boot NISSAN ALMERA N15 1995 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 300 of 1701

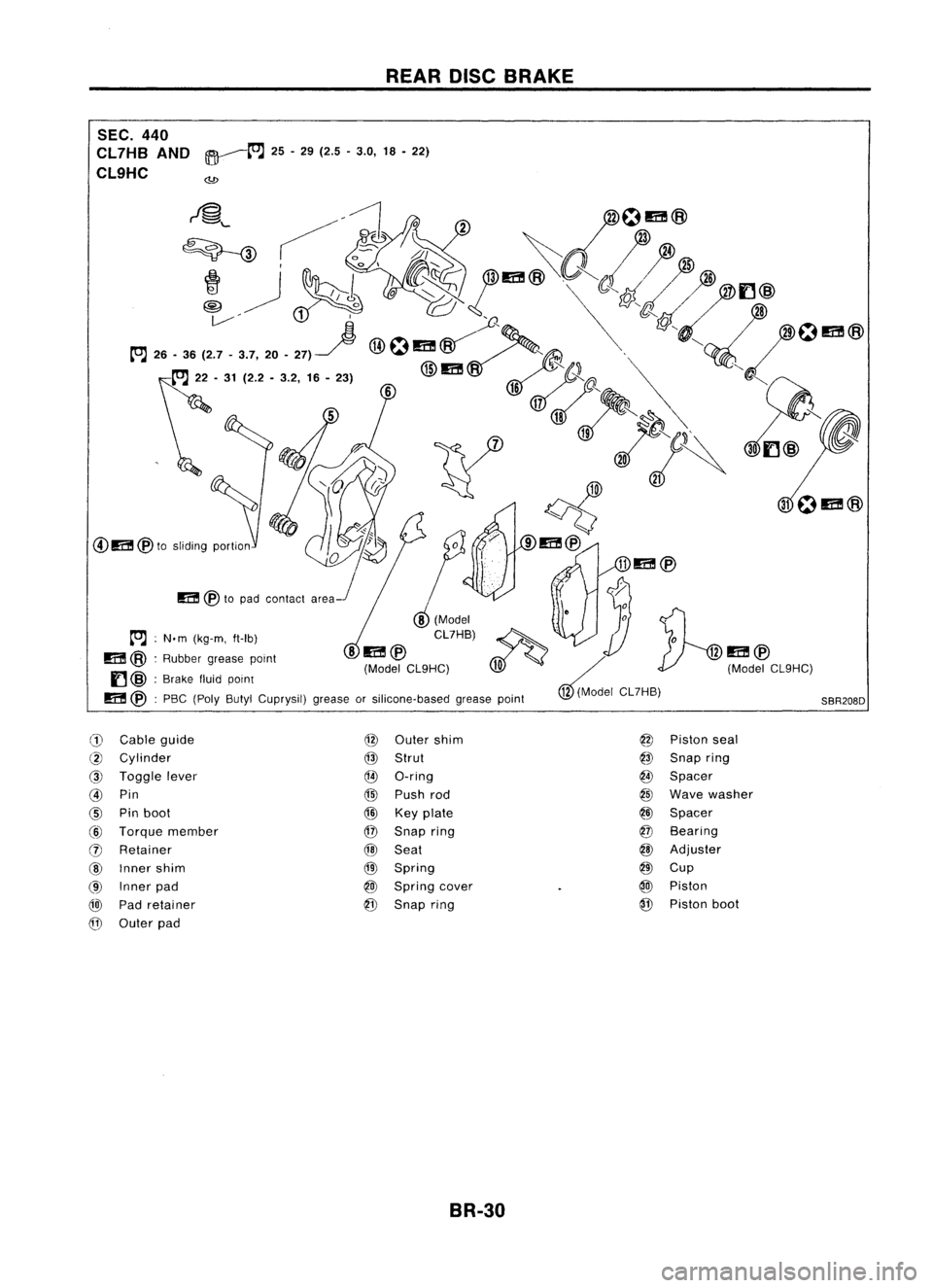

REARDISCBRAKE

SBR208D

Piston seal

@

@

Snap ring

@

Spacer

Wave washer

@

@l

Spacer

@

Bearing

@

Adjuster

@'J

Cup

@)

Piston

@

Piston boot

18

-22)

~ 25-29 (2.5 -3.0,

~

Cable guide

Cylinder

Toggle lever

Pin

Pin boot

ember

Torque m

Retainer

Inner shim

Inner pad

Pad retainer

Outer pad

SEC.

440

CL7HB AND

CL9HC

!

@m@to

,Ii""

pmli"

J

m

@to

p,d ,,,,,,, ""

@~~~:':'~) ~' ~

:d~CL9HC)

II-'b) •

m@

@

'f /

B)

""" .N.m (kg-m,. (ModelCL9HC) @(ModelCL7H

,-,

- "pom' .

'i'i' ,Robb" "" d""" pom'

m'O'

kfluid point eor silicone-base

in

@ :

Bra e Cuprysil)greas

U BC(Poly Butyl

m

@,

p

@

Oo'e"him

@

Strut

@

O-ring

@

Push rod

@

Keyplate

@

Snap ring

@

Seat

@

Spring

@l

Spring cover

@

Snap ring

CD

@

@

@

@

(6)

(j)

@

@

@

@

BR-30

Page 302 of 1701

l

--,II

~//

SBR656

SBR026D REAR

DISCBRAKE

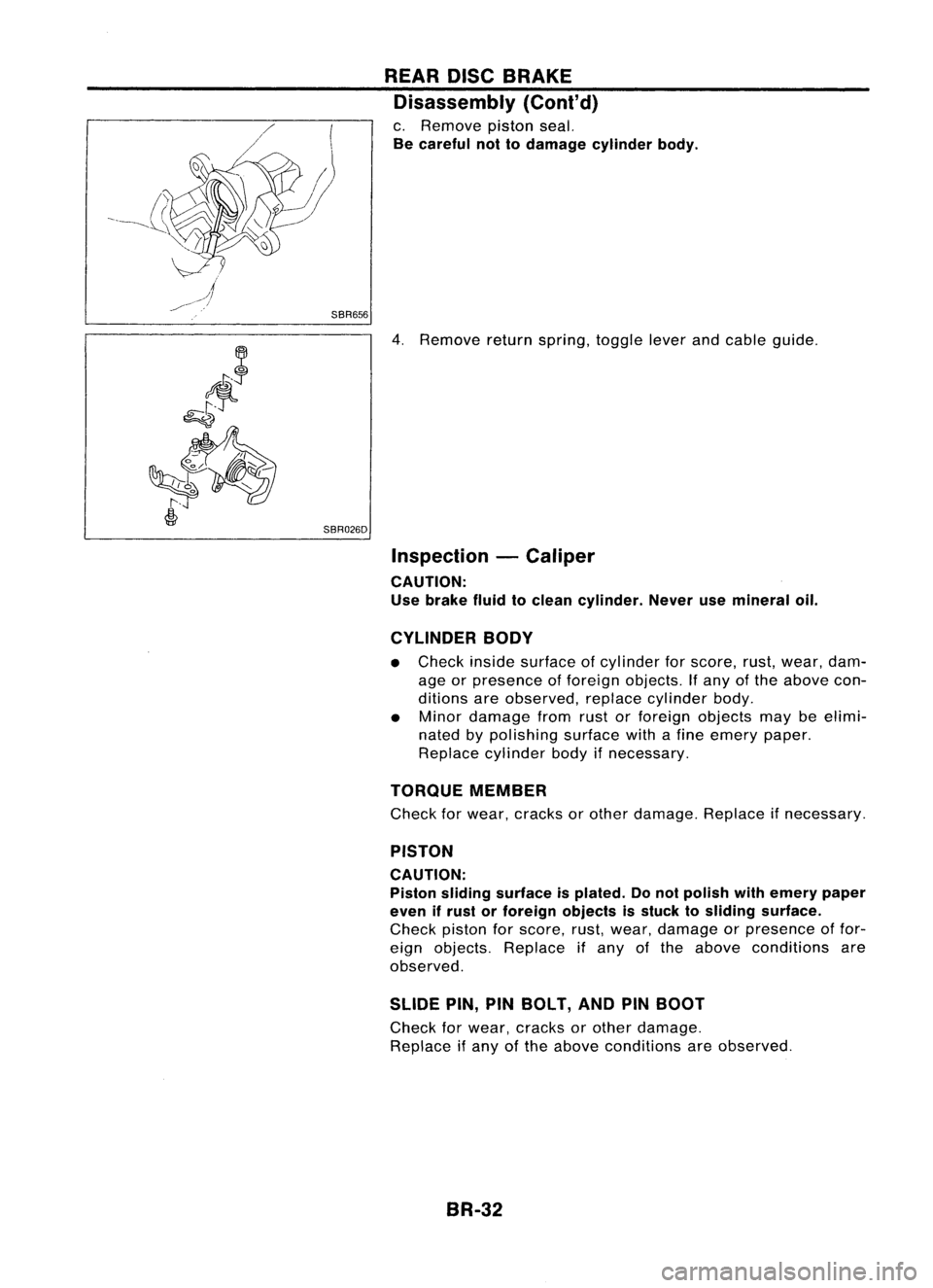

Disassembly (Cont'd)

c. Remove pistonseal.

Be careful nottodamage cylinderbody.

4. Remove returnspring, toggleleverandcable guide.

Inspection -Caliper

CAUTION: Use brake fluidtoclean cylinder. Neverusemineral

oil.

CYLINDER BODY

• Check insidesurface ofcylinder forscore, rust,wear, dam-

age orpresence offoreign objects. Ifany ofthe above con-

ditions areobserved, replacecylinder body.

• Minor damage fromrustorforeign objects maybeelimi-

nated bypolishing surfacewithafine emery paper.

Replace cylinder bodyifnecessary.

TORQUE MEMBER

Check forwear, cracks orother damage. Replaceifnecessary.

PISTON

CAUTION:

Piston sliding surface ;splated. Donot polish withemery paper

even ifrust orforeign objects isstuck tosliding surface.

Check pistonforscore, rust,wear, damage orpresence offor-

eign objects. Replace ifany ofthe above conditions are

observed.

SLIDE PIN,PINBOLT, ANDPINBOOT

Check forwear, cracks orother damage.

Replace ifany ofthe above conditions areobserved.

BR-32

Page 305 of 1701

SBR646REAR

DISCBRAKE

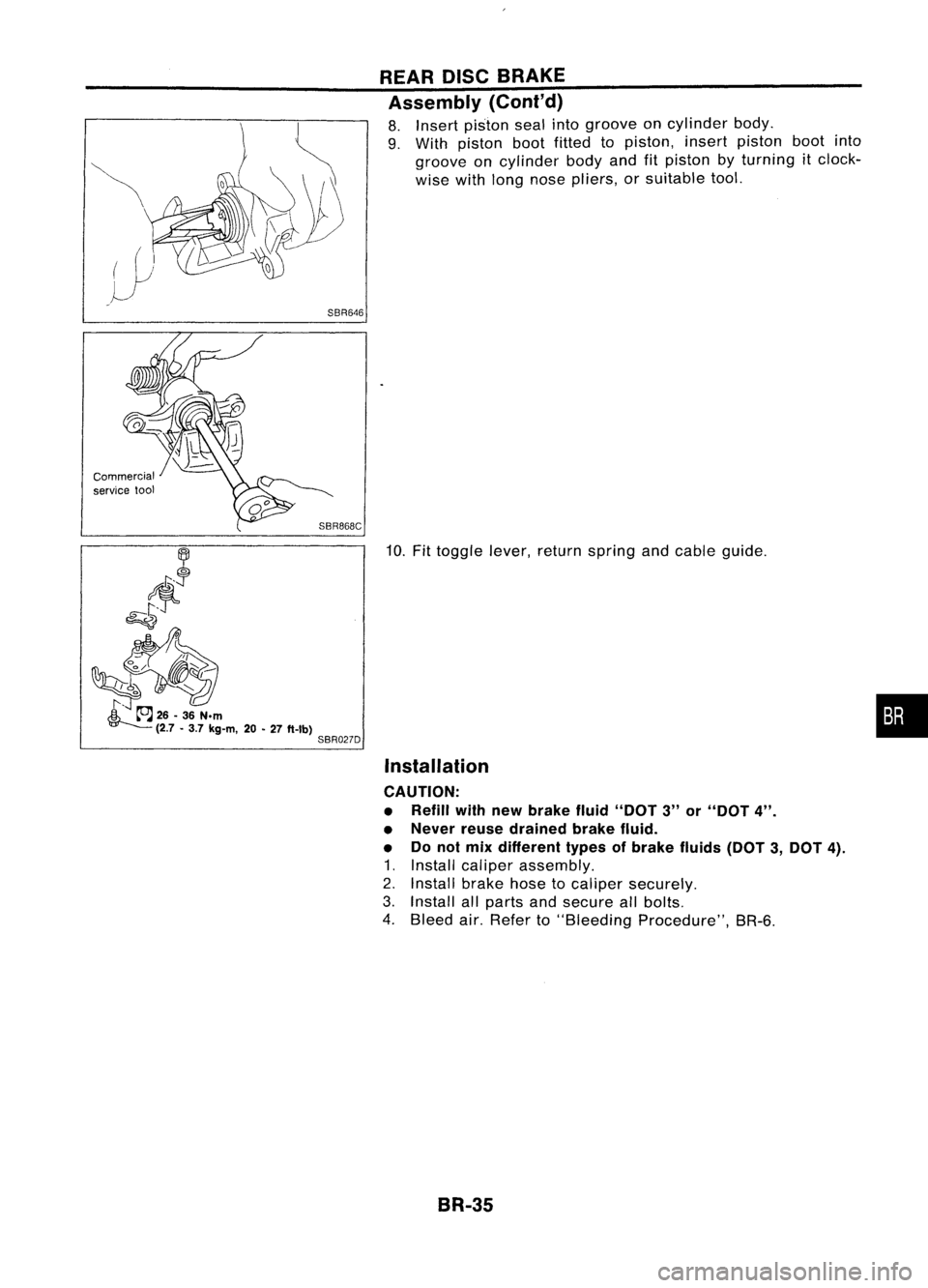

Assembly (Cont'd)

8. Insert piston sealintogroove oncylinder body.

9. With piston bootfitted topiston, insertpiston bootinto

groove oncylinder bodyandfitpiston byturning itclock-

wise withlong nose pliers, orsuitable tool.

Commercial

service

1001

SBR868C

10.Fittoggle lever,return spring andcable guide.

Installation

CAUTION:

• Refill withnewbrake fluid"DOT 3"or"DOT

4".

• Never reusedrained brakefluid.

• Donot mix different typesofbrake fluids(DOT3,DOT

4).

1. Install caliper assembly.

2. Install brakehosetocaliper securely.

3. Install allparts andsecure allbolts.

4. Bleed air.Refer to"Bleeding Procedure", BR-6.

BR-35

•

Page 306 of 1701

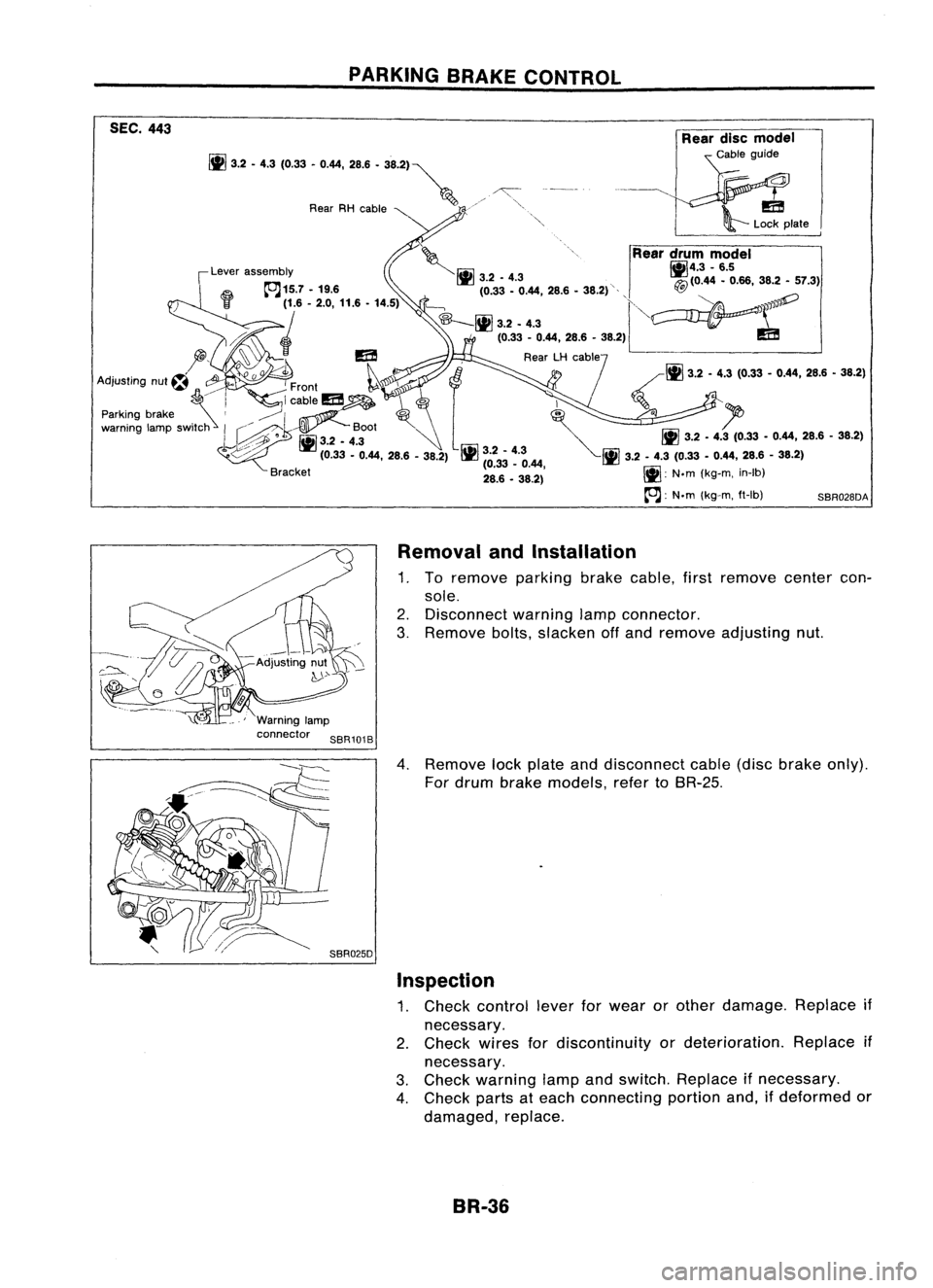

PARKINGBRAKECONTROL

ItJ

3.'.'~ (0.33.0.... 28.6 •38.2)~

Rear RHcable "'"

SEC.

443

\;..,Reardrum model

,Lever assembly

~r.iil

~4.3-6.5

I

llrJ

3.2•4.3 "~(0.44 •0.66, 38.2•57.3)

~ ~15.7 -19.6 (0.33.0.44,28.6.38.2)

','(5' ..--,

jjf ..

(y -

2.0, 11.6 •14.5) ~1iI3.2 •4.3

"""'...~)\)')'))Jl--'

/, f

(0.33-0.44, 28.6-38.2)

m

" ,RearLHcab7e

Ad'

t t~

J,

e

r

<~

3.2•4.3 (0.33 -0.44, 28.6•38.2)

IUS

Ing nu~ ~'

I

Front \

~/ i

!cablem. ~\ I

Parking brake ,,~'::\'

I'

<> ~ ~

warning lampswitch

I

(~./?' ~

Boot /-

JJ~?

iii

3.2•4.3 ~3.2.4.3 (0.33 •0.44, 28.6-38.2)

~ M___

(0.33•0.44, 28.6-38.2)

iii

~ci~3; ~'~.44,

II]

3.2•4.3 (0.33 •0.44',28.6 -38.2)

Bracket

28.6_38.2)

Ill:

N.m(kg-m, In-Ib)

~: N.m(kg-m, ft-Ib) SBR028DA

Removal andInstallation

1. To remove parkingbrakecable, firstremove centercon-

sole.

2. Disconnect warninglampconnector.

3. Remove bolts,slacken offand remove adjusting nut.

4. Remove lockplate anddisconnect cable(discbrake only).

For drum brake models, refertoBR-25.

Inspection

1. Check control leverforwear orother damage. Replaceif

necessary.

2. Check wiresfordiscontinuity ordeterioration. Replaceif

necessary.

3. Check warning lampandswitch. Replace ifnecessary.

4. Check partsateach connecting portionand,ifdeformed or

damaged, replace.

BR-36

Page 539 of 1701

WIPERANDWASHER

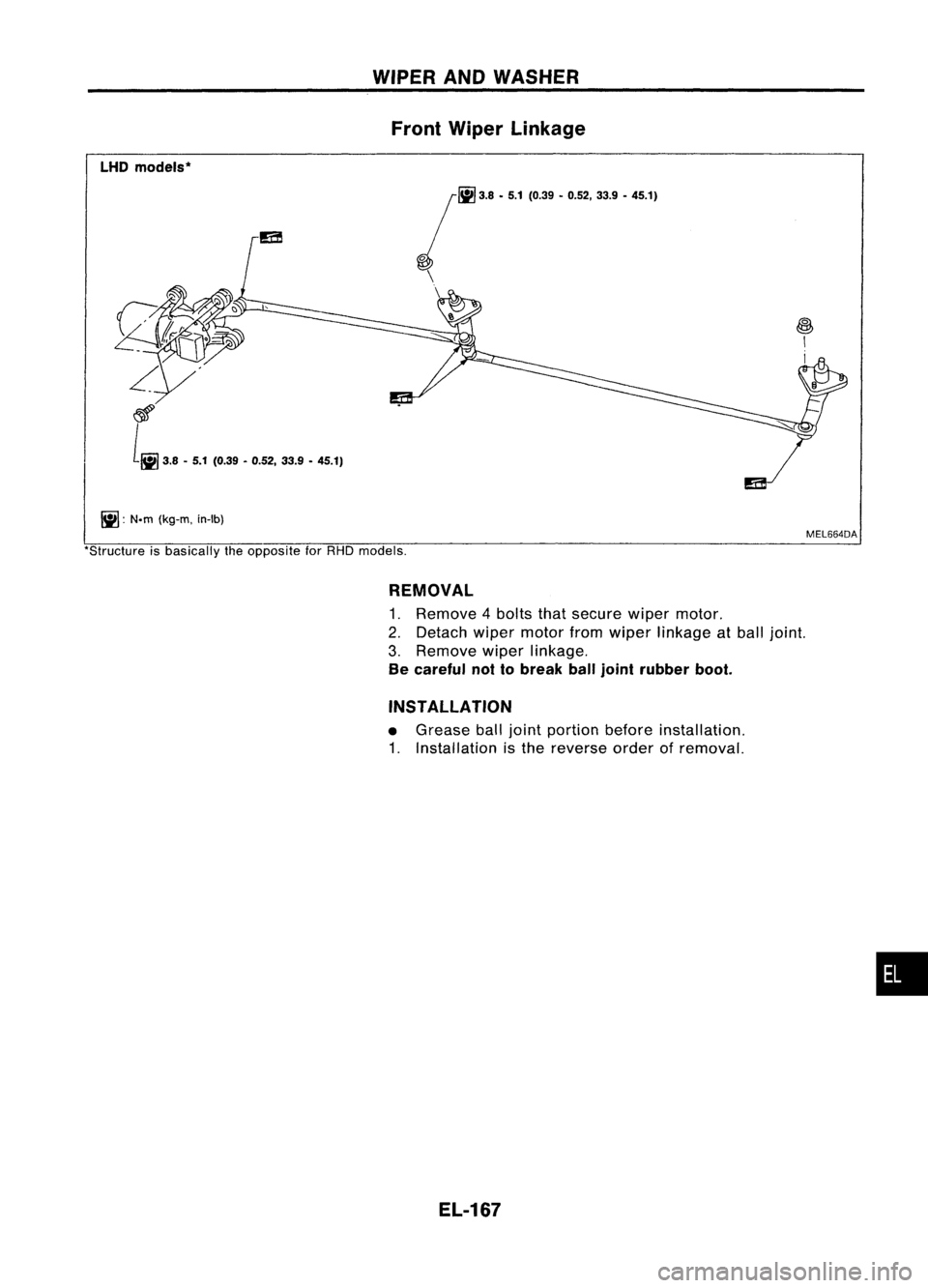

Front Wiper Linkage

LHD models*

jfiiJ

'.8.5.1('."•'.52, ".9.45.1)

\

\

~: N.m(kg-m, in-Ib)

~

I

I

MEL664DA

'Structure isbasically theopposite forRHD models,

REMOVAL

1. Remove 4bolts thatsecure wipermotor.

2. Detach wipermotor fromwiper linkage atball joint.

3. Remove wiperlinkage.

Be careful nottobreak balljoint rubber boot.

INSTALLATION

• Grease balljoint portion beforeinstallation.

1. Installation isthe reverse orderofremoval.

EL-167

•

Page 691 of 1701

SFA113AASFA114A

FRONT

AXLE

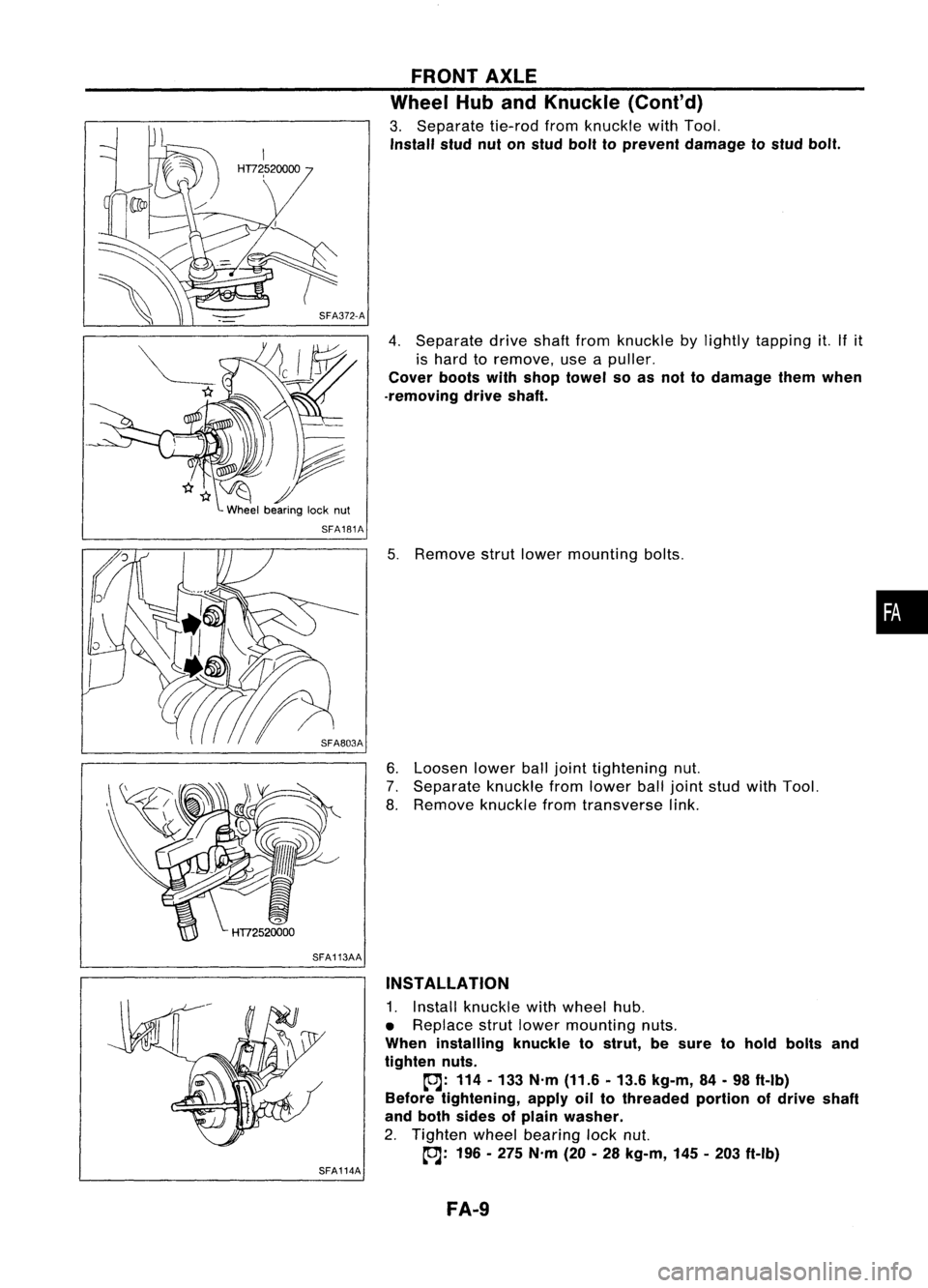

Wheel HubandKnuckle (Conl'd)

3. Separate tie-rodfromknuckle withTool.

Install studnutonstud bolttoprevent damage tostud bolt.

4. Separate driveshaftfrom knuckle bylightly tapping it.Ifit

is hard toremove, useapuller.

Cover bootswithshop towel soas not todamage themwhen

-removing driveshaft.

5. Remove strutlower mounting bolts.

6. Loosen lowerballjoint tightening nut.

7. Separate knucklefromlower balljoint studwithTool.

8. Remove knucklefromtransverse link.

INSTALLATION

1. Install knuckle withwheel hub.

• Replace strutlower mounting nuts.

When installing knuckletostrut, besure tohold bolts and

tighten nuts.

~: 114-133 N'm (11.6 •13.6 kg-m, 84.98 ft.lb)

Before tightening, applyoiltothreaded portionofdrive shaft

and both sides ofplain washer.

2. Tighten wheelbearing locknut.

~: 196-275 N'm (20•28 kg-m, 145-203 ft-Ib)

FA-9

•

Page 695 of 1701

AfTmodel

SFA730FRONT

AXLE

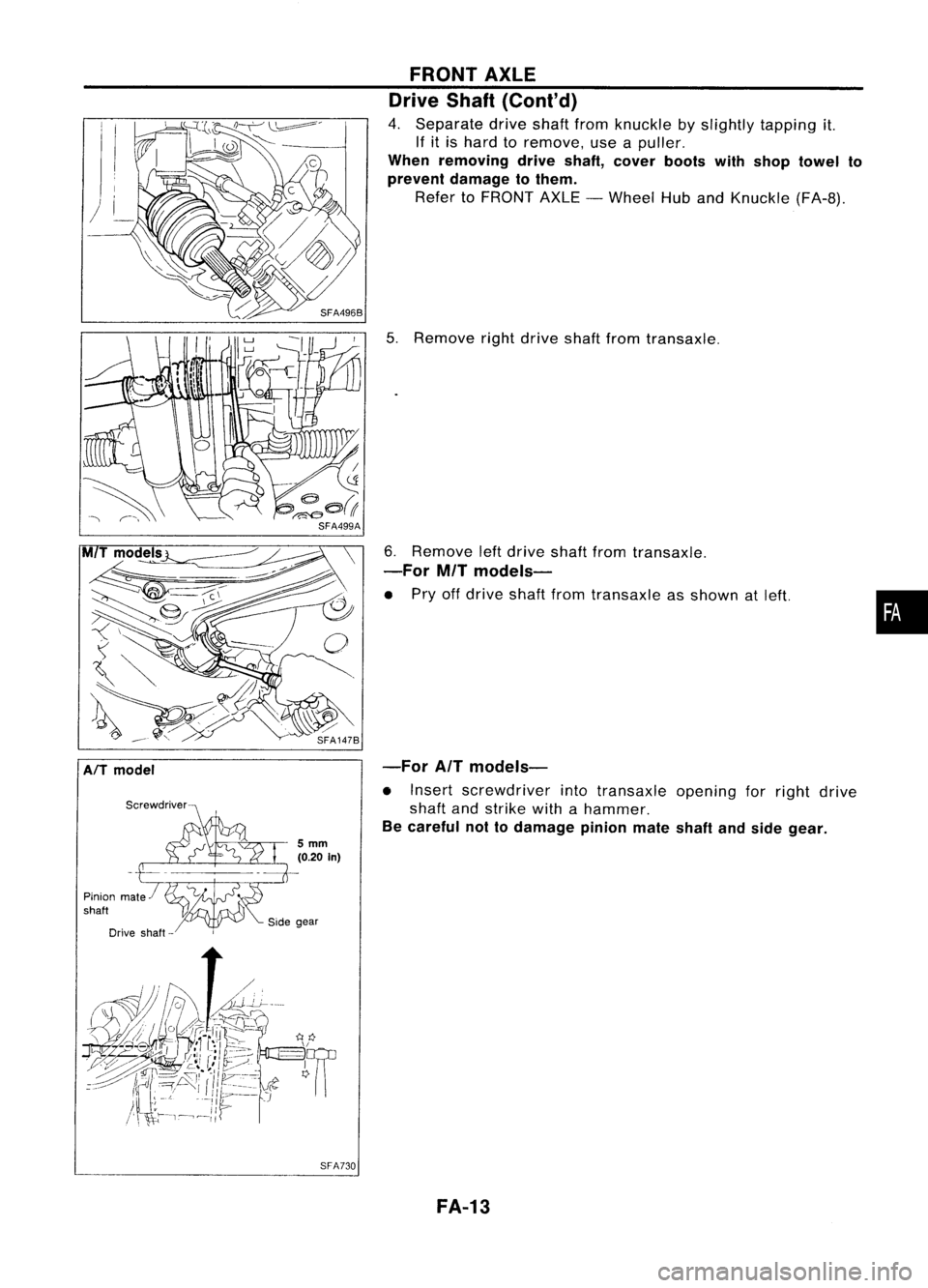

Drive Shaft(Coni' d)

4. Separate driveshaftfromknuckle byslightly tapping it.

If it is hard toremove, useapuller.

When removing driveshaft, cover bootswithshop towel to

prevent damage tothem.

Refer toFRONT AXLE-Wheel HubandKnuckle (FA-8).

5. Remove rightdrive shaftfromtransaxle.

6. Remove leftdrive shaftfromtransaxle.

-For MITmodels-

• Pry offdrive shaftfromtransaxle asshown atleft.

-For AITmodels-

• Insert screwdriver intotransaxle openingforright drive

shaft andstrike withahammer.

Be careful nottodamage pinionmateshaftandside gear.

FA-13

•

Page 697 of 1701

FRONTAXLE

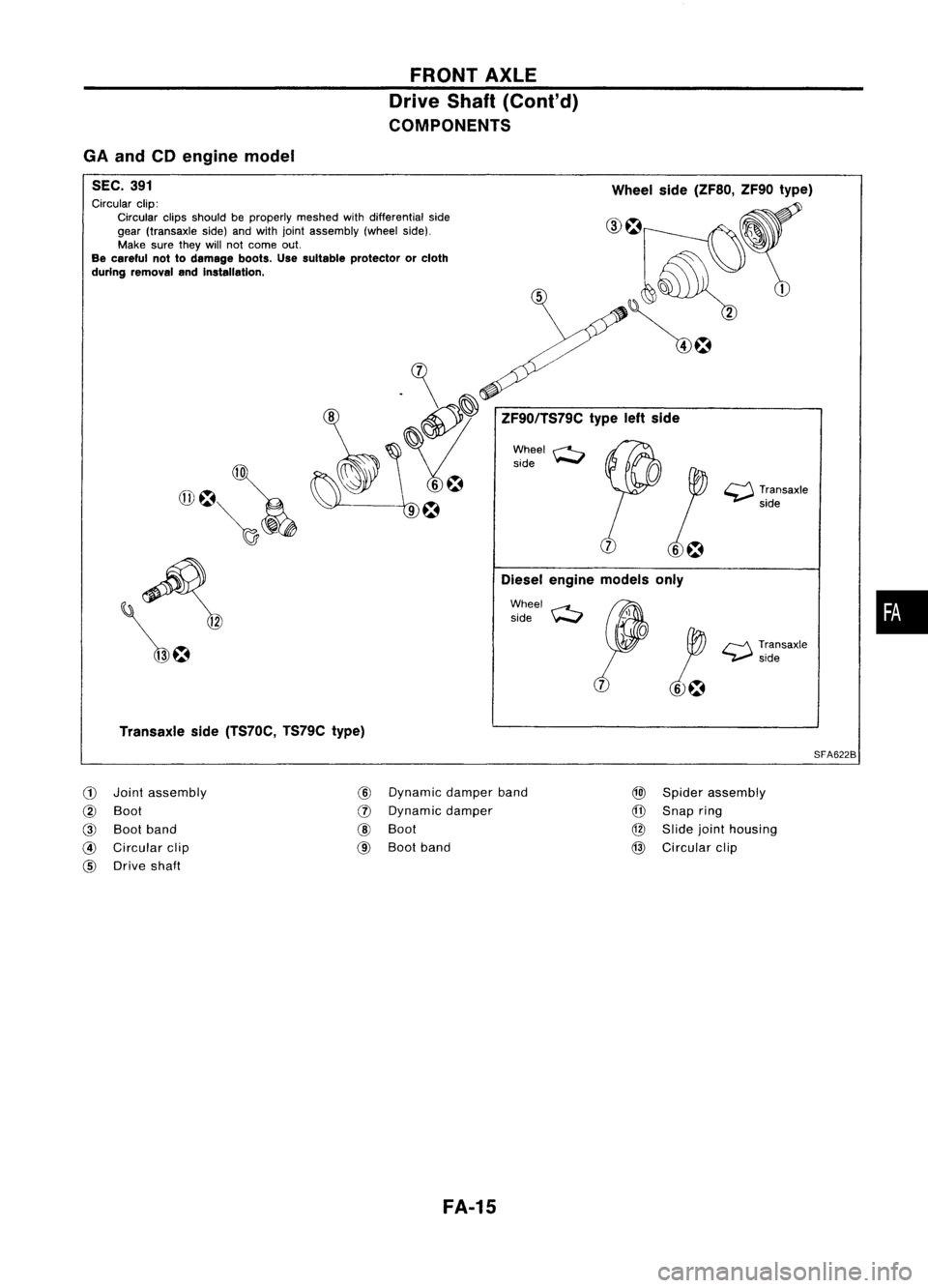

Drive Shaft(Cont'd)

COMPONENTS

ZF90/TS79Ctypeleftside

Diesel engine models only

•

~

Transaxle

side

r-J\

Transaxle

~side

o

p

,~

Wheel

side(ZF80, ZF90type)

Wheel ~

side

Wheel side

8

.~

\~

Circular

clip:

Circular clipsshould beproperly meshedwithdifferential side

gear (transaxle side)andwith joint assembly (wheelside).

Make suretheywillnotcome out.

Be careful nottodamage boots.Usesuitable protector orcloth

during removal andinstallation.

GA

and CDengine model

SEC. 391

Transaxle side(TS70C, TS79Ctype)

SFA622B

CD

Joint

assembly

@

Dynamic damperband

@)

Spider assembly

@

Boot

(J)

Dynamic damper

@

Snap ring

@

Boot band

@

Boot

@

Slide jointhousing

@

Circular clip

@

Boot band

@

Circular clip

@

Drive shaft

FA-15

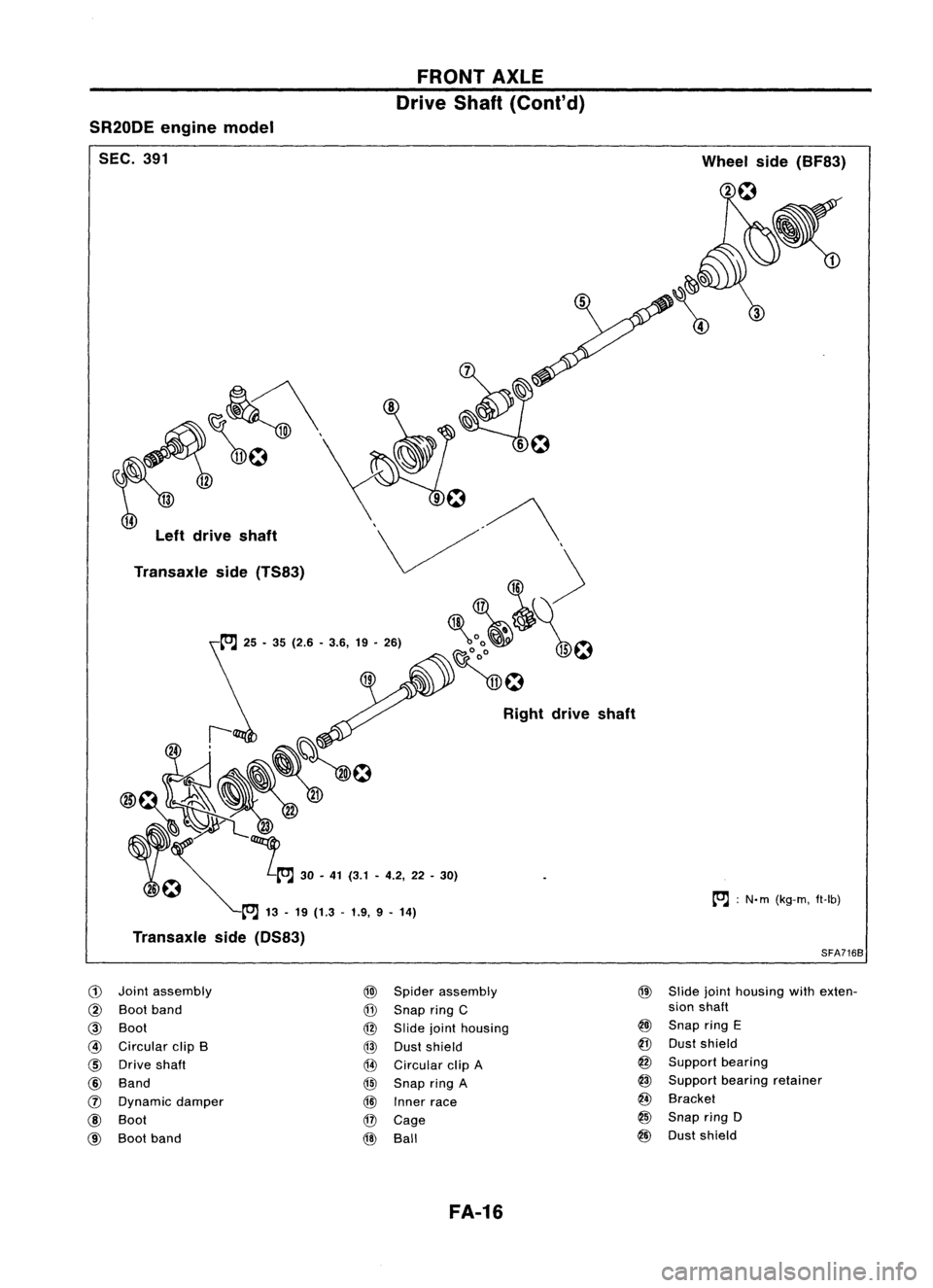

Page 698 of 1701

~RONTAXLE

Drive Sh

f

a t(Cont'd)

Wheelside(BF83)

20

tOJ :

N-m (kg-m,

ft-Ib)

SFA716B

@

Slide jointh'

S'

ouslng,

Ion shaft withexten-

@J

Snap ringE

@

Dustshield

@

S

@

upport bearing

Support bearin

@

Bracket gretainer

@

Snap ring0

@

Dust shield

Right

driveshaft

@l

S'd

@

pierassembly

Snap ringC

@

Slide jointh.

13'

0 ouslng

\!'V

ustshield

@

Circular clipA

@

Snap ringA

@l

Inner race

@

Cage

@

Ball

@~ti~~o

f:~~ 2!~ ~

30.41

(3.1.4.2,22 -301

T ~

13-19 (13

ransaxle side(0 .-

1.9, 9•

14)

S83)

~'Vz~

r:~~

@O'

Left drive h

s aft

Transa I

x

e side (TS83)

tOJ

25.35 (26

.

•3.6,

19.26)

SR20DE

eng-

me model

SEC. 391

G)

Jo'

t

In

assembly

@

Boot band

@

Boot

@

Circular clipB

@

Drive shaft

@

Band

tJ)

Dynamic dam

@

Boot per

@

Boot band

FA-16

Page 699 of 1701

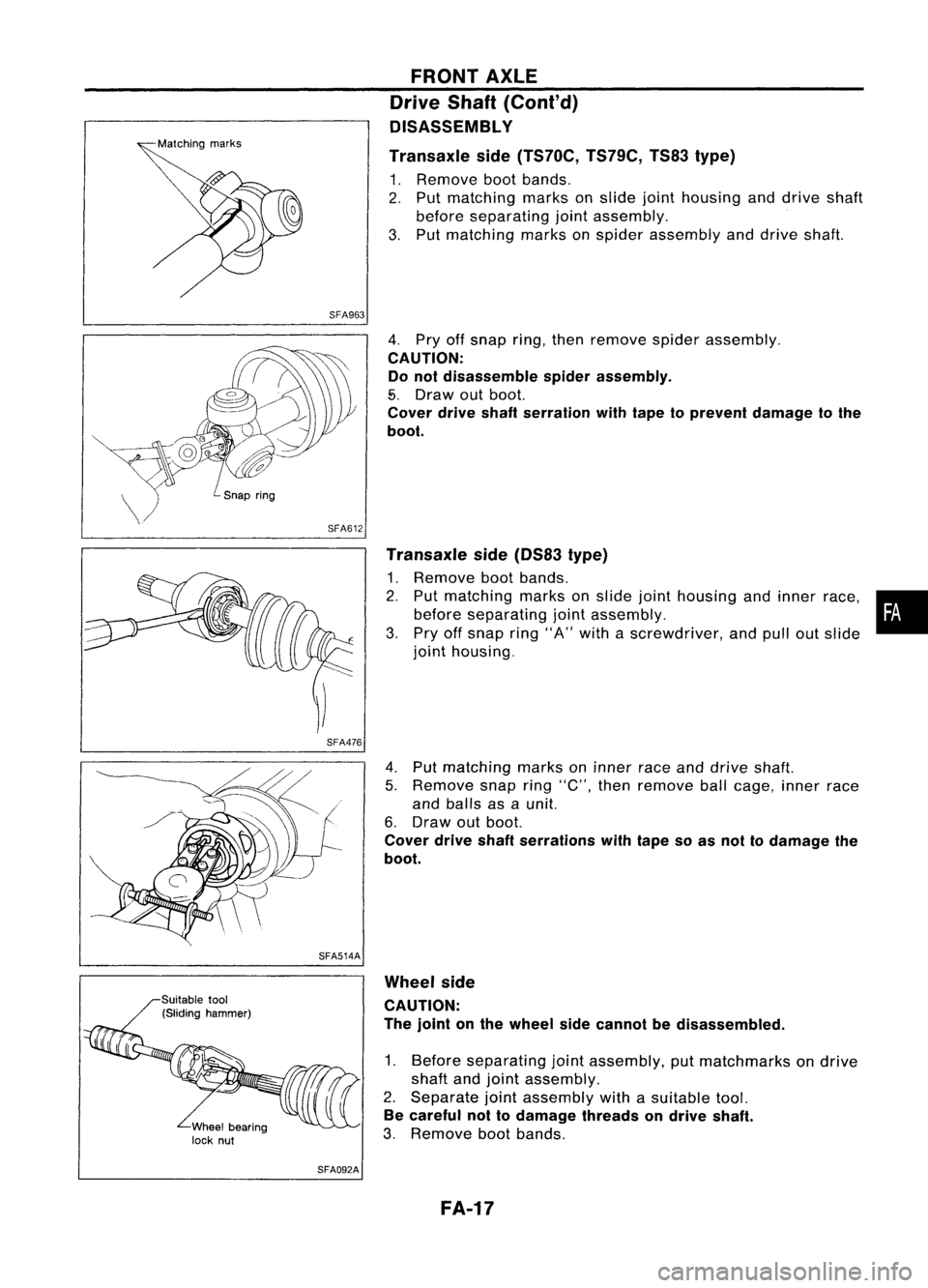

SFA963FRONT

AXLE

Drive Shaft(Cont'd)

OISASSEMBL Y

Transaxle side(TS70C, TS79C,TS83type)

1. Remove bootbands.

2. Put matching marksonslide jointhousing anddrive shaft

before separating jointassembly.

3. Put matching marksonspider assembly anddrive shaft.

SFA476

SFA514A

SFA092A

4.

Pry offsnap ring,thenremove spiderassembly.

CAUTION: Do not disassemble spiderassembly.

5. Draw outboot.

Cover driveshaftserration withtape toprevent damage tothe

boot.

Transaxle side(OS83 type)

1. Remove bootbands.

2. Put matching marksonslide jointhousing andinner race, •

before separating jointassembly.

i

3. Pry offsnap ring"A"with ascrewdriver, andpulloutslide

joint housing.

4. Put matching marksoninner raceanddrive shaft.

5. Remove snapring"C", then remove ballcage, innerrace

and balls asaunit.

6. Draw outboot.

Cover driveshaftserrations withtape soas not todamage the

boot.

Wheel side

CAUTION:

The joint onthe wheel sidecannot bedisassembled.

1. Before separating jointassembly, putmatchmarks ondrive

shaft andjoint assembly.

2. Separate jointassembly withasuitable tool.

Be careful nottodamage threadsondrive shaft.

3. Remove bootbands.

FA-17