engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1223 of 1701

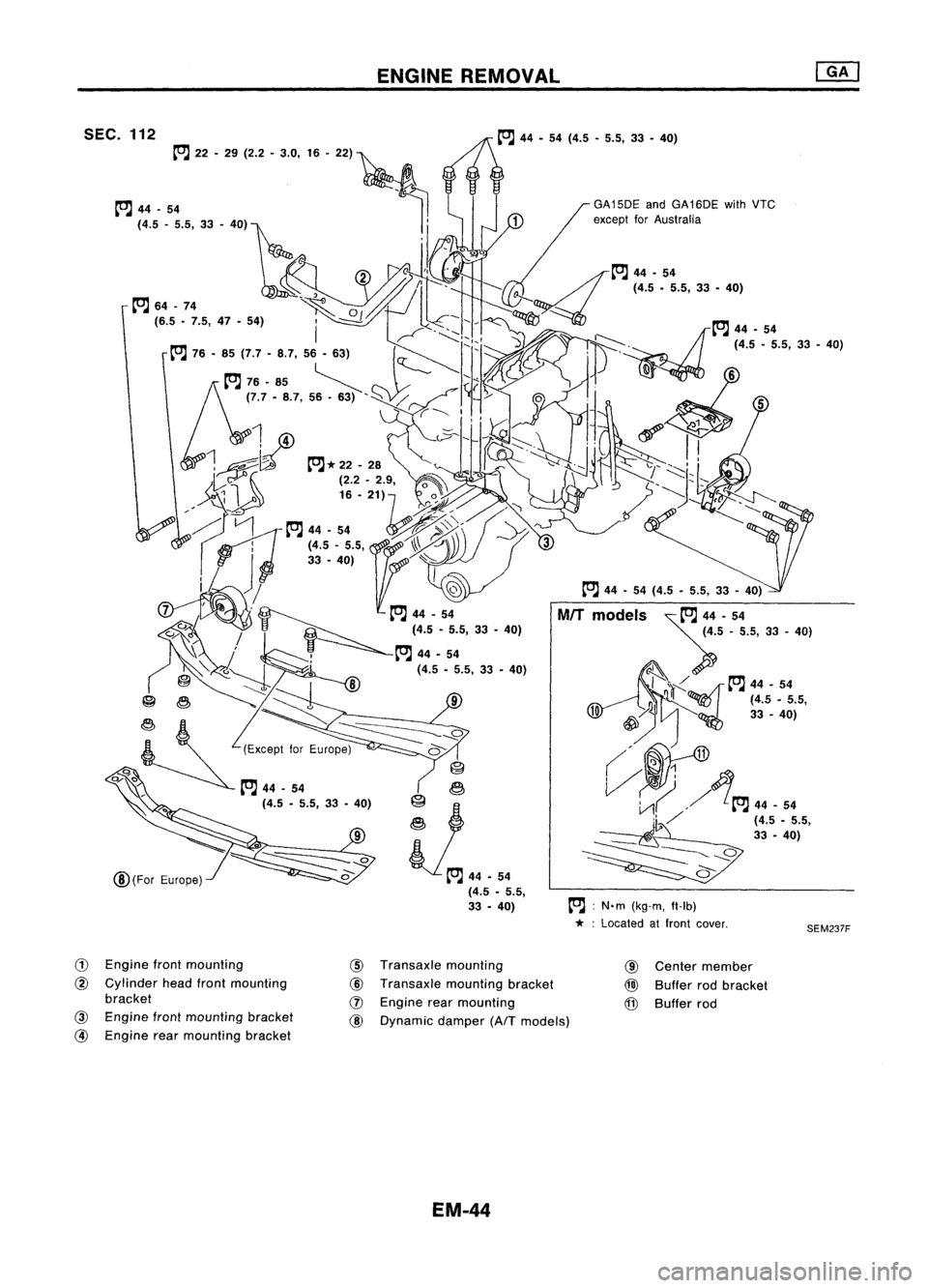

ENGINEREMOVAL

SEM237F

5

to.J :

N'm (kg-m, ft-Ib)

* :Located atfront cover.

to.J

44•54 (4.5 •5.5, 33•40)

MIT models

~44.54

(4.5 .5.5, 33.40)

~ I

)-<~

to.J

44-54

o

(4.5-5.5,

10

~;:J

33•40)

('.~

V~)

/$1

'v1( ./'"

L

[OJ

44•54

" / (4.5•5.5,

33 -40)

9

ffit"J

44-54 (4.5 -5.5. 33-40)

d

GA15DE andGA16DE withVTe

except forAustralia

u~

SEC.

112

@(For Europe)

(1)

Engine frontmounting

@

Cylinder headfrontmounting

bracket

@

Engine frontmounting bracket

@

Engine rearmounting bracket

@

Transaxle mounting

@

Transaxle mountingbracket

(f)

Engine rearmounting

@

Dynamic damper(AfTmodels)

@

Center member

@J

Buffer rodbracket

@

Buffer rod

EM-44

Page 1224 of 1701

ENGINEREMOVAL

WARNING:

a. Situate vehicle onaflat and solid surface.

b. Place chocks atfront andback ofrear wheels.

c. Donot remove engineuntilexhaust systemhascompletely

cooled off.

Otherwise, youmay burn yourself and/orfiremay break out

in fuel line.

d. For safety during subsequent steps,thetension ofwires

should beslackened againsttheengine.

e. Before disconnecting fuelhose, release fuelpressure from

fuel line.

Refer to"Releasing FuelPressure" inEC section.

f. Besure tohoist engine andtransaxle inasafe manner.

g. For engines notequipped withengine slingers, attach

proper slingers andbolts described inPARTS CATALOG.

CAUTION:

• When liftingengine, besure toclear surrounding parts.

Take special careforaccelerator wirecasing, brakelines

and brake master cylinder.

• Inhoisting theengine, alwaysuseengine slingers inasafe

manner.

• Inremoving driveshaft, becareful nottodamage grease

seal oftransaxle.

Engine cannotberemoved separately fromtransaxle. Remove

engine withtransaxle.

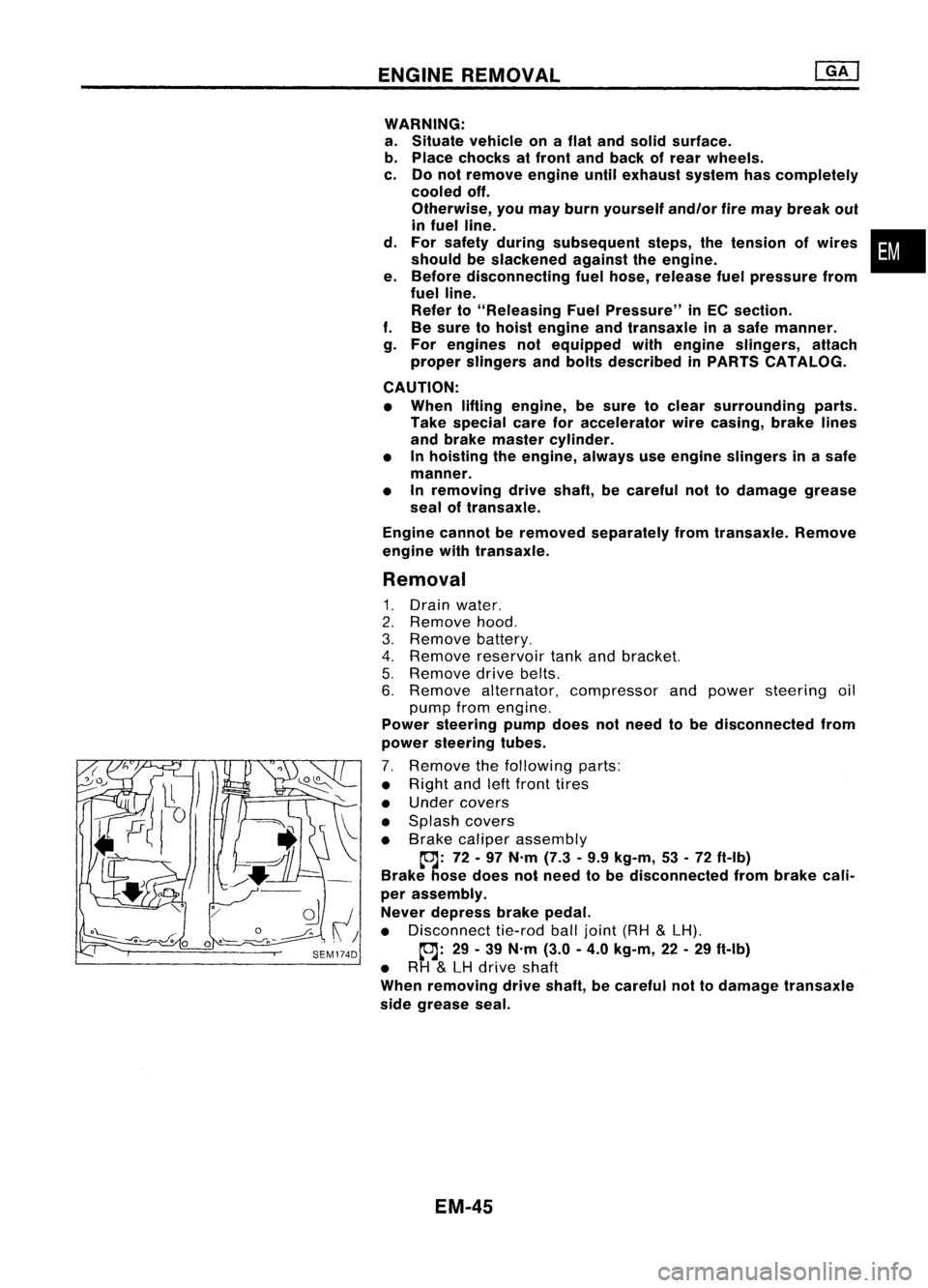

Removal

1. Drain water.

2. Remove hood.

3. Remove battery.

4. Remove reservoir tankandbracket.

5. Remove drivebelts.

6. Remove alternator, compressor andpower steering oil

pump fromengine.

Power steering pumpdoesnotneed tobe disconnected from

power steering tubes.

7. Remove thefollowing parts:

• Right andleftfront tires

• Under covers

• Splash covers

• Brake caliper assembly

~: 72-97 N'm (7.3•9.9 kg-m, 53•72 ft-Ib)

Brake hosedoes notneed tobe disconnected frombrake cali-

per assembly.

Never depress brakepedal.

• Disconnect tie-rodballjoint (RH

&

LH).

~: 29-39 N'm (3.0-4.0 kg-m, 22-29 ft-Ib)

• RH

&

LH drive shaft

When removing driveshaft, becareful nottodamage transaxle

side grease seal.

EM-45

•

Page 1225 of 1701

ENGINEREMOVAL

mJ

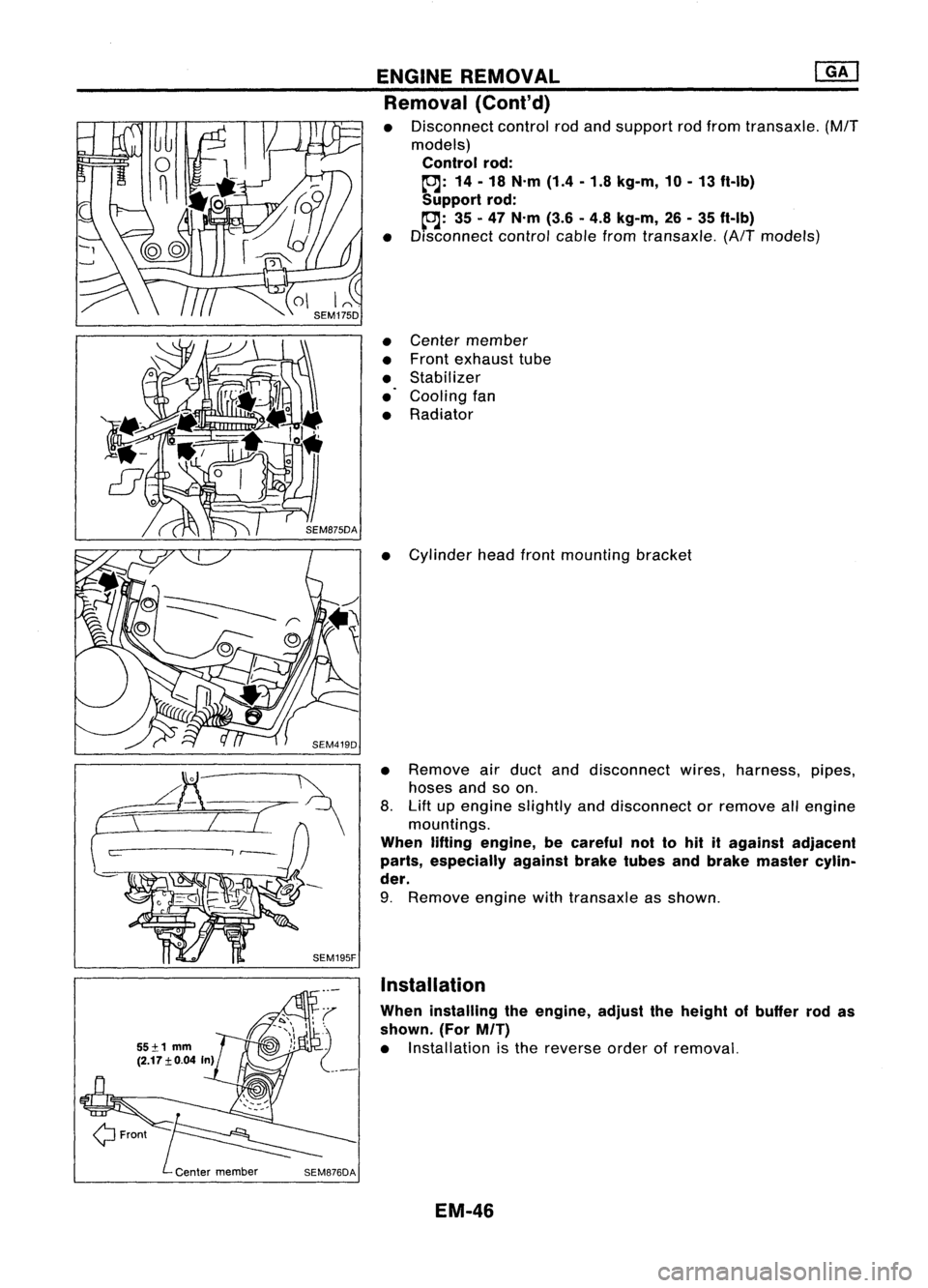

Removal (Cont'd)

• Disconnect controlrodand support rodfrom transaxle.

(M/T

models)

Control rod:

to:J:

14-18 N.m (1.4-1.8 kg-m, 10-13 ft-Ib)

Support rod:

to:J:

35-47 N.m (3.6-4.8 kg-m, 26-35 ft-Ib)

• Disconnect controlcablefromtransaxle.

(A/Tmodels)

• Center member

• Front exhaust tube

• Stabilizer

• Cooling fan

• Radiator

• Cylinder headfrontmounting bracket

• Remove airduct anddisconnect wires,harness, pipes,

hoses andsoon.

8. Lift upengine slightly anddisconnect orremove allengine

mountings.

When liftingengine, becareful nottohit itagainst adjacent

parts, especially againstbraketubesandbrake master cylin-

der.

9. Remove enginewithtransaxle asshown.

Installation

When installing theengine, adjusttheheight ofbuffer rodas

shown. (ForM/T)

• Installation isthe reverse orderofremoval.

EM-46

Page 1226 of 1701

![NISSAN ALMERA N15 1995 Service Manual CYLINDERBLOCK

SEC. 110.120

ij]

6.3•8.3

(0.641 •0.851, 55.6-73.9)

I]

to;J

83.5 •93.3

(8.51 -9.51,

61.6 •68.8)

f]

to.J

93.3 •103.1 (9.51-10.51, 68.8-76.0)

to;J :

N.

m

(kg-m, ft-Ib)

~ NISSAN ALMERA N15 1995 Service Manual CYLINDERBLOCK

SEC. 110.120

ij]

6.3•8.3

(0.641 •0.851, 55.6-73.9)

I]

to;J

83.5 •93.3

(8.51 -9.51,

61.6 •68.8)

f]

to.J

93.3 •103.1 (9.51-10.51, 68.8-76.0)

to;J :

N.

m

(kg-m, ft-Ib)

~](/img/5/57349/w960_57349-1225.png)

CYLINDERBLOCK

SEC. 110.120

ij]

6.3•8.3

(0.641 •0.851, 55.6-73.9)

I]

to;J

83.5 •93.3

(8.51 -9.51,

61.6 •68.8)

f]

to.J

93.3 •103.1 (9.51-10.51, 68.8-76.0)

to;J :

N.

m

(kg-m, ft-Ib)

~ :N.m (kg-m, in-Ib)

~ :Apply liquidgasket.

f] :

Lubricate withnew engine oil.

SEM238F

•

CD

Oillevel gauge guide

@

Cylinder block

@

Rear oilseal retainer

@

Rear oilseal

@

Rear plate

@

Flywheel

(J)

Rear lower plate

@

Drive plate

*: Applies toGA 16DE without VTC,14DE.

@

Drain plug

@)

Buffer plate

@

Topring

@

2ndring (Only Europe models*)

@

Oilring

@

Piston

@

Snap ring

@

Piston pin

EM-47

@

Connecting rod

@

Connecting rodbearing

@)

Connecting rodcap

@l

Key

@

Main bearing

@

Thrust bearing

@

Crankshaft

@

Main bearing cap

Page 1227 of 1701

CYLINDERBLOCK

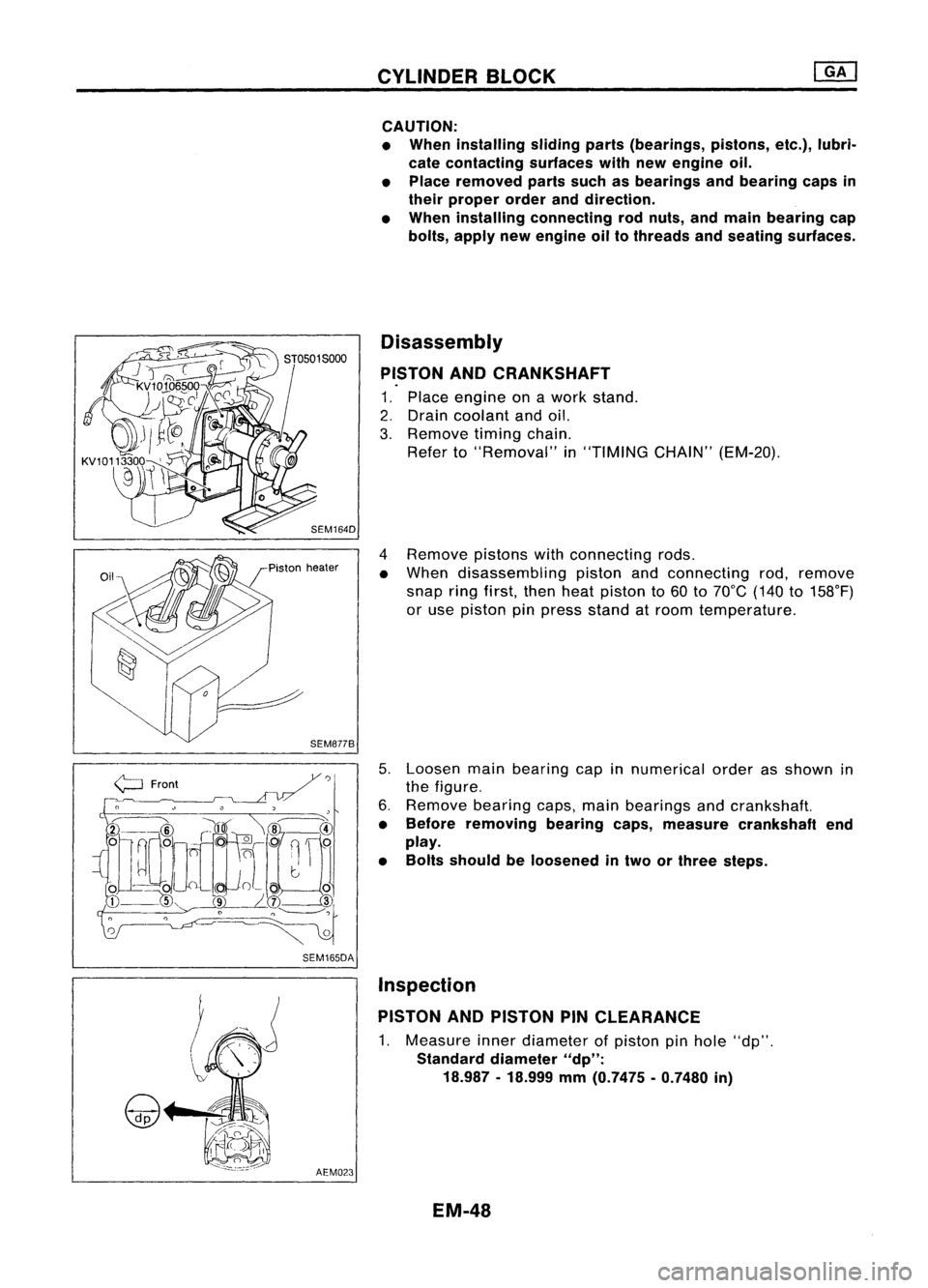

CAUTION:

• When installing slidingparts(bearings, pistons,etc.),lubri-

cate contacting surfaceswithnewengine oil.

• Place removed partssuchasbearings andbearing capsin

their proper orderanddirection.

• When installing connecting rodnuts, andmain bearing cap

bolts, apply newengine oiltothreads andseating surfaces.

Disassembly

PISTON ANDCRANKSHAFT

1. Place engine onawork stand.

2. Drain coolant andoil.

3. Remove timingchain.

Refer to"Removal" in"TIMING CHAIN"(EM-20).

4 Remove pistonswithconnecting rods.

• When disassembling pistonandconnecting rod,remove

snap ringfirst, thenheat piston to60 to70°C (140to158°F)

or use piston pinpress stand atroom temperature.

5. Loosen mainbearing capinnumerical orderasshown in

the figure.

6. Remove bearingcaps,mainbearings andcrankshaft.

• Before removing bearingcaps,measure crankshaft end

play.

• Bolts should beloosened intwo orthree steps.

AEM023 Inspection

PISTON ANDPISTON PINCLEARANCE

1. Measure innerdiameter ofpiston pinhole "dp".

Standard diameter

"dp":

18.987 -18.999

mm

(0.7475 -0.7480

in)

EM-48

Page 1229 of 1701

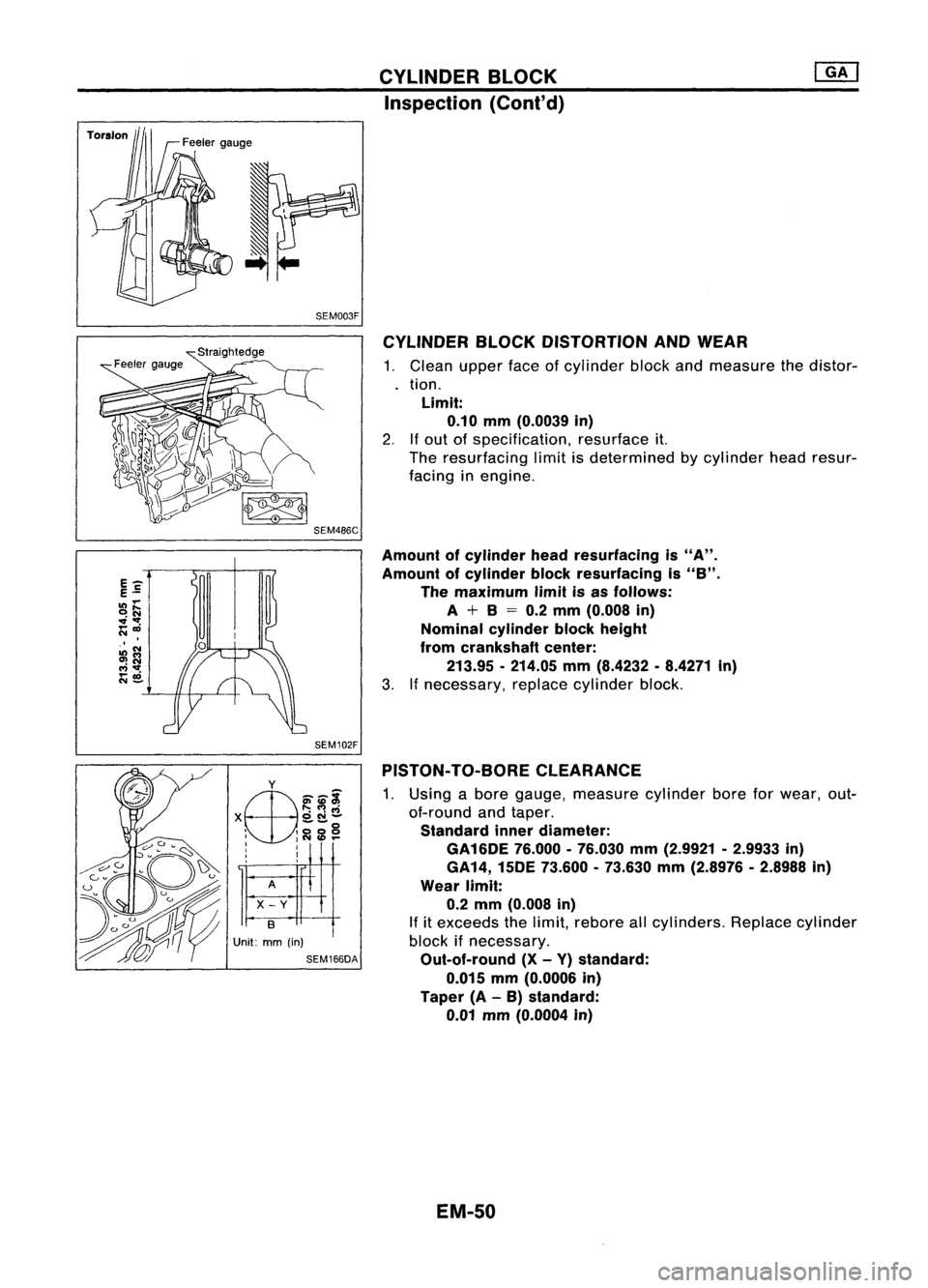

SEM003FCYLINDER

BLOCK

Inspection (Cont'd)

Feeler gauge Straightedge

SEM102F

I

I

,

,

!

,

A

X-V

B

Unit:

mm

(In)

SEM166DA CYLINDER

BLOCKDISTORTION ANDWEAR

1. Clean upperfaceofcylinder blockandmeasure thedistor-

tion.

Limit: 0.10 mm(0.0039 in)

2. Ifout ofspecification, resurface

it.

The resurfacing limitisdetermined bycylinder headresur-

facing inengine.

Amount ofcylinder headresurfacing is

"A".

Amount ofcylinder blockresurfacing is

"B".

The maximum limitisas follows:

A

+

B

= 0.2 mm (0.008 in)

Nominal cylinderblockheight

from crankshaft center:

213.95 -214.05 mm(8.4232 .8.4271 in)

3. Ifnecessary, replacecylinder block.

PISTON- TO-BORE CLEARANCE

1. Using abore gauge, measure cylinderboreforwear, out-

of-round andtaper.

Standard innerdiameter:

GA16DE 76.000-76.030 mm(2.9921 -2.9933 in)

GA14, 15DE73.600 -73.630 mm(2.8976 -2.8988 in)

Wear limit:

0.2 mm (0.008 in)

If itexceeds thelimit, rebore allcylinders. Replacecylinder

block ifnecessary.

Out-of-round (X-Y) standard:

0.015 mm(0.0006 in)

Taper (A-B) standard:

0.01 mm(0.0004 in)

EM-50

Page 1235 of 1701

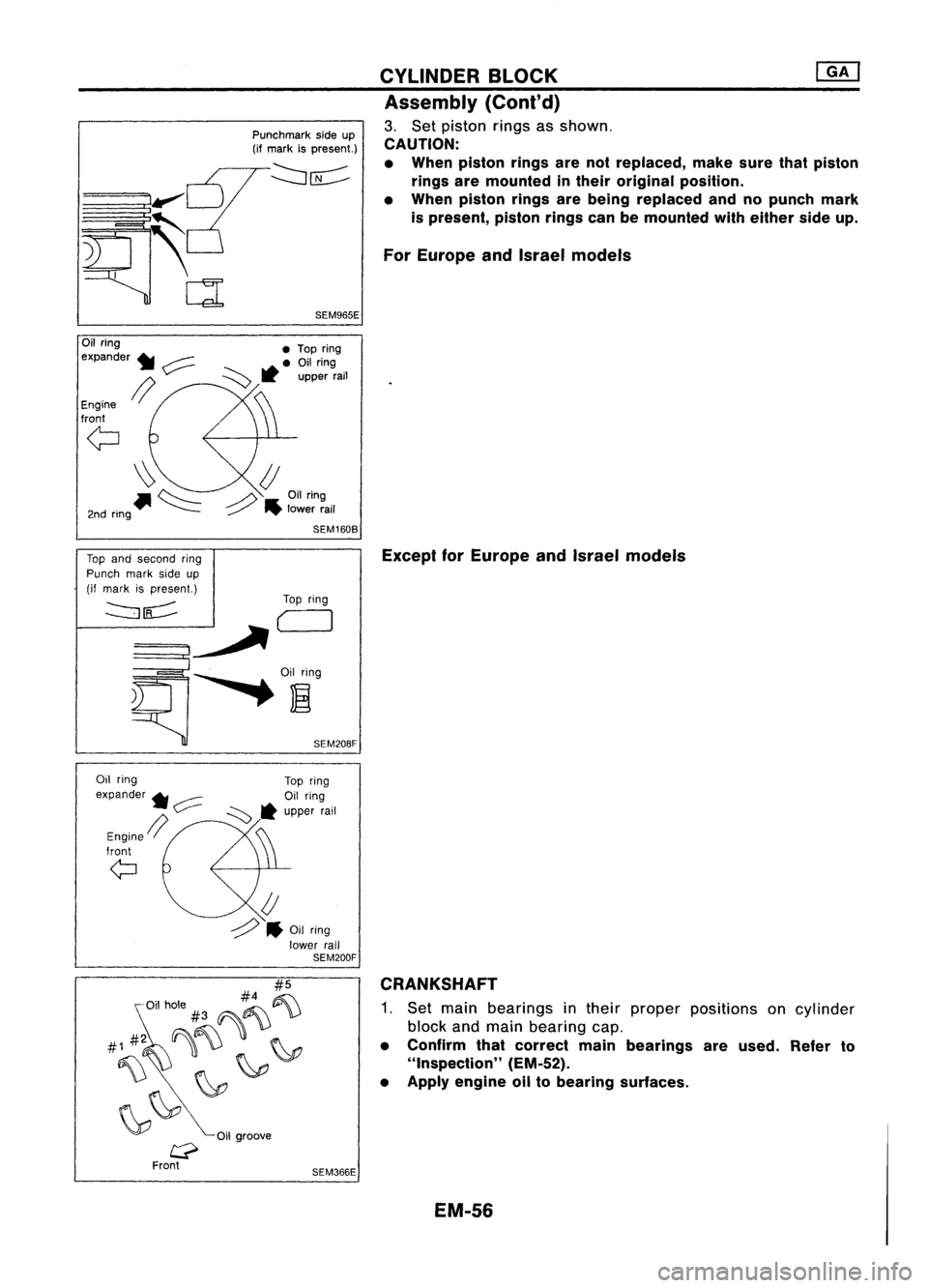

Punchmarksideup

(if mark ispresent.)

SEM965E CYLINDER

BLOCK @KJ

Assembly (Coni'd)

3. Set piston ringsasshown.

CAUTION:

• When piston ringsarenotreplaced, makesurethatpiston

rings aremounted intheir original position.

• When piston ringsarebeing replaced andnopunch mark

is present, pistonringscanbemounted witheither sideup.

For Europe andIsrael models

Engine

front

Q

Oil

ring

expander

tf

V

;l

Top and second ring

Punch marksideup

(if mark ispresen!.)

.::::::::J

c::

Oil ring

expander

*c:

Engine

il

front

~ •

Top ring

• Oil ring

~ upperrail

IJ

/') Oilring

~ ~lower rail

SEM160B

SEM208F

Top ring

Oil ring

~ It

upper rail

!J

~.Oil ring

lower rail

SEM200F Except

forEurope andIsrael models

#5

#4 ~

Oil hole #3 ~-'U

~"\)~ ~

~~

Oilgroove

SEM366E

CRANKSHAFT

1. Set main bearings intheir proper positions oncylinder

block andmain bearing cap.

• Confirm thatcorrect mainbearings areused. Referto

"Inspection" (EM-52).

• Apply engine oiltobearing surfaces.

EM-56

Page 1236 of 1701

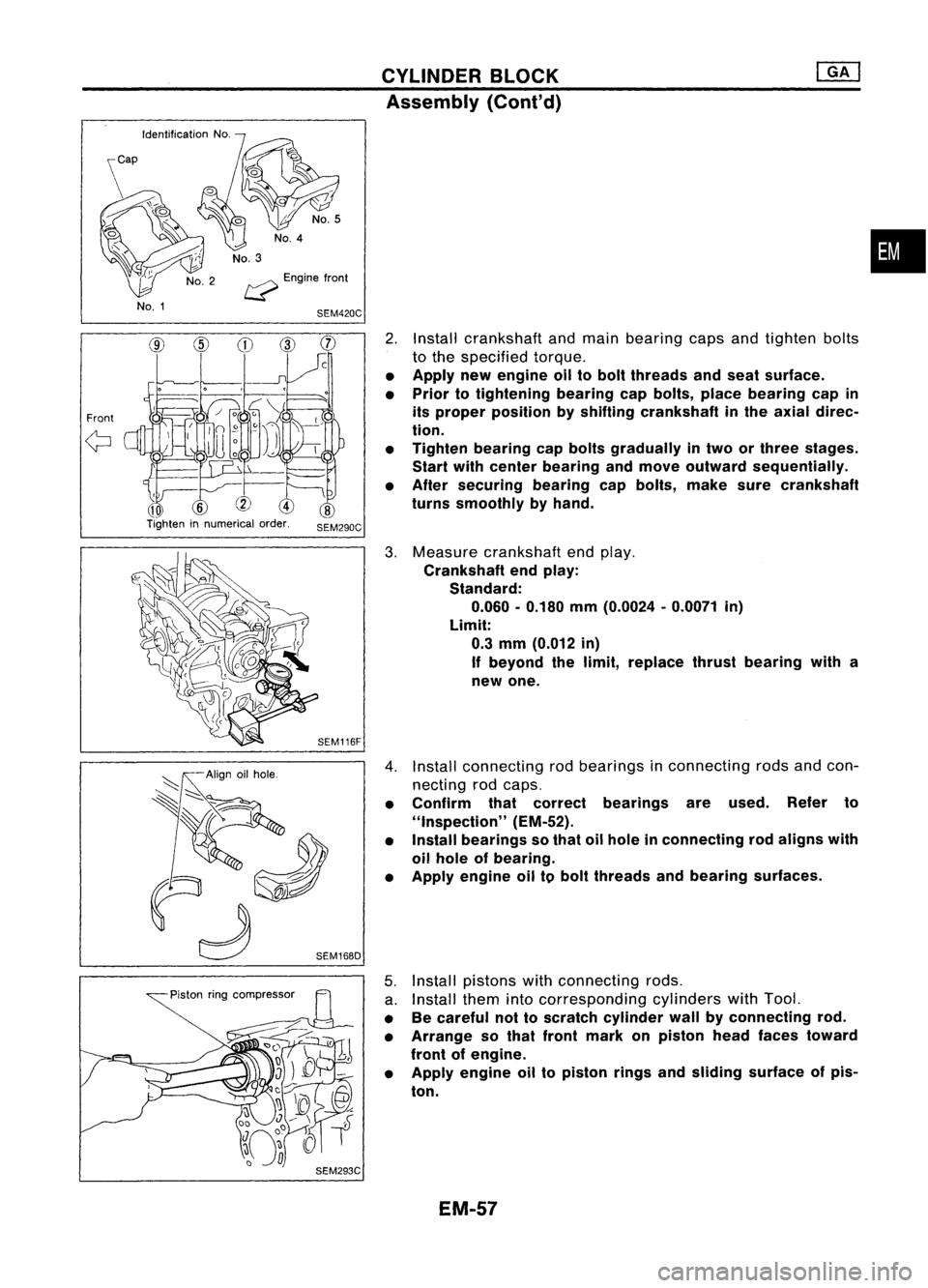

IdentificationNo.

\ca

p

\

NO.1

t.:?

Enginefront

SEM420C CYLINDER

BLOCK

Assembly (Cont'd)

•

Front

Pistonringcompressor

SEM293C

2.

Install crankshaft andmain bearing capsandtighten bolts

to the specified torque.

• Apply newengine oiltobolt threads andseat surface.

• Prior totightening bearingcapbolts, placebearing capin

its proper position byshifting crankshaft inthe axial direc-

tion.

• Tighten bearing capbolts gradually intwo orthree stages.

Start withcenter bearing andmove outward sequentially.

• After securing bearingcapbolts, makesurecrankshaft

turns smoothly byhand.

3. Measure crankshaft endplay.

Crankshaft endplay:

Standard:

0.060 -0.180 mm(0.0024 -0.0071 in)

Limit: 0.3 mm (0.012 in)

If beyond thelimit, replace thrustbearing witha

new one.

4. Install connecting rodbearings inconnecting rodsandcon-

necting rodcaps.

• Confirm thatcorrect bearings areused. Referto

"Inspection" (EM-52).

• Install bearings sothat oilhole inconnecting rodaligns with

oil hole ofbearing.

• Apply engine oiltobolt threads andbearing surfaces.

5. Install pistons withconnecting rods.

a. Install themintocorresponding cylinderswithTool.

• Becareful nottoscratch cylinder wallbyconnecting rod.

• Arrange sothat front mark onpiston headfaces toward

front ofengine.

• Apply engine oiltopiston ringsandsliding surface ofpis-

ton.

EM-57

Page 1238 of 1701

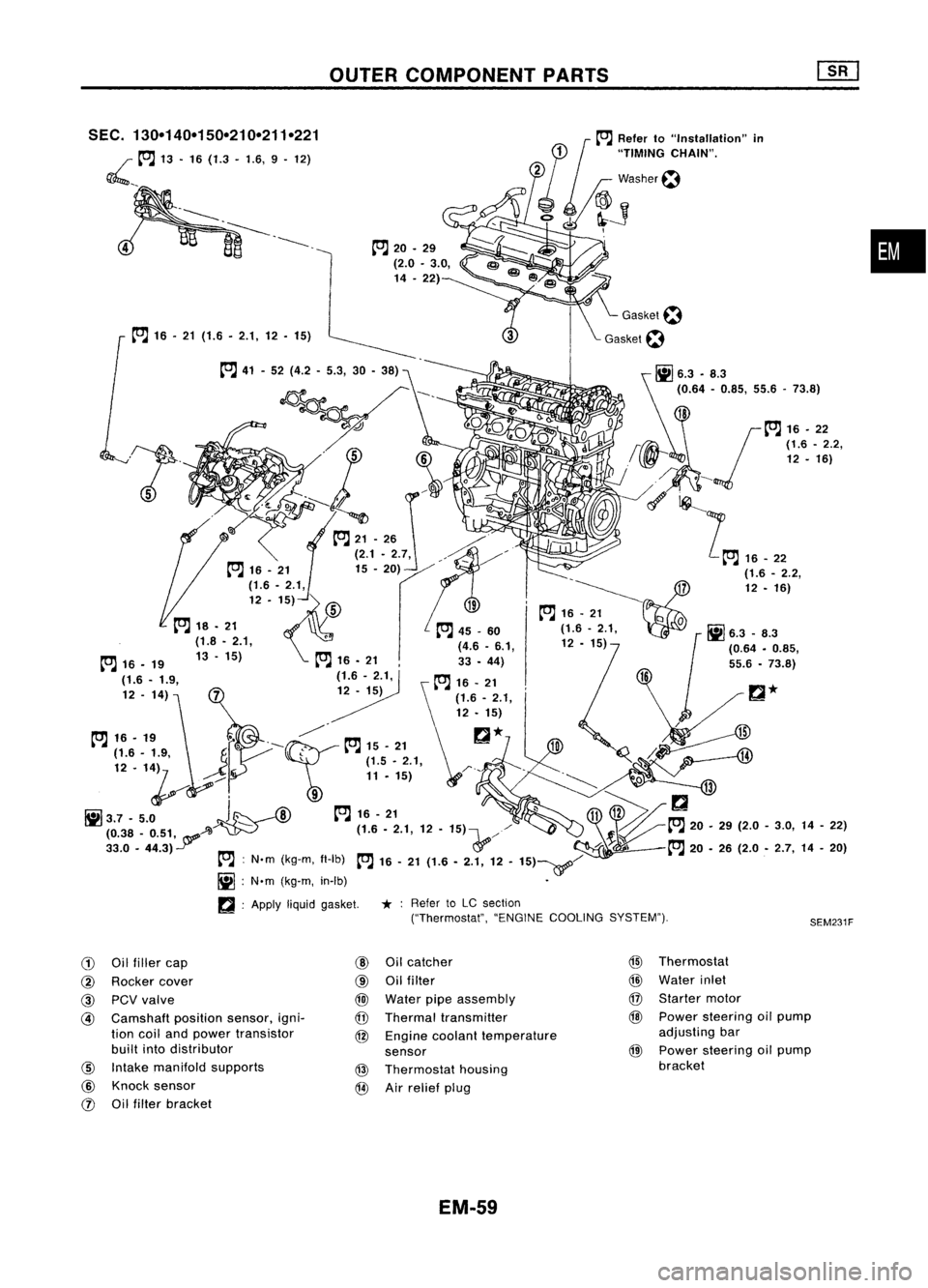

OUTERCOMPONENT PARTS

•

SEM231F

SEC.

130-140-150-210-211-221

~ __to:J

13•16 (1.3 -1.6, 9.12)

to:J

16•21 (1.6. 2.1,12. 15)

to:J

20•29

(2.0 •3.0,

14 .22)

to:J

41-52 (4.2 -5.3, 30-38)

~---- D_?

. 'J ~

~~~ 0

-t::;-.....~ /,

0

to:J

21-26 ./"

(2.1. 2.7, ,./"~/'

12 -1~)

fs\

19-~~7

~ to:J

16•21

Q

to:J

18. 21 ,

to:J

45_60 (1.6-2.1, 0

Ii]

6.3 _8.3

(1.8 •2.1, (4.6•6.1, 12•15)

1

(0.64•0.85,

to:J

16•19 13-15)

to:J

16•21 33•44)

(1.6 -1.9, (1.6-2.1,

to:J

16•21

12 -14)

12•15)

t"J

16•,.

f"-~

t"J

15•21

r::!

*

H

...----4lJ

~~'. '1~

J

r \~ ~~'..,:;

1,

~Q.

/¥i-;:

--'Il

1il3.7 -5.0

J~

--A)

to:J

16-21

~11V>/

(0.38 _0.51, A~ - (1.6.2.1,12•15)\...,//

~to:J

20.29(2.0-3.0, 14-22)

33.0 •44.3)

Y

&'/-

:f~l

to:J

20•26 (2.0 •2.7, 14-20)

to:J :

N'm (kg-m, fl-Ib)

to:J

16-21 (1.6 -2.1, 12-15)~/

Ii] :

N'm (kg-m, in-Ib) •

~ :Apply

liquidgasket.

*:

Refer toLC section

("Thermostat", "ENGINECOOLING SYSTEM").

G)

Oilfiller cap

@

Oilcatcher

@

Thermostat

@

Rocker cover

@

Oilfilter

@

Water inlet

@

PCVvalve

@

Water pipeassembly

@

Starter motor

@

Camshaft

positionsensor,igni-

@

Thermal transmitter

@

Power steering oilpump

tion coiland power transistor

@

Engine coolant temperature adjusting

bar

built intodistributor

sensor

@

Power

steering oilpump

@

Intake manifold supports

@

Thermostat housing bracket

@

Knock sensor

@

Airrelief plug

rJ)

Oilfilter bracket

EM-59

Page 1241 of 1701

COMPRESSIONPRESSURE

Measurement ofCompression Pressure

1. Warm upengine.

2. Turn ignition switchoff.

3. Release fuelpressure.

Refer to"Releasing FuelPressure" inEC section.

4. Remove allspark plugs.

5. Disconnect distributorcoilconnector.

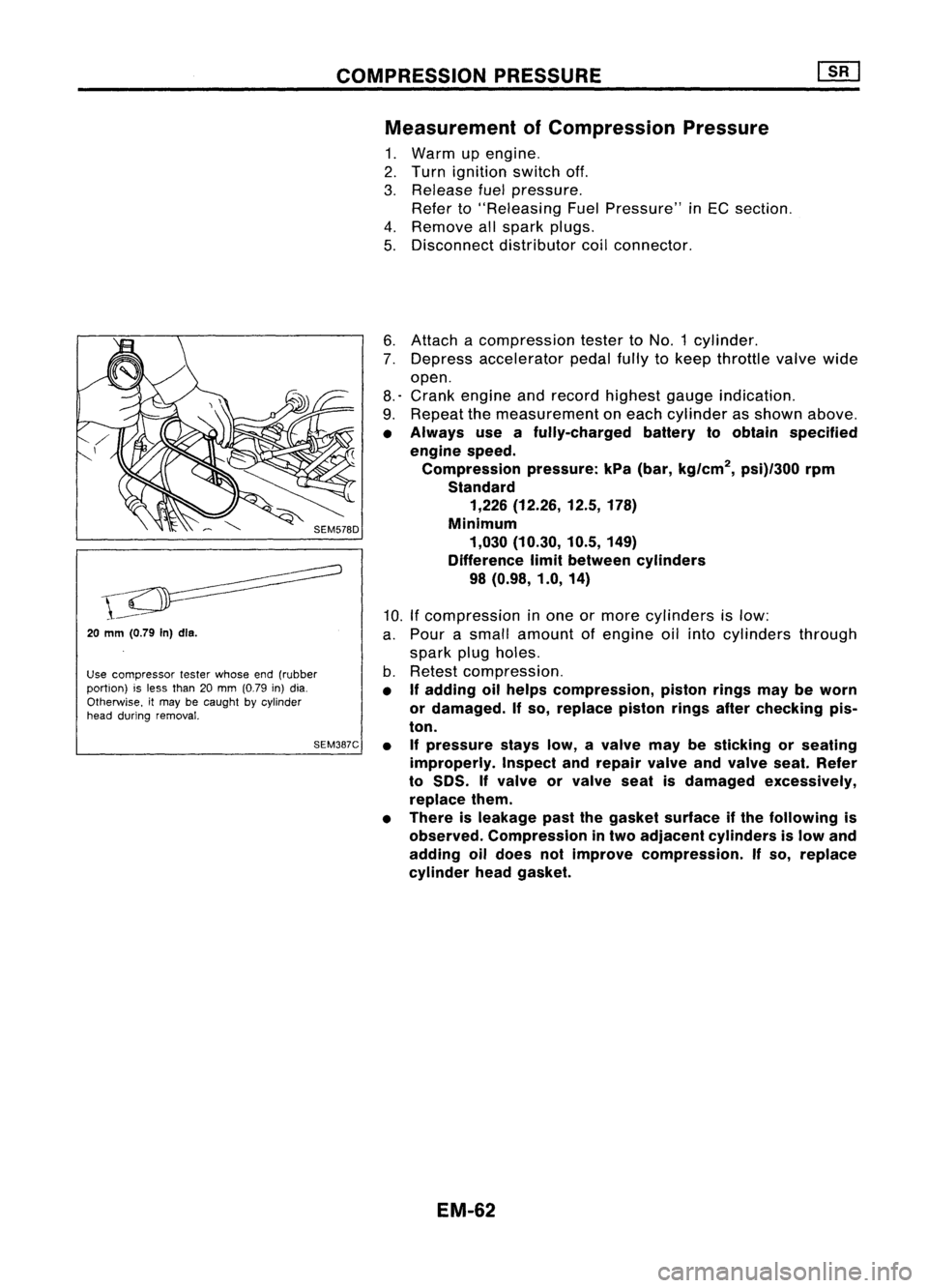

20

mm (0.79

In)dls.

Use compressor testerwhose end(rubber

portion) isless than 20mm (0.79 in)dia.

Otherwise. itmay becaught bycylinder

head during removal.

SEM387C6.

Attach acompression testertoNO.1 cylinder.

7. Depress accelerator pedalfullytokeep throttle valvewide

open.

8.' Crank engine andrecord highest gaugeindication.

9. Repeat themeasurement oneach cylinder asshown above.

• Always useafully-charged batterytoobtain specified

engine speed.

Compression pressure:kPa(bar, kg/cm

2,

psi)/300 rpm

Standard 1,226 (12.26, 12.5,178)

Minimum 1,030 (10.30, 10.5,149)

Difference limitbetween cylinders

98 (0.98, 1.0,14)

10. Ifcompression inone ormore cylinders islow:

a. Pour asmall amount ofengine oilinto cylinders through

spark plugholes.

b. Retest compression.

• If

adding oilhelps compression, pistonringsmaybeworn

or damaged.

If

so, replace pistonringsafterchecking pis-

ton.

• Ifpressure stayslow,avalve maybesticking orseating

improperly. Inspectandrepair valveandvalve seat.Refer

to

50S.

If

valve orvalve seatisdamaged excessively,

replace them.

• There isleakage pastthegasket surface ifthe following is

observed. Compression intwo adjacent cylinders islow and

adding oildoes notimprove compression.

If

so, replace

cylinder headgasket.

EM-62