torque NISSAN ALMERA 2001 Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 509 of 2898

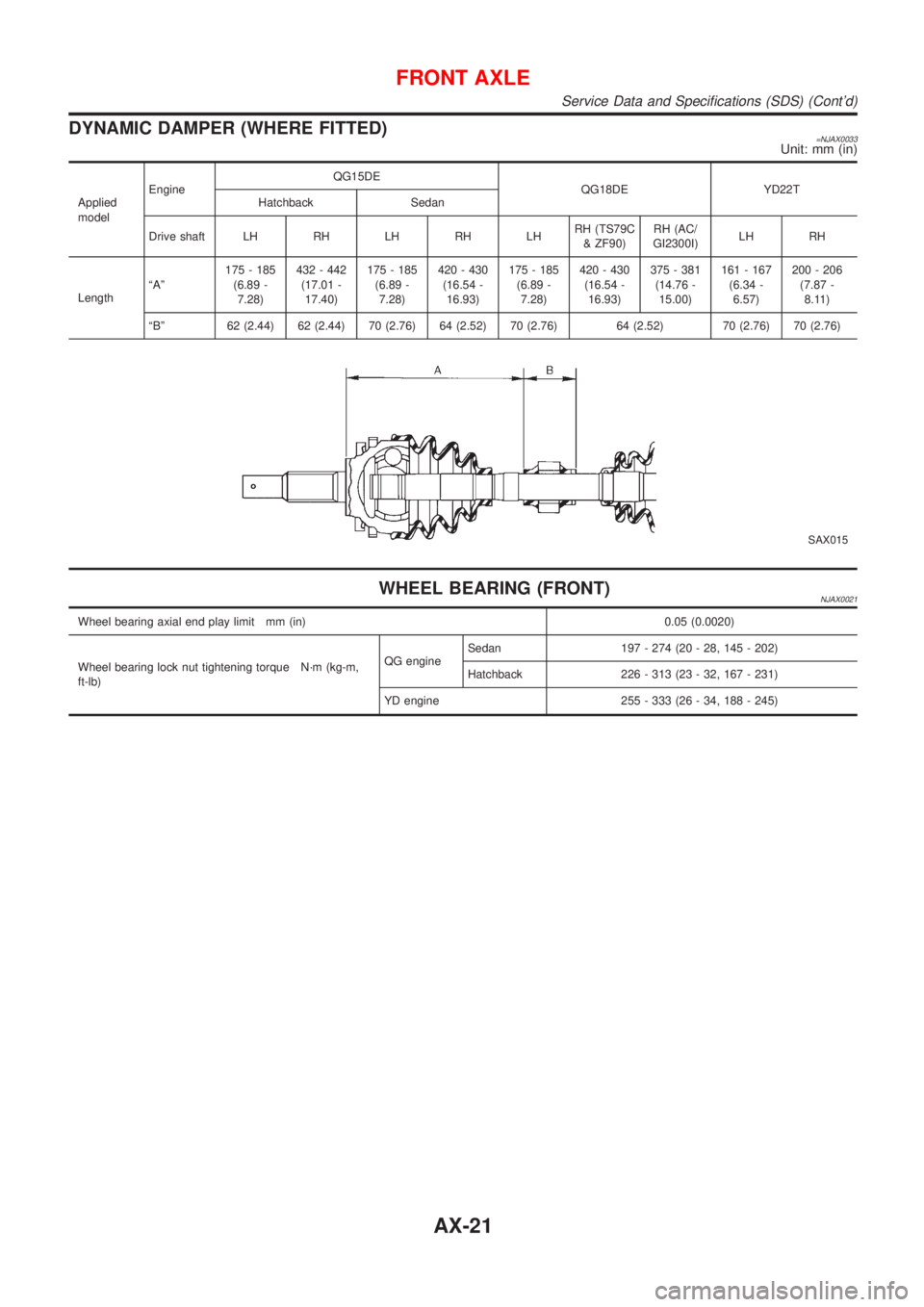

DYNAMIC DAMPER (WHERE FITTED)=NJAX0033Unit: mm (in)

Applied

modelEngineQG15DE

QG18DE YD22T

Hatchback Sedan

Drive shaft LH RH LH RH LHRH (TS79C

& ZF90)RH (AC/

GI2300I)LH RH

LengthªAº175 - 185

(6.89 -

7.28)432 - 442

(17.01 -

17.40)175 - 185

(6.89 -

7.28)420 - 430

(16.54 -

16.93)175 - 185

(6.89 -

7.28)420 - 430

(16.54 -

16.93)375 - 381

(14.76 -

15.00)161 - 167

(6.34 -

6.57)200 - 206

(7.87 -

8.11)

ªBº 62 (2.44) 62 (2.44) 70 (2.76) 64 (2.52) 70 (2.76) 64 (2.52) 70 (2.76) 70 (2.76)

SAX015

WHEEL BEARING (FRONT)NJAX0021

Wheel bearing axial end play limit mm (in) 0.05 (0.0020)

Wheel bearing lock nut tightening torque N´m (kg-m,

ft-lb)QG engineSedan 197 - 274 (20 - 28, 145 - 202)

Hatchback 226 - 313 (23 - 32, 167 - 231)

YD engine 255 - 333 (26 - 34, 188 - 245)

FRONT AXLE

Service Data and Specifications (SDS) (Cont'd)

AX-21

Page 510 of 2898

SBR686C

Precautions

PRECAUTIONSNJAX0022+When installing each rubber part, final tightening must be

carried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+Use flare nut wrench when removing or installing brake

tubes.

+After installing removed suspension parts, check wheel

alignment.

+Do not jack up at the trailing arm and lateral link.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNJAX0032

Tool number

Tool nameDescription

KV40104710

Drift

NT474

Install ABS sensor rotor

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.

ST3072000

Drift

NT115

Install ABS sensor rotor

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

COMMERCIAL SERVICE TOOLSNJAX0024

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing brake piping

a: 10 mm (0.39 in)

REAR AXLE

Precautions

AX-22

Page 511 of 2898

Noise, Vibration and Harshness (NVH)

Troubleshooting

NJAX0025Refer to ªNoise, Vibration and Harshness (NVH) Troubleshootingº,

ªFRONT AXLEº, AX-3.

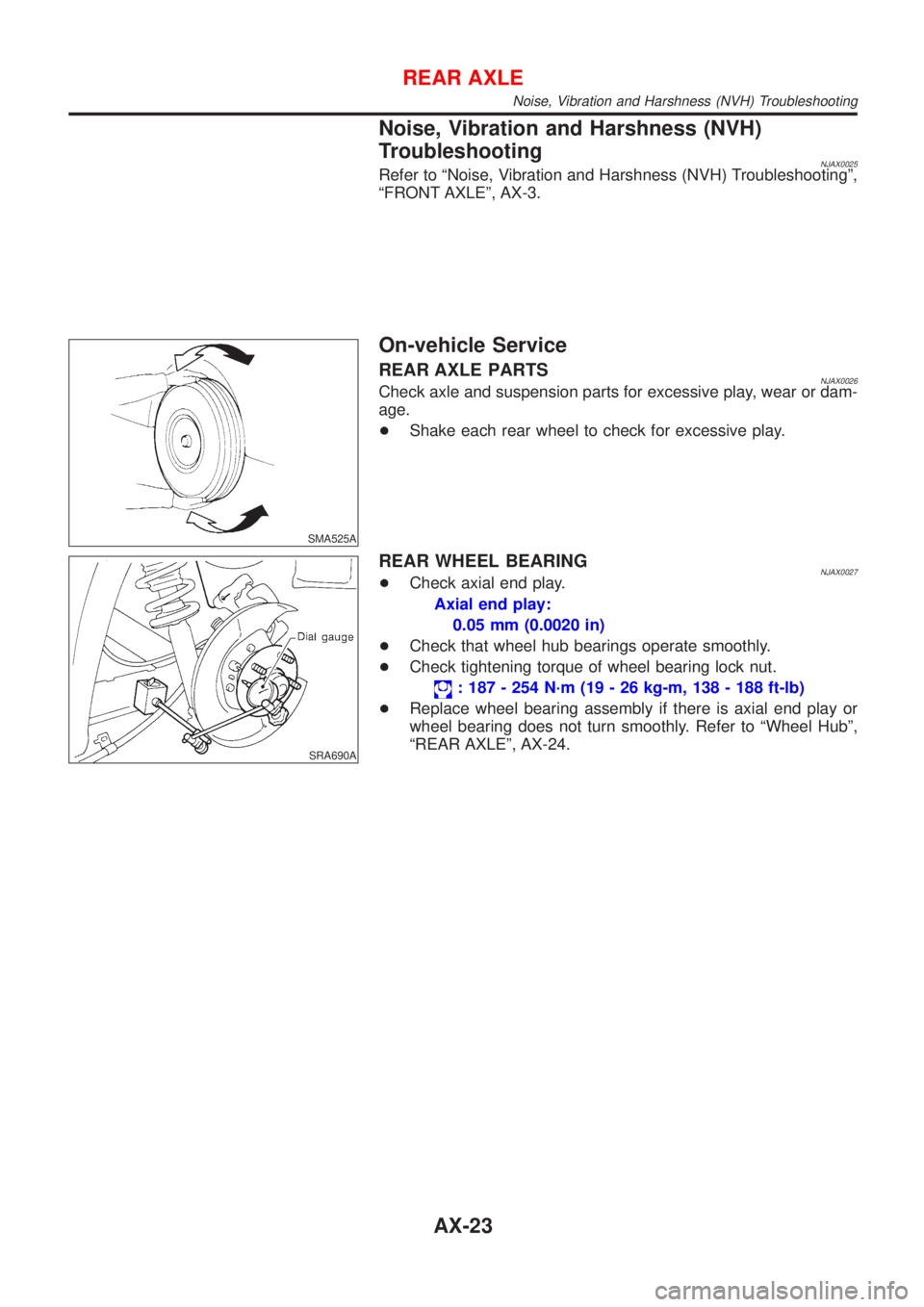

SMA525A

On-vehicle Service

REAR AXLE PARTSNJAX0026Check axle and suspension parts for excessive play, wear or dam-

age.

+Shake each rear wheel to check for excessive play.

SRA690A

REAR WHEEL BEARINGNJAX0027+Check axial end play.

Axial end play:

0.05 mm (0.0020 in)

+Check that wheel hub bearings operate smoothly.

+Check tightening torque of wheel bearing lock nut.

: 187 - 254 N´m (19 - 26 kg-m, 138 - 188 ft-lb)

+Replace wheel bearing assembly if there is axial end play or

wheel bearing does not turn smoothly. Refer to ªWheel Hubº,

ªREAR AXLEº, AX-24.

REAR AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-23

Page 512 of 2898

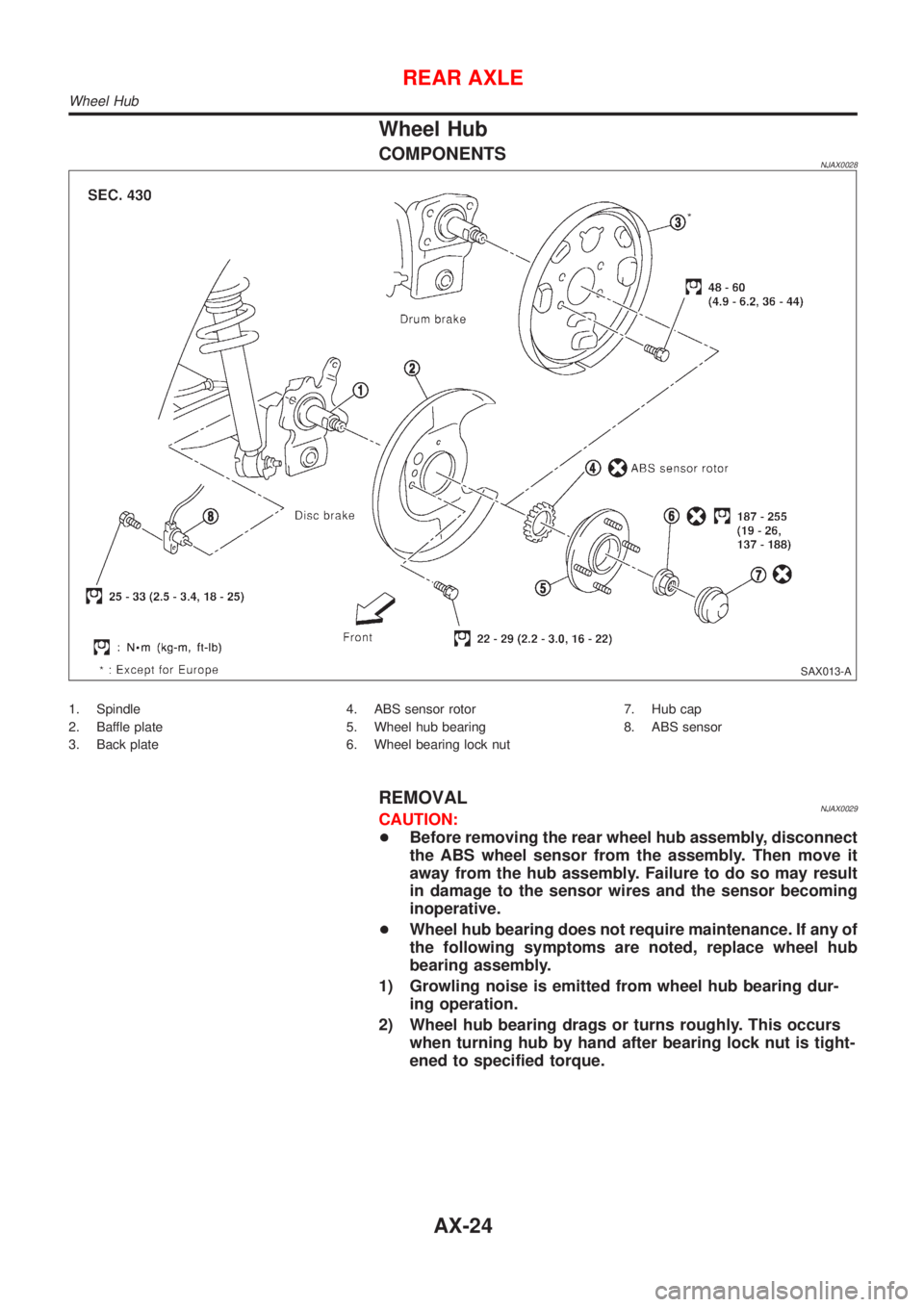

Wheel Hub

COMPONENTSNJAX0028

SAX013-A

1. Spindle

2. Baffle plate

3. Back plate4. ABS sensor rotor

5. Wheel hub bearing

6. Wheel bearing lock nut7. Hub cap

8. ABS sensor

REMOVALNJAX0029CAUTION:

+Before removing the rear wheel hub assembly, disconnect

the ABS wheel sensor from the assembly. Then move it

away from the hub assembly. Failure to do so may result

in damage to the sensor wires and the sensor becoming

inoperative.

+Wheel hub bearing does not require maintenance. If any of

the following symptoms are noted, replace wheel hub

bearing assembly.

1) Growling noise is emitted from wheel hub bearing dur-

ing operation.

2) Wheel hub bearing drags or turns roughly. This occurs

when turning hub by hand after bearing lock nut is tight-

ened to specified torque.

REAR AXLE

Wheel Hub

AX-24

Page 515 of 2898

Service Data and Specifications (SDS)

WHEEL BEARING (REAR)=NJAX0031

Wheel bearing axial end play mm (in) 0.05 (0.0020)

Wheel bearing lock nut tightening torque N´m (kg-m, ft-lb) 187 - 254 (19 - 26, 138 - 188)

REAR AXLE

Service Data and Specifications (SDS)

AX-27

Page 520 of 2898

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJBR0139The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

SBR686C

Precautions for Brake SystemNJBR0002+Recommended fluid is brake fluid ªDOT 4º.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas.

+To clean or wash all parts of master cylinder, disc brake

caliper and wheel cylinder, use clean brake fluid.

+Never use mineral oils such as gasoline or kerosene. They

will ruin rubber parts of the hydraulic system.

+Use flare nut wrench when removing and installing brake

tube.

+Always torque brake lines when installing.

+Burnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low mileage.

Refer to ªBrake Burnishing Procedureº, ªON-VEHICLE

SERVICEº, BR-8.

WARNING:

+Clean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

BR-4

Page 522 of 2898

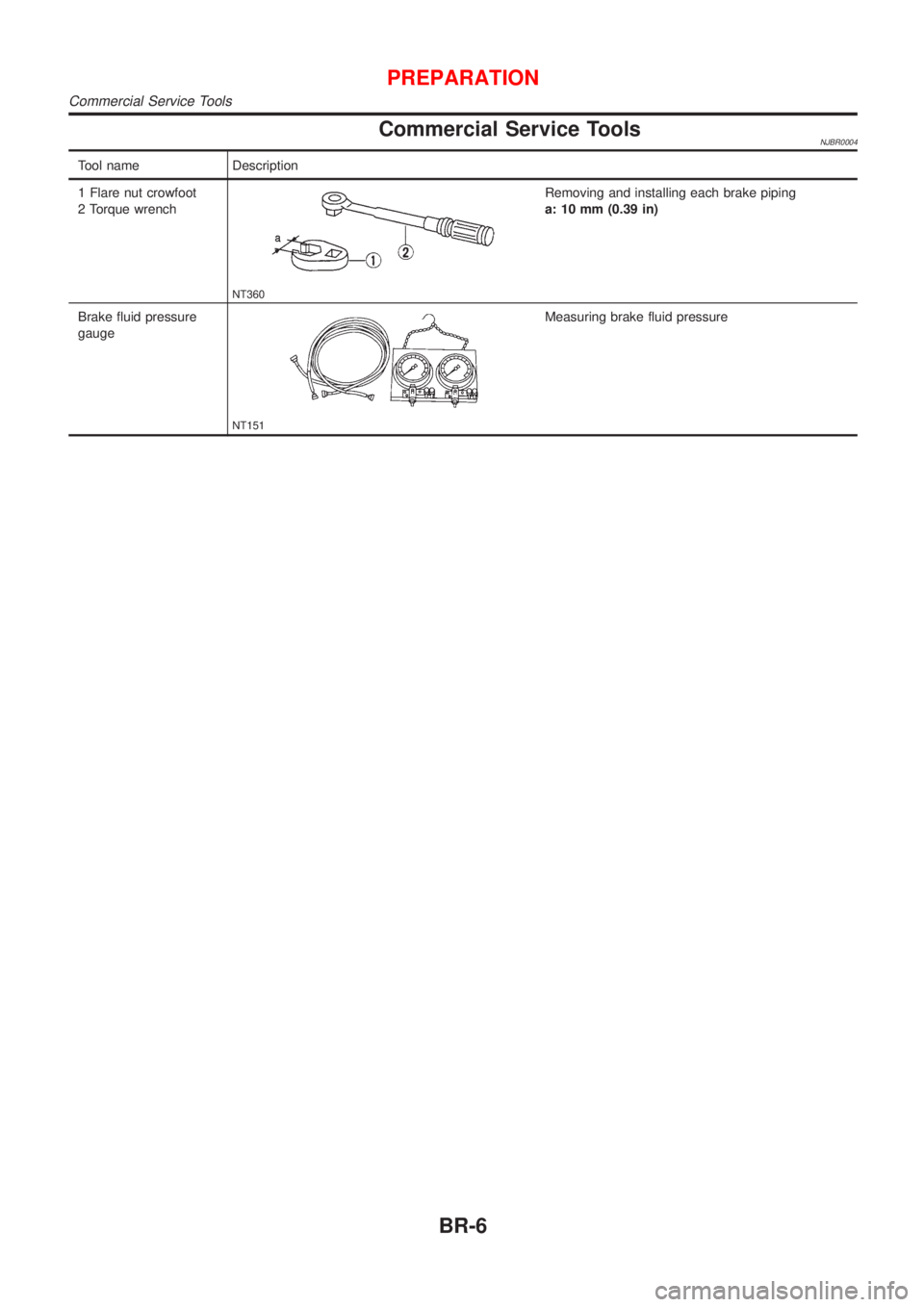

Commercial Service ToolsNJBR0004

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Brake fluid pressure

gauge

NT151

Measuring brake fluid pressure

PREPARATION

Commercial Service Tools

BR-6

Page 532 of 2898

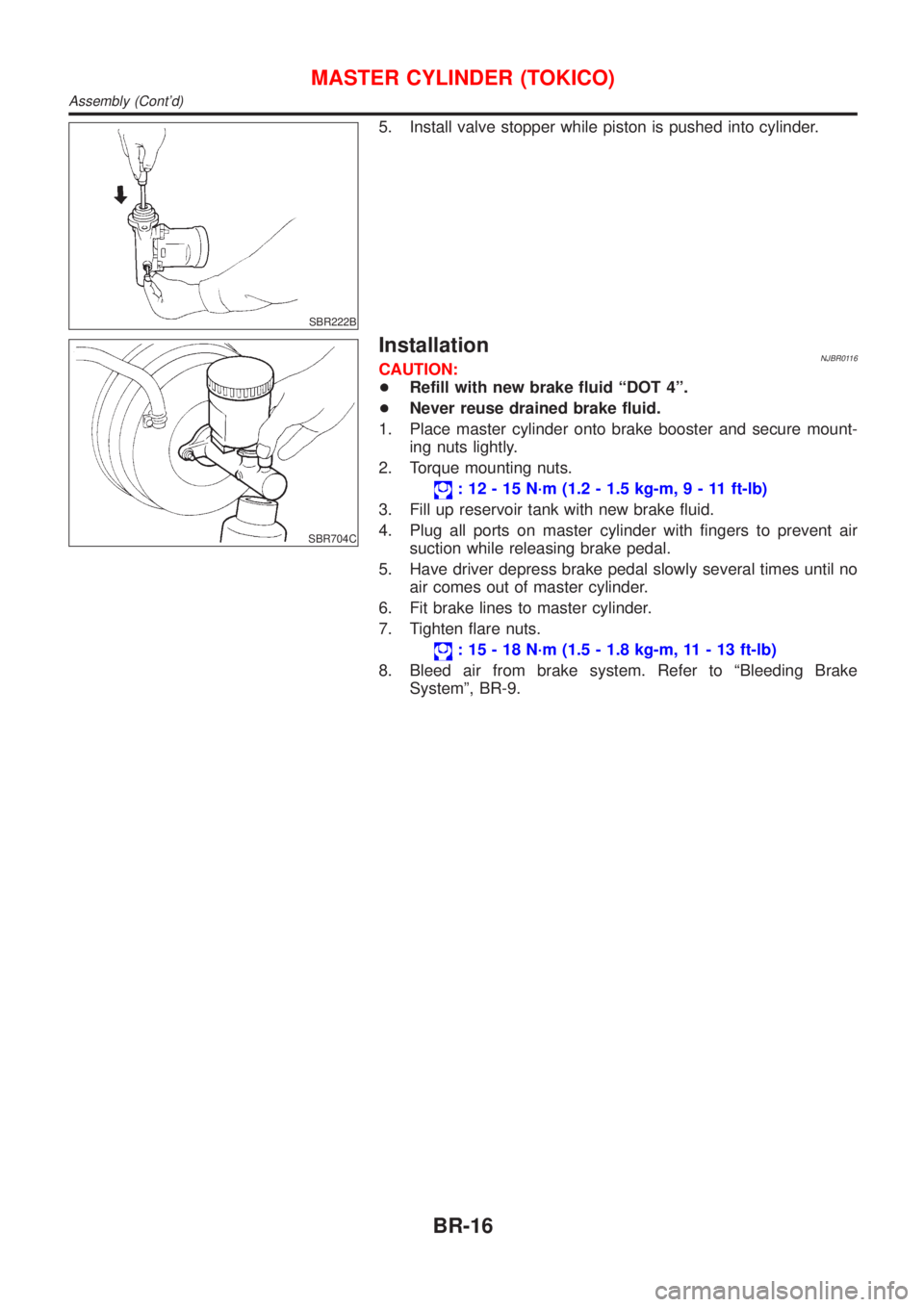

SBR222B

5. Install valve stopper while piston is pushed into cylinder.

SBR704C

InstallationNJBR0116CAUTION:

+Refill with new brake fluid ªDOT 4º.

+Never reuse drained brake fluid.

1. Place master cylinder onto brake booster and secure mount-

ing nuts lightly.

2. Torque mounting nuts.

: 12 - 15 N´m (1.2 - 1.5 kg-m,9-11ft-lb)

3. Fill up reservoir tank with new brake fluid.

4. Plug all ports on master cylinder with fingers to prevent air

suction while releasing brake pedal.

5. Have driver depress brake pedal slowly several times until no

air comes out of master cylinder.

6. Fit brake lines to master cylinder.

7. Tighten flare nuts.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

8. Bleed air from brake system. Refer to ªBleeding Brake

Systemº, BR-9.

MASTER CYLINDER (TOKICO)

Assembly (Cont'd)

BR-16

Page 535 of 2898

SBR236E

InstallationNJBR0121CAUTION:

+Refill with new brake fluid ªDOT 4º.

+Never reuse drained brake fluid.

1. Place master cylinder onto brake booster and secure mount-

ing nuts lightly.

2. Torque mounting nuts.

: 13 - 15 N´m (1.3 - 1.5 kg-m,9-11ft-lb)

3. Fill up reservoir tank with new brake fluid.

4. Plug all ports on master cylinder with fingers to prevent air

suction while releasing brake pedal.

5. Have driver depress brake pedal slowly several times until no

air comes out of master cylinder.

6. Fit brake lines to master cylinder.

7. Tighten flare nuts.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

8. Bleed air from brake system.

MASTER CYLINDER [BOSCH (NABCO)]

Installation

BR-19

Page 543 of 2898

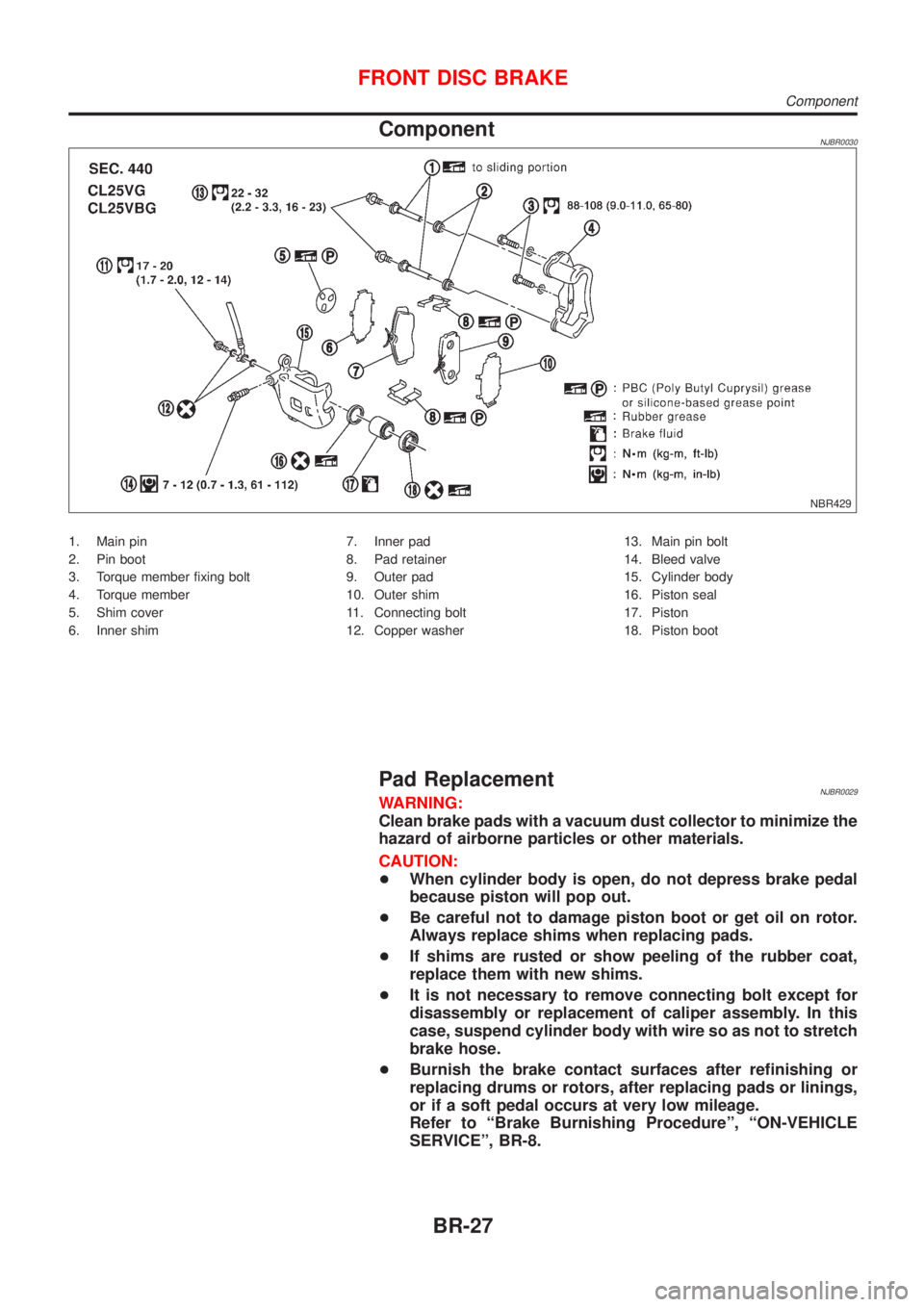

ComponentNJBR0030

NBR429

1. Main pin

2. Pin boot

3. Torque member fixing bolt

4. Torque member

5. Shim cover

6. Inner shim7. Inner pad

8. Pad retainer

9. Outer pad

10. Outer shim

11. Connecting bolt

12. Copper washer13. Main pin bolt

14. Bleed valve

15. Cylinder body

16. Piston seal

17. Piston

18. Piston boot

Pad ReplacementNJBR0029WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

+When cylinder body is open, do not depress brake pedal

because piston will pop out.

+Be careful not to damage piston boot or get oil on rotor.

Always replace shims when replacing pads.

+If shims are rusted or show peeling of the rubber coat,

replace them with new shims.

+It is not necessary to remove connecting bolt except for

disassembly or replacement of caliper assembly. In this

case, suspend cylinder body with wire so as not to stretch

brake hose.

+Burnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low mileage.

Refer to ªBrake Burnishing Procedureº, ªON-VEHICLE

SERVICEº, BR-8.

FRONT DISC BRAKE

Component

BR-27