boot NISSAN ALMERA N15 1995 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1686 of 1701

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

Removal andInstallation (Cont'd)

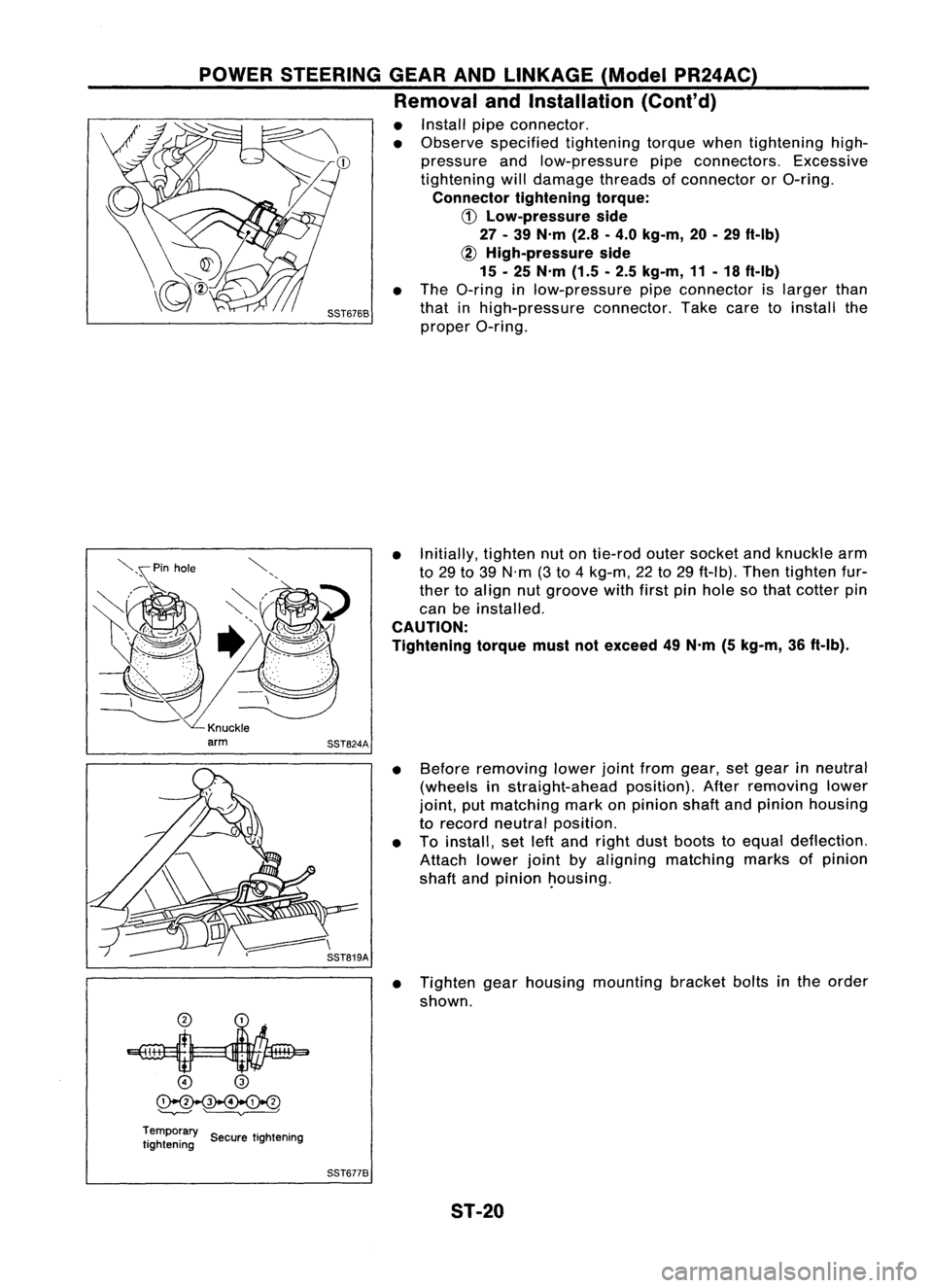

• Install pipeconnector.

• Observe specified tightening torquewhentightening high-

pressure andlow-pressure pipeconnectors. Excessive

tightening willdamage threadsofconnector orO-ring.

Connector tighteningtorque:

CD

Low-pressure side

27 -39 N'm (2.8-4.0 kg-m, 20-29 ft-Ib)

~ High-pressure side

15 -25 N'm (1.5-2.5 kg-m, 11-18 ft-Ib)

• The O-ring inlow-pressure pipeconnector islarger than

that inhigh-pressure connector.Takecaretoinstall the

proper O-ring.

• Initially, tightennutontie-rod outersocket andknuckle arm

to 29 to39 N'm (3to 4kg-m, 22to29 ft-Ib). Thentighten fur-

ther toalign nutgroove withfirstpinhole sothat cotter pin

can beinstalled.

CAUTION:

Tightening torquemustnotexceed 49N'm (5kg-m, 36ft-Ib).

• Before removing lowerjointfrom gear, setgear inneutral

(wheels instraight-ahead position).Afterremoving lower

joint, putmatching markonpinion shaftandpinion housing

to record neutral position.

• Toinstall, setleftand right dustboots toequal deflection.

Attach lowerjointbyaligning matching marksofpinion

shaft andpinion ~ousing.

• Tighten gearhousing mounting bracketboltsinthe order

shown.

o

@

~

'--v---' ~

Temporary ..

tightening SecuretIghtening

SST6778

ST-20

Page 1687 of 1701

![NISSAN ALMERA N15 1995 Workshop Manual POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

•

~ :N.m (kg-m. ft-lb)

f] :

Lubrication points

(With automatic

transmission fluid

"DEXRON'u" type

or equivalent)

I

@~~~~

~~(SRandCD

~ ~~ e NISSAN ALMERA N15 1995 Workshop Manual POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

•

~ :N.m (kg-m. ft-lb)

f] :

Lubrication points

(With automatic

transmission fluid

"DEXRON'u" type

or equivalent)

I

@~~~~

~~(SRandCD

~ ~~ e](/img/5/57349/w960_57349-1686.png)

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

•

~ :N.m (kg-m. ft-lb)

f] :

Lubrication points

(With automatic

transmission fluid

"DEXRON'u" type

or equivalent)

I

@~~~~

~~(SRandCD

~ ~~ enginemodels)

8

~78. 98

(8.0 •10.0,

58•72)

GA engine model

~ 37•46 (3.8 •4.7, 27.34)

CD and SRengine models

M

78.98

(8.0 •

10.0, 58•72)

(SR

,,'CD,",,",

m_"'7

~\Il~

m~

@,

~16.21

~~'" ~•'.1, ". 1S(

r

, @

l"J

::'0' ,':0,

1

I

~ /7'

~y

@ "-~~(]

tGi ~

~m

@

t:;;J

~20.

26

(2.0 •2.7, 14•20)

SEC.

492

@)(]~\-

.~

~'

r

L

~to:J59' 74

20~

(6.0 •

7.5, 43.54)

_~ @Donotdisas~smble.

0

to:J 29•39

{3.0 .4.0,22. "~~

SST506CA

Pinion oilseal

Lock nut

Adjusting screw

Spring

Spring disc

G)

Rear cover cap

@

Rear housing assembly

@

Pinion sealring

@

Pinion assembly

CID

O-ring

@

Shim

(J)

@

@

@)

@ @

Washer

@

Spring seat

@

Retainer

@

Gear housing

@

Center bushing

@

Rack oilseal

@

Rack assembly

@

Rack sealring

@)

O-ring

@

Rack oilseal

@

Endcover assembly

@

Boot clamp

@

Dust boot

@

Boot band

@l

Steering gearspacer

@

Lock plate

@

Tie-rod innersocket

@

Tie-rod outersocket

@

Cotter pin

@

Gear housing tube

ST-21

Page 1688 of 1701

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

Disassembly

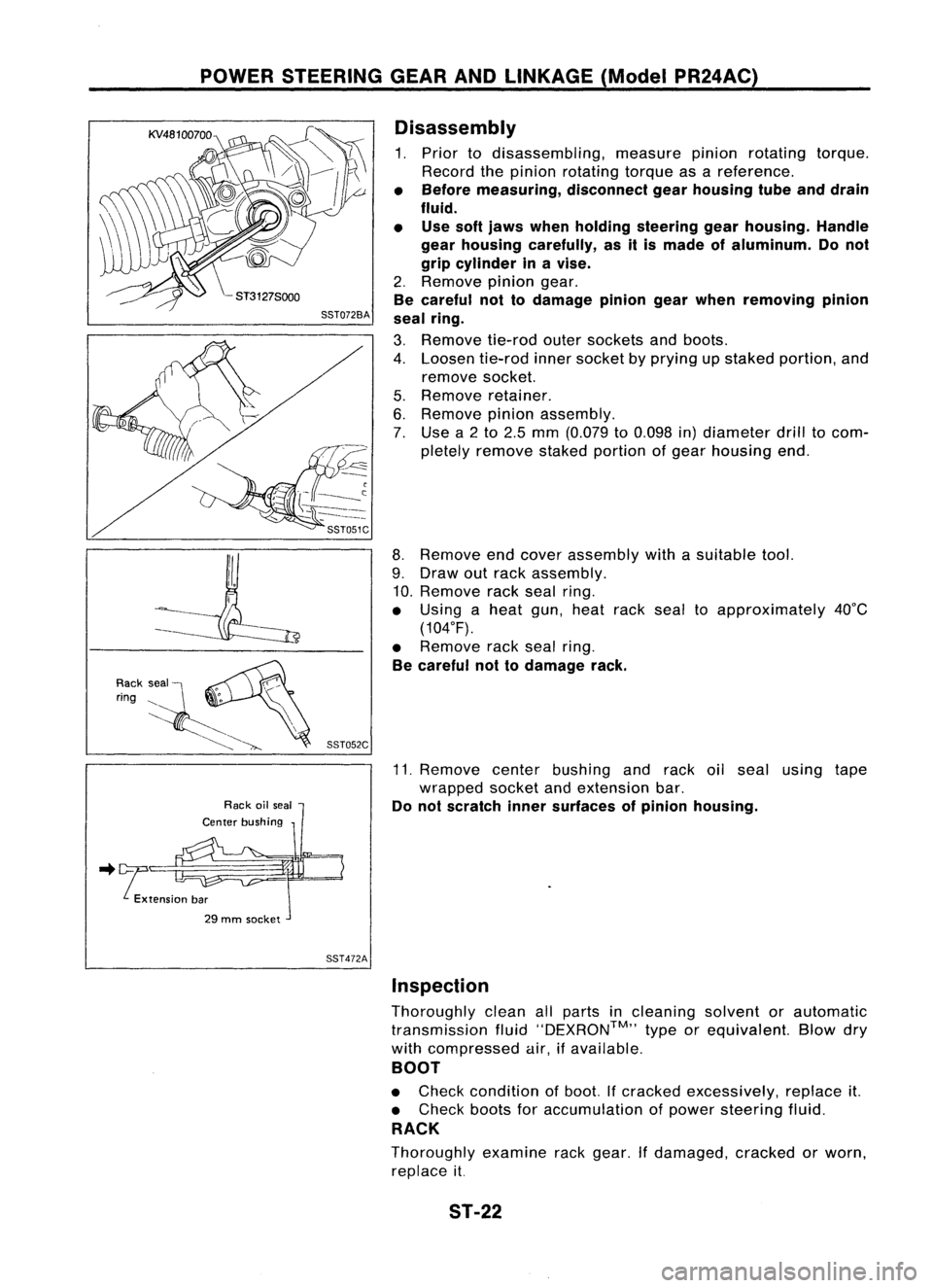

1. Prior todisassembling, measurepinionrotating torque.

Record thepinion rotating torqueasareference.

• Before measuring, disconnectgearhousing tubeanddrain

fluid.

• Use softjaws when holding steering gearhousing. Handle

gear housing carefully, asitis made ofaluminum. Donot

grip cylinder inavise.

2. Remove piniongear.

Be careful nottodamage piniongearwhen removing pinion

seal ring.

3. Remove tie-rodoutersockets andboots.

4. Loosen tie-rodinnersocket byprying upstaked portion, and

remove socket.

5. Remove retainer.

6. Remove pinionassembly.

7. Use a2to 2.5 mm (0.079 to0.098 in)diameter drilltocom-

pletely remove stakedportion ofgear housing end.

8. Remove endcover assembly withasuitable tool.

9. Draw outrack assembly.

10. Remove rackseal ring.

• Using aheat gun,heat racksealtoapproximately 40°C

(104°F).

• Remove racksealring.

Be careful nottodamage rack.

11. Remove centerbushing andrack oilseal using tape

wrapped socketandextension bar.

Do not scratch innersurfaces ofpinion housing .

.. !tension bar

29 mm socket

SST472AInspection

Thoroughly cleanallparts incleaning solventorautomatic

transmission fluid''DEXRON™,, typeorequivalent. Blowdry

with compressed air,ifavailable.

BOOT

• Check condition ofboot. Ifcracked excessively, replaceit.

• Check bootsforaccumulation ofpower steering fluid.

RACK

Thoroughly examinerackgear. Ifdamaged, crackedorworn,

replace it.

ST-22

Page 1692 of 1701

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

Assembly (Cont'd)

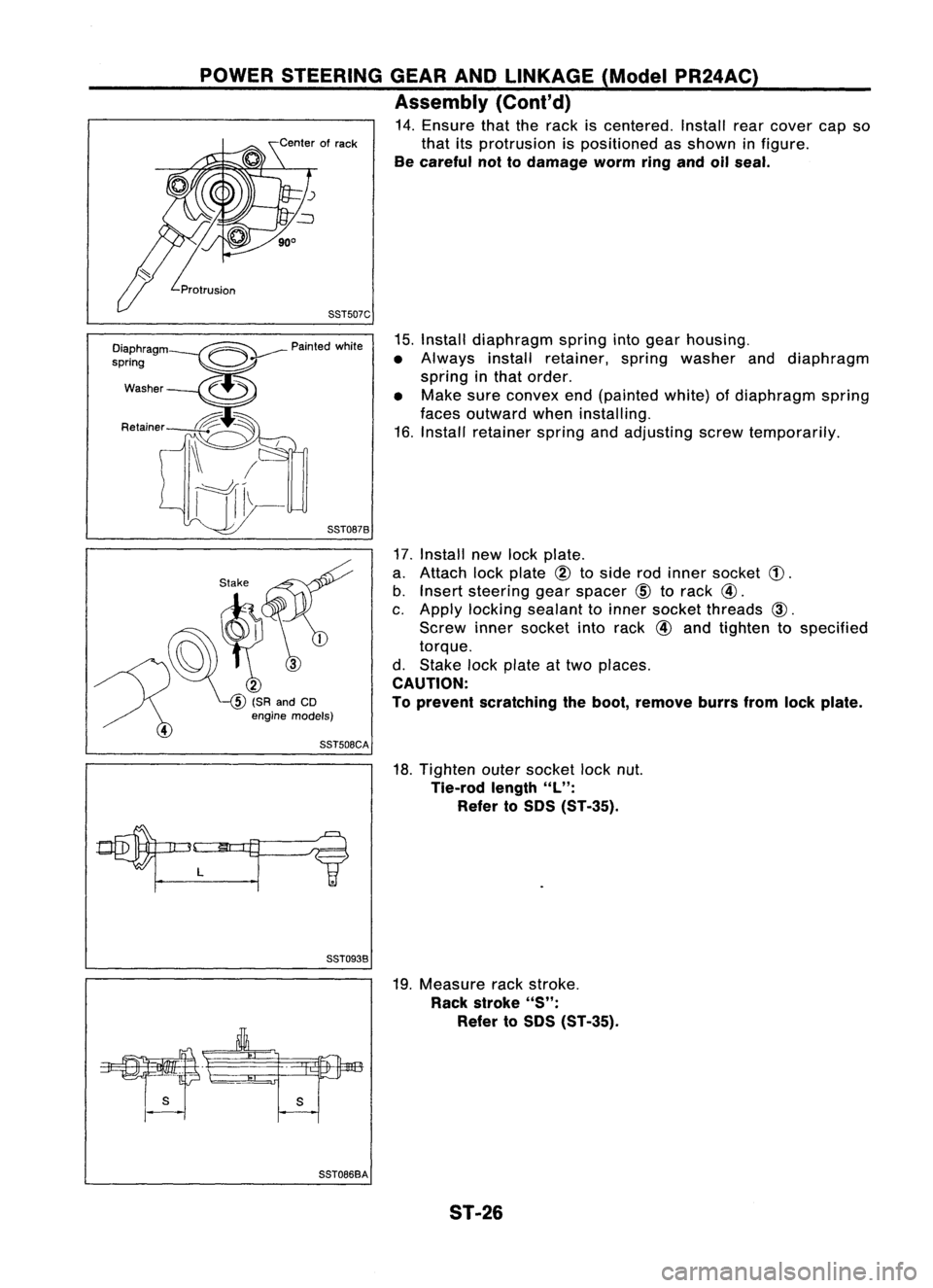

14. Ensure thattherack iscentered. Installrearcover capso

that itsprotrusion ispositioned asshown infigure.

Be careful nottodamage wormringandoilseal.

88T507C

15.Install diaphragm springintogear housing.

• Always installretainer, springwasher anddiaphragm

spring inthat order.

• Make sureconvex end(painted white)ofdiaphragm spring

faces outward wheninstalling.

16. Install retainer springandadjusting screwtemporarily.

88T0878

17.Install newlockplate.

a. Attach lockplate

@

toside rodinner socket

(!).

b. Insert steering gearspacer

CID

torack

@.

c. Apply locking sealant toinner socket threads

CID.

Screw innersocket intorack

@

and tighten tospecified

torque.

d. Stake lockplate attwo places.

CAUTION:

To prevent scratching theboot, remove burrsfromlockplate.

18. Tighten outersocket locknut.

Tie-rod length

"L":

Refer toSOS (ST-35).

88T0938

19.Measure rackstroke.

Rack stroke

"5":

Refer to50S (ST-35).

s

88T0868A ST-26

Page 1693 of 1701

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

Assembly (Cont'd)

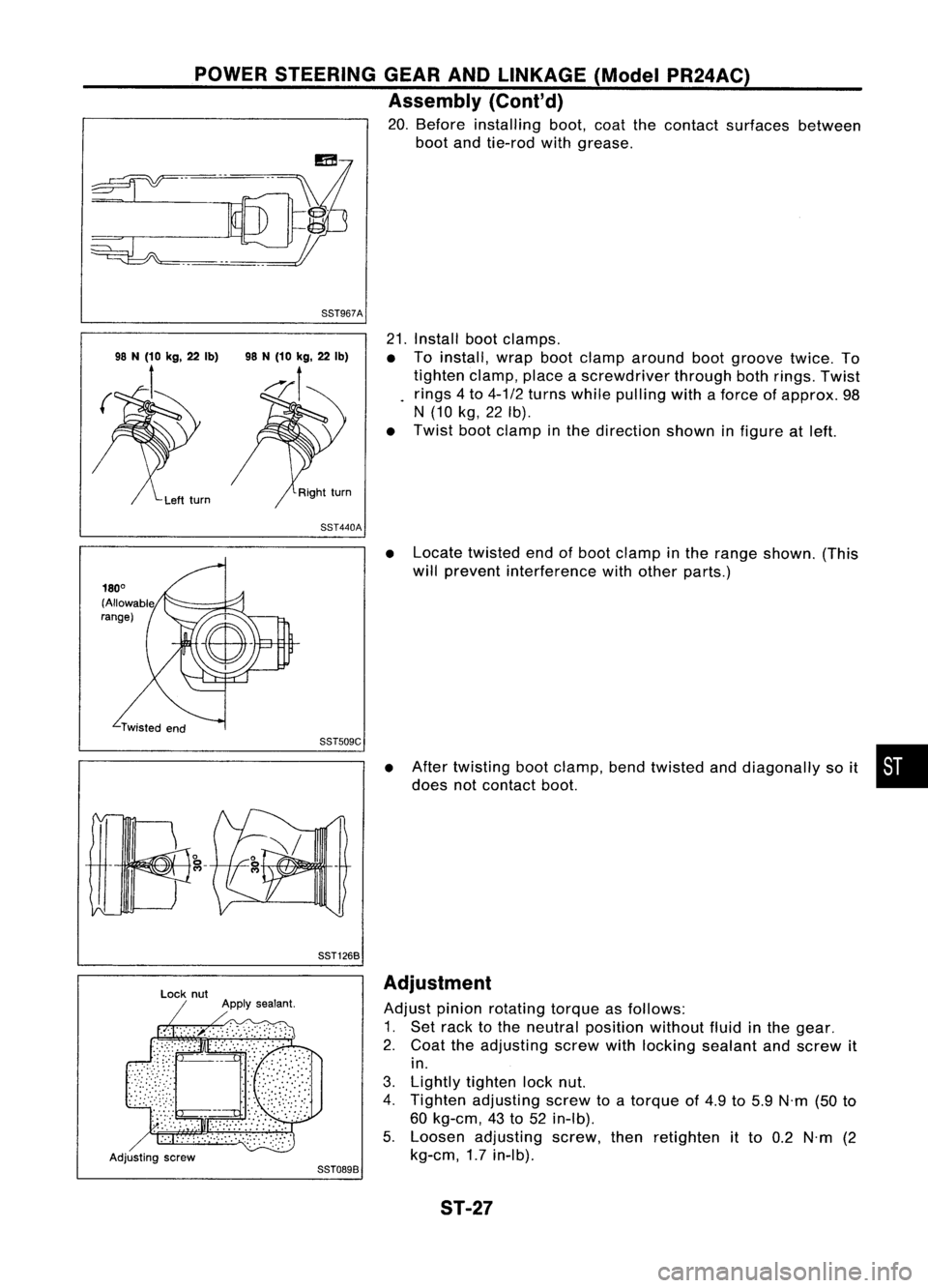

20. Before installing boot,coatthecontact surfaces between

boot andtie-rod withgrease.

88T967A

21.Install bootclamps.

• Toinstall, wrapbootclamp around bootgroove twice.To

tighten clamp,placeascrewdriver throughbothrings. Twist

rings 4to 4-1/2 turns while pulling withaforce ofapprox. 98

N (10 kg,22Ib).

• Twist bootclamp inthe direction showninfigure atleft.

88T440A

•Locate twisted endofboot clamp inthe range shown. (This

will prevent interference withother parts.)

88TS09C

88T1268

•

After twisting bootclamp, bendtwisted anddiagonally soit •

does notcontact boot.

Adjusting screw

88T0898Adjustment

Adjust pinionrotating torqueasfollows:

1. Set rack tothe neutral position withoutfluidinthe gear.

2. Coat theadjusting screwwithlocking sealant andscrew it

in.

3. Lightly tighten locknut.

4. Tighten adjusting screwtoatorque of4.9 to5.9 N'm (50to

60 kg-em, 43to52 in-Ib).

5. Loosen adjusting screw,thenretighten itto 0.2 N'm (2

kg-em, 1.7in-Ib).

ST-27