NISSAN ALMERA N15 1995 Service Manual

ALMERA N15 1995

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57349/w960_57349-0.png

NISSAN ALMERA N15 1995 Service Manual

Trending: fuse diagram, engine overheat, Correct, mirror controls, load capacity, coolant temperature, air

Page 1471 of 1701

SERVICEPROCEDURES

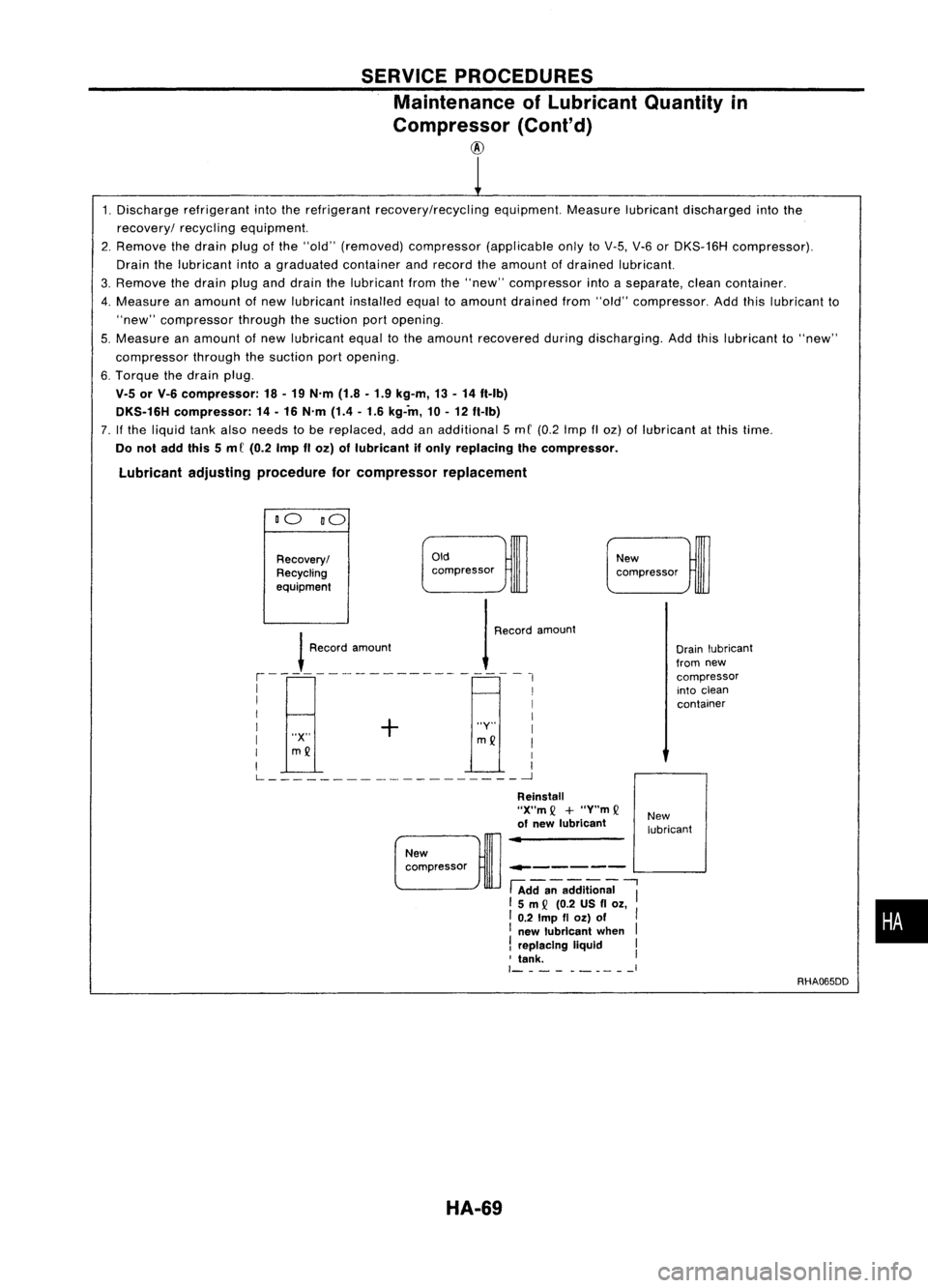

Maintenance ofLubricant Quantityin

Compressor (Cont'd)

@

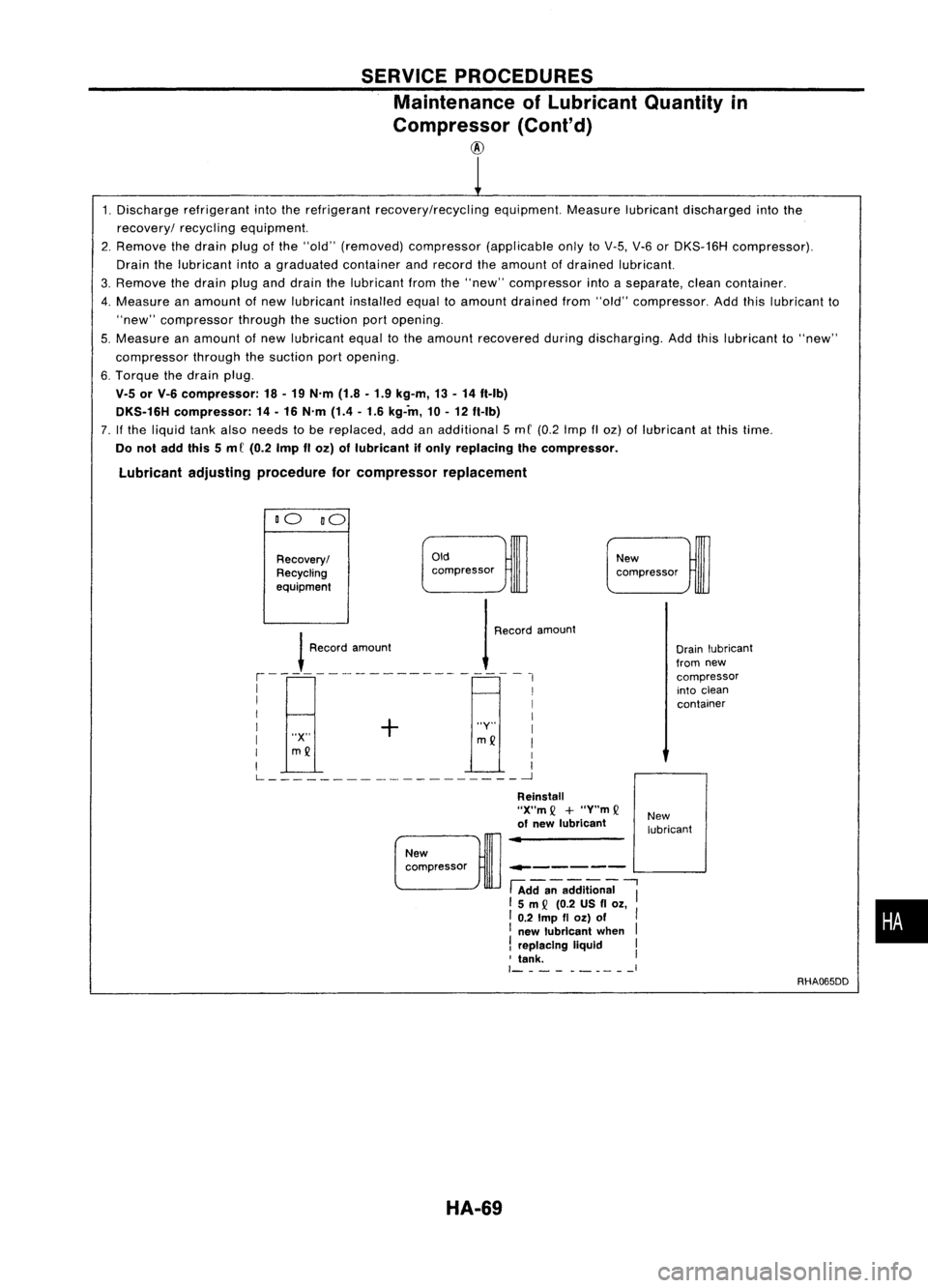

1. Discharge refrigerant intotherefrigerant recovery/recycling equipment.Measurelubricantdischarged intothe

recovery/ recyclingequipment.

2. Remove thedrain plugofthe "old" (removed) compressor (applicableonlytoV-5, V-6orDKS-16H compressor).

Drain thelubricant intoagraduated containerandrecord theamount ofdrained lubricant.

3. Remove thedrain pluganddrain thelubricant fromthe"new" compressor intoaseparate, cleancontainer.

4. Measure anamount ofnew lubricant installedequaltoamount drained from"old" compressor. Addthislubricant to

"new" compressor throughthesuction portopening.

5. Measure anamount ofnew lubricant equaltothe amount recovered duringdischarging. Addthislubricant to"new"

compressor throughthesuction portopening.

6. Torque thedrain plug.

V.5 orV-6 compressor: 18-19 N'm (1.8-1.9 kg-m, 13-14 ft-Ib)

DKS.16H compressor: 14-16 N'm (1.4-1.6 kg-in, 10-12 ft-Ib)

7. Ifthe liquid tankalso needs tobe replaced, addanadditional 5mC (0.2 Imp IIoz) oflubricant atthis time.

Do not add this5m C(0.2 ImpIIoz) oflubricant ifonly replacing thecompressor.

Lubricant adjustingprocedure forcompressor replacement

DO DO

Oldcompressor

Recovery/

Recycling

eqUipment

!

Roo'"

,m,,",

1

R,,,,'

,moo",

,--------------------,

I I

I I

I + I

I "Y"I

I "X"

mQ

I

I

mQ

I

I I

L ~

New

compressor

Drainlubricant

from new

compressor

into clean

container

------ L-...

.J

New

compressor

HA-69

Reinstall

"X"m

Q

+

"Y"m

Q

of new lubricant

-.-------

fAdda;-addition;;

"I

15m

Q

(0.2 USfl

Ol,

I 0.2

Imp

fl

Ol)

of

I

I new lubricant when

I

!

replacing liquid I

, tank. I

1- -__ I

New

lubricant

RHA065DD

•

Page 1472 of 1701

SERVICEPROCEDURES

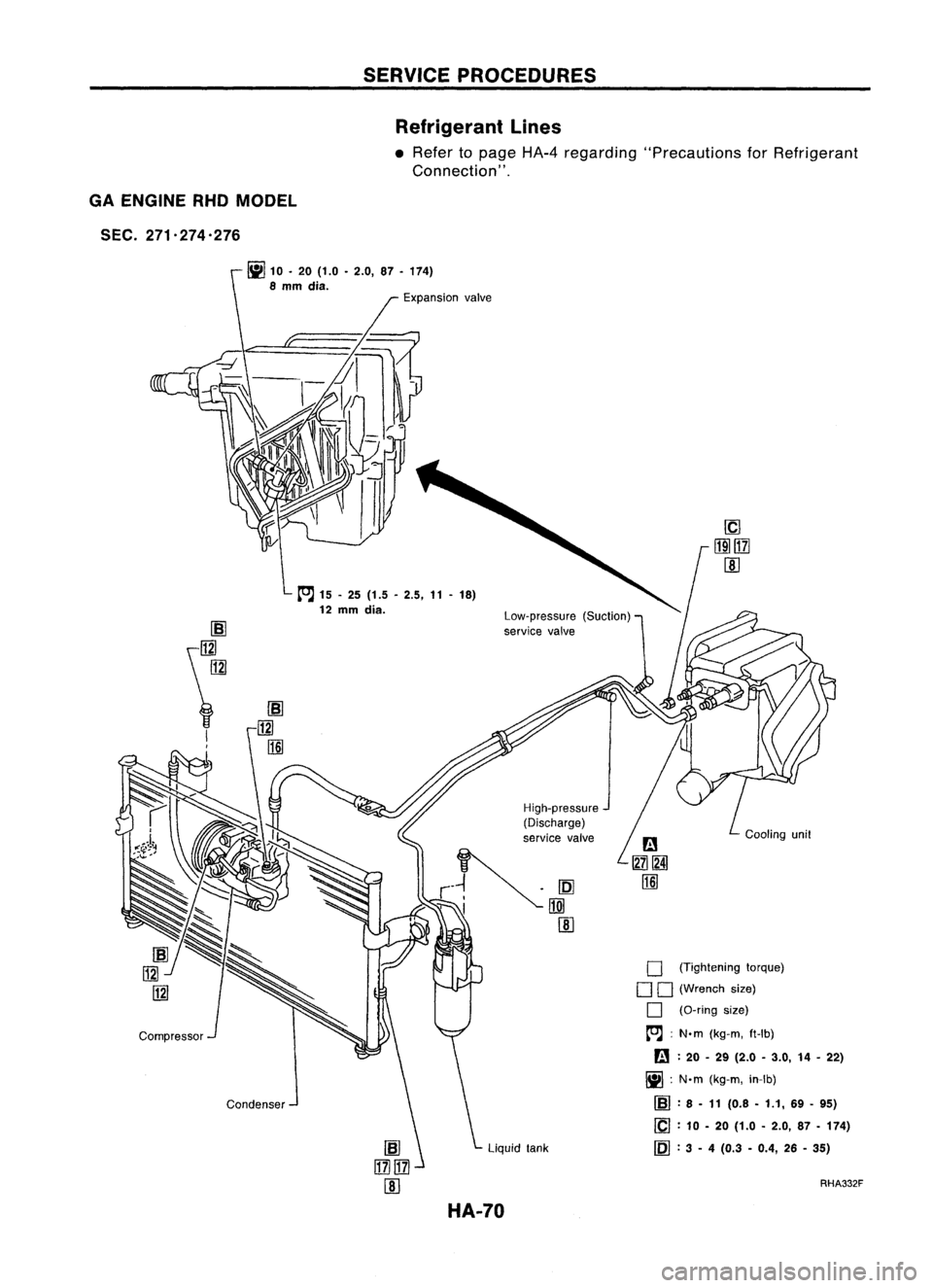

Refrigerant Lines

• Refer topage HA-4regarding "Precautions forRefrigerant

Connection" .

GA ENGINE

RHO

MODEL

SEC. 271.274.276

fil10'20(1.0 .2.0, 87.174)

8

mm

dia.

Liquidtank

Condenser Expansion

valve

[O;J

15-25 (1.5 -2.5, 11-18)

12

mm

dia.

Low-pressure(Suction)

service valve

o

(Tightening torque)

o

0

(Wrench size)

o

(O-ring size)

[O;J :

N.m (kg-m, ft-Ib)

rn :

20 •29 (2.0 •3.0, 14-22)

fiI :

N.m (kg-m, in-Ib)

IBl :

8 •11 (0.8 -1.1, 69-95)

[C] :

10 -20 (1.0 -2.0, 87-174)

~ :3 -4 (0.3 -0.4, 26-35)

RHA332F

HA-70

Page 1473 of 1701

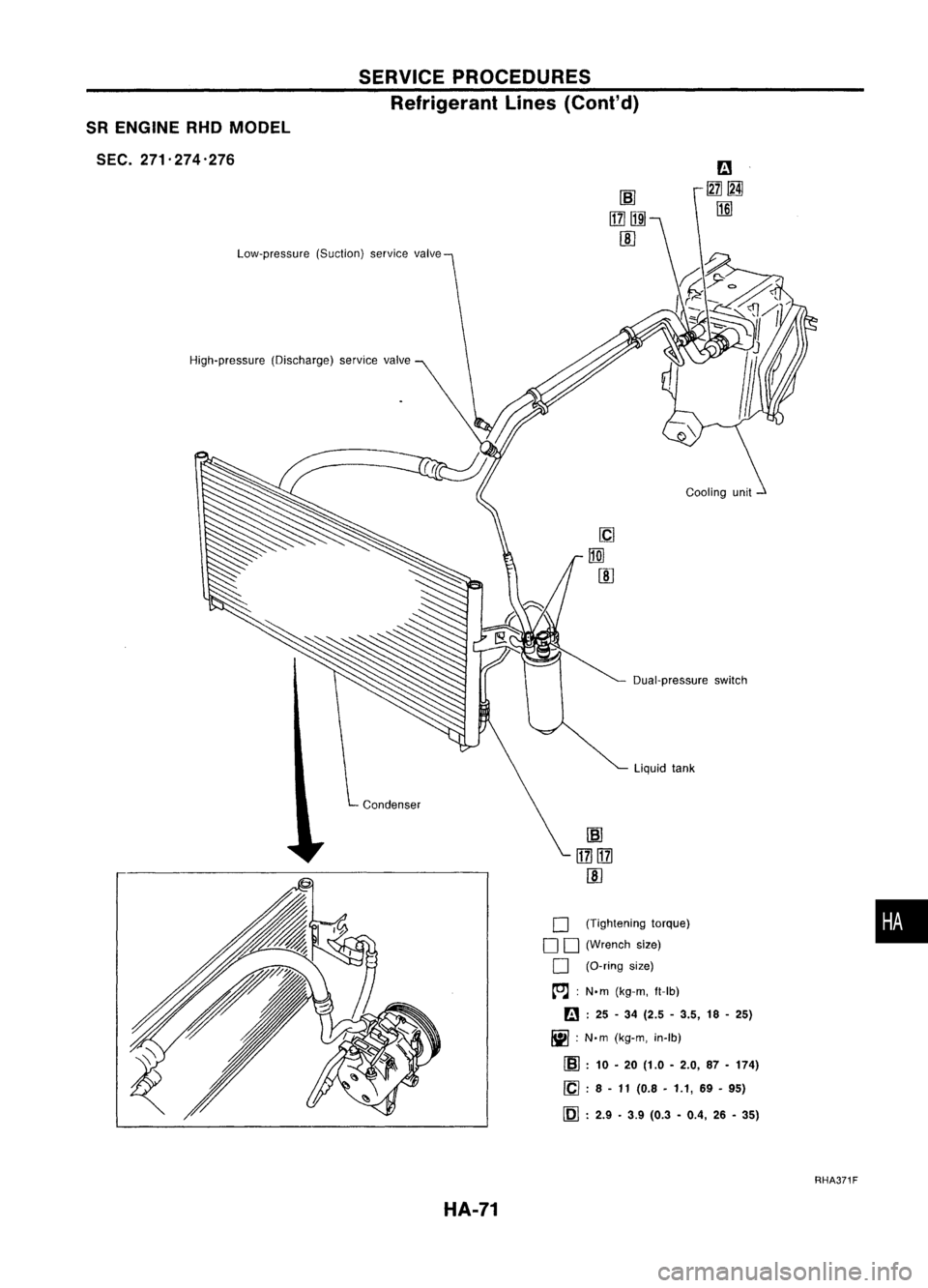

S~~~~:~::--_~S~ER ~V~1~C~E~P;.R;O~C¥E¥,D~U~fo;;r.:i) _

R ENGINE RHDMO Ref" RES

5

DEL

ngerant

L"

EC. 271.274 '276

mes(Cont' d)

Low-pressure (Suct'

Ion)

se'

rVlce valve

High-pressure (0'Ischarg )

e service valve

Coolingunit

Dual-pressure switch

Liquid tank

Condenser

o

(Tightening t

o

orque)

o

(Wrench size)

o

(D-ring size)

~: N'm(k

g-m,

ft-Ib)

r.:.1 :

25 -34 (

IiiiI

2.5-3.5 18

~ :N.m ( ,-25)

kg-m, in-Ib)

(SJ :

10 -20 (1

'Cl .

.0-2.0, 87-174)

~ .8 -11 (0

.8

-1.1 69

1)1 . '-95)

lMJ .2.9 .3 9 (

. 0.3 -04 26

., -35)

RHA371F

HA-71

•

Page 1474 of 1701

SERVICEPROCE

R

f•

DURES

e ngerant

L.

mes (Cont'd)

CD ENGINE RHOMODEL

SEC. 271'274-276

iii

10-20 (1.0 -2

8

mm

dia. .0,87-174)

Expansion valve

Liquid tank

[SJ

\~

il!1d

I

I

Compressor Condenser

[O.J

15-25 (1.5 -2

12

mm

d' .5,11-18)

la.

Low-pressure (

service valveSuction) Hi~h-pressure

(Discharge)

service valve

D

(Tightening t

DO orque)

(Wrench size)

o

(O-ring size)

[O.J :

N'm (k

g-m,

ft-Ib)

a :

20 -29 (20

iii :

N'm .-3.0, 14-22)

(kg-m, in-Ib)

[SJ :

8 -11 (0.8 -1

ICl :

10 .1,69-95)

- 20 (1.0 •2

[Q] :

3 _4 .0,87-174)

(0.3 -04 26

.,

•35)

RHA333F

HA-72

Page 1475 of 1701

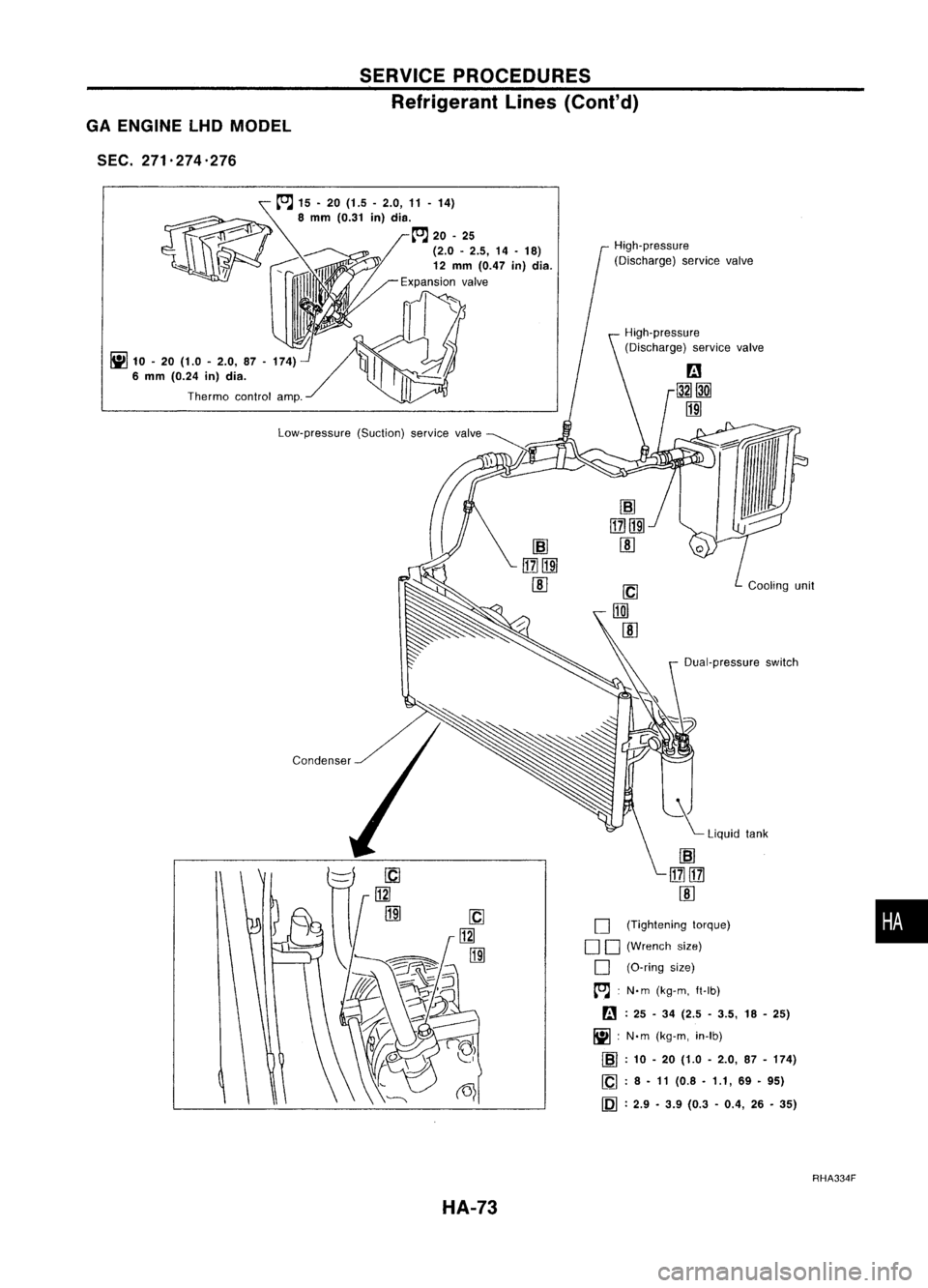

SERVICEPROCEDURES

Refrigerant Lines(Cont'd)

GA ENGINE lHDMODEL

SEC. 271.274.276

Low-pressure (Suction)servicevalve

~

10-20 (1.0 -2.0, 87-174)

6 mm (0.24 in)dia.

Thermo controlamp.

•

Dual-pressure

switch

~ Liquid tank

High-pressure

(Discharge) servicevalve

High-pressure

(Discharge) servicevalve

o

(Tightening torque)

D D (Wrench size)

D (O-ring size)

~ :N'm (kg-m, ft-lb)

~ :25 -34 (2.5 -3.5, 18-25)

~ :N'm (kg-m, in-Ib)

rm :

10 -20 (1.0 -2.0, 87-174)

~ :8 •11 (0.8 •1.1, 69•95)

~ :2.9 •3.9 (0.3 -0.4, 26•35)

~

15•20 (1.5 -2.0, 11-14)

~ 8

mm

(0.31

in)

die.

___ ==- - ~

20-25

(2.0 -2.5, 14-18)

."""\ ~t;,

12mm (0.47 in)dia.

Expansion valve

RHA334F

HA-73

Page 1476 of 1701

SERVICEPROCEDURES

Refrigerant Lines

(Cont'd)

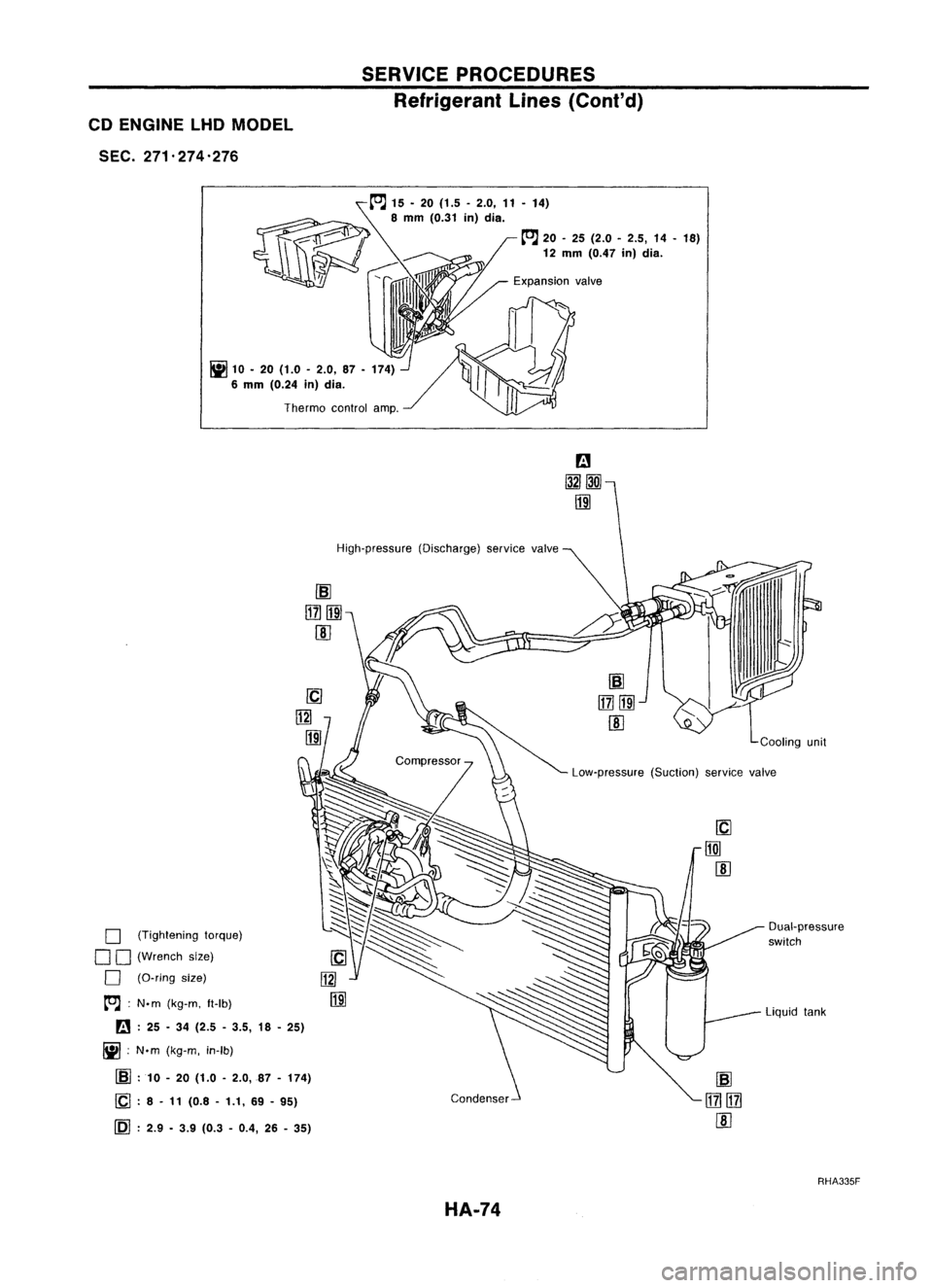

CD ENGINE LHDMODEL

SEC. 271'274'276

[O.J

15. 20(1.5 -2.0, 11-14)

8

mm

(0.31

in)

dia.

[O.J

20-25 (2.0 -2.5, 14-18)

12 mm (0.47 in)dia.

~ 10•20 (1.0 -2.0, 87•174)

6 mm (0.24 in)dia.

Thermo controlamp.

High-pressure (Discharge)servicevalve

o

(Tightening torque)

o

0

(Wrench size)

o

(O-ring size)

[O.J :

N'm (kg-m, It-Ib)

B :

25 -34 (2.5 -3.5, 18-25)

~ :N'm (kg-m, in-Ib)

[SJ

:10 -20 (1.0 -2.0,87 -174)

[Q :

8 -11 (0.8 -1.1, 69-95)

[Q] :

2.9 •3.9 (0.3 -0.4, 26-35)

HA-74

Cooling

unit

Low-pressure (Suction)service

valve

Liquid tank

RHA335F

Page 1477 of 1701

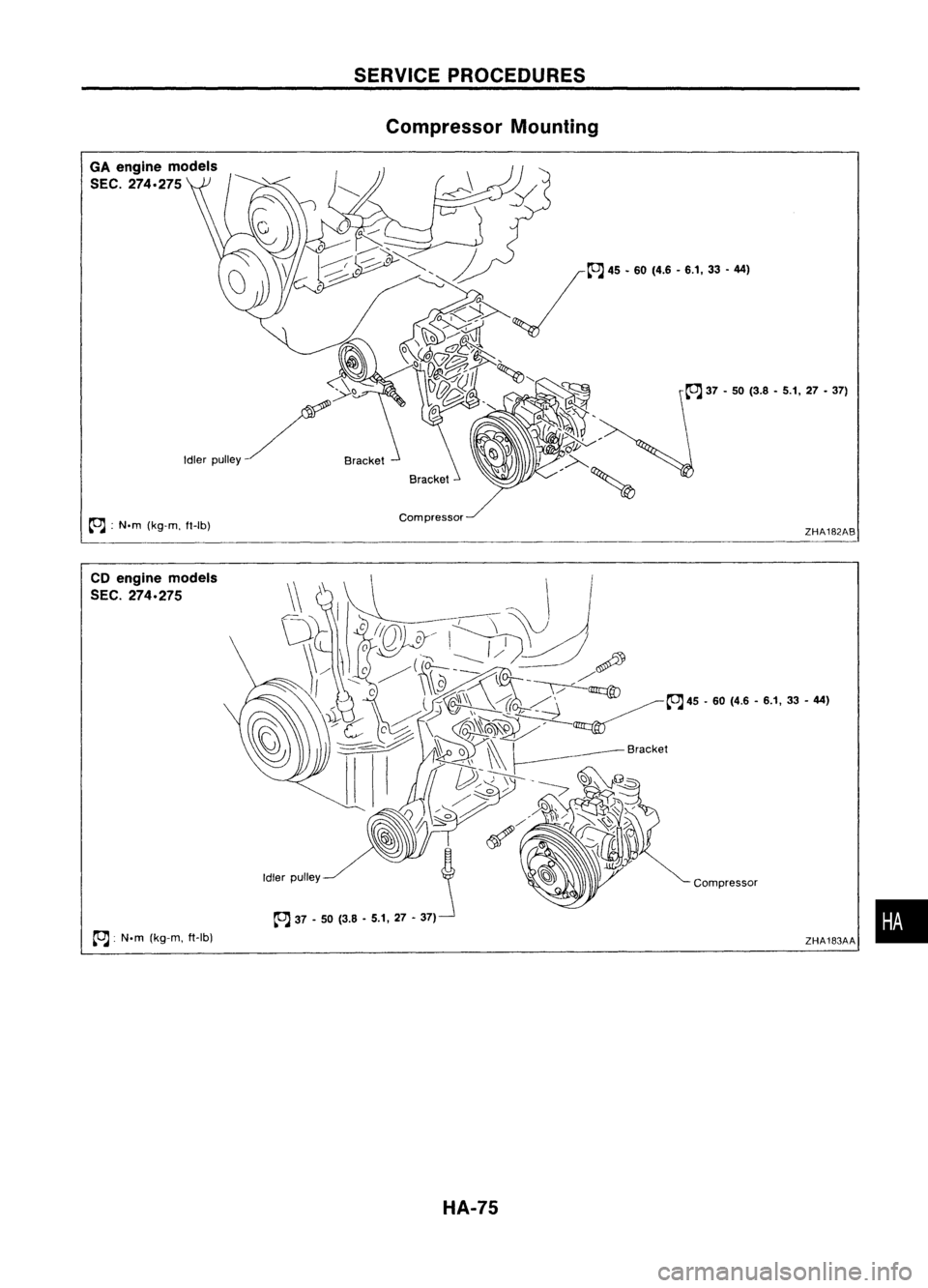

GAengine models

SEC.

274.275

~ :N.m (kg-m, ft-Ib)

CD engine models

SEC.

274.275

~ :N.m (kg-m, ft-Ib)

SERVICE

PROCEDURES

Compressor Mounting

HA-75 ZHA182AB

ZHA183AA •

Page 1478 of 1701

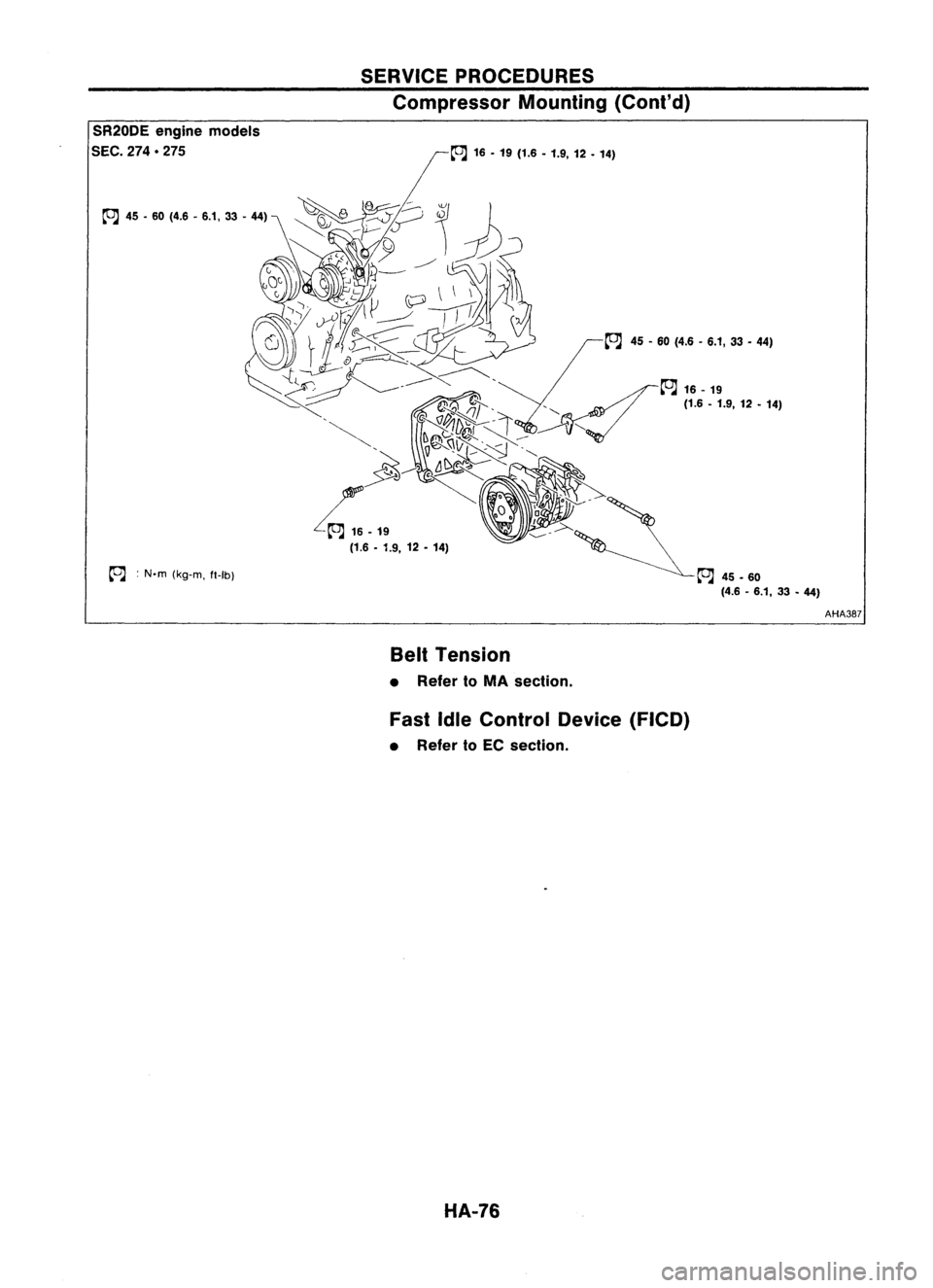

SR20DEenginemodels

SEC.

274.275

~ :N.m (kg-m, ft-Ib)

SERVICE

PROCEDURES

Compressor Mounting(Cont'd)

~ 16•19 (1.6 •1.9, 12•14)

~ 45-60 (4.6 -6.1, 33•44)

~45.60 (4.6-6.1, 33•44)

Belt Tension

• Refer toMA section.

Fast IdleControl Device(FICO)

• Refer toEC section.

HA-76 AHA387

Page 1479 of 1701

SERVICEPROCEDURES

Compressor -Model DKV-11D andDKV-14D

(ZEXEL make)

SHA927DB

SEC.

274

Clutchdisc ~4

-6

(0.4 -0.6, 35•52)

Thermalprotector

~ 15-18 (1.5 -1.8, 11•13)

~ :N'm (kg-m, in-Ib)

~ :N'm (kg-m, ft-Ib)

Drive plate

Shim SHA098EA Compressor

Clutch

REMOVAL

• When removing centerbolt,holdclutch discwithclutch disc

wrench.

• Remove thedrive plateusing ToolKV99232340.

Insert holder's threepinsintothedrive plate. Rotate the

holder clockwise tohook itonto theplate. Then, tighten the

center bolttoremove thedrive plate.

When tightening thecenter bolt,insert around bar

(screwdriver, etc.)between twoofthe pins (asshown inthe

left-hand figure)toprevent driveplaterotation. Afterremov-

ing the drive plate, remove theshims fromeither thedrive

shaft orthe drive plate.

HA-77

•

Page 1480 of 1701

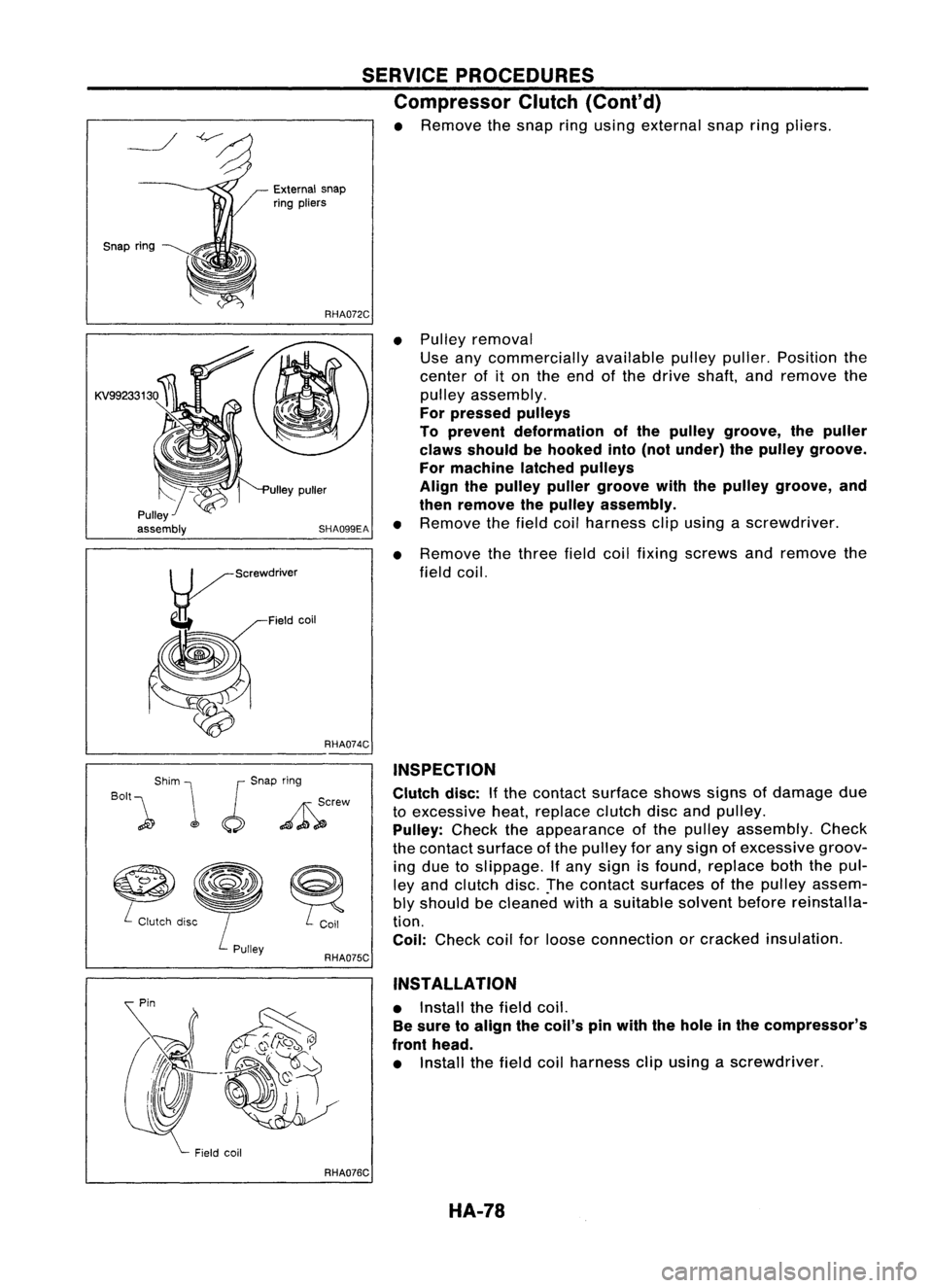

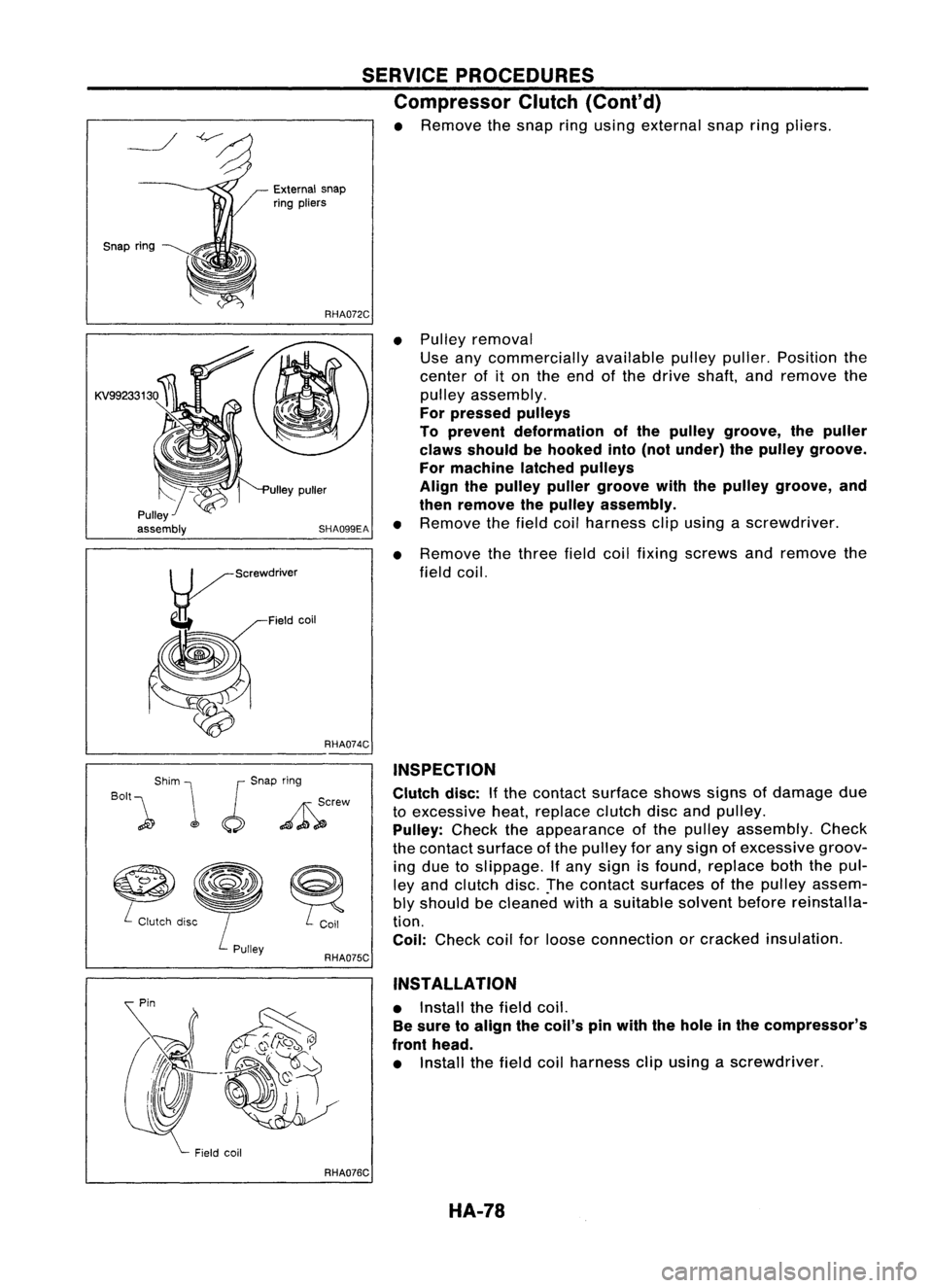

•Pulley removal

Use anycommercially availablepulleypuller. Position the

center ofiton the end ofthe drive shaft, andremove the

pulley assembly.

For pressed pulleys

To prevent deformation ofthe pulley groove, thepuller

claws should behooked into(not under) thepulley groove.

For machine latchedpulleys

Align thepulley pullergroove withthepulley groove, and

then remove thepulley assembly.

• Remove thefield coilharness clipusing ascrewdriver.

• Remove thethree fieldcoilfixing screws andremove the

field coil.

SERVICE

PROCEDURES

Compressor Clutch(Cont'd)

• Remove thesnap ringusing external snapringpliers.

RHA072C

SHA099EA

External

snap

ring pliers

ulley puller

~/S"'wd""'"

g-

Fieldcoil

Snap

ring

KV99233130

RHA074C

Shim

J

Snap ring

BOll\

1

JJ _

~crew

~

~

L

Clutch disc

RHA075CINSPECTION

Clutch disc:Ifthe contact surface showssignsofdamage due

to excessive heat,replace clutchdiscandpulley.

Pulley: Checktheappearance ofthe pulley assembly. Check

the contact surface ofthe pulley forany sign ofexcessive groov-

ing due toslippage. Ifany sign isfound, replace boththepul-

ley and clutch disc.!hecontact surfaces ofthe pulley assem-

bly should becleaned withasuitable solventbeforereinstalla-

tion.

Coil: Check coilforloose connection orcracked insulation.

INSTAllATION

• Install thefield coil.

Be sure toalign thecoil's pinwith thehole inthe compressor's

front head.

• Install thefield coilharness clipusing ascrewdriver.

RHA076C HA-78

Trending: service indicator, coolant, Check engine light, fuel pressure, air condition, length, fuel type