NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1451 of 1701

TROUBLEDIAGNOSES

Main Power Supply andGround CircuitCheck

POWER SUPPLY CIRCUIT CHECKFORAICSYSTEM

Check powersupply circuitforairconditioning system.

Refer to"POWER SUPPLYROUTING" inEL section andWiring

Diagram.

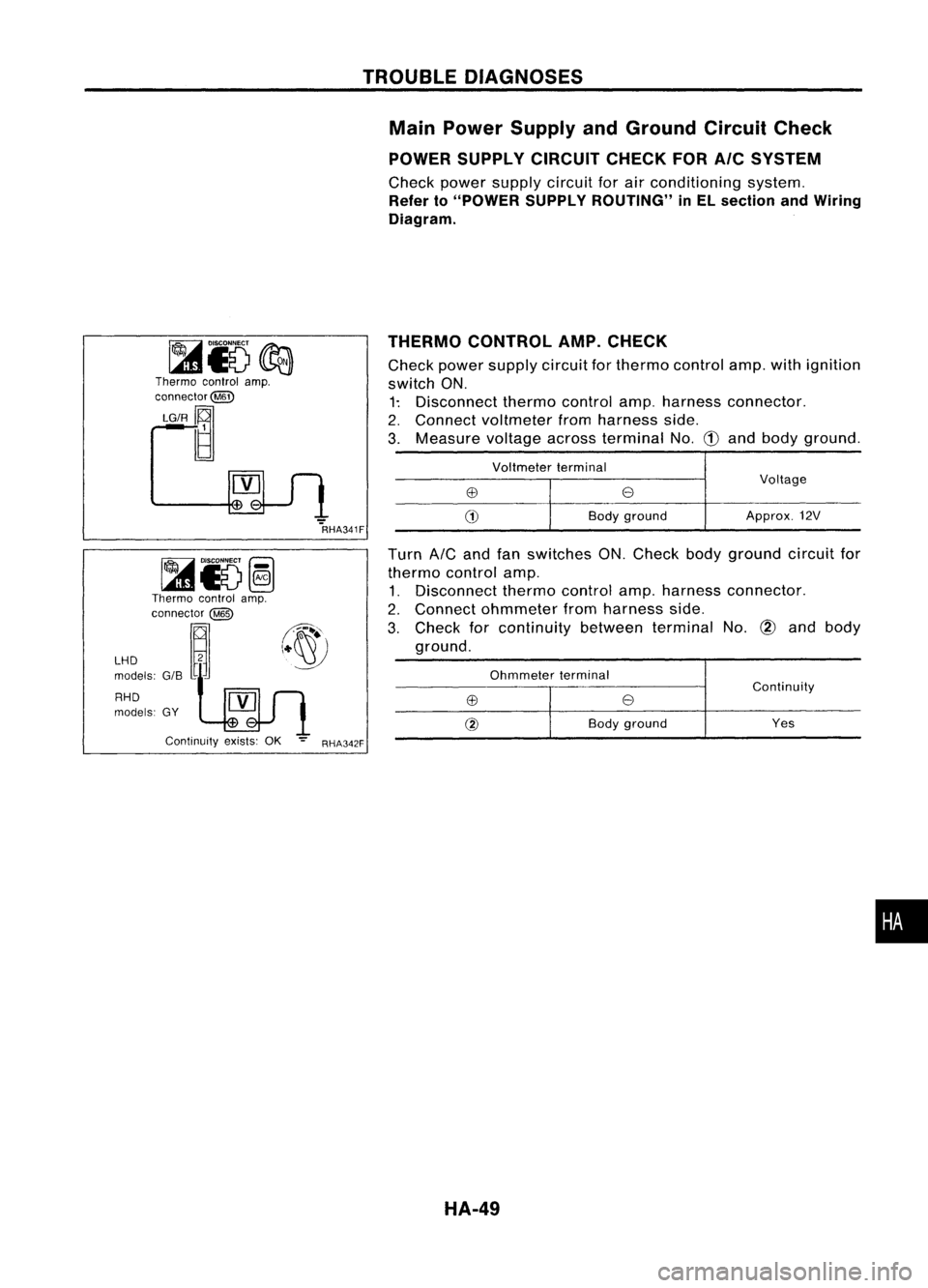

Voltmeterterminal

THERMO

CONTROL AMP.CHECK

Check powersupply circuitforthermo controlamp.withignition

switch ON.

1~ Disconnect thermocontrolamp.harness connector.

2. Connect voltmeter fromharness side.

3. Measure voltageacrossterminal No.

CD

and body ground.

Ohmmeter terminal

Turn

AIC

andfanswitches ON.Check bodyground circuitfor

thermo controlamp.

1. Disconnect thermocontrolamp.harness connector.

2. Connect ohmmeter fromharness side.

3. Check forcontinuity betweenterminalNo.@and body

ground.

~I()~

Thermo controlamp.

connector@

Lom ~

RHA341F

~Iv~

Thermo controlamp.

connector

@

;

~~.

LHD 2 \... ~

models:

GIS

Uw-i

RHD [][]

models: GY

Continuity exists:OK

'="RHA342F

EB

CD

EB

@

HA-49

e

Body ground

e

Body ground Voltage

Approx. 12V

Continuity

Yes

•

Page 1452 of 1701

TROUBLEDIAGNOSES

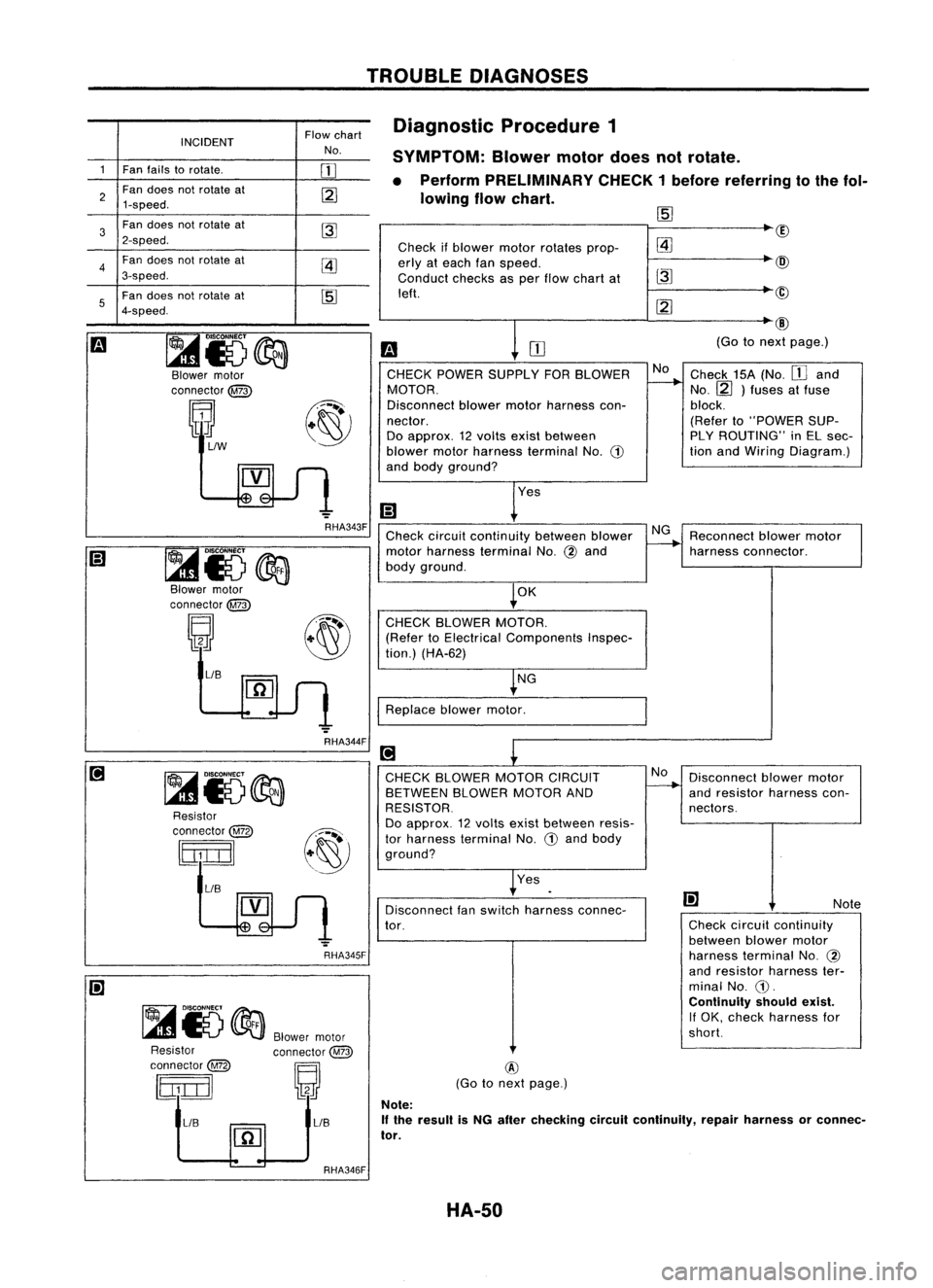

INCIDENT Flow

chart

No.

1 Fan fails torotate.

rn

2 Fan

does notrotate at

[2J

1-speed.

3 Fan

does notrotate at

~

2-speed.

4 Fan

does notrotate at

[1J

3-speed.

5 Fan

does notrotate at

[2]

4-speed. Diagnostic

Procedure1

CD

@

@

@

(Go tonext page.)

Check 15A(No.

rn

and

No.

[2J)

fuses atfuse

block.

(Refer to"POWER SUP-

PLY ROUTING" inEL sec-

tion and Wiring Diagram.)

No

Ves

Check

ifblower motorrotates prop-

erly ateach fanspeed.

Conduct checksasper flow chart at

left.

rn

SYMPTOM:

Blowermotordoesnotrotate.

• Perform PRELIMINARY CHECK1before referring tothe fol-

lowing flowchart.

CHECK POWER SUPPLVFOR BLOWER

MOTOR.

Disconnect blowermotorharness con-

nector.

Do approx. 12volts existbetween

blower motorharness terminal No.

CD

and body ground?

LlW

~i5~

Blower motor

connector

@)

m

RHA343F

~ DISCONNECT

IV@a

Blower motor

connector

@)

~ ~Check

circuitcontinuity betweenblower

motor harness terminal No.@and

body ground.

~OK

CHECK BLOWER MOTOR.

(Refer toElectrical Components Inspec-

tion.) (HA-62) Reconnect

blowermotor

harness connector.

LIB

NG

I

Replace blowermotor.

RHA344F

@J

Resistor

connector@

[Qli1JJ

LIB

CHECK

BLOWER MOTORCIRCUIT

BETWEEN BLOWERMOTORAND

RESISTOR

Do approx. 12volts existbetween resis-

tor harness terminal No.

CD

and body

ground?

Ves No

Disconnect blowermotor

and resistor harness con-

nectors.

Note: If the result isNG after checking circuitcontinuity, repairharness orconnec-

tor. Note

Check circuit continuity

between blowermotor

harness terminal No.@

and resistor harness ter-

minal No.

(1).

Continuity shouldexist.

If OK, check harness for

short.

@

(Go tonext page.)

Disconnect

fanswitch harness connec-

tor.

LIB

RHA345F

Blower motor

connector@

~

LIB

Resistor

connector@

61iJ]

RHA346FHA-50

Page 1453 of 1701

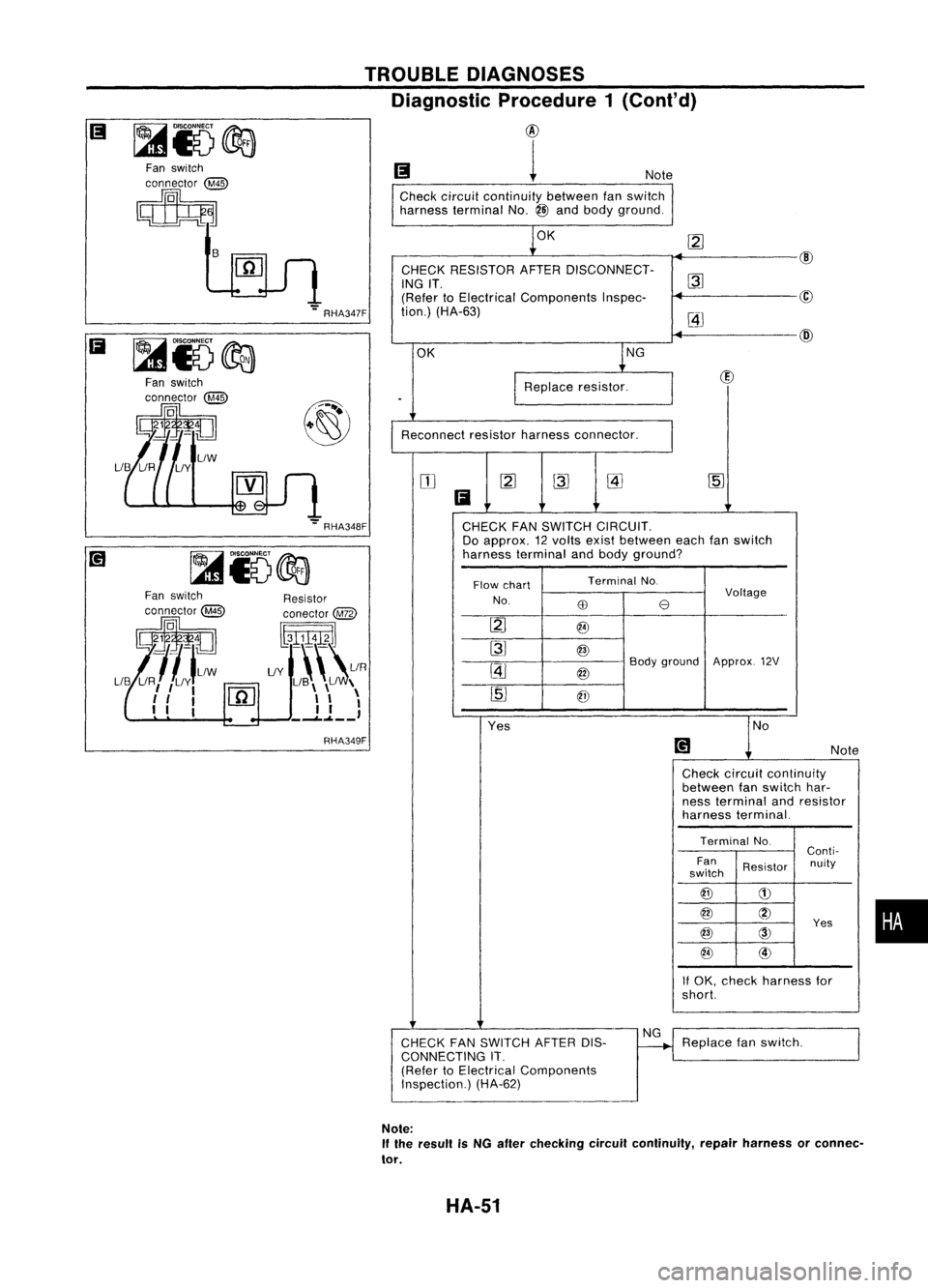

•

Note

Check circuit continuity betweenfanswitch

harness terminal No.@and body ground.

1

0K ~

@

CHECK RESISTOR AFTERDISCONNECT-

~

ING

IT.

(Refer toElectrical Components Inspec- @

tion.) (HA-63)

@]

@

OK NG

I

Replace resistor. @

.

Reconnect resistorharness connector.

ITJ

~

~

@]

~

Ii

CHECK FANSWITCH CIRCUIT.

Do approx. 12volts existbetween eachfanswitch

harness terminal andbody ground?

Flow chart Terminal

No.

No. Voltage

Ell

e

~

@

QJ

@

~ Body

ground Approx.

12V

@

~

@

Yes No

[!1

Note

Check circuit continuity

between fanswitch har-

ness terminal andresistor

harness terminal.

Terminal No.

Conti-

Fan Resistor nuity

switch

@

CD

@

~

Yes

@

CID

@ @

If OK, check harness for

short.

'-NG

CHECK FANSWITCH AFTERDIS-

H

Replace fanswitch.

CONNECTING IT.

(Refer toElectrical Components

Inspection.) (HA-62)

TROUBLE

DIAGNOSES

Diagnostic Procedure1(Cont'd)

@

1

RHA349F

.".

RHA347F

.". RHA348F

Resistor

conector@

[31\!:4Jli]

uy

'r'r\

LlR

LI~ 'LI~'

\

\

\

'I ,

_.1.1 __,

Fan

switch

connector

@

~

Fan switch

connector@

lQ~

UB UR71JLM

ff

I

I I

I

Ii

Note:

If

the result isNG after checking circuitcontinuity, repairharness orconnec-

tor.

HA-51

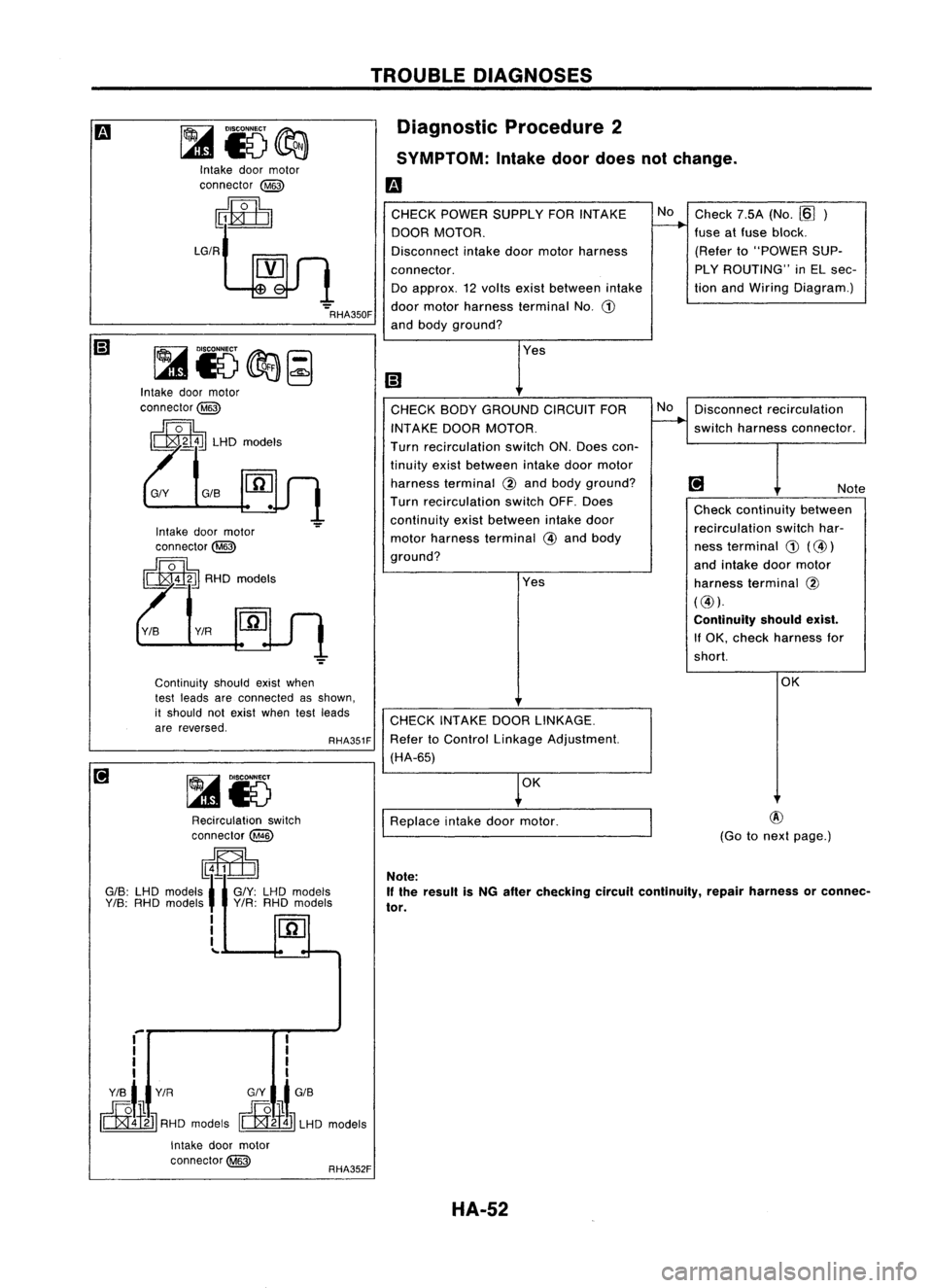

Page 1454 of 1701

TROUBLEDIAGNOSES

RHA351F @

(Go tonext page.)

Note:

If the result isNG after checking circuitcontinuity, repairharness orconnec-

tor.

Diagnostic

Procedure2

SYMPTOM: Intakedoordoes notchange.

m

CHECK POWER SUPPLY FORINTAKE No

Check 7.5A(No.~)

DOOR MOTOR.

f-----.-

fuseatfuse block.

Disconnect intakedoormotor harness (Refer

to"POWER SUP-

connector. PLY

ROUTING" inEL sec-

Do approx. 12volts exist between intake tion

and Wiring Diagram.)

door motor harness terminal No.

G)

and body ground?

Yes

(;J

CHECK BODYGROUND CIRCUITFORNo

Disconnect recirculation

INT AKE DOOR MOTOR.

~

switch harness connector.

Turn recirculation switchON.Does con-

tinuity existbetween intakedoormotor

harness terminal

@

and body ground?

@J

Note

Turn recirculation switchOFF.Does

Checkcontinuity between

continuity existbetween intakedoor

recirculationswitchhar-

motor harness terminal

@

and body

nessterminal

G)

(@)

ground? andintake doormotor

Yes harnessterminal @

(@).

Continuity shouldexist.

If OK, check harness for

short.

OK

CHECK INTAKE DOORLINKAGE.

Refer toControl Linkage Adjustment.

(HA-65)

OK

I

Replace intakedoormotor.

GIS

Intake

doormotor

connector @

~

LGIRt

~JJ

1

RHA350F

Continuity shouldexistwhen

test leads areconnected asshown,

it should notexist when testleads

are reversed.

~i5@a~

Intake doormotor

connector@

~ LHDmodels

~15 Recirculation switch

connector@

~

GIS: LHOmodels

1-

GIY: LHOmodels

Y/S:

RHO mOdels' VIR:RHO models

I

I

I

'"

RHA352F

.-

I

I

I

Y/S

t

Y/R G/Y

t

GIS

rERl-¥1Jl

RHDmodels ~ LHOmodels

Intake doormotor

connector@

HA-52

Page 1455 of 1701

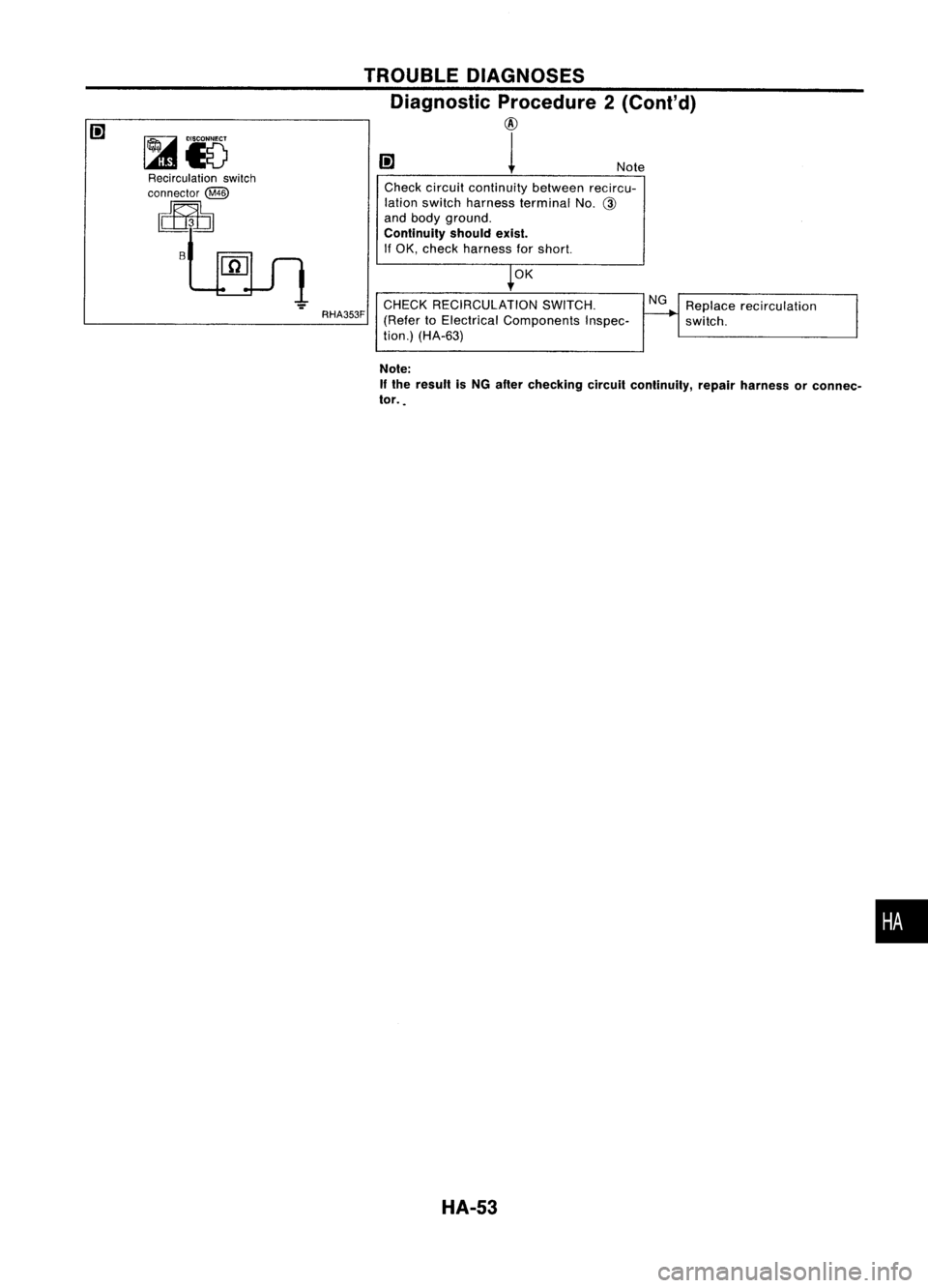

Replacerecirculation

switch.

Note

Check circuit continuity betweenrecircu-

lation switch harness terminal No.@

and body ground.

Continuity shouldexist.

If OK, check harness forshort.

~OK

CHECK RECIRCULATION SWITCH.

(Refer toElectrical Components Inspec-

tion.) (HA-63)

TROUBLE

DIAGNOSES

Diagnostic Procedure2(Cont'd)

@

1

RHA353F

~15

Recirculation switch

connector ~

[5b

B

Note:

If

the result isNG after checking circuitcontinuity, repairharness orconnec-

tor ..

•

HA-53

Page 1456 of 1701

TROUBLEDIAGNOSES

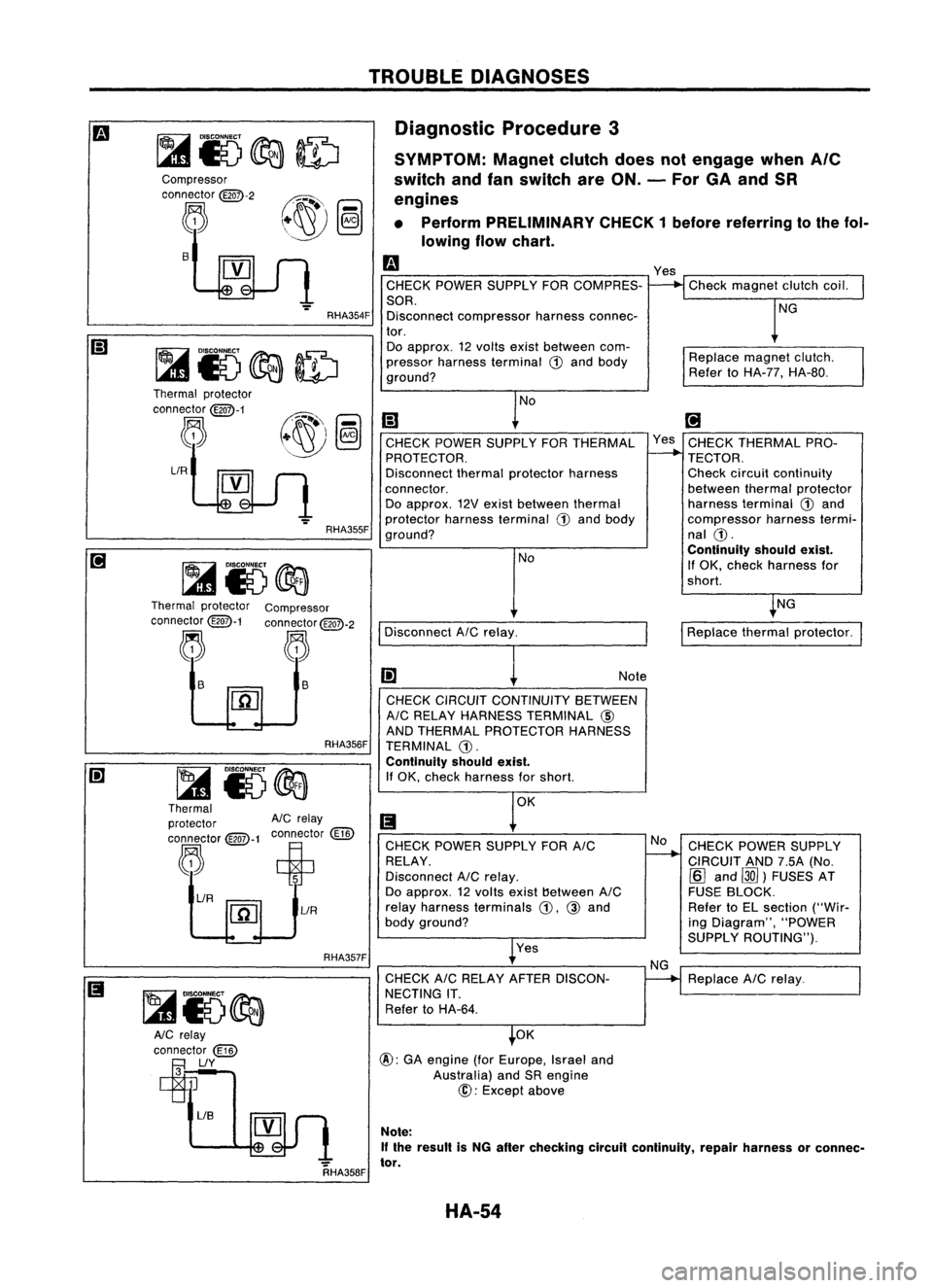

Diagnostic Procedure3

SYMPTOM: Magnetclutchdoesnotengage when

Ale

switch andfanswitch areON. -For GAand SR

engines

• Perform PRELIMINARY CHECK1before referring tothe fol-

lowing flowchart.

Replacemagnetclutch.

Refer toHA-77, HA-80.

Check

magnet clutchcoil.

NG

Yes

m

CHECK POWER SUPPLY FORCOMPRES-

SOR. Disconnect compressor harnessconnec-

tor. Do approx. 12volts existbetween com-

pressor harness terminal

ill

and body

ground?

RHA354F

s

Compressor

connector

@QD-2

~

RHA357FRHA356F

NG

CHECK POWER SUPPLY

CIRCUIT AND7.5A(No.

[Q]

and ~)FUSES AT

FUSE BLOCK.

Refer toEL section ("Wir-

ing Diagram", "POWER

SUPPLY ROUTING").

Replace AICrelay.

I

Replace thermalprotector.

[;J

Yes CHECK THERMAL PRO-

TECTOR.

Check circuit continuity

between thermalprotector

harness terminal

ill

and

compressor harnesstermi-

nal

ill.

Continuity shouldexist.

If OK, check harness for

shorl.

No

NG

CHECK

CIRCUIT CONTINUITY BETWEEN

AIC RELAY HARNESS TERMINAL @

AND THERMAL PROTECTOR HARNESS

TERMINAL

ill.

Continuity shouldexist.

If OK, check harness forshorl. Note

Yes

CHECK

POWER SUPPLY FORAIC

RELAY.

Disconnect AICrelay.

Do approx. 12volts exist!)etween AIC

relay harness terminals

ill,

@

and

body ground?

CHECK AICRELAY AFTER DISCON-

NECTING IT.

Refer toHA-64.

Disconnect

AICrelay. NoNo

[;)

CHECK POWER SUPPLY FORTHERMAL

PROTECTOR.

Disconnect thermalprotector harness

connector. Do approx. 12Vexist between thermal

protector harnessterminal

ill

and body

ground?

OK

@:

GAengine (forEurope, Israeland

Australia) andSRengine

@:

Except above

RHA355F

~ i5@a

Thermal protector

AIC

relay

connector

@-1

connector

(ill)

,"R~~t

[1[]

lIR

lIR

Thermal

protector

connector

@QD-1

~

Thermal protector Compressor

connector

@QD-1

connector

@QD-2

~ ~

~ ~ ls

~

~15~

AlC relay

connector

(ill)

~lIY

RHA358FNote:

If the result isNG after checking circuitcontinuity, repairharness orconnec-

tor.

HA-54

Page 1457 of 1701

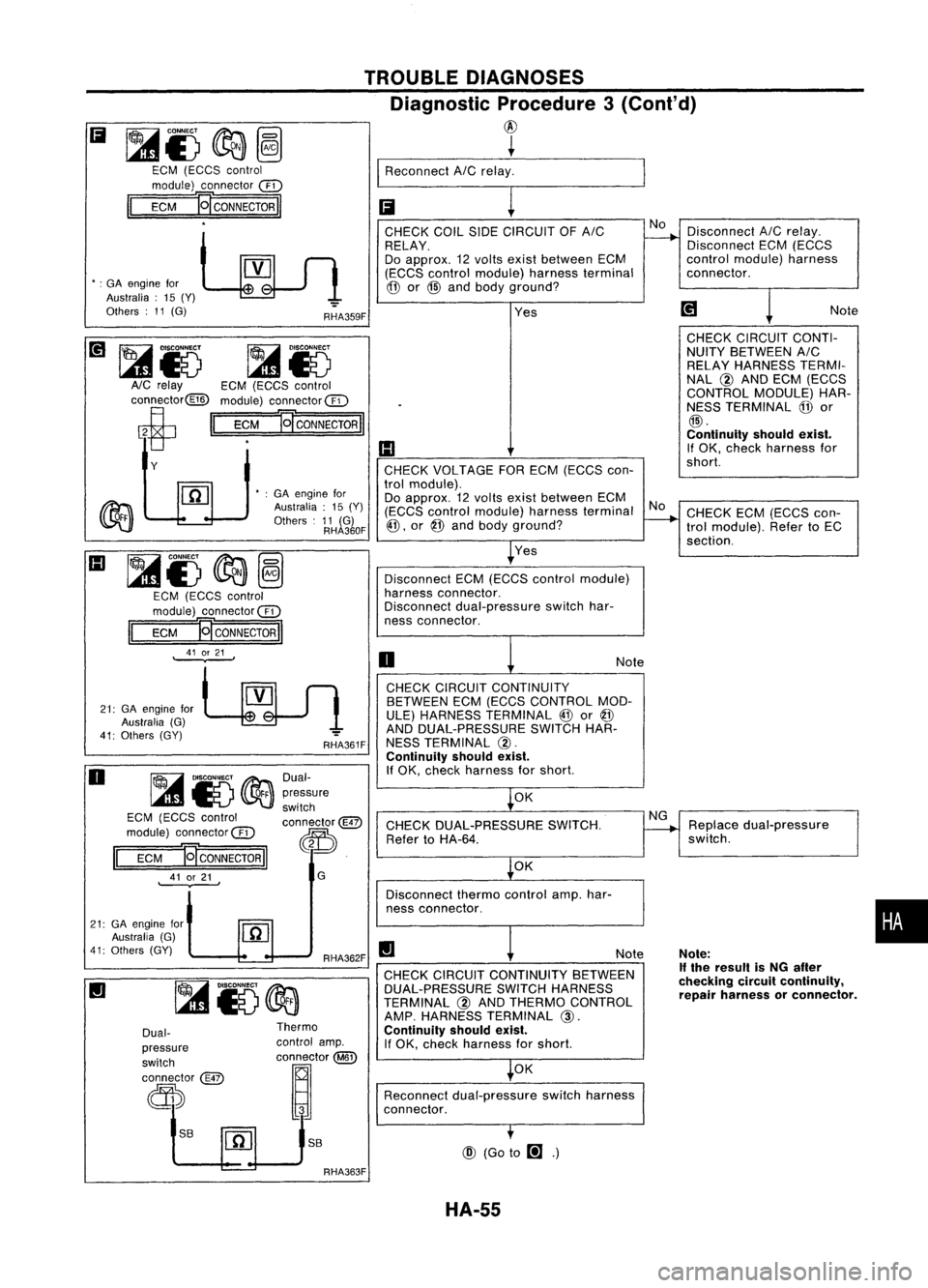

•

Replace

dual-pressure

switch.

Note:

If

the result isNG after

checking circuitcontinuity,

repair harness orconnector.

NG

Note

Note

OK

OK

CHECK DUAL-PRESSURE SWITCH.

Refer toHA-64.

Disconnect thermocontrolamp.har-

ness connector.

CHECK

CIRCUIT CONTINUITY

BETWEEN ECM(ECCS CONTROL MOD.

ULE) HARNESS TERMINAL

@

or

@

AND DUAL-PRESSURE SWITCHHAR-

NESS TERMINAL @.

Continuity shouldexist.

If OK, check harness forshort.

OK

@ (Go to

m .)

Disconnect

ECM(ECCS contraImodule)

harness connector.

Disconnect dual-pressure switchhar-

ness connector.

CHECK CIRCUIT CONTINUITY BETWEEN

DUAL.PRESSURE SWITCHHARNESS

TERMINAL @AND THERMO CONTROL

AMP. HARNESS TERMINAL

@.

Continuity shouldexist.

If OK, check harness forshort.

Reconnect dual-pressure switchharness

connector.

o

CHECK

COILSIDECIRCUIT OFAIC No

Disconnect A/Crelay.

~

RELAY. Disconnect

ECM(ECCS

Do approx. 12volts exist between ECM control

module) harness

(ECCS control module) harnessterminal connector.

@

or@ and body ground?

l

Yes

~Note

CHECK CIRCUIT CONTI-

NUITY BETWEEN AIC

RELAY HARNESS TERMI-

NAL @AND ECM (ECCS

CONTROL MODULE)HAR-

.

NESSTERMINAL

@

or

@.

Continuity shouldexist.

(I) If

OK, check harness for

CHECK VOLTAGE FORECM (ECCS con- short.

tral module) .

Do approx. 12volts exist between ECM

NoCHECK ECM(ECCS con-

(ECCS

control module) harnessterminal

-..

@, or@ and body ground?

trolmodule). RefertoEC

section.

Yes

TROUBLE

DIAGNOSES

Diagnostic Procedure3(Conl'd)

@

~

I

Reconnect AICrelay. _

Ii

!

RHA359F

RHA362F

II

RHA361F

G

Dual-

pressure

switch

connector@

~.

S8

Thermo

control amp.

OOD

tm

@

•

:GA engine for

Australia :15 (Y)

Others :11 (G)

RHA360F

S8

Dual-

pressure

switch

connector

@

d))

~15@a

EGM (EGGS control

module) connec1or@

EGM

E[CONNECTORII

41 or21

.

II

•

:GA engine for

Australia: 15(Y)

Others :11 (G)

21: GAengine for

Australia (G)

41: Others (GY)

~&)

~Io

AlG relay EGM(EGGS control

connector@ module)connector@

ci

II

EGM

]g

CONNECTOR

II

Y

21: GAengine for

Australia (G)

41: Others (GY)

Ii

~i)@a~

EGM (EGGS control

module) connector @

II

EGM

]g

CONNECTOR

II

o

III

~i)

@a~

EGM (EGGS control

module) connector@

II

EGM 'gCONNECTORII

41 or21

.

RHA363F HA-55

Page 1458 of 1701

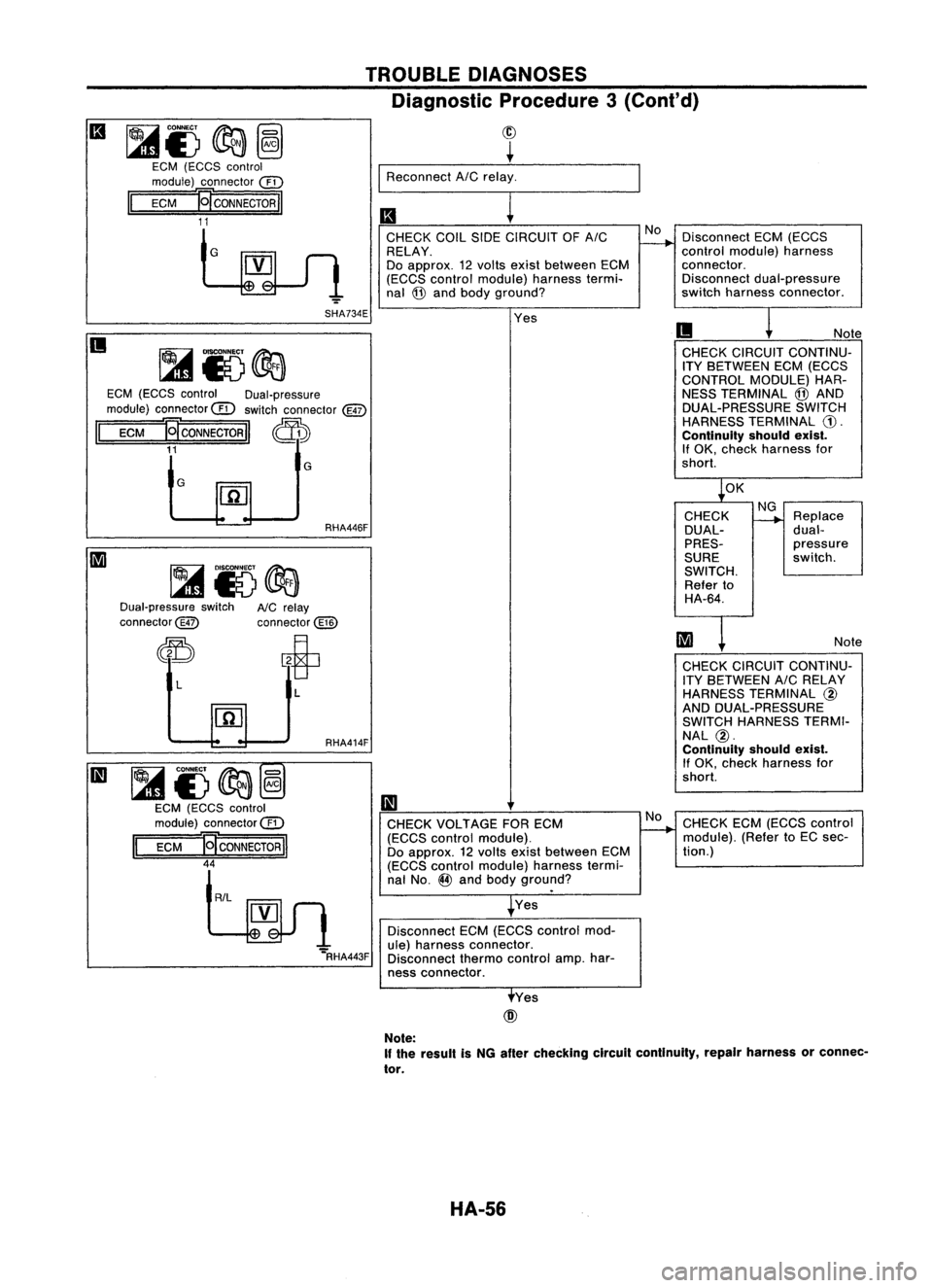

~CONNECT ~

(gl

l41E) ~

@

EGM (EGGS control

module) connector

@

II

EGM

J9"CONNECTORII

11 TROUBLE

DIAGNOSES

Diagnostic Procedure3

(Co nt'd)

~ ~

I

Reconnect AICrelay_. _..._

II

!

EGM (EGGS control Dual-pressure

module) connector

@

switch connector

@

II

ECM

Ej'coNNEcTORII ~

11

GSHA734E

Note

CHECK CIRCUIT CONTINU-

ITY BETWEEN ECM(ECCS

CONTROL MODULE)HAR-

NESS TERMINAL @AND

DUAL-PRESSURE SWITCH

HARNESS TERMINAL

CD.

Continuity shouldexist.

If OK, check harness for

short. Disconnect

ECM(ECCS

control module) harness

connector. Disconnect dual-pressure

switch harness connector.

II

CHECK

COILSIDECIRCUIT OFAIC

RELAY.

Do approx. 12volts exist between ECM

(ECCS control module) harnesstermi.

nal @and body ground?

Yes

G

II

G

Dual-pressure switch

connector@ RHA446F

NC relay

connector@ ~OK

CHECK

DUAL-

PRES-

SURE

SWITCH. Refer to

HA-64. NG

--+

Replace

dual-

pressure

switch.

Note

"='RHA443F

~i)~@

EGM (EGGS control

module) connector@

II

EGM

E[CONNECTORII

44

L

R/L

L

RHA414F

II

CHECK VOLTAGE FORECM

(ECCS control module).

Do approx. 12volts exist between ECM

(ECCS control module) harnesstermi-

nal No.

@

and body ground?

Yes

Disconnect ECM(ECCS control mod-

ule) harness connector.

Disconnect thermocontrol amp.har-

ness connector.

No

CHECK

CIRCUIT CONTINU-

ITY BETWEEN AICRELAY

HARNESS TERMINAL

@

AND DUAL-PRESSURE

SWITCH HARNESS TERMI-

NAL @.

Continuity shouldexist.

If OK, check harness for

short.

CHECK ECM(ECCS control

module). (RefertoEC sec-

tion.)

Yes

@

Note:

If the result isNG after checking circuilcontinuity, repairharness orconnec-

tor.

HA-56

Page 1459 of 1701

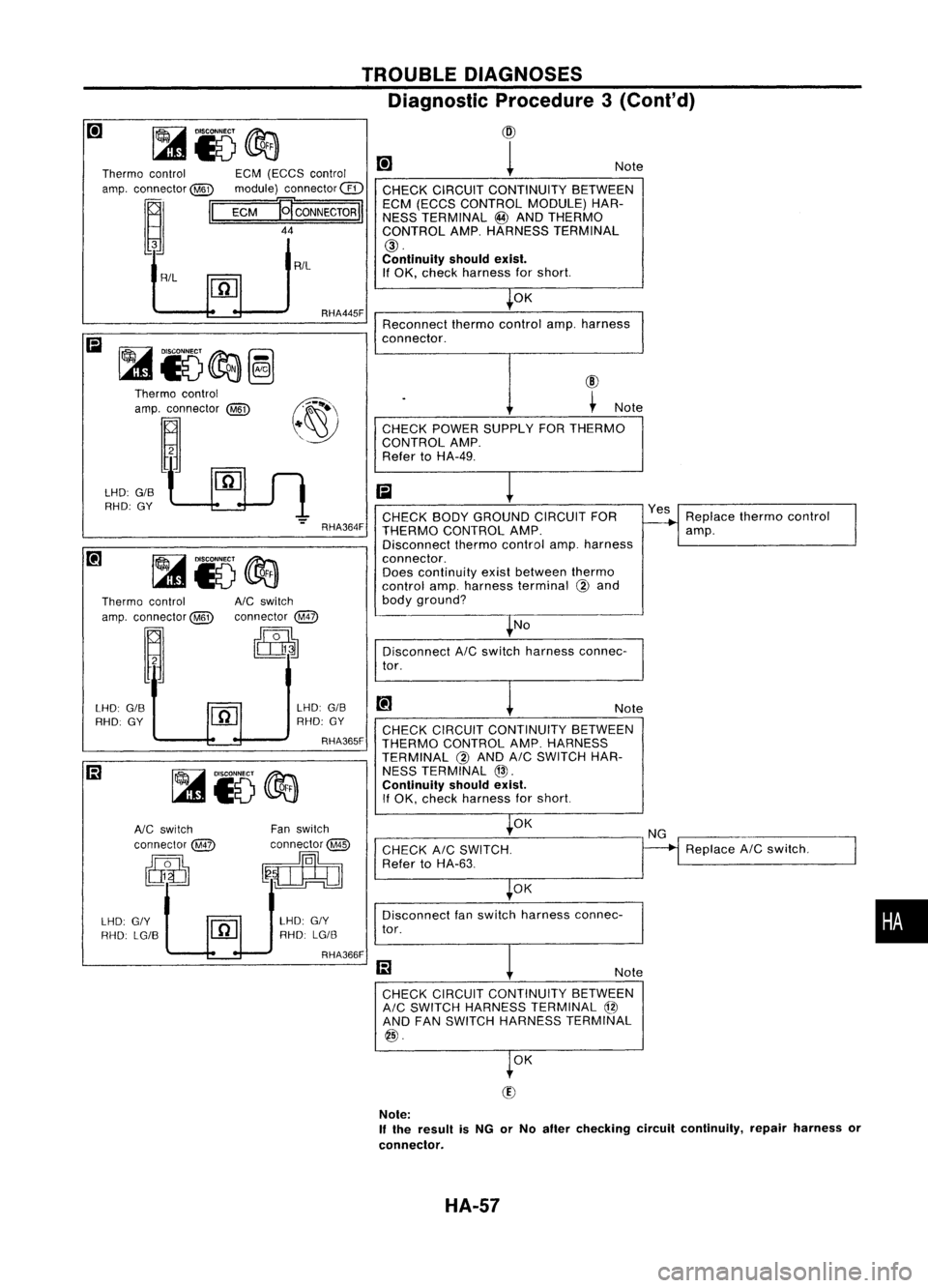

Note

CHECK CIRCUIT CONTINUITY BETWEEN

ECM (ECCS CONTROL MODULE)HAR-

NESS TERMINAL

@

AND THERMO

CONTROL AMP.HARNESS TERMINAL

@.

Continuity shouldexist.

If OK, check harness forshort.

TROUBLE

DIAGNOSES

Diagnostic Procedure3(Cont'd)

@

t

RIL

EGM

(EGGS control

module) connector@

EGM

ECONNECTORII

44

RIL

Thermo

control

amp. connector ~

~ II

~OK

Reconnect thermocontrol amp.harness

connector.

Thermo control

,mp;""",,,

@~

LHD:

G/S'~

rrIDl

rJ.

RHD: GY

L-.D--J

1

Replacethermocontrol

amp.

Note

No

CHECK CIRCUIT CONTINUITY BETWEEN

THERMO CONTROL AMP.HARNESS

TERMINAL

@

AND AICSWITCH HAR-

NESS TERMINAL

@.

Continuity shouldexist.

If

OK.

check harness forshort. Note

Disconnect

AIC

switch harness connec-

tor.

CHECK

BODYGROUND CIRCUITFOR

THERMO CONTROL AMP.

Disconnect thermocontrol amp.harness

connector. Does continuity existbetween thermo

control amp.harness terminal @and

body ground?

CHECK

POWER SUPPLY FORTHERMO

CONTROL AMP.

Refer toHA-49.

LHD:

GIS

RHD: GY

RHA365F

RHA364F

A/G

switch

connector @

i55lJ

Thermo

control

amp. connector

@)

~

LHD:

GIS

RHD: GY

NG

switch

connector@

62J

LHD: G/Y

RHD: LG/S

Fan

switch

connector@

~

LHD: G/Y

RHD: LG/B

RHA366F OK

CHECK AICSWITCH.

Refer toHA-63.

OK

Disconnect fanswitch harness connec-

tor.

NoteReplace

AIC

switch.

•

CHECK CIRCUIT CONTINUITY BETWEEN

AIC SWITCH HARNESS TERMINAL

@

AND FANSWITCH HARNESS TERMINAL

@.

OK

Note:

If

the result isNG orNo alter checking circuitcontinuity, repairharness or

connector.

HA-57

Page 1460 of 1701

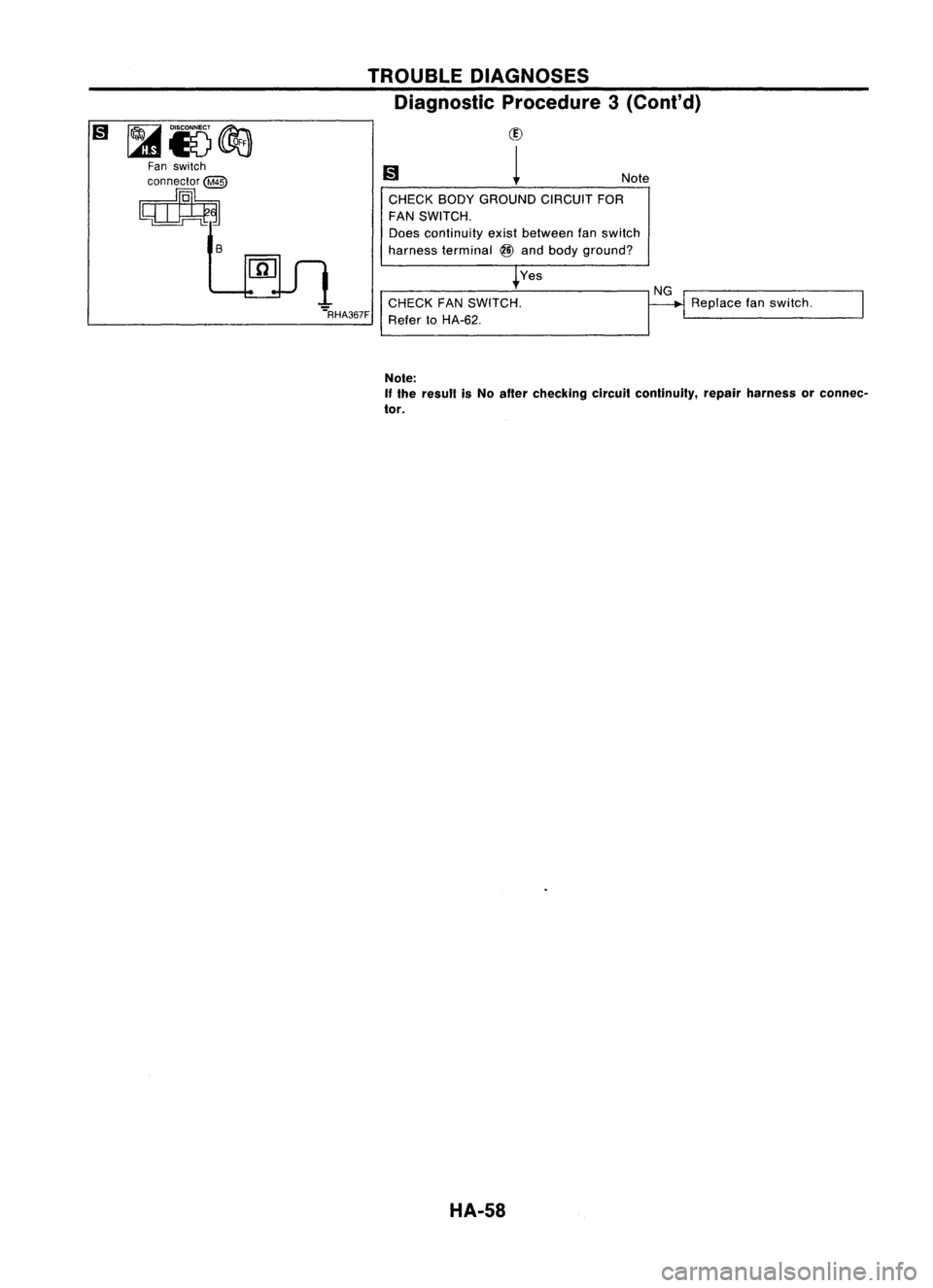

Replacefanswitch.

NG

Note

CHECK BODYGROUND CIRCUITFOR

FAN SWITCH.

Does continuity existbetween fanswitch

harness terminal

@

and body ground?

Yes

CHECK FANSWITCH.

Refer toHA-62.

TROUBLE

DIAGNOSES

Diagnostic Procedure3(Cont'd)

CID

1

'="RHA367F

~iv@a

Fan switch

connector@

~

B

Note:

If

the result isNo after checking circuitcontinuity, repairharness orconnec-

tor.

HA-58