NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1181 of 2493

General SpecificationsNJMT0024TRANSAXLENJMT0024S01

Applied modelEurope

YD22DDT

Model code numberWD807

Transaxle modelRS5F50A

Number of speeds5

Synchromesh typeWarner

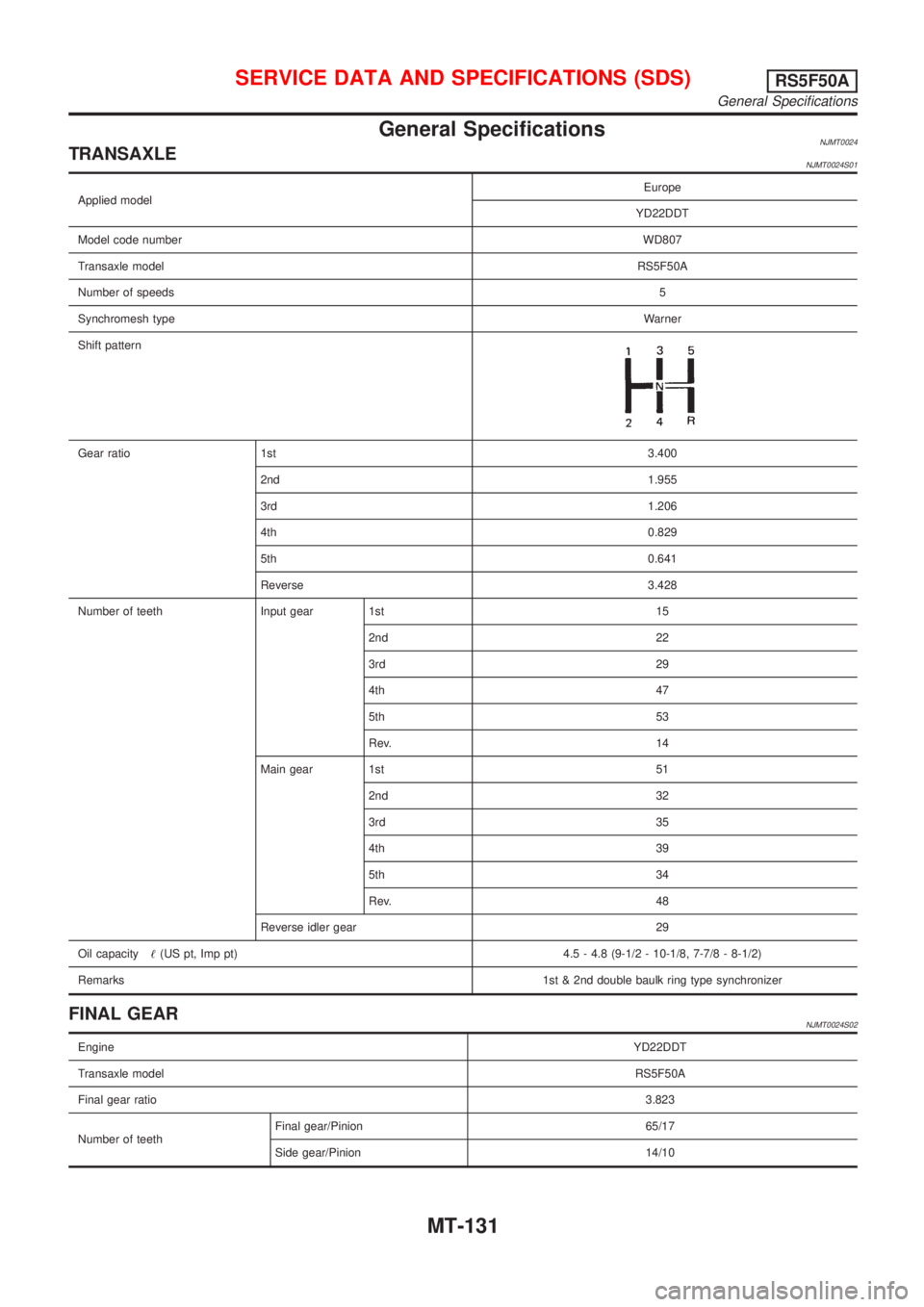

Shift pattern

Gear ratio 1st3.400

2nd 1.955

3rd 1.206

4th 0.829

5th 0.641

Reverse 3.428

Number of teeth Input gear 1st 15

2nd 22

3rd 29

4th 47

5th 53

Rev. 14

Main gear 1st 51

2nd 32

3rd 35

4th 39

5th 34

Rev. 48

Reverse idler gear 29

Oil capacity!(US pt, Imp pt) 4.5 - 4.8 (9-1/2 - 10-1/8, 7-7/8 - 8-1/2)

Remarks1st & 2nd double baulk ring type synchronizer

FINAL GEARNJMT0024S02

EngineYD22DDT

Transaxle modelRS5F50A

Final gear ratio3.823

Number of teethFinal gear/Pinion 65/17

Side gear/Pinion 14/10

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F50A

General Specifications

MT-131

Page 1182 of 2493

Gear End PlayNJMT0025Unit: mm (in)

Gear End play

1st main gear

2nd main gear

3rd input gear

4th input gear

5th input gear0.23 - 0.43 (0.0091 - 0.0169)

0.23 - 0.58 (0.0091 - 0.0228)

0.23 - 0.43 (0.0091 - 0.0169)

0.25 - 0.55 (0.0098 - 0.0217)

0.23 - 0.48 (0.0091 - 0.0189)

Clearance Between Baulk Ring and GearNJMT00263RD, 4TH & 5TH BAULK RINGNJMT0026S01Unit: mm (in)

Gear Standard Wear limit

3rd, 4th & 5th 1.0 - 1.35 (0.0394 - 0.0531) 0.7 (0.028)

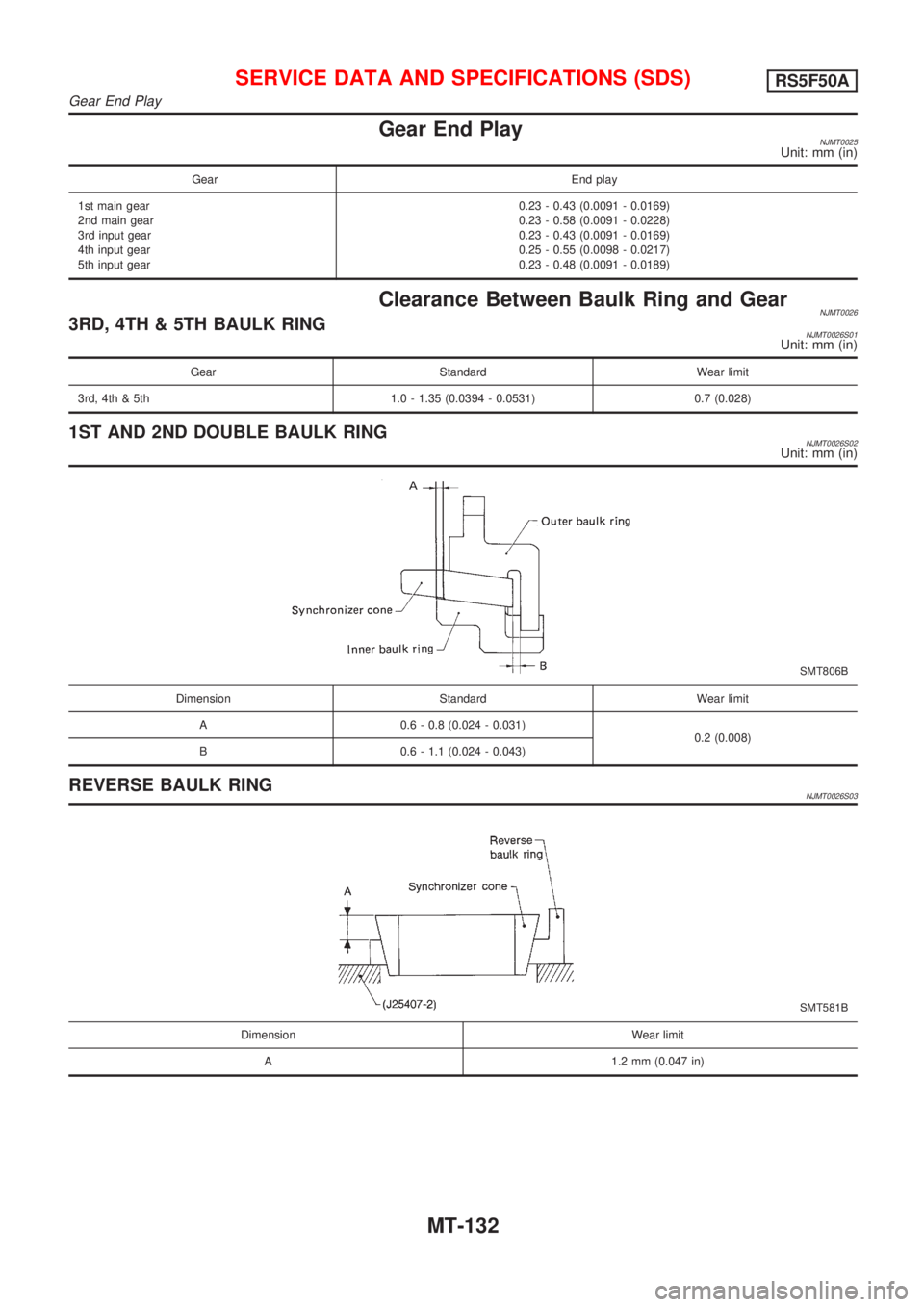

1ST AND 2ND DOUBLE BAULK RINGNJMT0026S02Unit: mm (in)

SMT806B

Dimension Standard Wear limit

A 0.6 - 0.8 (0.024 - 0.031)

0.2 (0.008)

B 0.6 - 1.1 (0.024 - 0.043)

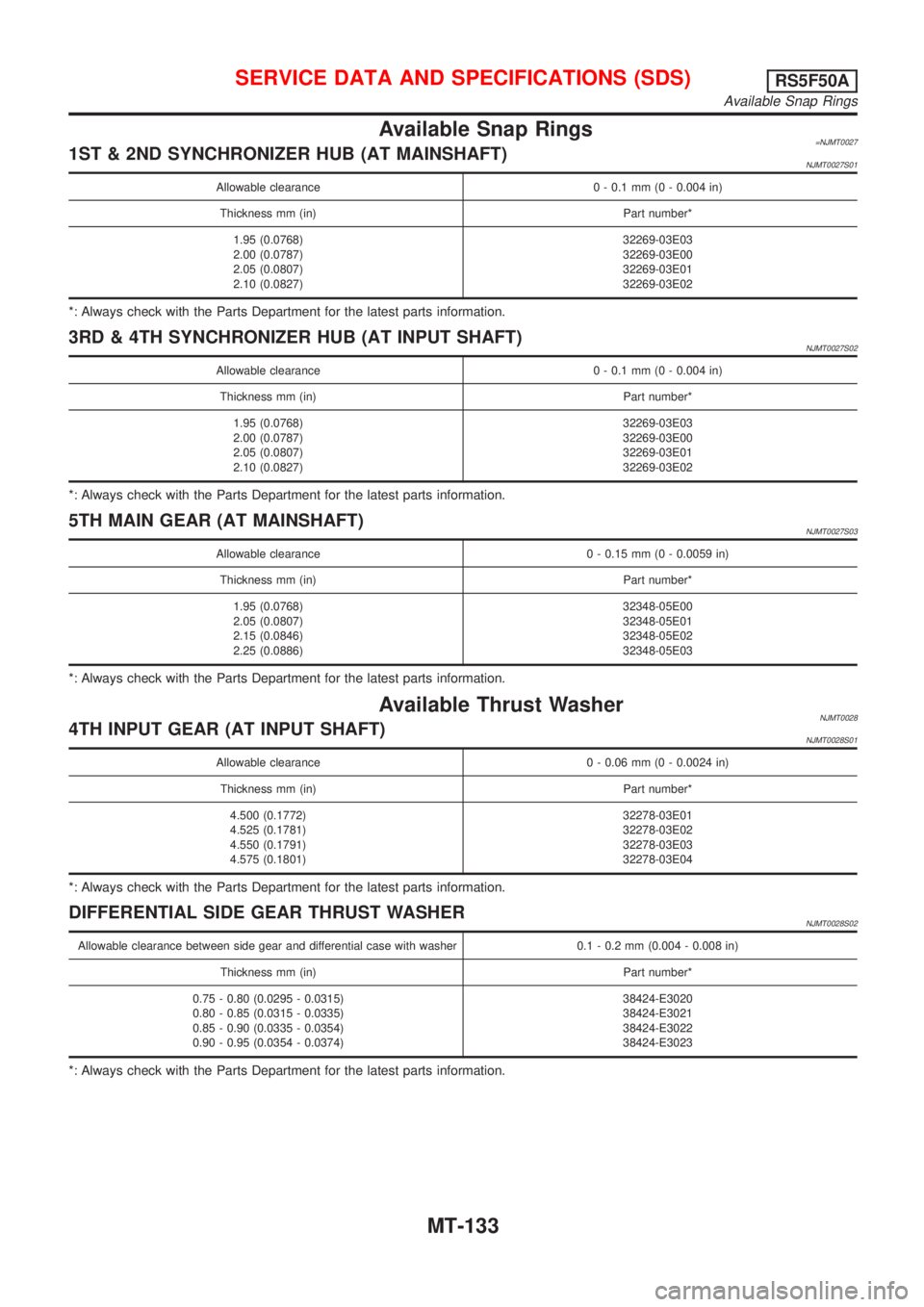

REVERSE BAULK RINGNJMT0026S03

SMT581B

Dimension Wear limit

A 1.2 mm (0.047 in)

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F50A

Gear End Play

MT-132

Page 1183 of 2493

Available Snap Rings=NJMT00271ST & 2ND SYNCHRONIZER HUB (AT MAINSHAFT)NJMT0027S01

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number*

1.95 (0.0768)

2.00 (0.0787)

2.05 (0.0807)

2.10 (0.0827)32269-03E03

32269-03E00

32269-03E01

32269-03E02

*: Always check with the Parts Department for the latest parts information.

3RD & 4TH SYNCHRONIZER HUB (AT INPUT SHAFT)NJMT0027S02

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number*

1.95 (0.0768)

2.00 (0.0787)

2.05 (0.0807)

2.10 (0.0827)32269-03E03

32269-03E00

32269-03E01

32269-03E02

*: Always check with the Parts Department for the latest parts information.

5TH MAIN GEAR (AT MAINSHAFT)NJMT0027S03

Allowable clearance 0 - 0.15 mm (0 - 0.0059 in)

Thickness mm (in) Part number*

1.95 (0.0768)

2.05 (0.0807)

2.15 (0.0846)

2.25 (0.0886)32348-05E00

32348-05E01

32348-05E02

32348-05E03

*: Always check with the Parts Department for the latest parts information.

Available Thrust WasherNJMT00284TH INPUT GEAR (AT INPUT SHAFT)NJMT0028S01

Allowable clearance 0 - 0.06 mm (0 - 0.0024 in)

Thickness mm (in) Part number*

4.500 (0.1772)

4.525 (0.1781)

4.550 (0.1791)

4.575 (0.1801)32278-03E01

32278-03E02

32278-03E03

32278-03E04

*: Always check with the Parts Department for the latest parts information.

DIFFERENTIAL SIDE GEAR THRUST WASHERNJMT0028S02

Allowable clearance between side gear and differential case with washer 0.1 - 0.2 mm (0.004 - 0.008 in)

Thickness mm (in) Part number*

0.75 - 0.80 (0.0295 - 0.0315)

0.80 - 0.85 (0.0315 - 0.0335)

0.85 - 0.90 (0.0335 - 0.0354)

0.90 - 0.95 (0.0354 - 0.0374)38424-E3020

38424-E3021

38424-E3022

38424-E3023

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F50A

Available Snap Rings

MT-133

Page 1184 of 2493

Available Shims=NJMT0029Ð INPUT SHAFT END PLAY AND MAINSHAFT AND DIFFERENTIAL SIDE BEARING PRELOAD AND

ADJUSTING SHIM

BEARING PRELOAD AND END PLAYNJMT0029S01Unit: mm (in)

Mainshaft bearing preload 0.06 - 0.11 (0.0024 - 0.0043)

Input shaft end play0 - 0.05 (0 - 0.0020)

Differential side bearing preload 0.40 - 0.45 (0.0157 - 0.0177)

TOTAL TURNING TORQUE (NEW BEARING)NJMT0029S02Unit: N´m (kg-cm, in-lb)

Total turning torque (new bearing) 8.8 - 21.6 (90 - 220, 78 - 191)

MAINSHAFT BEARING ADJUSTING SHIMNJMT0029S03

Thickness mm (in) Part number*

0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

1.20 (0.0472)32139-03E11

32139-03E00

32139-03E01

32139-03E12

32139-03E02

32139-03E03

32139-03E04

32139-03E05

32139-03E06

32139-03E07

32139-03E08

32139-03E13

*: Always check with the Parts Department for the latest parts information.

TABLE FOR SELECTING MAINSHAFT BEARING ADJUSTING SHIM(S)NJMT0029S04Unit: mm (in)

Dimension ªCº Suitable shim(s)

0.30 - 0.34 (0.0118 - 0.0134)

0.34 - 0.38 (0.0134 - 0.0150)

0.38 - 0.42 (0.0150 - 0.0165)

0.42 - 0.46 (0.0165 - 0.0181)

0.46 - 0.50 (0.0181 - 0.0197)

0.50 - 0.54 (0.0197 - 0.0213)

0.54 - 0.58 (0.0213 - 0.0228)

0.58 - 0.62 (0.0228 - 0.0244)

0.62 - 0.66 (0.0244 - 0.0260)

0.66 - 0.70 (0.0260 - 0.0276)

0.70 - 0.74 (0.0276 - 0.0291)

0.74 - 0.78 (0.0291 - 0.0307)

0.78 - 0.82 (0.0307 - 0.0323)

0.82 - 0.86 (0.0323 - 0.0339)

0.86 - 0.90 (0.0339 - 0.0354)

0.90 - 0.94 (0.0354 - 0.0370)

0.94 - 0.98 (0.0370 - 0.0386)

0.98 - 1.02 (0.0386 - 0.0402)

1.02 - 1.06 (0.0402 - 0.0417)

1.06 - 1.10 (0.0417 - 0.0433)

1.10 - 1.14 (0.0433 - 0.0449)

1.14 - 1.18 (0.0449 - 0.0465)

1.18 - 1.22 (0.0465 - 0.0480)

1.22 - 1.26 (0.0480 - 0.0496)

1.26 - 1.30 (0.0496 - 0.0512)

1.30 - 1.34 (0.0512 - 0.0528)

1.34 - 1.38 (0.0528 - 0.0543)

1.38 - 1.42 (0.0543 - 0.0559)

1.42 - 1.46 (0.0559 - 0.0575)

1.46 - 1.50 (0.0575 - 0.0591)0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

0.40 + 0.44 (0.0157 + 0.0173)

0.44 + 0.44 (0.0173 + 0.0173)

0.44 + 0.48 (0.0173 + 0.0189)

0.48 + 0.48 (0.0189 + 0.0189)

0.48 + 0.52 (0.0189 + 0.0205)

0.52 + 0.52 (0.0205 + 0.0205)

0.52 + 0.56 (0.0205 + 0.0220)

0.56 + 0.56 (0.0220 + 0.0220)

0.56 + 0.60 (0.0220 + 0.0236)

0.60 + 0.60 (0.0236 + 0.0236)

0.60 + 0.64 (0.0236 + 0.0252)

0.64 + 0.64 (0.0252 + 0.0252)

0.64 + 0.68 (0.0252 + 0.0268)

0.68 + 0.68 (0.0268 + 0.0268)

0.68 + 0.72 (0.0268 + 0.0283)

0.72 + 0.72 (0.0283 + 0.0283)

0.72 + 0.76 (0.0283 + 0.0299)

0.76 + 0.76 (0.0299 + 0.0299)

0.76 + 0.80 (0.0299 + 0.0315)

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F50A

Available Shims

MT-134

Page 1185 of 2493

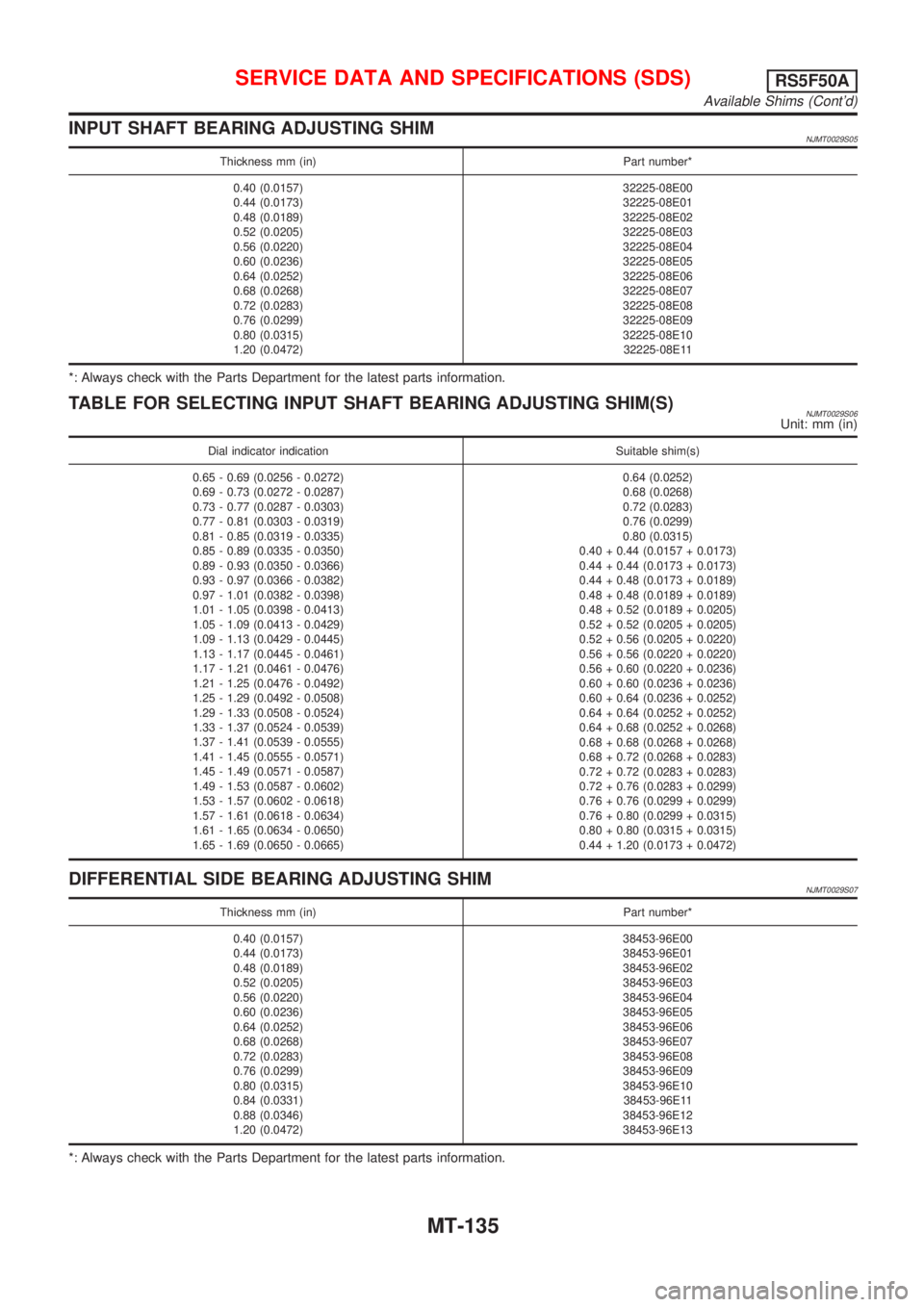

INPUT SHAFT BEARING ADJUSTING SHIMNJMT0029S05

Thickness mm (in) Part number*

0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

1.20 (0.0472)32225-08E00

32225-08E01

32225-08E02

32225-08E03

32225-08E04

32225-08E05

32225-08E06

32225-08E07

32225-08E08

32225-08E09

32225-08E10

32225-08E11

*: Always check with the Parts Department for the latest parts information.

TABLE FOR SELECTING INPUT SHAFT BEARING ADJUSTING SHIM(S)NJMT0029S06Unit: mm (in)

Dial indicator indication Suitable shim(s)

0.65 - 0.69 (0.0256 - 0.0272)

0.69 - 0.73 (0.0272 - 0.0287)

0.73 - 0.77 (0.0287 - 0.0303)

0.77 - 0.81 (0.0303 - 0.0319)

0.81 - 0.85 (0.0319 - 0.0335)

0.85 - 0.89 (0.0335 - 0.0350)

0.89 - 0.93 (0.0350 - 0.0366)

0.93 - 0.97 (0.0366 - 0.0382)

0.97 - 1.01 (0.0382 - 0.0398)

1.01 - 1.05 (0.0398 - 0.0413)

1.05 - 1.09 (0.0413 - 0.0429)

1.09 - 1.13 (0.0429 - 0.0445)

1.13 - 1.17 (0.0445 - 0.0461)

1.17 - 1.21 (0.0461 - 0.0476)

1.21 - 1.25 (0.0476 - 0.0492)

1.25 - 1.29 (0.0492 - 0.0508)

1.29 - 1.33 (0.0508 - 0.0524)

1.33 - 1.37 (0.0524 - 0.0539)

1.37 - 1.41 (0.0539 - 0.0555)

1.41 - 1.45 (0.0555 - 0.0571)

1.45 - 1.49 (0.0571 - 0.0587)

1.49 - 1.53 (0.0587 - 0.0602)

1.53 - 1.57 (0.0602 - 0.0618)

1.57 - 1.61 (0.0618 - 0.0634)

1.61 - 1.65 (0.0634 - 0.0650)

1.65 - 1.69 (0.0650 - 0.0665)0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

0.40 + 0.44 (0.0157 + 0.0173)

0.44 + 0.44 (0.0173 + 0.0173)

0.44 + 0.48 (0.0173 + 0.0189)

0.48 + 0.48 (0.0189 + 0.0189)

0.48 + 0.52 (0.0189 + 0.0205)

0.52 + 0.52 (0.0205 + 0.0205)

0.52 + 0.56 (0.0205 + 0.0220)

0.56 + 0.56 (0.0220 + 0.0220)

0.56 + 0.60 (0.0220 + 0.0236)

0.60 + 0.60 (0.0236 + 0.0236)

0.60 + 0.64 (0.0236 + 0.0252)

0.64 + 0.64 (0.0252 + 0.0252)

0.64 + 0.68 (0.0252 + 0.0268)

0.68 + 0.68 (0.0268 + 0.0268)

0.68 + 0.72 (0.0268 + 0.0283)

0.72 + 0.72 (0.0283 + 0.0283)

0.72 + 0.76 (0.0283 + 0.0299)

0.76 + 0.76 (0.0299 + 0.0299)

0.76 + 0.80 (0.0299 + 0.0315)

0.80 + 0.80 (0.0315 + 0.0315)

0.44 + 1.20 (0.0173 + 0.0472)

DIFFERENTIAL SIDE BEARING ADJUSTING SHIMNJMT0029S07

Thickness mm (in) Part number*

0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

0.84 (0.0331)

0.88 (0.0346)

1.20 (0.0472)38453-96E00

38453-96E01

38453-96E02

38453-96E03

38453-96E04

38453-96E05

38453-96E06

38453-96E07

38453-96E08

38453-96E09

38453-96E10

38453-96E11

38453-96E12

38453-96E13

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F50A

Available Shims (Cont'd)

MT-135

Page 1186 of 2493

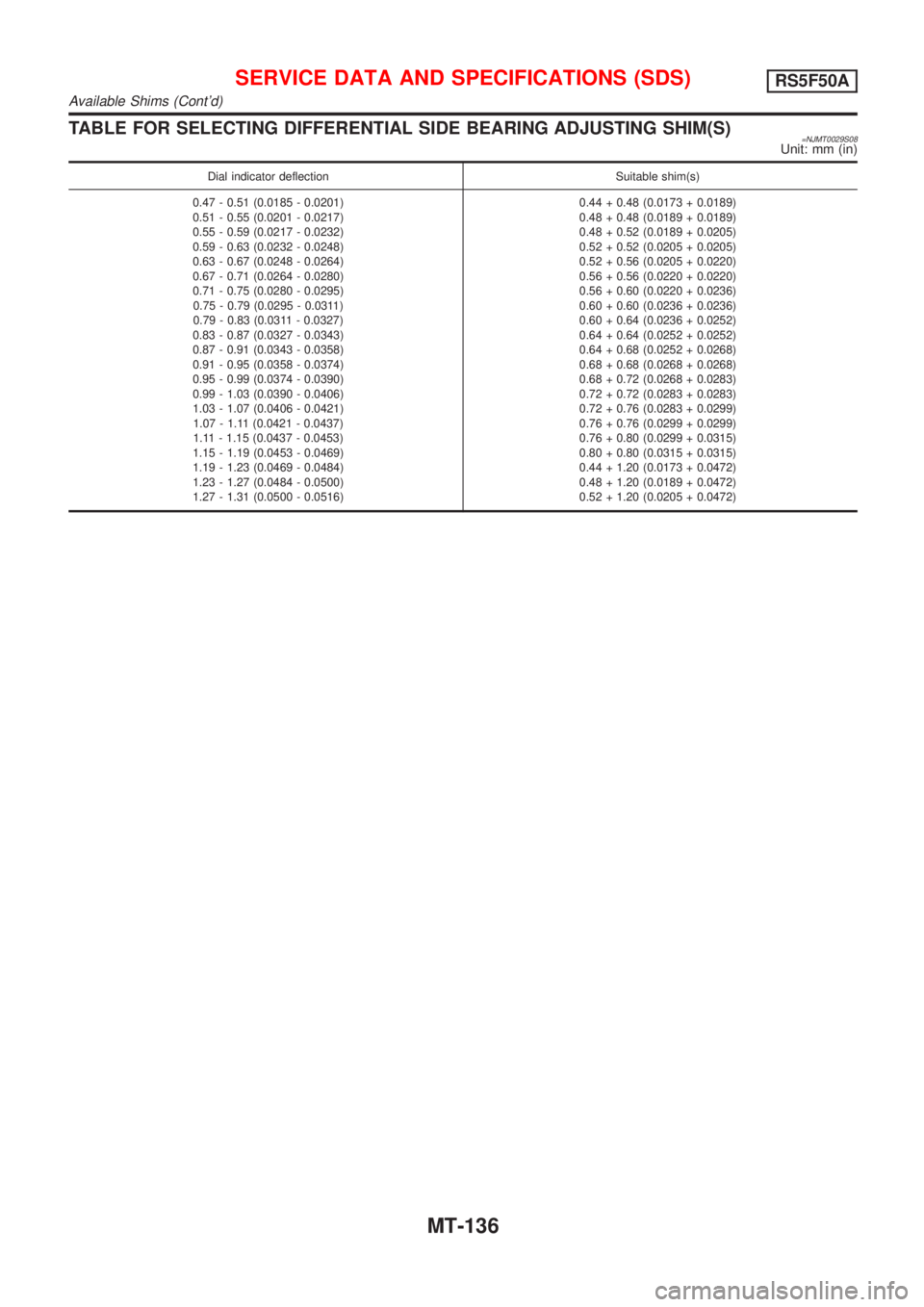

TABLE FOR SELECTING DIFFERENTIAL SIDE BEARING ADJUSTING SHIM(S)=NJMT0029S08Unit: mm (in)

Dial indicator deflection Suitable shim(s)

0.47 - 0.51 (0.0185 - 0.0201)

0.51 - 0.55 (0.0201 - 0.0217)

0.55 - 0.59 (0.0217 - 0.0232)

0.59 - 0.63 (0.0232 - 0.0248)

0.63 - 0.67 (0.0248 - 0.0264)

0.67 - 0.71 (0.0264 - 0.0280)

0.71 - 0.75 (0.0280 - 0.0295)

0.75 - 0.79 (0.0295 - 0.0311)

0.79 - 0.83 (0.0311 - 0.0327)

0.83 - 0.87 (0.0327 - 0.0343)

0.87 - 0.91 (0.0343 - 0.0358)

0.91 - 0.95 (0.0358 - 0.0374)

0.95 - 0.99 (0.0374 - 0.0390)

0.99 - 1.03 (0.0390 - 0.0406)

1.03 - 1.07 (0.0406 - 0.0421)

1.07 - 1.11 (0.0421 - 0.0437)

1.11 - 1.15 (0.0437 - 0.0453)

1.15 - 1.19 (0.0453 - 0.0469)

1.19 - 1.23 (0.0469 - 0.0484)

1.23 - 1.27 (0.0484 - 0.0500)

1.27 - 1.31 (0.0500 - 0.0516)0.44 + 0.48 (0.0173 + 0.0189)

0.48 + 0.48 (0.0189 + 0.0189)

0.48 + 0.52 (0.0189 + 0.0205)

0.52 + 0.52 (0.0205 + 0.0205)

0.52 + 0.56 (0.0205 + 0.0220)

0.56 + 0.56 (0.0220 + 0.0220)

0.56 + 0.60 (0.0220 + 0.0236)

0.60 + 0.60 (0.0236 + 0.0236)

0.60 + 0.64 (0.0236 + 0.0252)

0.64 + 0.64 (0.0252 + 0.0252)

0.64 + 0.68 (0.0252 + 0.0268)

0.68 + 0.68 (0.0268 + 0.0268)

0.68 + 0.72 (0.0268 + 0.0283)

0.72 + 0.72 (0.0283 + 0.0283)

0.72 + 0.76 (0.0283 + 0.0299)

0.76 + 0.76 (0.0299 + 0.0299)

0.76 + 0.80 (0.0299 + 0.0315)

0.80 + 0.80 (0.0315 + 0.0315)

0.44 + 1.20 (0.0173 + 0.0472)

0.48 + 1.20 (0.0189 + 0.0472)

0.52 + 1.20 (0.0205 + 0.0472)

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F50A

Available Shims (Cont'd)

MT-136

Page 1187 of 2493

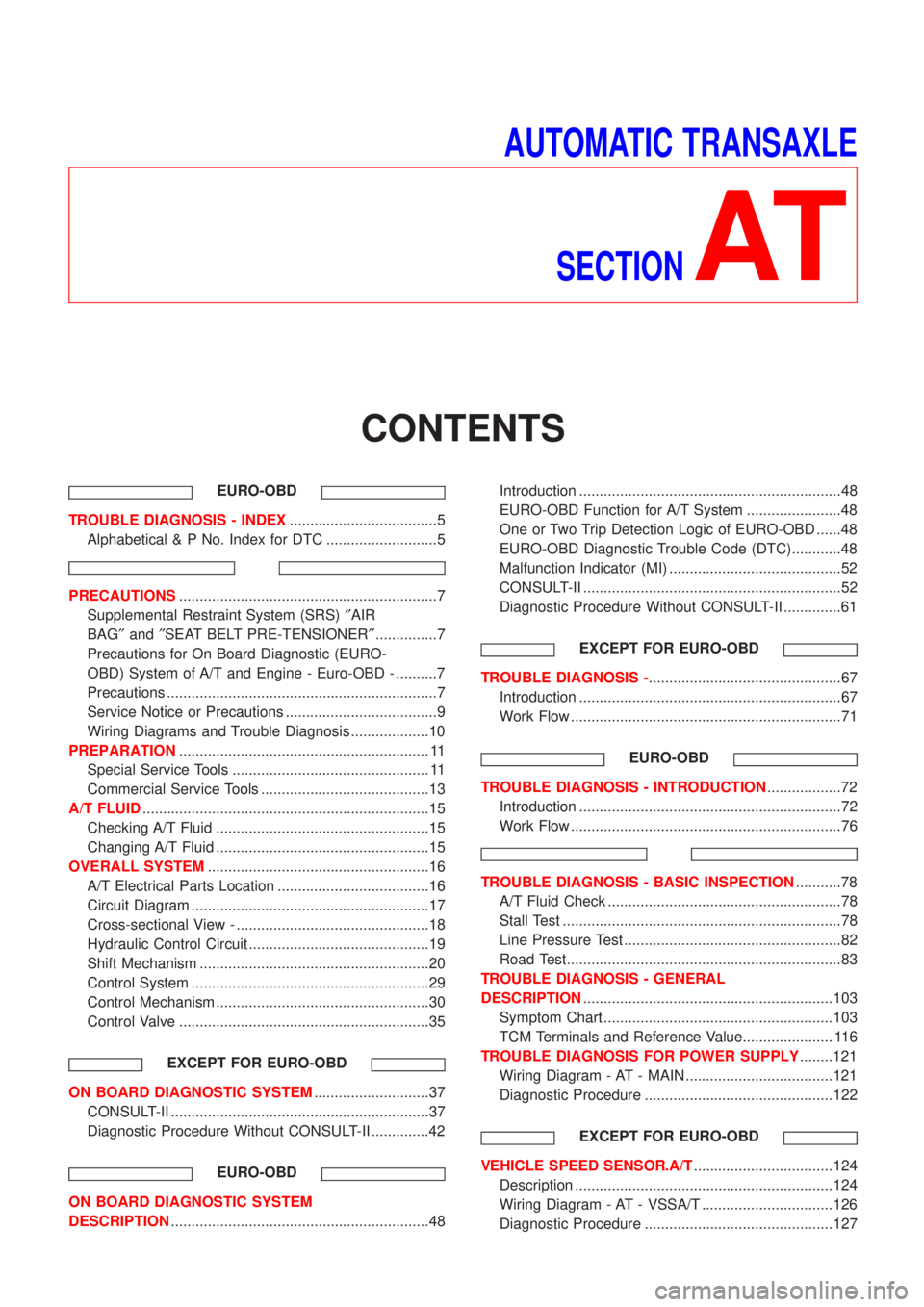

AUTOMATIC TRANSAXLE

SECTION

AT

CONTENTS

EURO-OBD

TROUBLE DIAGNOSIS - INDEX....................................5

Alphabetical & P No. Index for DTC ...........................5

PRECAUTIONS...............................................................7

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............7

Precautions for On Board Diagnostic (EURO-

OBD) System of A/T and Engine - Euro-OBD - ..........7

Precautions ..................................................................7

Service Notice or Precautions .....................................9

Wiring Diagrams and Trouble Diagnosis ...................10

PREPARATION............................................................. 11

Special Service Tools ................................................ 11

Commercial Service Tools .........................................13

A/T FLUID......................................................................15

Checking A/T Fluid ....................................................15

Changing A/T Fluid ....................................................15

OVERALL SYSTEM......................................................16

A/T Electrical Parts Location .....................................16

Circuit Diagram ..........................................................17

Cross-sectional View - ...............................................18

Hydraulic Control Circuit ............................................19

Shift Mechanism ........................................................20

Control System ..........................................................29

Control Mechanism ....................................................30

Control Valve .............................................................35

EXCEPT FOR EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM............................37

CONSULT-II ...............................................................37

Diagnostic Procedure Without CONSULT-II ..............42

EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................48Introduction ................................................................48

EURO-OBD Function for A/T System .......................48

One or Two Trip Detection Logic of EURO-OBD ......48

EURO-OBD Diagnostic Trouble Code (DTC)............48

Malfunction Indicator (MI) ..........................................52

CONSULT-II ...............................................................52

Diagnostic Procedure Without CONSULT-II ..............61

EXCEPT FOR EURO-OBD

TROUBLE DIAGNOSIS -...............................................67

Introduction ................................................................67

Work Flow ..................................................................71

EURO-OBD

TROUBLE DIAGNOSIS - INTRODUCTION..................72

Introduction ................................................................72

Work Flow ..................................................................76

TROUBLE DIAGNOSIS - BASIC INSPECTION...........78

A/T Fluid Check .........................................................78

Stall Test ....................................................................78

Line Pressure Test .....................................................82

Road Test...................................................................83

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................103

Symptom Chart ........................................................103

TCM Terminals and Reference Value...................... 116

TROUBLE DIAGNOSIS FOR POWER SUPPLY........121

Wiring Diagram - AT - MAIN ....................................121

Diagnostic Procedure ..............................................122

EXCEPT FOR EURO-OBD

VEHICLE SPEED SENSOR.A/T..................................124

Description ...............................................................124

Wiring Diagram - AT - VSSA/T ................................126

Diagnostic Procedure ..............................................127

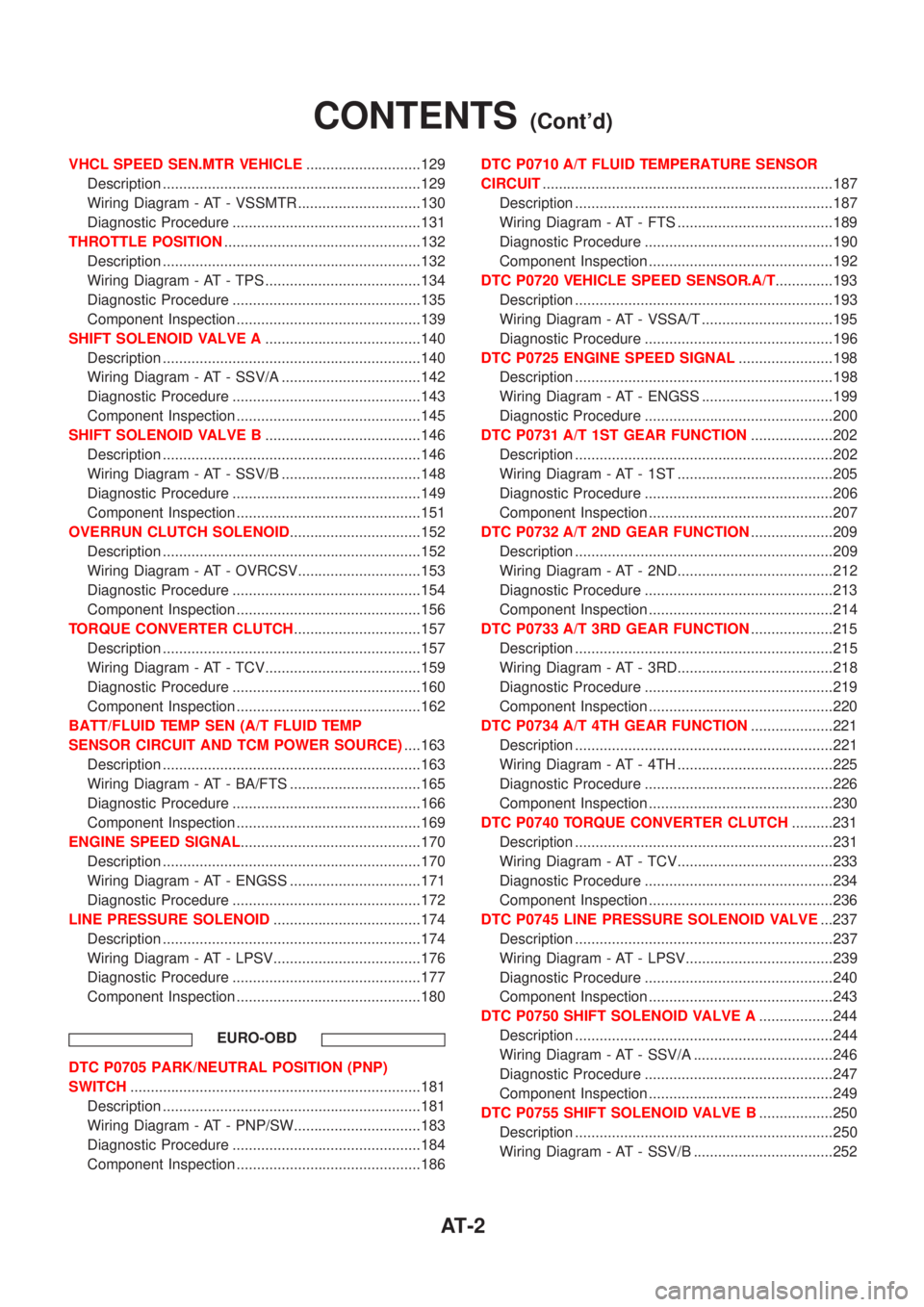

Page 1188 of 2493

VHCL SPEED SEN.MTR VEHICLE............................129

Description ...............................................................129

Wiring Diagram - AT - VSSMTR ..............................130

Diagnostic Procedure ..............................................131

THROTTLE POSITION................................................132

Description ...............................................................132

Wiring Diagram - AT - TPS ......................................134

Diagnostic Procedure ..............................................135

Component Inspection .............................................139

SHIFT SOLENOID VALVE A......................................140

Description ...............................................................140

Wiring Diagram - AT - SSV/A ..................................142

Diagnostic Procedure ..............................................143

Component Inspection .............................................145

SHIFT SOLENOID VALVE B......................................146

Description ...............................................................146

Wiring Diagram - AT - SSV/B ..................................148

Diagnostic Procedure ..............................................149

Component Inspection .............................................151

OVERRUN CLUTCH SOLENOID................................152

Description ...............................................................152

Wiring Diagram - AT - OVRCSV..............................153

Diagnostic Procedure ..............................................154

Component Inspection .............................................156

TORQUE CONVERTER CLUTCH...............................157

Description ...............................................................157

Wiring Diagram - AT - TCV......................................159

Diagnostic Procedure ..............................................160

Component Inspection .............................................162

BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE)....163

Description ...............................................................163

Wiring Diagram - AT - BA/FTS ................................165

Diagnostic Procedure ..............................................166

Component Inspection .............................................169

ENGINE SPEED SIGNAL............................................170

Description ...............................................................170

Wiring Diagram - AT - ENGSS ................................171

Diagnostic Procedure ..............................................172

LINE PRESSURE SOLENOID....................................174

Description ...............................................................174

Wiring Diagram - AT - LPSV....................................176

Diagnostic Procedure ..............................................177

Component Inspection .............................................180

EURO-OBD

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................181

Description ...............................................................181

Wiring Diagram - AT - PNP/SW...............................183

Diagnostic Procedure ..............................................184

Component Inspection .............................................186DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT.......................................................................187

Description ...............................................................187

Wiring Diagram - AT - FTS ......................................189

Diagnostic Procedure ..............................................190

Component Inspection .............................................192

DTC P0720 VEHICLE SPEED SENSOR.A/T..............193

Description ...............................................................193

Wiring Diagram - AT - VSSA/T ................................195

Diagnostic Procedure ..............................................196

DTC P0725 ENGINE SPEED SIGNAL.......................198

Description ...............................................................198

Wiring Diagram - AT - ENGSS ................................199

Diagnostic Procedure ..............................................200

DTC P0731 A/T 1ST GEAR FUNCTION....................202

Description ...............................................................202

Wiring Diagram - AT - 1ST ......................................205

Diagnostic Procedure ..............................................206

Component Inspection .............................................207

DTC P0732 A/T 2ND GEAR FUNCTION....................209

Description ...............................................................209

Wiring Diagram - AT - 2ND......................................212

Diagnostic Procedure ..............................................213

Component Inspection .............................................214

DTC P0733 A/T 3RD GEAR FUNCTION....................215

Description ...............................................................215

Wiring Diagram - AT - 3RD......................................218

Diagnostic Procedure ..............................................219

Component Inspection .............................................220

DTC P0734 A/T 4TH GEAR FUNCTION....................221

Description ...............................................................221

Wiring Diagram - AT - 4TH ......................................225

Diagnostic Procedure ..............................................226

Component Inspection .............................................230

DTC P0740 TORQUE CONVERTER CLUTCH..........231

Description ...............................................................231

Wiring Diagram - AT - TCV......................................233

Diagnostic Procedure ..............................................234

Component Inspection .............................................236

DTC P0745 LINE PRESSURE SOLENOID VALVE...237

Description ...............................................................237

Wiring Diagram - AT - LPSV....................................239

Diagnostic Procedure ..............................................240

Component Inspection .............................................243

DTC P0750 SHIFT SOLENOID VALVE A..................244

Description ...............................................................244

Wiring Diagram - AT - SSV/A ..................................246

Diagnostic Procedure ..............................................247

Component Inspection .............................................249

DTC P0755 SHIFT SOLENOID VALVE B..................250

Description ...............................................................250

Wiring Diagram - AT - SSV/B ..................................252

CONTENTS(Cont'd)

AT-2

Page 1189 of 2493

Diagnostic Procedure ..............................................253

Component Inspection .............................................255

DTC P1705 THROTTLE POSITION SENSOR...........256

Description ...............................................................256

Wiring Diagram - AT - TPS ......................................259

Diagnostic Procedure ..............................................260

Component Inspection .............................................264

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE..........................................................................265

Description ...............................................................265

Wiring Diagram - AT - OVRCSV..............................267

Diagnostic Procedure ..............................................268

Component Inspection .............................................270

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE)....271

Description ...............................................................271

Wiring Diagram - AT - BA/FTS ................................273

Diagnostic Procedure ..............................................274

Component Inspection .............................................277

DTC VHCL SPEED SEN.MTR VEHICLE SPEED......278

Description ...............................................................278

Wiring Diagram - AT - VSSMTR ..............................280

Diagnostic Procedure ..............................................281

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM)...........................................................................282

Description ...............................................................282

Diagnostic Procedure ..............................................282

DTC CONTROL UNIT (EEP ROM).............................284

Description ...............................................................284

Diagnostic Procedure ..............................................285

TROUBLE DIAGNOSES FOR SYMPTOMS...............286

Wiring Diagram - AT - NONDTC .............................286

1. O/D OFF Indicator Lamp Does Not Come On....288

2. Engine Cannot Be Started In²P²and²N²

Position ....................................................................291

3. In²P²Position, Vehicle Moves Forward Or

Backward When Pushed .........................................292

4. In²N²Position, Vehicle Moves ...........................293

5. Large Shock.²N²->²R²Position .......................295

6. Vehicle Does Not Creep Backward In²R²

Position ....................................................................297

7. Vehicle Does Not Creep Forward In²D²,²2²

Or²1²Position .........................................................300

8. Vehicle Cannot Be Started From D

1...................303

9. A/T Does Not Shift: D

1-> D2Or Does Not

Kickdown: D

4-> D2..................................................306

10. A/T Does Not Shift: D

2-> D3.............................309

11. A/T Does Not Shift: D

3-> D4.............................312

12. A/T Does Not Perform Lock-up .........................315

13. A/T Does Not Hold Lock-up Condition ..............31714. Lock-up Is Not Released ...................................319

15. Engine Speed Does Not Return To Idle (Light

Braking D

4-> D3).....................................................320

16. Vehicle Does Not Start From D

1.......................322

17. A/T Does Not Shift: D

4-> D3, When

Overdrive Control Switch²ON²->²OFF²...............323

18. A/T Does Not Shift: D

3-> 22, When Selector

Lever²D²->²2²Position.........................................324

19. A/T Does Not Shift: 2

2-> 11, When Selector

Lever²2²->²1²Position .........................................325

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................326

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................326

A/T SHIFT LOCK SYSTEM.........................................335

Description ...............................................................335

Shift Lock System Electrical Parts Location............335

Wiring Diagram - SHIFT -........................................336

Diagnostic Procedure ..............................................337

KEY INTERLOCK CABLE..........................................341

Components.............................................................341

Removal ...................................................................341

Installation ................................................................342

ON-VEHICLE SERVICE..............................................343

Control Valve Assembly and Accumulators .............343

Control Cable Adjustment ........................................344

Park/Neutral Position (PNP) Switch Adjustment .....344

Differential Side Oil Seal Replacement ...................345

Revolution Sensor Replacement .............................345

REMOVAL AND INSTALLATION...............................346

Removal ...................................................................346

Installation ................................................................347

OVERHAUL.................................................................349

Components-1 .........................................................349

Components-2 .........................................................350

Components-3 .........................................................351

Oil Channel ..............................................................352

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ............................353

DISASSEMBLY............................................................354

REPAIR FOR COMPONENT PARTS.........................368

Manual Shaft............................................................368

Oil Pump ..................................................................371

Control Valve Assembly ...........................................375

Control Valve Upper Body .......................................384

Control Valve Lower Body .......................................388

Reverse Clutch ........................................................390

High Clutch ..............................................................394

Forward Clutch and Overrun Clutch........................399

Low & Reverse Brake..............................................406

CONTENTS(Cont'd)

AT-3

Page 1190 of 2493

Rear Internal Gear, Forward Clutch Hub and

Overrun Clutch Hub .................................................410

Output Shaft, Idler Gear, Reduction Pinion Gear

and Bearing Retainer...............................................414

Band Servo Piston Assembly ..................................419

Final Drive................................................................424

ASSEMBLY..................................................................428

Assembly (1) ............................................................428

Adjustment (1) .........................................................429

Assembly (2) ............................................................434

Adjustment (2) .........................................................438

Assembly (3) ............................................................442

Assembly (4) ............................................................444

SERVICE DATA AND SPECIFICATIONS (SDS).......449

General Specifications .............................................449

Shift Schedule..........................................................449

Stall Revolution ........................................................450

Line Pressure...........................................................450

Control Valves..........................................................450Clutch and Brakes ...................................................451

Clutch and Brake Return Springs............................452

Oil Pump ..................................................................453

Input Shaft ...............................................................453

Planetary Carrier......................................................453

Final Drive................................................................453

Reduction Pinion Gear ............................................455

Output Shaft.............................................................456

Bearing Retainer ......................................................457

Total End Play..........................................................457

Reverse Clutch End Play ........................................457

Accumulator .............................................................457

Band Servo ..............................................................458

Removal and Installation .........................................458

Shift Solenoid Valves ...............................................458

Resistance ...............................................................458

ATF Temp. Sensor ...................................................458

Revolution Sensor ...................................................458

Dropping Resistor ....................................................458

CONTENTS(Cont'd)

AT-4