engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1180 of 1701

ENGINEMECHANICAL

SECTION

EM

CONTENTS

•

PRECAUTIONS

3

Parts Requiring AngularTightening 3

Liquid Gasket Application Procedure 3

PREPARATION 4

Special Service Tools 4

Commercial ServiceTools 8

GA

OUTER COMPONENT PARTS 9

COMPRESSION PRESSURE 15

Measurement ofCompression Pressure 15

OIL PAN 16

Removal 16

installation 17

TIMING CHAIN

18

Removal. 20

Inspection 23

Installation 23

OIL SEAL REPLACEMENT 30

CYLINDER HEAD 32

Removal 34

Disassembly 34

Inspection 34

Assembly 40

Installation 40

VALVE CLEARANCE 41

Checking 41

Adjusti ng 41

ENGINE REMOVAL .44

Removal 45

Ins taIIat ion " 46

CYLINDER BLOCK 47

Disassembly 48

Inspection 48

Assembly 55

SR

OUTER COMPONENT PARTS 59

COMPRESSION PRESSURE 62

Measurement ofCompression Pressure 62

OIL PAN

63

Removal 63

Installation ,66

TIMING CHAIN 68

Removal 69

Inspection 73

Installation ,73

OIL SEAL REPLACEMENT 82

ACCEL-DRUM UNIT 84

CYLINDER HEAD

85

Removal 86

Disassembly 86

Inspection 88

Assembly 93

Installation , 97

ENGINE REMOVAL 98

RemGval 99

Installation "100

CYLINDER BLOCK 101

Disassembly 102

Inspection , 102

Assembly 109

CD

OUTER COMPONENT PARTS

113

COMPRESSION PRESSURE 115

OIL PAN 118

Removal 118

Installation 118

Page 1181 of 1701

CONTENTS(Conl'd.)

TIMING BELT

120

Camshaft TimingBelt 120

Injection PumpTiming Belt 124

OIL SEAL REPLACEMENT

126

CYLINDER HEAD 128

Removal 129

Disassembly 129

Inspection 130

Assembly 136

Installation 137

ENGINE REMOVAL

140

CYLINDER

BLOCK 143

Preparation 144

Disassembly 144

Inspection 145

Assembly 152

GA

SERVICE DATAANDSPECIFICATIONS

(505)

155

General Specifications ,155

Inspection andAdjustment. 156

SR

SERVICE DATAANDSPECIFICATIONS

(505)

163

General Specifications 163

Inspection andAdjustment. 163

CD

SERVICE DATAANDSPECIFICATIONS

(50S)

171

Inspection andAdjustment.. 171

Page 1182 of 1701

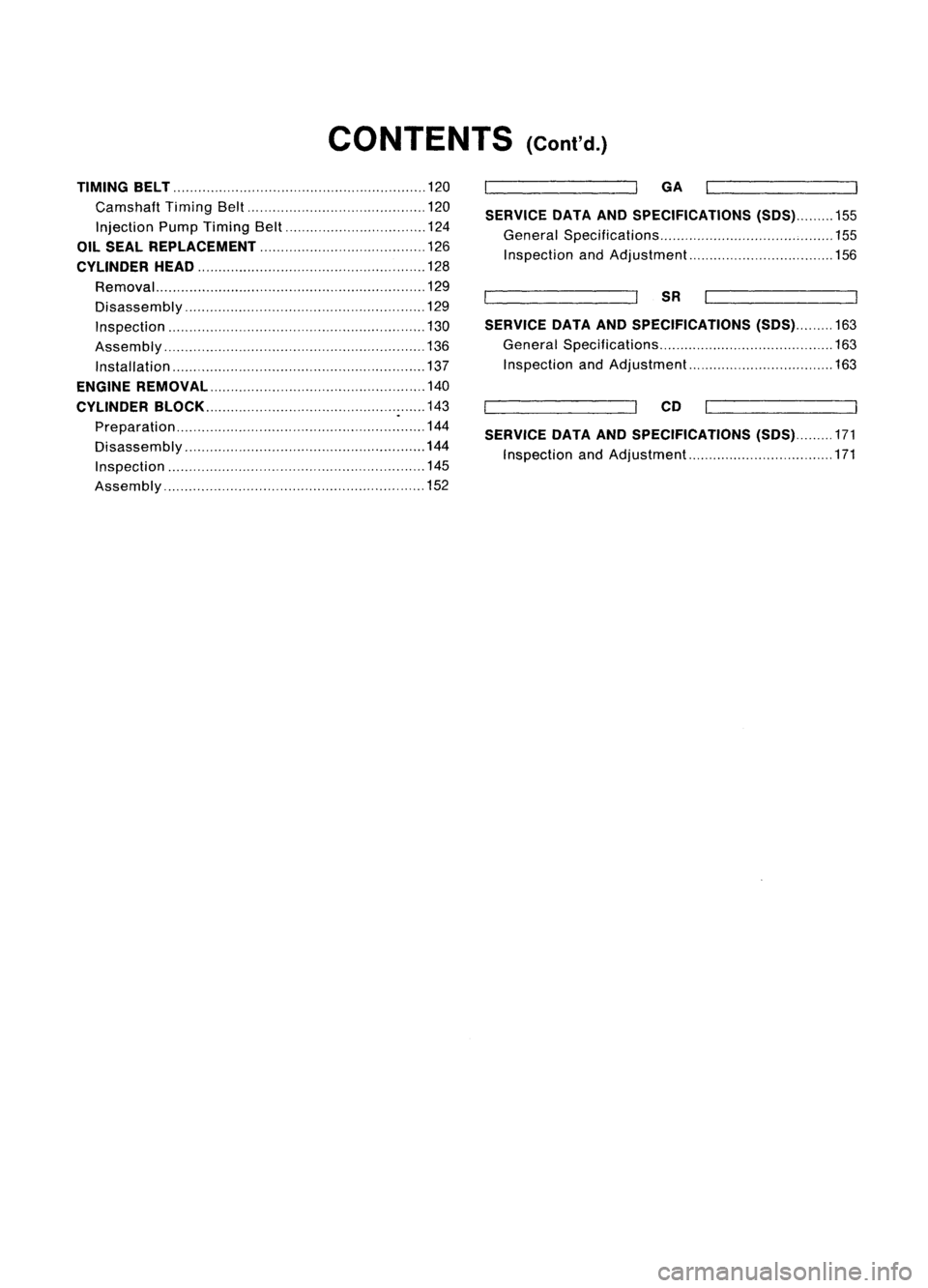

Innerside

SEM164F PRECAUTIONS

Parts Requiring AngularTightening

• Use anangle wrench forthe final tightening ofthe follow-

ing engine parts:

(1) Cylinder headbolts

(2) Main bearing capbolts (SRengine only)

(3) Connecting rodcap nuts (SRand CDengine)

• Donot use atorque valueforfinal tightening. •

• The torque values forthese partsareforapreliminary step.

• Ensure threadandseat surfaces areclean andcoated with

engine oil.

Liquid Gasket Application Procedure

a. Use ascraper toremove alltraces ofold liquid gasket from

mating surfaces andgrooves. Also,completely cleananyoil

from these areas.

b. Apply acontinuous beadofliquid gasket tomating surfaces.

(Use Genuine LiquidGasket orequivalent.)

• For oilpan, besure liquid gasket diameter is4.0 to5.0

mm (0.157 to0.197 in)for SR engine. Besure liquid

gasket diameter is3.5 to4.5 mm (0.138 to0.177 in)for

GA and CDengine.

• For areas except oilpan, besure liquid gasket diame-

ter is2.0 to3.0 mm (0.079 to0.118 in).

c. Apply liquidgasket toinner surface aroundholeperimeter

area.

d. Assembly shouldbedone within 5minutes aftercoating.

e. Wait atleast 30minutes beforerefilling engineoiland

engine coolant.

EM.3

Page 1183 of 1701

PREPARATION

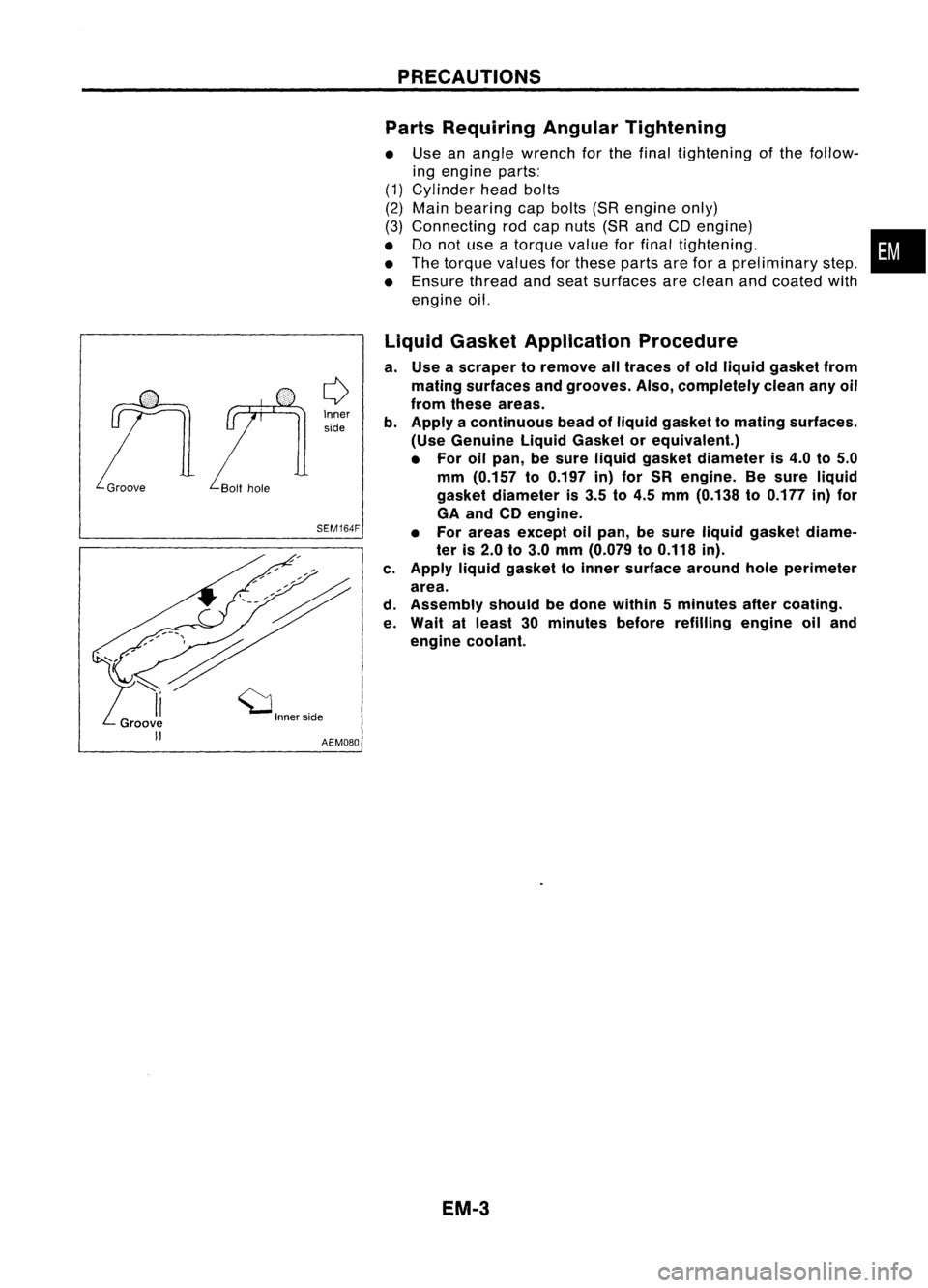

Special Service Tools

Engine

Tool number

Description application

Tool name

GA

SRCD

ST0501S000 When

overhauling engine

Engine standassem-

bly

G)

ST05011000

Engine stand

XX

X

@

ST05012000

Base

NT042

KV10106500

~

When

overhauling engine

Engine standshaft

X

NT028

KV10115300

~

When

overhauling engine

Engine sub-attach-

ment

X

NTOO8

Engine attachment When

overhauling engine

assembly

G)

KV10106500

Engine attach-

ment

X

@

KV10113300

Sub-attachment

NT029

G)

KV10108101 Whenoverhauling engine

Engine attach-

ment

KV10106500

1

~

Engine

stand

X

shaft

or

@

KV10102500

Engine stand

shaft

NT366

ST10120000

b

Loosening

andtightening

Cylinder headbolt

~~

cylinder

headbolt

wrench

a;13 (0.51) dia.

XX

b: 12 (0.47)

c: 10 (0.39)

NT583

C

Unit:mm(in)

EM.4

Page 1184 of 1701

PREPARATION

Special Service Tools(Cont'd)

Engine

Tool number

Description application

Tool name

GASRCD

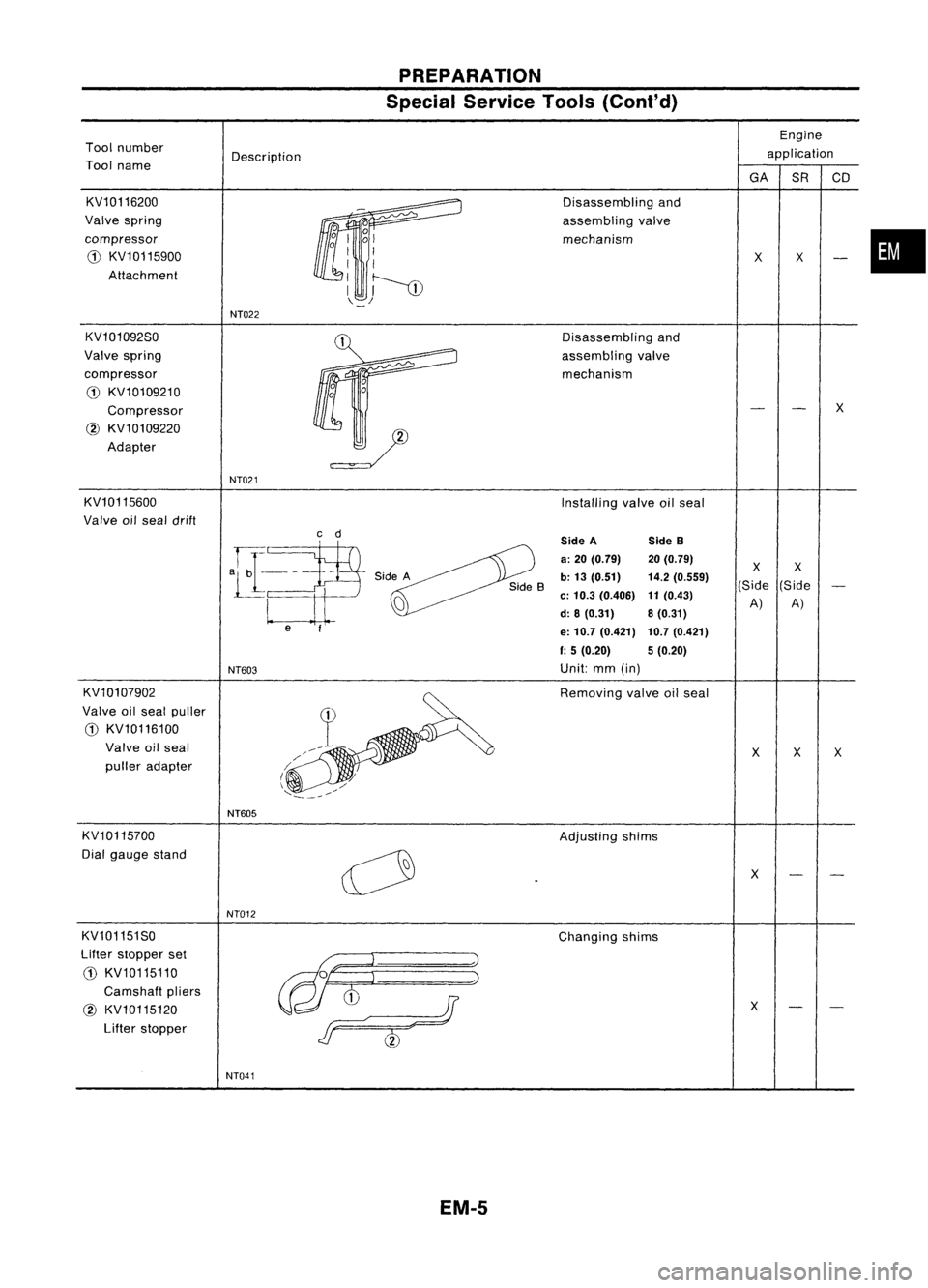

KV10116200 Disassemblingand

Valve spring

assemblingvalve

compressor mechanism

•

CD

KV10115900

XX

Attachment

NT022

KV101092S0 Disassemblingand

Valve spring

assemblingvalve

compressor mechanism

0

CD

KV10109210

0

Compressor

X

@

KV10109220

Adapter

NT021

KV10115600 Installingvalveoilseal

Valve oilseal drift

c

d

SideA SideB

-HaP

a:

20 (0.79) 20(0.79)

XX

Side A

b:13 (0.51) 14.2(0.559)

(Side(Side

a

c:

10.3 (0.406)

11

(0.43)

A)A)

d: 8(0.31) 8(0.31)

e

f

e:10.7 (0.421) 10.7(0.421)

f:

5(0.20) 5(0.20)

NT603

Unit:

mm(in)

KV10107902

~

Removing

valveoilseal

Valve oilseal puller

CD

KV10116100

Valve oilseal

XXX

puller adapter

I~

\

./

'...:_.~---/

NT605

KV10115700 Adjustingshims

Dial gauge stand

0

X

NT012

KV101151 SO

Changingshims

Lifter stopper set

@t

l

:~

CD

KV10115110

Camshaft pliers

as

J

@

KV10115120

X

Lifter stopper

F

&)

NT041

EM-5

Page 1185 of 1701

PREPARATION

Special Service Tools(Cont'd)

Engine

Tool number

Description application

Tool name

GA

SRCD

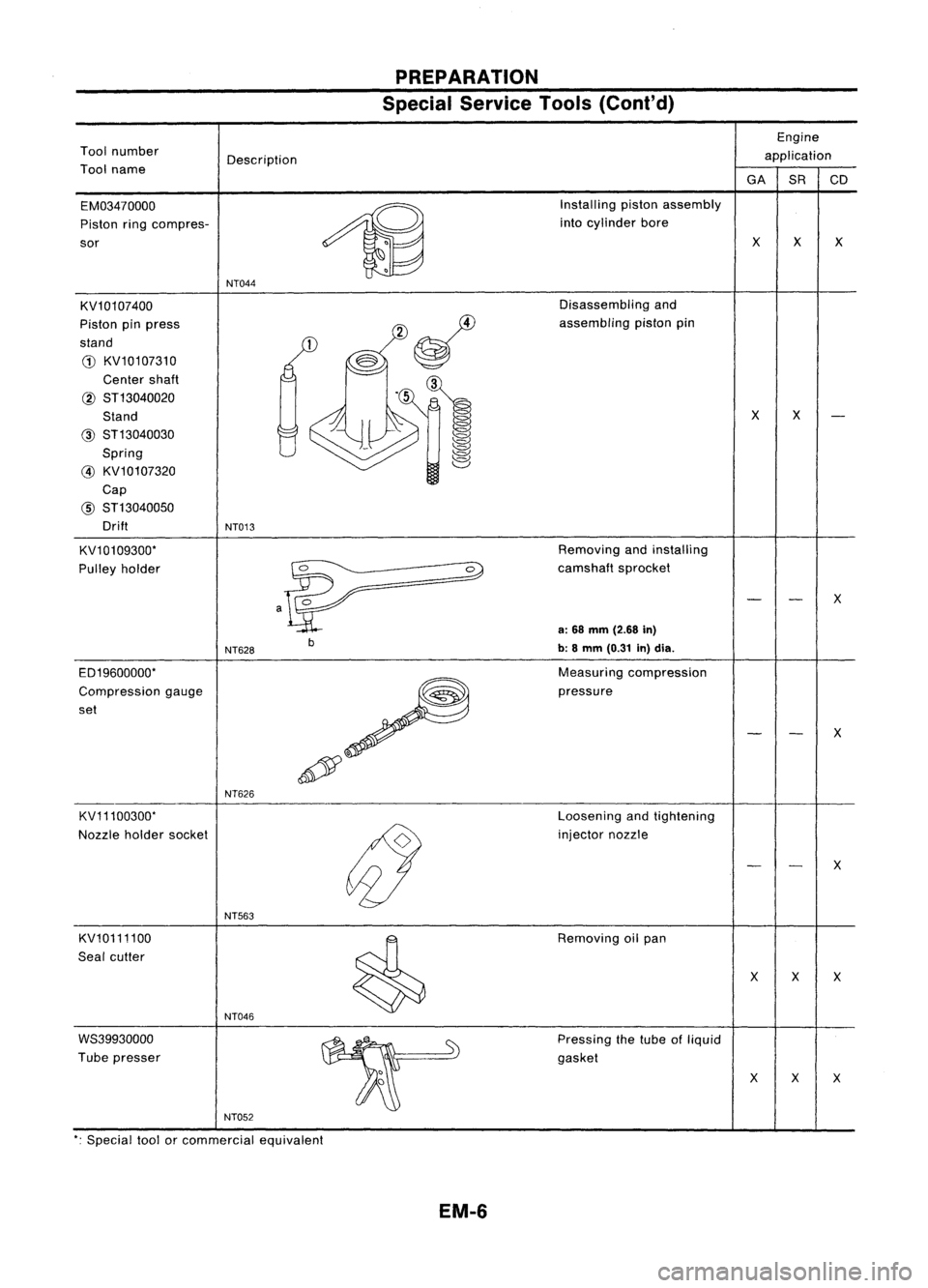

EM03470000

~

Installing

pistonassembly

Piston ringcompres- into

cylinder bore

sor

X

X

X

NT044

KV10107400 Disassembling

and

Piston pinpress assembling

pistonpin

stand

G)

KV10107310

Center shaft

@ ST13040020

Stand

X

X

@ ST13040030

Spring

@ KV10107320

Cap

@

ST13040050

Drift

NT013

KV10109300* Removing

andinstalling

Pulley holder

0

camshaftsprocket

X

a

a:

68 mm (2.68

in)

b b:8mm (0.31

in)dia.

NT628

ED19600000* Measuring

compression

Compression gauge pressure

set

X

p'

NT626

KV11100300* Loosening

andtightening

Nozzle holdersocket

(J

injector

nozzle

X

NT563

KV10111100

~

Removing

oilpan

Seal cutter

X

X

X

NT046

WS39930000 Pressingthetube ofliquid

Tube presser gasket

XXX

NT052

*: Special toolorcommercial equivalent

EM-6

Page 1186 of 1701

Toolnumber

Tool name Description

PREPARATION

Special Service Tools(Cont'd)

Engine

application

GA SRCD

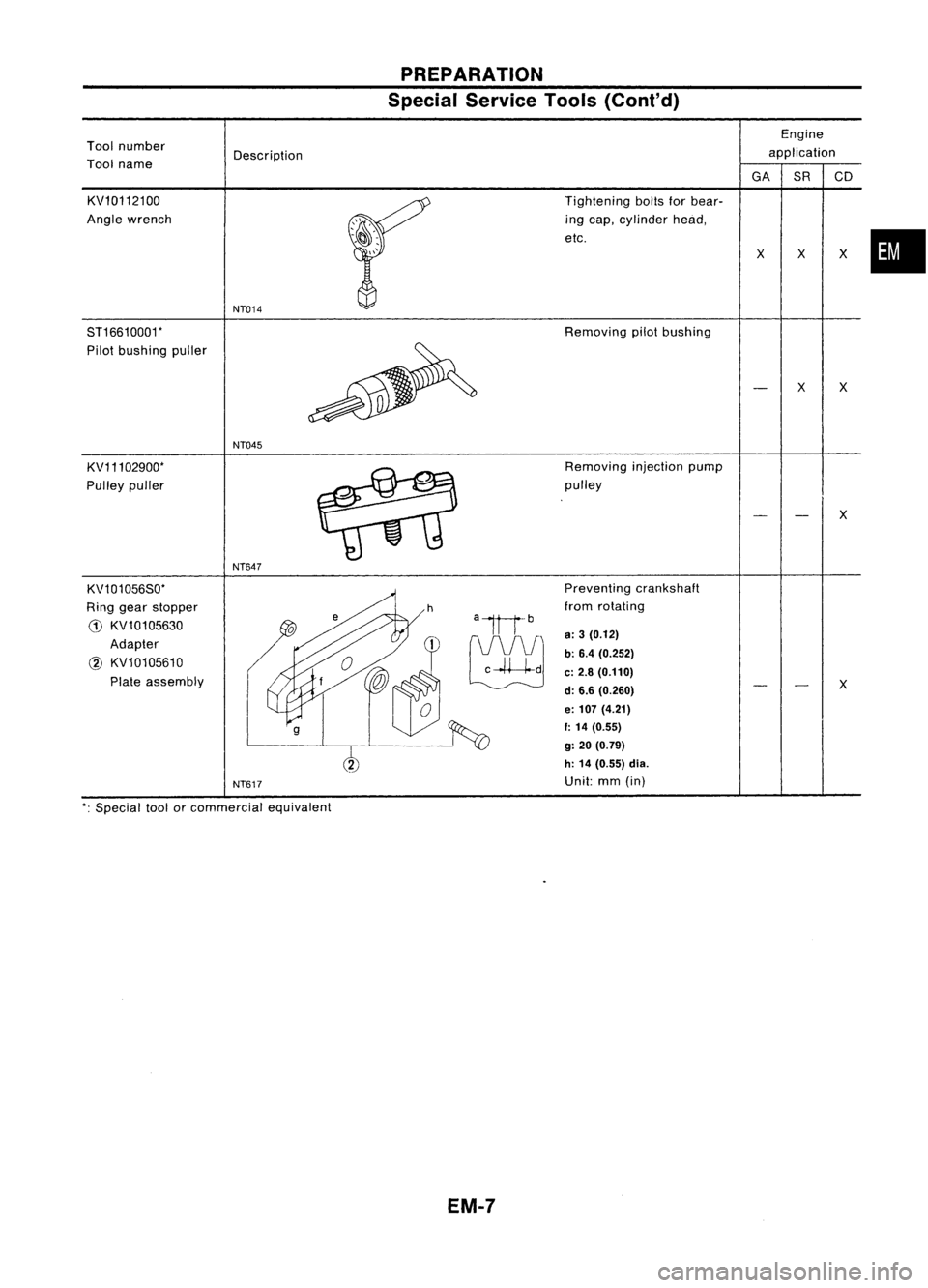

KV10112100

Angle wrench

ST16610001*

Pilot bushing puller

KV11102900*

Pulley puller

KV101056S0*

Ring gear stopper

G) KV10105630

Adapter

@ KV10105610

Plate assembly

NT014

NT045

NT647

NT617

Tightening

boltsforbear-

ing cap, cylinder head,

etc.

Removing pilotbushing

Removing injectionpump

pulley

Preventing crankshaft

from rotating

a:

3(0.12)

b: 6.4 (0.252)

c:

2.8 (0.110)

d: 6.6 (0.260)

e:

107 (4.21)

f:

14 (0.55)

g:

20 (0.79)

h: 14 (0.55) dia.

Unit: mm(in)

x

x

x

X

X

x

*:

Special toolorcommercial equivalent

EM-7

Page 1187 of 1701

PREPARATION

Commercial ServiceTools

Engine

Tool name Description application

GA

SRCD

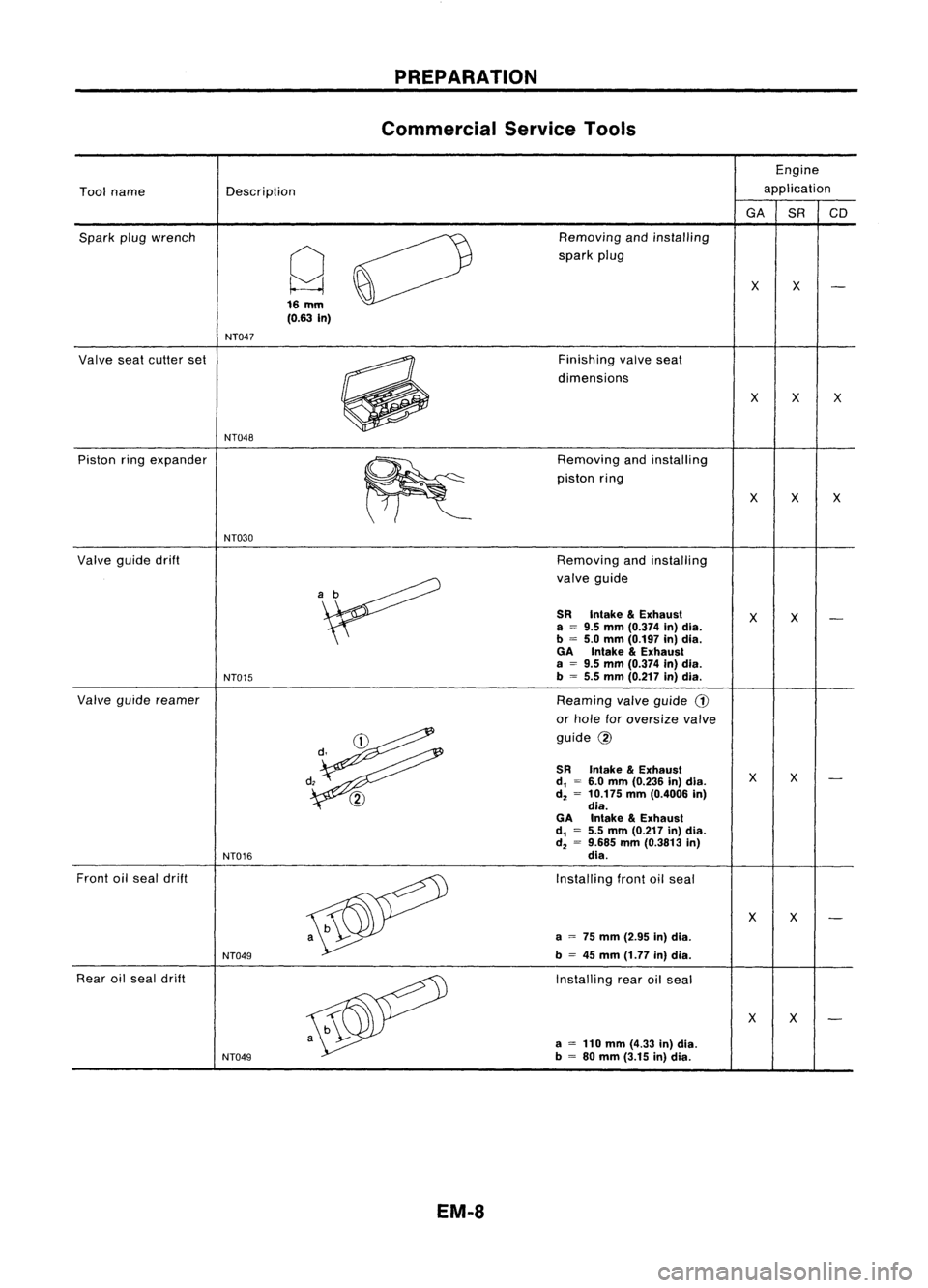

Spark plugwrench

0

Removing

andinstalling

Q

spark

plug

XX

16

mm

(0.63

In)

NT047

Valve seatcutter set

~

Finishing

valveseat

dimensions

XX

X

NT048

Piston ringexpander

~

Removing

andinstalling

piston ring

X

X

X

NT030

Valve guidedrift Removingandinstalling

'~

valve

guide

SR

Intake

&

Exhaust

XX

a

=

9.5

mm

(0.374 in)dia.

b

=

5.0

mm

(0.197 in)dia.

GA

Inlake

&

Exhaust

a

=

9.5

mm

(0.374 In)dla.

NT015

b

=

5.5

mm

(0.217 in)dla.

Valve guide reamer

Reaming

valve

guide

G)

or hole foroversize valve

~

guide

@

d,

\J

SR

Intake

&

Exhausl

XX

d,

=

6.0

mm

(0.236 in)dia.

@

d,

=

10.175

mm

(0.4006 in)

dia.

GA

Intake

&

Exhausl

d,

=

5.5

mm

(0.217 in)dia.

d,

=

9.685

mm

(0.3813 in)

NT016

dia.

Front oilseal drift

Installingfrontoilseal

XX

a

=

75

mm

(2.95 In)dla.

NT049

b

=

45

mm

(1.77 in)dia.

Rear oilseal drift

Installingrearoilseal

X

X

a

=

110

mm

(4.33 In)dla.

NT049

b

=

80

mm

(3.15 in)dia.

EM-8

Page 1189 of 1701

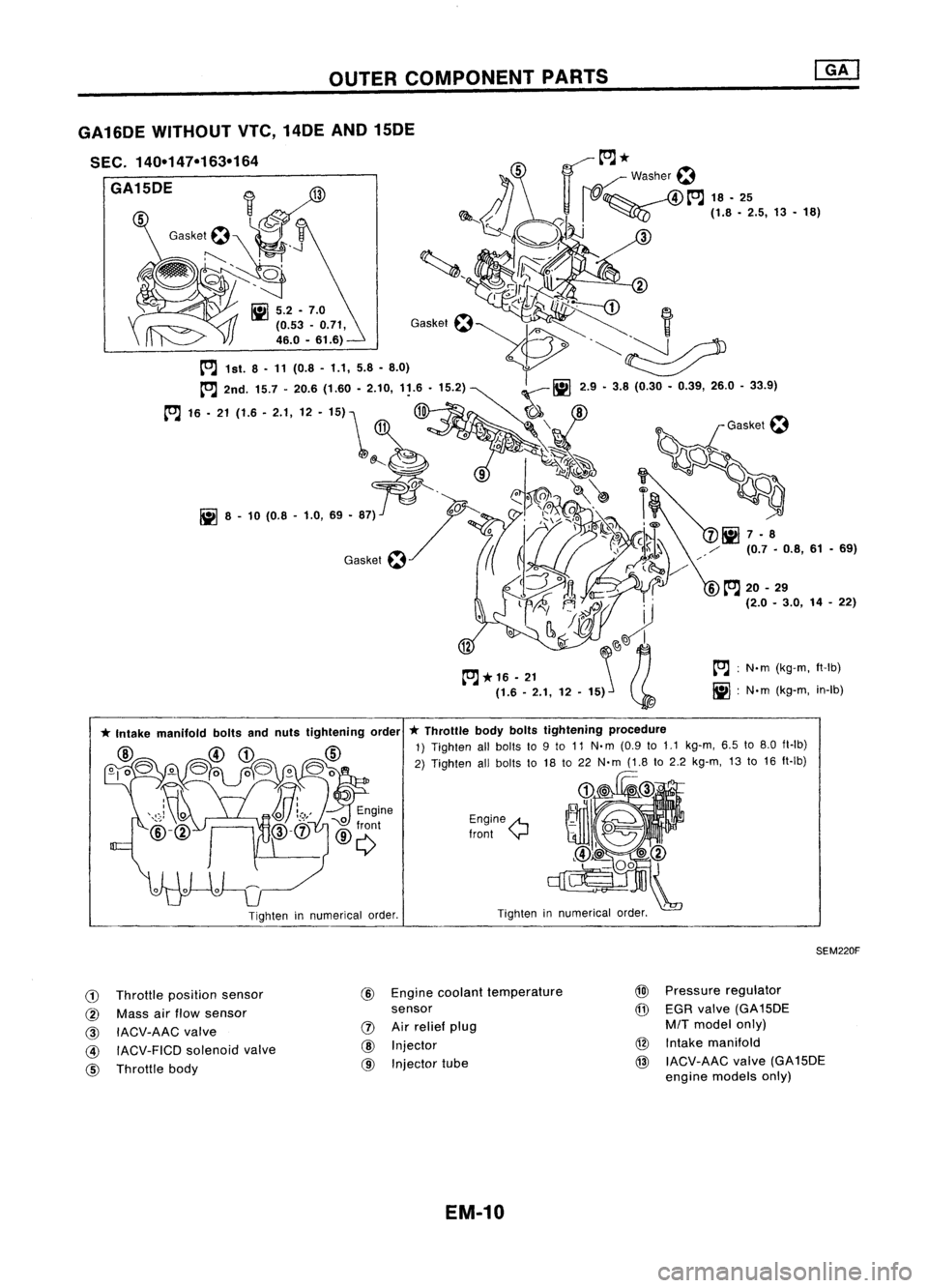

OUTERCOMPONENT PARTS

tOJ:

N.m (kg-m, ft-Ib)

iii :

N'm (kg-m, in-Ib)

Tighten innumerical order.

Engine

A

Iront

y

*

Throttle bodyboltstightening procedure

1) Tighten allbolts to9to 11 N.m (0.9 to

1.1

kg-m, 6.5to8.0 fl-Ib)

2) Tighten allbolts to18 to22 N'm (1.8to2.2 kg-m, 13to16 ft-Ib)

Tighten innumerical order.

GA16DE

WITHOUT VTe,14DE AND15DE

SEC. 140-147-163-164

GA15DE

SEM220F

CD

Throttle position sensor

@ Mass airflow sensor

@

IACV-AAC valve

@ IACV-FICD solenoidvalve

@ Throttle body @

Engine coolant temperature

sensor

IJ)

Airrelief plug

@

Injector

@ Injector tube

@l

Pressure regulator

@

EGR valve (GA15DE

M/T

model only)

@ Intake manifold

@ IACV-AAC valve(GA15DE

engine models only)

EM-10

Page 1194 of 1701

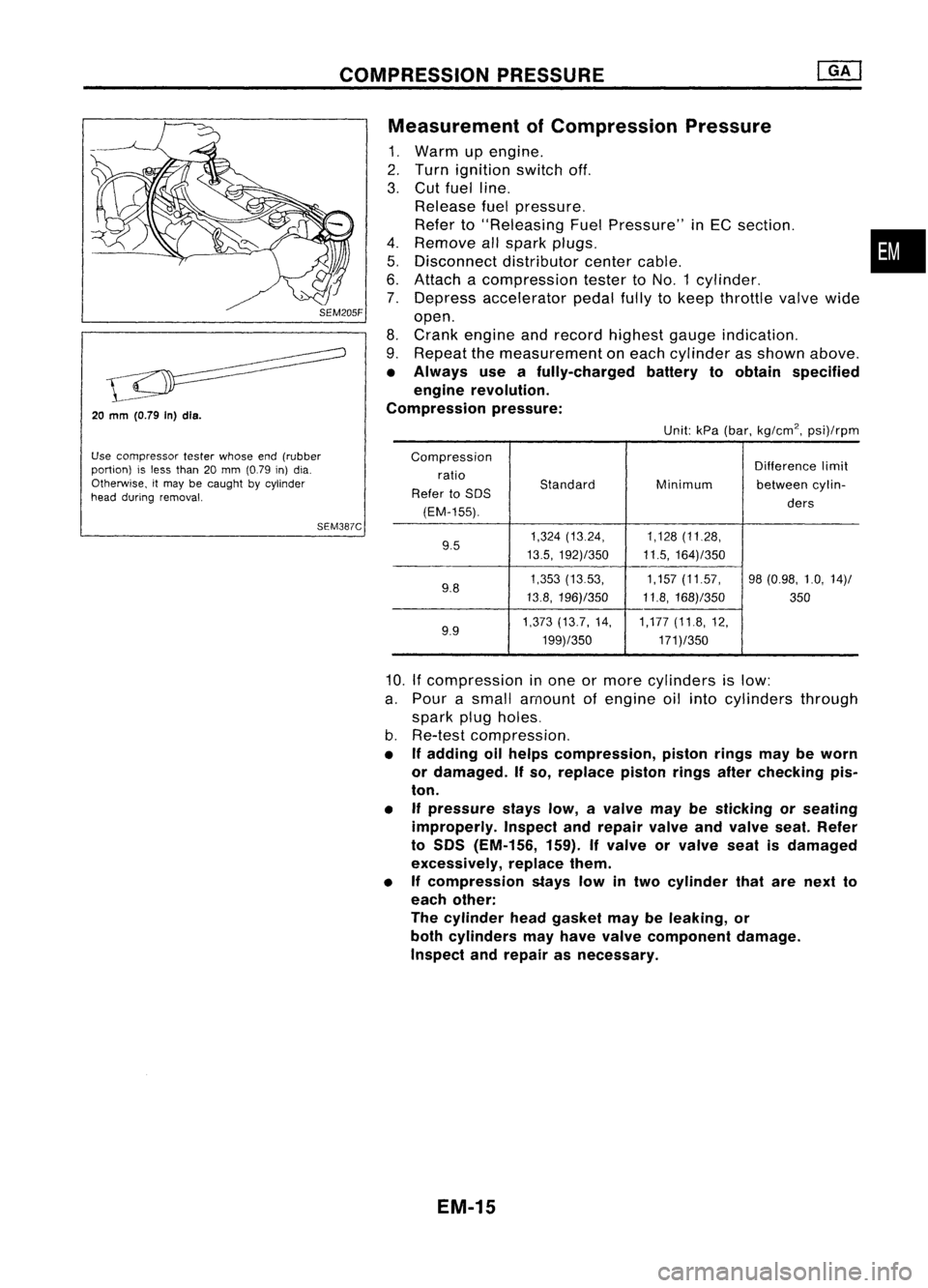

COMPRESSIONPRESSURE

20

mm

(O.79 In)dls.

Use compressor testerwhose end(rubber

portion) isless than 20mm (0.79 in)dia.

Otherwise, itmay becaught bycylinder

head during removal.

SEM387CMeasurement

ofCompression Pressure

1. Warm upengine.

2. Turn ignition switchoff.

3. Cut fuel line.

Release fuelpressure.

Refer to"Releasing FuelPressure" inEC section. •

4. Remove allspark plugs.

5. Disconnect distributorcentercable.

6. Attach acompression testertoNO.1 cylinder.

7. Depress accelerator pedalfullytokeep throttle valvewide

open.

8. Crank engine andrecord highest gaugeindication.

9. Repeat themeasurement oneach cylinder asshown above.

• Always useafully-charged batterytoobtain specified

engine revolution.

Compression pressure:

Unit:kPa(bar, kg/cm

2,

psi)/rpm

Compression Differencelimit

ratio

Standard

Refer toSOS Minimum

betweencylin-

(EM-155). ders

9.5 1,324

(13.24, 1,128(11.28,

13.5, 192)/350 11.5,164)/350

9.8 1,353

(1353, 1,157(11.57, 98(0.98, 1.0,14)/

13.8, 196)/350 11.8,168)/350

350

9.9 1,373

(13.7, 14, 1,177(11.8,12,

199)/350 171)/350

10.

If

compression inone ormore cylinders islow:

a. Pour asmall amount ofengine oilinto cylinders through

spark plugholes.

b. Re-test compression,

• Ifadding oilhelps compression, pistonringsmaybeworn

or damaged. Ifso, replace pistonringsafterchecking pis-

ton.

• Ifpressure stayslow,avalve maybesticking orseating

improperly. Inspectandrepair valveandvalve seat.Refer

to SOS (EM-156, 159).Ifvalve orvalve seatisdamaged

excessively, replacethem.

• Ifcompression stayslowintwo cylinder thatarenext to

each other:

The cylinder headgasket maybeleaking, or

both cylinders mayhave valve component damage.

Inspect andrepair asnecessary.

EM-15