engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1242 of 1701

![NISSAN ALMERA N15 1995 Service Manual OILPAN

SEC. 110

~ReIer to

"Installation".

@ @

~o o~

@ojooEE~CD

~]DOCn[l[ ~

~ @o

JCJC)Ol~CI /

i

CID

~:~~ne ~~

l[lCJL

L~

@ ~ ~'llrrlriQ)

@

=0

Q]J

5

Loosen innumerical order. S NISSAN ALMERA N15 1995 Service Manual OILPAN

SEC. 110

~ReIer to

"Installation".

@ @

~o o~

@ojooEE~CD

~]DOCn[l[ ~

~ @o

JCJC)Ol~CI /

i

CID

~:~~ne ~~

l[lCJL

L~

@ ~ ~'llrrlriQ)

@

=0

Q]J

5

Loosen innumerical order. S](/img/5/57349/w960_57349-1241.png)

OILPAN

SEC. 110

~ReIer to

"Installation".

@ @

~o o~

@ojooEE~CD

~]DOCn[l[ ~

~ @o

JCJC)Ol~CI /

i

CID

~:~~ne ~~

l[lCJL

L~

@ ~ ~'llrrlriQ)

@

=0

Q]J

5

Loosen innumerical order. SEM040D 6

Removal

1. Remove engineundercover.

2. Drain engine oil.

3. Remove steeloilpan bolts.

~

I ~

1.9-2.5

(0.19 -0.25,

16.5 -21.7)

CD

Side gallery baffleplate

W

Aluminum

011

pan

@

Rear cover plate

@l

DraIn plug

@ Steel

011

pan

SEM142FA

•

SEM602E

4.

Remove steeloilpan.

a. Insert Toolbetween aluminum oilpan and steel oilpan.

• Becareful nottodamage aluminum matingsurface.

• Do not insert screwdriver, oroil pan flange willbe

deformed.

EM-53

Page 1243 of 1701

![NISSAN ALMERA N15 1995 Service Manual SEM603E

SEM717E OIL

PAN [][]

Removal (Coni'd)

b. Slide Toolbytapping onthe side ofthe Tool withahammer.

c. Remove steeloilpan.

d. Remove

bafflepl

e.

5. Remove fronttube.

6. Set asuitable transm NISSAN ALMERA N15 1995 Service Manual SEM603E

SEM717E OIL

PAN [][]

Removal (Coni'd)

b. Slide Toolbytapping onthe side ofthe Tool withahammer.

c. Remove steeloilpan.

d. Remove

bafflepl

e.

5. Remove fronttube.

6. Set asuitable transm](/img/5/57349/w960_57349-1242.png)

SEM603E

SEM717E OIL

PAN [][]

Removal (Coni'd)

b. Slide Toolbytapping onthe side ofthe Tool withahammer.

c. Remove steeloilpan.

d. Remove

bafflepl

e.

5. Remove fronttube.

6. Set asuitable transmission jackunder transaxle andhoist

engine withengine slinger.

7. Remove centermember.

8. Remove

AIT

shift control cable.

(A/T

only)

9. Remove compressor gussets.

EM-64

Page 1244 of 1701

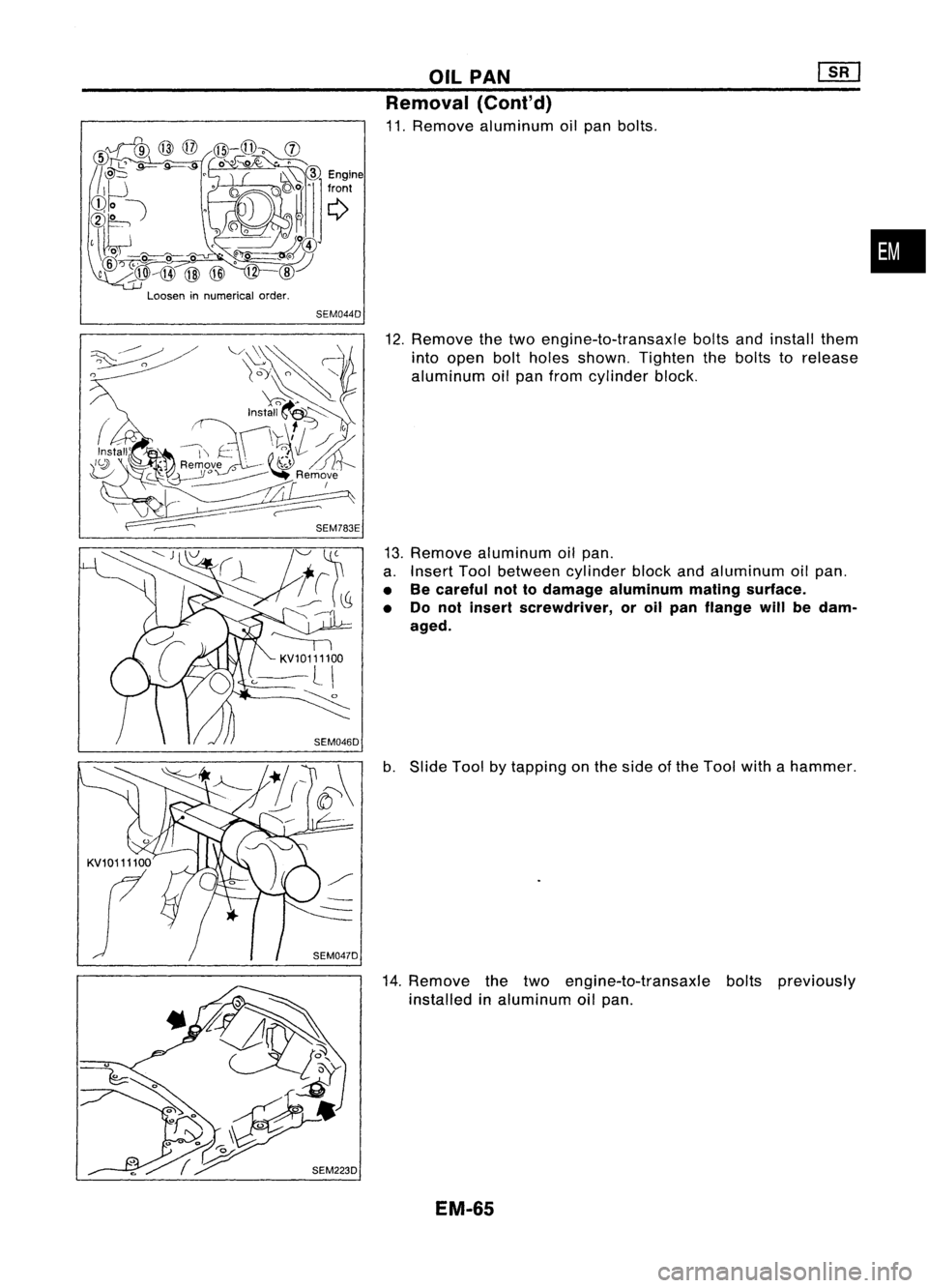

Looseninnumerical order.

SEM044D OIL

PAN

Removal (Cont'd)

11. Remove aluminum oilpan bolts.

•

KV10111100

r

SEM047D

12.

Remove thetwo engine-to-transaxle boltsandinstall them

into open boltholes shown. Tighten thebolts torelease

aluminum oilpan from cylinder block.

13. Remove aluminum oilpan.

a. Insert Toolbetween cylinderblockandaluminum oilpan.

• Becareful nottodamage aluminum matingsurface.

• Do not insert screwdriver, oroil pan flange willbedam-

aged.

b. Slide Toolbytapping onthe side ofthe Tool withahammer.

14. Remove thetwo engine-to-transaxle boltspreviously

installed inaluminum oilpan.

EM-65

Page 1245 of 1701

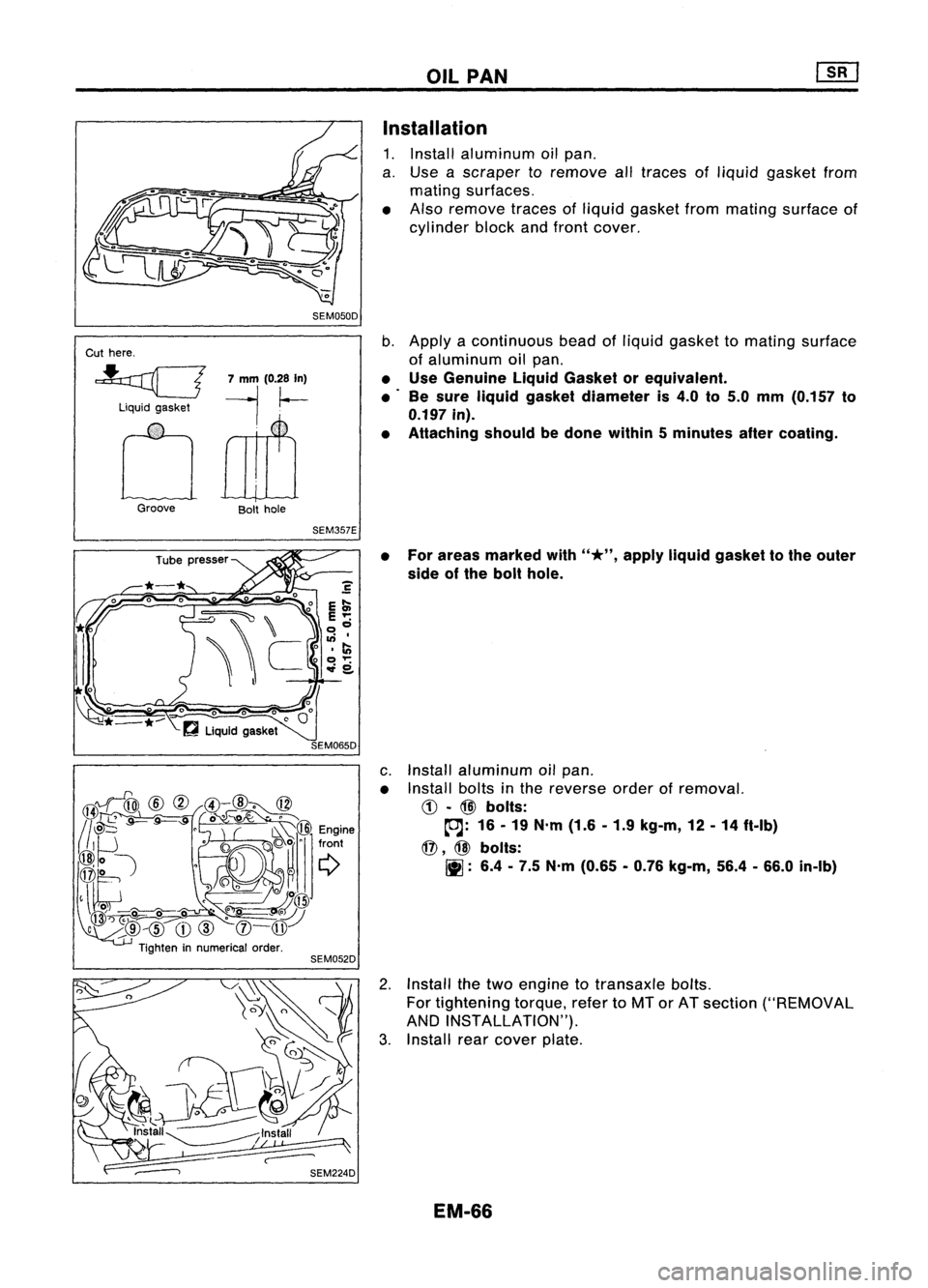

SEM050D

Cut here.

~ 7mm (0.28 In)

liquid gasket

---j.~

oruu

Groove Bolthole

SEM357E

SEM065D OIL

PAN

Installation

1. Install aluminum oilpan.

a. Use ascraper toremove alltraces ofliquid gasket from

mating surfaces.

• Also remove tracesofliquid gasket frommating surface of

cylinder blockandfront cover.

b. Apply acontinuous beadofliquid gasket tomating surface

of aluminum oilpan.

• Use Genuine LiquidGasket orequivalent.

• Besure liquid gasket diameter is4.0 to5.0 mm (0.157 to

0.197 in).

• Attaching shouldbedone within 5minutes aftercoating.

• For areas marked with

"*",

apply liquid gasket tothe outer

side ofthe bolt hole.

c. Install aluminum oilpan.

• Install boltsinthe reverse orderofremoval.

CD •

@)

bolts:

~: 16-19 N'm (1.6-1.9 kg-m, 12-14 ft-Ib)

@,

@

bolts:

~: 6.4-7.5 N'm (0.65 •0.76 kg-m, 56.4-66.0 in-Ib)

2. Install thetwo engine totransaxle bolts.

For tightening torque,refertoMT orAT section ("REMOVAL

AND INSTALLATION").

3. Install rearcover plate.

EM-66

Page 1246 of 1701

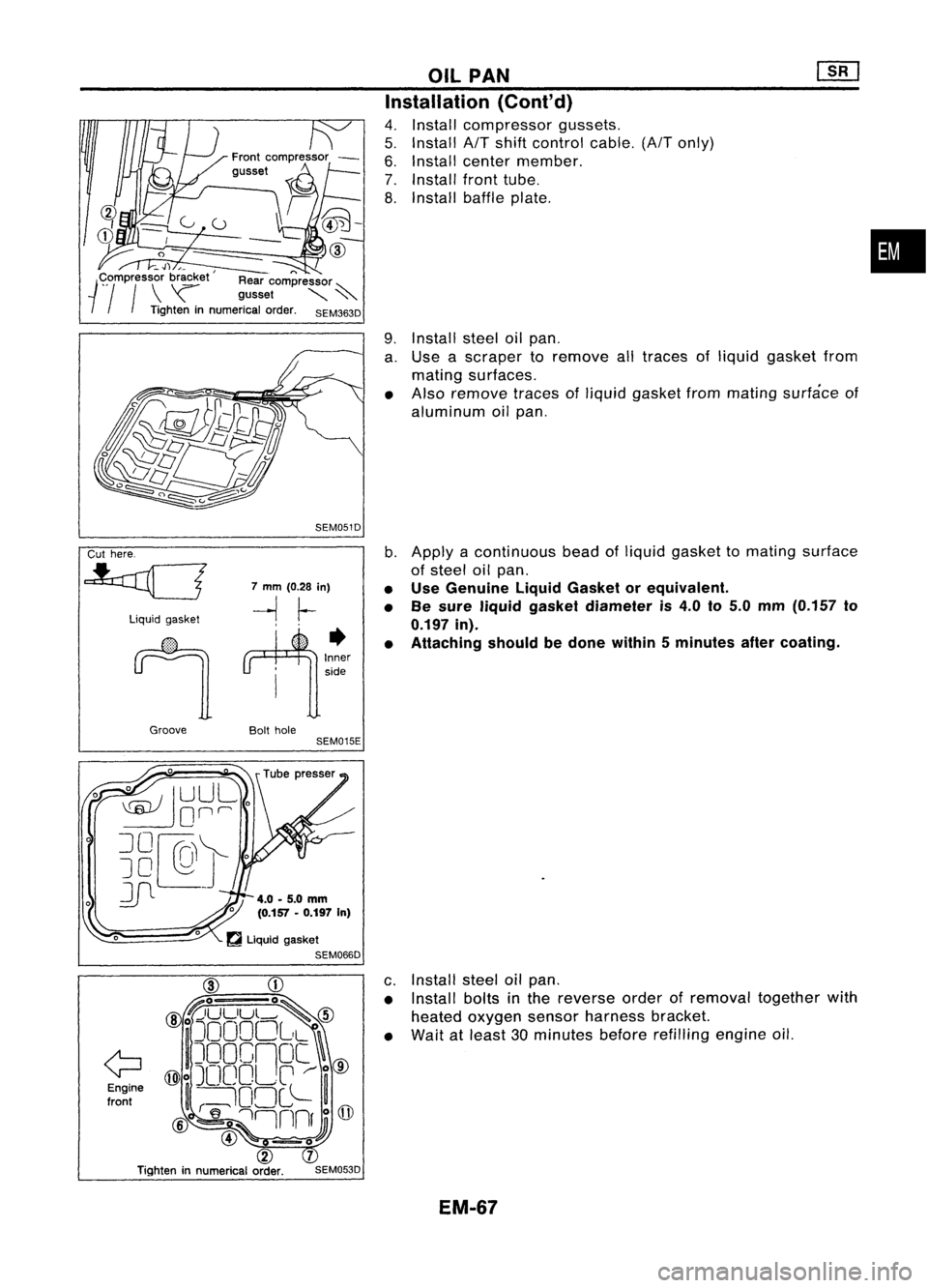

_4) ,_

1

\ ~ gusset ~~

I

I

Tighten innumerical order.SEM363D

SEM051D OIL

PAN

Installation (Cont'd)

4. Install compressor gussets.

5. Install

AfT

shift control cable.

(AfT

only)

6. Install center member.

7. Install fronttube.

8. Install baffleplate.

9. Install steeloilpan.

a. Use ascraper toremove alltraces ofliquid gasket from

mating surfaces.

• Also remove tracesofliquid gasket frommating surface of

aluminum oilpan.

•

Cut here.

~ Liquidgasket

7

mm

(0.28

in)

~ f-

~.

- j'u ~::'

b.

Apply acontinuous beadofliquid gasket tomating surface

of steel oilpan.

• Use Genuine LiquidGasket orequivalent.

• Besure liquid gasket diameter is4.0 to5.0 mm (0.157 to

0.197

in).

• Attaching shouldbedone within 5minutes aftercoating.

Groove Bolthole

SEM015E

@

CD

@~IUUUl~~@

iJOOOOLL ~,

~lOOGnO[ \~

~ @o

]C)e]OLoL/"'

o~@

Engine ~~O(l( \

front ~(--.. I

I~

L.,

@ ~

'1'lrlnr

j

QD

@

~o

@

7

Tighten innumerical order. SEM053D

o

o

~f

JUUL

o

~ 0

01'

JO~~ JO

(QJ

0

;)JL-

o

4.0.5.0

mm

(0.157 -0.197 In)

c.Install steeloilpan.

• Install boltsinthe reverse orderofremoval together with

heated oxygen sensorharness bracket.

• Wait atleast 30minutes beforerefilling engineoil.

EM-67

Page 1247 of 1701

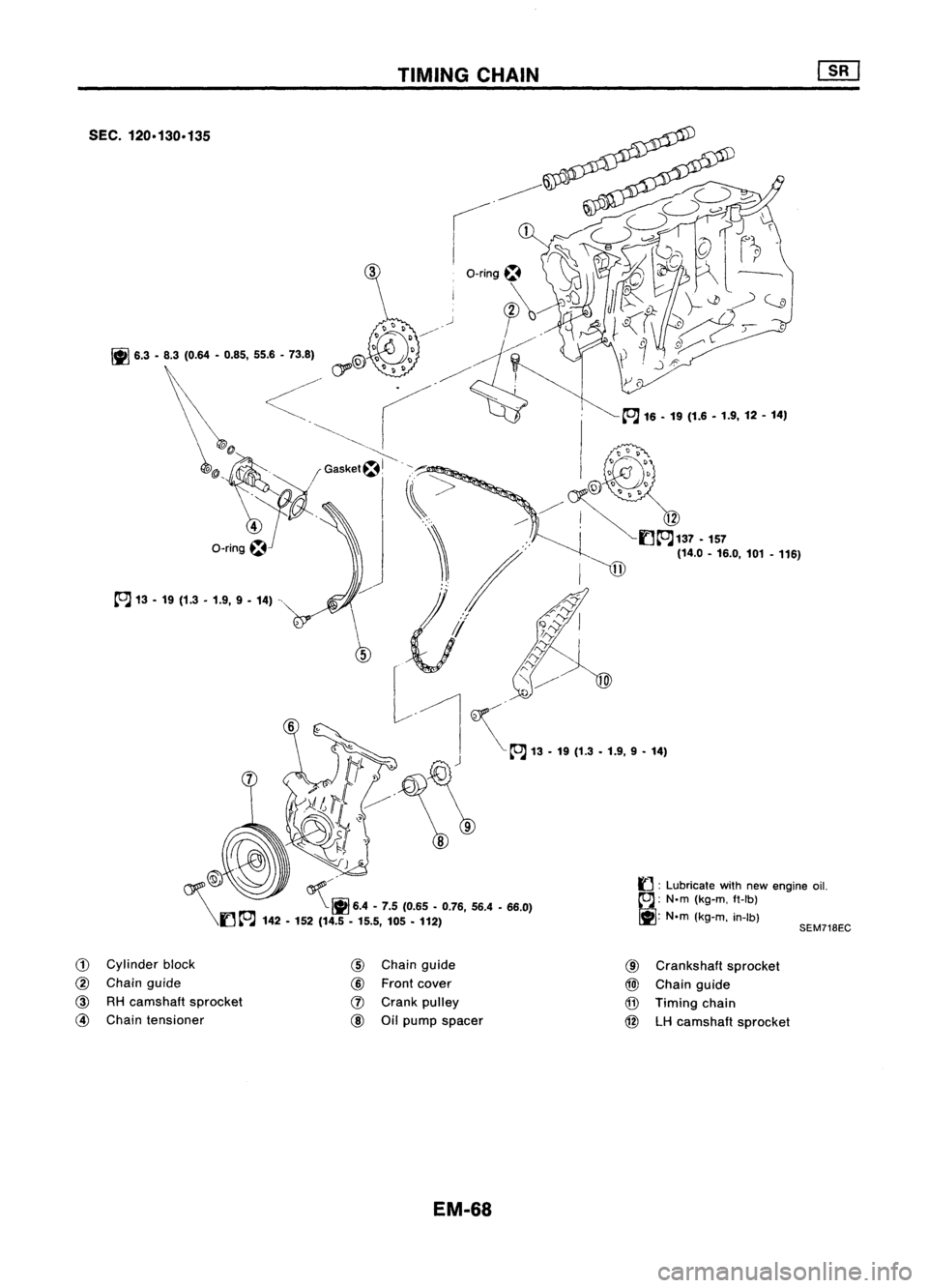

TIMINGCHAIN

(14.0•16.0, 101-116)

SEM718EC

rJ

:

Lubricate withnewengine oil.

~; N.m(kg-m, ft-rb)

~: N.m (kg-m. in-Ib)

~

16•19 (1.6 •1.9, 12-14)

~ 13. 19(1.3 •1.9, 9-14) ~~

SEC.

120.130.135

CD

Cylinder

block

@

Chain guide

@

Chain guide

@

Front cover

@

RHcamshaft sprocket

(J)

Crank pulley

@

Chain tensioner

@

Oilpump spacer

@

Crankshaft sprocket

@l

Chain guide

@

Timing chain

@

LHcamshaft sprocket

EM-68

Page 1248 of 1701

TIMINGCHAIN

CAUTION:

• After removing timingchain,donot turn crankshaft and

camshaft separately, orvalves willstrike piston heads.

• When installing rockerarms,camshafts, chaintensioner, oil

seals, orother sliding parts,lubricate contacting surfaces

with newengine oil.

• Apply newengine oiltobolt threads andseat surfaces when•

installing cylinderhead,camshaft sprockets, crankshaft

pulley, andcamshaft brackets.

Removal

1. Release fuelpressure.

Refer to"Releasing FuelPressure" inEC section.

2. Remove engineundercovers.

3. Remove frontRHwheel andengine sidecover.

4. Drain coolant byremoving cylinderblockdrainplugand

radiator draincock.

5. Remove radiator.

6. Remove airduct tointake manifold.

7. Remove drivebeltsandwater pumppulley.

8. Remove alternator andpower steering oilpump.

9. Remove vacuumhoses,fuelhoses, wires,harness, connec-

tors andsoon.

10. Remove allspark plugs.

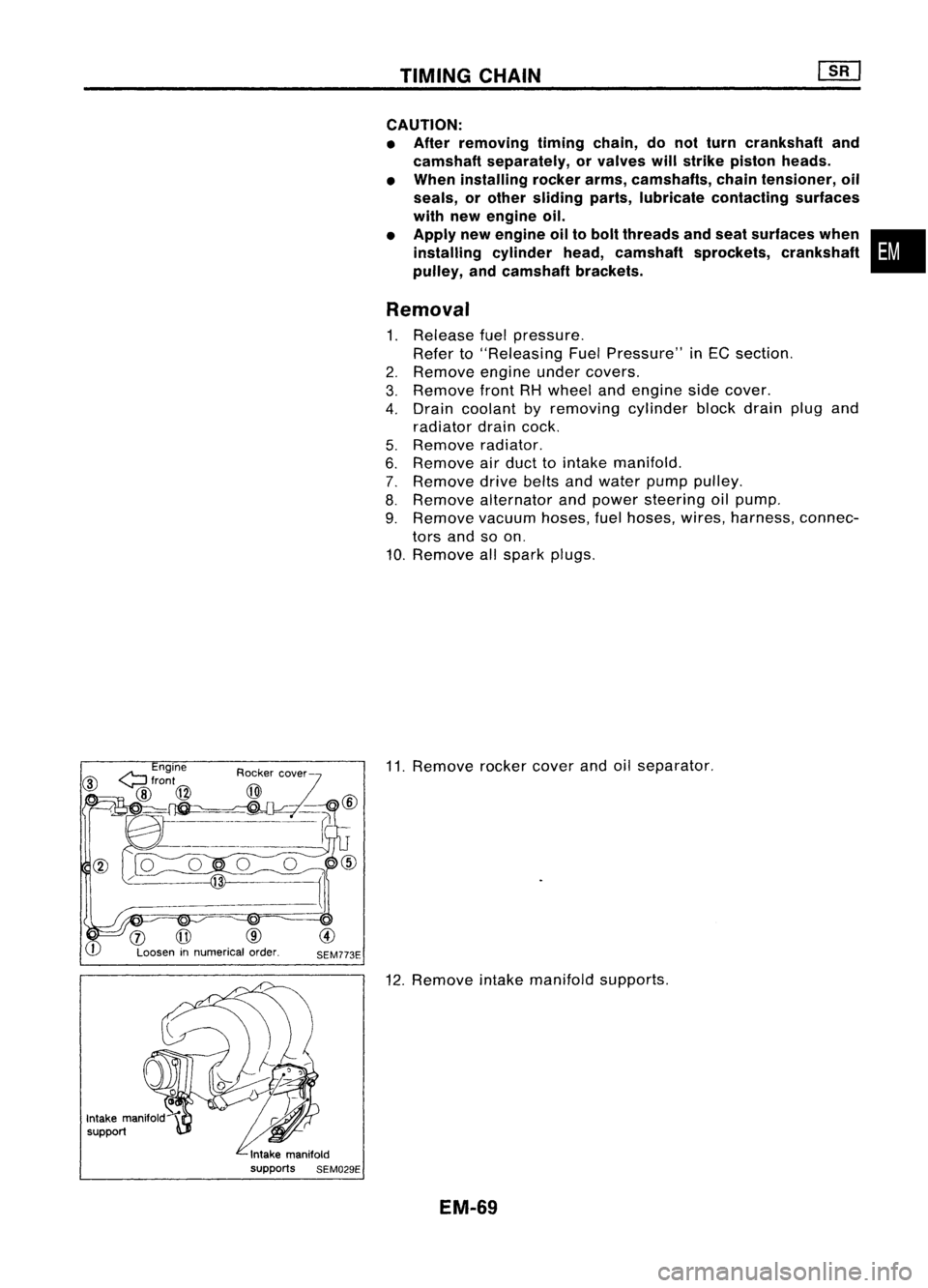

11. Remove rockercoverandoilseparator.

12. Remove intakemanifold supports.

EM-69

Page 1252 of 1701

Engine~

front

Y--J

SEM721E

SEM984C

~ Crankshaft

!..--..V

side

Crankshaft sprocket

SEM470E TIMING

CHAIN

Removal (Cont'd)

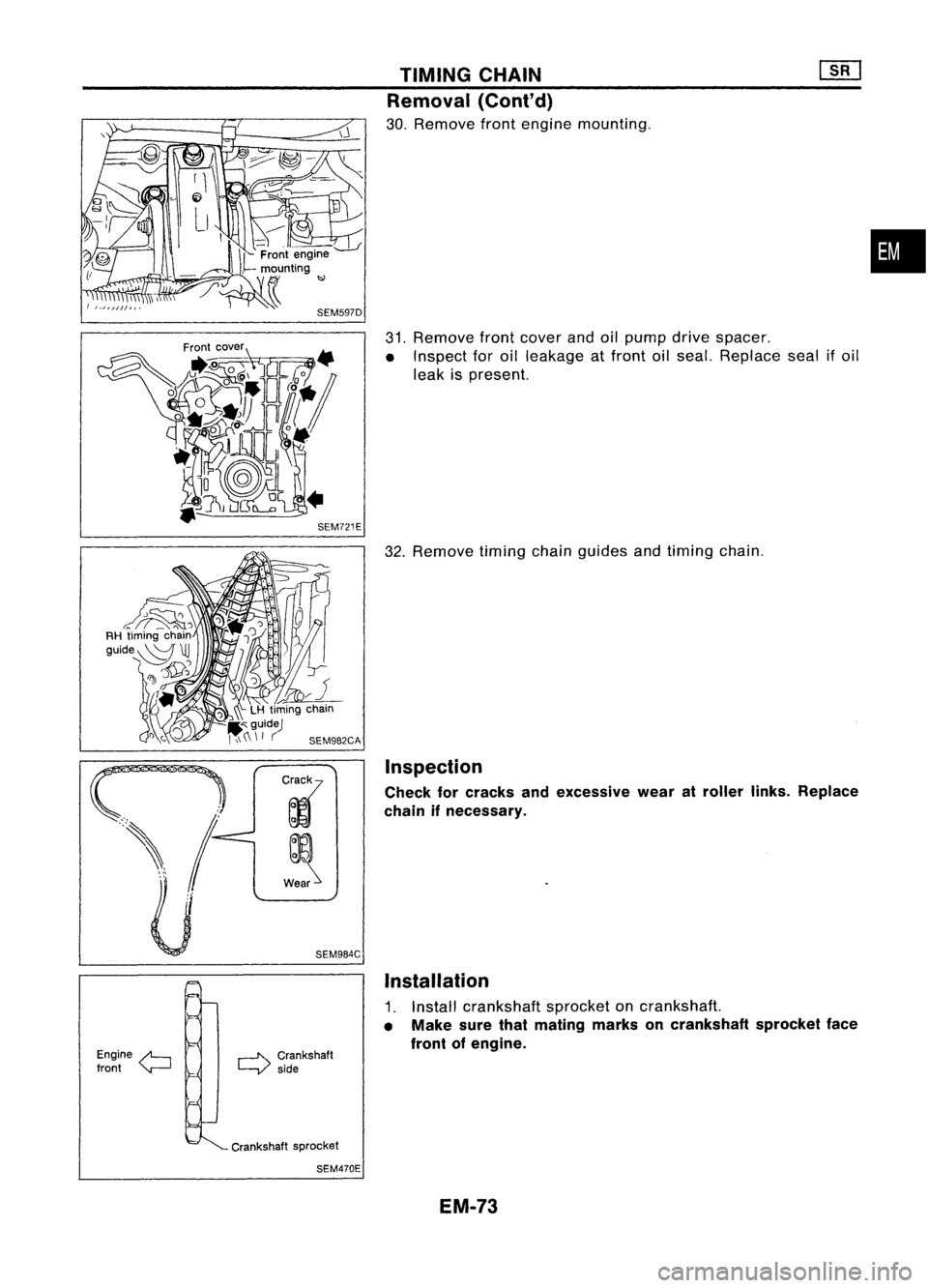

30. Remove frontengine mounting.

31. Remove frontcover andoilpump drivespacer.

• Inspect foroilleakage atfront oilseal. Replace sealifoil

leak ispresent.

32. Remove timingchainguides andtiming chain.

Inspection

Check forcracks andexcessive wearatroller links.Replace

chain ifnecessary.

Installation

1. Install crankshaft sprocketoncrankshaft.

• Make surethatmating marksoncrankshaft sprocketface

front ofengine.

EM-73

•

Page 1254 of 1701

Wipeoff

liquid gasket

SEM214FTIMING

CHAIN ~

Installation (Cont'd)

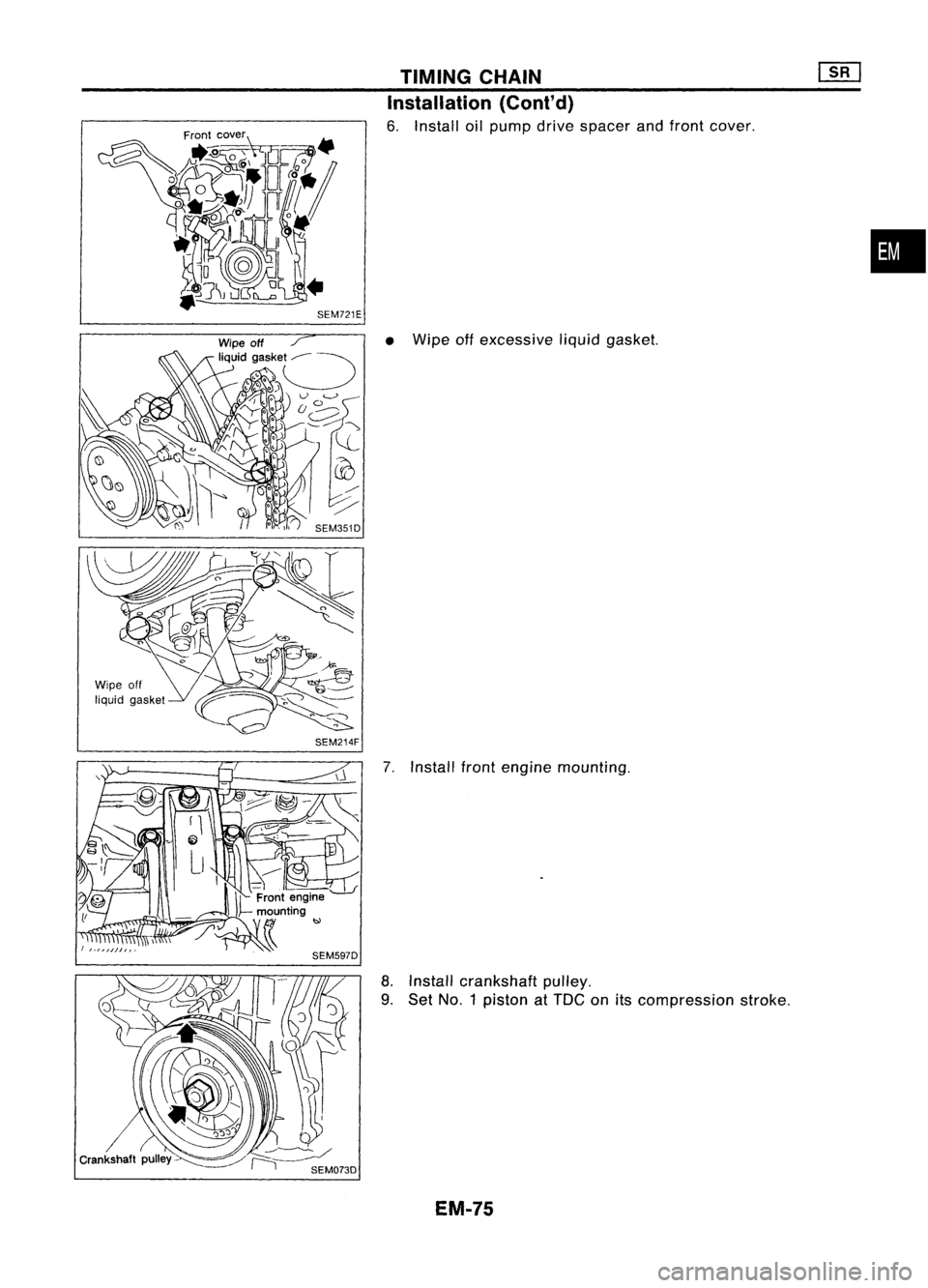

6. Install oilpump drivespacer andfront cover .

• Wipe offexcessive liquidgasket.

•

7. Install frontengine mounting.

8. Install crankshaft pulley.

9. Set NO.1 piston atTDG onitscompression stroke.

EM.75

Page 1255 of 1701

Cylinderheadbolt

OJ

1I111111111111111111111111111111D

L'A,,=J

SEM020D

Cylinder headboltwasher

0 __ 0

•

Cylinder headside

SEM877A

Tighten innumerical order.

SEM986C TIMING

CHAIN

Installation (Cont'd)

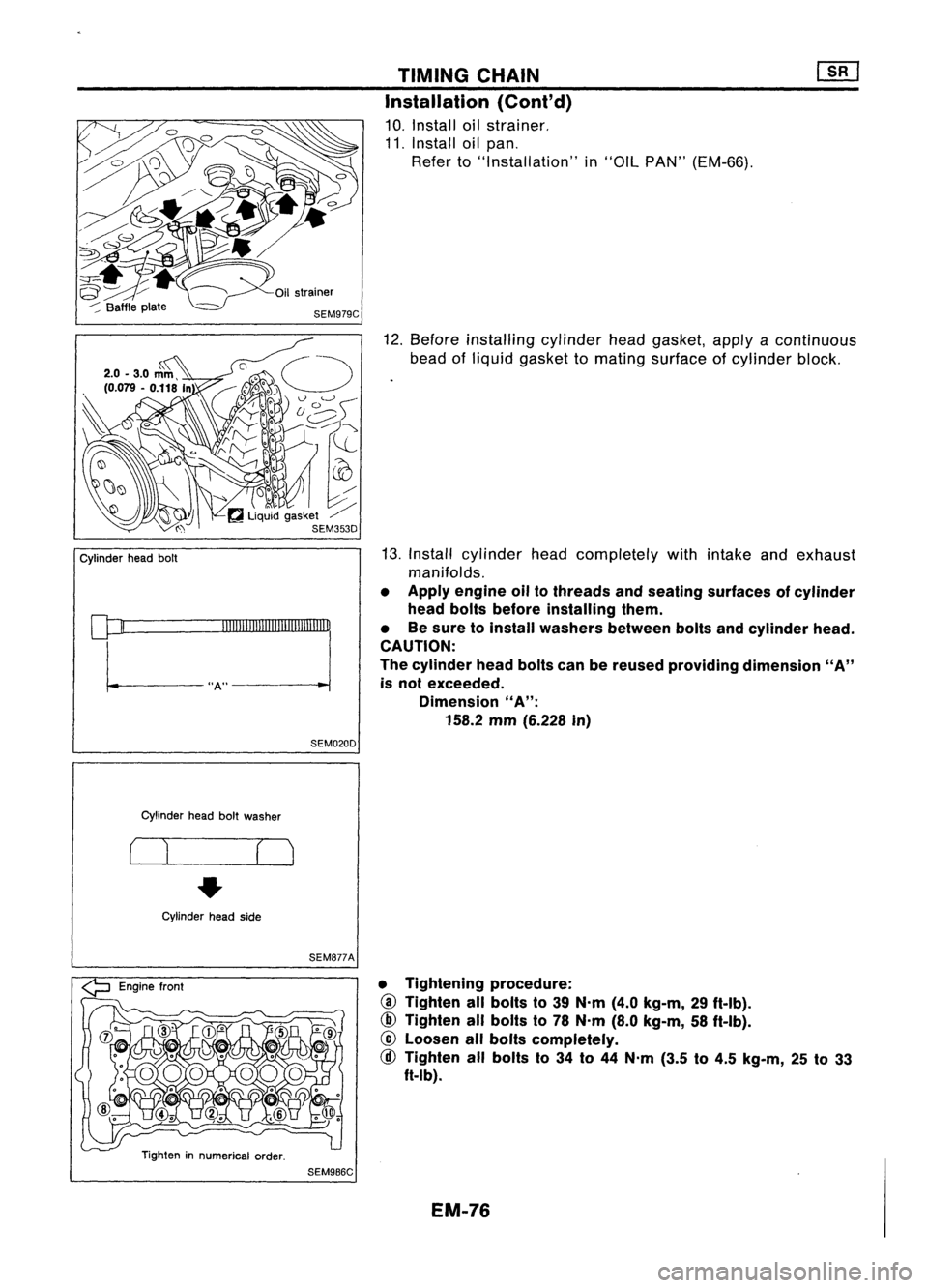

10. Install oilstrainer.

11. Install oilpan.

Refer to"Installation" in

"Oil

PAN" (EM-66).

12. Before installing cylinderheadgasket, applyacontinuous

bead ofliquid gasket tomating surface ofcylinder block.

13. Install cylinder headcompletely withintake andexhaust

manifolds.

• Apply engine oiltothreads andseating surfaces ofcylinder

head bolts before installing them.

• Besure toinstall washers betweenboltsandcylinder head.

CAUTION:

The cylinder headboltscanbereused providing dimension

"A"

is not exceeded.

Dimension

"A":

158.2 mm(6.228 in)

• Tightening procedure:

@ Tighten allbolts to39 N'm (4.0kg-m, 29ft-Ib).

@ Tighten allbolts to78 N'm (8.0kg-m, 58ft-Ib).

@ Loosen allbolts completely.

@ Tighten allbolts to34 to44 N'm (3.5to4.5 kg-m, 25to33

ft-Ib).

EM-76