NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1101 of 3189

DESCRIPTION FOR WORK FLOW=NJEC0631S01

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using

the “DIAGNOSTIC WORKSHEET”, EC-44.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II) the DTC, then erase the

DTC. Refer to EC-34.

If the incident cannot be verified, perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-71.

Study the relationship between the cause, specified by DTC, and the symptom described by the customer. (The

“Symptom Matrix Chart” will be useful. Refer to EC-53.) Also check relatedservice bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The “DIAGNOSTIC WORK SHEET” is useful to verify the incident. Connect CONSULT-II to the vehicle in DATA

MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-71.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the DTC by driving in (or performing) the “DTC Confirmation Procedure”. Check and read the DTC

by using CONSULT-II.

During the DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO TRIG)

mode and check real time diagnosis results.

If the incident cannot be verified, perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-71.

In case the “DTC Confirmation Procedure” is not available, perform the “Overall Function Check” instead. The

DTC cannot be displayed by this check, however, this simplified “check” isan effective alternative.

The “NG” result of the “Overall Function Check” is the same as the DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTCPXXXX.

If the normal code is indicated, proceed to the Basic Inspection, EC-48. Then perform inspections according to

the Symptom Matrix Chart. Refer to EC-53.

STEP VIIdentify where to begin diagnosis based on the relationship study betweensymptom and possible causes.

Inspect the system for mechanical binding, loose connectors or wiring damage using (tracing) “Harness Layouts”.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in “DATA MONITOR

(AUTO TRIG)” mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-66 or EC-63.

The “Diagnostic Procedure” in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to GI-25, “Circuit

Inspection”.

Repair or replace the malfunction parts.

If the malfunctioning part cannot be detected, perform “TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT”, EC-71.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer’s initial complaint.

Perform the “DTC Confirmation Procedure” and confirm the normal code (DTCP0000 or 0505) is detected. If the

incident is still detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) DTC in ECM.

(Refer to EC-34.)GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS — INTRODUCTIONYD

Work Flow (Cont’d)

EC-47

Page 1102 of 3189

Basic InspectionNJEC0632Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

Headlamp switch is OFF,

On vehicles equipped with daytime light systems, set

lighting switch to the 1st position to light only small

lamps.

Air conditioner switch is OFF,

Rear defogger switch is OFF,

Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a relatedincident.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to MA-4, “Peri-

odic Maintenance”.

3. Open engine hood and check the following:

Harness connectors for improper connections

Vacuum hoses for splits, kinks, or improper connections

Wiring for improper connections, pinches, or cuts

SEF142I

4. Start engine and warm it up to the normal operating temperature.

GO TO 2.

2 PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

Without CONSULT-II

Install diesel tacho tester to the vehicle.

GO TO 3.

TROUBLE DIAGNOSIS — BASIC INSPECTIONYD

Basic Inspection

EC-48

Page 1103 of 3189

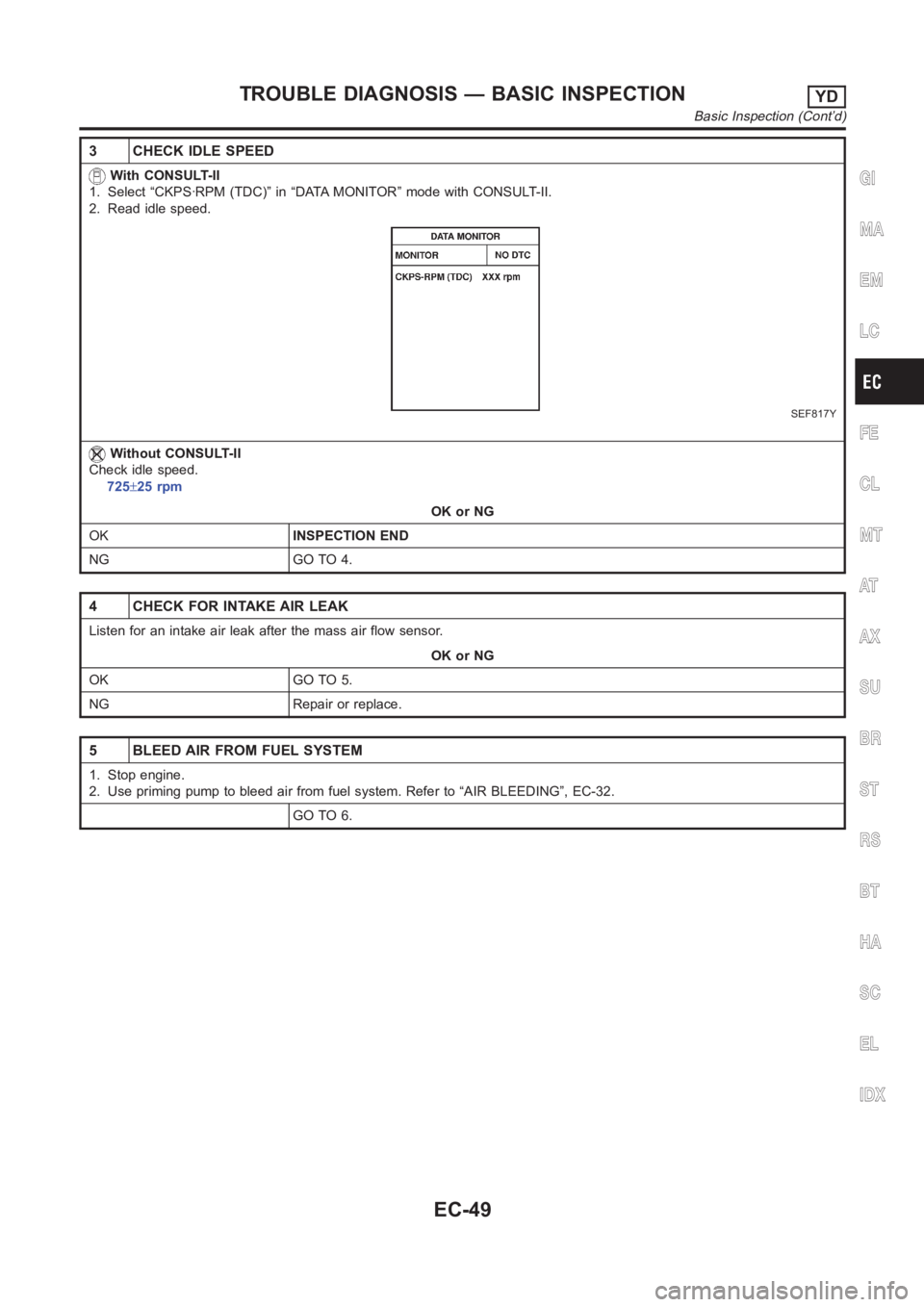

3 CHECK IDLE SPEED

With CONSULT-II

1. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

2. Read idle speed.

SEF817Y

Without CONSULT-II

Check idle speed.

725±25 rpm

OK or NG

OKINSPECTION END

NG GO TO 4.

4 CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK GO TO 5.

NG Repair or replace.

5 BLEED AIR FROM FUEL SYSTEM

1. Stop engine.

2. Use priming pump to bleed air from fuel system. Refer to “AIR BLEEDING”, EC-32.

GO TO 6.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS — BASIC INSPECTIONYD

Basic Inspection (Cont’d)

EC-49

Page 1104 of 3189

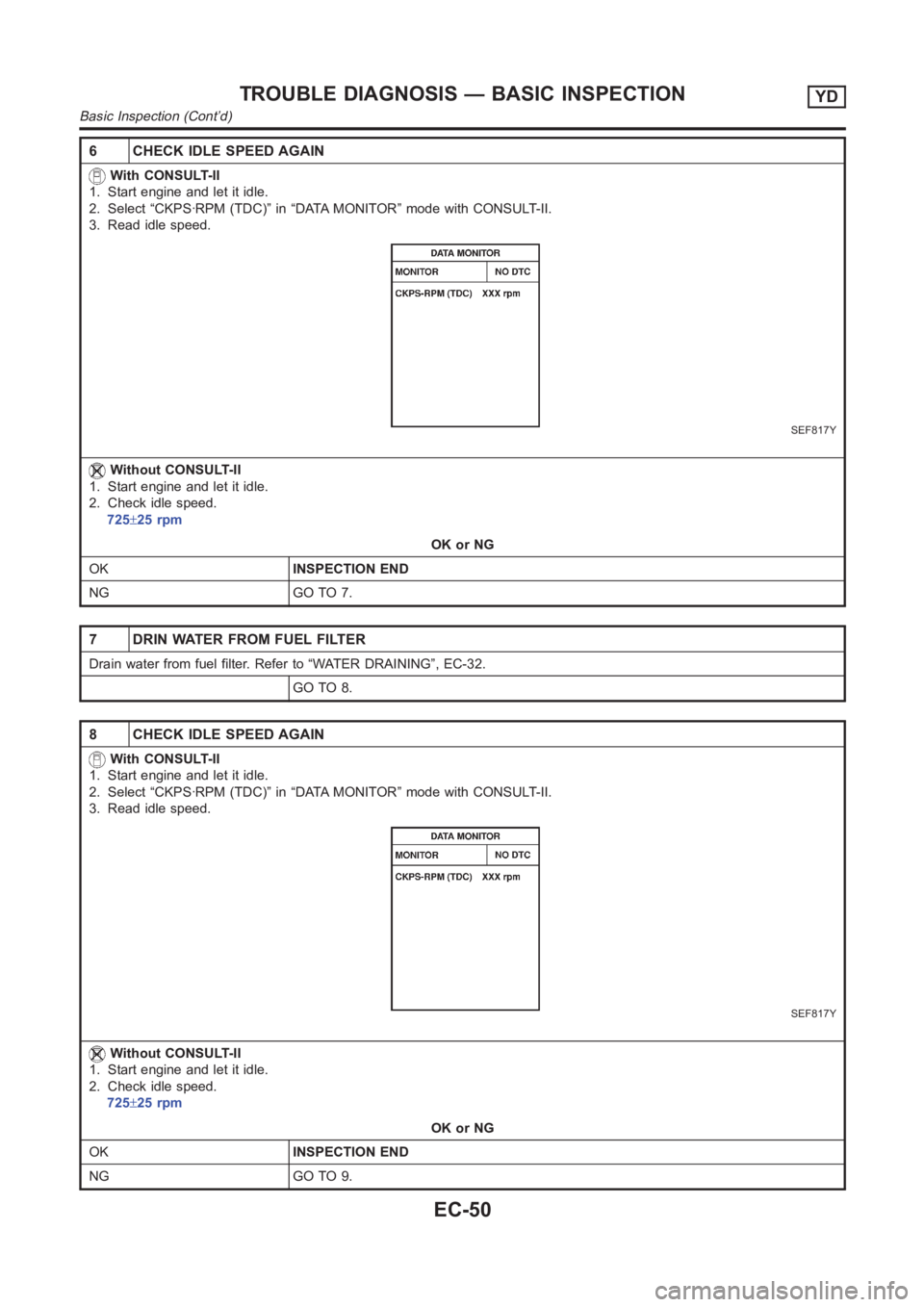

6 CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

SEF817Y

Without CONSULT-II

1. Start engine and let it idle.

2. Check idle speed.

725±25 rpm

OK or NG

OKINSPECTION END

NG GO TO 7.

7 DRIN WATER FROM FUEL FILTER

Drain water from fuel filter. Refer to “WATER DRAINING”, EC-32.

GO TO 8.

8 CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

SEF817Y

Without CONSULT-II

1. Start engine and let it idle.

2. Check idle speed.

725±25 rpm

OK or NG

OKINSPECTION END

NG GO TO 9.

TROUBLE DIAGNOSIS — BASIC INSPECTIONYD

Basic Inspection (Cont’d)

EC-50

Page 1105 of 3189

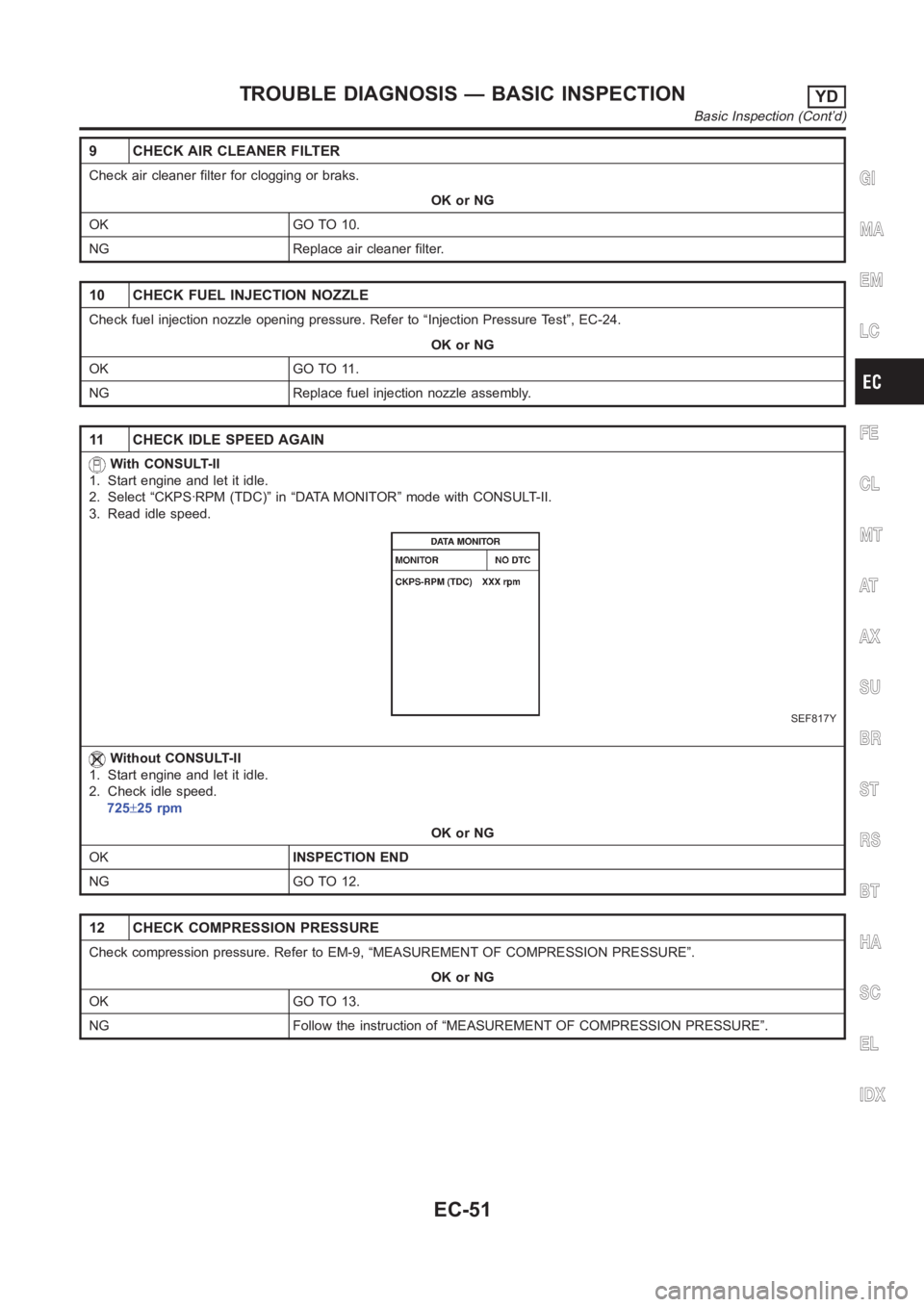

9 CHECK AIR CLEANER FILTER

Check air cleaner filter for clogging or braks.

OK or NG

OK GO TO 10.

NG Replace air cleaner filter.

10 CHECK FUEL INJECTION NOZZLE

Check fuel injection nozzle opening pressure. Refer to “Injection Pressure Test”, EC-24.

OK or NG

OK GO TO 11.

NG Replace fuel injection nozzle assembly.

11 CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

SEF817Y

Without CONSULT-II

1. Start engine and let it idle.

2. Check idle speed.

725±25 rpm

OK or NG

OKINSPECTION END

NG GO TO 12.

12 CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-9, “MEASUREMENT OF COMPRESSION PRESSURE”.

OK or NG

OK GO TO 13.

NG Follow the instruction of “MEASUREMENT OF COMPRESSION PRESSURE”.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS — BASIC INSPECTIONYD

Basic Inspection (Cont’d)

EC-51

Page 1106 of 3189

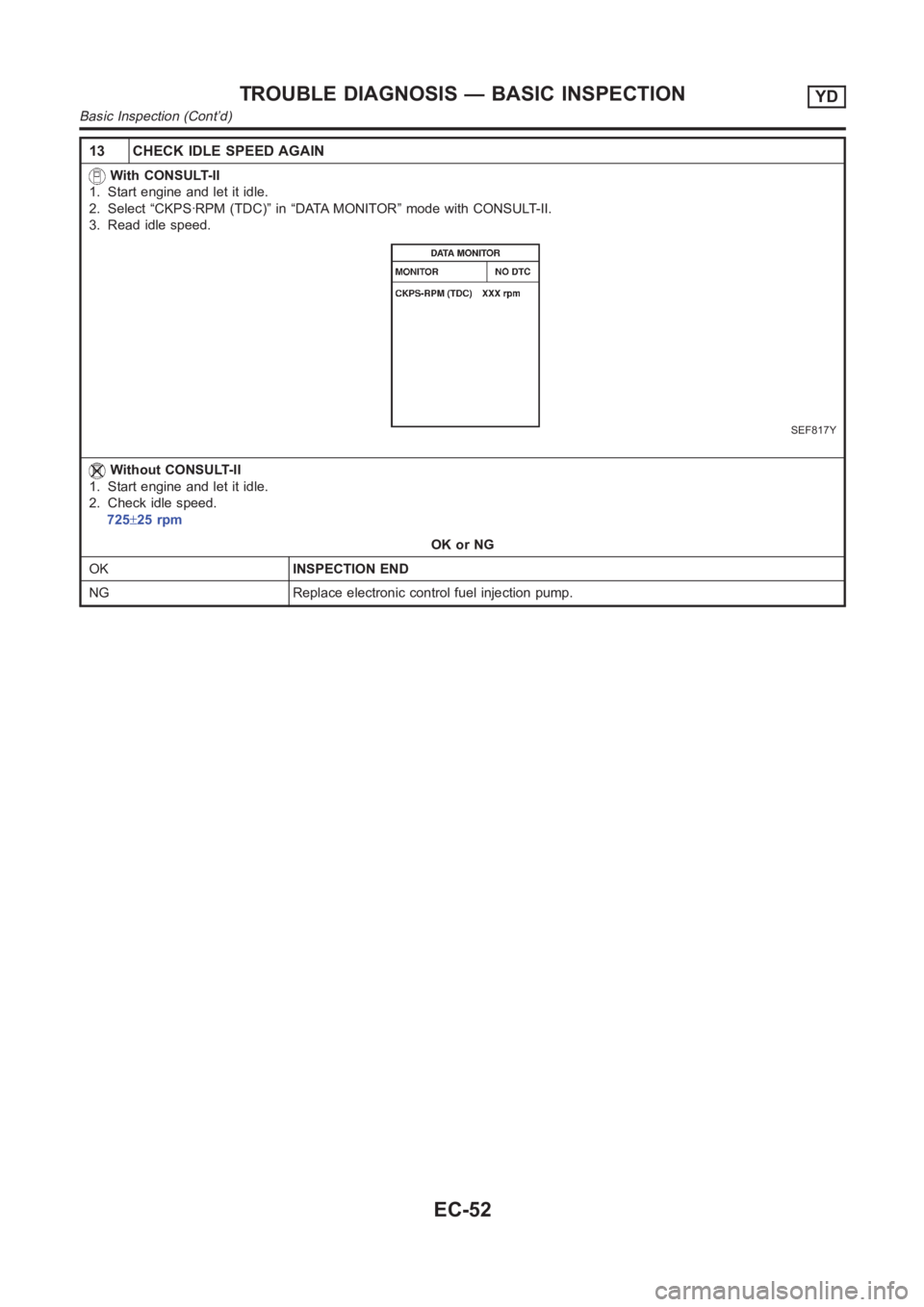

13 CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

SEF817Y

Without CONSULT-II

1. Start engine and let it idle.

2. Check idle speed.

725±25 rpm

OK or NG

OKINSPECTION END

NG Replace electronic control fuel injection pump.

TROUBLE DIAGNOSIS — BASIC INSPECTIONYD

Basic Inspection (Cont’d)

EC-52

Page 1107 of 3189

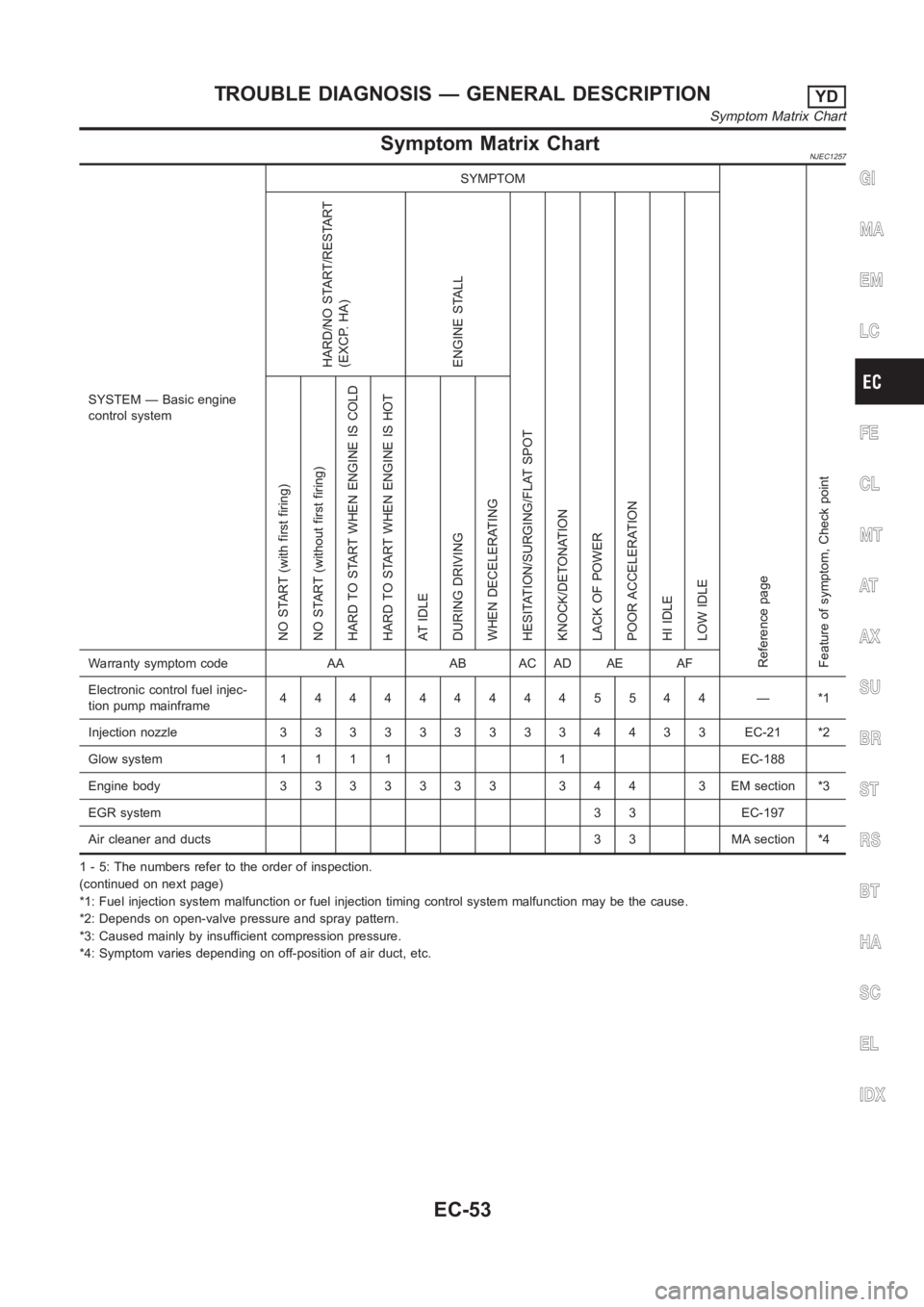

Symptom Matrix ChartNJEC1257

SYSTEM — Basic engine

control systemSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART

(EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGWarranty symptom code AA AB AC AD AE AF

Electronic control fuel injec-

tion pump mainframe4444444445544 — *1

Injection nozzle 3 3 3 3333334433 EC-21 *2

Glow system 1 1 1 1 1 EC-188

Engine body 3 3 3 3 3 3 3 3 4 4 3 EM section *3

EGR system3 3 EC-197

Air cleaner and ducts 3 3 MA section *4

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*1: Fuel injection system malfunction or fuel injection timing control system malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS — GENERAL DESCRIPTIONYD

Symptom Matrix Chart

EC-53

Page 1108 of 3189

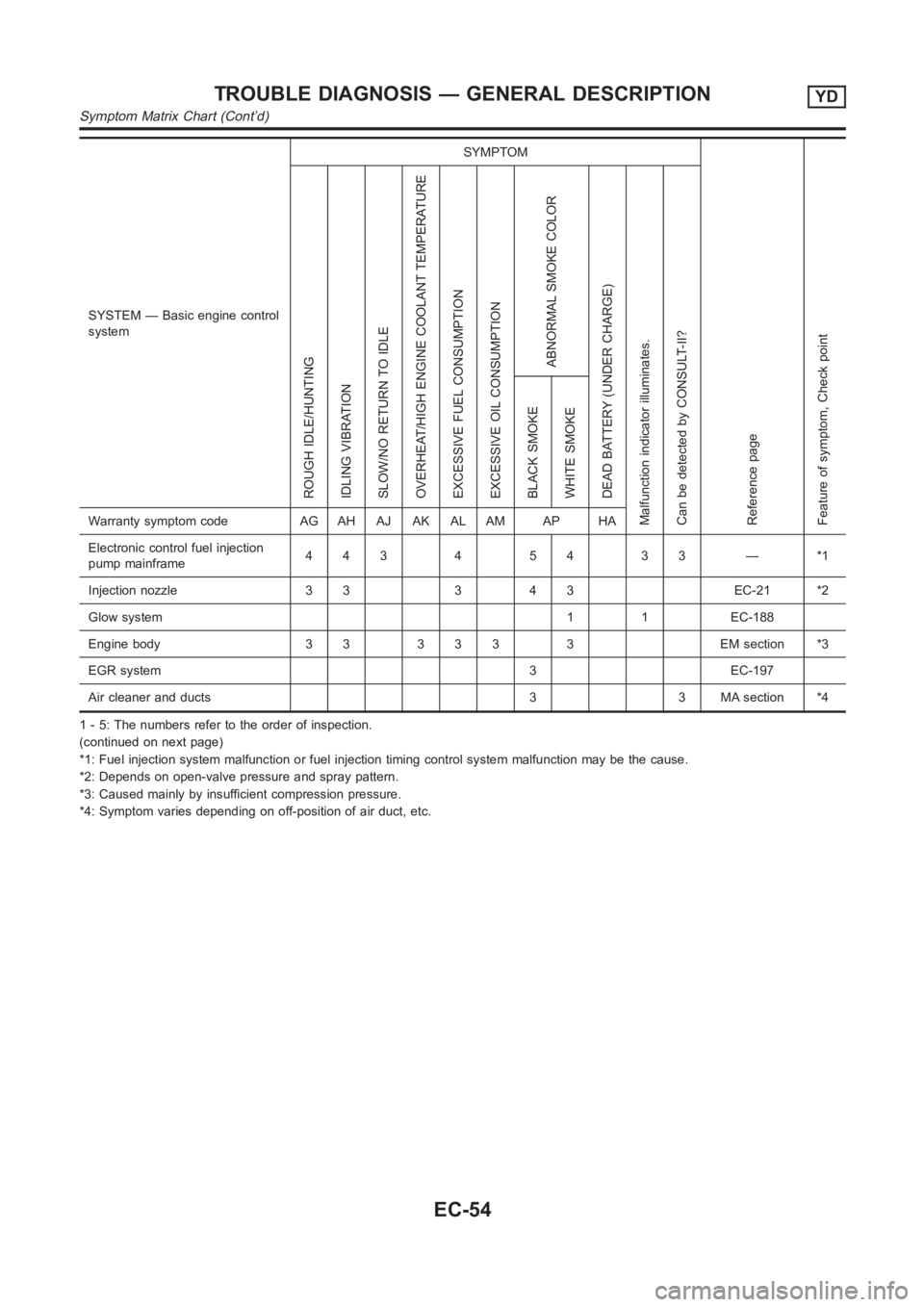

SYSTEM — Basic engine control

systemSYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator illuminates.

Can be detected by CONSULT-II?BLACK SMOKE

WHITE SMOKEWarranty symptom code AG AH AJ AK AL AM AP HA

Electronic control fuel injection

pump mainframe44345433—*1

Injection nozzle 3 3 3 4 3 EC-21 *2

Glow system 1 1 EC-188

Engine body 3 3 3 3 3 3 EM section *3

EGR system 3 EC-197

Air cleaner and ducts 3 3 MA section *4

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*1: Fuel injection system malfunction or fuel injection timing control system malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSIS — GENERAL DESCRIPTIONYD

Symptom Matrix Chart (Cont’d)

EC-54

Page 1109 of 3189

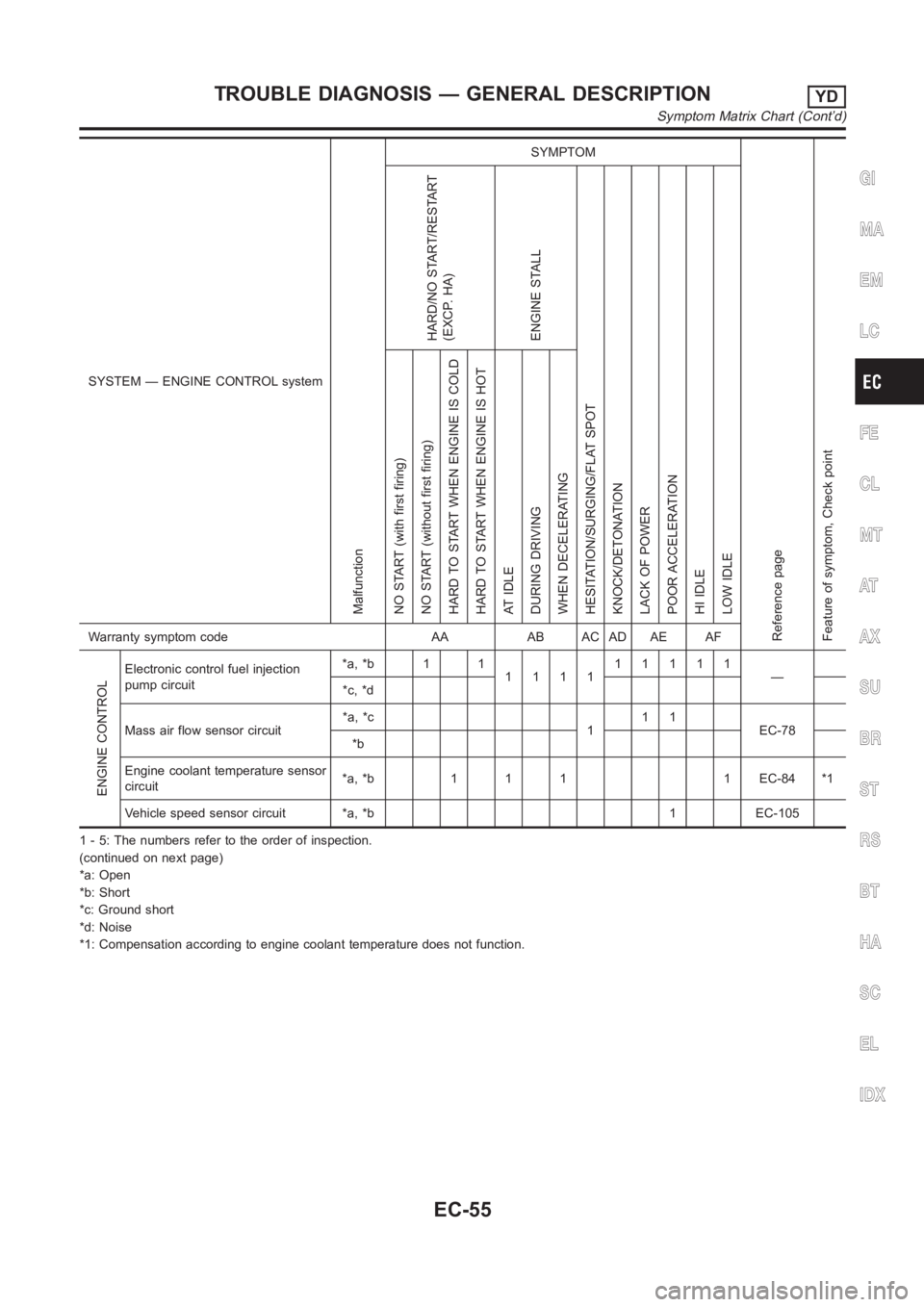

SYSTEM — ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART

(EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGWarranty symptom code AA AB AC AD AE AF

ENGINE CONTROL

Electronic control fuel injection

pump circuit*a, *b 1 1

111111111

—

*c, *d

Mass air flow sensor circuit*a, *c

111

EC-78

*b

Engine coolant temperature sensor

circuit*a, *b 1 1 1 1 EC-84 *1

Vehicle speed sensor circuit *a, *b 1 EC-105

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*1: Compensation according to engine coolant temperature does not function.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS — GENERAL DESCRIPTIONYD

Symptom Matrix Chart (Cont’d)

EC-55

Page 1110 of 3189

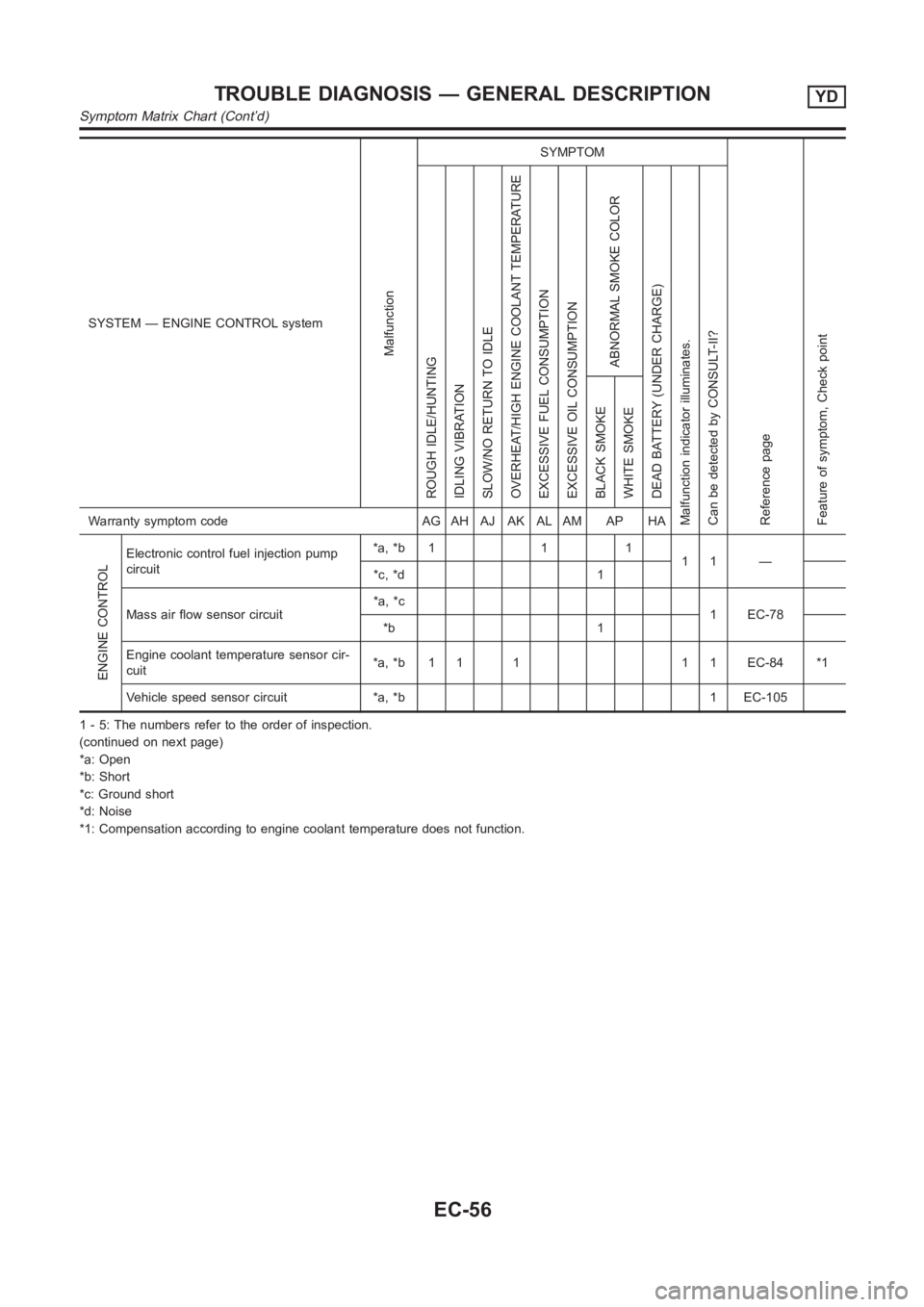

SYSTEM — ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator illuminates.

Can be detected by CONSULT-II?BLACK SMOKE

WHITE SMOKEWarranty symptom code AG AH AJ AK AL AM AP HA

ENGINE CONTROL

Electronic control fuel injection pump

circuit*a, *b 1 1 1

11 —

*c, *d 1

Mass air flow sensor circuit*a, *c

1 EC-78

*b 1

Engine coolant temperature sensor cir-

cuit*a, *b 1 1 1 1 1 EC-84 *1

Vehicle speed sensor circuit *a, *b 1 EC-105

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*1: Compensation according to engine coolant temperature does not function.

TROUBLE DIAGNOSIS — GENERAL DESCRIPTIONYD

Symptom Matrix Chart (Cont’d)

EC-56