torque NISSAN ALMERA 2001 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 324 of 2898

6 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

7 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Shift valve B

+Overrun clutch control valve

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following items:

+Servo piston assembly

+Brake band

+Torque converter

+Oil pump assembly

OK or NG

OK©GO TO 6.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

11. A/T Does Not Shift: D3®D4(Cont'd)

AT-322

Page 325 of 2898

12. A/T Does Not Perform Lock-up=NJAT0342SYMPTOM:

A/T does not perform lock-up at the specified speed.

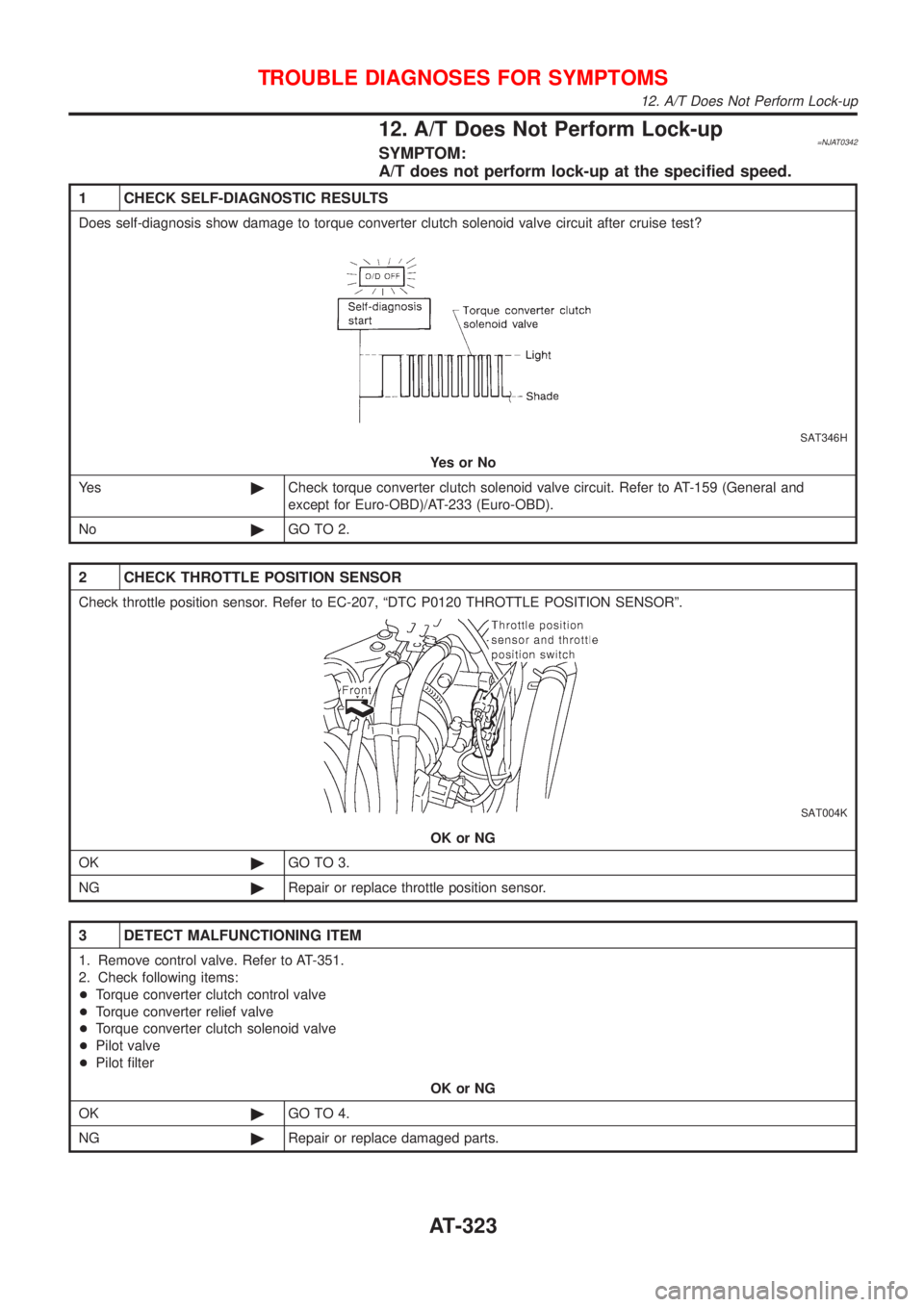

1 CHECK SELF-DIAGNOSTIC RESULTS

Does self-diagnosis show damage to torque converter clutch solenoid valve circuit after cruise test?

SAT346H

YesorNo

Ye s©Check torque converter clutch solenoid valve circuit. Refer to AT-159 (General and

except for Euro-OBD)/AT-233 (Euro-OBD).

No©GO TO 2.

2 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-207, ªDTC P0120 THROTTLE POSITION SENSORº.

SAT004K

OK or NG

OK©GO TO 3.

NG©Repair or replace throttle position sensor.

3 DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-351.

2. Check following items:

+Torque converter clutch control valve

+Torque converter relief valve

+Torque converter clutch solenoid valve

+Pilot valve

+Pilot filter

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

12. A/T Does Not Perform Lock-up

AT-323

Page 327 of 2898

13. A/T Does Not Hold Lock-up Condition=NJAT0343SYMPTOM:

A/T does not hold lock-up condition for more than 30 seconds.

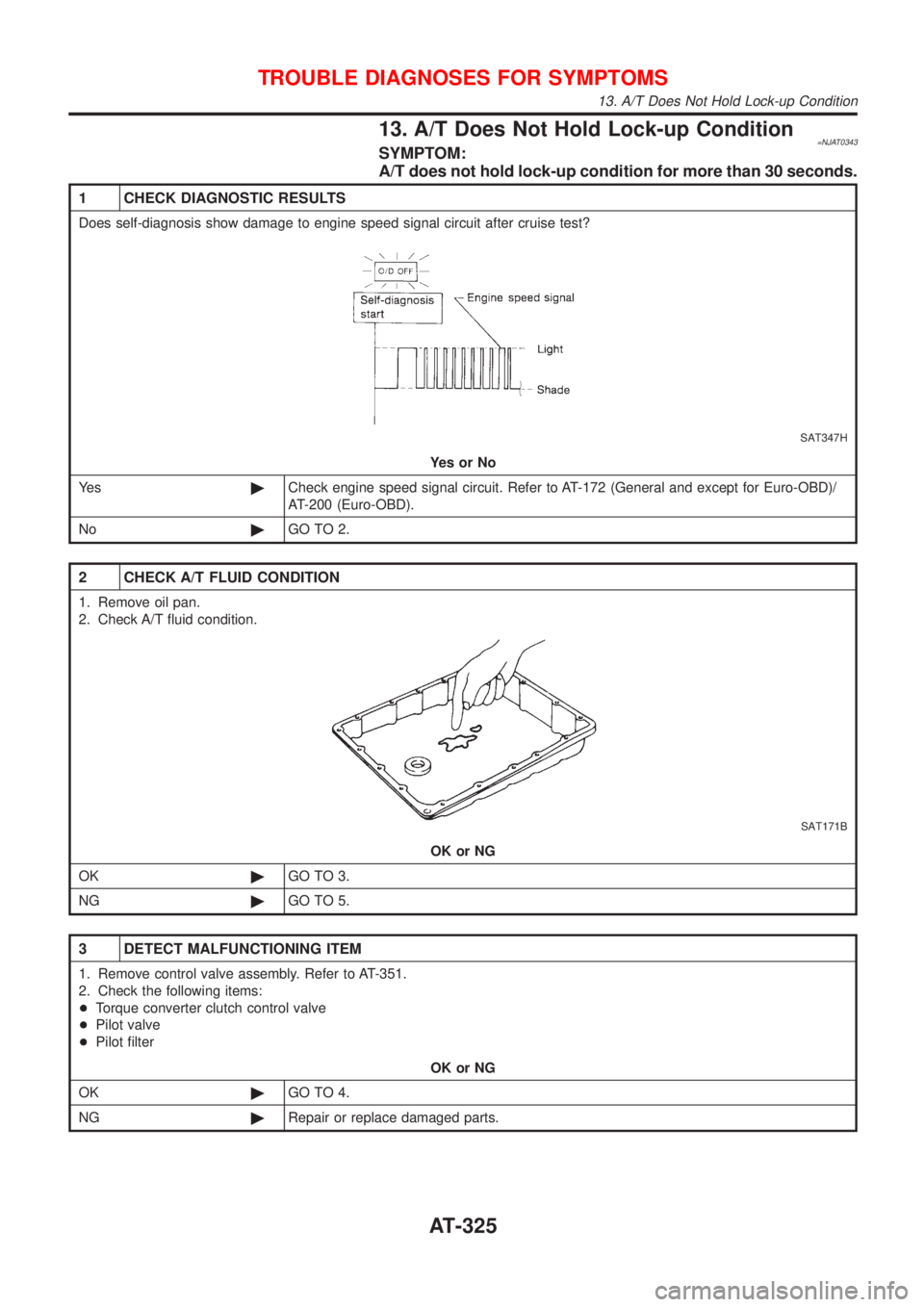

1 CHECK DIAGNOSTIC RESULTS

Does self-diagnosis show damage to engine speed signal circuit after cruise test?

SAT347H

YesorNo

Ye s©Check engine speed signal circuit. Refer to AT-172 (General and except for Euro-OBD)/

AT-200 (Euro-OBD).

No©GO TO 2.

2 CHECK A/T FLUID CONDITION

1. Remove oil pan.

2. Check A/T fluid condition.

SAT171B

OK or NG

OK©GO TO 3.

NG©GO TO 5.

3 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Torque converter clutch control valve

+Pilot valve

+Pilot filter

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

13. A/T Does Not Hold Lock-up Condition

AT-325

Page 328 of 2898

4 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

5 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Torque converter clutch control valve

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check torque converter and oil pump assembly.

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

13. A/T Does Not Hold Lock-up Condition (Cont'd)

AT-326

Page 356 of 2898

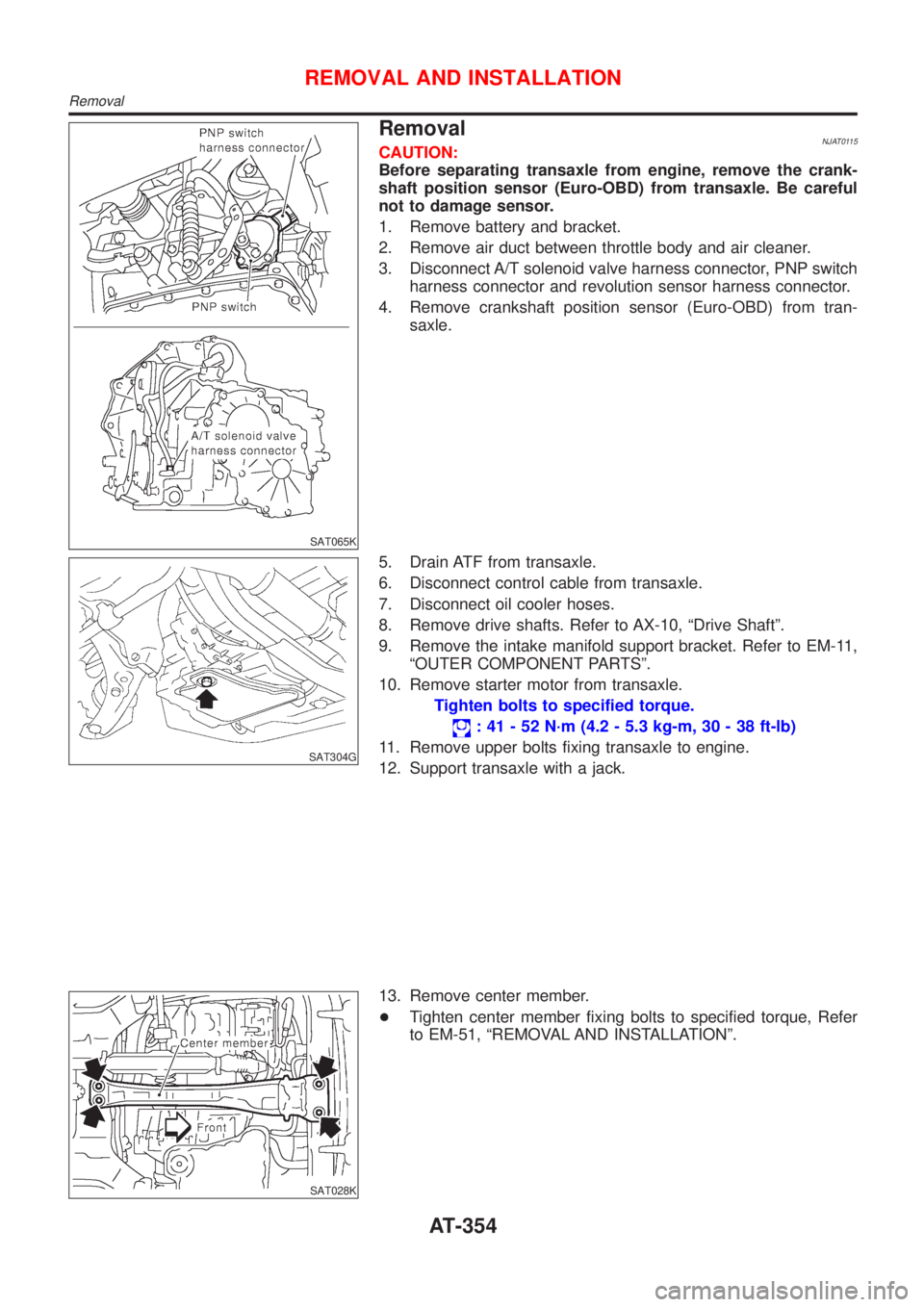

SAT065K

RemovalNJAT0115CAUTION:

Before separating transaxle from engine, remove the crank-

shaft position sensor (Euro-OBD) from transaxle. Be careful

not to damage sensor.

1. Remove battery and bracket.

2. Remove air duct between throttle body and air cleaner.

3. Disconnect A/T solenoid valve harness connector, PNP switch

harness connector and revolution sensor harness connector.

4. Remove crankshaft position sensor (Euro-OBD) from tran-

saxle.

SAT304G

5. Drain ATF from transaxle.

6. Disconnect control cable from transaxle.

7. Disconnect oil cooler hoses.

8. Remove drive shafts. Refer to AX-10, ªDrive Shaftº.

9. Remove the intake manifold support bracket. Refer to EM-11,

ªOUTER COMPONENT PARTSº.

10. Remove starter motor from transaxle.

Tighten bolts to specified torque.

: 41 - 52 N´m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

11. Remove upper bolts fixing transaxle to engine.

12. Support transaxle with a jack.

SAT028K

13. Remove center member.

+Tighten center member fixing bolts to specified torque, Refer

to EM-51, ªREMOVAL AND INSTALLATIONº.

REMOVAL AND INSTALLATION

Removal

AT-354

Page 357 of 2898

AAT259A

14. Remove rear plate cover.

15. Remove torque converter bolts.

Rotate crankshaft to gain access to securing bolts.

16. Remove rear transaxle to engine bracket. Refer to EM-51,

ªREMOVAL AND INSTALLATIONº.

17. Support engine with a jack.

18. Remove rear transaxle mount. Refer to EM-51, ªREMOVAL

AND INSTALLATIONº.

19. Remove lower bolts fixing transaxle to engine.

20. Lower transaxle while supporting it with a jack.

SAT977H

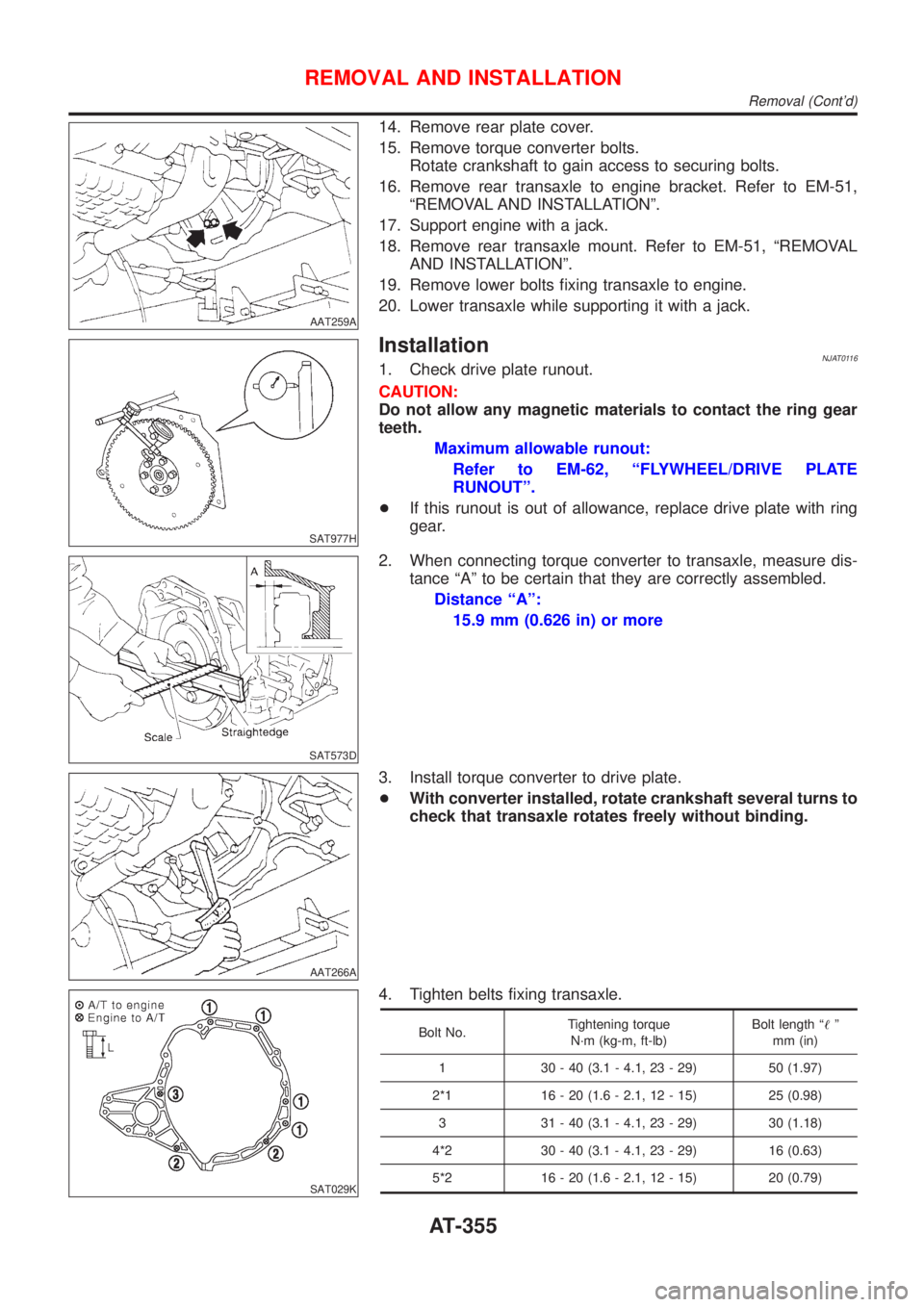

InstallationNJAT01161. Check drive plate runout.

CAUTION:

Do not allow any magnetic materials to contact the ring gear

teeth.

Maximum allowable runout:

Refer to EM-62, ªFLYWHEEL/DRIVE PLATE

RUNOUTº.

+If this runout is out of allowance, replace drive plate with ring

gear.

SAT573D

2. When connecting torque converter to transaxle, measure dis-

tance ªAº to be certain that they are correctly assembled.

Distance ªAº:

15.9 mm (0.626 in) or more

AAT266A

3. Install torque converter to drive plate.

+With converter installed, rotate crankshaft several turns to

check that transaxle rotates freely without binding.

SAT029K

4. Tighten belts fixing transaxle.

Bolt No.Tightening torque

N´m (kg-m, ft-lb)Bolt length ª!º

mm (in)

1 30 - 40 (3.1 - 4.1, 23 - 29) 50 (1.97)

2*1 16 - 20 (1.6 - 2.1, 12 - 15) 25 (0.98)

3 31 - 40 (3.1 - 4.1, 23 - 29) 30 (1.18)

4*2 30 - 40 (3.1 - 4.1, 23 - 29) 16 (0.63)

5*2 16 - 20 (1.6 - 2.1, 12 - 15) 20 (0.79)

REMOVAL AND INSTALLATION

Removal (Cont'd)

AT-355

Page 368 of 2898

NJAT0120

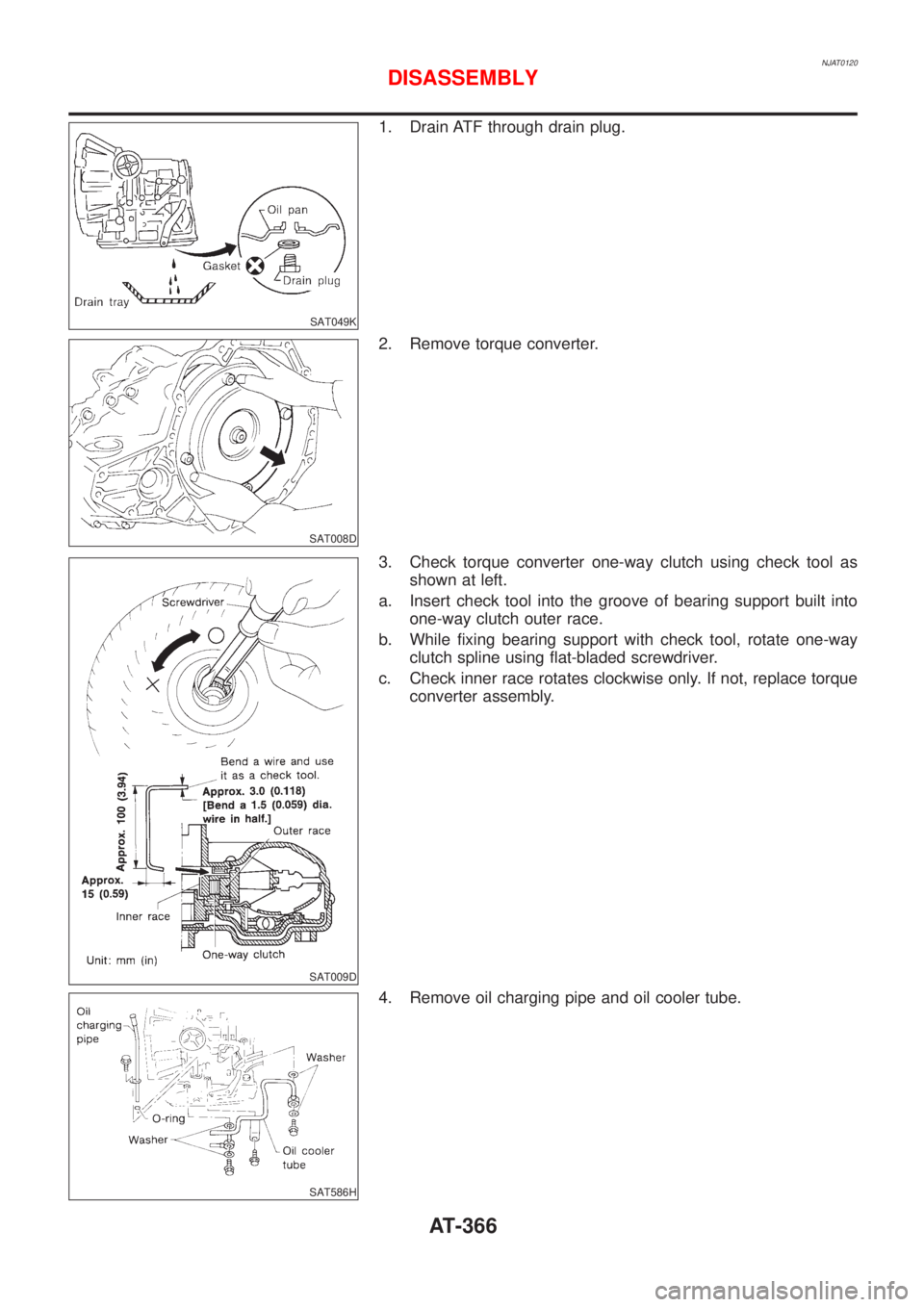

SAT049K

1. Drain ATF through drain plug.

SAT008D

2. Remove torque converter.

SAT009D

3. Check torque converter one-way clutch using check tool as

shown at left.

a. Insert check tool into the groove of bearing support built into

one-way clutch outer race.

b. While fixing bearing support with check tool, rotate one-way

clutch spline using flat-bladed screwdriver.

c. Check inner race rotates clockwise only. If not, replace torque

converter assembly.

SAT586H

4. Remove oil charging pipe and oil cooler tube.

DISASSEMBLY

AT-366

Page 394 of 2898

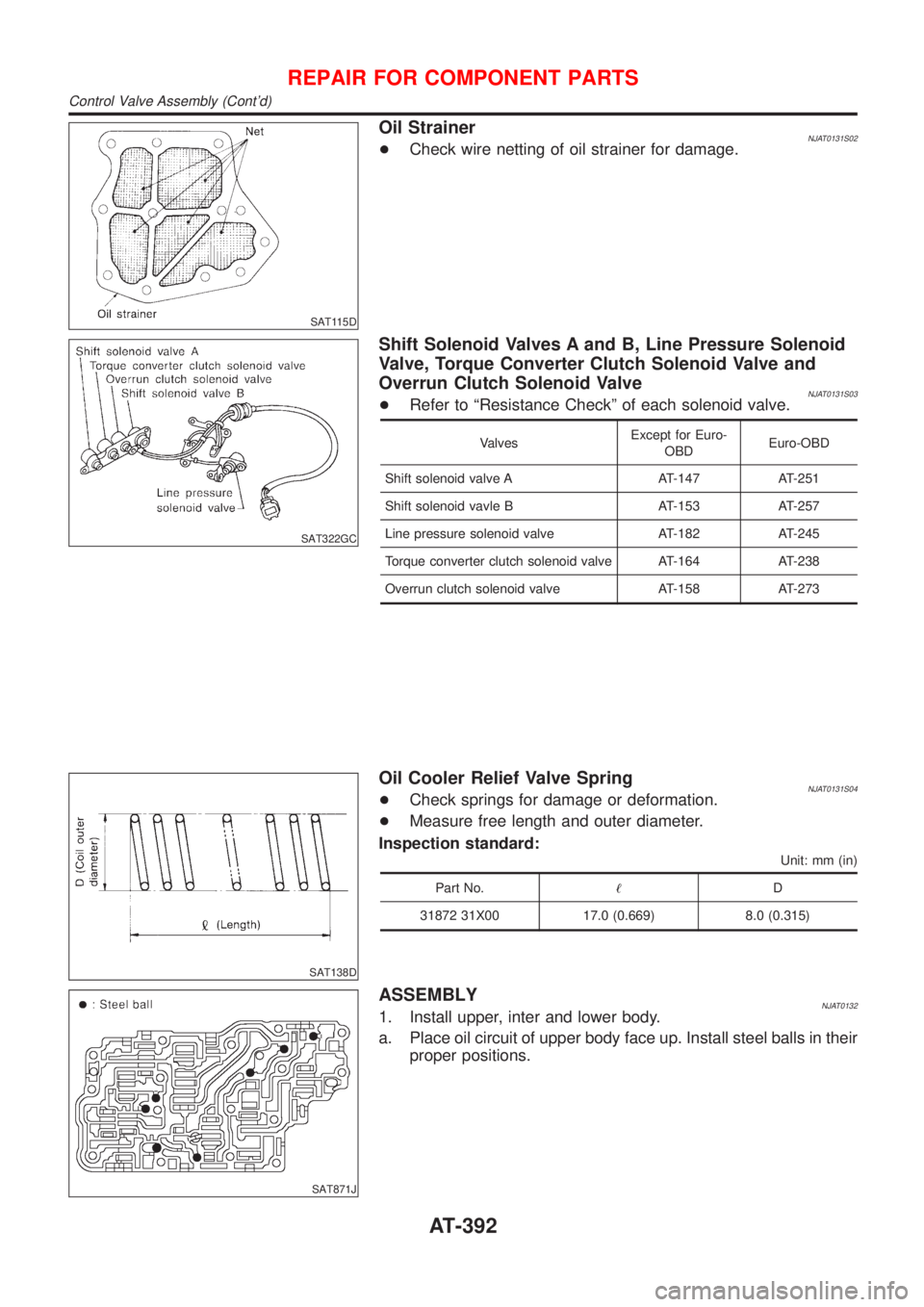

SAT115D

Oil StrainerNJAT0131S02+Check wire netting of oil strainer for damage.

SAT322GC

Shift Solenoid Valves A and B, Line Pressure Solenoid

Valve, Torque Converter Clutch Solenoid Valve and

Overrun Clutch Solenoid Valve

NJAT0131S03+Refer to ªResistance Checkº of each solenoid valve.

ValvesExcept for Euro-

OBDEuro-OBD

Shift solenoid valve A AT-147 AT-251

Shift solenoid vavle B AT-153 AT-257

Line pressure solenoid valve AT-182 AT-245

Torque converter clutch solenoid valve AT-164 AT-238

Overrun clutch solenoid valve AT-158 AT-273

SAT138D

Oil Cooler Relief Valve SpringNJAT0131S04+Check springs for damage or deformation.

+Measure free length and outer diameter.

Inspection standard:

Unit: mm (in)

Part No.!D

31872 31X00 17.0 (0.669) 8.0 (0.315)

SAT871J

ASSEMBLYNJAT01321. Install upper, inter and lower body.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-392

Page 397 of 2898

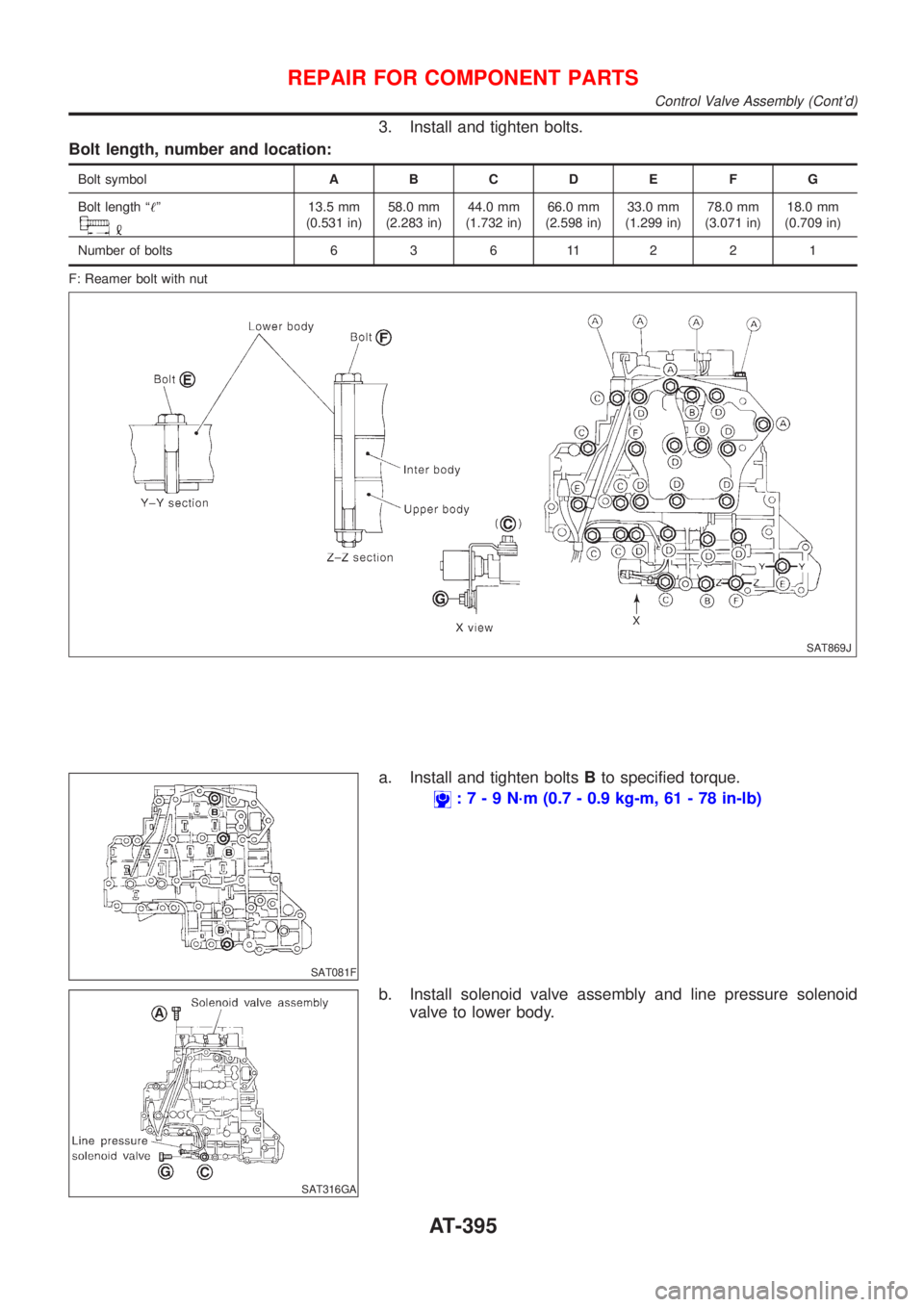

3. Install and tighten bolts.

Bolt length, number and location:

Bolt symbolABCDE FG

Bolt length ª!º

13.5 mm

(0.531 in)58.0 mm

(2.283 in)44.0 mm

(1.732 in)66.0 mm

(2.598 in)33.0 mm

(1.299 in)78.0 mm

(3.071 in)18.0 mm

(0.709 in)

Number of bolts 6 3 6 11 2 2 1

F: Reamer bolt with nut

SAT869J

SAT081F

a. Install and tighten boltsBto specified torque.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

SAT316GA

b. Install solenoid valve assembly and line pressure solenoid

valve to lower body.

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-395

Page 398 of 2898

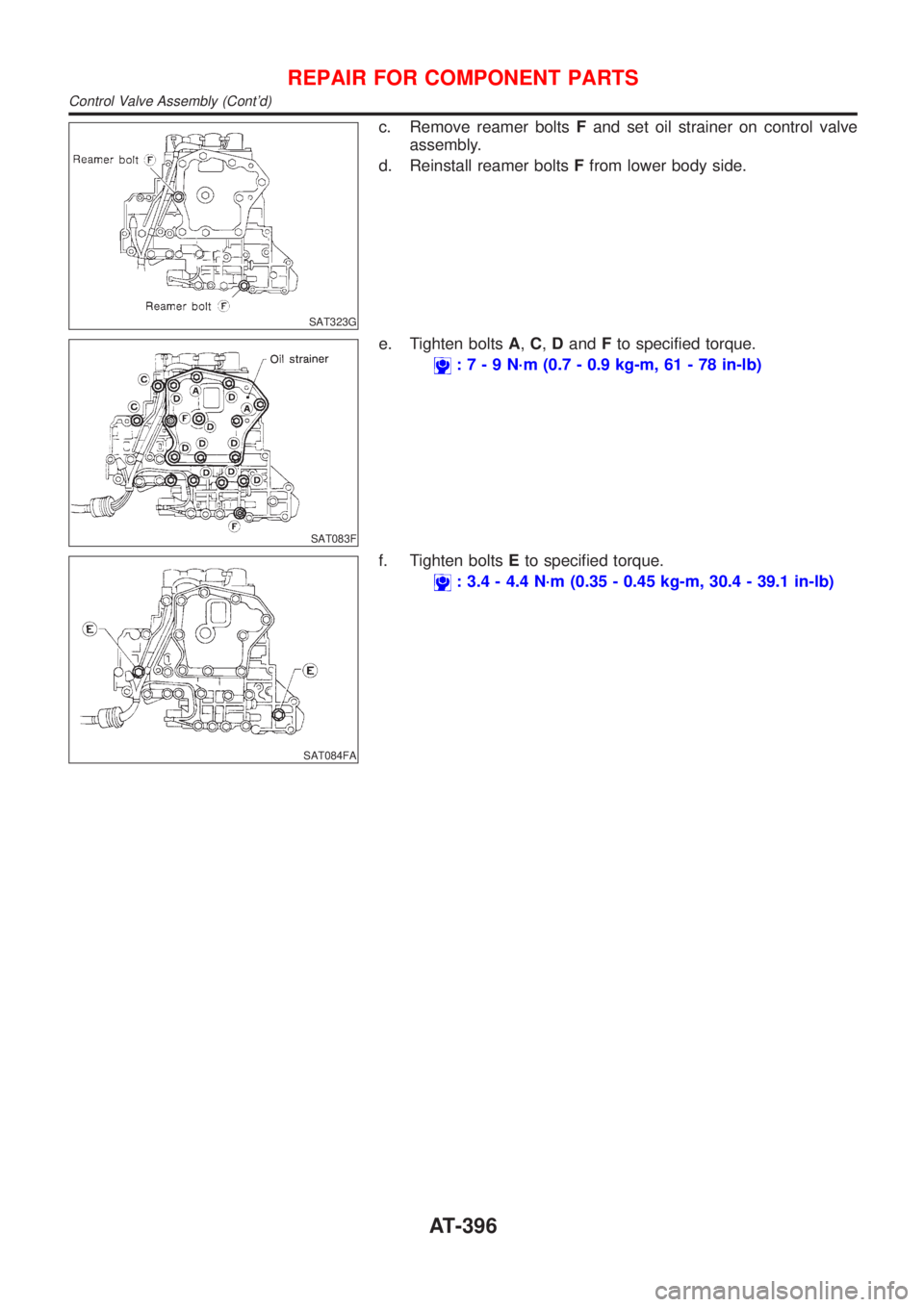

SAT323G

c. Remove reamer boltsFand set oil strainer on control valve

assembly.

d. Reinstall reamer boltsFfrom lower body side.

SAT083F

e. Tighten boltsA,C,DandFto specified torque.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

SAT084FA

f. Tighten boltsEto specified torque.

: 3.4 - 4.4 N´m (0.35 - 0.45 kg-m, 30.4 - 39.1 in-lb)

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-396