NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1091 of 3189

Diagnostic Test Mode I — Bulb CheckNJEC0628S03In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to EL-129,

EL-129, “WARNING LAMPS” or see EC-213.

Diagnostic Test Mode I — Malfunction WarningNJEC0628S04

MI Condition

ON When the malfunction is detected or the ECM’s CPU is malfunctioning.

OFF No malfunction.

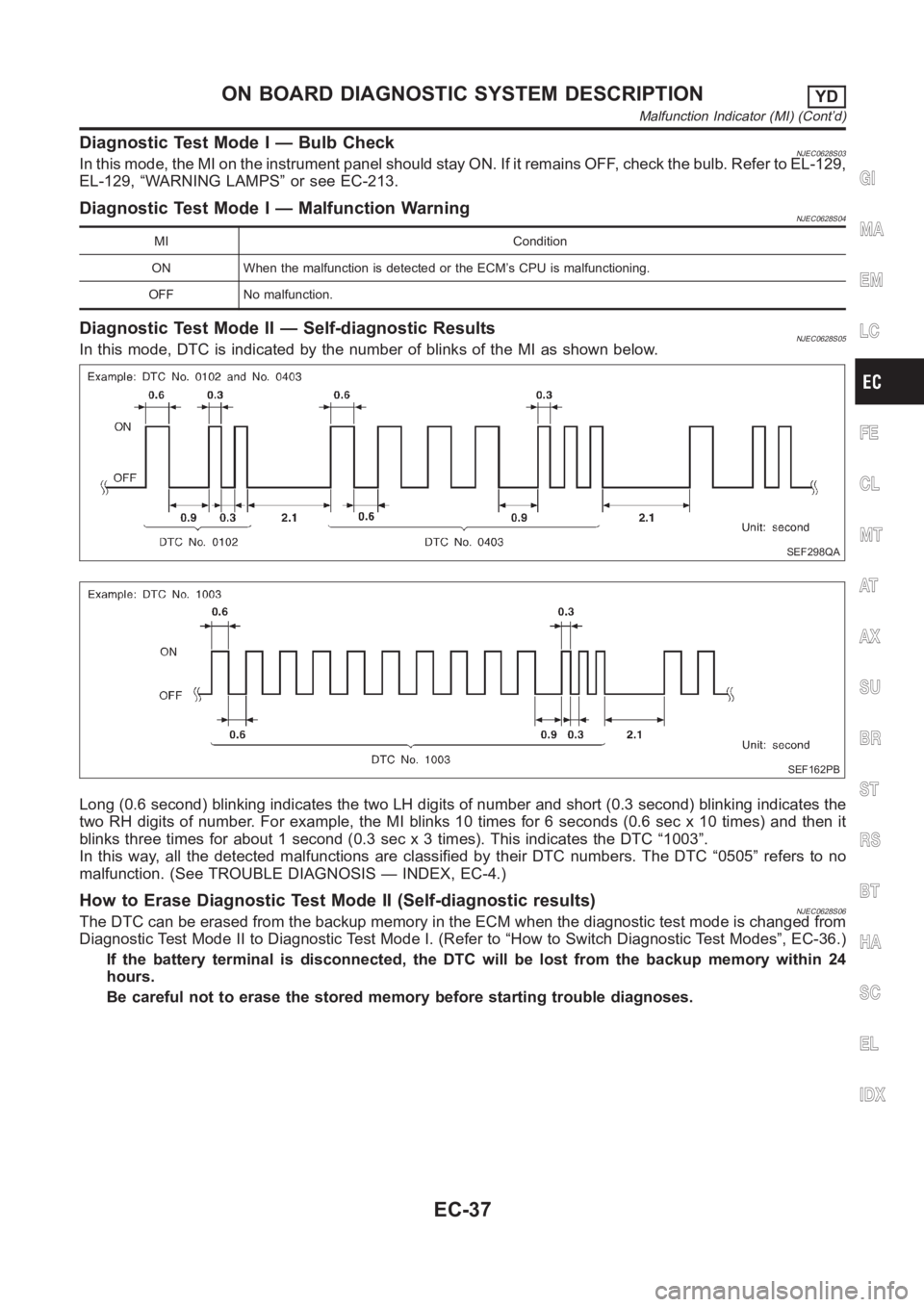

Diagnostic Test Mode II — Self-diagnostic ResultsNJEC0628S05In this mode, DTC is indicated by the number of blinks of the MI as shown below.

SEF298QA

SEF162PB

Long (0.6 second) blinking indicates the two LH digits of number and short (0.3 second) blinking indicates the

two RH digits of number. For example, the MI blinks 10 times for 6 seconds (0.6 sec x 10 times) and then it

blinks three times for about 1 second (0.3 sec x 3 times). This indicates theDTC “1003”.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC “0505” refers to no

malfunction. (See TROUBLE DIAGNOSIS — INDEX, EC-4.)

How to Erase Diagnostic Test Mode II (Self-diagnostic results)NJEC0628S06The DTC can be erased from the backup memory in the ECM when the diagnostic test mode is changed from

Diagnostic Test Mode II to Diagnostic Test Mode I. (Refer to “How to Switch Diagnostic Test Modes”, EC-36.)

If the battery terminal is disconnected, the DTC will be lost from the backup memory within 24

hours.

Be careful not to erase the stored memory before starting trouble diagnoses.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

Malfunction Indicator (MI) (Cont’d)

EC-37

Page 1092 of 3189

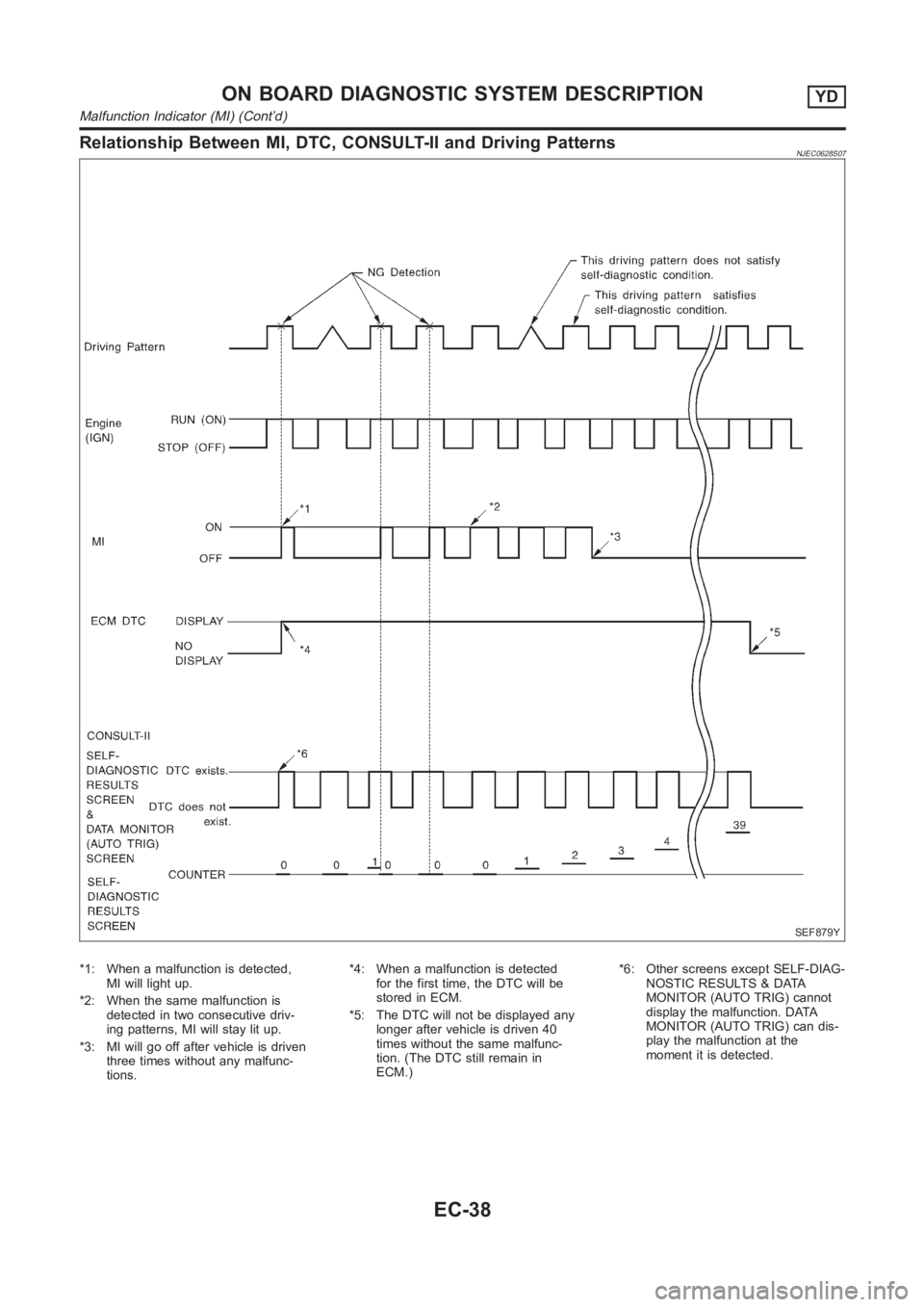

Relationship Between MI, DTC, CONSULT-II and Driving PatternsNJEC0628S07

SEF879Y

*1: When a malfunction is detected,

MI will light up.

*2: When the same malfunction is

detected in two consecutive driv-

ing patterns, MI will stay lit up.

*3: MI will go off after vehicle is driven

three times without any malfunc-

tions.*4: When a malfunction is detected

for the first time, the DTC will be

stored in ECM.

*5: The DTC will not be displayed any

longer after vehicle is driven 40

times without the same malfunc-

tion. (The DTC still remain in

ECM.)*6: Other screens except SELF-DIAG-

NOSTIC RESULTS & DATA

MONITOR (AUTO TRIG) cannot

display the malfunction. DATA

MONITOR (AUTO TRIG) can dis-

play the malfunction at the

moment it is detected.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

Malfunction Indicator (MI) (Cont’d)

EC-38

Page 1093 of 3189

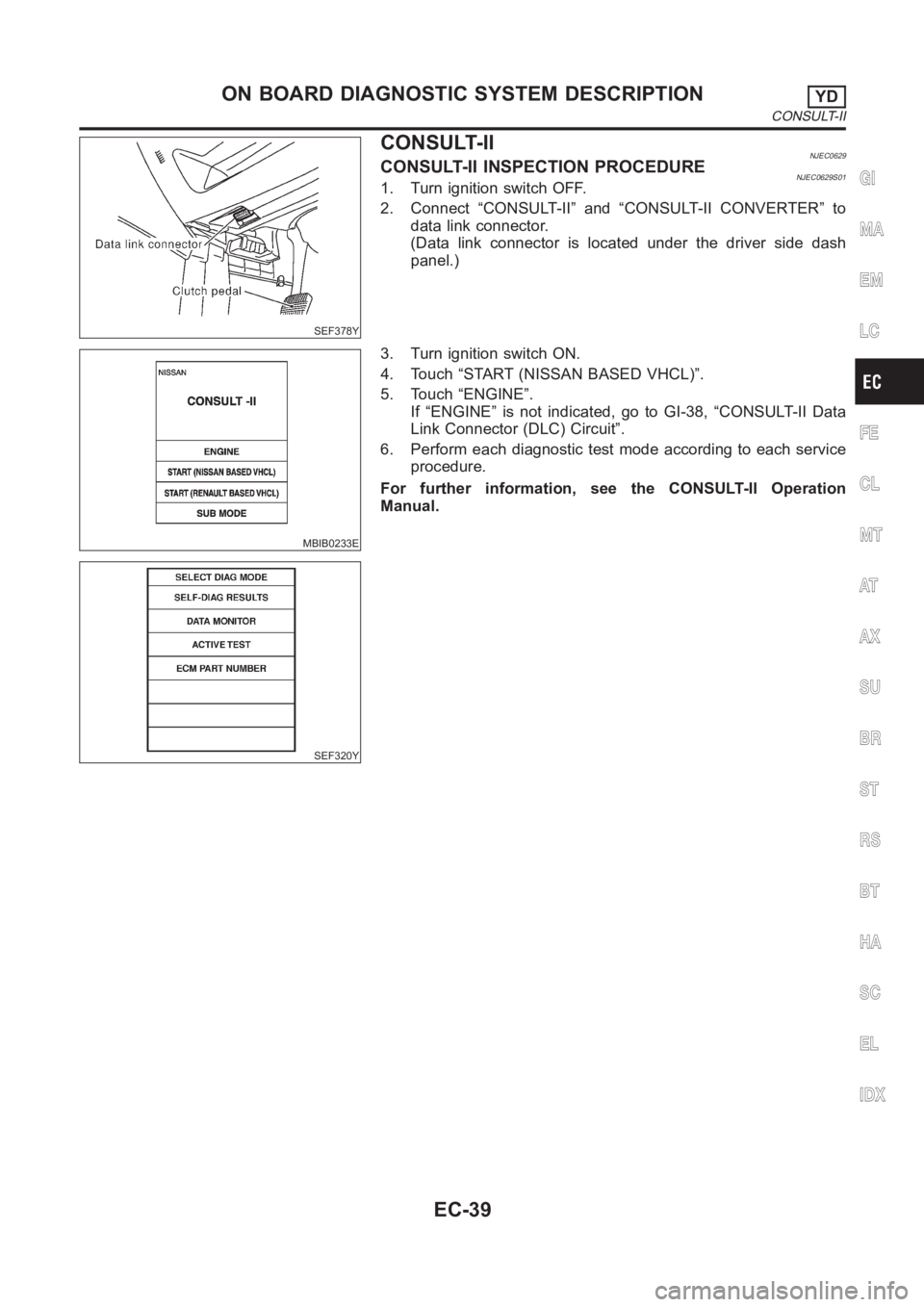

SEF378Y

CONSULT-IINJEC0629CONSULT-II INSPECTION PROCEDURENJEC0629S011. Turn ignition switch OFF.

2. Connect “CONSULT-II” and “CONSULT-II CONVERTER” to

data link connector.

(Data link connector is located under the driver side dash

panel.)

MBIB0233E

SEF320Y

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)”.

5. Touch “ENGINE”.

If “ENGINE” is not indicated, go to GI-38, “CONSULT-II Data

Link Connector (DLC) Circuit”.

6. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT-II Operation

Manual.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

CONSULT-II

EC-39

Page 1094 of 3189

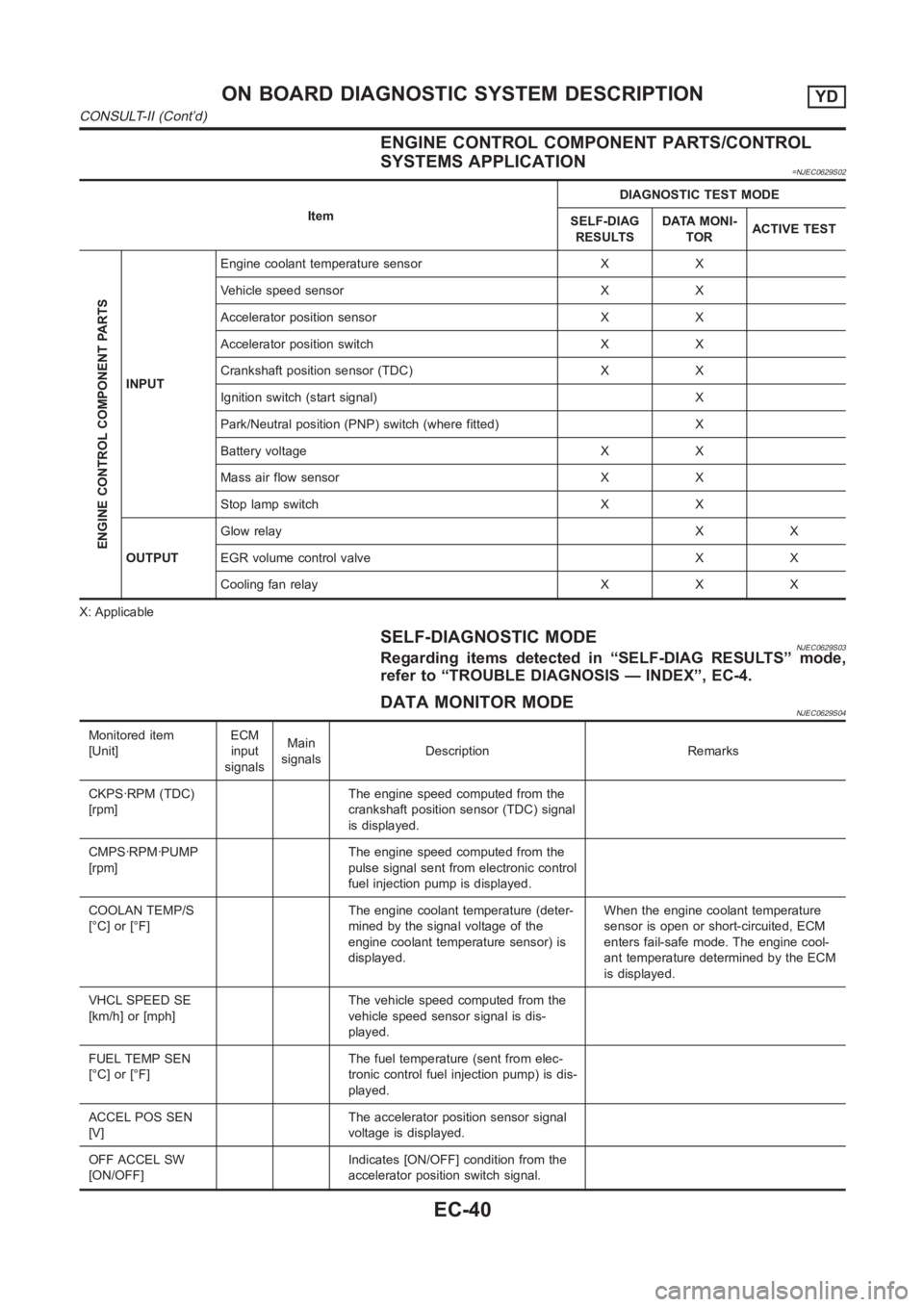

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

=NJEC0629S02

ItemDIAGNOSTIC TEST MODE

SELF-DIAG

RESULTSDATA MONI-

TORACTIVE TEST

ENGINE CONTROL COMPONENT PARTS

INPUTEngine coolant temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X

Accelerator position switch X X

Crankshaft position sensor (TDC) X X

Ignition switch (start signal) X

Park/Neutral position (PNP) switch (where fitted) X

Battery voltage X X

Mass air flow sensor X X

Stop lamp switch X X

OUTPUTGlow relayXX

EGR volume control valve X X

Cooling fan relay X X X

X: Applicable

SELF-DIAGNOSTIC MODENJEC0629S03Regarding items detected in “SELF-DIAG RESULTS” mode,

refer to “TROUBLE DIAGNOSIS — INDEX”, EC-4.

DATA MONITOR MODENJEC0629S04

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CKPS·RPM (TDC)

[rpm]The engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CMPS·RPM·PUMP

[rpm]The engine speed computed from the

pulse signal sent from electronic control

fuel injection pump is displayed.

COOLAN TEMP/S

[°C] or [°F]The engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the ECM

is displayed.

VHCL SPEED SE

[km/h] or [mph]The vehicle speed computed from the

vehicle speed sensor signal is dis-

played.

FUEL TEMP SEN

[°C] or [°F]The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL POS SEN

[V]The accelerator position sensor signal

voltage is displayed.

OFF ACCEL SW

[ON/OFF]Indicates [ON/OFF] condition from the

accelerator position switch signal.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

CONSULT-II (Cont’d)

EC-40

Page 1095 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [°CA] The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [ NISSAN ALMERA N16 2003 Electronic Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [°CA] The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [](/img/5/57350/w960_57350-1094.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [°CA] The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [V] The power supply voltage of ECM is

displayed.

P/N POSI SW*1

[ON/OFF] (where

fitted)Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF]Indicates [ON/OFF] condition from the

starter signal.After starting the engine, [OFF] is dis-

played regardless of the starter signal.

BRAKE SW

[ON/OFF]Indicates [ON/OFF] condition from the

stop lamp switch signal.

BRAKE SW2

[ON/OFF]Indicates [ON/OFF] condition from the

brake pedal position switch signal.

IGN SW

[ON/OFF]Indicates [ON/OFF] condition from igni-

tion switch signal.

MAS AIR/FL SE [V] The signal voltage of the mass air flow

sensor is displayed.When the engine is stopped, a certain

value is indicated.

INT/A VOLUME [mg/] The intake air volume computed from

the mass air flow sensor signal is dis-

played.

F/CUT SIGNAL

[ON/OFF]The [ON/OFF] condition from decelera-

tion fuel cut signal (sent from electronic

control fuel injection pump) is displayed.

O F F ···F u e l i s c u t o ff .

O N ···F u e l i s n o t c u t o ff .

GLOW RLY

[ON/OFF]The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[LOW/HI/OFF]Indicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

LOW ... Operates at low speed.

HI ... Operates at high speed.

OFF ... Stopped.

BARO SEN [kPa] The barometric pressure (determined by

the signal voltage from the barometric

pressure sensor built into the ECM) is

displayed.

EGR VOL CON/V

[step]Indicates the EGR volume control value

computed by the ECM according to the

input signals.

The opening becomes larger as the

value increases.

*1: On models not equipped with park/neutral position (PNP) switch, “OFF”is always displayed regardless of gear shift position.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

CONSULT-II (Cont’d)

EC-41

Page 1096 of 3189

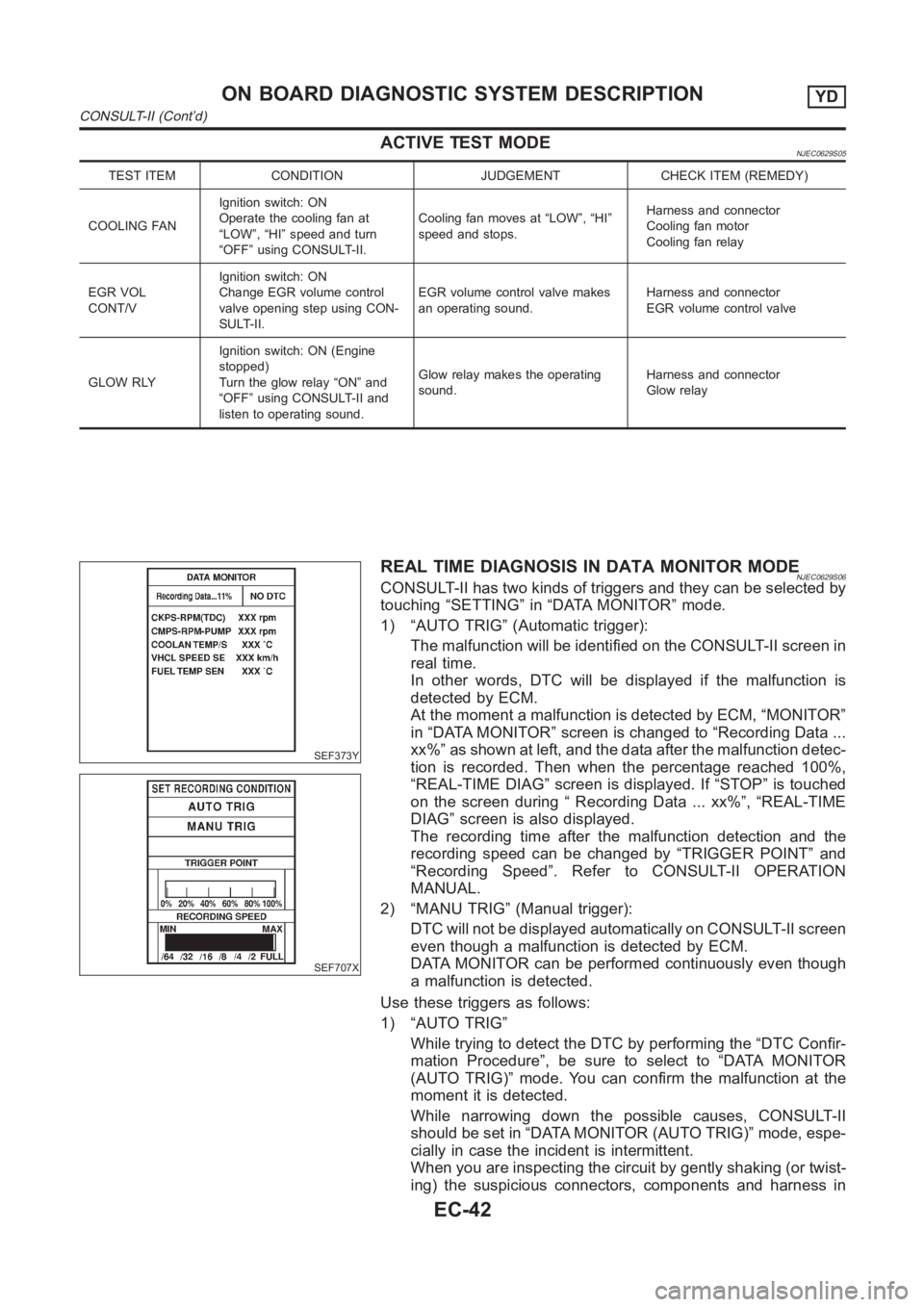

ACTIVE TEST MODENJEC0629S05

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

COOLING FANIgnition switch: ON

Operate the cooling fan at

“LOW”, “HI” speed and turn

“OFF” using CONSULT-II.Cooling fan moves at “LOW”, “HI”

speed and stops.Harness and connector

Cooling fan motor

Cooling fan relay

EGR VOL

CONT/VIgnition switch: ON

Change EGR volume control

valve opening step using CON-

SULT-II.EGR volume control valve makes

an operating sound.Harness and connector

EGR volume control valve

GLOW RLYIgnition switch: ON (Engine

stopped)

Turn the glow relay “ON” and

“OFF” using CONSULT-II and

listen to operating sound.Glow relay makes the operating

sound.Harness and connector

Glow relay

SEF373Y

SEF707X

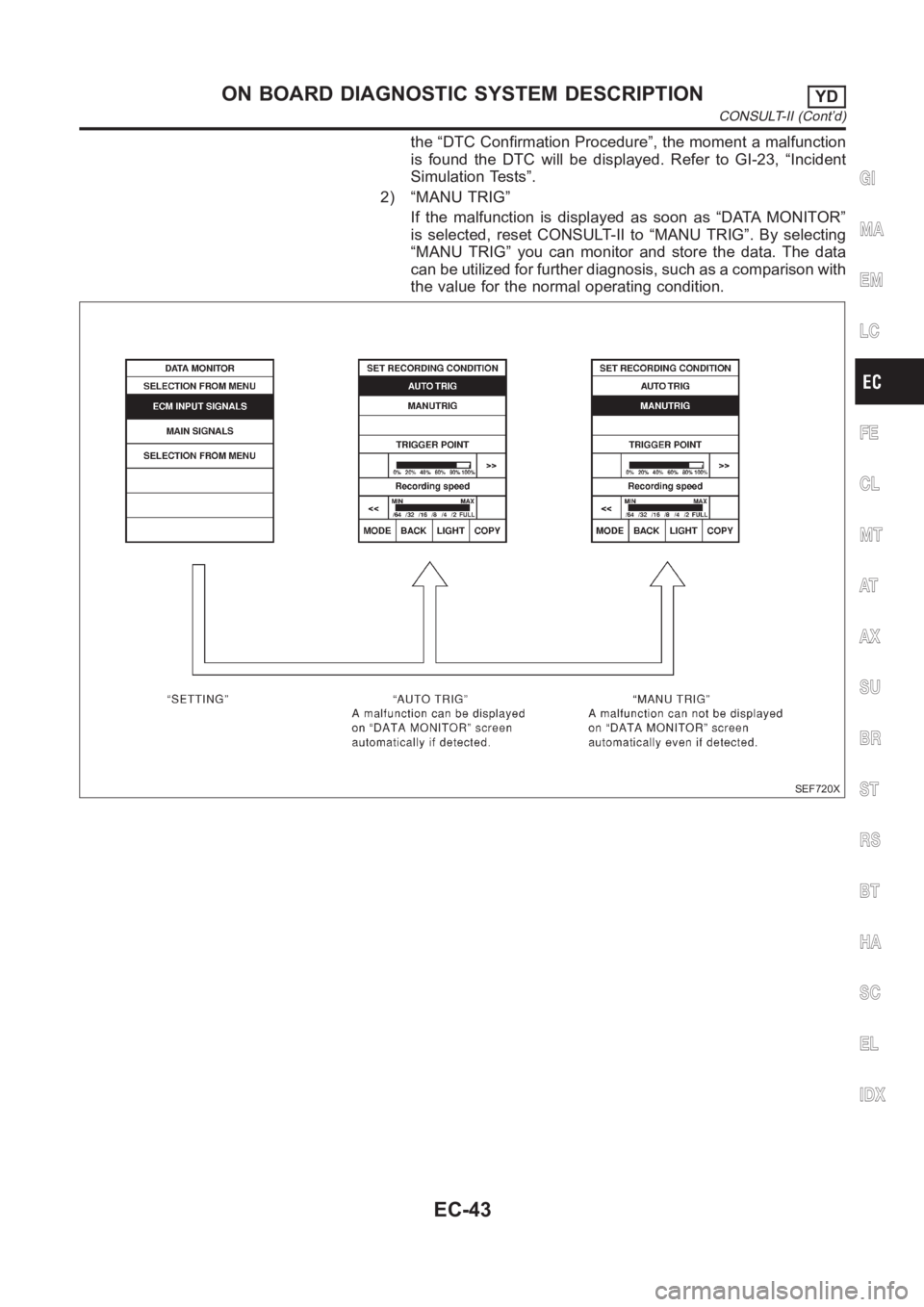

REAL TIME DIAGNOSIS IN DATA MONITOR MODENJEC0629S06CONSULT-II has two kinds of triggers and they can be selected by

touching “SETTING” in “DATA MONITOR” mode.

1) “AUTO TRIG” (Automatic trigger):

The malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC will be displayed if the malfunction is

detected by ECM.

At the moment a malfunction is detected by ECM, “MONITOR”

in “DATA MONITOR” screen is changed to “Recording Data ...

xx%” as shown at left, and the data after the malfunction detec-

tion is recorded. Then when the percentage reached 100%,

“REAL-TIME DIAG” screen is displayed. If “STOP” is touched

on the screen during “ Recording Data ... xx%”, “REAL-TIME

DIAG” screen is also displayed.

The recording time after the malfunction detection and the

recording speed can be changed by “TRIGGER POINT” and

“Recording Speed”. Refer to CONSULT-II OPERATION

MANUAL.

2) “MANU TRIG” (Manual trigger):

DTC will not be displayed automatically on CONSULT-II screen

even though a malfunction is detected by ECM.

DATA MONITOR can be performed continuously even though

a malfunction is detected.

Use these triggers as follows:

1) “AUTO TRIG”

While trying to detect the DTC by performing the “DTC Confir-

mation Procedure”, be sure to select to “DATA MONITOR

(AUTO TRIG)” mode. You can confirm the malfunction at the

moment it is detected.

While narrowing down the possible causes, CONSULT-II

should be set in “DATA MONITOR (AUTO TRIG)” mode, espe-

cially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twist-

ing) the suspicious connectors, components and harness in

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

CONSULT-II (Cont’d)

EC-42

Page 1097 of 3189

the “DTC Confirmation Procedure”, the moment a malfunction

is found the DTC will be displayed. Refer to GI-23, “Incident

Simulation Tests”.

2) “MANU TRIG”

If the malfunction is displayed as soon as “DATA MONITOR”

is selected, reset CONSULT-II to “MANU TRIG”. By selecting

“MANU TRIG” you can monitor and store the data. The data

can be utilized for further diagnosis, such as a comparison with

the value for the normal operating condition.

SEF720X

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

CONSULT-II (Cont’d)

EC-43

Page 1098 of 3189

SEF858S

Introduction

SEF233G

SEF234G

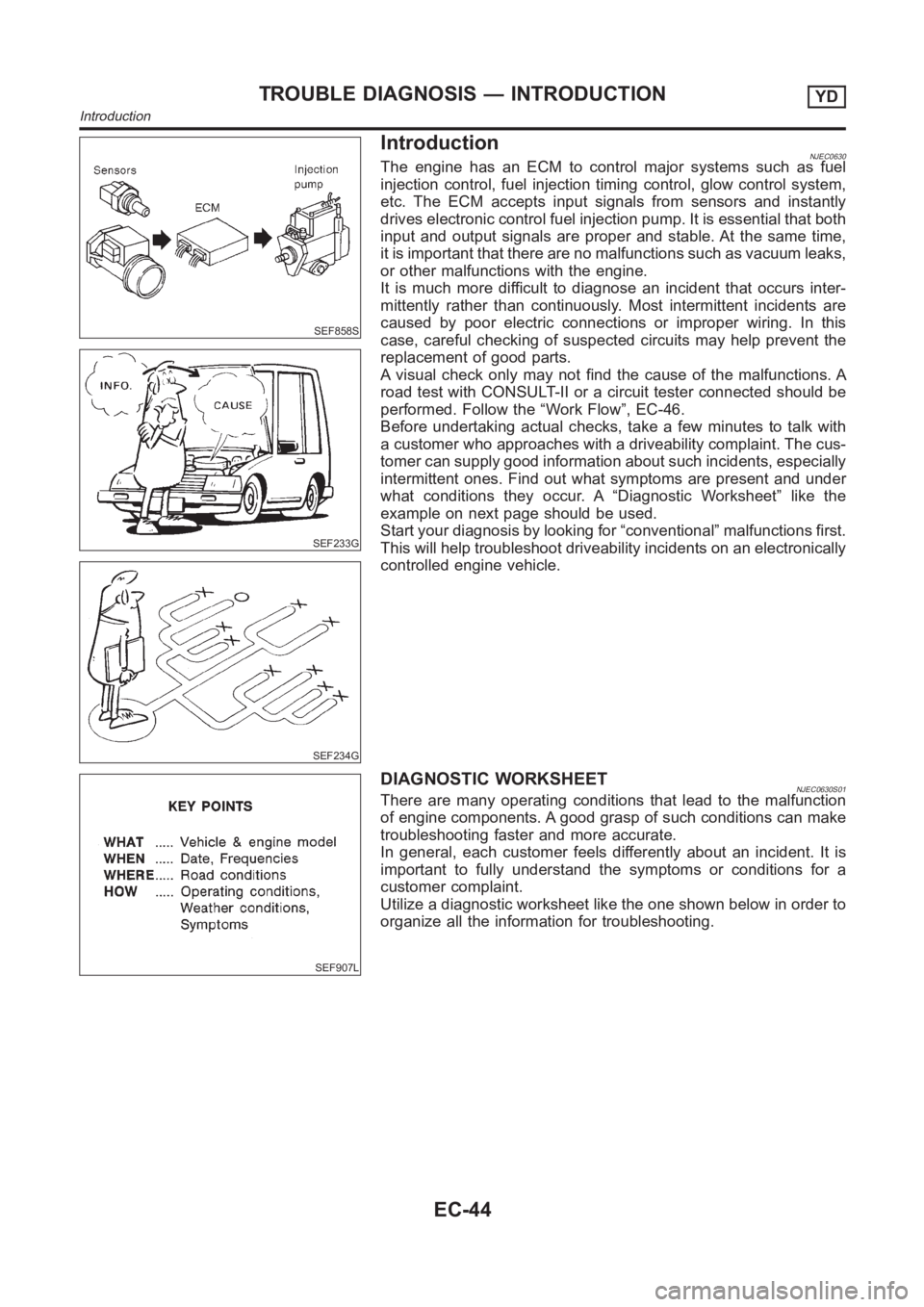

NJEC0630The engine has an ECM to control major systems such as fuel

injection control, fuel injection timing control, glow control system,

etc. The ECM accepts input signals from sensors and instantly

drives electronic control fuel injection pump. It is essential that both

input and output signals are proper and stable. At the same time,

it is important that there are no malfunctions such as vacuum leaks,

or other malfunctions with the engine.

It is much more difficult to diagnose an incident that occurs inter-

mittently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the malfunctions. A

road test with CONSULT-II or a circuit tester connected should be

performed. Follow the “Work Flow”, EC-46.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic Worksheet” like the

example on next page should be used.

Start your diagnosis by looking for “conventional” malfunctions first.

This will help troubleshoot driveability incidents on an electronically

controlled engine vehicle.

SEF907L

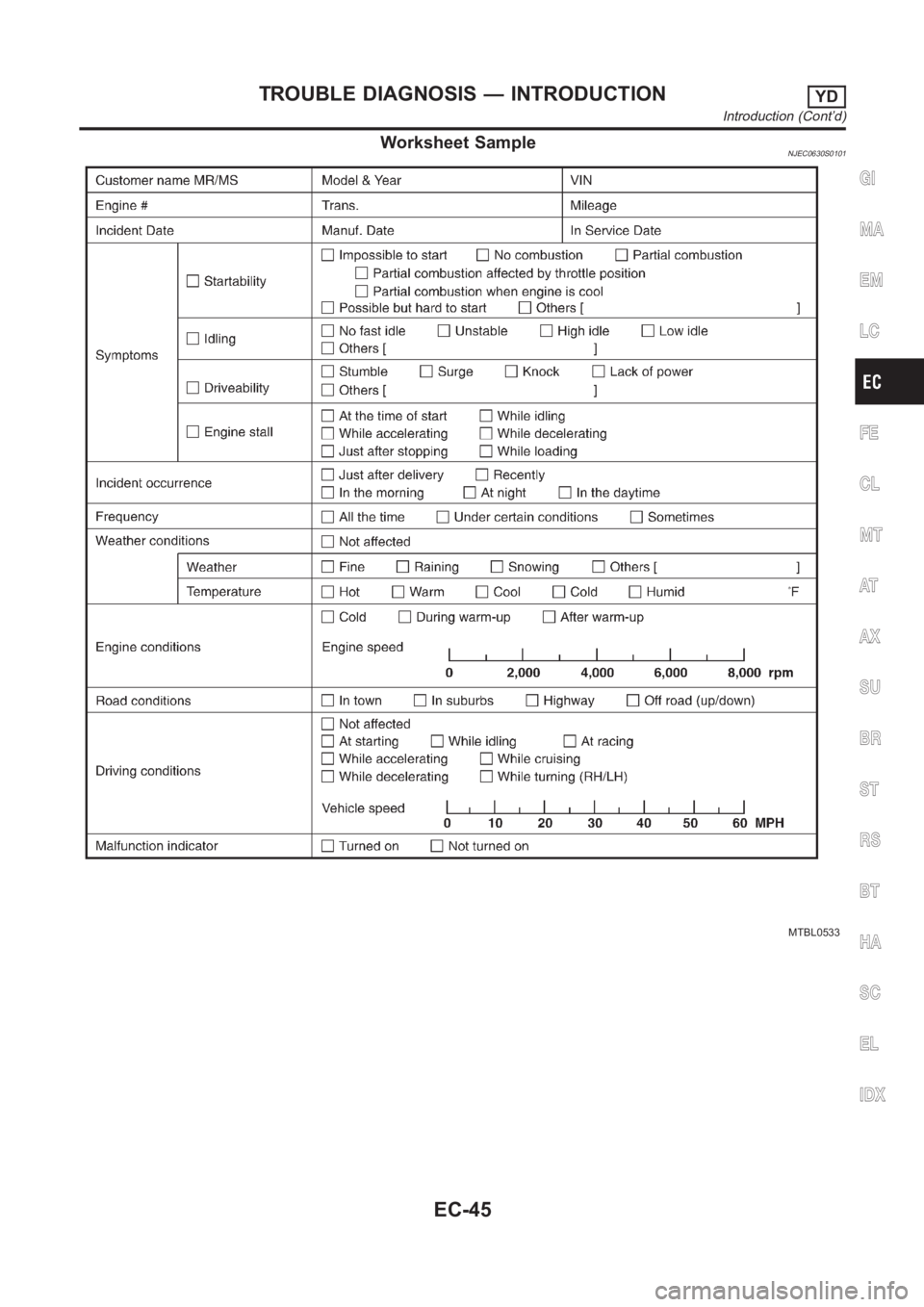

DIAGNOSTIC WORKSHEETNJEC0630S01There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

troubleshooting faster and more accurate.

In general, each customer feels differently about an incident. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one shown below in order to

organize all the information for troubleshooting.

TROUBLE DIAGNOSIS — INTRODUCTIONYD

Introduction

EC-44

Page 1099 of 3189

Worksheet SampleNJEC0630S0101

MTBL0533

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS — INTRODUCTIONYD

Introduction (Cont’d)

EC-45

Page 1100 of 3189

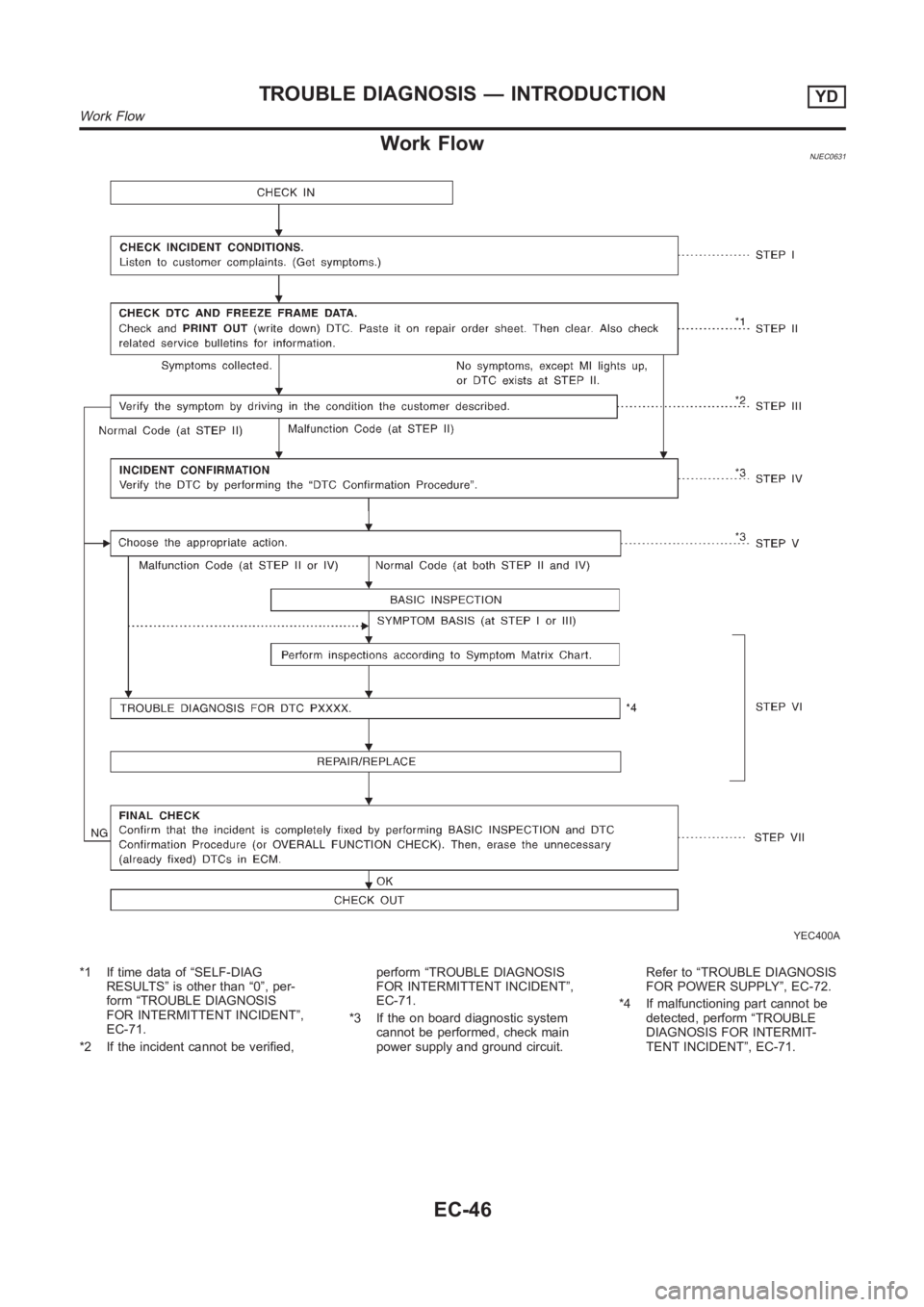

Work FlowNJEC0631

YEC400A

*1 If time data of “SELF-DIAG

RESULTS” is other than “0”, per-

form “TROUBLE DIAGNOSIS

FOR INTERMITTENT INCIDENT”,

EC-71.

*2 If the incident cannot be verified,perform “TROUBLE DIAGNOSIS

FOR INTERMITTENT INCIDENT”,

EC-71.

*3 If the on board diagnostic system

cannot be performed, check main

power supply and ground circuit.Refer to “TROUBLE DIAGNOSIS

FOR POWER SUPPLY”, EC-72.

*4 If malfunctioning part cannot be

detected, perform “TROUBLE

DIAGNOSIS FOR INTERMIT-

TENT INCIDENT”, EC-71.

TROUBLE DIAGNOSIS — INTRODUCTIONYD

Work Flow

EC-46