NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1481 of 1701

Pulleyassembly SERVICE

PROCEDURES

Compressor Clutch(Cont'd)

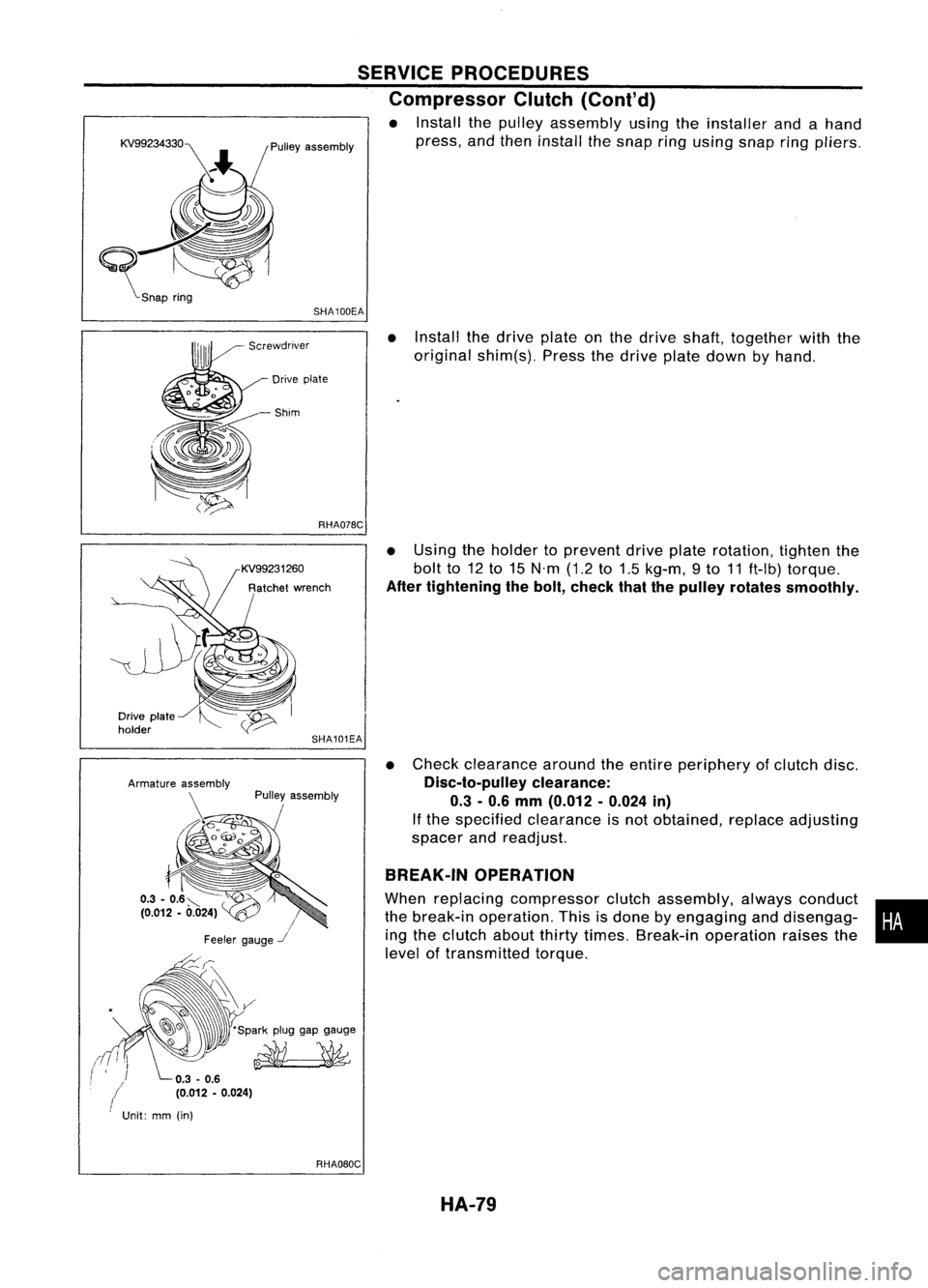

• Install thepulley assembly usingtheinstaller andahand

press, andthen install thesnap ringusing snapring

pliers.

SHA100EA

•Install thedrive plateonthe drive shaft, together withthe

original shim(s). Pressthedrive platedown byhand.

Drive plate

-Shim

RHA07BC

•Using theholder toprevent driveplaterotation, tightenthe

bolt to12to15 N'm (1.2to1.5 kg-m, 9to 11ft-Ib) torque.

After tightening thebolt, check thatthepulley rotates smoothly.

• Check clearance aroundtheentire periphery ofclutch disc.

Disc-to-pulley clearance:

0.3 -0.6 mm (0.012 -0.024 in)

If the specified clearance isnot obtained, replaceadjusting

spacer andreadjust.

BREAK-IN OPERATION

When replacing compressor clutchassembly, alwaysconduct •

the break-in operation. Thisisdone byengaging anddisengag-

i

ing the clutch aboutthirtytimes. Break-in operation raisesthe

level oftransmitted torque.

SHA101EA

Pulley assembly

/

Feeler gauge

-.I

-~~ 'Sparkpluggapgauge

~

Drive

plate

holder

(

Unit:mm(in)

RHAOBOCHA-79

Page 1482 of 1701

SERVICEPROCEDURES

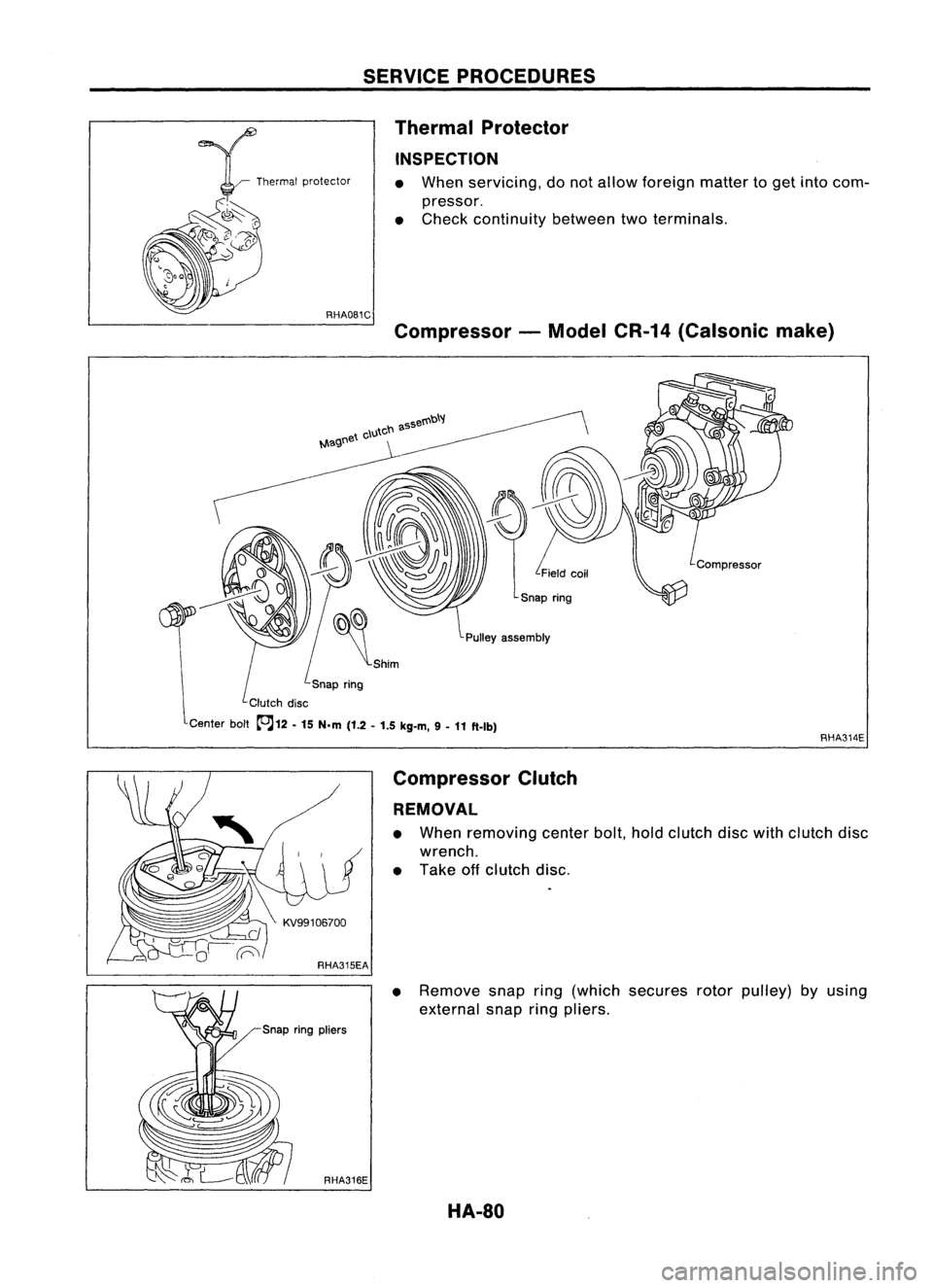

Thermal Protector

INSPECTION

• When servicing, donot allow foreign mattertoget into com-

pressor.

• Check continuity betweentwoterminals.

Compressor -Model CR-14(Calsonic make)

Pulley assembly

Snap ring

Clutch disc

Center bolt~12 -

15 N.m

(1.2-1.5 kg-m, 9-

11 ft-Ib)

RHA314E

Compressor Clutch

REMOVAL

• When removing centerbolt,holdclutch discwithclutch disc

wrench.

• Take offclutch disc.

• Remove snapring(which secures rotorpulley) byusing

external snapringpliers.

HA-80

Page 1483 of 1701

RHA317ESERVICE

PROCEDURES

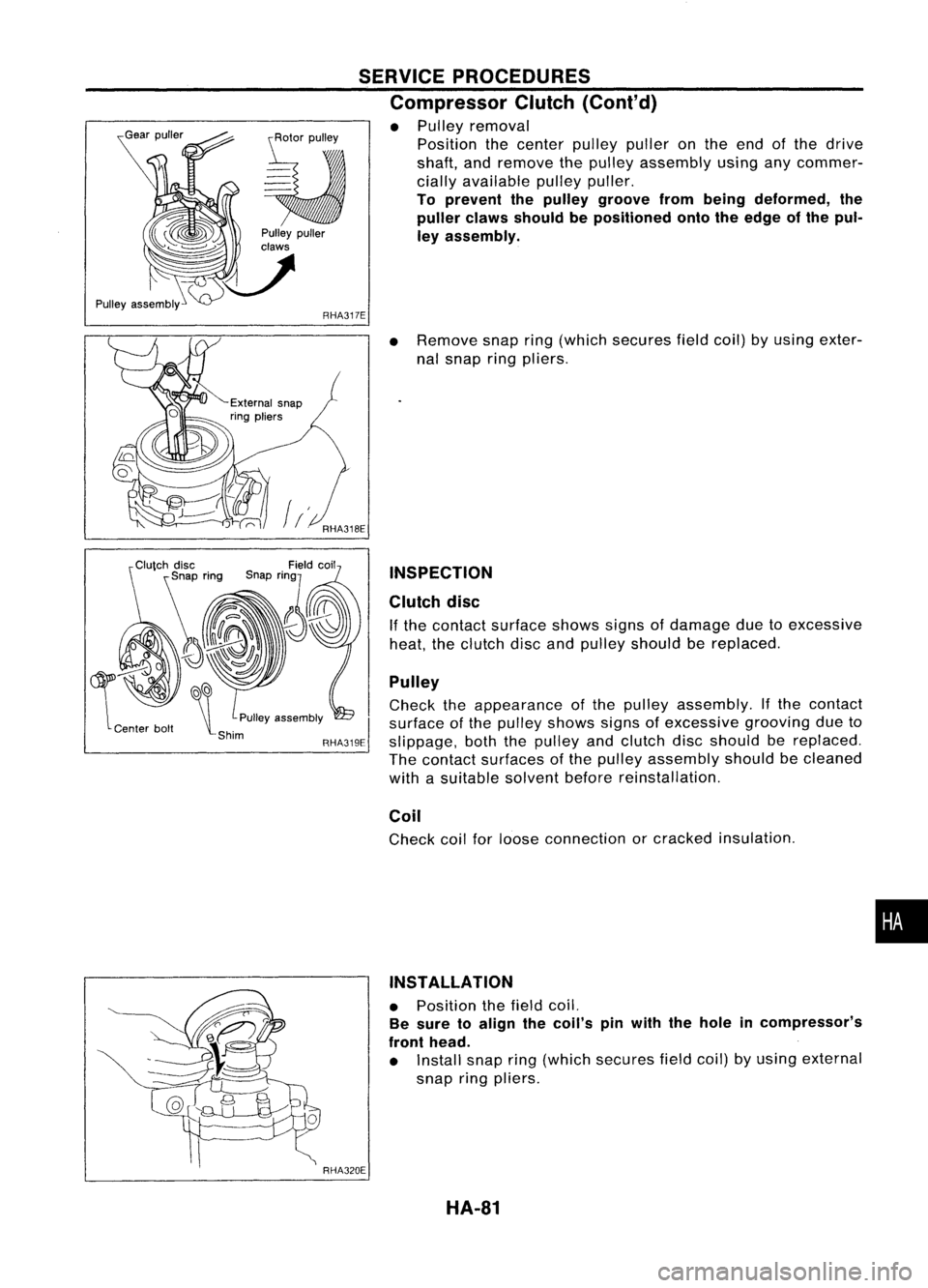

Compressor Clutch(Cont'd)

• Pulley removal

Position thecenter pulleypulleronthe end ofthe drive

shaft, andremove thepulley assembly usinganycommer-

cially available pulleypuller.

To prevent thepulley groove frombeing deformed, the

puller clawsshould bepositioned ontotheedge ofthe pul-

ley assembly.

~~

\t

PUlleyassembly

-Shim RHA319E

RHA320E

•

Remove snapring(which secures fieldcoil)byusing exter-

nal snap ringpliers.

INSPECTION

Clutch disc

If the contact surface showssignsofdamage duetoexcessive

heat, theclutch discandpulley should bereplaced.

Pulley

Check theappearance ofthe pulley assembly. Ifthe contact

surface ofthe pulley shows signsofexcessive groovingdueto

slippage, boththepulley andclutch discshould bereplaced.

The contact surfaces ofthe pulley assembly shouldbecleaned

with asuitable solventbeforereinstallation.

Coil

Check coilforloose connection orcracked insulation .

INSTALLATION

• Position thefield coil.

Be sure toalign thecoil's pinwith thehole incompressor's

front head.

• Install snapring(which secures fieldcoil)byusing external

snap ringpliers.

HA-81

•

Page 1484 of 1701

KV99106800

~ RHA321EA

~

s~

~ Clutchdisc

SERVICE

PROCEDURES

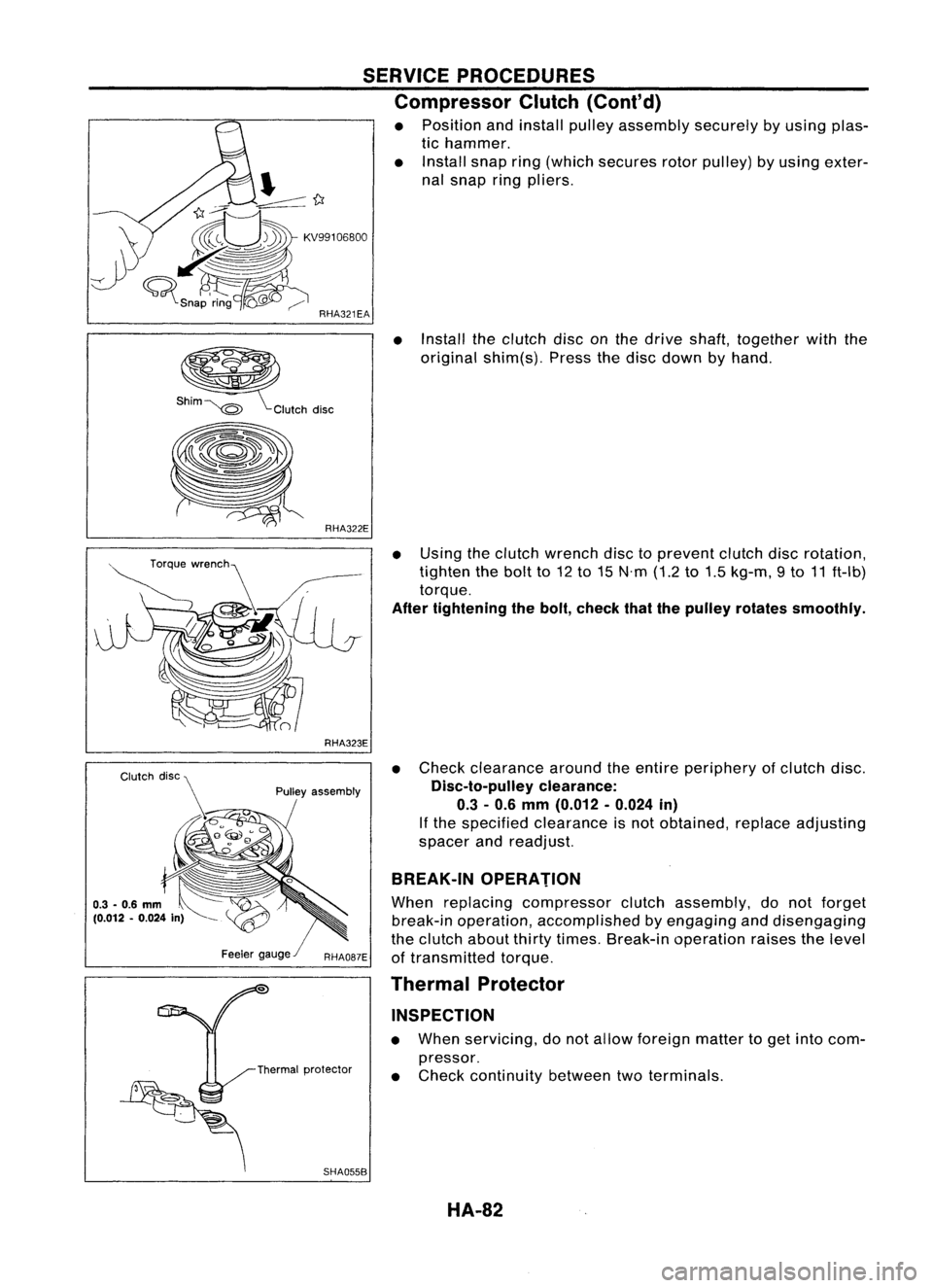

Compressor Clutch(Cont'd)

• Position andinstall pulleyassembly securelybyusing plas-

tic hammer.

• Install snapring(which secures rotorpulley) byusing exter-

nal snap ringpliers.

• Install theclutch disconthe drive shaft, together withthe

original shim(s). Pressthedisc down byhand.

RHA323E

Pulley assembly

SHA055B

•

Using theclutch wrench disctoprevent clutchdiscrotation,

tighten thebolt to12 to15 N'm (1.2to1.5 kg-m, 9to 11ft-Ib)

torque.

After tightening thebolt, check thatthepulley rotates smoothly.

• Check clearance aroundtheentire periphery ofclutch disc.

Disc-to-pulley clearance:

0.3 -0.6 mm (0.012 -0.024 in)

If the specified clearance isnot obtained, replaceadjusting

spacer andreadjust.

BREAK-IN OPERATION

When replacing compressor clutchassembly, donot forget

break-in operation, accomplished byengaging anddisengaging

the clutch aboutthirtytimes. Break-in operation raisesthelevel

of transmitted torque.

Thermal Protector

INSPECTION

• When servicing, donot allow foreign mattertoget into com-

pressor.

• Check continuity betweentwoterminals.

HA-82

Page 1485 of 1701

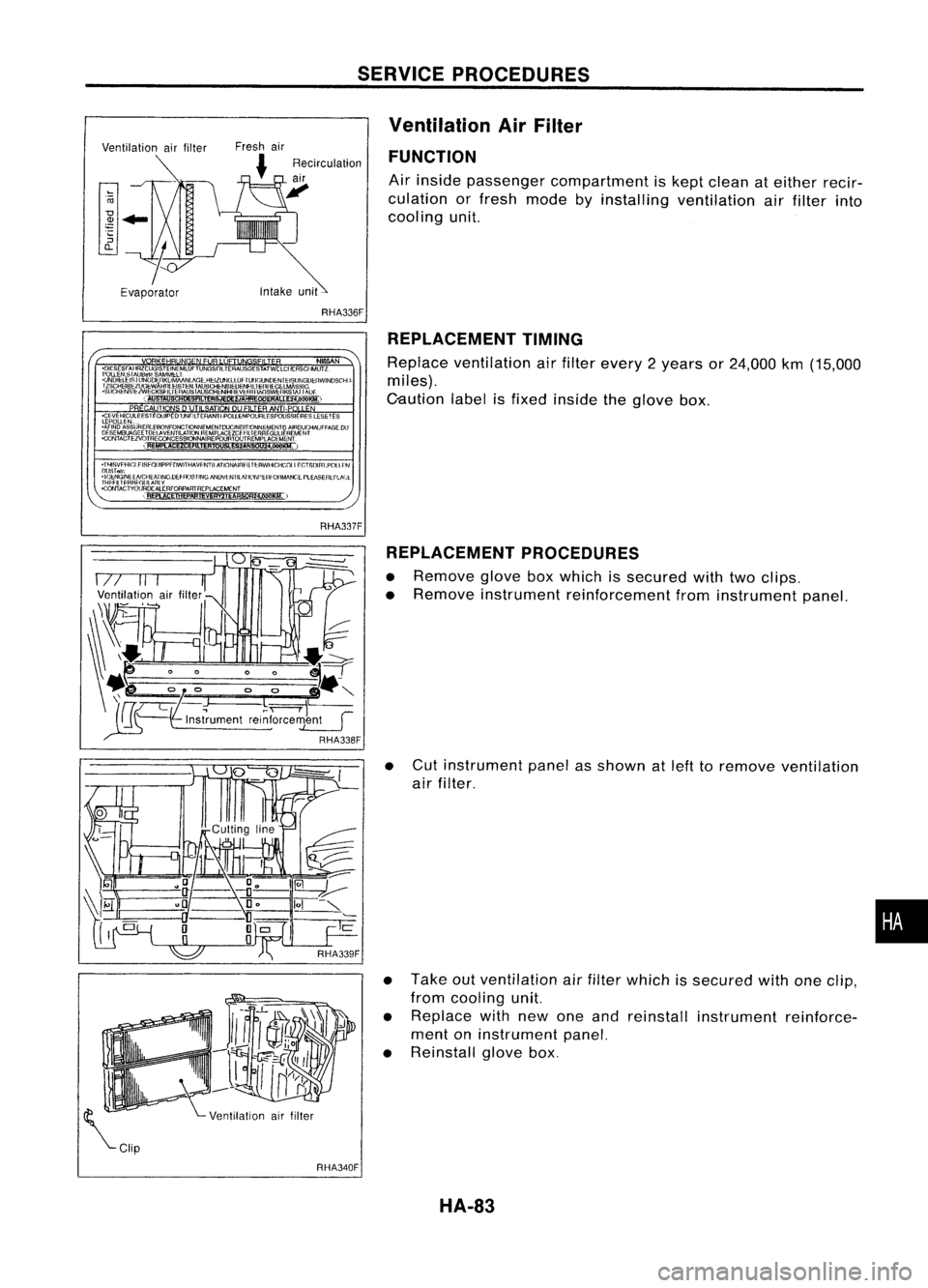

Ventilationairfilter

Evaporator SERVICE

PROCEDURES

Ventilation AirFilter

FUNCTION

Air inside passenger compartment iskept clean ateither recir-

culation orfresh mode byinstalling ventilation airfilter into

cooling unit.

RHA336F REPLACEMENT TIMING

Replace ventilation airfilter every 2years or24,000 km(15,000

miles).

C-aution labelisfixed inside theglove box.

REPLACEMENT PROCEDURES

• Remove gloveboxwhich issecured withtwoclips.

• Remove instrument reinforcement frominstrument panel.

• Cut instrument panelasshown atleft toremove ventilation

air filter.

• Take outventilation airfilter which issecured withoneclip,

from cooling unit.

• Replace withnewoneand reinstall instrument reinforce-

ment oninstrument panel.

• Reinstall glovebox.

•

RHA340F HA-83

Page 1486 of 1701

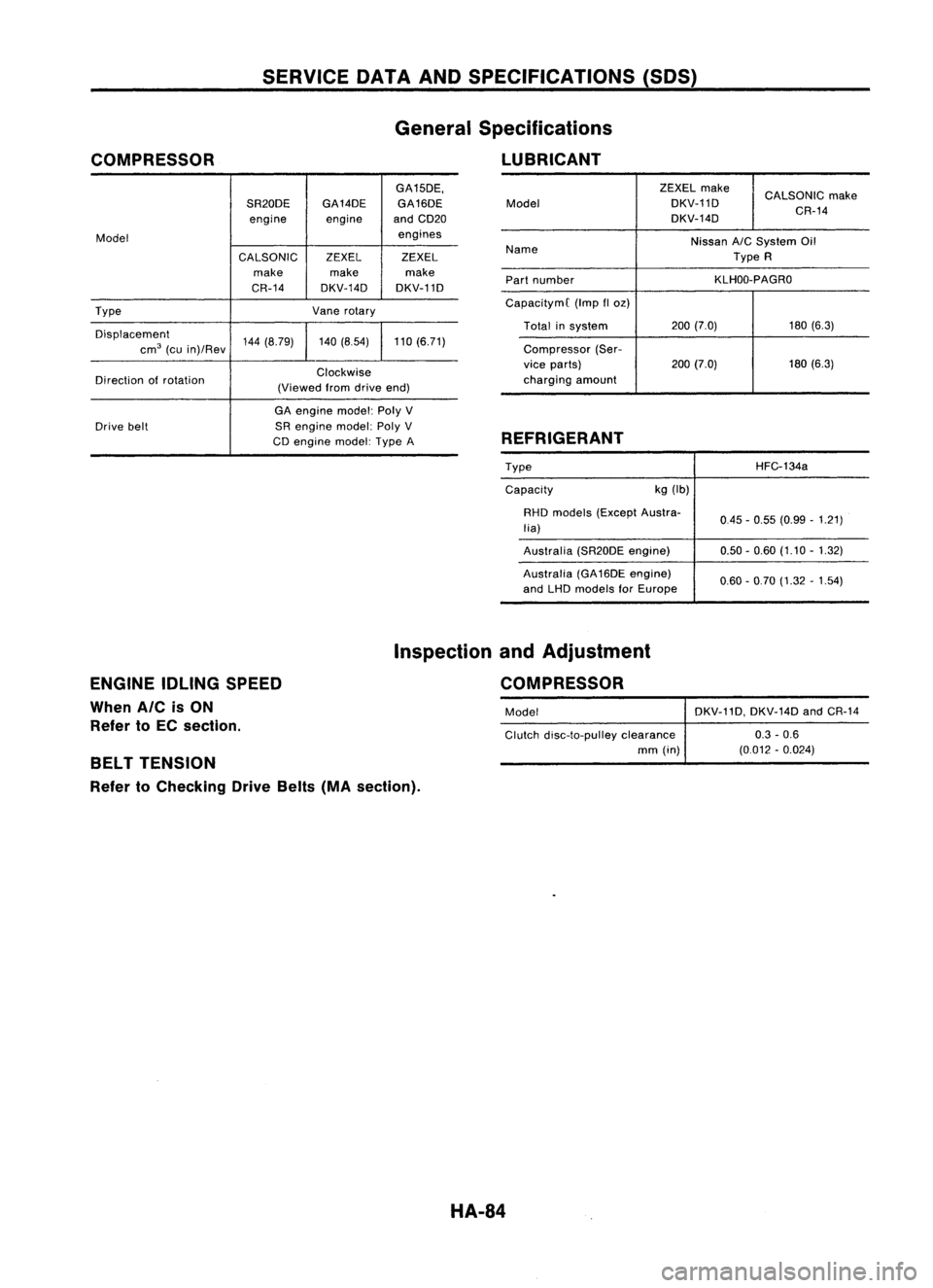

COMPRESSOR SERVICE

DATAANDSPECIFICATIONS (50S)

General Specifications

LUBRICANT

GA15DE,

SR20DE GA14DE

GA16DE

engine engineandCD20

Model engines

CALSONIC ZEXELZEXEL

make makemake

CR-14 DKV-14D DKV-11D

Type Vanerotary

Displacement 144(8.79) 140(8.54) 110(6.71)

cm

3

(cuin)/Rev

Direction ofrotation Clockwise

(Viewed fromdrive end)

GA engine model:PolyV

Drive belt SRengine model:PolyV

CD engine model:TypeA ZEXEL

make

CALSONIC make

Model DKV-11D

DKV-14D CR-14

Name Nissan

A/C

System Oil

Type R

Part number KLHOO-PAGRO

CapacitymC (Impfloz)

Total insystem 200

(7.0) 180(6.3)

Compressor (Ser-

vice parts) 200(7.0) 180

(6.3)

charging amount

REFRIGERANT

TypeCapacity kg

(Ib) HFC-134a

RHD models (Except Austra-

lia)

Australia (SR20DEengine)

Australia (GA16DE engine)

and LHD models forEurope 0.45

-0.55 (0.99 -1.21)

0.50 -0.60 (1.10 -1.32)

0.60 -0.70 (1.32 -1.54)

ENGINE IDLINGSPEED

When AICisON

Refer toEC section. Inspection

andAdjustment

COMPRESSOR

Model DKV-11D,DKV-14DandCR-14

Clutch disc-to-pulley clearance 0.3-0.6

mm (in) (0.012-0.024)

BELT TENSION

Refer toChecking DriveBelts(MAsection).

HA-84

Page 1487 of 1701

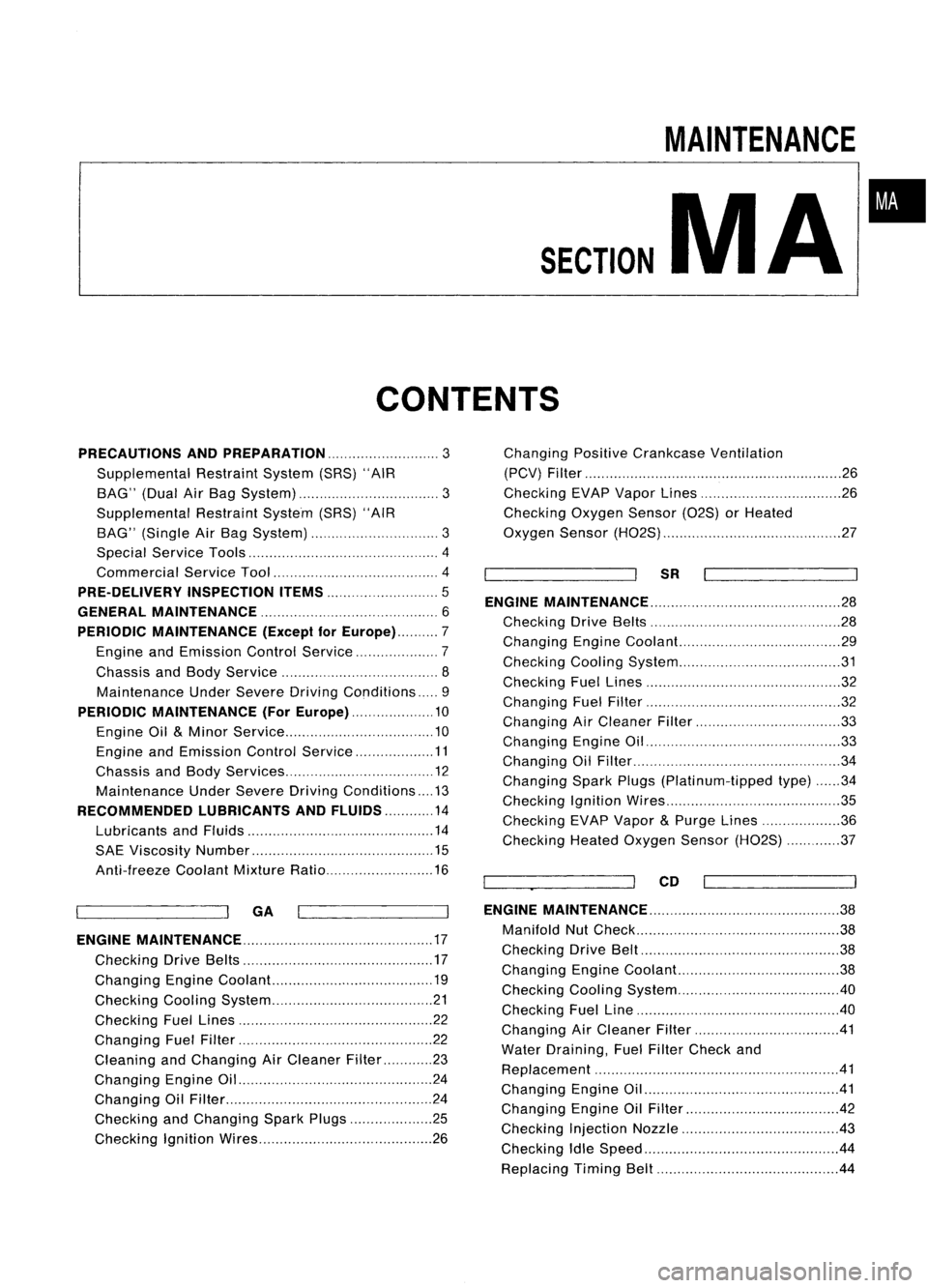

SECTION

CONTENTS

MAINTENANCE

MA

•

PRECAUTIONS ANDPREPARATION

3

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 3

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 3

Special Service Tools 4

Commercial ServiceTool 4

PRE-DELIVERY INSPECTIONITEMS

5

GENERAL MAINTENANCE 6

PERIODIC MAINTENANCE (Exceptfor

Europe) 7

Engine andEmission ControlService 7

Chassis andBody Service 8

Maintenance UnderSevere DrivingConditions 9

PERIODIC MAINTENANCE (ForEurope) 10

Engine Oil

&

Minor Service 10

Engine andEmission ControlService 11

Chassis andBody Services 12

Maintenance UnderSevere Driving Conditions 13

RECOMMENDED LUBRICANTSANDFLUIDS 14

Lubricants andFluids 14

SAE Viscosity Number 15

Anti-freeze CoolantMixtureRatio 16

~ --ll

GA

I I

ENGINE MAINTENANCE 17

Checking DriveBelts 17

Changing EngineCoolant... 19

Checking CoolingSystem 21

Checking FuelLines 22

Changing FuelFilter 22

Cleaning andChanging AirCleaner Filter 23

Changing EngineOil 24

Changing OilFilter 24

Checking andChanging SparkPlugs 25

Checking IgnitionWires 26Changing

PositiveCrankcase Ventilation

(PCV) Filter 26

Checking EVAPVapor Lines 26

Checking OxygenSensor(02S)orHeated

Oxygen Sensor(H02S) 27

~ --ll

SR

I I

ENGINE MAINTENANCE 28

Checking DriveBelts 28

Changing EngineCoolant... 29

Checking CoolingSystem 31

Checking FuelLines 32

Changing FuelFilter 32

Changing AirCleaner Filter 33

Changing EngineOil 33

Changing OilFilter 34

Changing SparkPlugs(Platinum-tipped type)34

Checking IgnitionWires 35

Checking EVAPVapor

&

Purge Lines 36

Checking HeatedOxygen Sensor(H02S) 37

~_~ ..-JI

CD

I I

ENGINE MAINTENANCE

38

Manifold NutCheck 38

Checking DriveBelt 38

Changing EngineCoolant. 38

Checking CoolingSystem .40

Checking FuelLine .40

Changing AirCleaner Filter 41

Water Draining, FuelFilter Check and

Replacement 41

Changing EngineOil .41

Changing EngineOilFilter 42

Checking InjectionNozzle 43

Checking IdleSpeed .44

Replacing TimingBelt 44

Page 1488 of 1701

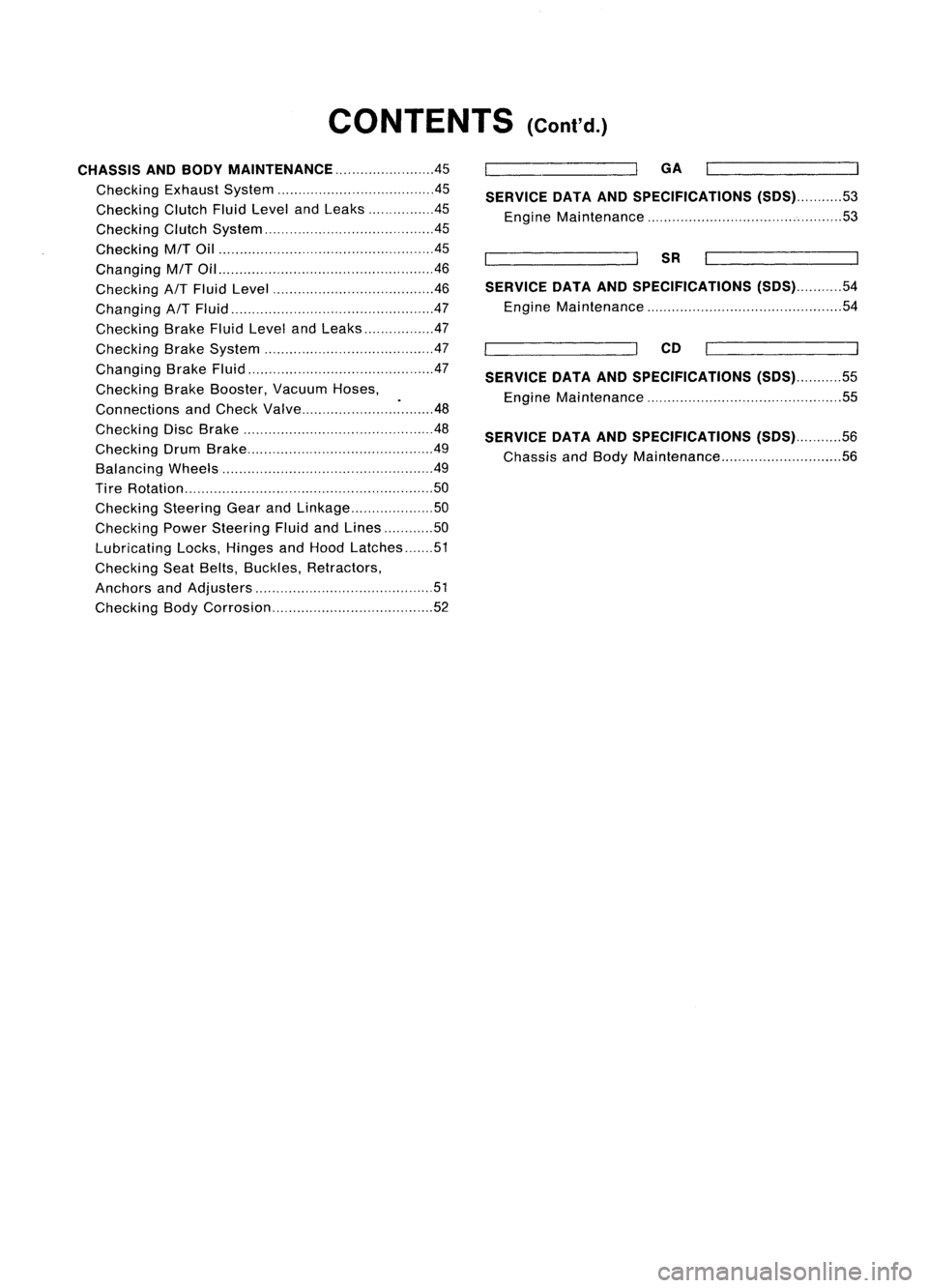

CONTENTS(Cont'd.)

CHASSIS ANDBODY MAINTENANCE 45

Checking ExhaustSystem .45

Checking ClutchFluidLevel andLeaks .45

Checking ClutchSystem .45

Checking MfTOil .45

Changing MfTOil 46

Checking

AfT

Fluid Level .46

Changing

AfT

Fluid .47

Checking BrakeFluidLevel andLeaks 47

Checking BrakeSystem .47

Changing BrakeFluid .47

Checking BrakeBooster, VacuumHoses,

Connections andCheck Valve ~48

Checking DiscBrake .48

Checking DrumBrake .49

Balancing Wheels 49

Ti re Rotation 50

Checking SteeringGearandLinkage 50

Checking PowerSteering FluidandLines 50

Lubricating Locks,Hinges andHood Latches 51

Checking SeatBelts, Buckles, Retractors,

Anchors andAdjusters 51

Checking BodyCorrosion 52

GA

SERVICE DATAANDSPECIFICATIONS

(505)53

Engine Maintenance 53

SR

SERVICE DATAANDSPECIFICATIONS

(505)54

Engine Maintenance 54

CD

SERVICE DATAANDSPECIFICATIONS

(505)55

Engine Maintenance 55

SERVICE DATAANDSPECIFICATIONS

(505)56

Chassis andBody Maintenance 56

Page 1489 of 1701

PRECAUTIONSANDPREPARATION

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or•

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

i

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side).adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists ofan

air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS.

MA-3

Page 1490 of 1701

PRECAUTIONSANDPREPARATION

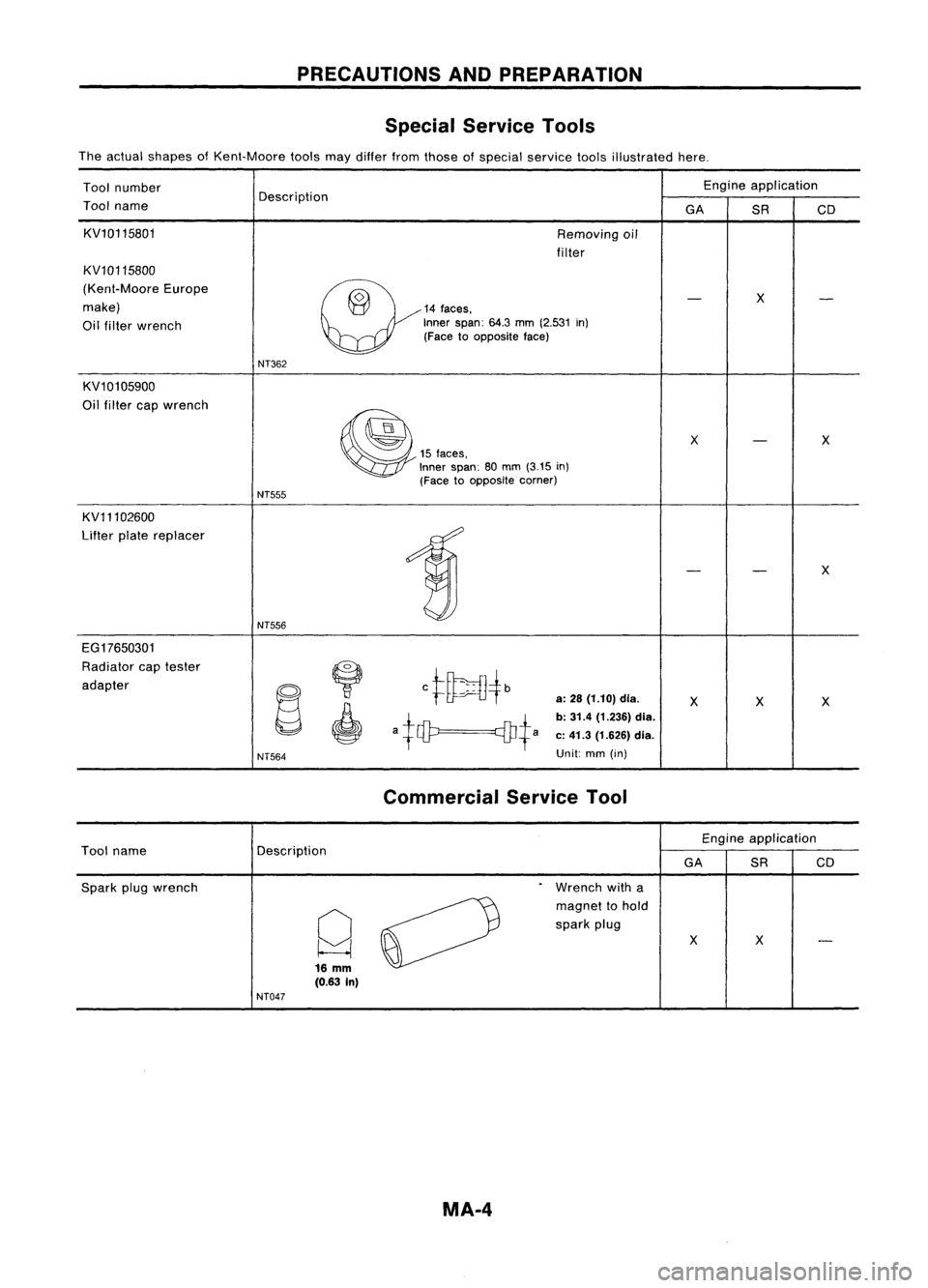

Special Service Tools

The actual shapes ofKent-Moore toolsmaydiffer fromthose ofspecial service toolsillustrated here.

Tool number Engine

application

Tool name Description

GASRCD

KV10115801 Removingoil

filter

KV10115800

(Kent-Moore Europe

~14"'"

-

X

-

make)

Oil filter wrench Inner

span:

64.3

mm

(2.531

in)

(Face toopposite face)

NT362

KV10105900

Oil filter capwrench

~

X

-

X

15

faces,

Inner span: 80mm

(3.15

in)

(Face toopposite corner)

NT555

KV11102600

Lifter platereplacer

1

-

-

X

NT556

EG17650301 Radiator captester

~

ct~4b

adapter

~

"

a:

28

(1.10) dia.

XX X

a+ciP q]J+a

b:

31.4 (1.236) dia.

c: 41.3 (1.626) dia.

I

NT564

Unit:

mm(in)

Commercial ServiceTool

Engineapplication

Tool name Description

GASRCD

Spark plugwrench

.

Wrench witha

Q

0

magnet

tohold

spark plug

XX

-

16

mm

(0.63 In)

NT047

MA.4