engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1206 of 1701

![NISSAN ALMERA N15 1995 Service Manual

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

cam NISSAN ALMERA N15 1995 Service Manual

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

cam](/img/5/57349/w960_57349-1205.png)

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

camshaft sprockets.

• Make suresprocket's matingmarksfaceengine front.

20. Install camshaft sprocketbolts.

• Apply newengine oiltobolt threads andseat surface .

•

SEM657D

2.0.3.0

mm

(0.079 -0.118 In)

21.

Install upperchaintensioner.

• Before installing chaintensioner, insertasuitable pininto

pin hole ofchain tensioner.

• After installing chaintensioner, removethepin.

22. Install lowerchaintensioner.

CAUTION:

• Check noproblems occurwhenengine isrotated.

• Make surethatNo.1piston isset atTOC onitscompres-

sion stroke.

• Make sureofthe direction ofthe gasket beforeinstalling

lower chaintensioner.

23. Apply liquidgasket tothermostat housing.

• Use Genuine LiquidGasket orequivalent.

24. Install thermostat housing.

25. Install waterpump pulley.

EM-27

Page 1208 of 1701

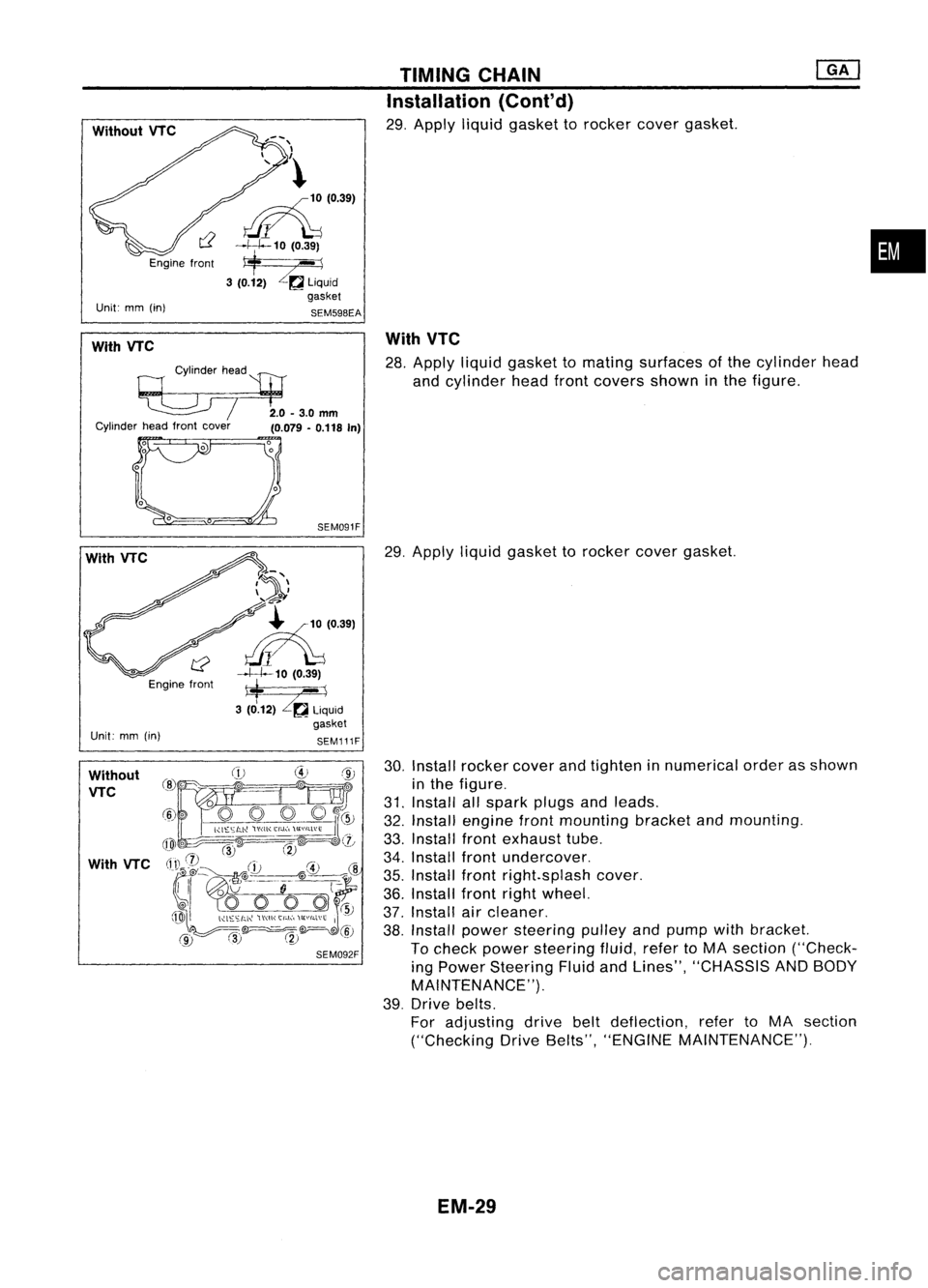

WithoutVTC

Engine front

Unit: mm(in)

~(0.39)

~1-J--10 (0.39)

* -\

3 (0.12)

Z~

Liquid

gasket

SEM59BEA TIMING

CHAIN

Installation (Cont'd)

29. Apply liquidgasket torocker covergasket.

•

With VTC

Cylinderhead

'l:tJ

~ /2.0-3.0mm

Cylinder headfront cover

(0.079-0.118 In)

With

VTC

28. Apply liquidgasket tomating surfaces ofthe cylinder head

and cylinder headfrontcovers showninthe figure.

With VTC

Engine front

Unit: mm(in)

SEM091F

7~'\

\ ..... -4'

~-'?

~'0391

~10 (0.39)

*

--1

3 (0.12)

Zr.a

liquid

gasket

SEM111F

29.

Apply liquidgasket torocker covergasket.

Without VTC

With VTC

30.

Install rocker coverandtighten innumerical orderasshown

in the figure.

31. Install allspark plugsandleads.

32. Install engine frontmounting bracketandmounting.

33. Install frontexhaust tube.

34. Install frontundercover.

35. Install frontright.splash cover.

36. Install frontrightwheel.

37. Install aircleaner.

38. Install power steering pulleyandpump withbracket.

To check power steering fluid,refertoMA section ("Check-

ing Power Steering FluidandLines", "CHASSIS ANDBODY

MAINTENANCE").

39. Drive belts.

For adjusting drivebeltdeflection, refertoMA section

("Checking DriveBelts", "ENGINE MAINTENANCE").

EM-29

Page 1209 of 1701

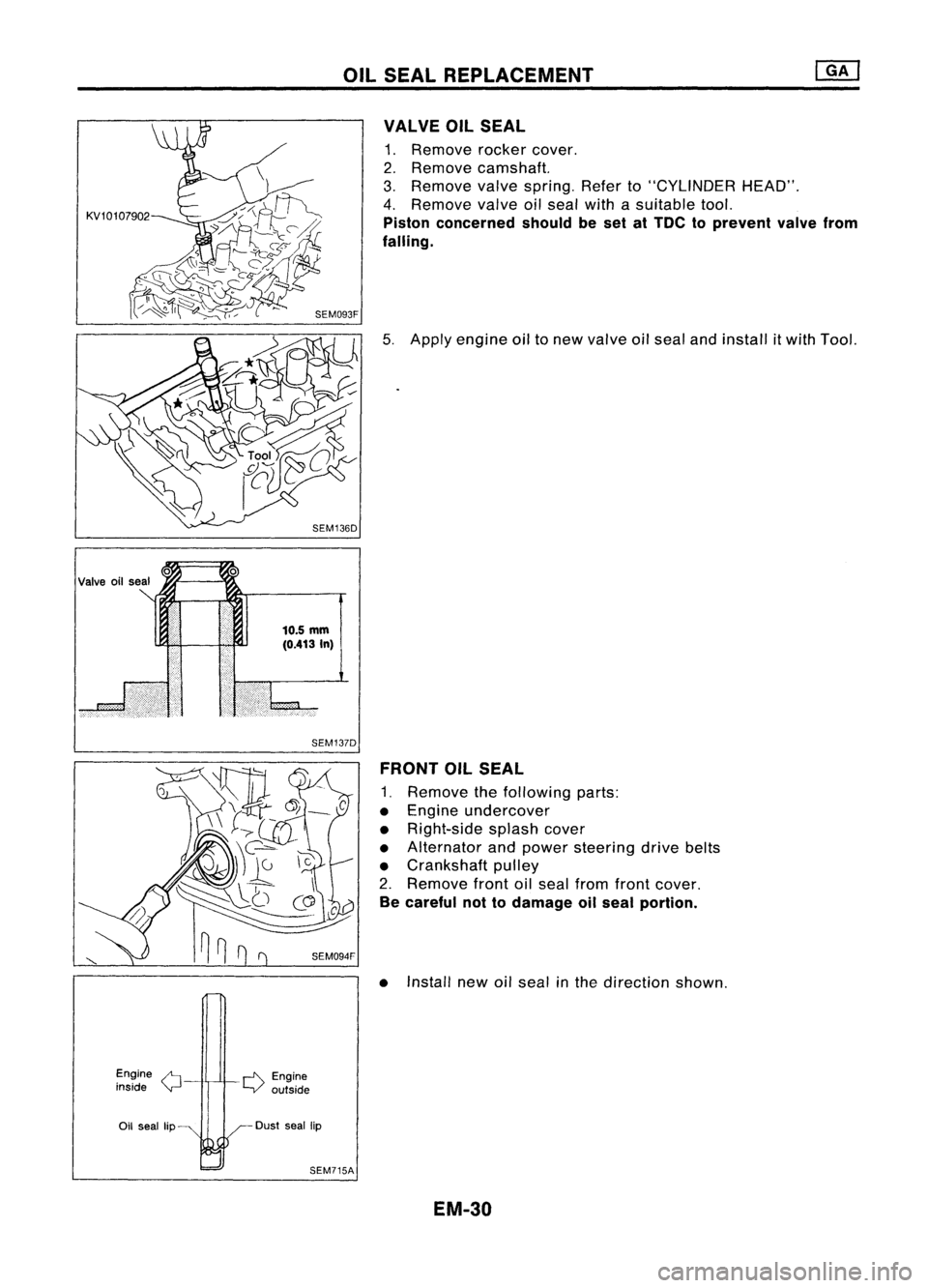

OILSEAL REPLACEMENT

KV10l07902

VALVE

OilSEAL

1. Remove rockercover.

2. Remove camshaft.

3. Remove valvespring. Referto"CYLINDER HEAD".

4. Remove valveoilseal withasuitable tool.

Piston concerned shouldbeset atTOC toprevent valvefrom

falling.

5. Apply engine oiltonew valve oilseal andinstall itwith Tool.

SEM136D

10.5

mm

(0.413 In)

SEM137D

FRONTOilSEAL

1. Remove thefollowing parts:

• Engine undercover

• Right-side splashcover

• Alternator andpower steering drivebelts

• Crankshaft pulley

2. Remove frontoilseal from front cover.

Be careful nottodamage oilseal portion.

• Install newoilseal inthe direction shown.

Engine /',

inside

Y

~

Engine

Youtside

Oil seal lip Dust

seal

lip

SEM715A EM-30

Page 1210 of 1701

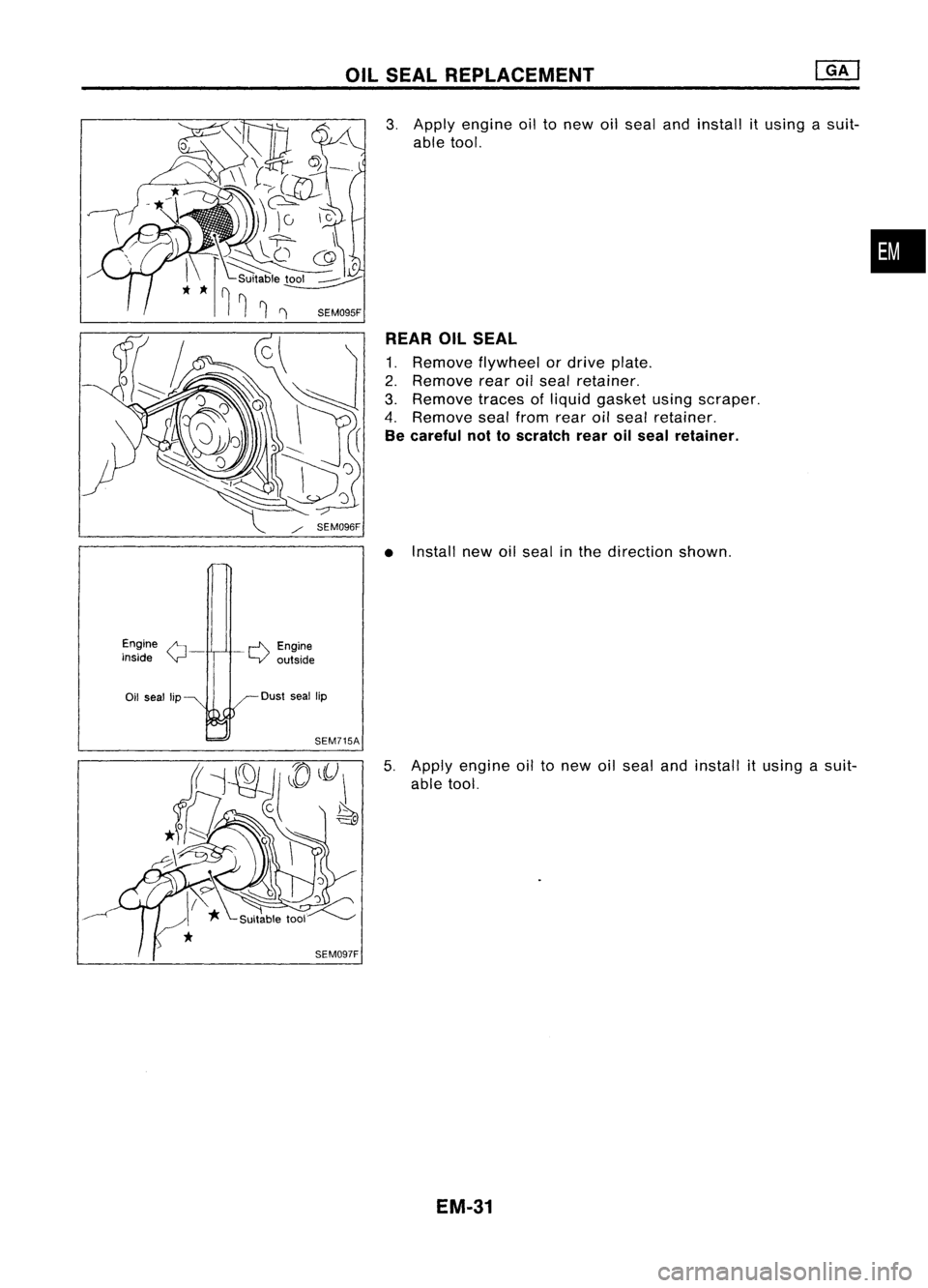

OILSEAL REPLACEMENT

3. Apply engine oiltonew oilseal andinstall itusing asuit-

able tool.

REAR OILSEAL

1. Remove flywheel ordrive plate.

2. Remove rearoilseal retainer.

3. Remove tracesofliquid gasket usingscraper.

4. Remove sealfrom rearoilseal retainer.

Be careful nottoscratch rearoilseal retainer.

/' SEM096F

•Install newoilseal inthe direction shown.

Engine

/'-l_ _~

Engine

inside

Y LV

outside

Oil seal lip Dustseallip

SEM715A

5.Apply engine oiltonew oilseal andinstall itusing asuit-

able tool.

SEM097F

EM-31

•

Page 1211 of 1701

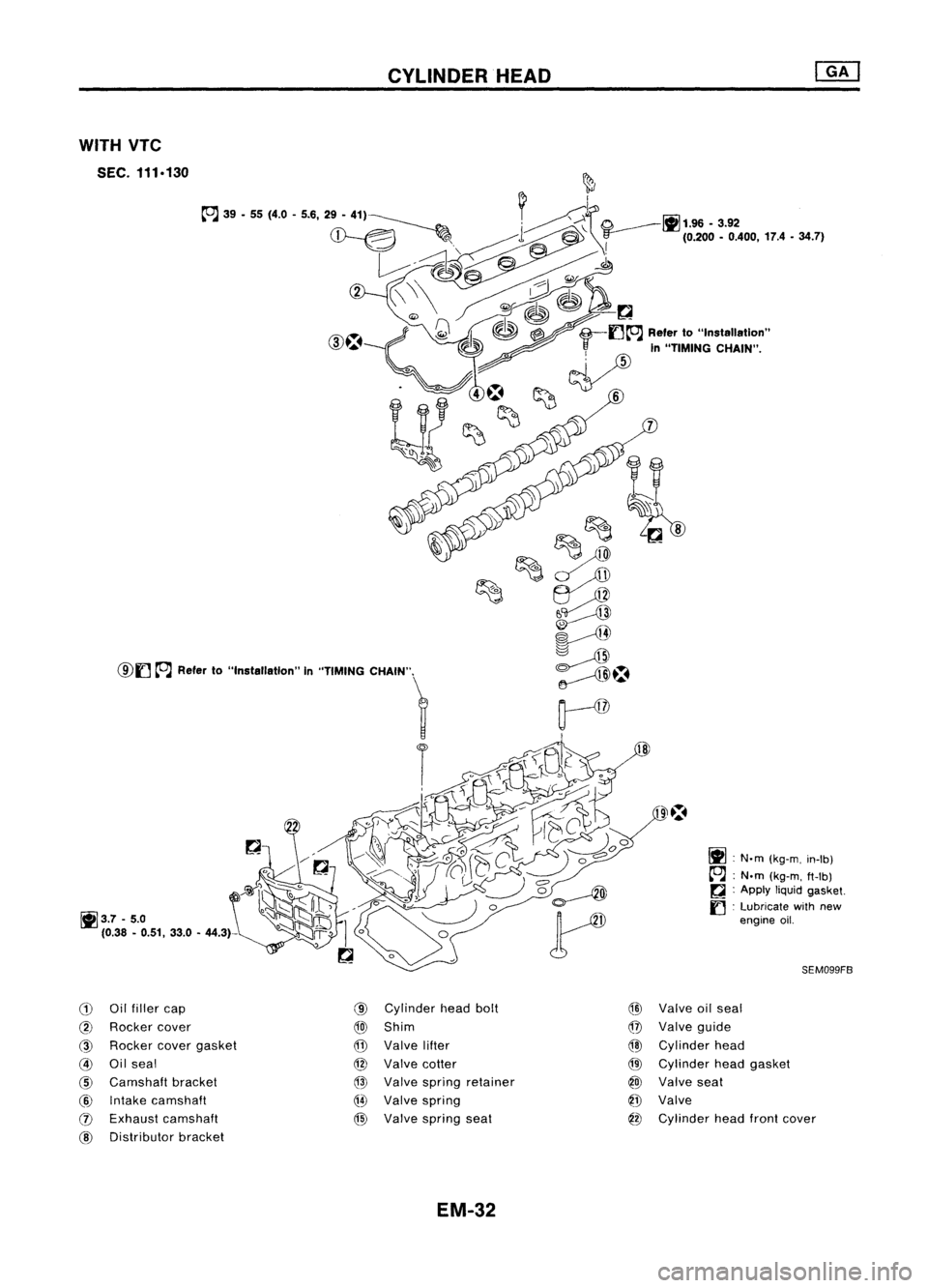

WITHVTC

SEC. 111.130

G)

Oilfiller cap

@

Rocker cover

@

Rocker covergasket

@

Oilseal

@

Camshaft bracket

@

Intake camshaft

(J)

Exhaust camshaft

@

Distributor bracket

CYLINDER

HEAD

@

Cylinder headbolt

@

Shim

@

Valve lifter

@

Valve cotter

@

Valve spring retainer

@

Valve spring

@

Valve spring seat

EM-32

7

~:N.m (kg-m, in-Ib)

A :

N.m (kg-m, ft-Ib)

~ :Apply

liquidgasket.

f] :

Lubricate withnew

engine oil.

SEM099FB

@

Valve oilseal

@

Valve guide

@

Cylinder head

@)

Cylinder headgasket

@)

Valve seat

@

Valve

@

Cylinder headfrontcover

Page 1212 of 1701

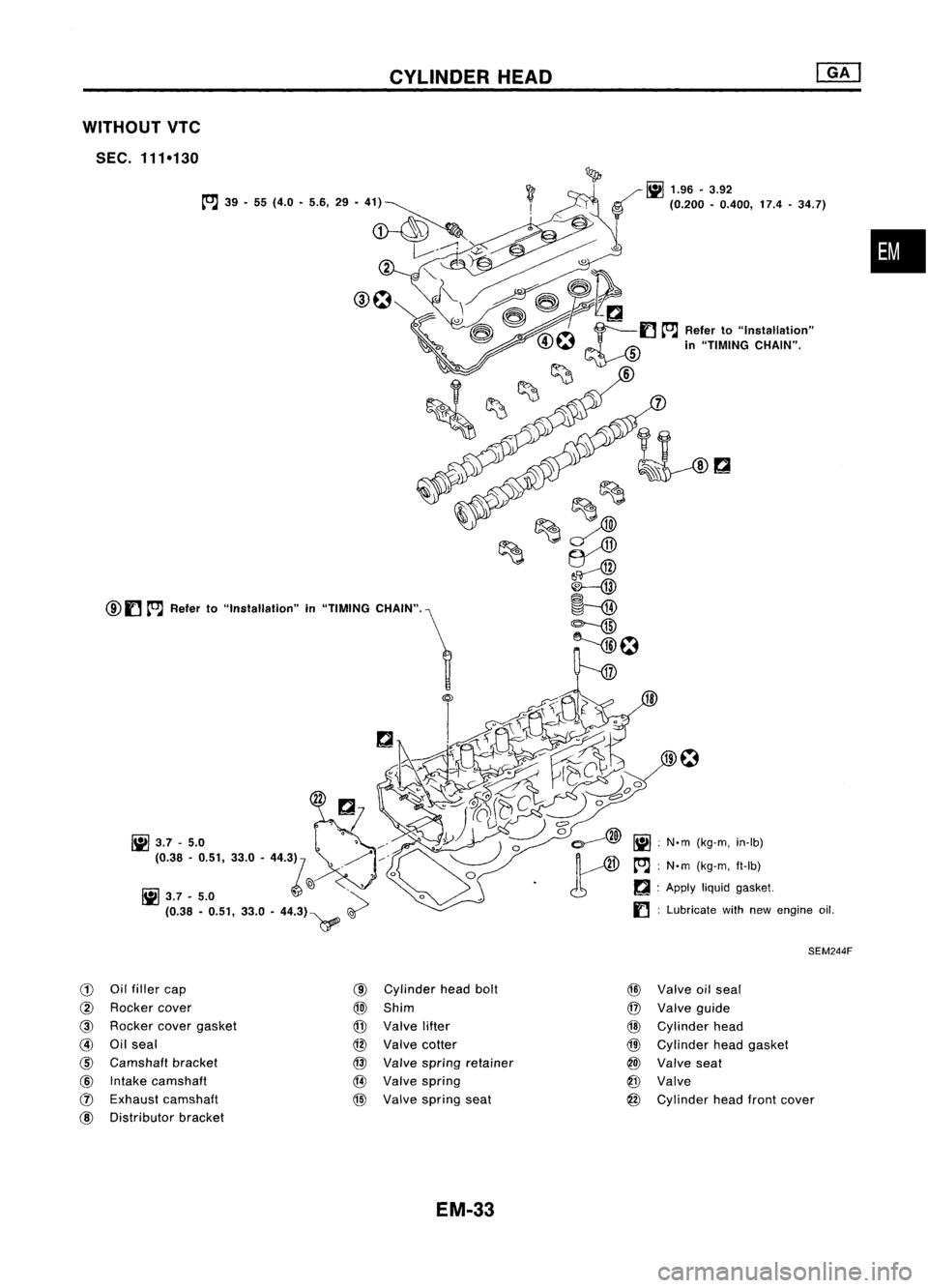

WITHOUT VTC

SEC. 111-130

G)

Oilfiller cap

@

Rocker cover

@

Rocker covergasket

@

Oilseal

@

Camshaft bracket

@

Intake camshaft

(J)

Exhaust camshaft

@

Distributor bracket

CYLINDER

HEAD

@

Cylinder headbolt

@)

Shim

@

Valve lifter

@

Valve cotter

@

Valve spring retainer

@

Valve spring

@

Valve spring seat

EM-33

Ij]

.

N.m (kg-m, in-Ib)

~ :N.m (kg-m, ft-Ib)

~ :Apply

liquidgasket.

f) :

Lubricate withnewengine oil.

SEM244F

@

Valve oilseal

@

Valve guide

@

Cylinder head

@

Cylinder headgasket

@

Valve seat

@

Valve

@

Cylinder headfrontcover

•

Page 1213 of 1701

CYLINDERHEAD

CAUTION:

• When installing camshaft, oilseals orother sliding parts,

lubricate contacting surfaceswithnewengine oil.

• When tightening cylinderheadbolts, camshaft sprocket

bolts andcamshaft bracketbolts,lubricate threadportions

and seat surfaces ofbolts withnewengine oil.

• Attach tagstovalve lifters soas not tomix them up.

Removal

• This removal isthe same procedure asthose fortiming

chain. Referto"Removal" in"TIMING CHAIN"(EM-20).

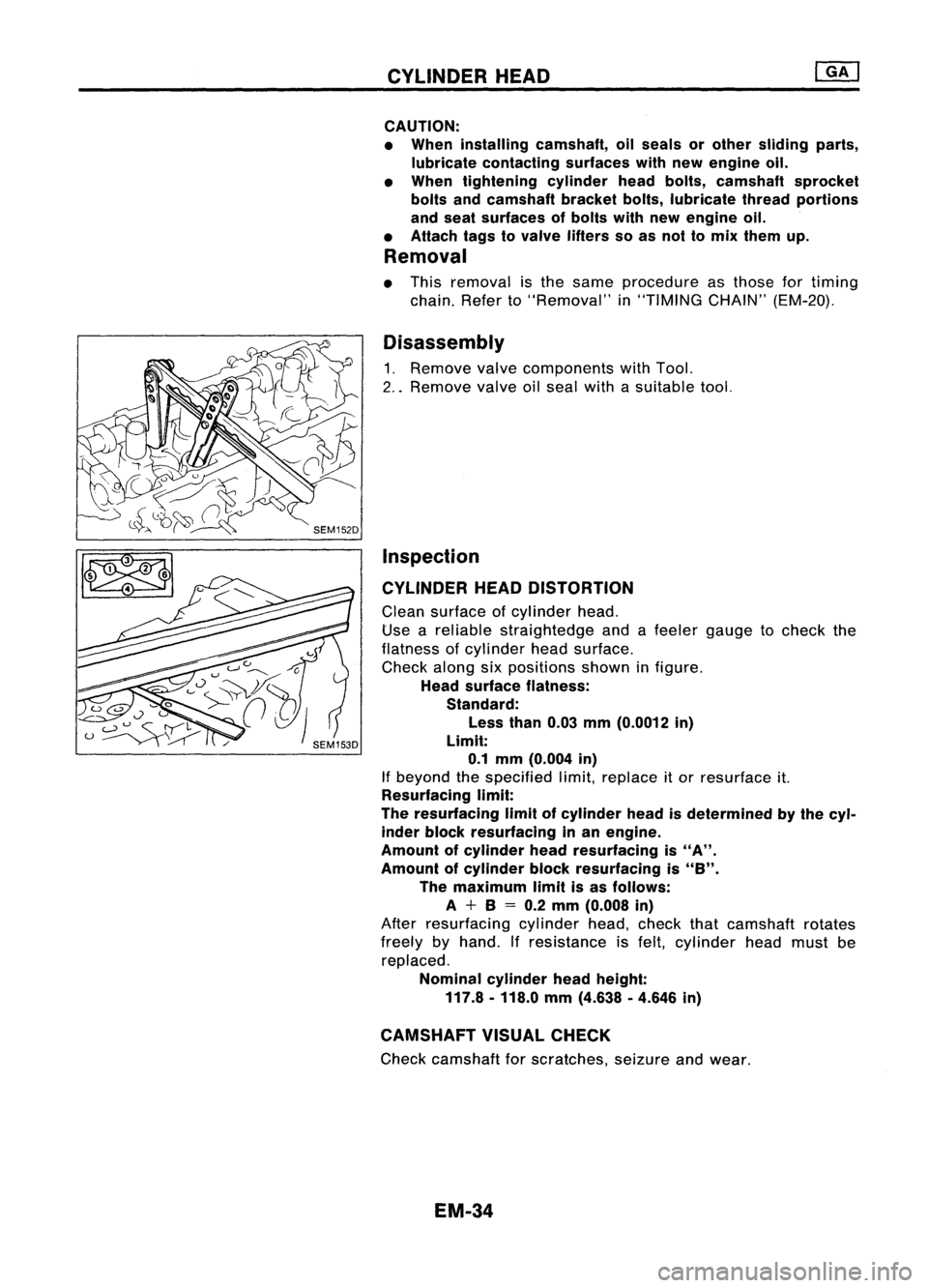

Disassembly

1. Remove valvecomponents withTool.

2 .. Remove valveoilseal withasuitable tool.

Inspection

CYLINDER HEADDISTORTION

Clean surface ofcylinder head.

Use areliable straightedge andafeeler gauge tocheck the

flatness ofcylinder headsurface.

Check alongsixpositions showninfigure.

Head surface flatness:

Standard:

Less than0.03mm(0.0012 in)

Limit: 0.1 mm (0.004 in)

If beyond thespecified limit,replace itor resurface it.

Resurfacing limit:

The resurfacing limitofcylinder headisdetermined bythe cyl-

inder block resurfacing inan engine.

Amount ofcylinder headresurfacing is

"A".

Amount ofcylinder blockresurfacing is

"8".

The maximum limitisas follows:

A +8

=

0.2 mm (0.008 in)

After resurfacing cylinderhead,check thatcamshaft rotates

freely byhand. Ifresistance isfelt, cylinder headmust be

replaced.

Nominal cylinderheadheight:

117.8 -118.0 mm(4.638 .4.646 in)

CAMSHAFT VISUALCHECK

Check camshaft forscratches, seizureandwear.

EM-34

Page 1214 of 1701

SEM154D

SEM549A CYLINDER

HEAD

Inspection (Cont'd)

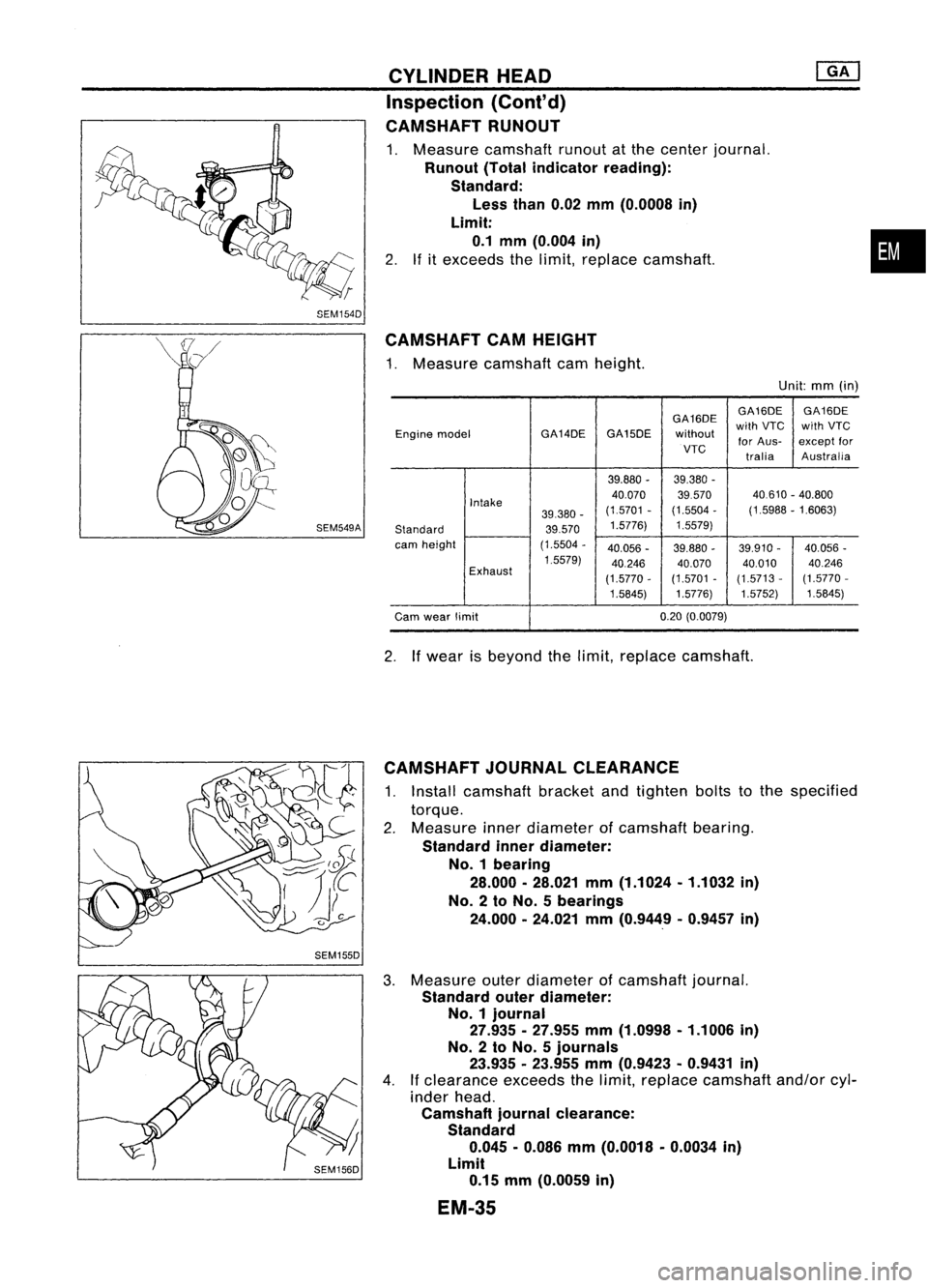

CAMSHAFT RUNOUT

1. Measure camshaft runoutatthe center journal.

Runout (Totalindicator reading):

Standard: Less than0.02mm(0.0008 in)

Limit: 0.1 mm (0.004 in)

2. Ifitexceeds thelimit, replace camshaft.

CAMSHAFT CAMHEIGHT

1. Measure camshaft camheight.

Unit:mm(in)

GA16DE GA16DE

GA16DE

Engine model GA14DEGA15DE

withoutwith

VTC withVTC

for Aus- except

for

VTC traliaAustralia

39.880 -39.380 -

Intake 40.070

39570 40.610

-40.800

39.380 -(1.5701

-(1.5504 -(1.5988 -1.6063)

Standard 39.5701.5776)

1.5579)

cam height (1.5504-

40.056 -39.880 -39.910 -40.056

-

1.5579) 40.24640.07040.01040.246

Exhaust (1.5770-(1.5701

-(1.5713 -(1.5770

-

1.5845) 1.5776}1.5752)

1.5845}

Cam wear limit 0.20

(O.0079)

2. Ifwear isbeyond thelimit, replace camshaft.

•

CAMSHAFT JOURNALCLEARANCE

1. Install camshaft bracketandtighten boltstothe specified

torque.

2. Measure innerdiameter ofcamshaft bearing.

Standard innerdiameter:

No. 1bearing

28.000.28.021 mm(1.1024.1.1032 in)

No. 2to No. 5bearings

24.000 •24.021 mm(0.9449 .0.9457 in)

3. Measure outerdiameter ofcamshaft journal.

Standard outerdiameter:

No.1 journal

27.935.27.955 mm(1.0998 .1.1006 in)

No.2 toNo.5 journals

23.935 -23.955 mm(0.9423 •0.9431 in)

4. Ifclearance exceedsthelimit, replace camshaft and/orcyl-

inder head.

Camshaft journalclearance:

Standard 0.045 •0.086 mm(0.0018 •0.0034 in)

Limit 0.15 mm(0.0059 in)

EM-3S

Page 1217 of 1701

I

Recess

1

diameter

I

SEM795A CYLINDER

HEAD

Inspection (Cont'd)

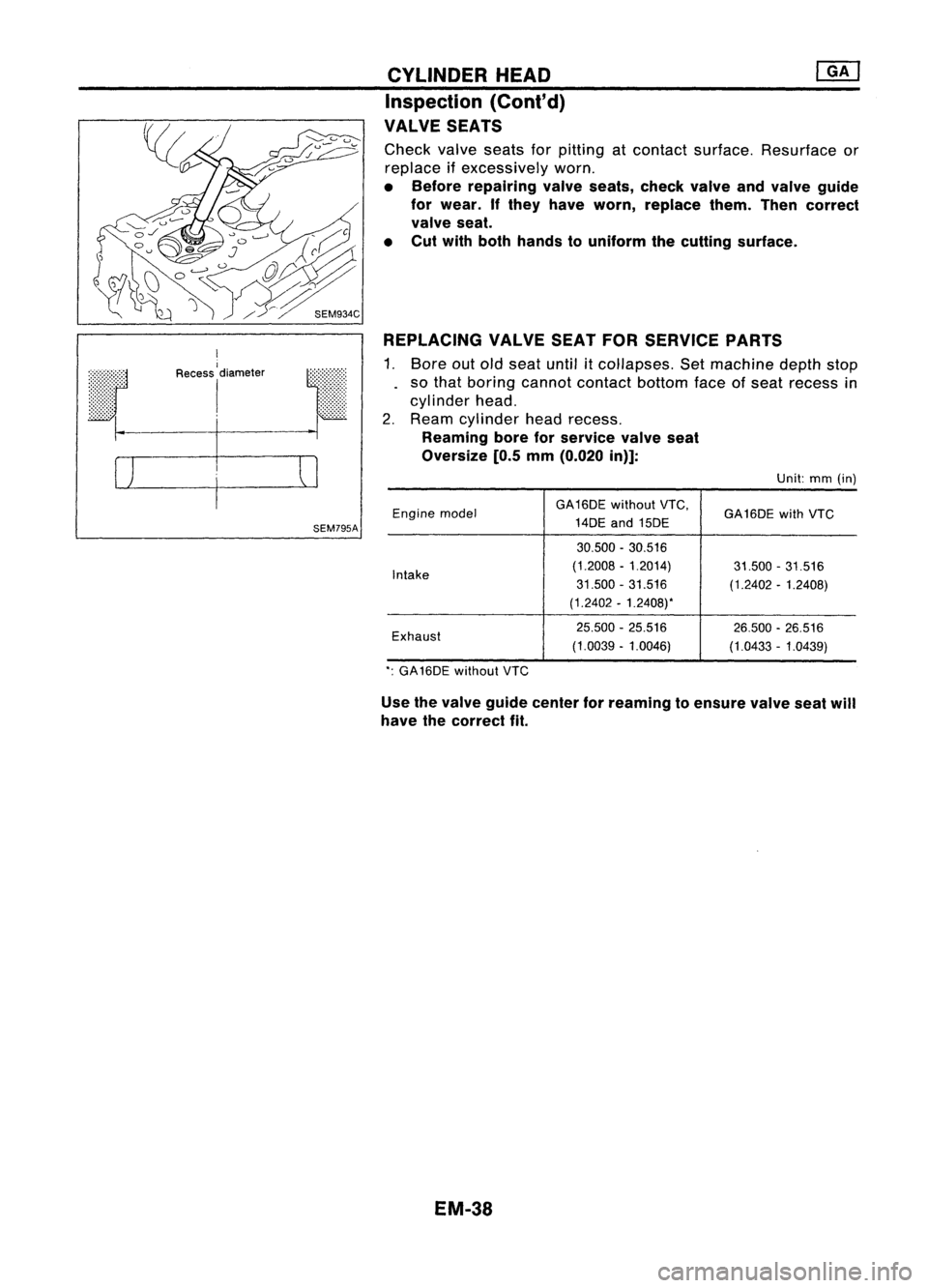

VALVE SEATS

Check valveseats forpitting atcontact surface. Resurface or

replace ifexcessively worn.

• Before repairing valveseats, checkvalveandvalve guide

for wear. Ifthey have worn, replace them.Thencorrect

valve seat.

• Cut with both hands touniform thecutting surface.

REPLACING VALVESEATFORSERVICE PARTS

1. Bore outold seat until

it

collapses. Setmachine depthstop

so that boring cannot contact bottomfaceofseat recess in

cylinder head.

2. Ream cylinder headrecess.

Reaming boreforservice valveseat

Oversize [0.5mm(0.020 in)]:

Unit:mm(in)

Engine model GA16DE

withoutVTC,

GA16DE withVTC

14DE and15DE

30.500 -30.516

Intake (1.2008

-1.2014)

31.500-31.516

31.500 -31.516

(1.2402-1.2408)

(1.2402 -1.2408).

Exhaust 25.500

-25.516

26.500-26.516

(1.0039 -1.0046)

(1.0433-1.0439)

.: GA 16DE without VTC

Use thevalve guide center forreaming toensure valveseatwill

have thecorrect fit.

EM-38

Page 1220 of 1701

VALVECLEARANCE

1 1 22

2 2 44

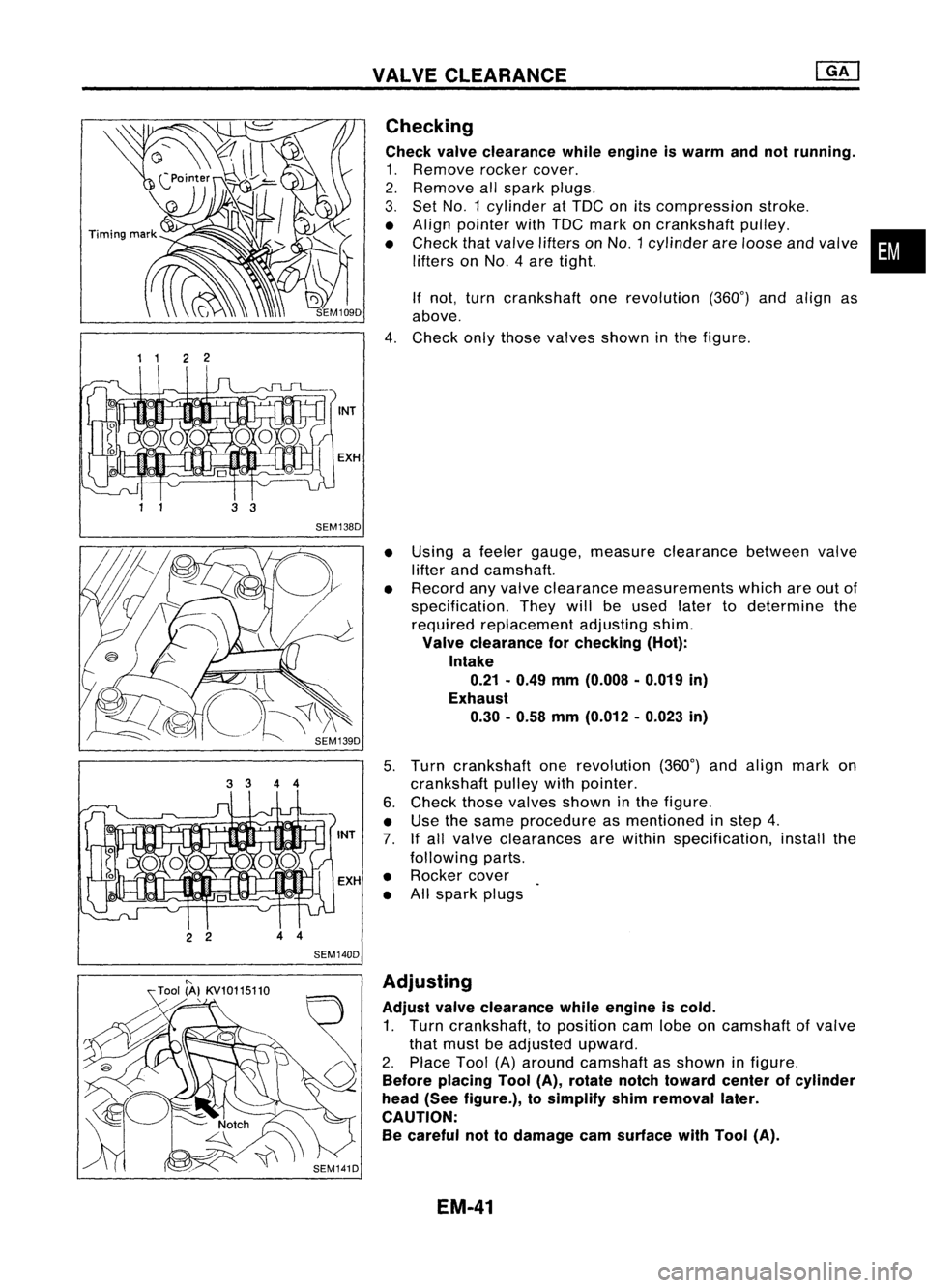

SEM140D Checking

Check valveclearance whileengine iswarm andnotrunning.

1. Remove rockercover.

2. Remove allspark plugs.

3. Set

NO.1

cylinder atTOC onitscompression stroke.

• Align pointer withTOC mark oncrankshaft pulley.

• Check thatvalve lifters on

NO.1

cylinder areloose andvalve

lifters on

NO.4

aretight.

If not, turn crankshaft onerevolution (360°)andalign as

above.

4. Check onlythose valves showninthe figure.

• Using afeeler gauge, measure clearance betweenvalve

lifter andcamshaft.

• Record anyvalve clearance measurements whichareoutof

specification. Theywillbeused latertodetermine the

required replacement adjustingshim.

Valve clearance forchecking (Hot):

Intake 0.21 -0.49 mm(0.008 .0.019 in)

Exhaust 0.30. 0.58mm(0.012 -0.023 in)

5. Turn crankshaft onerevolution (360°)andalign markon

crankshaft pulleywithpointer.

6. Check thosevalves shown inthe figure.

• Use thesame procedure asmentioned instep 4.

7. Ifall valve clearances arewithin specification, installthe

following parts.

• Rocker cover

• Allspark plugs

•

"-

Tool (A}KV10115110

,

SEM141DAdjusting

Adjust valveclearance whileengine iscold.

1. Turn crankshaft, toposition camlobeoncamshaft ofvalve

that must beadjusted upward.

2. Place Tool(A)around camshaft asshown infigure.

Before placing Tool(A),rotate notchtoward centerofcylinder

head (Seefigure.), tosimplify shimremoval later.

CAUTION: Be careful nottodamage camsurface withTool (A).

EM-41