torque NISSAN ALMERA 2001 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 235 of 2898

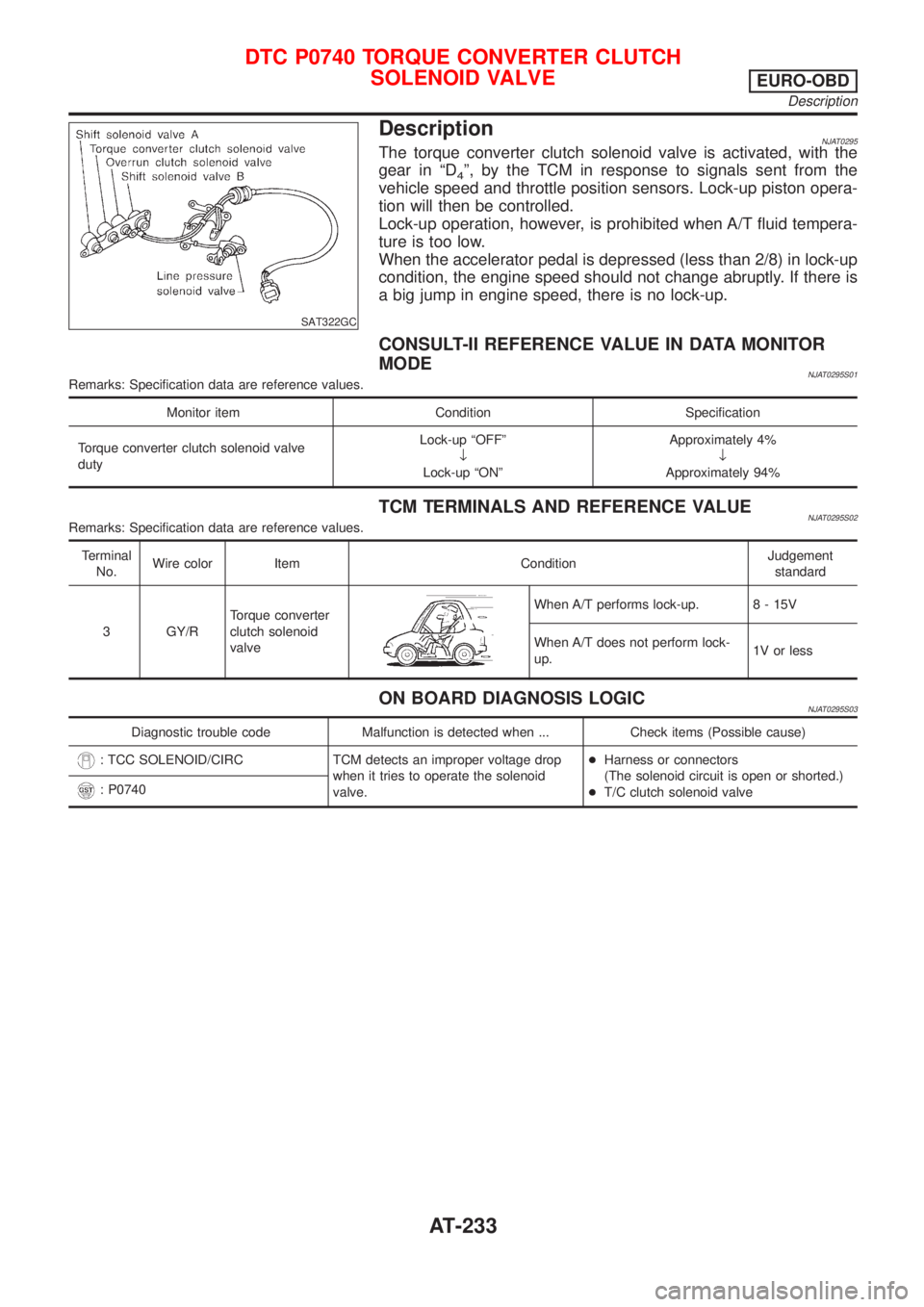

SAT322GC

DescriptionNJAT0295The torque converter clutch solenoid valve is activated, with the

gear in ªD

4º, by the TCM in response to signals sent from the

vehicle speed and throttle position sensors. Lock-up piston opera-

tion will then be controlled.

Lock-up operation, however, is prohibited when A/T fluid tempera-

ture is too low.

When the accelerator pedal is depressed (less than 2/8) in lock-up

condition, the engine speed should not change abruptly. If there is

a big jump in engine speed, there is no lock-up.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NJAT0295S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Torque converter clutch solenoid valve

dutyLock-up ªOFFº

¯

Lock-up ªONºApproximately 4%

¯

Approximately 94%

TCM TERMINALS AND REFERENCE VALUENJAT0295S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

3 GY/RTorque converter

clutch solenoid

valve

When A/T performs lock-up. 8 - 15V

When A/T does not perform lock-

up.1V or less

ON BOARD DIAGNOSIS LOGICNJAT0295S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: TCC SOLENOID/CIRC TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+T/C clutch solenoid valve

: P0740

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EURO-OBD

Description

AT-233

Page 236 of 2898

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0295S04NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode for ªENGINEº with CON-

SULT-II and wait at least 1 second.

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EURO-OBD

Description (Cont'd)

AT-234

Page 237 of 2898

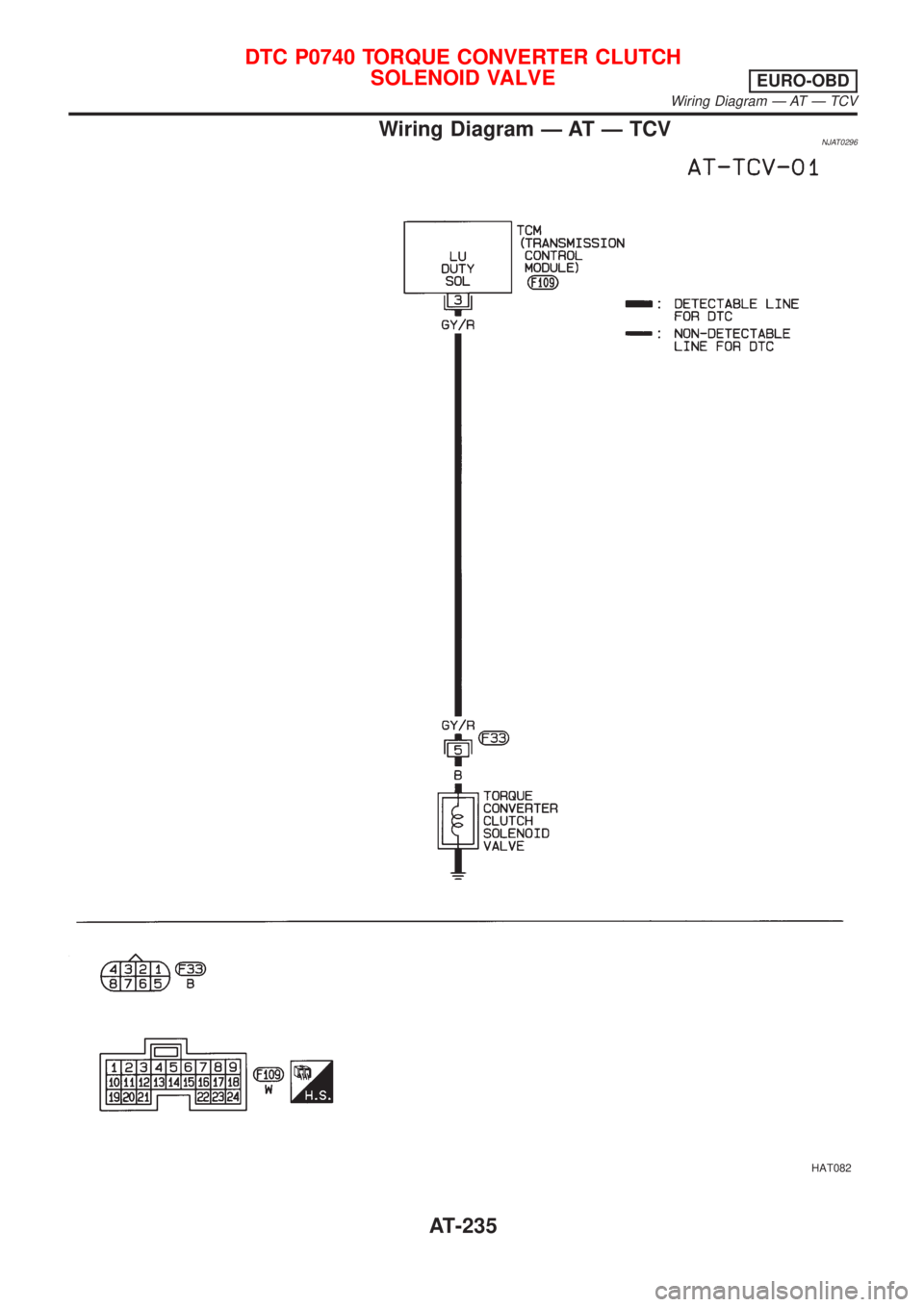

Wiring Diagram Ð AT Ð TCVNJAT0296

HAT082

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EURO-OBD

Wiring Diagram Ð AT Ð TCV

AT-235

Page 238 of 2898

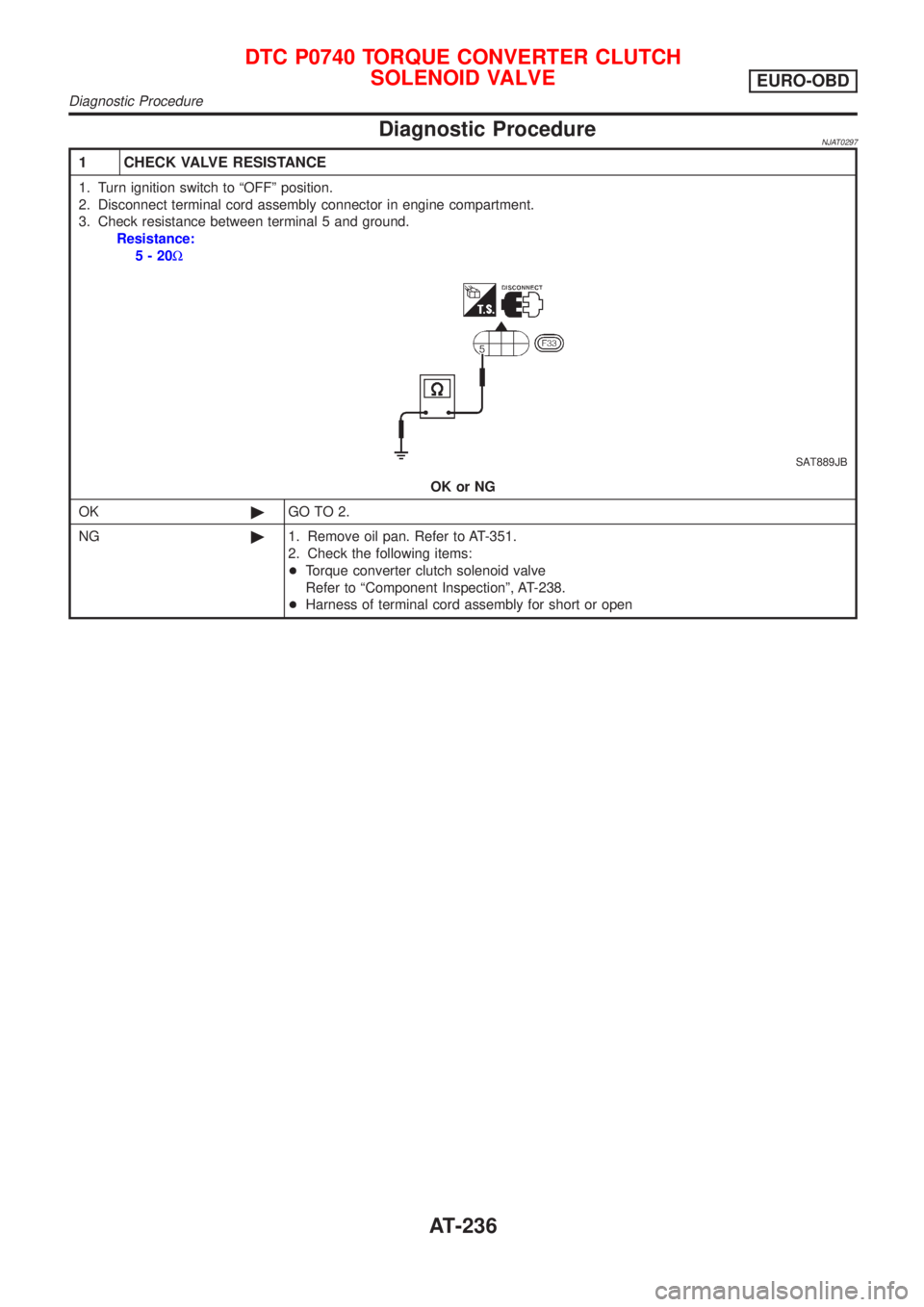

Diagnostic ProcedureNJAT0297

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 5 and ground.

Resistance:

5-20W

SAT889JB

OK or NG

OK©GO TO 2.

NG©1. Remove oil pan. Refer to AT-351.

2. Check the following items:

+Torque converter clutch solenoid valve

Refer to ªComponent Inspectionº, AT-238.

+Harness of terminal cord assembly for short or open

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EURO-OBD

Diagnostic Procedure

AT-236

Page 239 of 2898

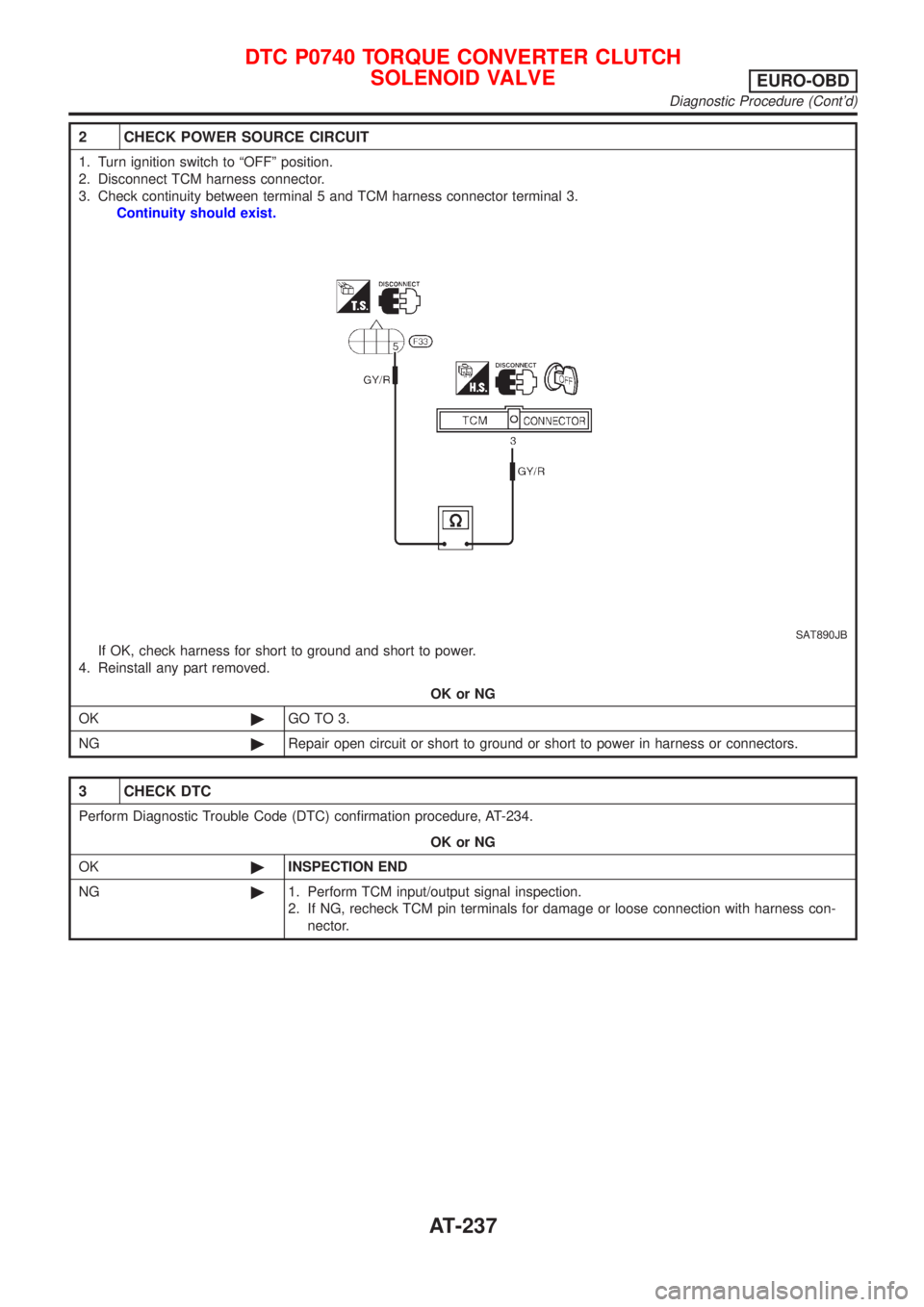

2 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check continuity between terminal 5 and TCM harness connector terminal 3.

Continuity should exist.

SAT890JB

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-234.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EURO-OBD

Diagnostic Procedure (Cont'd)

AT-237

Page 240 of 2898

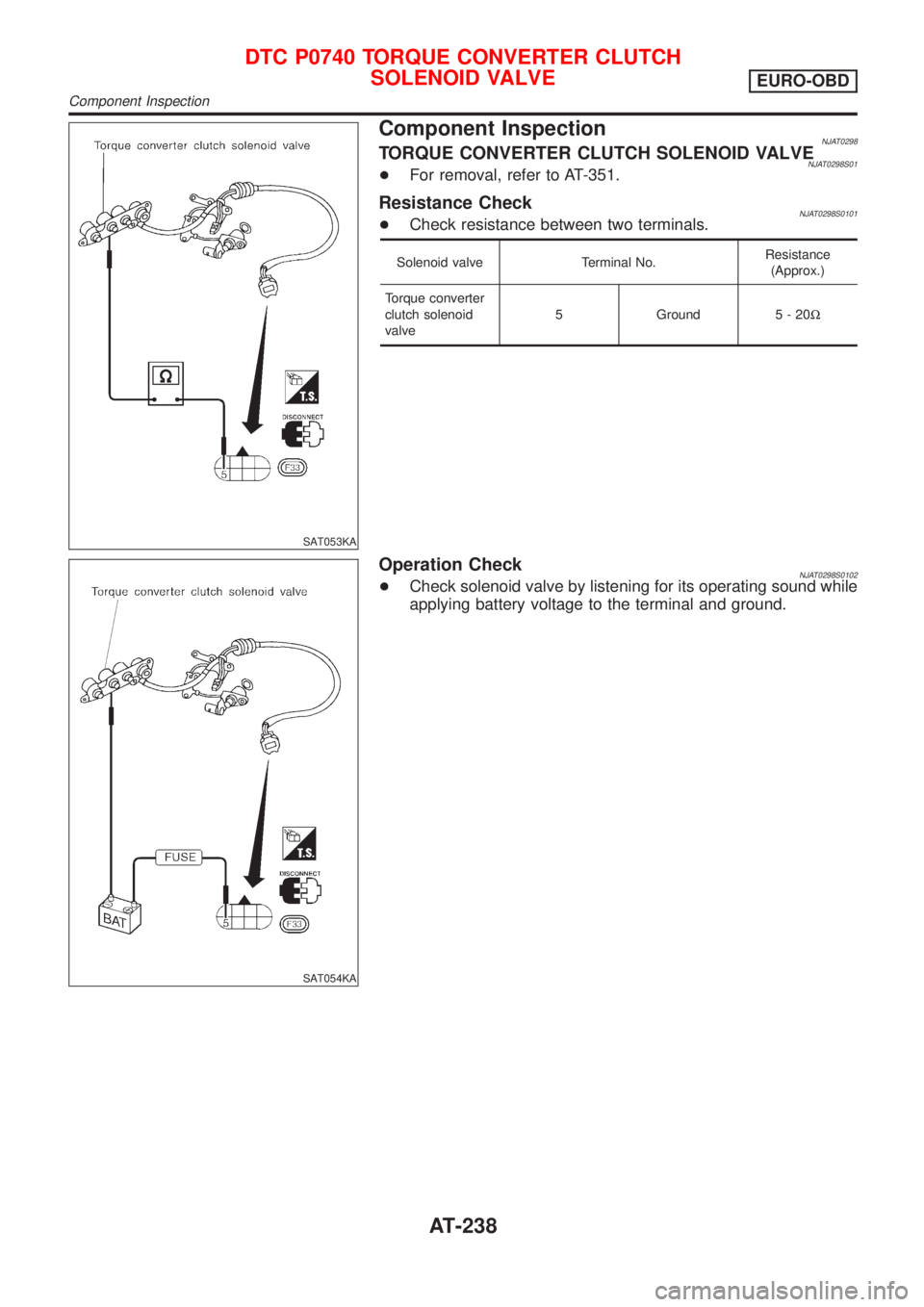

SAT053KA

Component InspectionNJAT0298TORQUE CONVERTER CLUTCH SOLENOID VALVENJAT0298S01+For removal, refer to AT-351.

Resistance CheckNJAT0298S0101+Check resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Torque converter

clutch solenoid

valve5 Ground 5 - 20W

SAT054KA

Operation CheckNJAT0298S0102+Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EURO-OBD

Component Inspection

AT-238

Page 307 of 2898

6. Vehicle Does Not Creep Backward In ªRº

Position

=NJAT0336SYMPTOM:

Vehicle does not creep backward when selecting ªRº position.

1 CHECK A/T FLUID LEVEL

Check A/T fluid level again.

SAT638A

OK or NG

OK©GO TO 2.

NG©Refill ATF.

2 CHECK STALL TEST

Check stall revolution with selector lever in ª1º and ªRº positions.

Refer to ªSTALL TESTº, AT-80.

SAT493G

OK or NG

OK©GO TO 3.

OK in ª1º position, NG in

ªRº position©1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-351.

2. Check the following items:

+Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot

valve and pilot filter)

+Line pressure solenoid valve (AT-176: General and except for Euro-OBD/AT-239:

Euro-OBD)

3. Disassemble A/T.

4. Check the following items:

+Oil pump assembly

+Torque converter

+Reverse clutch assembly

+High clutch assembly

+Low & reverse brake assembly

+Low one-way clutch

NG in both ª1º and ªRº

positions©GO TO 6.

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position

AT-305

Page 309 of 2898

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-351.

2. Check the following items:

+Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot filter)

+Line pressure solenoid valve (AT-176: General and except for Euro-OBD/AT-239: Euro-OBD)

3. Disassemble A/T.

4. Check the following items:

+Oil pump assembly

+Torque converter

+Reverse clutch assembly

+High clutch assembly

+Low & reverse brake assembly

+Low one-way clutch

OK or NG

OK©GO TO 5.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position (Cont'd)

AT-307

Page 312 of 2898

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot filter)

+Line pressure solenoid valve (AT-176: General and except for Euro-OBD/AT-239: Euro-OBD)

3. Disassemble A/T.

4. Check the following items:

+Oil pump assembly

+Forward clutch assembly

+Forward one-way clutch

+Low one-way clutch

+Low & reverse brake assembly

+Torque converter

OK or NG

OK©GO TO 5.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position (Cont'd)

AT-310

Page 315 of 2898

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Shift valve A

+Shift valve B

+Shift solenoid valve A

+Shift solenoid valve B

+Pilot valve

+Pilot filter

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

7 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

8 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Shift valve A

+Shift valve B

+Shift solenoid valve A

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following items:

+Forward clutch assembly

+Forward one-way clutch

+Low one-way clutch

+High clutch assembly

+Torque converter

+Oil pump assembly

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

8. Vehicle Cannot Be Started From D1(Cont'd)

AT-313