NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 291 of 2493

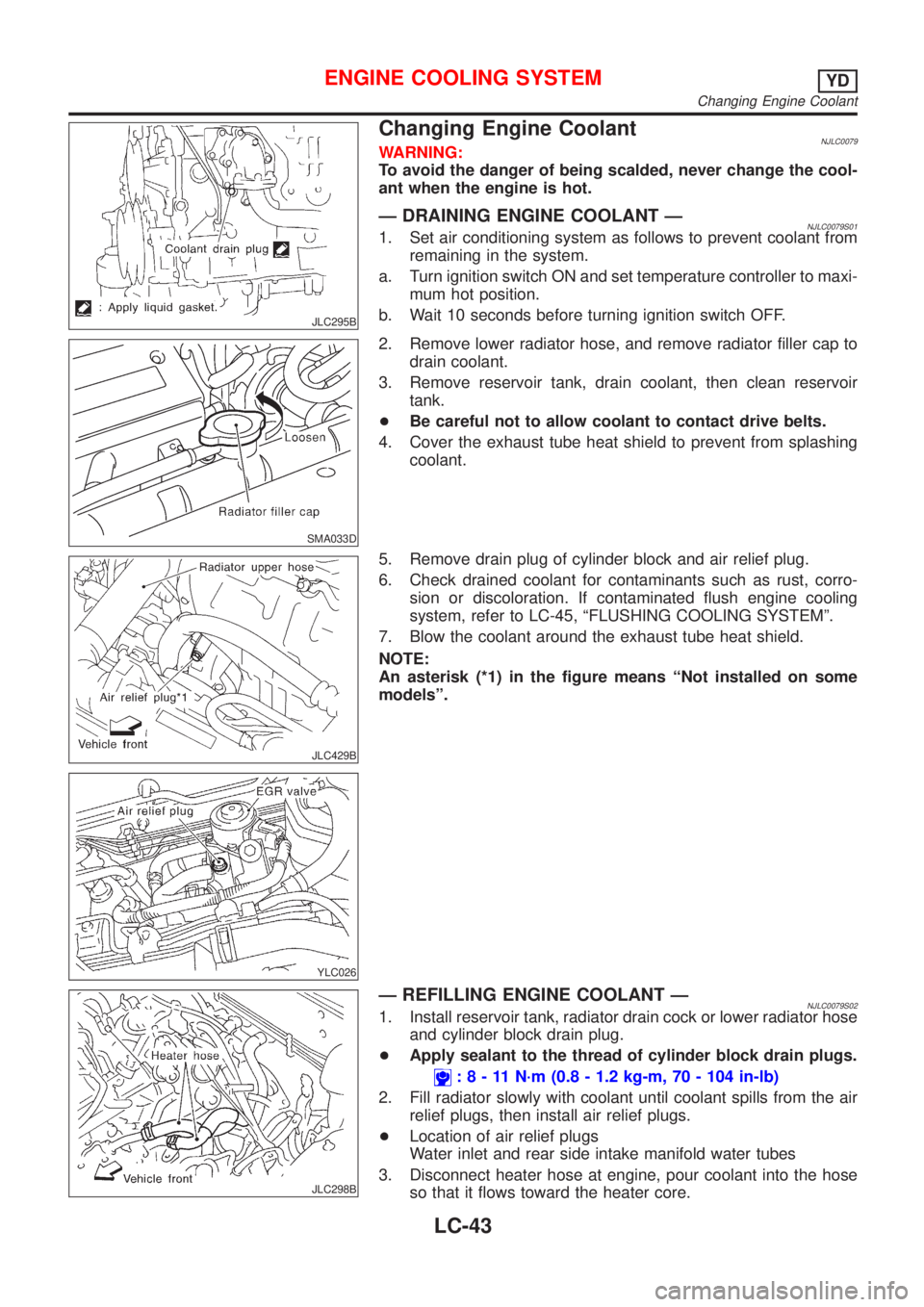

JLC295B

Changing Engine CoolantNJLC0079WARNING:

To avoid the danger of being scalded, never change the cool-

ant when the engine is hot.

Ð DRAINING ENGINE COOLANT ÐNJLC0079S011. Set air conditioning system as follows to prevent coolant from

remaining in the system.

a. Turn ignition switch ON and set temperature controller to maxi-

mum hot position.

b. Wait 10 seconds before turning ignition switch OFF.

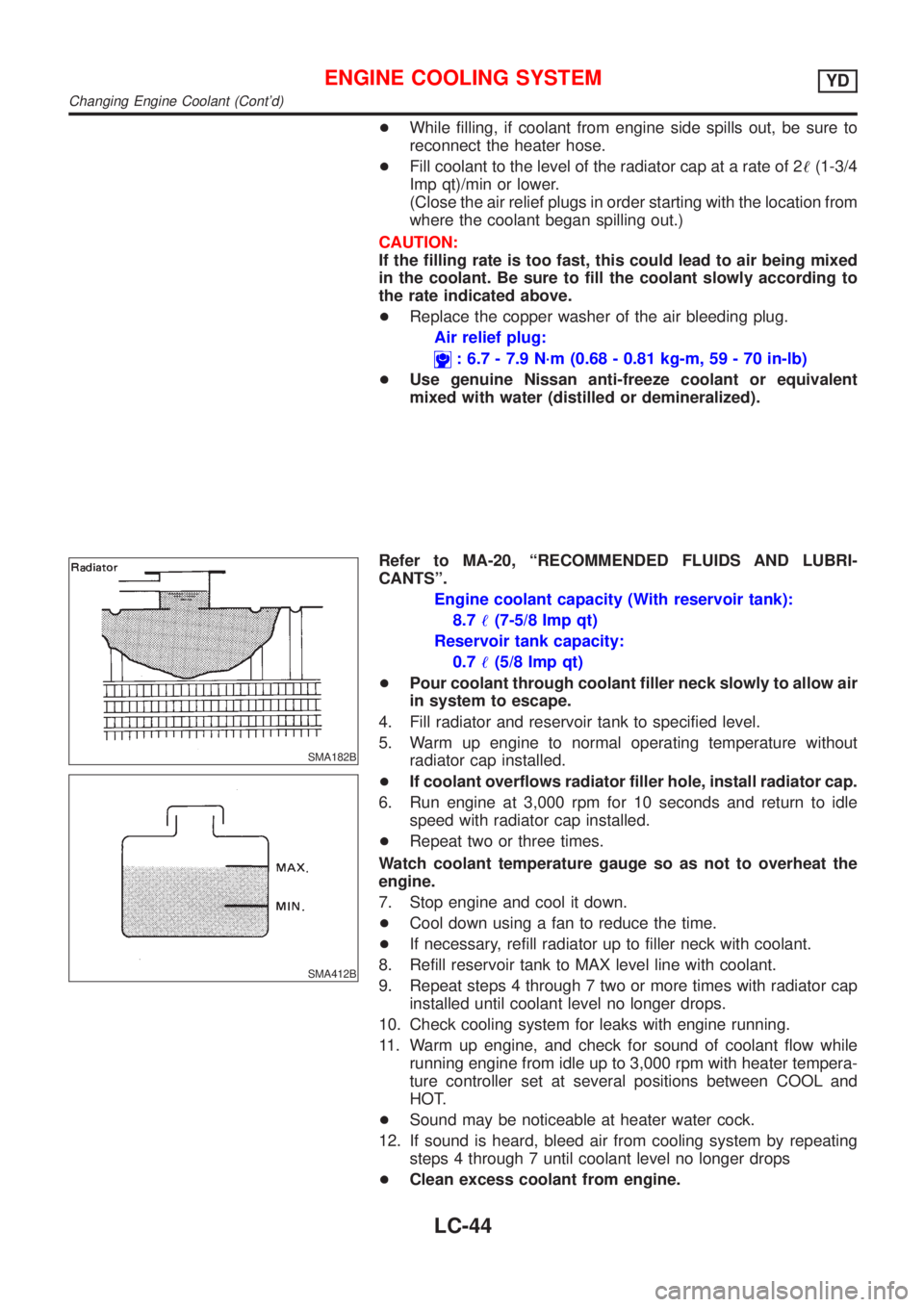

SMA033D

2. Remove lower radiator hose, and remove radiator filler cap to

drain coolant.

3. Remove reservoir tank, drain coolant, then clean reservoir

tank.

+Be careful not to allow coolant to contact drive belts.

4. Cover the exhaust tube heat shield to prevent from splashing

coolant.

JLC429B

YLC026

5. Remove drain plug of cylinder block and air relief plug.

6. Check drained coolant for contaminants such as rust, corro-

sion or discoloration. If contaminated flush engine cooling

system, refer to LC-45, ªFLUSHING COOLING SYSTEMº.

7. Blow the coolant around the exhaust tube heat shield.

NOTE:

An asterisk (*1) in the figure means ªNot installed on some

modelsº.

JLC298B

Ð REFILLING ENGINE COOLANT ÐNJLC0079S021. Install reservoir tank, radiator drain cock or lower radiator hose

and cylinder block drain plug.

+Apply sealant to the thread of cylinder block drain plugs.

:8-11N´m(0.8 - 1.2 kg-m, 70 - 104 in-lb)

2. Fill radiator slowly with coolant until coolant spills from the air

relief plugs, then install air relief plugs.

+Location of air relief plugs

Water inlet and rear side intake manifold water tubes

3. Disconnect heater hose at engine, pour coolant into the hose

so that it flows toward the heater core.

ENGINE COOLING SYSTEMYD

Changing Engine Coolant

LC-43

Page 292 of 2493

+While filling, if coolant from engine side spills out, be sure to

reconnect the heater hose.

+Fill coolant to the level of the radiator cap at a rate of 2!(1-3/4

Imp qt)/min or lower.

(Close the air relief plugs in order starting with the location from

where the coolant began spilling out.)

CAUTION:

If the filling rate is too fast, this could lead to air being mixed

in the coolant. Be sure to fill the coolant slowly according to

the rate indicated above.

+Replace the copper washer of the air bleeding plug.

Air relief plug:

: 6.7 - 7.9 N´m (0.68 - 0.81 kg-m, 59 - 70 in-lb)

+Use genuine Nissan anti-freeze coolant or equivalent

mixed with water (distilled or demineralized).

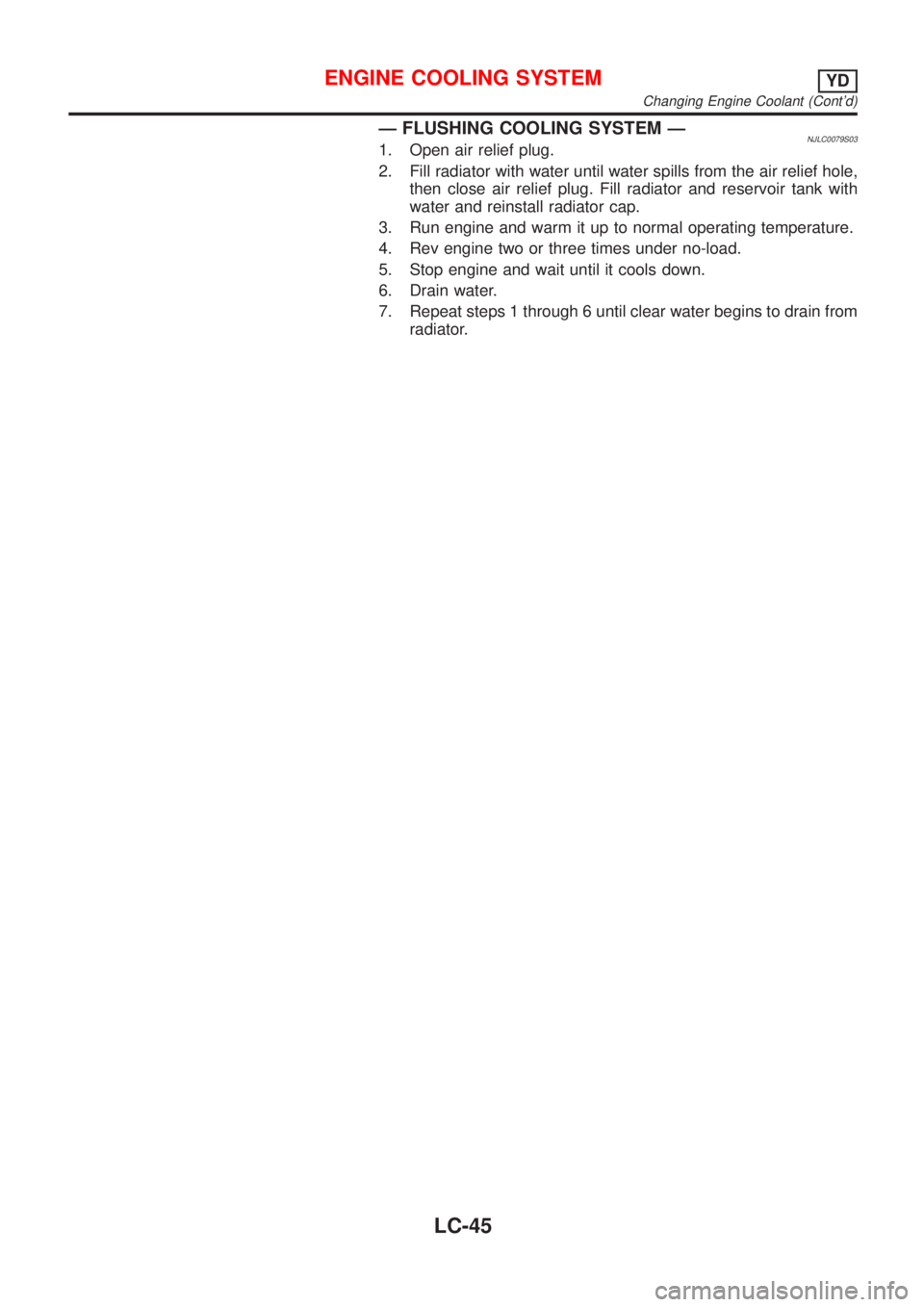

SMA182B

SMA412B

Refer to MA-20, ªRECOMMENDED FLUIDS AND LUBRI-

CANTSº.

Engine coolant capacity (With reservoir tank):

8.7!(7-5/8 Imp qt)

Reservoir tank capacity:

0.7!(5/8 Imp qt)

+Pour coolant through coolant filler neck slowly to allow air

in system to escape.

4. Fill radiator and reservoir tank to specified level.

5. Warm up engine to normal operating temperature without

radiator cap installed.

+If coolant overflows radiator filler hole, install radiator cap.

6. Run engine at 3,000 rpm for 10 seconds and return to idle

speed with radiator cap installed.

+Repeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

7. Stop engine and cool it down.

+Cool down using a fan to reduce the time.

+If necessary, refill radiator up to filler neck with coolant.

8. Refill reservoir tank to MAX level line with coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap

installed until coolant level no longer drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 3,000 rpm with heater tempera-

ture controller set at several positions between COOL and

HOT.

+Sound may be noticeable at heater water cock.

12. If sound is heard, bleed air from cooling system by repeating

steps 4 through 7 until coolant level no longer drops

+Clean excess coolant from engine.

ENGINE COOLING SYSTEMYD

Changing Engine Coolant (Cont'd)

LC-44

Page 293 of 2493

Ð FLUSHING COOLING SYSTEM ÐNJLC0079S031. Open air relief plug.

2. Fill radiator with water until water spills from the air relief hole,

then close air relief plug. Fill radiator and reservoir tank with

water and reinstall radiator cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

7. Repeat steps 1 through 6 until clear water begins to drain from

radiator.

ENGINE COOLING SYSTEMYD

Changing Engine Coolant (Cont'd)

LC-45

Page 294 of 2493

Radiator (Aluminum type)=NJLC0082Refer to LC-20, ªRadiator (Aluminum type)º.

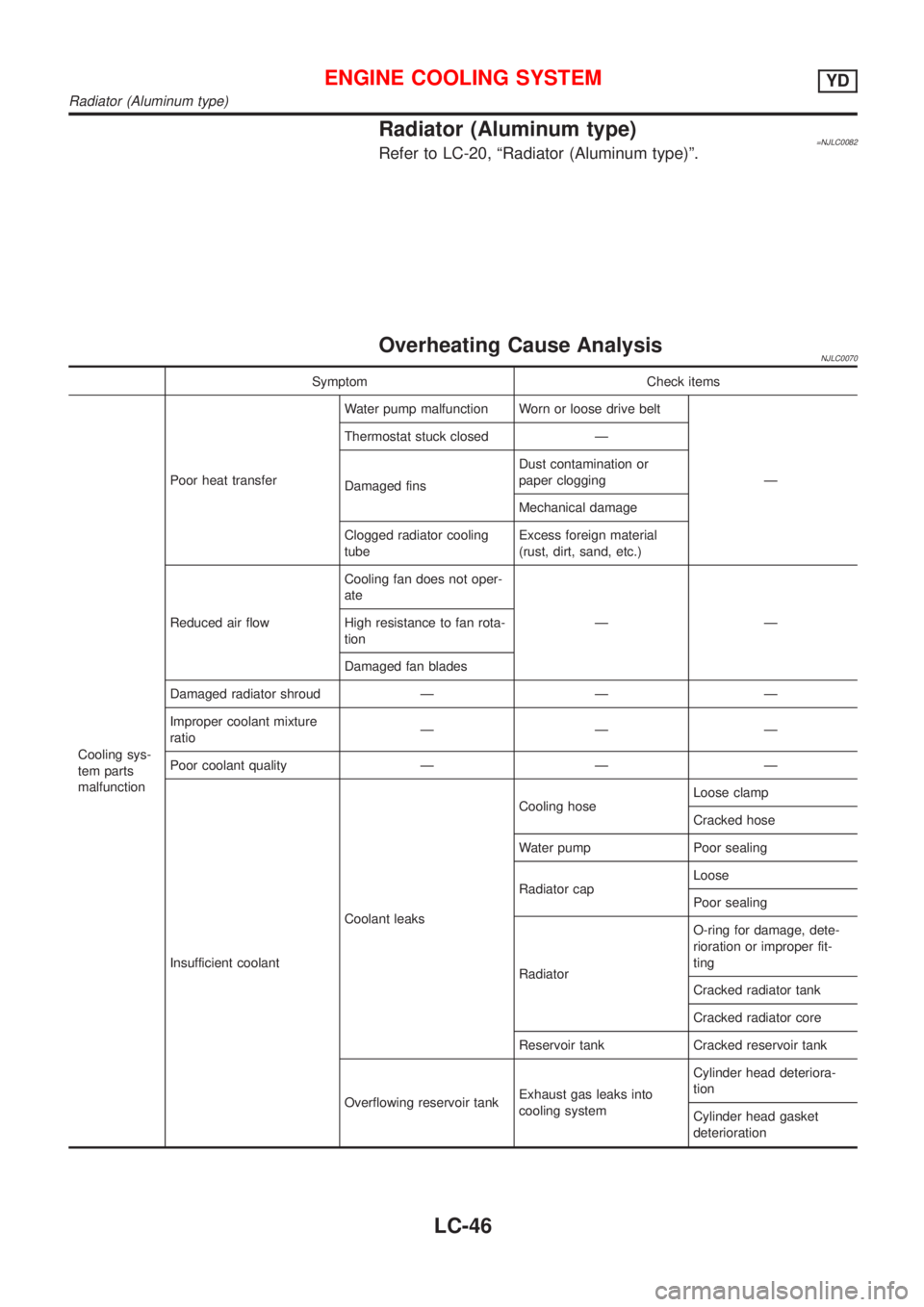

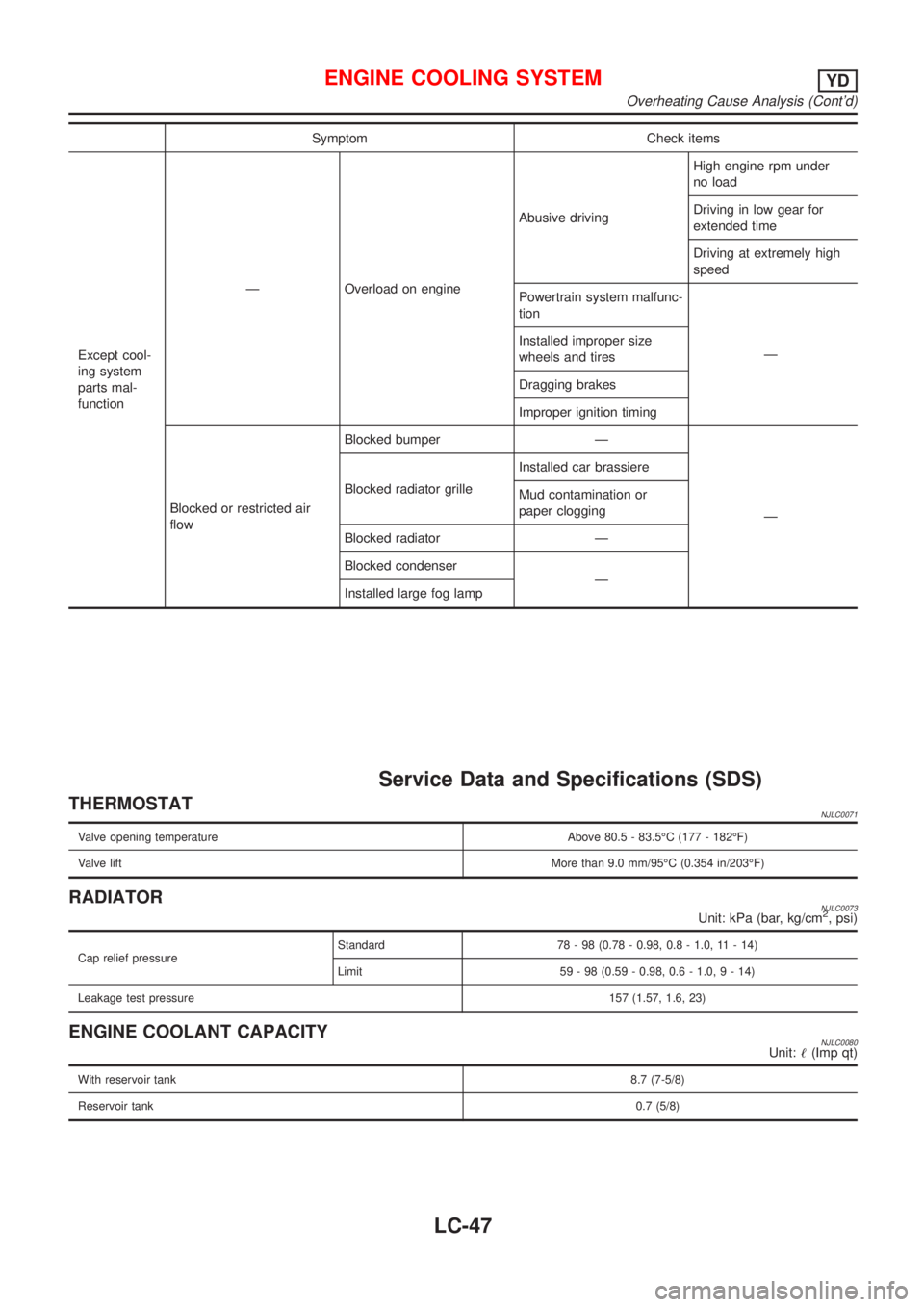

Overheating Cause AnalysisNJLC0070

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

ÐÐ High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture

ratioÐÐÐ

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, dete-

rioration or improper fit-

ting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deteriora-

tion

Cylinder head gasket

deterioration

ENGINE COOLING SYSTEMYD

Radiator (Aluminum type)

LC-46

Page 295 of 2493

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under

no load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0071

Valve opening temperature Above 80.5 - 83.5ÉC (177 - 182ÉF)

Valve liftMore than 9.0 mm/95ÉC (0.354 in/203ÉF)

RADIATORNJLC0073Unit: kPa (bar, kg/cm2, psi)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

ENGINE COOLANT CAPACITYNJLC0080Unit:!(Imp qt)

With reservoir tank8.7 (7-5/8)

Reservoir tank0.7 (5/8)

ENGINE COOLING SYSTEMYD

Overheating Cause Analysis (Cont'd)

LC-47

Page 296 of 2493

ENGINE COOLING SYSTEM

Service Data and Specifications (SDS) (Cont'd)

LC-48

Page 297 of 2493

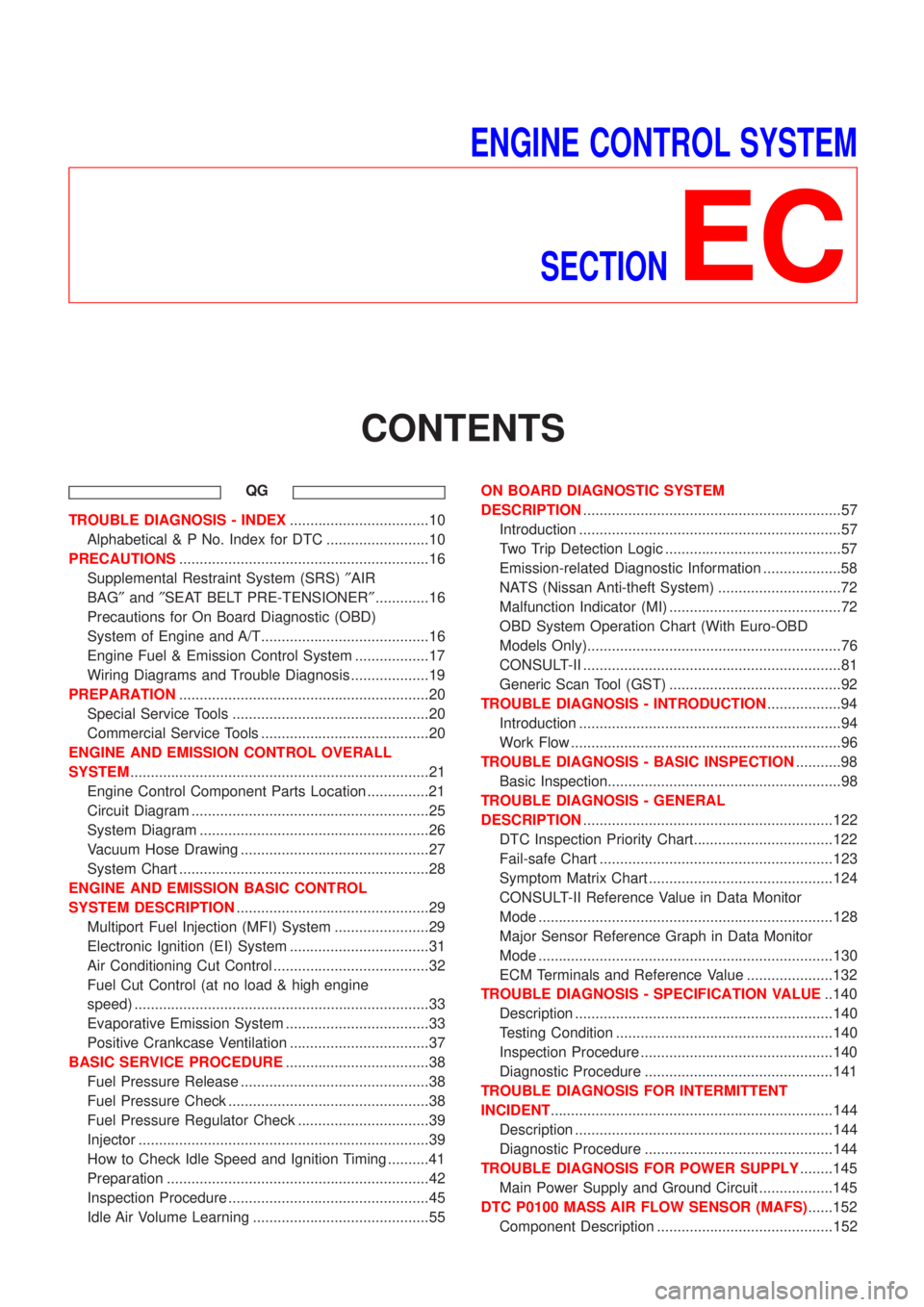

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

QG

TROUBLE DIAGNOSIS - INDEX..................................10

Alphabetical & P No. Index for DTC .........................10

PRECAUTIONS.............................................................16

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER².............16

Precautions for On Board Diagnostic (OBD)

System of Engine and A/T.........................................16

Engine Fuel & Emission Control System ..................17

Wiring Diagrams and Trouble Diagnosis ...................19

PREPARATION.............................................................20

Special Service Tools ................................................20

Commercial Service Tools .........................................20

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................21

Engine Control Component Parts Location ...............21

Circuit Diagram ..........................................................25

System Diagram ........................................................26

Vacuum Hose Drawing ..............................................27

System Chart .............................................................28

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................29

Multiport Fuel Injection (MFI) System .......................29

Electronic Ignition (EI) System ..................................31

Air Conditioning Cut Control ......................................32

Fuel Cut Control (at no load & high engine

speed) ........................................................................33

Evaporative Emission System ...................................33

Positive Crankcase Ventilation ..................................37

BASIC SERVICE PROCEDURE...................................38

Fuel Pressure Release ..............................................38

Fuel Pressure Check .................................................38

Fuel Pressure Regulator Check ................................39

Injector .......................................................................39

How to Check Idle Speed and Ignition Timing ..........41

Preparation ................................................................42

Inspection Procedure .................................................45

Idle Air Volume Learning ...........................................55ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................57

Introduction ................................................................57

Two Trip Detection Logic ...........................................57

Emission-related Diagnostic Information ...................58

NATS (Nissan Anti-theft System) ..............................72

Malfunction Indicator (MI) ..........................................72

OBD System Operation Chart (With Euro-OBD

Models Only)..............................................................76

CONSULT-II ...............................................................81

Generic Scan Tool (GST) ..........................................92

TROUBLE DIAGNOSIS - INTRODUCTION..................94

Introduction ................................................................94

Work Flow ..................................................................96

TROUBLE DIAGNOSIS - BASIC INSPECTION...........98

Basic Inspection.........................................................98

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................122

DTC Inspection Priority Chart..................................122

Fail-safe Chart .........................................................123

Symptom Matrix Chart .............................................124

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................128

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................130

ECM Terminals and Reference Value .....................132

TROUBLE DIAGNOSIS - SPECIFICATION VALUE..140

Description ...............................................................140

Testing Condition .....................................................140

Inspection Procedure ...............................................140

Diagnostic Procedure ..............................................141

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................144

Description ...............................................................144

Diagnostic Procedure ..............................................144

TROUBLE DIAGNOSIS FOR POWER SUPPLY........145

Main Power Supply and Ground Circuit ..................145

DTC P0100 MASS AIR FLOW SENSOR (MAFS)......152

Component Description ...........................................152

Page 298 of 2493

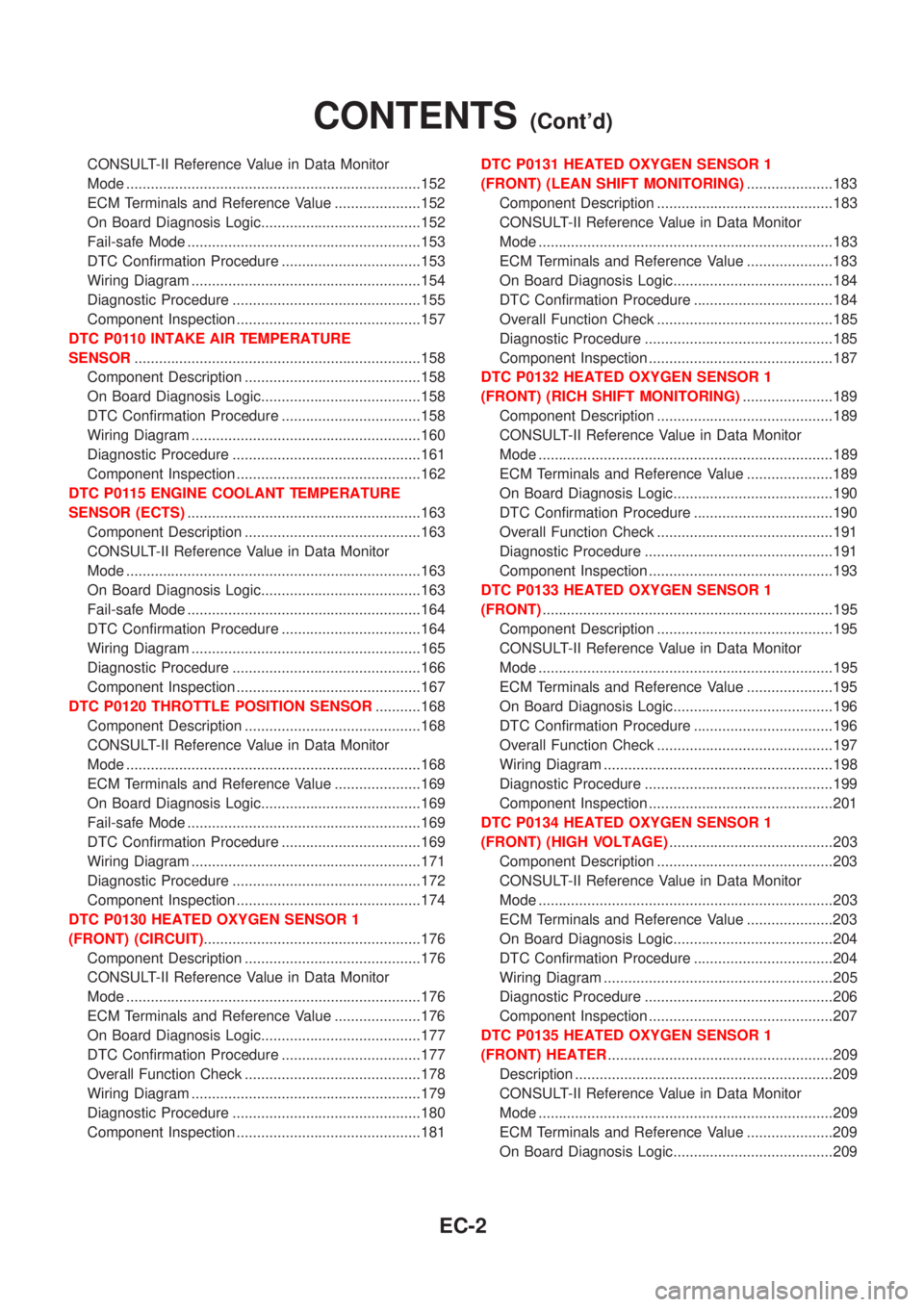

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................152

ECM Terminals and Reference Value .....................152

On Board Diagnosis Logic.......................................152

Fail-safe Mode .........................................................153

DTC Confirmation Procedure ..................................153

Wiring Diagram ........................................................154

Diagnostic Procedure ..............................................155

Component Inspection .............................................157

DTC P0110 INTAKE AIR TEMPERATURE

SENSOR......................................................................158

Component Description ...........................................158

On Board Diagnosis Logic.......................................158

DTC Confirmation Procedure ..................................158

Wiring Diagram ........................................................160

Diagnostic Procedure ..............................................161

Component Inspection .............................................162

DTC P0115 ENGINE COOLANT TEMPERATURE

SENSOR (ECTS).........................................................163

Component Description ...........................................163

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................163

On Board Diagnosis Logic.......................................163

Fail-safe Mode .........................................................164

DTC Confirmation Procedure ..................................164

Wiring Diagram ........................................................165

Diagnostic Procedure ..............................................166

Component Inspection .............................................167

DTC P0120 THROTTLE POSITION SENSOR...........168

Component Description ...........................................168

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................168

ECM Terminals and Reference Value .....................169

On Board Diagnosis Logic.......................................169

Fail-safe Mode .........................................................169

DTC Confirmation Procedure ..................................169

Wiring Diagram ........................................................171

Diagnostic Procedure ..............................................172

Component Inspection .............................................174

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT).....................................................176

Component Description ...........................................176

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................176

ECM Terminals and Reference Value .....................176

On Board Diagnosis Logic.......................................177

DTC Confirmation Procedure ..................................177

Overall Function Check ...........................................178

Wiring Diagram ........................................................179

Diagnostic Procedure ..............................................180

Component Inspection .............................................181DTC P0131 HEATED OXYGEN SENSOR 1

(FRONT) (LEAN SHIFT MONITORING).....................183

Component Description ...........................................183

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................183

ECM Terminals and Reference Value .....................183

On Board Diagnosis Logic.......................................184

DTC Confirmation Procedure ..................................184

Overall Function Check ...........................................185

Diagnostic Procedure ..............................................185

Component Inspection .............................................187

DTC P0132 HEATED OXYGEN SENSOR 1

(FRONT) (RICH SHIFT MONITORING)......................189

Component Description ...........................................189

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................189

ECM Terminals and Reference Value .....................189

On Board Diagnosis Logic.......................................190

DTC Confirmation Procedure ..................................190

Overall Function Check ...........................................191

Diagnostic Procedure ..............................................191

Component Inspection .............................................193

DTC P0133 HEATED OXYGEN SENSOR 1

(FRONT).......................................................................195

Component Description ...........................................195

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................195

ECM Terminals and Reference Value .....................195

On Board Diagnosis Logic.......................................196

DTC Confirmation Procedure ..................................196

Overall Function Check ...........................................197

Wiring Diagram ........................................................198

Diagnostic Procedure ..............................................199

Component Inspection .............................................201

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)........................................203

Component Description ...........................................203

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................203

ECM Terminals and Reference Value .....................203

On Board Diagnosis Logic.......................................204

DTC Confirmation Procedure ..................................204

Wiring Diagram ........................................................205

Diagnostic Procedure ..............................................206

Component Inspection .............................................207

DTC P0135 HEATED OXYGEN SENSOR 1

(FRONT) HEATER.......................................................209

Description ...............................................................209

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................209

ECM Terminals and Reference Value .....................209

On Board Diagnosis Logic.......................................209

CONTENTS(Cont'd)

EC-2

Page 299 of 2493

DTC Confirmation Procedure ..................................210

Wiring Diagram ........................................................ 211

Diagnostic Procedure ..............................................212

Component Inspection .............................................213

DTC P0137 HEATED OXYGEN SENSOR 2

(REAR) (MIN. VOLTAGE MONITORING)...................214

Component Description ...........................................214

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................214

ECM Terminals and Reference Value .....................214

On Board Diagnosis Logic.......................................214

DTC Confirmation Procedure ..................................215

Overall Function Check ...........................................216

Wiring Diagram ........................................................217

Diagnostic Procedure ..............................................218

Component Inspection .............................................220

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING).................222

Component Description ...........................................222

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................222

ECM Terminals and Reference Value .....................222

On Board Diagnosis Logic.......................................222

DTC Confirmation Procedure ..................................223

Overall Function Check ...........................................224

Wiring Diagram ........................................................225

Diagnostic Procedure ..............................................226

Component Inspection .............................................227

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR).........................................................................229

Component Description ...........................................229

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................229

ECM Terminals and Reference Value .....................229

On Board Diagnosis Logic.......................................229

DTC Confirmation Procedure ..................................230

Overall Function Check ...........................................231

Wiring Diagram ........................................................232

Diagnostic Procedure ..............................................233

Component Inspection .............................................235

DTC P0140 HEATED OXYGEN SENSOR 2

(REAR) (HIGH VOLTAGE)..........................................237

Component Description ...........................................237

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................237

ECM Terminals and Reference Value .....................237

On Board Diagnosis Logic.......................................237

DTC Confirmation Procedure ..................................238

Overall Function Check ...........................................238

Wiring Diagram ........................................................239

Diagnostic Procedure ..............................................240

Component Inspection .............................................241DTC P0141 HEATED OXYGEN SENSOR 2

HEATER (REAR).........................................................243

Description ...............................................................243

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................243

ECM Terminals and Reference Value .....................243

On Board Diagnosis Logic.......................................244

DTC Confirmation Procedure ..................................244

Wiring Diagram ........................................................245

Diagnostic Procedure ..............................................246

Component Inspection .............................................247

DTC P0171 FUEL INJECTION SYSTEM

FUNCTION (LEAN SIDE)............................................248

On Board Diagnosis Logic.......................................248

DTC Confirmation Procedure ..................................248

Wiring Diagram ........................................................250

Diagnostic Procedure ..............................................251

DTC P0172 FUEL INJECTION SYSTEM

FUNCTION (RICH SIDE).............................................255

On Board Diagnosis Logic.......................................255

DTC Confirmation Procedure ..................................255

Wiring Diagram ........................................................257

Diagnostic Procedure ..............................................258

DTC P0300 - P0304 NO.4-1CYLINDER

MISFIRE, MULTIPLE CYLINDER MISFIRE...............262

On Board Diagnosis Logic.......................................262

DTC Confirmation Procedure ..................................262

Diagnostic Procedure ..............................................263

DTC P0325 KNOCK SENSOR (KS)...........................268

Component Description ...........................................268

ECM Terminals and Reference Value .....................268

On Board Diagnosis Logic.......................................268

DTC Confirmation Procedure ..................................268

Wiring Diagram ........................................................269

Diagnostic Procedure ..............................................270

Component Inspection .............................................271

DTC P0335 CRANKSHAFT POSITION SENSOR

(POS)............................................................................272

Component Description ...........................................272

ECM Terminals and Reference Value .....................272

On Board Diagnosis Logic.......................................273

DTC Confirmation Procedure ..................................273

Wiring Diagram ........................................................274

Diagnostic Procedure ..............................................275

Component Inspection .............................................277

DTC P0340 CAMSHAFT POSITION SENSOR

(CMPS) (PHASE).........................................................278

Component Description ...........................................278

ECM Terminals and Reference Value .....................278

On Board Diagnosis Logic.......................................279

DTC Confirmation Procedure ..................................279

Wiring Diagram ........................................................280

CONTENTS(Cont'd)

EC-3

Page 300 of 2493

Diagnostic Procedure ..............................................281

Component Inspection .............................................284

DTC P0400 EGR FUNCTION (CLOSED) (WHERE

FITTED)........................................................................285

Description ...............................................................285

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................286

ECM Terminals and Reference Value .....................286

On Board Diagnosis Logic.......................................286

DTC Confirmation Procedure ..................................287

Wiring Diagram ........................................................289

Diagnostic Procedure ..............................................290

Component Inspection .............................................292

DTC P0403 EGR VOLUME CONTROL VALVE

(CIRCUIT).....................................................................293

Description ...............................................................293

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................294

ECM Terminals and Reference Value .....................294

On Board Diagnosis Logic.......................................294

DTC Confirmation Procedure ..................................294

Wiring Diagram ........................................................296

Diagnostic Procedure ..............................................297

Component Inspection .............................................298

DTC P0420 THREE WAY CATALYST FUNCTION...299

On Board Diagnosis Logic.......................................299

DTC Confirmation Procedure ..................................299

Overall Function Check ...........................................300

Diagnostic Procedure ..............................................300

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................304

Description ...............................................................304

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................304

ECM Terminals and Reference Value .....................305

On Board Diagnosis Logic.......................................305

DTC Confirmation Procedure ..................................305

Wiring Diagram ........................................................306

Diagnostic Procedure ..............................................307

Component Inspection .............................................308

DTC P0500 VEHICLE SPEED SENSOR (VSS).........309

Component Description ...........................................309

ECM Terminals and Reference Value .....................309

On Board Diagnosis Logic.......................................309

DTC Confirmation Procedure ..................................309

Wiring Diagram ........................................................ 311

Diagnostic Procedure ..............................................312

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............313

Description ...............................................................313

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................314ECM Terminals and Reference Value .....................314

On Board Diagnosis Logic.......................................314

DTC Confirmation Procedure ..................................314

Wiring Diagram ........................................................315

Diagnostic Procedure ..............................................316

Component Inspection .............................................320

DTC P0510 CLOSED THROTTLE POSITION

SWITCH (WHERE FITTED).........................................321

Component Description ...........................................321

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................321

ECM Terminals and Reference Value .....................321

On Board Diagnosis Logic.......................................321

DTC Confirmation Procedure ..................................321

Overall Function Check ...........................................322

Wiring Diagram ........................................................323

Diagnostic Procedure ..............................................324

Component Inspection .............................................325

DTC P0605 ECM.........................................................327

Component Description ...........................................327

On Board Diagnosis Logic.......................................327

DTC Confirmation Procedure ..................................327

Diagnostic Procedure ..............................................328

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE......................................................329

Component Description ...........................................329

Operation .................................................................329

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................329

ECM Terminals and Reference Value .....................329

On Board Diagnosis Logic.......................................329

DTC Confirmation Procedure ..................................330

Wiring Diagram ........................................................331

Diagnostic Procedure ..............................................332

Component Inspection .............................................333

DTC P1217 OVERHEAT (COOLING SYSTEM).........334

System Description ..................................................334

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................334

ECM Terminals and Reference Value .....................335

On Board Diagnosis Logic.......................................335

Overall Function Check ...........................................336

Wiring Diagram ........................................................337

Diagnostic Procedure ..............................................339

Main 12 Causes of Overheating..............................345

Component Inspection .............................................345

DTC P1401 EGR TEMPERATURE SENSOR

(WHERE FITTED)........................................................347

Component Description ...........................................347

On Board Diagnosis Logic.......................................347

DTC Confirmation Procedure ..................................347

Wiring Diagram ........................................................350

CONTENTS(Cont'd)

EC-4