boot NISSAN ALMERA N15 1995 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1548 of 1701

SwitchGearposition Continuity

Reverse Yes

Back-up lampswitch

No

Except reverse

Neutral Yes

Neutral position switch

Exceptneutral No

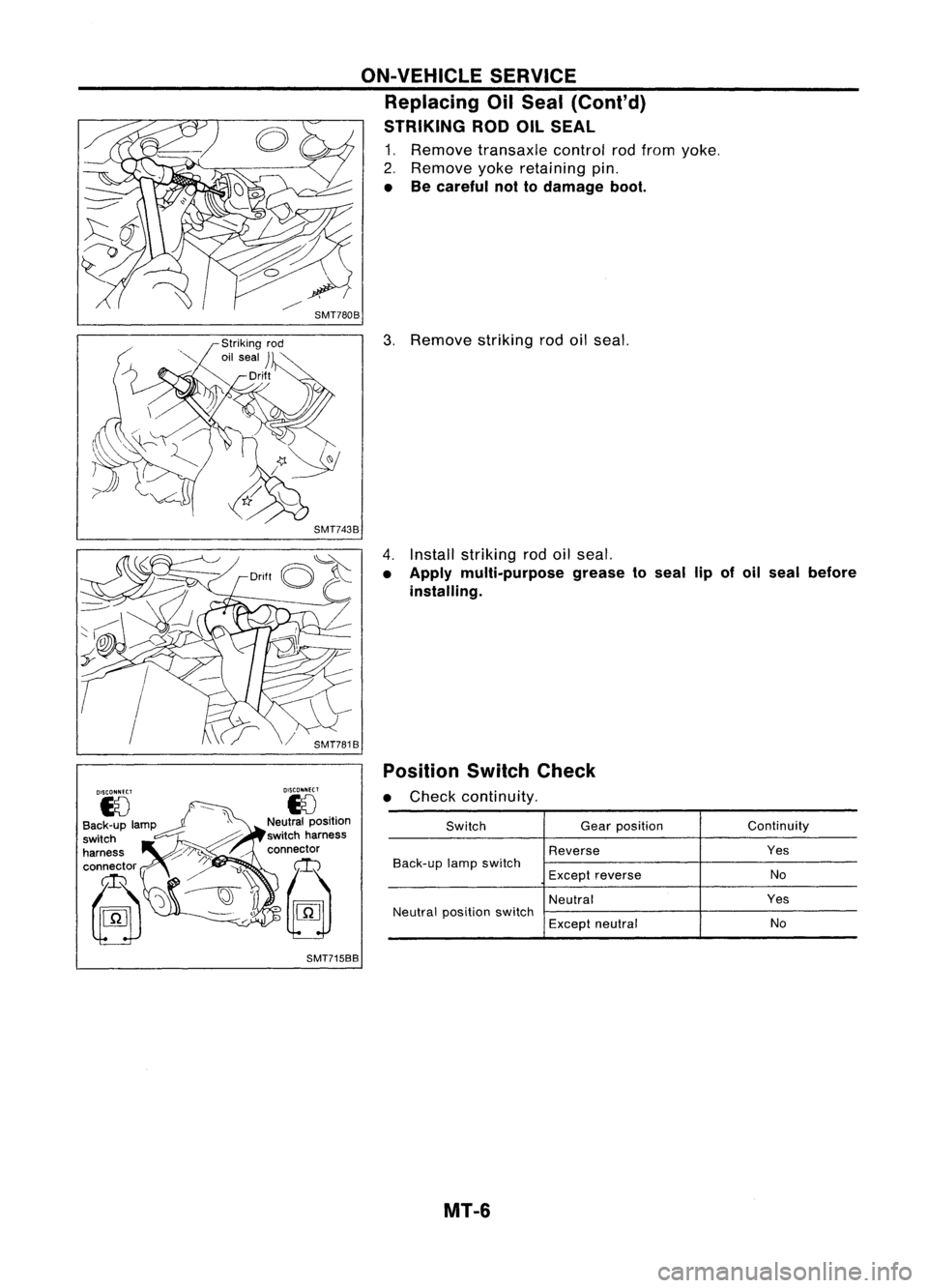

3.

Remove strikingrodoilseal.

Position SwitchCheck

• Check continuity.

4.

Install striking rodoilseal.

• Apply multi-purpose greasetoseal lipofoil seal before

installing.

ON-VEHICLE

SERVICE

Replacing OilSeal (Cont'd)

STRIKING RODOILSEAL

1. Remove transaxle controlrodfrom yoke.

2. Remove yokeretaining pin.

• Becareful nottodamage boot.

DISCONNECT

eJ

Neutral position

switch harness

connector

~ SMT715BB

MT-6

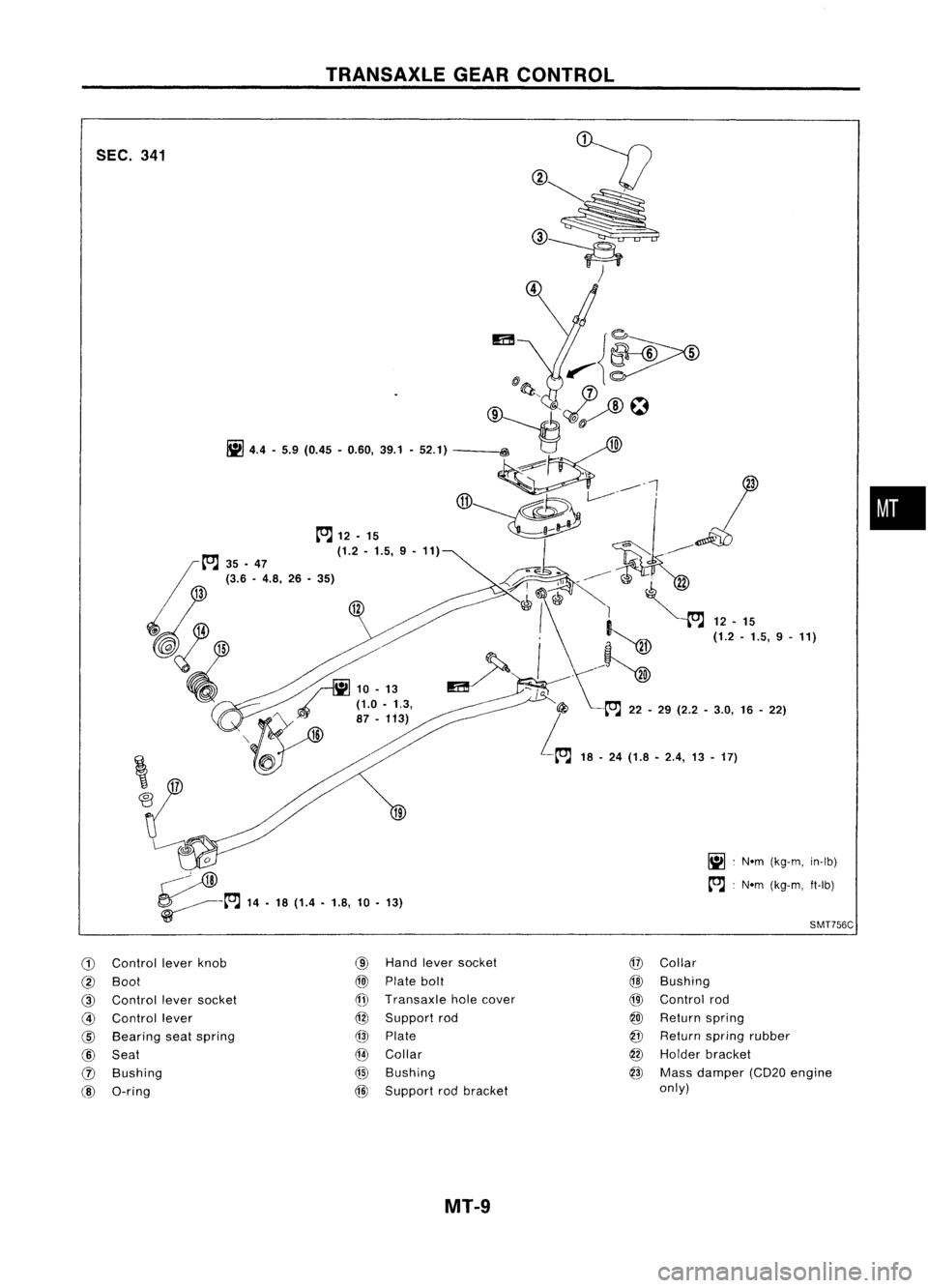

Page 1551 of 1701

TRANSAXlEGEAR

CONTROL

•

~ .Nom (k

g-m, in-Ib)

~ :Nom (kg-m, ft-Ib)

12

~

4.4.5.9 (0.45

•060

.

,39.1. 52.1)

m

.

..--~~

~~O 't~~~

t"J t"J

12•15

(jj)~~~~l '

3

35 •47 (1.2•15

._le'

(3 6 .,9 •11)

~~

-

.

..--~

/" rIiJ

10.13 ~

I\~~ ~ ;~;

'~.5, 9•11)

, {y"'''

(1.0•

1.3, "",/'

>

"@

'\ _Y 87•113)

I

16

iI5J

t

t"J

22•29 (2.2 .

L,

3.0.16•22)

-~ 18.24(1.8 •2

.4, 13•17)

f?:!-

:g.~

~

14. 18(1

W

.4.18 1

.,

O.13)

SEC.

341

Control leverknb

Boot

0

Control leversocke

Control lever t

Bearing seats.

Seat pring

Bushing

O-ring Hand

Iever socket

Plate bolt

Transaxle hI

S

0

e cover

upport rod

Plate

Collar

Bushing

Support rodbracket

@

@

@)

@

@

@

@

Collar

Bushing

Control rod

Return spring

Return s.

pring rubb

Hold er

er bracket

Mass dame

only) pr(CD20 engine

MT-9

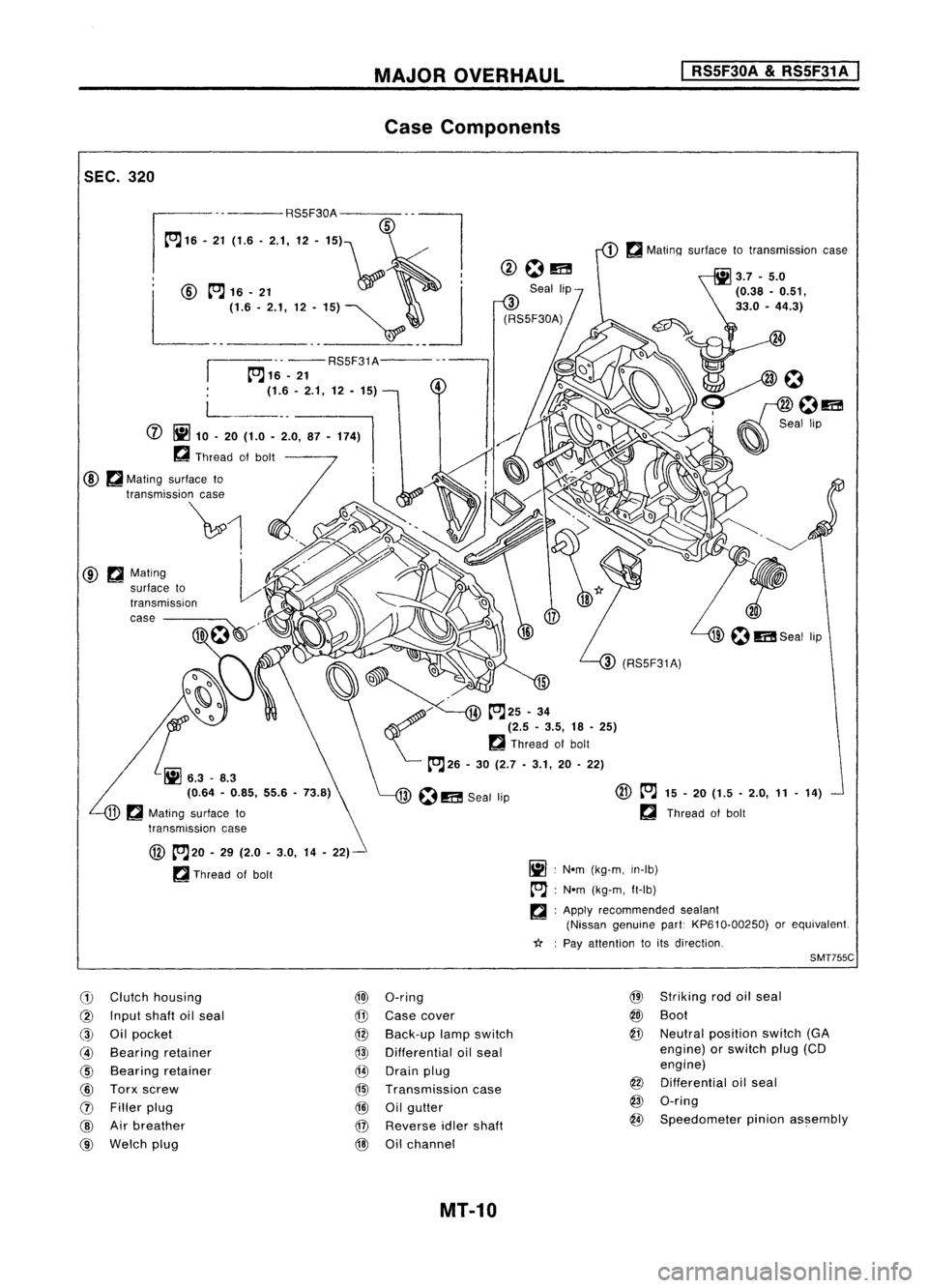

Page 1552 of 1701

SEC.320 MAJOR

OVERHAUL

Case Components

I

RS5F30A

&

RS5F31 A

I

.. -- RS5F31A---

~16 -21

(1.6 -2.1, 12. 15)

@ ~Mating

surface to

transmiSSion

case ----

@

~20 -29 (2.0 -3.0, 14-22)-

~ Thread ofbolt

(1)

Clutch housing

@)

O-ring

@

Input shaftoilseal

@

Case cover

@

Oilpocket

@

Back-up lampswitch

@

Bearing retainer

@

Differential oilseal

@

Bearing retainer

@

Drain plug

@

Torx screw

@l

Transmission case

(J)

Filler plug

@

Oilgutter

@

Airbreather

@

Reverse idlershaft

@

Welch plug

@

Oilchannel

MT-10

@

~

15-20 (1.5 -2.0, 11-14)

~ Thread ofbolt

Ij] :

Nom (kg-m, in-Ib)

tr'J :

Nom (kg-m, ft-Ib)

~ :Apply recommended sealant

(Nissan genuine part:KP610-00250) orequivalent.

*: :

Pay attention toits direction.

SMT755C

@

Striking rodoilseal

@J

Boot

@

Neutral position switch(GA

engine) orswitch plug(CD

engine)

@

Differential oilseal

@

O-ring

@

Speedometer pinionassembly

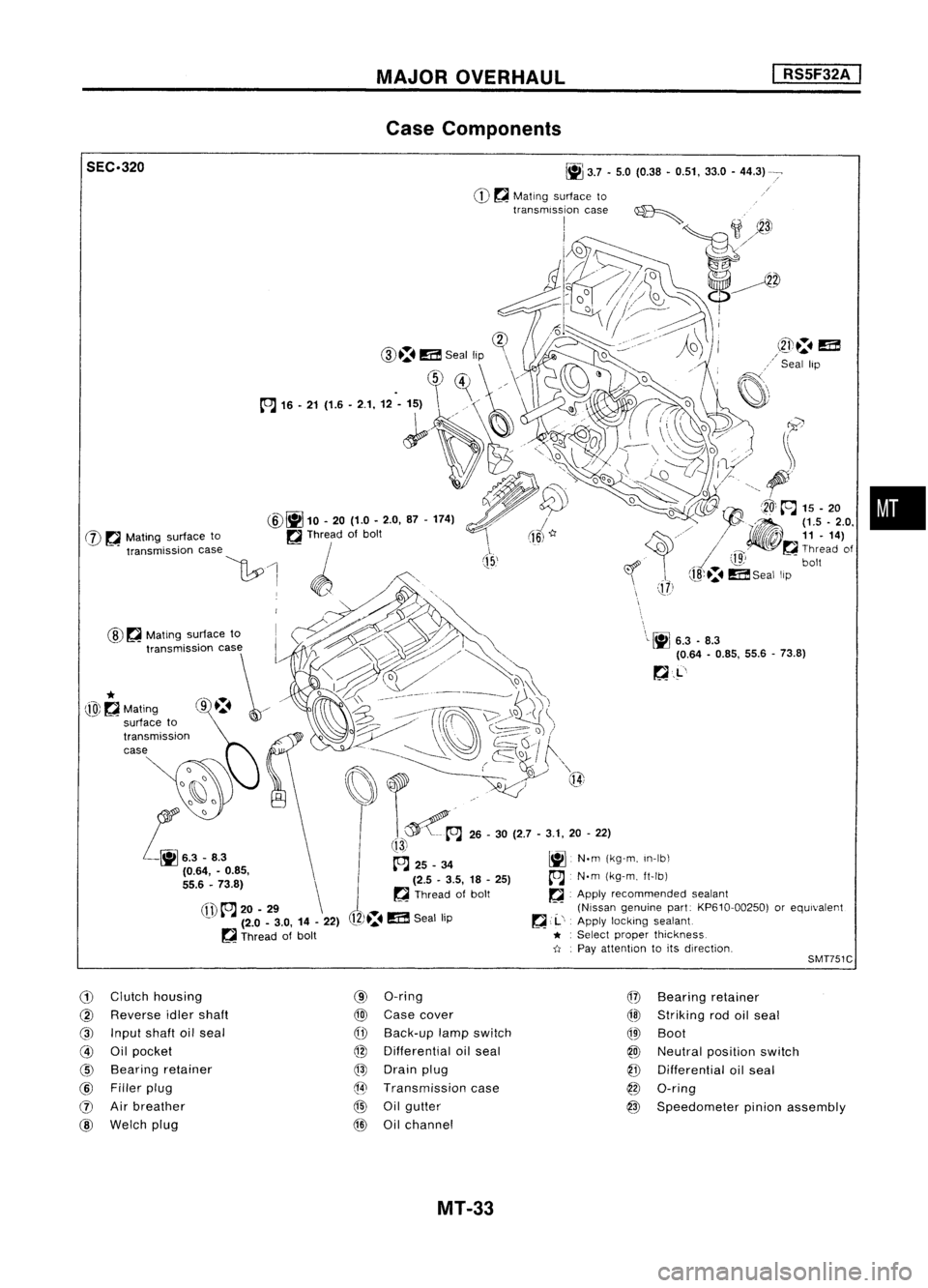

Page 1575 of 1701

MAJOROVERHAUL

I

RS5F32A

I

Case Components

•

\

\L~

6.3.8.3

(0.64 -0.85, 55.6-73.8)

~.L'

J

(15,'

~

3.7•5.0 (0.38 •0.51, 33.0-44.3)

CD ~

Mating surface to

transmission case~

I

;1

~3J

1J2»~

o//~

d~~~

!-~~

i~=1D.

(]?

CID.:.

m

Seal lip \

\

.

~)~

//\

1~

~'

(fl)

to.J

20-29 \

- (2.0-3.0, 14-22)

~ Thread ofbolt

@

~

Mating surface to

SEC.320

@~

10.20 (1.0-2.0, 87-174)

W ~

Mating surface to ~Thread ofbolt

"""mi"ioo '""

\1:.0

1 ~ /',

. WO,,~., .,.~

~~~> '\

t,,~~~~

o

I:::t:\ ~___-- __~

j)\~

~i)~/

(ro\~\~)

. ------ ~~,/ ~Q~

I

f""\

~~~ ..~ Q{

t~A

26-30 (2.7 -3.1, 20-22)

!13i

~ 25_34 ~N.m(kg-m, In-Ib\

(2.5 -3.5, 18-25)

A

N.m(kg-m, ft-Ib)

~ Thread ofbolt ~.Apply recommended sealant

(Nissan genuine part:KP610-00250) orequivalent

12)~.

m

Seal lip ~

,.1..',

Apply locking sealant

* :

Select proper thickness.

-tI .

Pay attention toits direction,

*

@~Mating

SMT751C

G)

Clutch housing

@

Reverse idlershaft

@

Input shaftoilseal

@

Oilpocket

@

Bearing retainer

@

Filler plug

(J)

Airbreather

@

Welch plug

(9)

O-ring

@

Case cover

CfD

Back-up lampswitch

@

Differential oilseal

@

Drain plug

@

Transmission case

@

Oilgutter

@

Oilchannel

@

Bearing retainer

@l

Striking rodoilseal

QID

Boot

@

Neutral position switch

@

Differential oilseal

@

O-ring

@

Speedometer pinionassembly

MT-33

Page 1672 of 1701

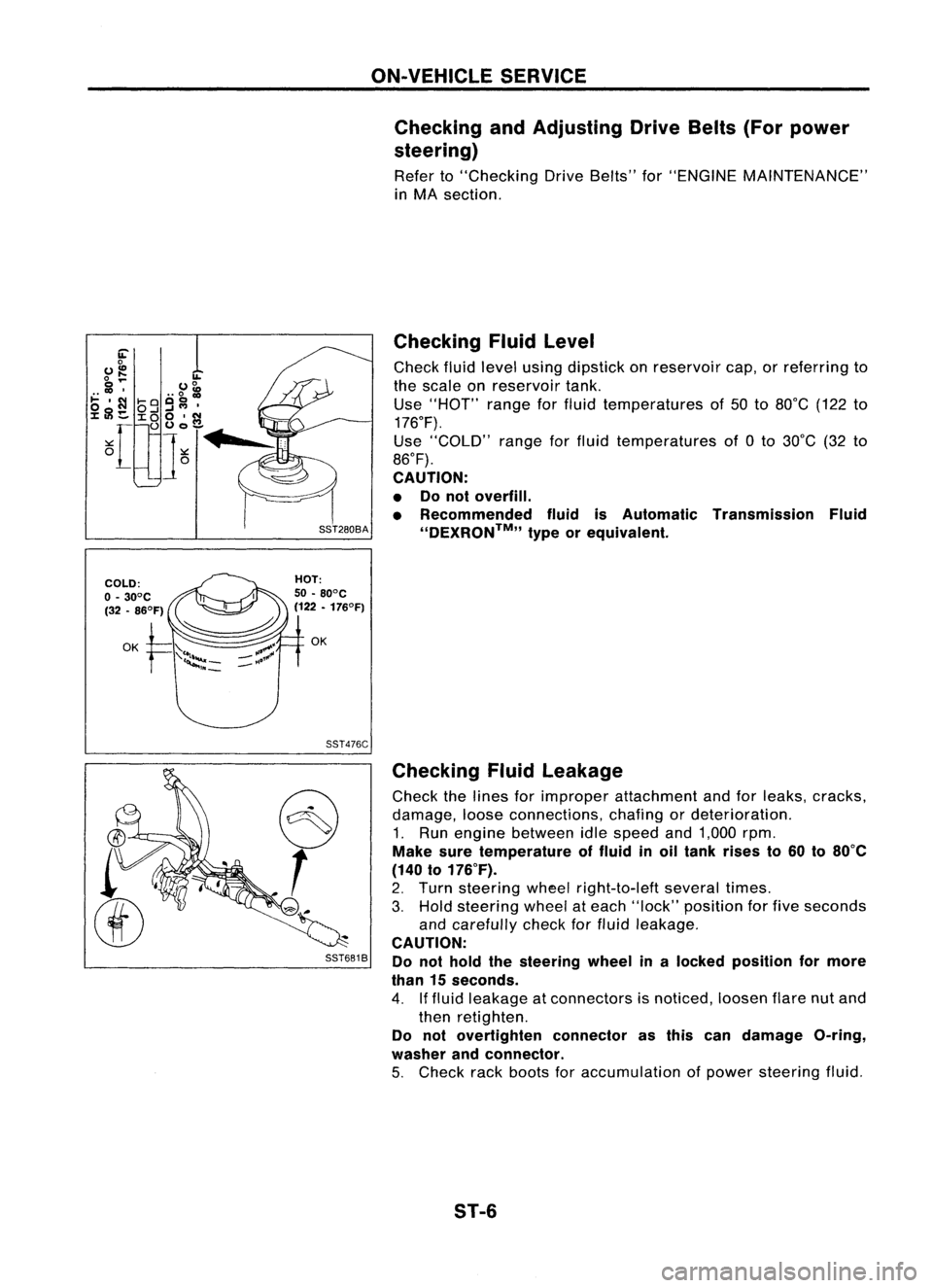

ON-VEHICLESERVICE

Checking andAdjusting DriveBelts(Forpower

steering)

Refer to"Checking DriveBelts" for"ENGINE MAINTENANCE"

in MA section.

SST476C

S

r

SST681B Checking

Fluidlevel

Check fluidlevel using dipstick onreservoir cap,orreferring to

the scale onreservoir tank.

Use "HOT" rangeforfluid temperatures of50 to80°C (122to

176°F).

Use "COLD" rangeforfluid temperatures of0to 30°C (32to

86°F).

CAUTION:

• Donot overfill.

• Recommended fluidisAutomatic Transmission Fluid

''DEXRON™,, typeorequivalent.

Checking Fluidleakage

Check thelines forimproper attachment andforleaks, cracks,

damage, looseconnections, chafingordeterioration.

1. Run engine between idlespeed and1,000 rpm.

Make suretemperature offluid inoil tank rises to60 to80°C

(140 to176°F).

2. Turn steering wheelright-to-Ieft severaltimes.

3. Hold steering wheelateach "lock" position forfive seconds

and carefully checkforfluid leakage.

CAUTION:

Do not hold thesteering wheelinalocked position formore

than 15seconds.

4. Iffluid leakage atconnectors isnoticed, loosenflarenutand

then retighten.

Do not overtighten connectorasthis candamage O-ring,

washer andconnector.

5. Check rackboots foraccumulation ofpower steering fluid.

ST-6

Page 1675 of 1701

![NISSAN ALMERA N15 1995 Owners Guide STEERINGWHEELANDSTEERING COLUMN

Removal andInstallation

SEC. 484.487.488

_~ ~4.0-4.9 (0.4 -0.5, 35-43)

ij] :

N.m (kg-m, in-Ib)

co;J :

N.m (kg-m. ft-Ib) With

airbag

Withoutairbag

SST538C

G)

Airb NISSAN ALMERA N15 1995 Owners Guide STEERINGWHEELANDSTEERING COLUMN

Removal andInstallation

SEC. 484.487.488

_~ ~4.0-4.9 (0.4 -0.5, 35-43)

ij] :

N.m (kg-m, in-Ib)

co;J :

N.m (kg-m. ft-Ib) With

airbag

Withoutairbag

SST538C

G)

Airb](/img/5/57349/w960_57349-1674.png)

STEERINGWHEELANDSTEERING COLUMN

Removal andInstallation

SEC. 484.487.488

_~ ~4.0-4.9 (0.4 -0.5, 35-43)

ij] :

N.m (kg-m, in-Ib)

co;J :

N.m (kg-m. ft-Ib) With

airbag

Withoutairbag

SST538C

G)

Airbag module

@

Horn pad

@

Steering wheel

@

Spiral cable

@

Column cover

@

Combination switch

(J)

Steering columnassembly

@

Lower joint

@

Boot

CAUTION (SRSmodels only): •

• The rotation ofthe spiral cable(SRS"Airbag" component

part) islimited. Ifthe steering gearmust beremoved, set

the front wheels inthe straight-ahead direction.Donot

rotate thesteering columnwhilethesteering gearis

removed.

• Remove thesteering wheelbefore removing thesteering

lower jointtoavoid damaging theSRS spiral cable.

STEERING WHEEL

With AirBag

• Remove airbag module andspiral cable.

Refer to"Removal -Air Bag Module andSpiral Cable",

"SUPPLEMENTAL RESTRAINTSYSTEM"inRS section.

SBF812E ST-9

Page 1678 of 1701

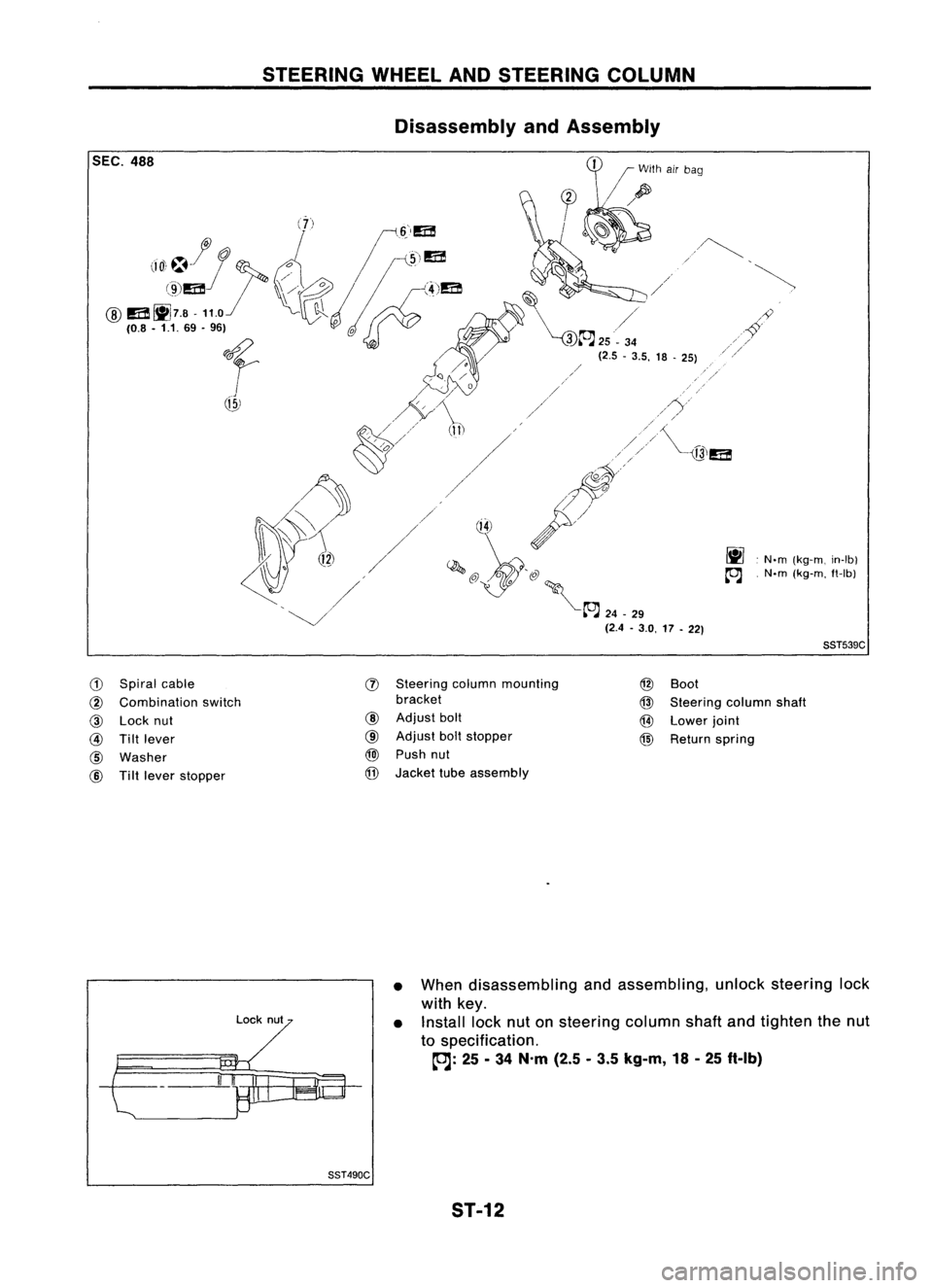

SEC.488 STEERING

WHEELANDSTEERING COLUMN

Disassembly andAssembly

~.N.m (kg-m, in-Ib)

~ .N.m (kg-m, ft-Ib)

SST539C

G)

Spiral cable

@

Combination switch

@

Lock nut

@

Tiltlever

@

Washer

@

Tiltlever stopper

!J)

Steering columnmounting

bracket

@

Adjust bolt

CID

Adjust boltstopper

@J

Push nut

@

Jacket tubeassembly

@

Boot

@

Steering columnshaft

@

Lower joint

@

Return spring

Lock nut

II

I

•

When disassembling andassembling, unlocksteering lock

with key.

• Install locknutonsteering columnshaftandtighten thenut

to specification.

~: 25-34 N.m (2.5-3.5 kg-m, 18-25 ft-Ib)

SST490C ST-12

Page 1681 of 1701

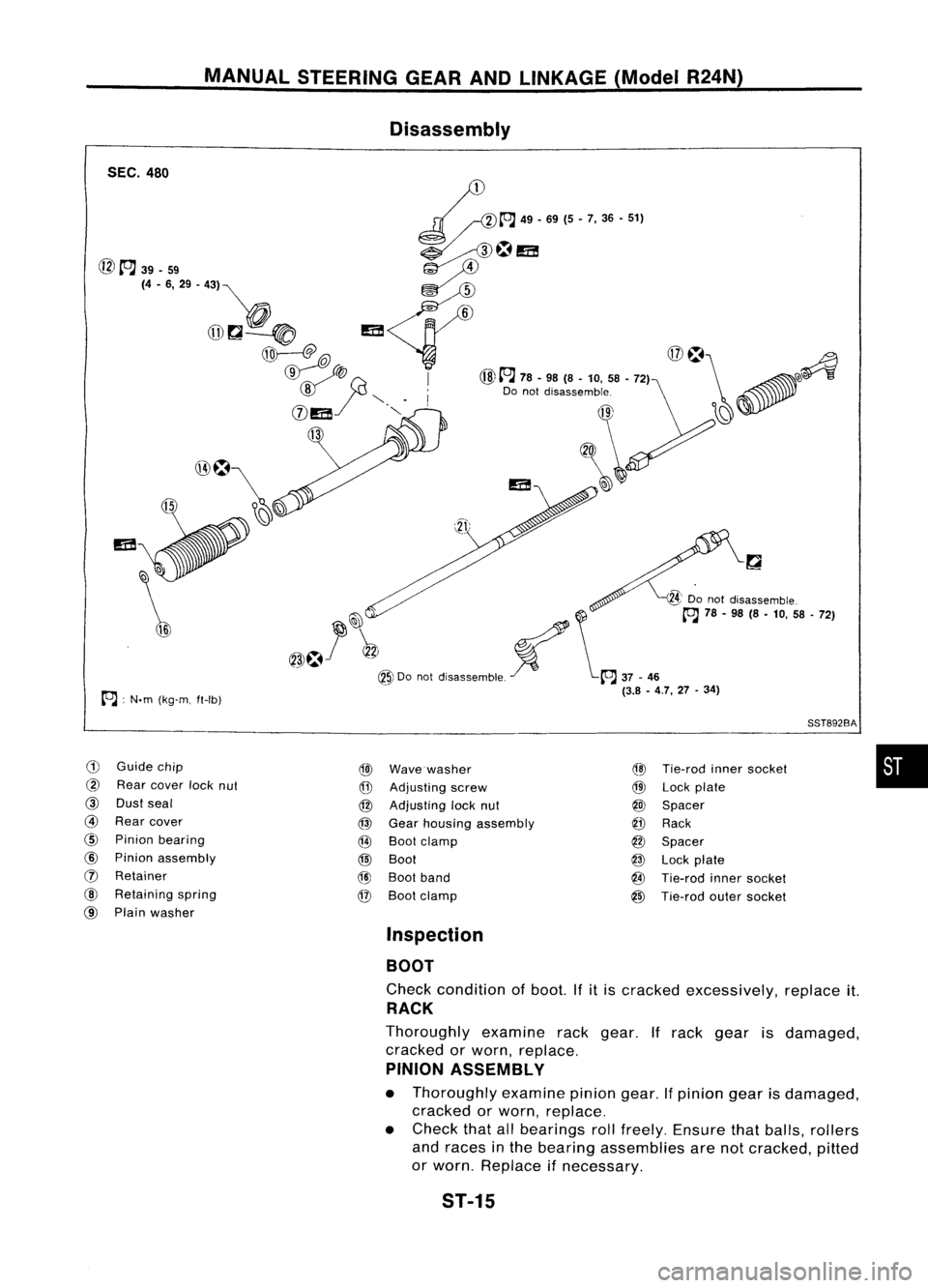

MANUALSTEERING GEARANDLINKAGE (ModelR24N)

Disassembly

SEC. 480

•

SST892BA

@

Tie-rod innersocket

@

Lock plate

@)

Spacer

@

Rack

@

Spacer

@

Lock plate

@

Tie-rod innersocket

@

Tie-rod outersocket

@)

Wave washer

@

Adjusting screw

@

Adjusting locknut

@

Gear housing assembly

@

Boot clamp

@

Boot

@J

Boot band

@

Boot clamp

24'

Do not disassemble.

!ill \

[OJ

78-98 (S-10, 58-72)

~~;:1' \~~~

Dooot d,,,,,,mbt, ~

[OJ

37_"

(3.8 -4.7, 27-34)

~[OJ

49-69(5 -7,36 -51}

~~~m

@ A 39-59 ~

)!l

(4 -6, 29 .43) ""

-=-

q=

5

_~ 0

6

@~~

m

(j];=-@

@~

8

'Donotdisassemble

WIlEi'! "-".

~9

0

13

\

A :

N.m (kg-m, ft-Ib)

CD

Guide chip

@

Rear cover locknut

@

Dustseal

@

Rear cover

@

Pinion bearing

@

Pinion assembly

(j)

Retainer

@

Retaining spring

@

Plain washer

Inspection

BOOT

Check condition ofboot. Ifitis cracked excessively, replaceit.

RACK

Thoroughly examinerackgear. Ifrack gear isdamaged,

cracked orworn, replace.

PINION ASSEMBLY

• Thoroughly examinepiniongear.Ifpinion gearisdamaged,

cracked orworn, replace.

• Check thatallbearings rollfreely. Ensure thatballs, rollers

and races inthe bearing assemblies arenotcracked, pitted

or worn. Replace ifnecessary.

ST-15

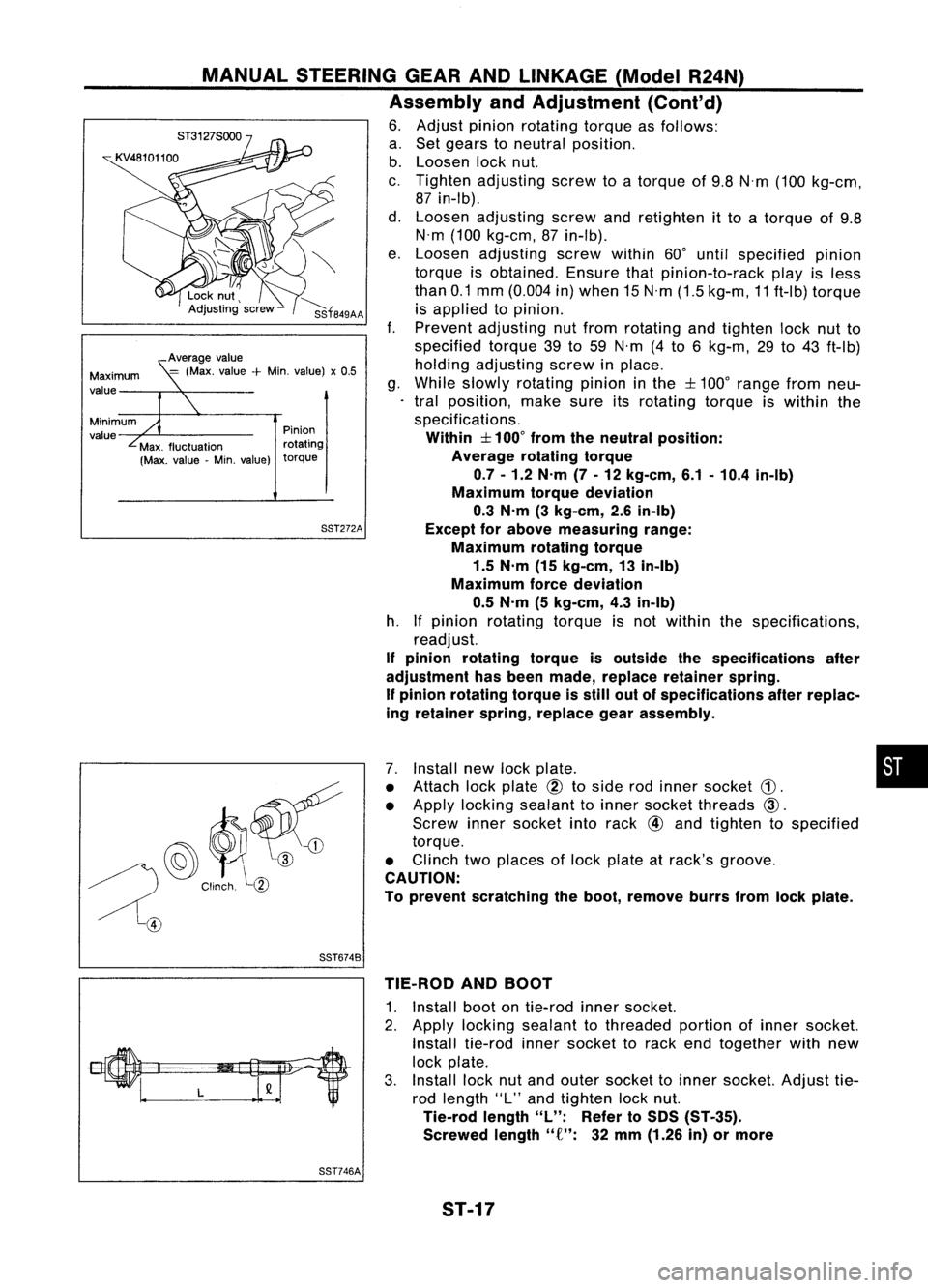

Page 1683 of 1701

SST272A

Pinion

rotating

torque

MANUAL

STEERING GEARANDLINKAGE (ModelR24N)

Assembly andAdjustment (Cant'd)

6. Adjust pinionrotating torqueasfollows:

a. Set gears toneutral position.

b. Loosen locknut.

c. Tighten adjusting screwtoatorque of9.8 N'm (100 kg-cm,

87 in-Ib).

d. Loosen adjusting screwandretighten itto atorque of9.8

N'm (100 kg-cm, 87in-Ib).

e. Loosen adjusting screwwithin60°until specified pinion

torque isobtained. Ensurethatpinion-to-rack playisless

than 0.1mm (0.004 in)when 15N'm (1.5kg-m, 11ft-Ib) torque

is applied topinion.

f. Prevent adjusting nutfrom rotating andtighten locknutto

specified torque39to59 N'm (4to 6kg-m, 29to43 ft-Ib)

holding adjusting screwinplace.

g. While slowly rotating pinioninthe

:f::

100° range fromneu-

tral position, makesureitsrotating torqueiswithin the

specifications.

Within

:f::

100° from theneutral position:

Average rotatingtorque

0.7 -1.2 N'm (7-12 kg-em, 6.1-10.4 in-Ib)

Maximum torquedeviation

0.3 N'm (3kg-em, 2.6in-Ib)

Except forabove measuring range:

Maximum rotatingtorque

1.5 N'm (15kg-em, 13in-Ib)

Maximum forcedeviation

0.5 N'm (5kg-em, 4.3in-Ib)

h. Ifpinion rotating torqueisnot within thespecifications,

readjust.

If pinion rotating torqueisoutside thespecifications after

adjustment hasbeen made, replace retainer spring.

If pinion rotating torqueisstill outofspecifications afterreplac-

ing retainer spring,replace gearassembly.

Average

value

=

(Max. value

+

Min. value) x0.5

Minimum

value Maximum

value

@~~

/) Clinch

l(1)

~@

7.

Install newlockplate. •

• Attach lockplate

@

toside rodinner socket

CD.

• Apply locking sealant toinner socket threads

CID.

Screw innersocket intorack

@

and tighten tospecified

torque.

• Clinch twoplaces oflock plate atrack's

groove.

CAUTION:

To prevent scratching theboot, remove burrsfromlockplate.

SST6748 TIE-ROD ANDBOOT

1. Install bootontie-rod innersocket.

2. Apply locking sealant tothreaded portionofinner socket.

Install tie-rod innersocket torack endtogether withnew

lock plate.

3. Install locknutand outer socket toinner socket. Adjusttie-

rod length "L"and tighten locknut.

Tie-rod length

"L":

Referto50S (ST-35).

Screwed length"

f":

32mm (1.26 in)ormore

SST746A

ST-17

Page 1684 of 1701

MANUALSTEERING GEARANDLINKAGE (ModelR24N)

Assembly andAdjustment

(Cont'd)

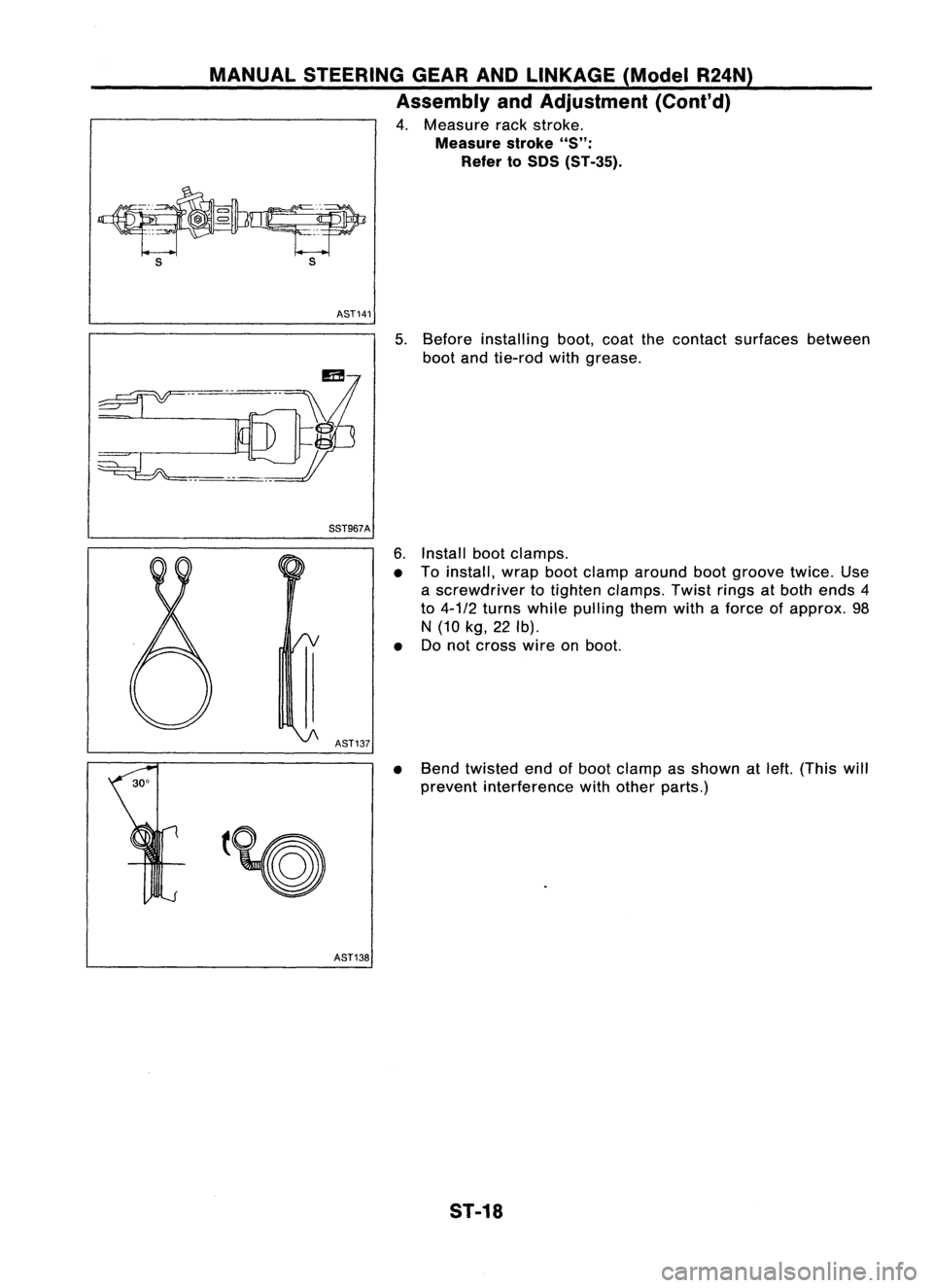

4. Measure rackstroke.

Measure stroke

"S":

Refer toSOS (ST-35).

AST141

5.Before installing boot,coatthecontact surfaces between

boot andtie-rod withgrease.

~==--

SST967A

6.Install bootclamps.

• Toinstall, wrapbootclamp around bootgroove twice.Use

a screwdriver totighten clamps. Twistringsatboth ends 4

to 4-1/2 turns while pulling themwithaforce ofapprox. 98

N (10 kg,22lb).

• Donot cross wireonboot.

AST137

•Bend twisted endofboot clamp asshown atleft. (This will

prevent interference withother parts.)

AST138

ST-18