Nissan XZ gear oil or exact equivalent.

Automatic transaxle fluid Genuine Nissan ATF or equivalent*4

Power steering fluid Type Dexron

TMIII or equivalent

Brake and clutch fluid DOT 3 or DOT 4 (US FMVSS No. 116)*5

Multi-purpose grease NLGI No. 2 (Lithium soap base)

*1: For further details, see ªSAE Viscosity Numberº.

*2: Never use API CG-4.

*3: Use Nissan genuine engine coolant [For Europe, use Genuine Nissan Anti-freeze Coolant (L2N)] or equivalent in its quality, in order

to avoid possible aluminum corrosion within the engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of Dexron

TMIII/MerconTM

Automatic Transmission Fluid.

*5: Never mix different types of fluids (DOT 3 and DOT 4).

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

MA-16

Page 2728 of 2898

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NJRS0006The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL N16 is as follows (The composition

varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PRECAUTIONS FOR SRS ªAIR BAGº AND ªSEAT BELT PRE-TENSIONERº SERVICENJRS0007+Do not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

+Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

+Diagnosis sensor unit must always be installed with their arrow marks ªÜº pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

+The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

+Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module standing with stud bolt side setting bottom.

+Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

+After air bag inflates, the front instrument panel assembly should be replaced if damaged.

WIRING DIAGRAMS AND TROUBLE DIAGNOSISNJRS0008When you read wiring diagrams, refer to the following:

+GI-11, ªHOW TO READ WIRING DIAGRAMSº

+EL-10, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

+GI-32, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

+GI-21, ªHOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENTº

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Precautions

RS-20

Page 2837 of 2898

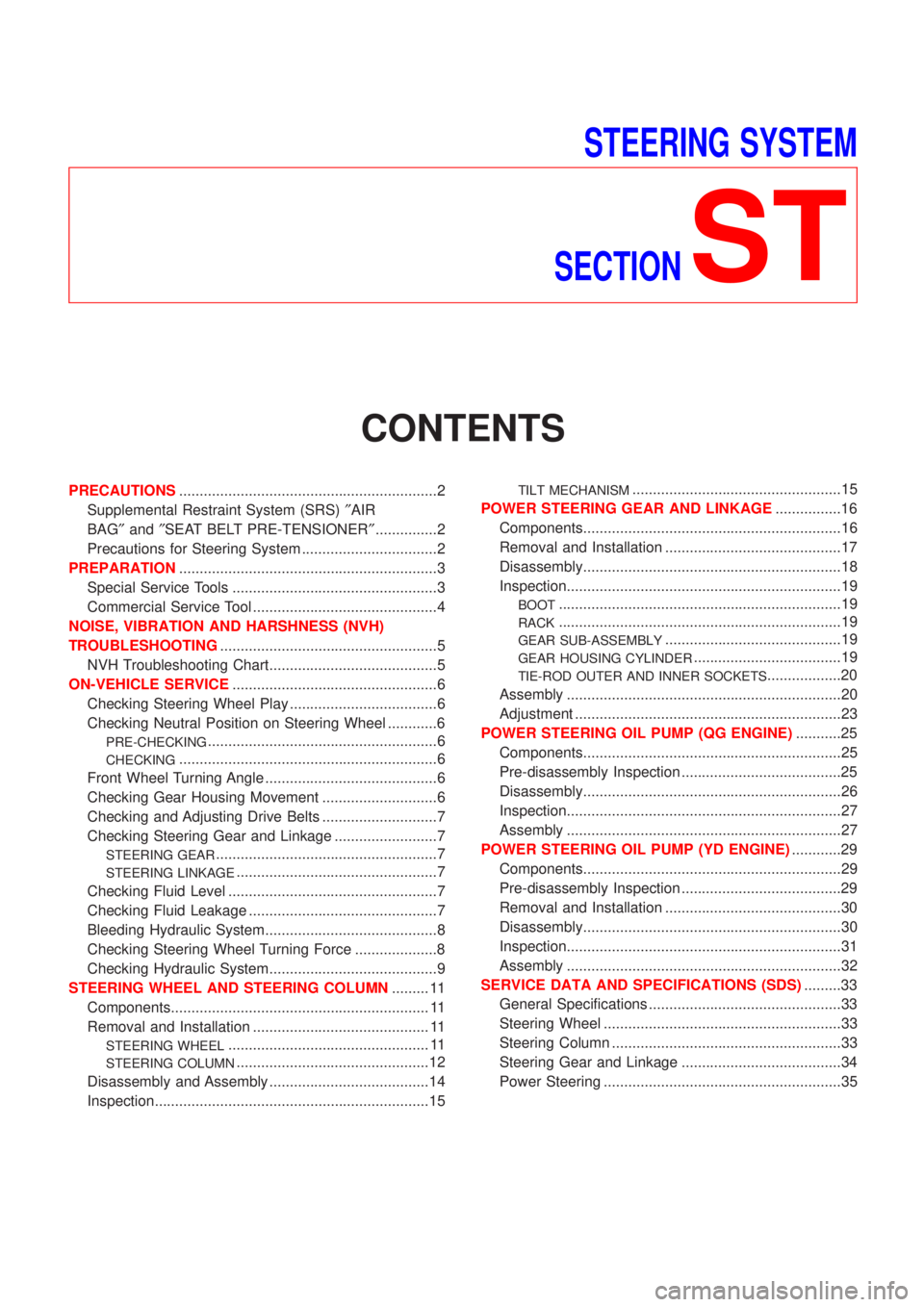

STEERING SYSTEM

SECTION

ST

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Precautions for Steering System .................................2

PREPARATION...............................................................3

Special Service Tools ..................................................3

Commercial Service Tool .............................................4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................5

NVH Troubleshooting Chart.........................................5

ON-VEHICLE SERVICE..................................................6

Checking Steering Wheel Play ....................................6

Checking Neutral Position on Steering Wheel ............6

PRE-CHECKING........................................................6

CHECKING...............................................................6

Front Wheel Turning Angle ..........................................6

Checking Gear Housing Movement ............................6

Checking and Adjusting Drive Belts ............................7

Checking Steering Gear and Linkage .........................7

STEERING GEAR......................................................7

STEERING LINKAGE.................................................7

Checking Fluid Level ...................................................7

Checking Fluid Leakage ..............................................7

Bleeding Hydraulic System..........................................8

Checking Steering Wheel Turning Force ....................8

Checking Hydraulic System.........................................9

STEERING WHEEL AND STEERING COLUMN......... 11

Components............................................................... 11

Removal and Installation ........................................... 11

STEERING WHEEL................................................. 11

STEERING COLUMN...............................................12

Disassembly and Assembly .......................................14

Inspection...................................................................15

TILT MECHANISM...................................................15

POWER STEERING GEAR AND LINKAGE................16

Components...............................................................16

Removal and Installation ...........................................17

Disassembly...............................................................18

Inspection...................................................................19

BOOT.....................................................................19

RACK.....................................................................19

GEAR SUB-ASSEMBLY...........................................19

GEAR HOUSING CYLINDER....................................19

TIE-ROD OUTER AND INNER SOCKETS..................20

Assembly ...................................................................20

Adjustment .................................................................23

POWER STEERING OIL PUMP (QG ENGINE)...........25

Components...............................................................25

Pre-disassembly Inspection .......................................25

Disassembly...............................................................26

Inspection...................................................................27

Assembly ...................................................................27

POWER STEERING OIL PUMP (YD ENGINE)............29

Components...............................................................29

Pre-disassembly Inspection .......................................29

Removal and Installation ...........................................30

Disassembly...............................................................30

Inspection...................................................................31

Assembly ...................................................................32

SERVICE DATA AND SPECIFICATIONS (SDS).........33

General Specifications ...............................................33

Steering Wheel ..........................................................33

Steering Column ........................................................33

Steering Gear and Linkage .......................................34

Power Steering ..........................................................35