boot NISSAN ALMERA N15 1995 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 701 of 1701

FRONTAXLE

Drive Shaft(Cont'd)

Boot

Check bootforfatigue, cracks,orwear. Replace bootwithnew

boot bands.

Joint assembly (Transaxle side)

• Check spider assembly forbearing, rollerandwasher dam-

age. Replace spiderassembly ifnecessary.

• Check housing forany damage. Replacehousingsetand

spider assembly, ifnecessary.

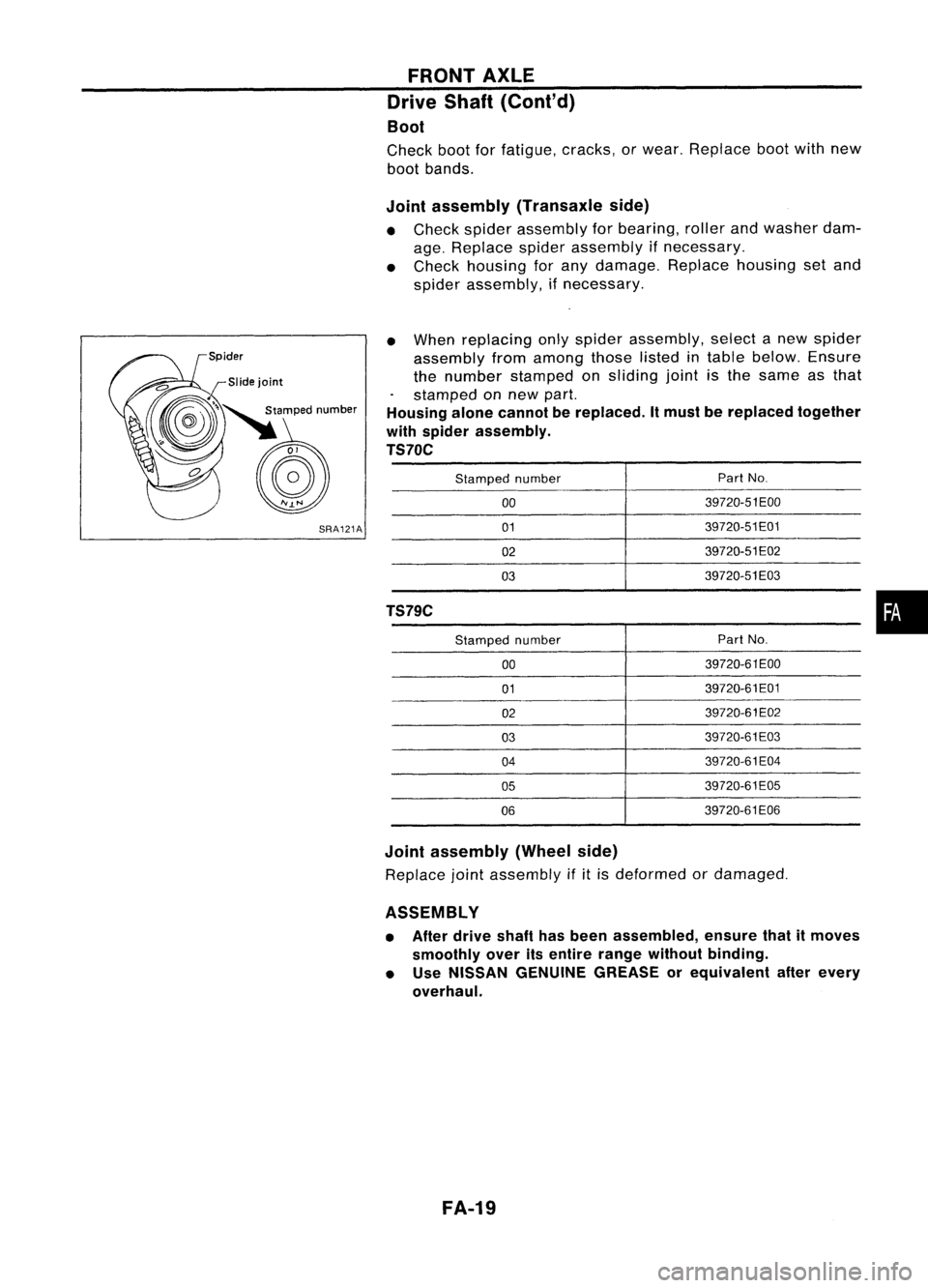

• When replacing onlyspider assembly, selectanew spider

assembly fromamong thoselistedintable below. Ensure

the number stamped onsliding jointisthe same asthat

stamped onnew part.

Housing alonecannot bereplaced. Itmust bereplaced together

with spider assembly.

TS70C

Stampednumber Part

No.

00 39720-61

EOO

01 39720-61

E01

02 39720-61

E02

03 39720-61

E03

04 39720-61

E04

05 39720-61E05

06 39720-61

E06

Slide

joint

SRA121A

TS79C

Stamped

number

00

01

02

03

Part

No.

39720-51 EOO

39720-51E01

39720-51 E02

39720-51 E03

•

Joint assembly (Wheelside)

Replace jointassembly ifitis deformed ordamaged.

ASSEMBLY • After drive shafthasbeen assembled, ensurethatitmoves

smoothly overitsentire range without binding.

• Use NISSAN GENUINE GREASEorequivalent afterevery

overhaul.

FA-19

Page 702 of 1701

SFA800

r:r

1..--*

-Wheel bearing

lock nut

SFA130A

SFA4568

SFA4438

FRONT

AXLE

Drive Shaft(Cont'd)

Wheel side

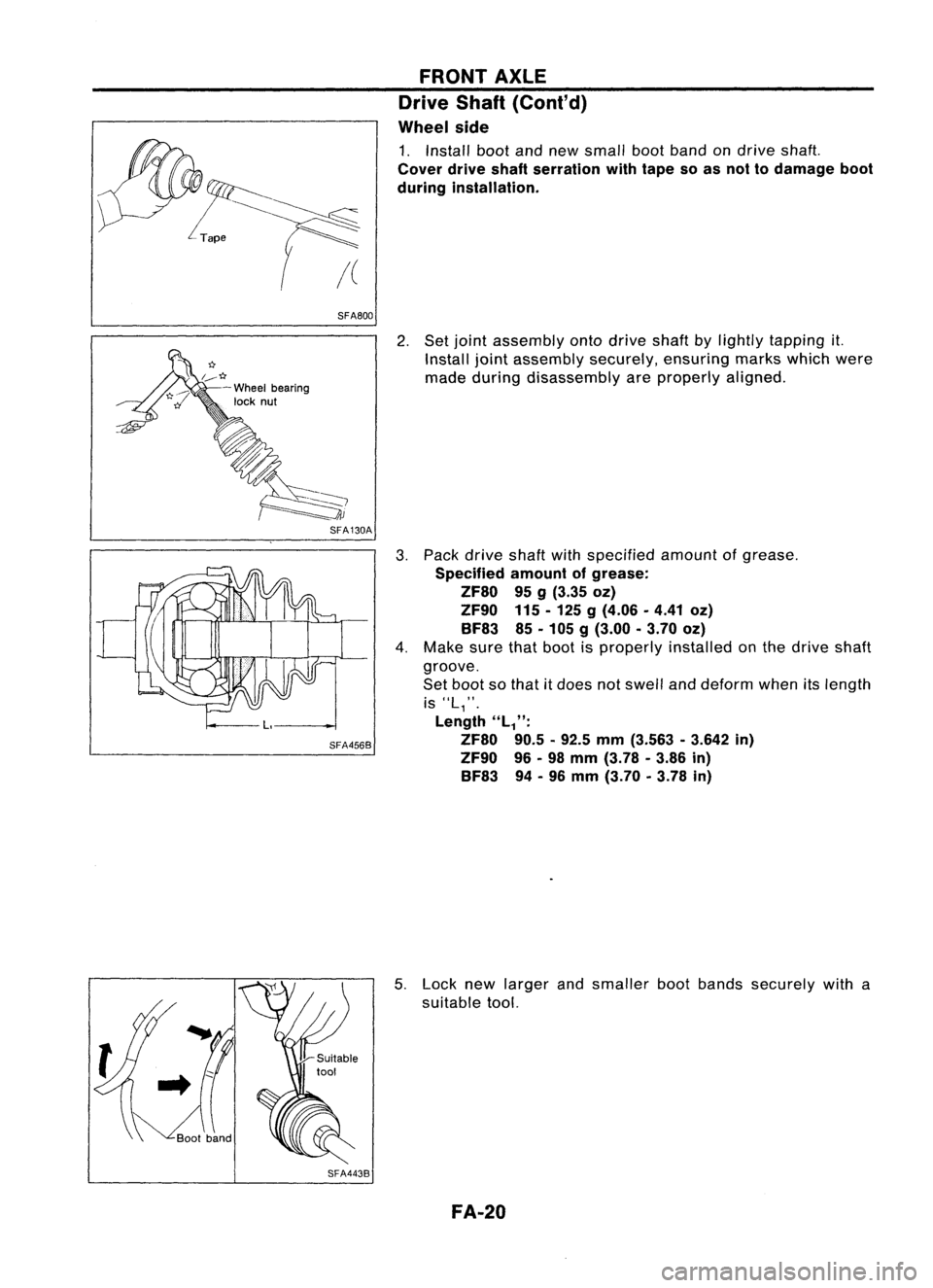

1. Install bootandnew small bootband on

drive

shaft.

Cover driveshaftserration withtape soas not todamage boot

during installation.

2. Set joint assembly onto

drive

shaftbylightly tapping it.

Install jointassembly securely,ensuringmarkswhichwere

made during disassembly areproperly aligned.

3. Pack

drive

shaftwithspecified amountofgrease.

Specified amountofgrease:

ZF80 95g(3.35

oz)

ZF90 115-125

g

(4.06 .4.41 oz)

BF83 85.105g(3.00 -3.70 oz)

4. Make surethatboot isproperly installedonthe drive shaft

groove.

Set boot sothat itdoes notswell anddeform whenitslength

is

"L,".

Length

"L/':

ZF80 90.5-92.5 mm(3.563 -3.642 in)

ZF90 96-98 mm (3.78 -3.86 in)

BF83 94-96 mm (3.70 -3.78 in)

5. Lock newlarger andsmaller bootbands securely witha

suitable tool.

FA-20

Page 703 of 1701

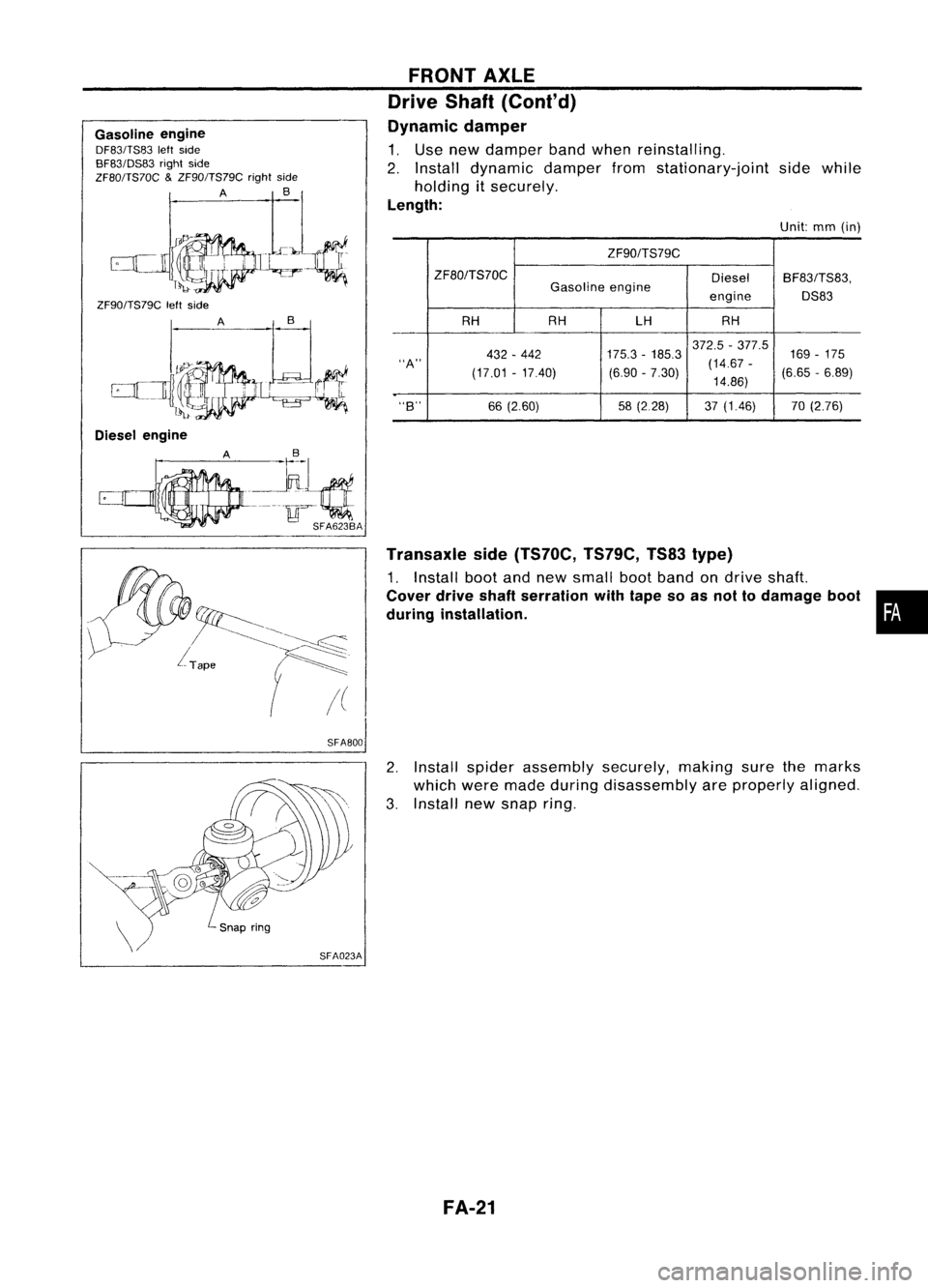

Gasolineengine

DF83/TS83 leftside

BF83/DS83 rightside

ZF80/TS70C

&

ZF90/TS79C rightside

A

B_1

.":JJ.Ci

ZF90/TS79C leftside

SFA800FRONT

AXLE

Drive Shaft(Cont'd)

Dynamic damper

1. Use new damper bandwhen reinstalling.

2. Install dynamic damperfromstationary-joint sidewhile

holding itsecurely.

Length:

Unit:mm(in)

ZF90/TS79C

ZF80/TS70C DieselBF83/TS83,

Gasoline engine

engineDS83

RH RH LHRH

372.5 -377.5

169-175

432 -442 175.3

-185.3

"A"

(17.01-17.40) (6.90

-7.30) (14.67

-

(6.65-6.89)

14.86)

"B"

66(2.60) 58(2.28) 37(1.46) 70(2.76)

Transaxle side(TS70C, TS79C,TS83type)

1. Install bootandnew small bootband ondrive shaft.

Cover driveshaftserration withtape soas not todamage boot•

during installation.

2. Install spider assembly securely.makingsurethemarks

which weremade during disassembly areproperly aligned.

3. Install newsnap ring.

FA-21

Page 704 of 1701

SFA993

SFA395

SFA800

SFA514A

SFA149A

FRONT

AXLE

Drive Shaft

(Cont'd)

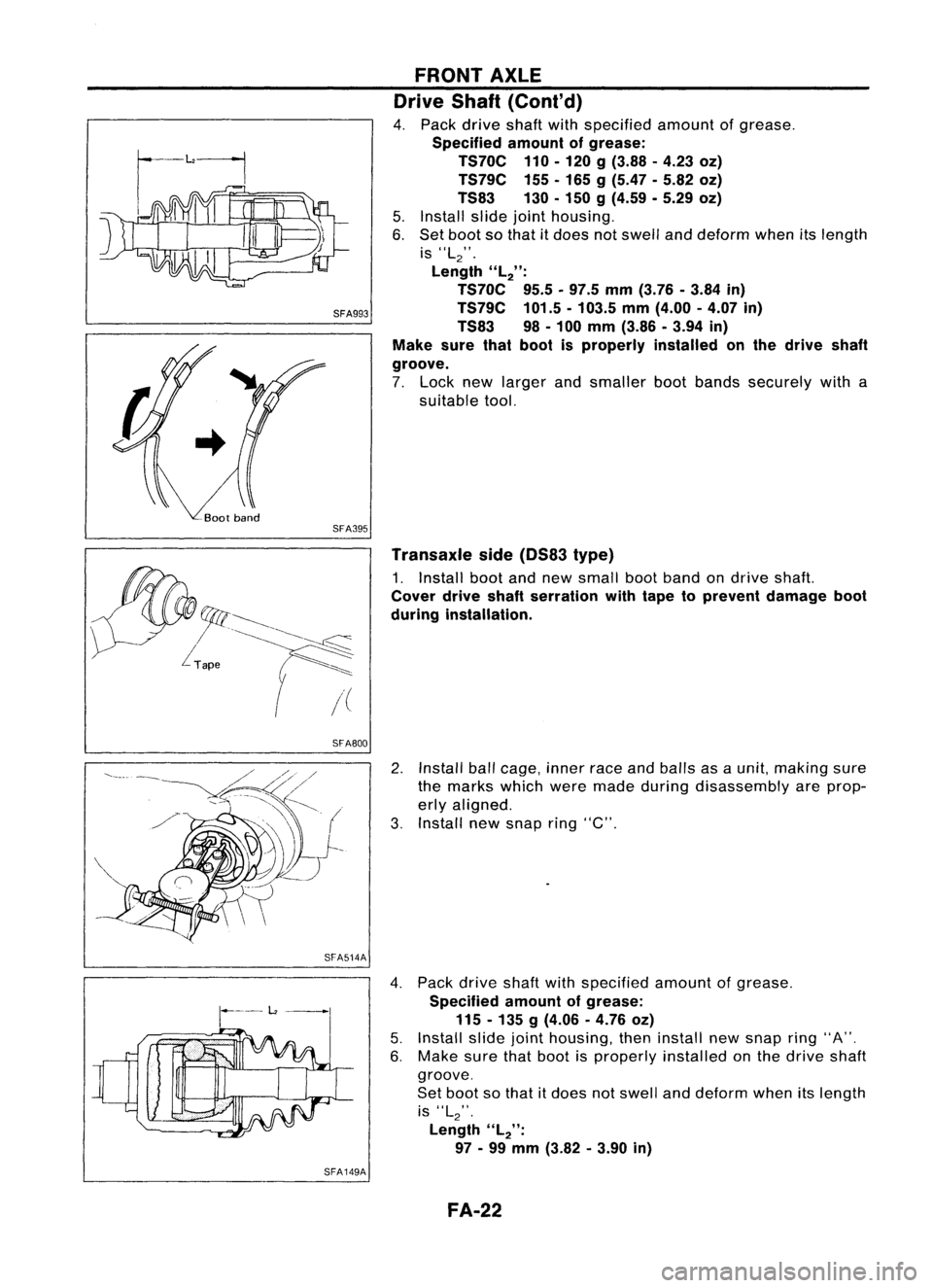

4. Pack drive shaftwithspecified amountofgrease.

Specified amountofgrease:

TS70C 110-120

g

(3.88 -4.23 oz)

TS79C 155-165

g

(5.47 -5.82 oz)

TS83 130-150 g(4.59 •5.29 oz)

5. Install slidejointhousing.

6. Set boot sothat itdoes notswell anddeform whenitslength

is

"L

2".

Length

"L

2":

TS70C 95.5-97.5 mm(3.76 -3.84 in)

TS79C 101.5-103.5

mm

(4.00 -4.07

in)

TS83 98-100 mm (3.86.3.94 in)

Make surethatboot isproperly installedonthe drive shaft

groove.

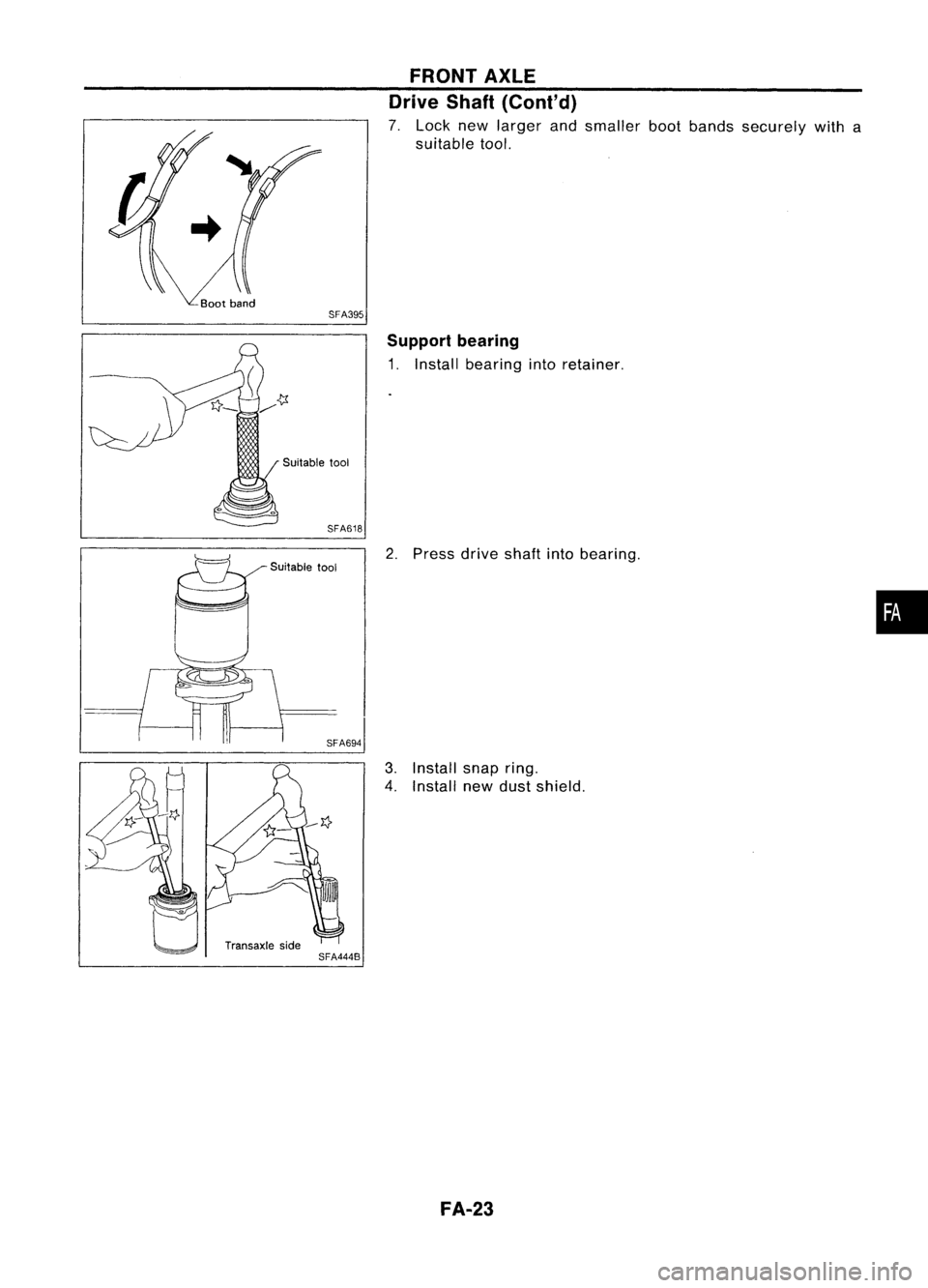

7. Lock newlarger andsmaller bootbands securely witha

suitable tool.

Transaxle side(OS83 type)

1. Install bootandnew small bootband ondrive shaft.

Cover driveshaftserration withtape toprevent damage boot

during installation.

2. Install ballcage, innerraceandballs asaunit, making sure

the marks whichweremade during disassembly areprop-

erly aligned.

3. Install newsnap ring"C".

4. Pack drive shaftwithspecified amountofgrease.

Specified amountofgrease:

115 -135

g

(4.06 -4.76 oz)

5. Install slidejointhousing, theninstall newsnap ring"A".

6. Make surethatboot isproperly installed onthe drive shaft

groove.

Set boot sothat itdoes notswell anddeform whenitslength

is

"L

2".

Length

"L

2":

97 -99 mm (3.82 -3.90 in)

FA-22

Page 705 of 1701

SFA395FRONT

AXLE

Drive Shaft(Cont'd)

7. Lock newlarger andsmaller bootbands securely witha

suitable tool.

Suitable tool

SFA618

Suitable tool

SFA694

Transaxle side

SFA444B Support

bearing

1. Install bearing intoretainer.

2. Press driveshaftintobearing.

3. Install snapring.

4. Install newdust shield.

FA-23

•

Page 709 of 1701

View

from

B FRONT

SUSPENSION

Stabilizer Bar(Cont'd)

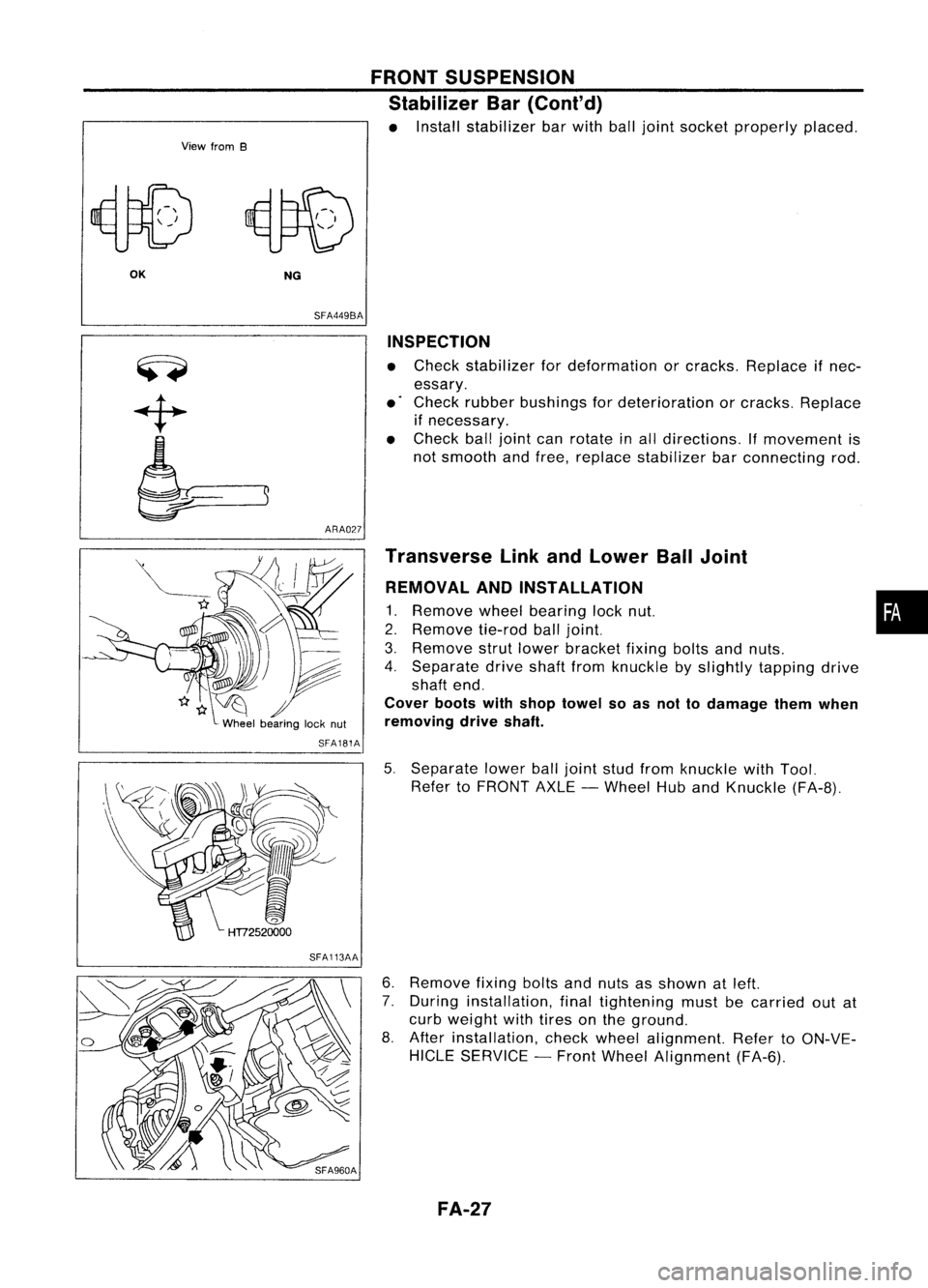

• Install stabilizer barwith balljoint socket properly placed.

OK NG

SFA449BA

ARA027 INSPECTION

• Check stabilizer fordeformation orcracks. Replace ifnec-

essary.

• Check rubber bushings fordeterioration orcracks. Replace

if necessary.

• Check balljoint canrotate inall directions. If

movement

is

not smooth andfree, replace stabilizer barconnecting rod.

SFA181A

SFA113AA Transverse

LinkandLower BallJoint

REMOVAL ANDINSTALLATION

1. Remove

wheelbearing locknut. •

2. Remove

tie-rodballjoint.

3. Remove

strutlower bracket fixingboltsandnuts.

4. Separate driveshaftfromknuckle byslightly tapping drive

shaft end.

Cover bootswithshop towel soas not todamage themwhen

removing driveshaft.

5. Separate lowerballjoint studfrom knuckle withTool.

Refer toFRONT AXLE-Wheel HubandKnuckle (FA-8).

6. Remove

fixingboltsandnuts asshown atleft.

7. During installation, finaltightening mustbecarried outat

curb weight withtires onthe ground.

8. After installation, checkwheel alignment. RefertoON-VE-

HICLE SERVICE -Front Wheel Alignment (FA-6).

FA-27

Page 712 of 1701

SERVICEDATAANDSPECIFICATIONS (SDS)

Inspection andAdjustment (Cont'd)

Nissan genuine greaseorequivalent

g

(oz)

Grease

Capacity

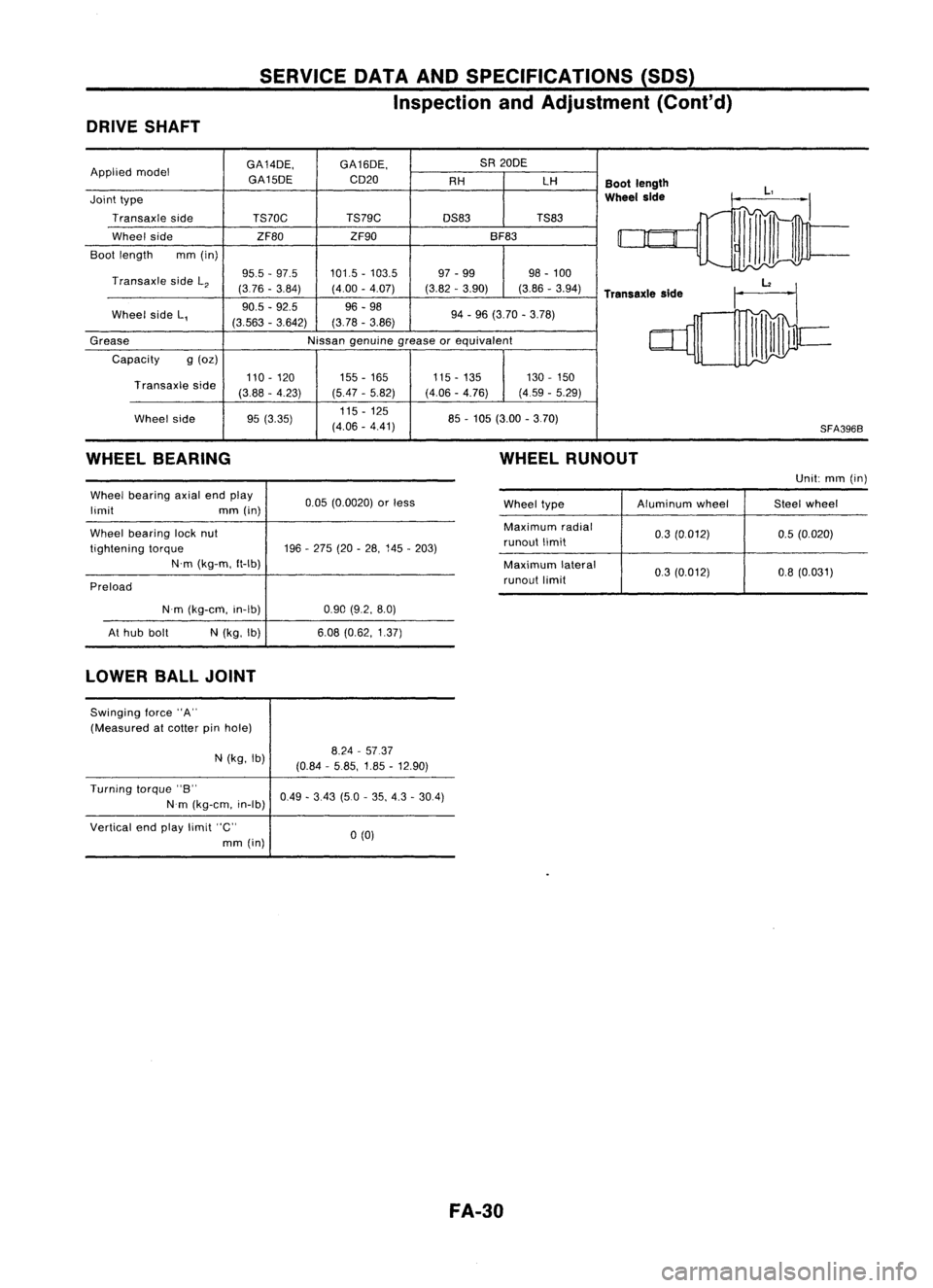

DRIVE

SHAFT

GA14DE,GA16DE, SA

20DE

Applied model

GA15DECD20

AHLH

Bootlength

Joint type

Wheel

side

Transaxle side TS70C TS79C

DS83TS83

Wheel side ZF80ZF90 BF83

Boot length mm(in)

Transaxle sideL

2

95.5

-97.5 101.5-103.5 97

-99 98-100

(376 -3.84) (4.00-4.07) (3.82-3.90) (3.86-3.94)

Transaxle side

Wheel sideL, 90.5

-92.5 96-98

94-96 (3.70 -3.78)

(3.563 -3.642) (3.78

-3.86)

85-105 (3.00 -3.70)

Transaxle

side

Wheel side 110

-120

(388 -4.23)

95 (3.35) 155

-165

(5.47 -5.82)

115 -125

(4.06 -4.41) 115

-135

(4.06 -4.76) 130

-150

(4.59 -5.29)

SFA3968

WHEEL BEARING WHEEL

RUNOUT

Unit:mm(in)

Wheel bearing axialendplay

limit mm(in)

Wheel bearing locknut

tightening torque

N'm (kg-m, ft-Ib)

Preload 0.05

(0.0020) orless

196 -275 (20-28, 145 -203) Wheel

type Aluminum

wheel Steelwheel

Maximum radial

0.3(0.012) 0.5(0.020)

runout limit

Maximum lateral

03(0.012) 0.8(0.031)

runout limit

N'm (kg-em, in-Ib)

At hub bolt

N

(kg, Ib)

0.90

(9.2, 8.0)

6.08 (0.62, 1.37)

LOWER BALLJOINT

Swinging force"A"

(Measured atcotter pinhole)

N (kg, Ib)

8.24

-5737

(0.84 -5.85, 1.85-12.90)

Turning torque"B"

Nm (kg-em, in-Ib)

Vertical endplay limit "C"

mm (in)

0.49

-3.43 (5.0-35, 4.3 -30.4)

0(0)

FA-30

Page 1511 of 1701

ENGINEMAINTENANCE ~

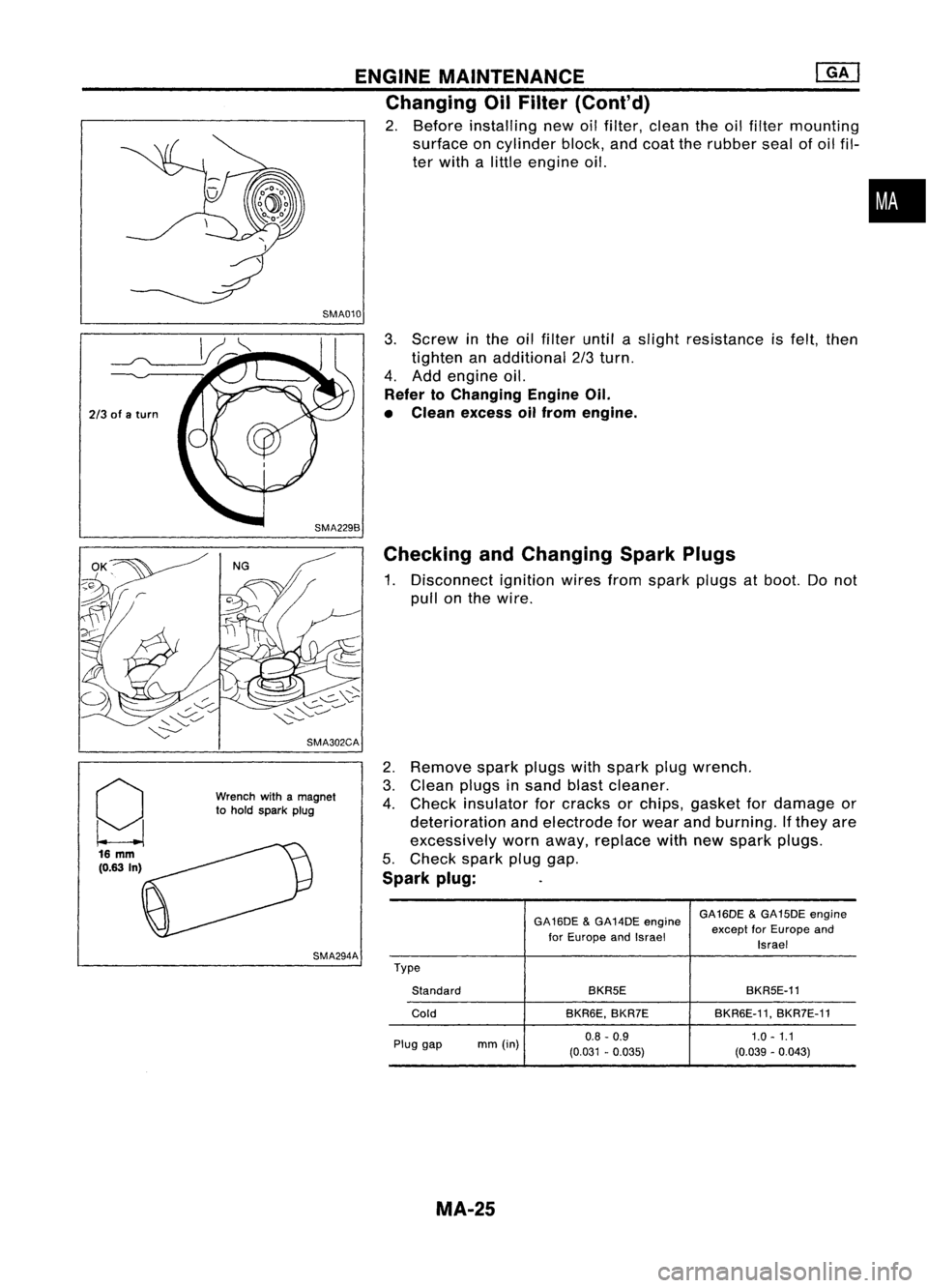

Changing OilFilter (Cont'd)

2. Before installing newoilfilter, clean theoilfilter mounting

surface oncylinder block,andcoat therubber sealofoil fil-

ter with alittle engine oil.

SMA010

•

2/3 ofaturn

g 16

mm

(0.63 In) SMA302CA

Wrench withamagnet

to hold spark plug

SMA294A

3.

Screw inthe oilfilter untilaslight resistance isfelt, then

tighten anadditional 2/3turn.

4. Add engine oil.

Refer toChanging EngineOil.

• Clean excess oilfrom engine.

Checking andChanging SparkPlugs

1. Disconnect ignitionwiresfromspark plugsatboot. Donot

pull onthe wire.

2. Remove sparkplugswithspark plugwrench.

3. Clean plugsinsand blastcleaner.

4. Check insulator forcracks orchips, gasket fordamage or

deterioration andelectrode forwear andburning. Ifthey are

excessively wornaway, replace withnewspark plugs.

5. Check sparkpluggap.

Spark plug:

GA16DE&GA14DE engine GA16DE

&GA15DE engine

for Europe andIsrael except

forEurope and

Israel

Type Standard BKR5E

BKR5E-11

Cold BKR6E,BKR7E BKR6E-11,

BKR7E-11

Plug gap mm(in) 0.8

-0.9 1.0-1.1

(0.031 -0.035) (0.039-0.043)

MA-25

Page 1520 of 1701

![NISSAN ALMERA N15 1995 Owners Manual ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After NISSAN ALMERA N15 1995 Owners Manual ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After](/img/5/57349/w960_57349-1519.png)

ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After several

minutes, checkoillevel.

Refill oil10this

"H" level.

Do not overfill.

SMA390C

Changing OilFilter

1. Remove oilfilter withTool.

WARNING:

Be careful nottoburn yourself, asthe engine andtheengine

oil are hot.

2. Clean oilfilter mounting surfaceoncylinder block.Coat

rubber sealofnew oilfilter withengine oil.

2/3

ofaturn

-------

OK SMA010

3.Screw inthe oilfilter untilaslight resistance isfelt, then

tighten anadditional 2/3turn.

4. Add engine oil.

Refer toChanging EngineOil.

• Clean excess oilfrom engine.

Changing SparkPlugs(Platinum-tipped type)

1. Disconnect ignitionwiresfromspark plugsatboot. Donot

pull onthe wire.

MA-34

Page 1536 of 1701

0

0

•

0

0

~ /0

H

H

0

0

(2)

4wheels

5 wheels

SMA785C

Radial

tires

CHASSIS

ANDBODY MAINTENANCE

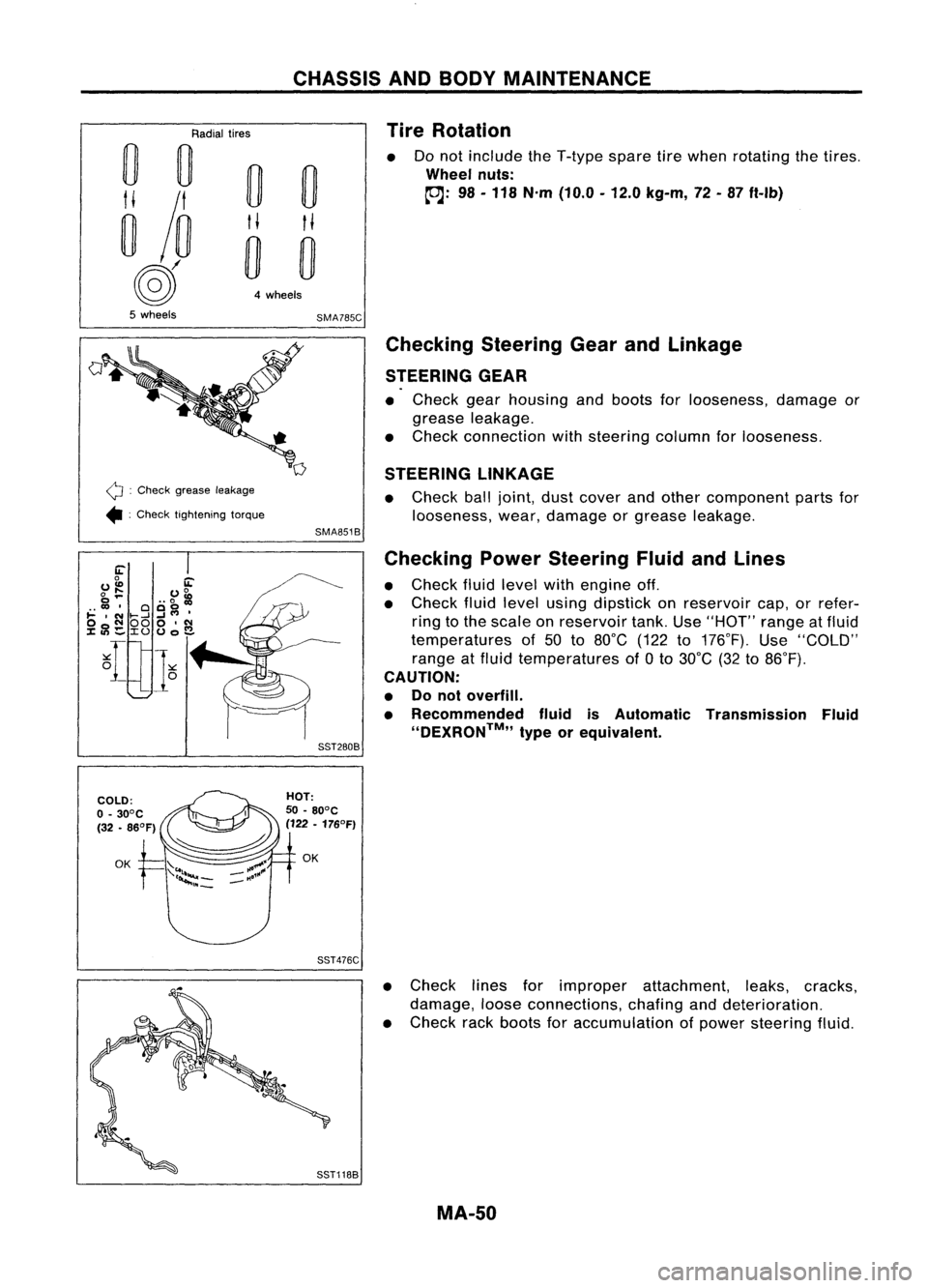

Tire Rotation

Do not include theT-type sparetirewhen rotating thetires .

Wheel nuts:

~: 98-118 N'm (10.0 -12.0 kg-m, 72-87 ft-Ib)

Q :

Check grease leakage

• :Check tightening torque

Checking

SteeringGearandLinkage

STEERING GEAR

• Check gearhousing andboots forlooseness, damageor

grease leakage.

• Check connection withsteering columnforlooseness.

STEERING LINKAGE

• Check balljoint, dustcover andother component partsfor

looseness, wear,damage orgrease leakage.

SMA851B

Checking PowerSteering FluidandLines

• Check fluidlevel withengine off.

• Check fluidlevel using dipstick onreservoir cap,orrefer-

ring tothe scale onreservoir tank.Use"HOT" rangeatfluid

temperatures of50 to80°C (122to176°F). Use"COLD"

range atfluid temperatures of

a

to 30°C (32to86°F).

CAUTION:

• Donot overfill.

• Recommended fluidisAutomatic Transmission Fluid

''DEXRON™,, typeorequivalent.

SST280B

SST476C

•Check linesforimproper attachment, leaks,cracks,

damage, looseconnections, chafinganddeterioration.

• Check rackboots foraccumulation ofpower steering fluid.

MA-50