torque NISSAN ALMERA 2001 Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 470 of 2898

SAT023JB

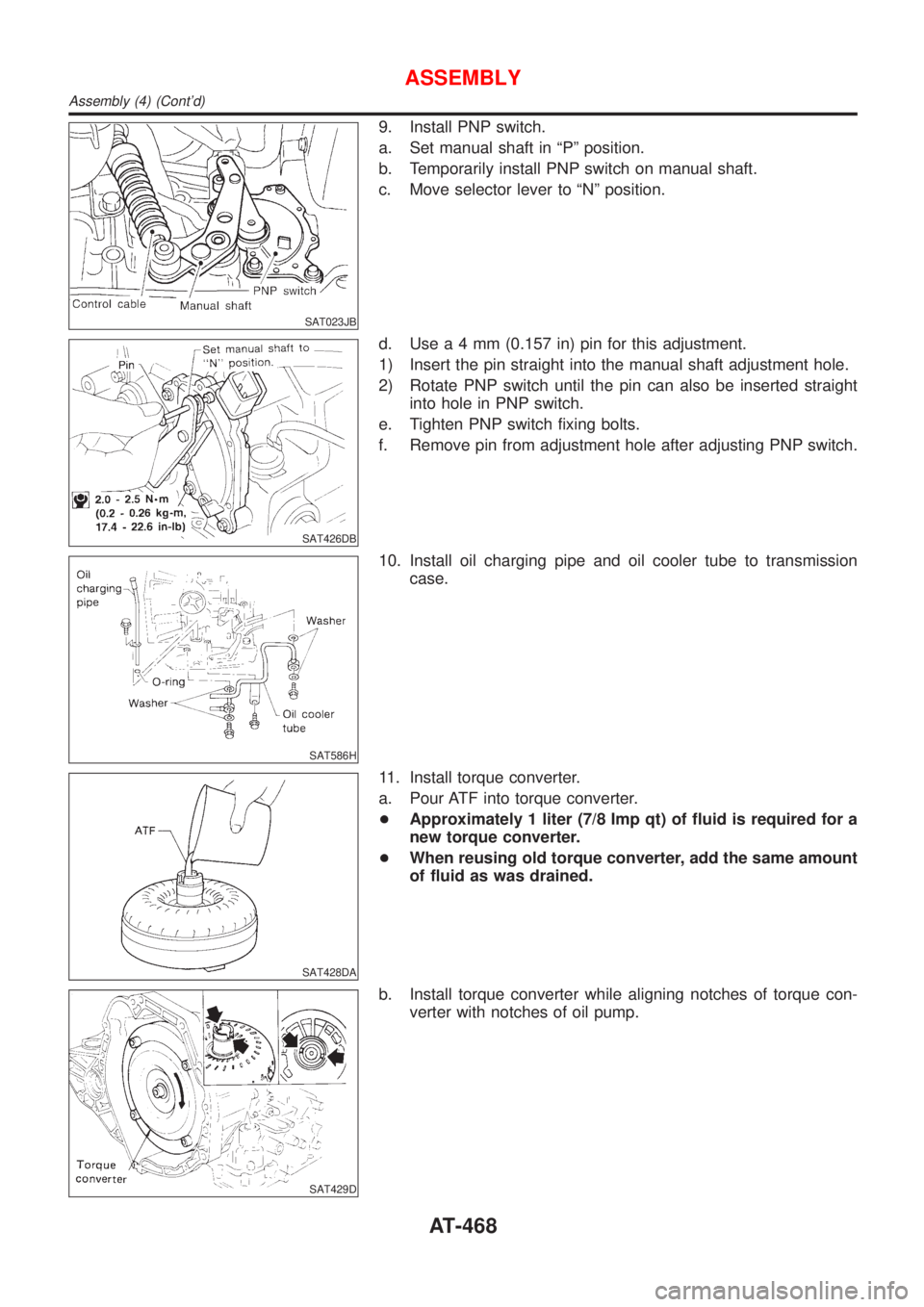

9. Install PNP switch.

a. Set manual shaft in ªPº position.

b. Temporarily install PNP switch on manual shaft.

c. Move selector lever to ªNº position.

SAT426DB

d. Usea4mm(0.157 in) pin for this adjustment.

1) Insert the pin straight into the manual shaft adjustment hole.

2) Rotate PNP switch until the pin can also be inserted straight

into hole in PNP switch.

e. Tighten PNP switch fixing bolts.

f. Remove pin from adjustment hole after adjusting PNP switch.

SAT586H

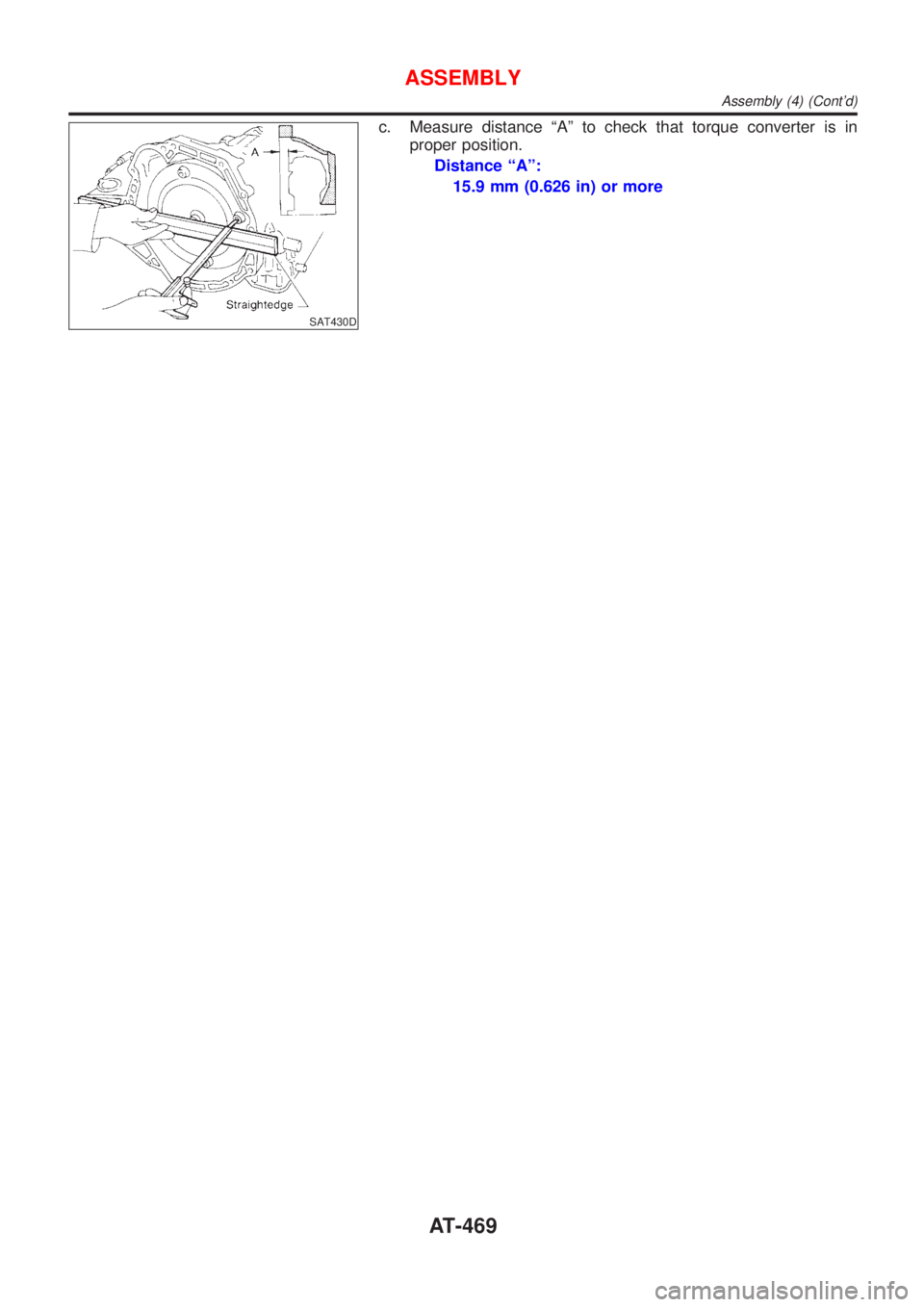

10. Install oil charging pipe and oil cooler tube to transmission

case.

SAT428DA

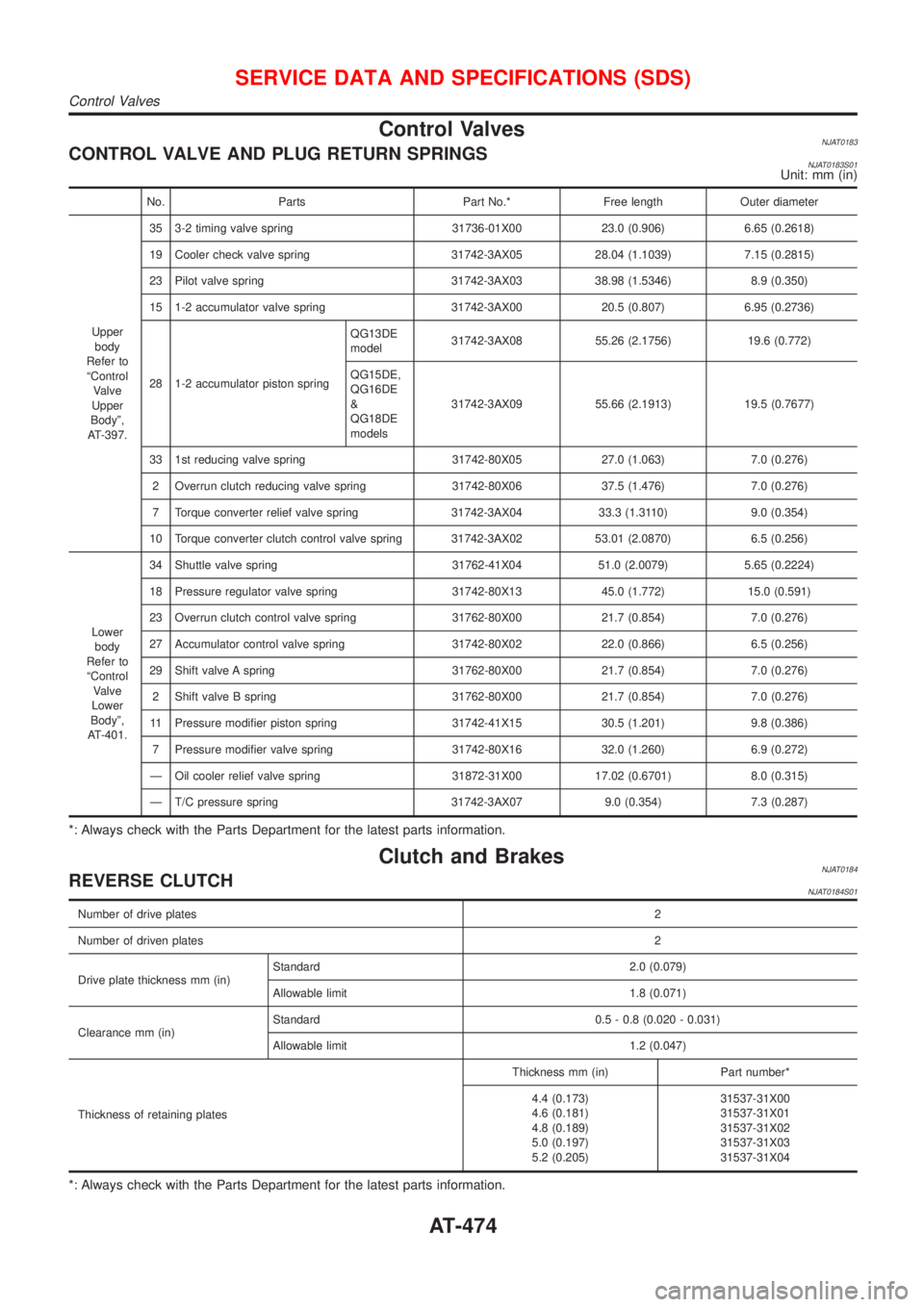

11. Install torque converter.

a. Pour ATF into torque converter.

+Approximately 1 liter (7/8 Imp qt) of fluid is required for a

new torque converter.

+When reusing old torque converter, add the same amount

of fluid as was drained.

SAT429D

b. Install torque converter while aligning notches of torque con-

verter with notches of oil pump.

ASSEMBLY

Assembly (4) (Cont'd)

AT-468

Page 471 of 2898

SAT430D

c. Measure distance ªAº to check that torque converter is in

proper position.

Distance ªAº:

15.9 mm (0.626 in) or more

ASSEMBLY

Assembly (4) (Cont'd)

AT-469

Page 476 of 2898

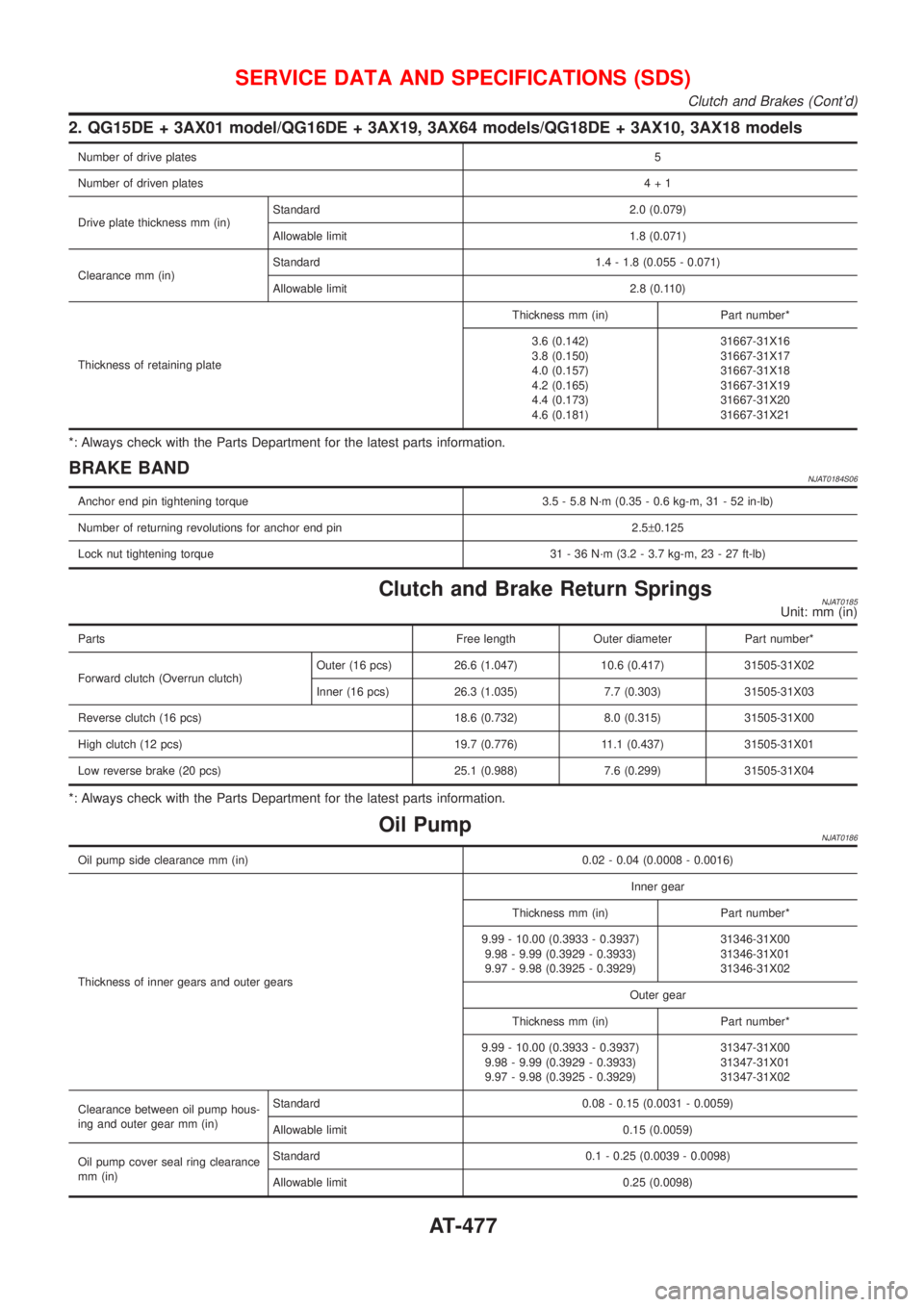

Control ValvesNJAT0183CONTROL VALVE AND PLUG RETURN SPRINGSNJAT0183S01Unit: mm (in)

No. Parts Part No.* Free length Outer diameter

Upper

body

Refer to

ªControl

Valve

Upper

Bodyº,

AT-397.35 3-2 timing valve spring 31736-01X00 23.0 (0.906) 6.65 (0.2618)

19 Cooler check valve spring 31742-3AX05 28.04 (1.1039) 7.15 (0.2815)

23 Pilot valve spring 31742-3AX03 38.98 (1.5346) 8.9 (0.350)

15 1-2 accumulator valve spring 31742-3AX00 20.5 (0.807) 6.95 (0.2736)

28 1-2 accumulator piston springQG13DE

model31742-3AX08 55.26 (2.1756) 19.6 (0.772)

QG15DE,

QG16DE

&

QG18DE

models31742-3AX09 55.66 (2.1913) 19.5 (0.7677)

33 1st reducing valve spring 31742-80X05 27.0 (1.063) 7.0 (0.276)

2 Overrun clutch reducing valve spring 31742-80X06 37.5 (1.476) 7.0 (0.276)

7 Torque converter relief valve spring 31742-3AX04 33.3 (1.3110) 9.0 (0.354)

10 Torque converter clutch control valve spring 31742-3AX02 53.01 (2.0870) 6.5 (0.256)

Lower

body

Refer to

ªControl

Valve

Lower

Bodyº,

AT-401.34 Shuttle valve spring 31762-41X04 51.0 (2.0079) 5.65 (0.2224)

18 Pressure regulator valve spring 31742-80X13 45.0 (1.772) 15.0 (0.591)

23 Overrun clutch control valve spring 31762-80X00 21.7 (0.854) 7.0 (0.276)

27 Accumulator control valve spring 31742-80X02 22.0 (0.866) 6.5 (0.256)

29 Shift valve A spring 31762-80X00 21.7 (0.854) 7.0 (0.276)

2 Shift valve B spring 31762-80X00 21.7 (0.854) 7.0 (0.276)

11 Pressure modifier piston spring 31742-41X15 30.5 (1.201) 9.8 (0.386)

7 Pressure modifier valve spring 31742-80X16 32.0 (1.260) 6.9 (0.272)

Ð Oil cooler relief valve spring 31872-31X00 17.02 (0.6701) 8.0 (0.315)

Ð T/C pressure spring 31742-3AX07 9.0 (0.354) 7.3 (0.287)

*: Always check with the Parts Department for the latest parts information.

Clutch and BrakesNJAT0184REVERSE CLUTCHNJAT0184S01

Number of drive plates2

Number of driven plates2

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 0.5 - 0.8 (0.020 - 0.031)

Allowable limit 1.2 (0.047)

Thickness of retaining platesThickness mm (in) Part number*

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)31537-31X00

31537-31X01

31537-31X02

31537-31X03

31537-31X04

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Control Valves

AT-474

Page 479 of 2898

2. QG15DE + 3AX01 model/QG16DE + 3AX19, 3AX64 models/QG18DE + 3AX10, 3AX18 models

Number of drive plates5

Number of driven plates4+1

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.8 (0.110)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)31667-31X16

31667-31X17

31667-31X18

31667-31X19

31667-31X20

31667-31X21

*: Always check with the Parts Department for the latest parts information.

BRAKE BANDNJAT0184S06

Anchor end pin tightening torque 3.5 - 5.8 N´m (0.35 - 0.6 kg-m, 31 - 52 in-lb)

Number of returning revolutions for anchor end pin 2.5±0.125

Lock nut tightening torque 31 - 36 N´m (3.2 - 3.7 kg-m, 23 - 27 ft-lb)

Clutch and Brake Return SpringsNJAT0185Unit: mm (in)

Parts Free length Outer diameter Part number*

Forward clutch (Overrun clutch)Outer (16 pcs) 26.6 (1.047) 10.6 (0.417) 31505-31X02

Inner (16 pcs) 26.3 (1.035) 7.7 (0.303) 31505-31X03

Reverse clutch (16 pcs) 18.6 (0.732) 8.0 (0.315) 31505-31X00

High clutch (12 pcs) 19.7 (0.776) 11.1 (0.437) 31505-31X01

Low reverse brake (20 pcs) 25.1 (0.988) 7.6 (0.299) 31505-31X04

*: Always check with the Parts Department for the latest parts information.

Oil PumpNJAT0186

Oil pump side clearance mm (in) 0.02 - 0.04 (0.0008 - 0.0016)

Thickness of inner gears and outer gearsInner gear

Thickness mm (in) Part number*

9.99 - 10.00 (0.3933 - 0.3937)

9.98 - 9.99 (0.3929 - 0.3933)

9.97 - 9.98 (0.3925 - 0.3929)31346-31X00

31346-31X01

31346-31X02

Outer gear

Thickness mm (in) Part number*

9.99 - 10.00 (0.3933 - 0.3937)

9.98 - 9.99 (0.3929 - 0.3933)

9.97 - 9.98 (0.3925 - 0.3929)31347-31X00

31347-31X01

31347-31X02

Clearance between oil pump hous-

ing and outer gear mm (in)Standard 0.08 - 0.15 (0.0031 - 0.0059)

Allowable limit 0.15 (0.0059)

Oil pump cover seal ring clearance

mm (in)Standard 0.1 - 0.25 (0.0039 - 0.0098)

Allowable limit 0.25 (0.0098)

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch and Brakes (Cont'd)

AT-477

Page 480 of 2898

*: Always check with the Parts Department for the latest parts information.

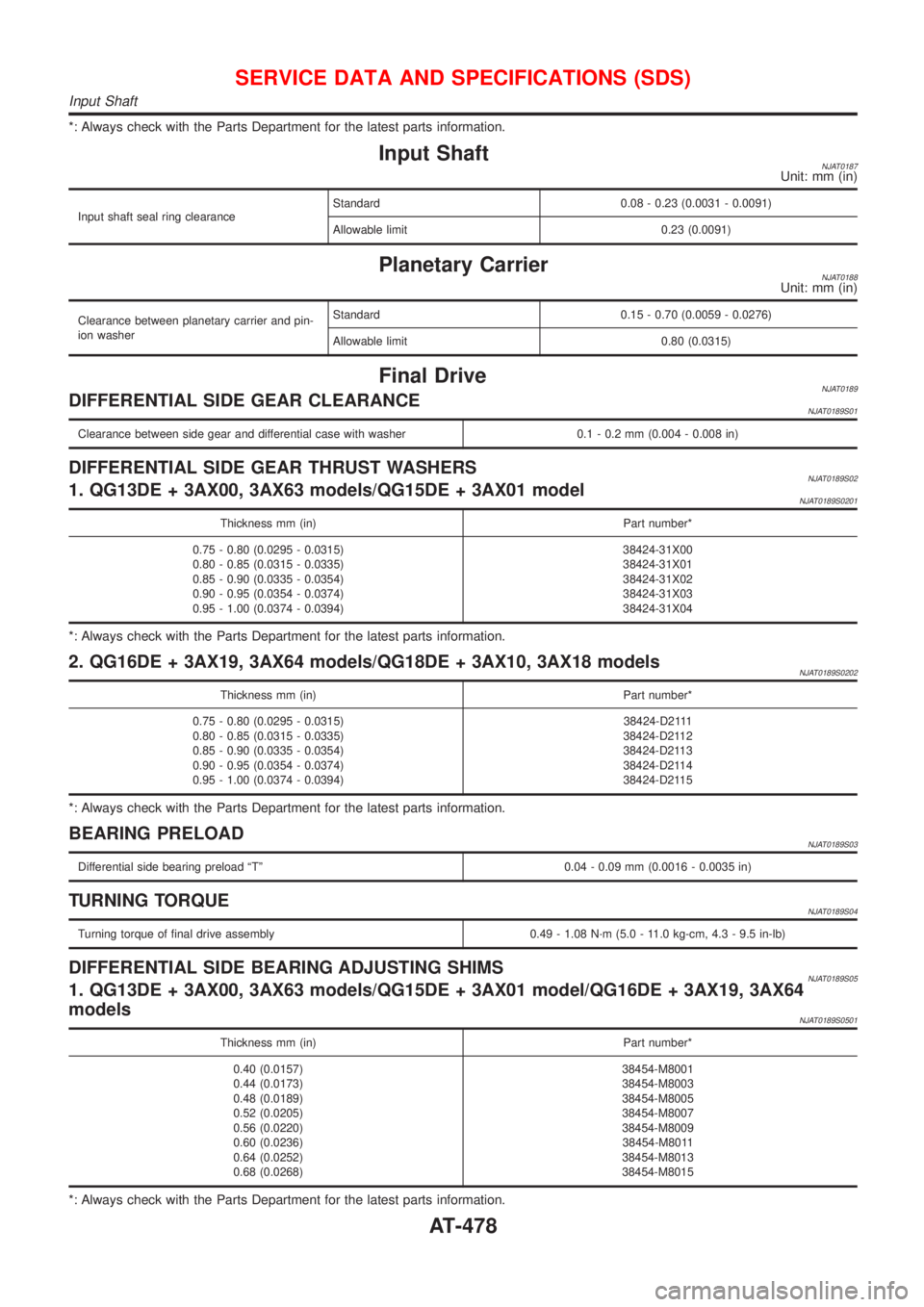

Input ShaftNJAT0187Unit: mm (in)

Input shaft seal ring clearanceStandard 0.08 - 0.23 (0.0031 - 0.0091)

Allowable limit 0.23 (0.0091)

Planetary CarrierNJAT0188Unit: mm (in)

Clearance between planetary carrier and pin-

ion washerStandard 0.15 - 0.70 (0.0059 - 0.0276)

Allowable limit 0.80 (0.0315)

Final DriveNJAT0189DIFFERENTIAL SIDE GEAR CLEARANCENJAT0189S01

Clearance between side gear and differential case with washer 0.1 - 0.2 mm (0.004 - 0.008 in)

DIFFERENTIAL SIDE GEAR THRUST WASHERSNJAT0189S021. QG13DE + 3AX00, 3AX63 models/QG15DE + 3AX01 modelNJAT0189S0201

Thickness mm (in) Part number*

0.75 - 0.80 (0.0295 - 0.0315)

0.80 - 0.85 (0.0315 - 0.0335)

0.85 - 0.90 (0.0335 - 0.0354)

0.90 - 0.95 (0.0354 - 0.0374)

0.95 - 1.00 (0.0374 - 0.0394)38424-31X00

38424-31X01

38424-31X02

38424-31X03

38424-31X04

*: Always check with the Parts Department for the latest parts information.

2. QG16DE + 3AX19, 3AX64 models/QG18DE + 3AX10, 3AX18 modelsNJAT0189S0202

Thickness mm (in) Part number*

0.75 - 0.80 (0.0295 - 0.0315)

0.80 - 0.85 (0.0315 - 0.0335)

0.85 - 0.90 (0.0335 - 0.0354)

0.90 - 0.95 (0.0354 - 0.0374)

0.95 - 1.00 (0.0374 - 0.0394)38424-D2111

38424-D2112

38424-D2113

38424-D2114

38424-D2115

*: Always check with the Parts Department for the latest parts information.

BEARING PRELOADNJAT0189S03

Differential side bearing preload ªTº 0.04 - 0.09 mm (0.0016 - 0.0035 in)

TURNING TORQUENJAT0189S04

Turning torque of final drive assembly 0.49 - 1.08 N´m (5.0 - 11.0 kg-cm, 4.3 - 9.5 in-lb)

DIFFERENTIAL SIDE BEARING ADJUSTING SHIMSNJAT0189S051. QG13DE + 3AX00, 3AX63 models/QG15DE + 3AX01 model/QG16DE + 3AX19, 3AX64

models

NJAT0189S0501

Thickness mm (in) Part number*

0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)38454-M8001

38454-M8003

38454-M8005

38454-M8007

38454-M8009

38454-M8011

38454-M8013

38454-M8015

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Input Shaft

AT-478

Page 482 of 2898

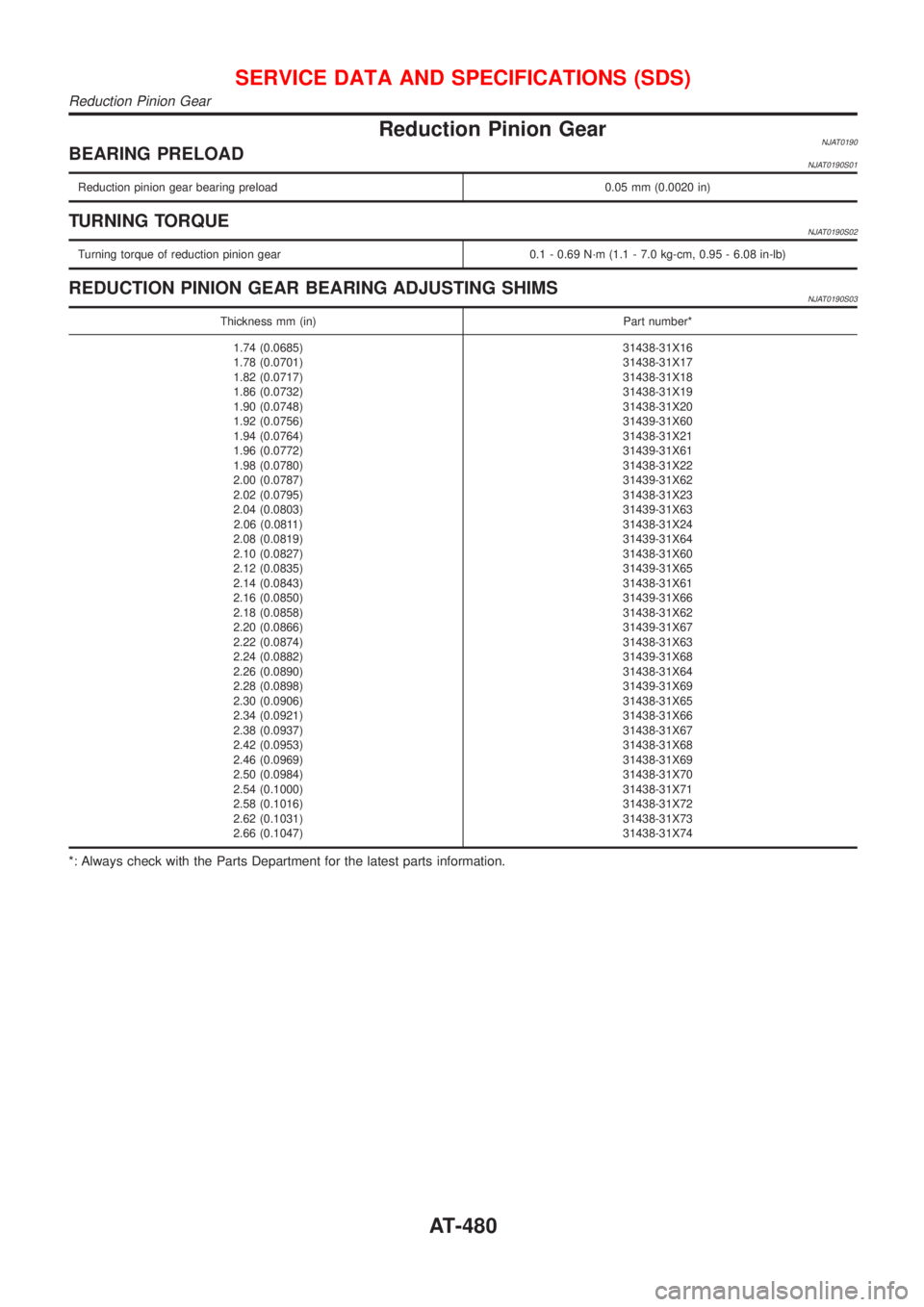

Reduction Pinion GearNJAT0190BEARING PRELOADNJAT0190S01

Reduction pinion gear bearing preload 0.05 mm (0.0020 in)

TURNING TORQUENJAT0190S02

Turning torque of reduction pinion gear 0.1 - 0.69 N´m (1.1 - 7.0 kg-cm, 0.95 - 6.08 in-lb)

REDUCTION PINION GEAR BEARING ADJUSTING SHIMSNJAT0190S03

Thickness mm (in) Part number*

1.74 (0.0685)

1.78 (0.0701)

1.82 (0.0717)

1.86 (0.0732)

1.90 (0.0748)

1.92 (0.0756)

1.94 (0.0764)

1.96 (0.0772)

1.98 (0.0780)

2.00 (0.0787)

2.02 (0.0795)

2.04 (0.0803)

2.06 (0.0811)

2.08 (0.0819)

2.10 (0.0827)

2.12 (0.0835)

2.14 (0.0843)

2.16 (0.0850)

2.18 (0.0858)

2.20 (0.0866)

2.22 (0.0874)

2.24 (0.0882)

2.26 (0.0890)

2.28 (0.0898)

2.30 (0.0906)

2.34 (0.0921)

2.38 (0.0937)

2.42 (0.0953)

2.46 (0.0969)

2.50 (0.0984)

2.54 (0.1000)

2.58 (0.1016)

2.62 (0.1031)

2.66 (0.1047)31438-31X16

31438-31X17

31438-31X18

31438-31X19

31438-31X20

31439-31X60

31438-31X21

31439-31X61

31438-31X22

31439-31X62

31438-31X23

31439-31X63

31438-31X24

31439-31X64

31438-31X60

31439-31X65

31438-31X61

31439-31X66

31438-31X62

31439-31X67

31438-31X63

31439-31X68

31438-31X64

31439-31X69

31438-31X65

31438-31X66

31438-31X67

31438-31X68

31438-31X69

31438-31X70

31438-31X71

31438-31X72

31438-31X73

31438-31X74

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Reduction Pinion Gear

AT-480

Page 483 of 2898

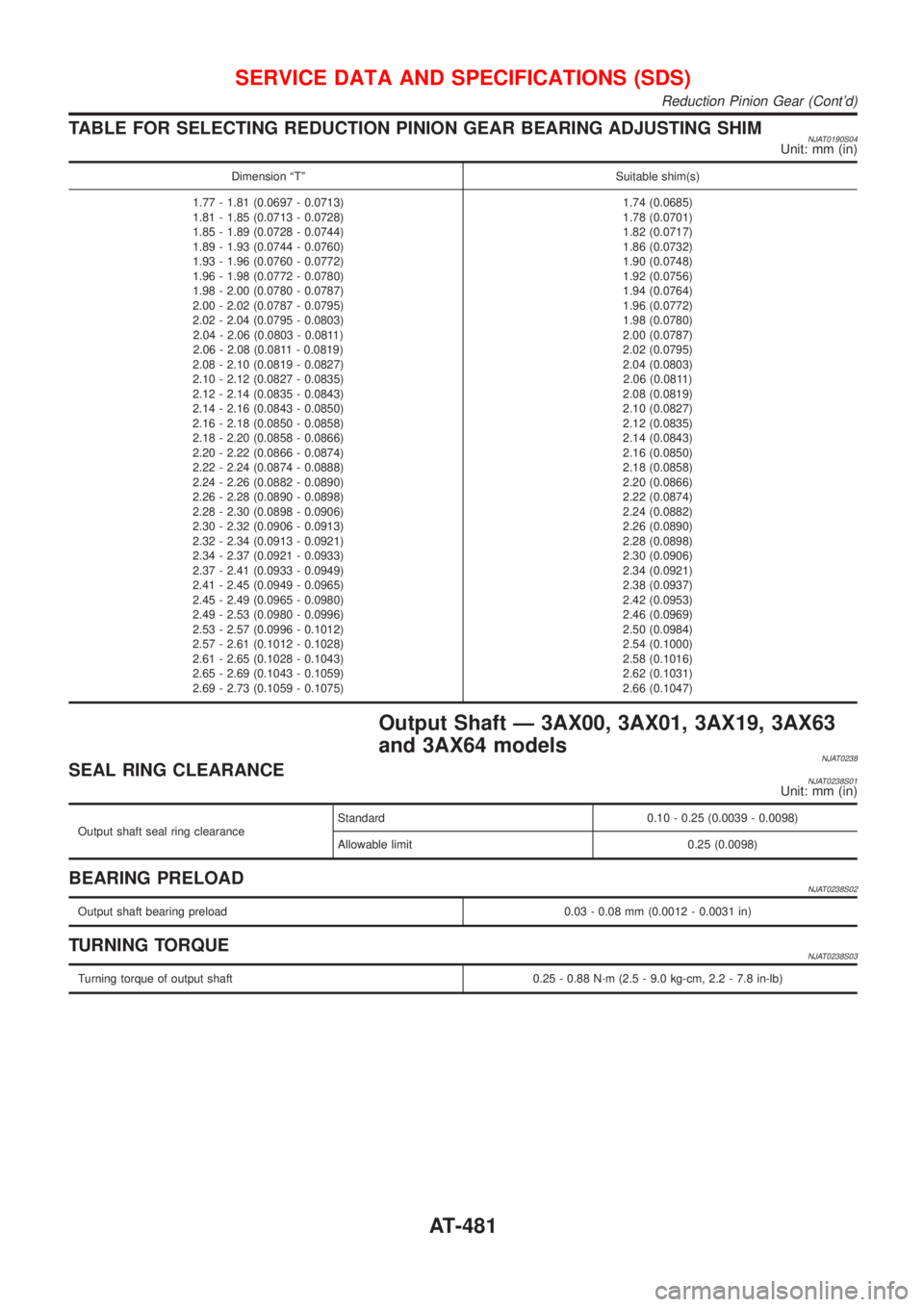

TABLE FOR SELECTING REDUCTION PINION GEAR BEARING ADJUSTING SHIMNJAT0190S04Unit: mm (in)

Dimension ªTº Suitable shim(s)

1.77 - 1.81 (0.0697 - 0.0713)

1.81 - 1.85 (0.0713 - 0.0728)

1.85 - 1.89 (0.0728 - 0.0744)

1.89 - 1.93 (0.0744 - 0.0760)

1.93 - 1.96 (0.0760 - 0.0772)

1.96 - 1.98 (0.0772 - 0.0780)

1.98 - 2.00 (0.0780 - 0.0787)

2.00 - 2.02 (0.0787 - 0.0795)

2.02 - 2.04 (0.0795 - 0.0803)

2.04 - 2.06 (0.0803 - 0.0811)

2.06 - 2.08 (0.0811 - 0.0819)

2.08 - 2.10 (0.0819 - 0.0827)

2.10 - 2.12 (0.0827 - 0.0835)

2.12 - 2.14 (0.0835 - 0.0843)

2.14 - 2.16 (0.0843 - 0.0850)

2.16 - 2.18 (0.0850 - 0.0858)

2.18 - 2.20 (0.0858 - 0.0866)

2.20 - 2.22 (0.0866 - 0.0874)

2.22 - 2.24 (0.0874 - 0.0888)

2.24 - 2.26 (0.0882 - 0.0890)

2.26 - 2.28 (0.0890 - 0.0898)

2.28 - 2.30 (0.0898 - 0.0906)

2.30 - 2.32 (0.0906 - 0.0913)

2.32 - 2.34 (0.0913 - 0.0921)

2.34 - 2.37 (0.0921 - 0.0933)

2.37 - 2.41 (0.0933 - 0.0949)

2.41 - 2.45 (0.0949 - 0.0965)

2.45 - 2.49 (0.0965 - 0.0980)

2.49 - 2.53 (0.0980 - 0.0996)

2.53 - 2.57 (0.0996 - 0.1012)

2.57 - 2.61 (0.1012 - 0.1028)

2.61 - 2.65 (0.1028 - 0.1043)

2.65 - 2.69 (0.1043 - 0.1059)

2.69 - 2.73 (0.1059 - 0.1075)1.74 (0.0685)

1.78 (0.0701)

1.82 (0.0717)

1.86 (0.0732)

1.90 (0.0748)

1.92 (0.0756)

1.94 (0.0764)

1.96 (0.0772)

1.98 (0.0780)

2.00 (0.0787)

2.02 (0.0795)

2.04 (0.0803)

2.06 (0.0811)

2.08 (0.0819)

2.10 (0.0827)

2.12 (0.0835)

2.14 (0.0843)

2.16 (0.0850)

2.18 (0.0858)

2.20 (0.0866)

2.22 (0.0874)

2.24 (0.0882)

2.26 (0.0890)

2.28 (0.0898)

2.30 (0.0906)

2.34 (0.0921)

2.38 (0.0937)

2.42 (0.0953)

2.46 (0.0969)

2.50 (0.0984)

2.54 (0.1000)

2.58 (0.1016)

2.62 (0.1031)

2.66 (0.1047)

Output Shaft Ð 3AX00, 3AX01, 3AX19, 3AX63

and 3AX64 models

NJAT0238SEAL RING CLEARANCENJAT0238S01Unit: mm (in)

Output shaft seal ring clearanceStandard 0.10 - 0.25 (0.0039 - 0.0098)

Allowable limit 0.25 (0.0098)

BEARING PRELOADNJAT0238S02

Output shaft bearing preload 0.03 - 0.08 mm (0.0012 - 0.0031 in)

TURNING TORQUENJAT0238S03

Turning torque of output shaft 0.25 - 0.88 N´m (2.5 - 9.0 kg-cm, 2.2 - 7.8 in-lb)

SERVICE DATA AND SPECIFICATIONS (SDS)

Reduction Pinion Gear (Cont'd)

AT-481

Page 487 of 2898

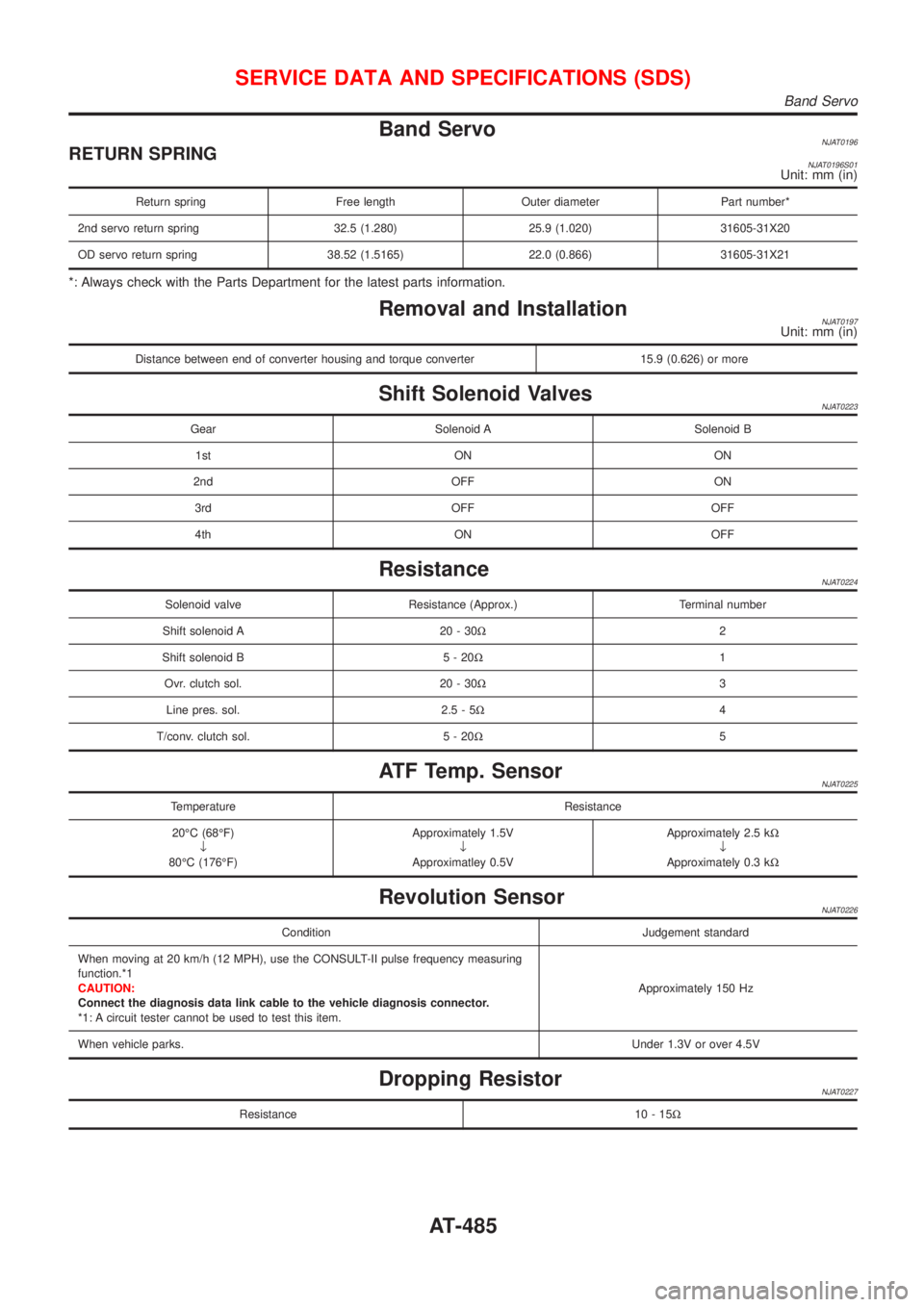

Band ServoNJAT0196RETURN SPRINGNJAT0196S01Unit: mm (in)

Return spring Free length Outer diameter Part number*

2nd servo return spring 32.5 (1.280) 25.9 (1.020) 31605-31X20

OD servo return spring 38.52 (1.5165) 22.0 (0.866) 31605-31X21

*: Always check with the Parts Department for the latest parts information.

Removal and InstallationNJAT0197Unit: mm (in)

Distance between end of converter housing and torque converter 15.9 (0.626) or more

Shift Solenoid ValvesNJAT0223

Gear Solenoid A Solenoid B

1st ON ON

2nd OFF ON

3rd OFF OFF

4th ON OFF

ResistanceNJAT0224

Solenoid valve Resistance (Approx.) Terminal number

Shift solenoid A 20 - 30W2

Shift solenoid B 5 - 20W1

Ovr. clutch sol. 20 - 30W3

Line pres. sol. 2.5 - 5W4

T/conv. clutch sol. 5 - 20W5

ATF Temp. SensorNJAT0225

Temperature Resistance

20ÉC (68ÉF)

¯

80ÉC (176ÉF)Approximately 1.5V

¯

Approximatley 0.5VApproximately 2.5 kW

¯

Approximately 0.3 kW

Revolution SensorNJAT0226

Condition Judgement standard

When moving at 20 km/h (12 MPH), use the CONSULT-II pulse frequency measuring

function.*1

CAUTION:

Connect the diagnosis data link cable to the vehicle diagnosis connector.

*1: A circuit tester cannot be used to test this item.Approximately 150 Hz

When vehicle parks.Under 1.3V or over 4.5V

Dropping ResistorNJAT0227

Resistance 10 - 15W

SERVICE DATA AND SPECIFICATIONS (SDS)

Band Servo

AT-485

Page 490 of 2898

SBR686C

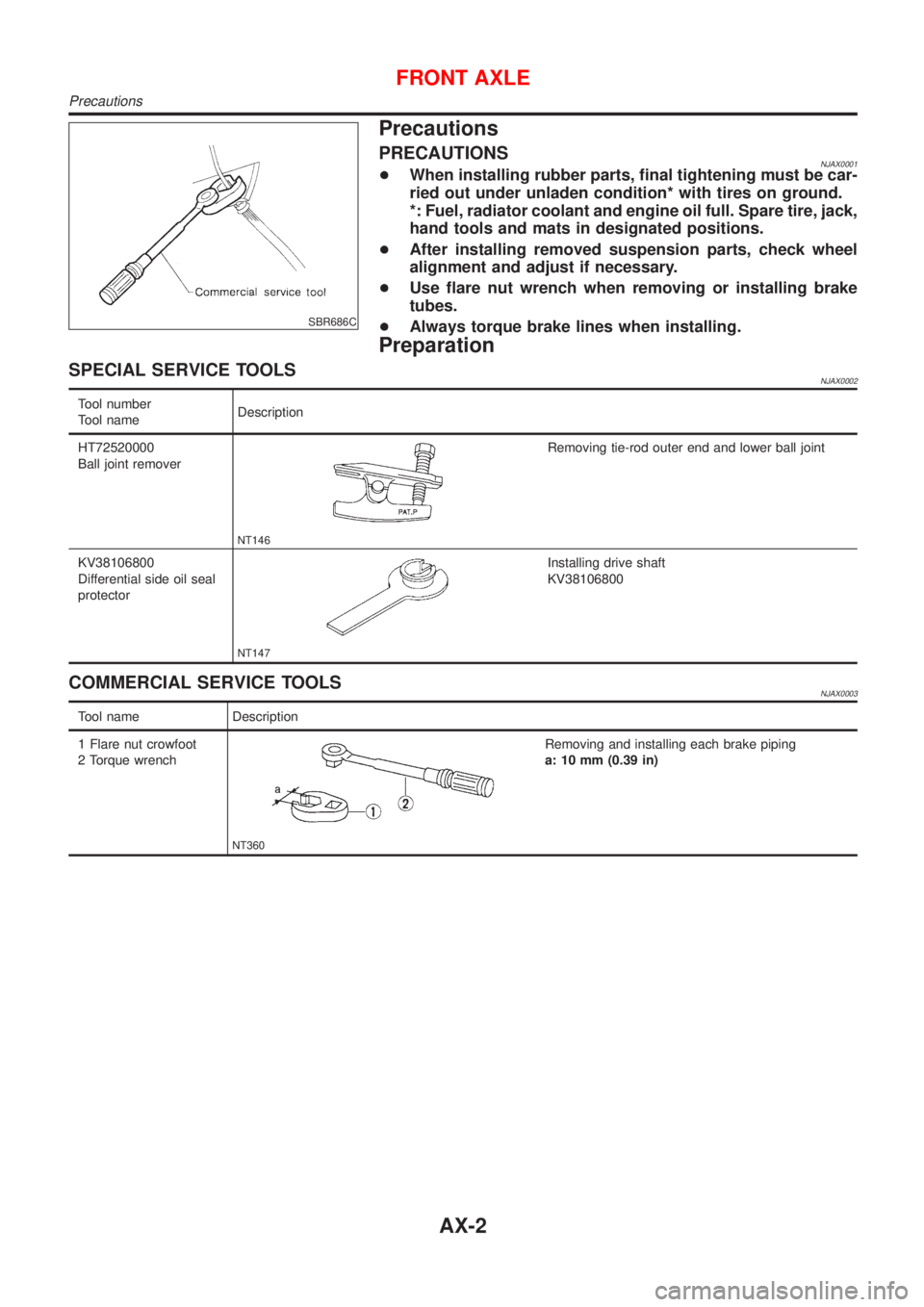

Precautions

PRECAUTIONSNJAX0001+When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Use flare nut wrench when removing or installing brake

tubes.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNJAX0002

Tool number

Tool nameDescription

HT72520000

Ball joint remover

NT146

Removing tie-rod outer end and lower ball joint

KV38106800

Differential side oil seal

protector

NT147

Installing drive shaft

KV38106800

COMMERCIAL SERVICE TOOLSNJAX0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

FRONT AXLE

Precautions

AX-2

Page 491 of 2898

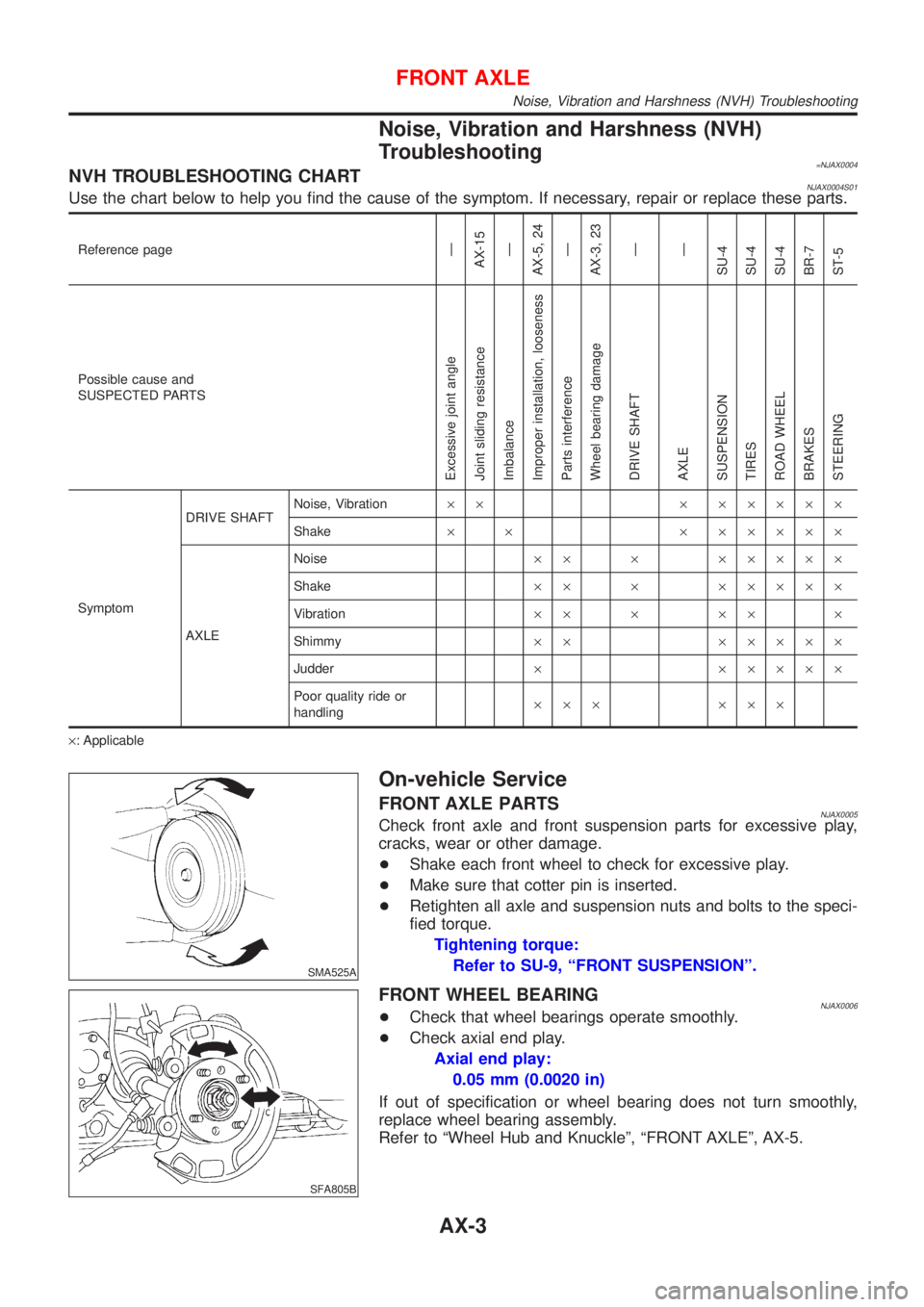

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NJAX0004NVH TROUBLESHOOTING CHARTNJAX0004S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

AX-15

Ð

AX-5, 24

Ð

AX-3, 23

Ð

Ð

SU-4

SU-4

SU-4

BR-7

ST-5

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration´´ ´ ´´´´´

Shake´ ´ ´ ´´´´´

AXLENoise´´ ´ ´´´´´

Shake´´ ´ ´´´´´

Vibration´´ ´ ´´ ´

Shimmy´´ ´´´´´

Judder´ ´´´´´

Poor quality ride or

handling´´´ ´´´

´: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNJAX0005Check front axle and front suspension parts for excessive play,

cracks, wear or other damage.

+Shake each front wheel to check for excessive play.

+Make sure that cotter pin is inserted.

+Retighten all axle and suspension nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to SU-9, ªFRONT SUSPENSIONº.

SFA805B

FRONT WHEEL BEARINGNJAX0006+Check that wheel bearings operate smoothly.

+Check axial end play.

Axial end play:

0.05 mm (0.0020 in)

If out of specification or wheel bearing does not turn smoothly,

replace wheel bearing assembly.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, AX-5.

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3