belt NISSAN ALMERA N16 2003 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 287 of 3189

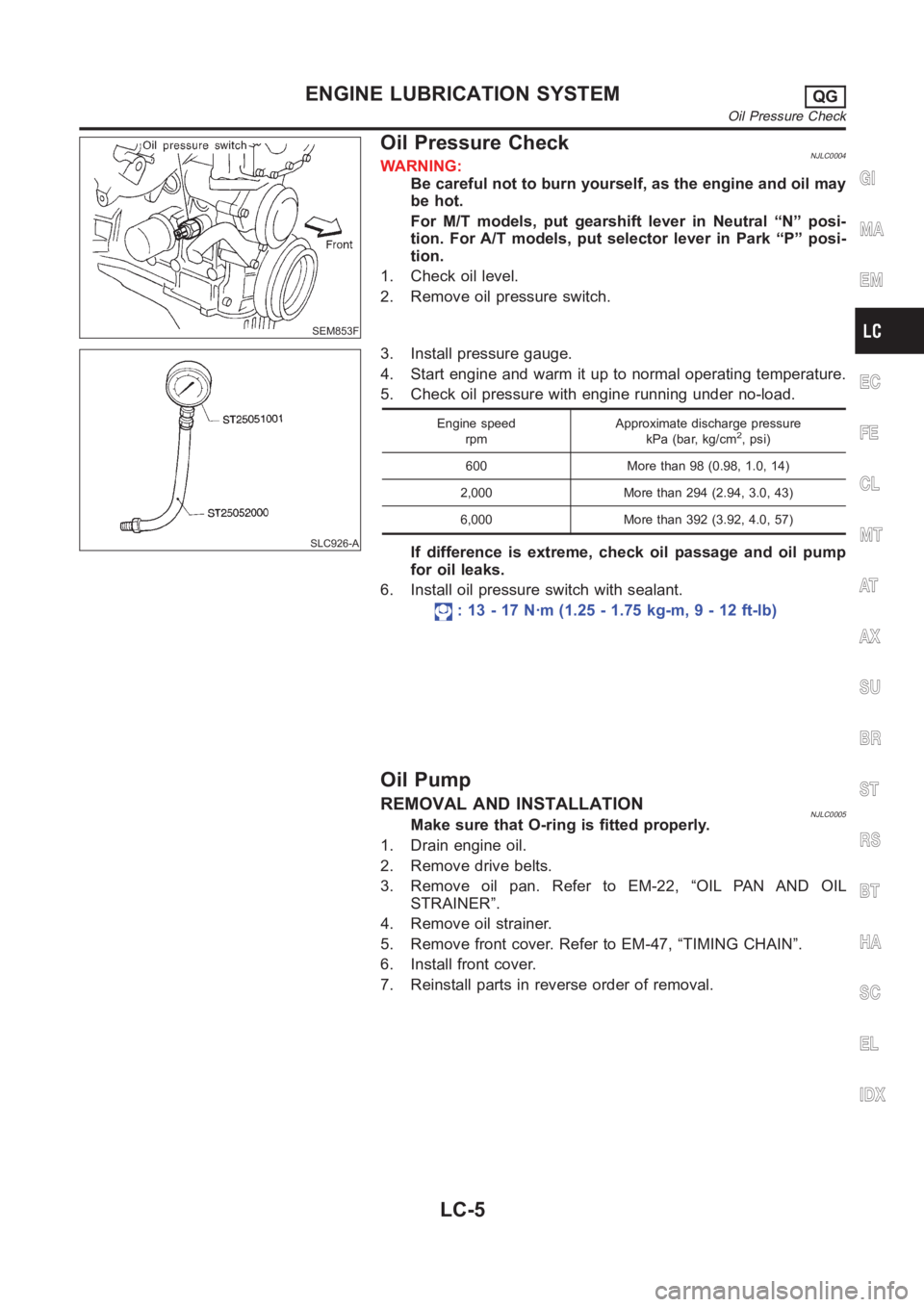

SEM853F

Oil Pressure CheckNJLC0004WARNING:

Be careful not to burn yourself, as the engine and oil may

be hot.

For M/T models, put gearshift lever in Neutral “N” posi-

tion. For A/T models, put selector lever in Park “P” posi-

tion.

1. Check oil level.

2. Remove oil pressure switch.

SLC926-A

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

600 More than 98 (0.98, 1.0, 14)

2,000 More than 294 (2.94, 3.0, 43)

6,000 More than 392 (3.92, 4.0, 57)

If difference is extreme, check oil passage and oil pump

for oil leaks.

6. Install oil pressure switch with sealant.

: 13 - 17 N·m (1.25 - 1.75 kg-m, 9 - 12 ft-lb)

Oil Pump

REMOVAL AND INSTALLATIONNJLC0005Make sure that O-ring is fitted properly.

1. Drain engine oil.

2. Remove drive belts.

3. Remove oil pan. Refer to EM-22, “OIL PAN AND OIL

STRAINER”.

4. Remove oil strainer.

5. Remove front cover. Refer to EM-47, “TIMING CHAIN”.

6. Install front cover.

7. Reinstall parts in reverse order of removal.

GI

MA

EM

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE LUBRICATION SYSTEMQG

Oil Pressure Check

LC-5

Page 296 of 3189

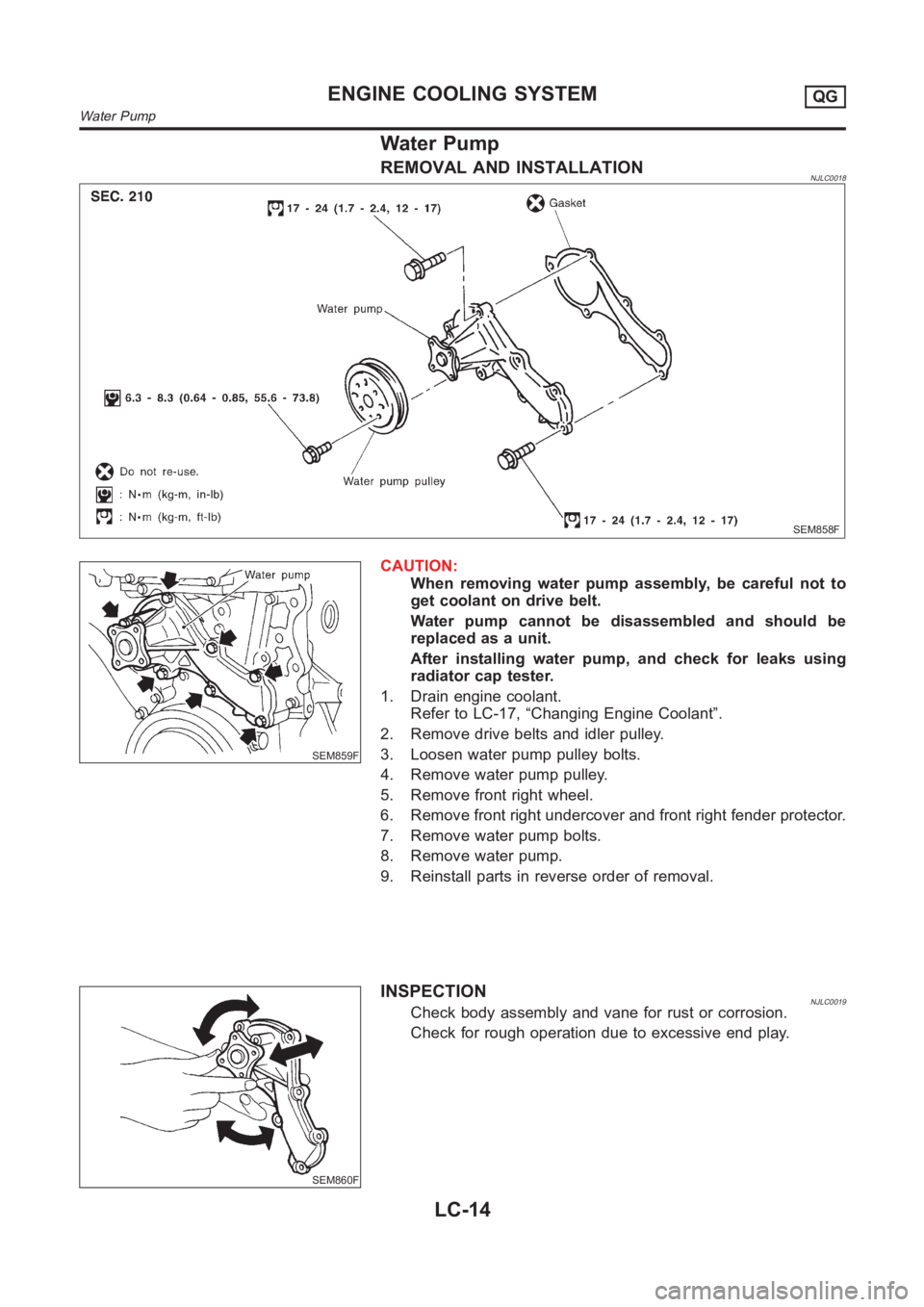

Water Pump

REMOVAL AND INSTALLATIONNJLC0018

SEM858F

SEM859F

CAUTION:

When removing water pump assembly, be careful not to

get coolant on drive belt.

Water pump cannot be disassembled and should be

replaced as a unit.

After installing water pump, and check for leaks using

radiator cap tester.

1. Drain engine coolant.

Refer to LC-17, “Changing Engine Coolant”.

2. Remove drive belts and idler pulley.

3. Loosen water pump pulley bolts.

4. Remove water pump pulley.

5. Remove front right wheel.

6. Remove front right undercover and front right fender protector.

7. Remove water pump bolts.

8. Remove water pump.

9. Reinstall parts in reverse order of removal.

SEM860F

INSPECTIONNJLC0019Check body assembly and vane for rust or corrosion.

Check for rough operation due to excessive end play.

ENGINE COOLING SYSTEMQG

Water Pump

LC-14

Page 300 of 3189

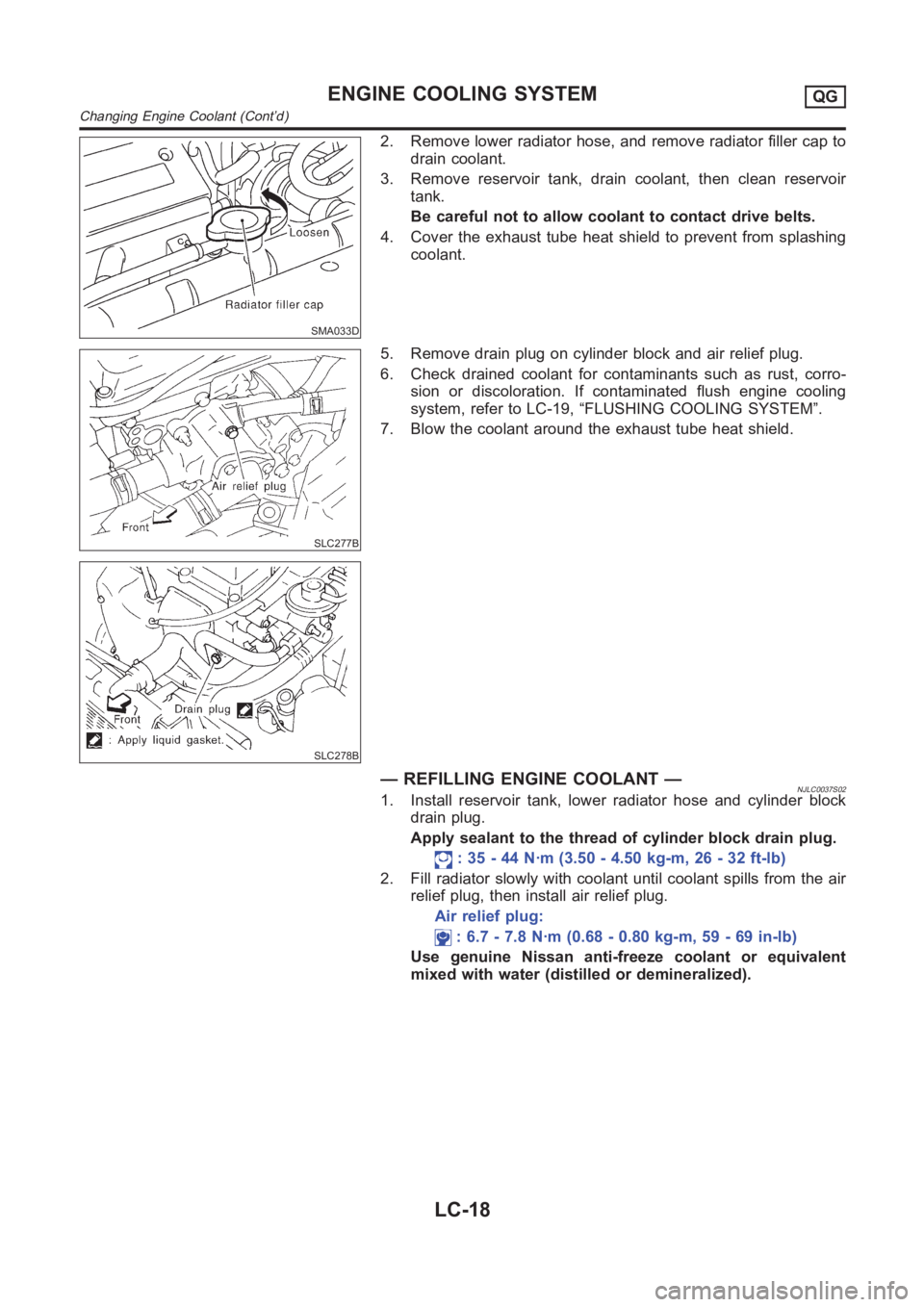

SMA033D

2. Remove lower radiator hose, and remove radiator filler cap to

drain coolant.

3. Remove reservoir tank, drain coolant, then clean reservoir

tank.

Be careful not to allow coolant to contact drive belts.

4. Cover the exhaust tube heat shield to prevent from splashing

coolant.

SLC277B

SLC278B

5. Remove drain plug on cylinder block and air relief plug.

6. Check drained coolant for contaminants such as rust, corro-

sion or discoloration. If contaminated flush engine cooling

system, refer to LC-19, “FLUSHING COOLING SYSTEM”.

7. Blow the coolant around the exhaust tube heat shield.

— REFILLING ENGINE COOLANT —NJLC0037S021. Install reservoir tank, lower radiator hose and cylinder block

drain plug.

Apply sealant to the thread of cylinder block drain plug.

: 35 - 44 N·m (3.50 - 4.50 kg-m, 26 - 32 ft-lb)

2. Fill radiator slowly with coolant until coolant spills from the air

relief plug, then install air relief plug.

Air relief plug:

: 6.7 - 7.8 N·m (0.68 - 0.80 kg-m, 59 - 69 in-lb)

Use genuine Nissan anti-freeze coolant or equivalent

mixed with water (distilled or demineralized).

ENGINE COOLING SYSTEMQG

Changing Engine Coolant (Cont’d)

LC-18

Page 305 of 3189

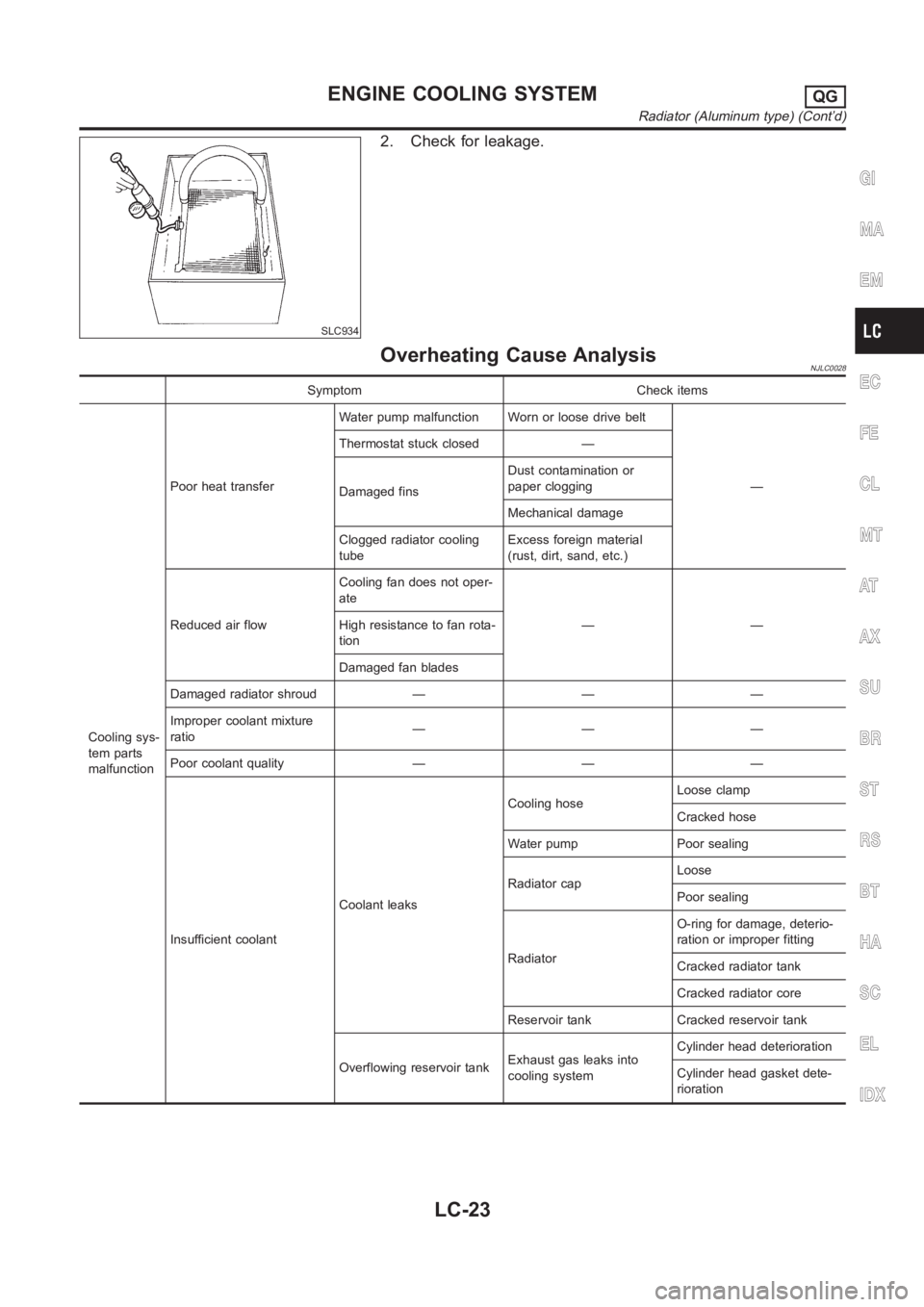

SLC934

2. Check for leakage.

Overheating Cause AnalysisNJLC0028

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

—— High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper coolant mixture

ratio———

Poor coolant quality — — —

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

GI

MA

EM

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEMQG

Radiator (Aluminum type) (Cont’d)

LC-23

Page 320 of 3189

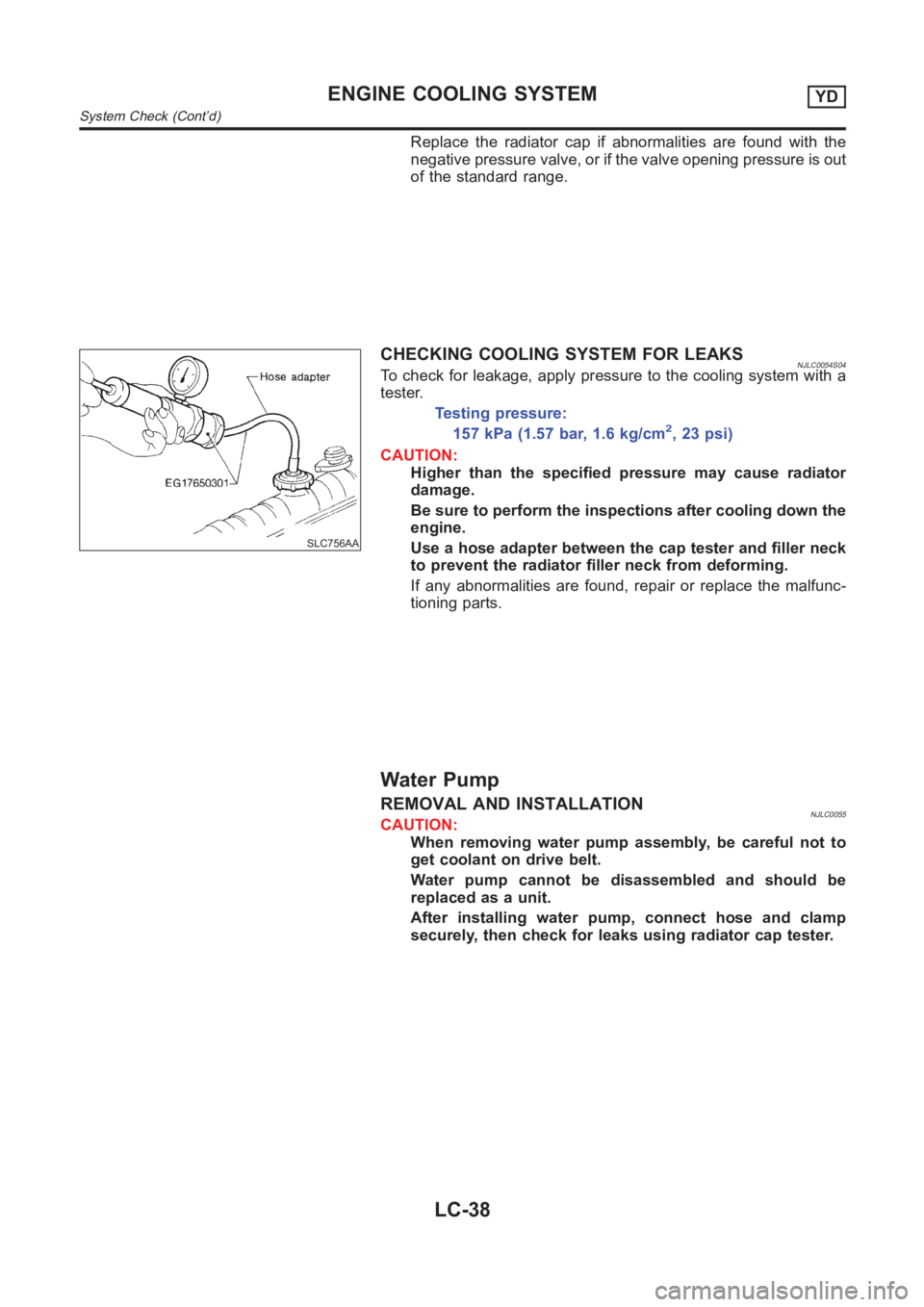

Replace the radiator cap if abnormalities are found with the

negative pressure valve, or if the valve opening pressure is out

of the standard range.

SLC756AA

CHECKING COOLING SYSTEM FOR LEAKSNJLC0054S04To check for leakage, apply pressure to the cooling system with a

tester.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm2,23psi)

CAUTION:

Higher than the specified pressure may cause radiator

damage.

Be sure to perform the inspections after cooling down the

engine.

Use a hose adapter between the cap tester and filler neck

to prevent the radiator filler neck from deforming.

If any abnormalities are found, repair or replace the malfunc-

tioning parts.

Water Pump

REMOVAL AND INSTALLATIONNJLC0055CAUTION:

When removing water pump assembly, be careful not to

get coolant on drive belt.

Water pump cannot be disassembled and should be

replaced as a unit.

After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

ENGINE COOLING SYSTEMYD

System Check (Cont’d)

LC-38

Page 321 of 3189

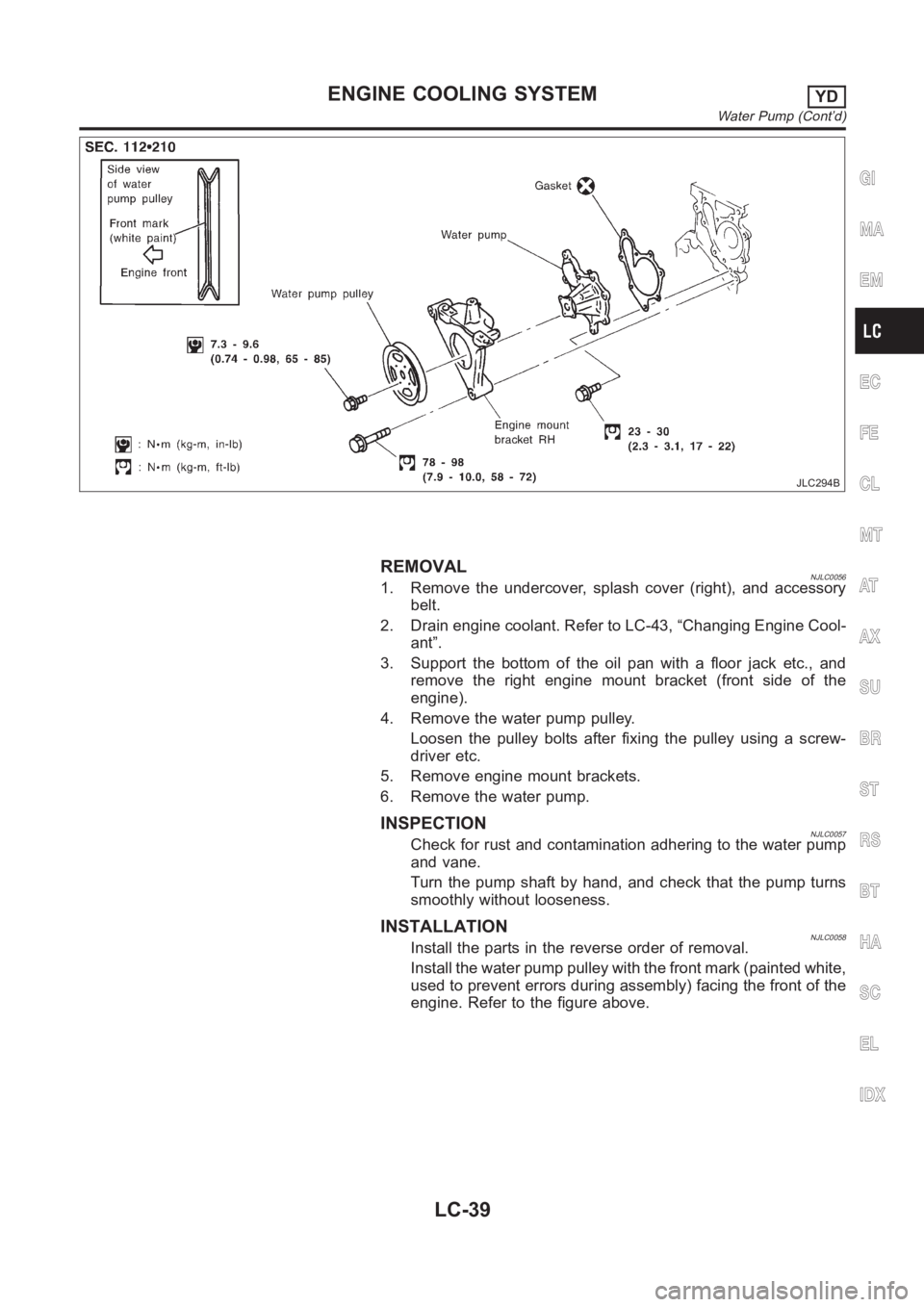

JLC294B

REMOVALNJLC00561. Remove the undercover, splash cover (right), and accessory

belt.

2. Drain engine coolant. Refer to LC-43, “Changing Engine Cool-

ant”.

3. Support the bottom of the oil pan with a floor jack etc., and

remove the right engine mount bracket (front side of the

engine).

4. Remove the water pump pulley.

Loosen the pulley bolts after fixing the pulley using a screw-

driver etc.

5. Remove engine mount brackets.

6. Remove the water pump.

INSPECTIONNJLC0057Check for rust and contamination adhering to the water pump

and vane.

Turn the pump shaft by hand, and check that the pump turns

smoothly without looseness.

INSTALLATIONNJLC0058Install the parts in the reverse order of removal.

Install the water pump pulley with the front mark (painted white,

used to prevent errors during assembly) facing the front of the

engine. Refer to the figure above.

GI

MA

EM

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEMYD

Water Pump (Cont’d)

LC-39

Page 325 of 3189

JLC295B

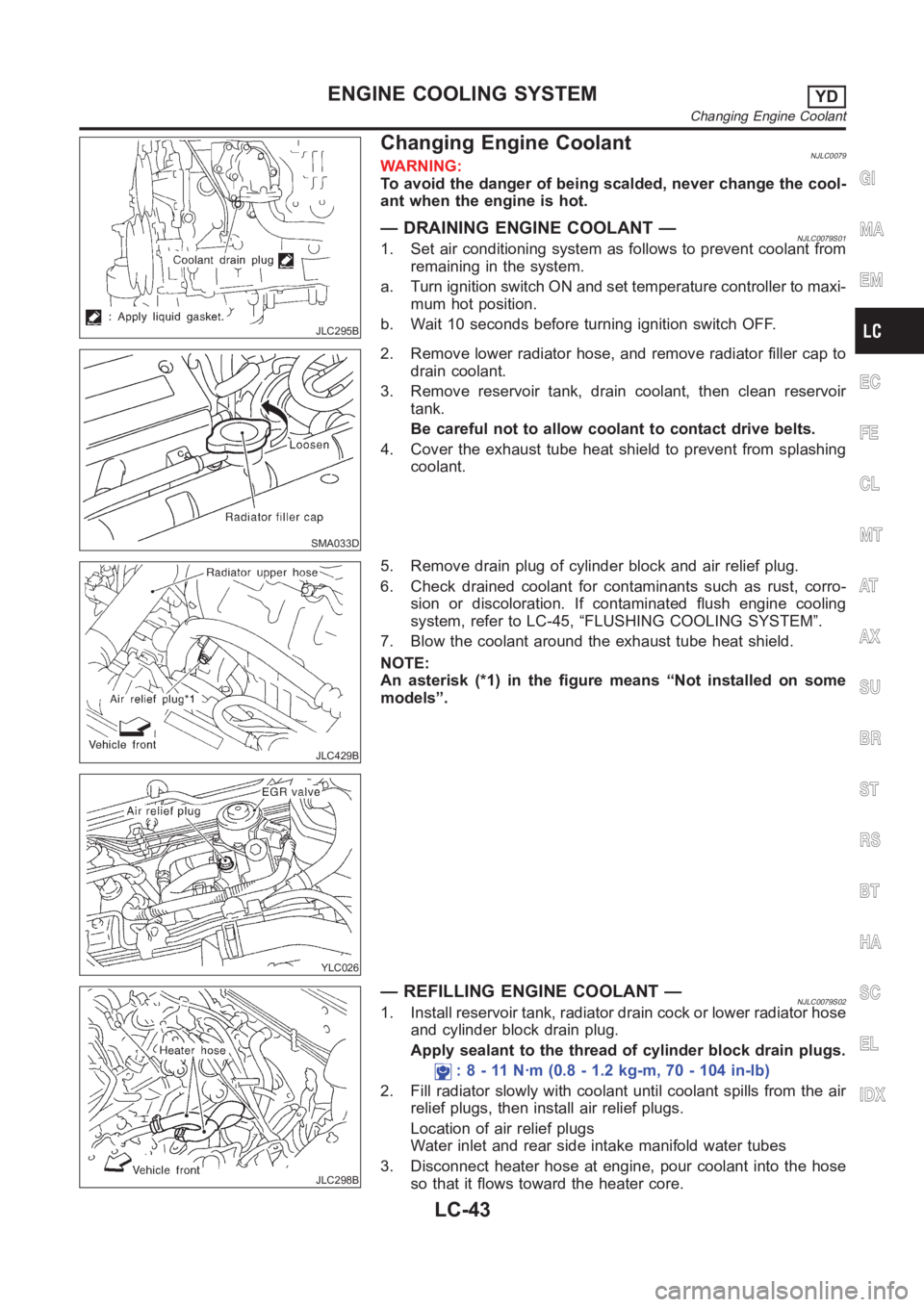

Changing Engine CoolantNJLC0079WARNING:

To avoid the danger of being scalded, never change the cool-

ant when the engine is hot.

— DRAINING ENGINE COOLANT —NJLC0079S011. Set air conditioning system as follows to prevent coolant from

remaining in the system.

a. Turn ignition switch ON and set temperature controller to maxi-

mum hot position.

b. Wait 10 seconds before turning ignition switch OFF.

SMA033D

2. Remove lower radiator hose, and remove radiator filler cap to

drain coolant.

3. Remove reservoir tank, drain coolant, then clean reservoir

tank.

Be careful not to allow coolant to contact drive belts.

4. Cover the exhaust tube heat shield to prevent from splashing

coolant.

JLC429B

YLC026

5. Remove drain plug of cylinder block and air relief plug.

6. Check drained coolant for contaminants such as rust, corro-

sion or discoloration. If contaminated flush engine cooling

system, refer to LC-45, “FLUSHING COOLING SYSTEM”.

7. Blow the coolant around the exhaust tube heat shield.

NOTE:

An asterisk (*1) in the figure means “Not installed on some

models”.

JLC298B

— REFILLING ENGINE COOLANT —NJLC0079S021. Install reservoir tank, radiator drain cock or lower radiator hose

and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plugs.

: 8 - 11 N·m (0.8 - 1.2 kg-m, 70 - 104 in-lb)

2. Fill radiator slowly with coolant until coolant spills from the air

relief plugs, then install air relief plugs.

Location of air relief plugs

Water inlet and rear side intake manifold water tubes

3. Disconnect heater hose at engine, pour coolant into the hose

so that it flows toward the heater core.

GI

MA

EM

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEMYD

Changing Engine Coolant

LC-43

Page 328 of 3189

Radiator (Aluminum type)=NJLC0082Refer to LC-20, “Radiator (Aluminum type)”.

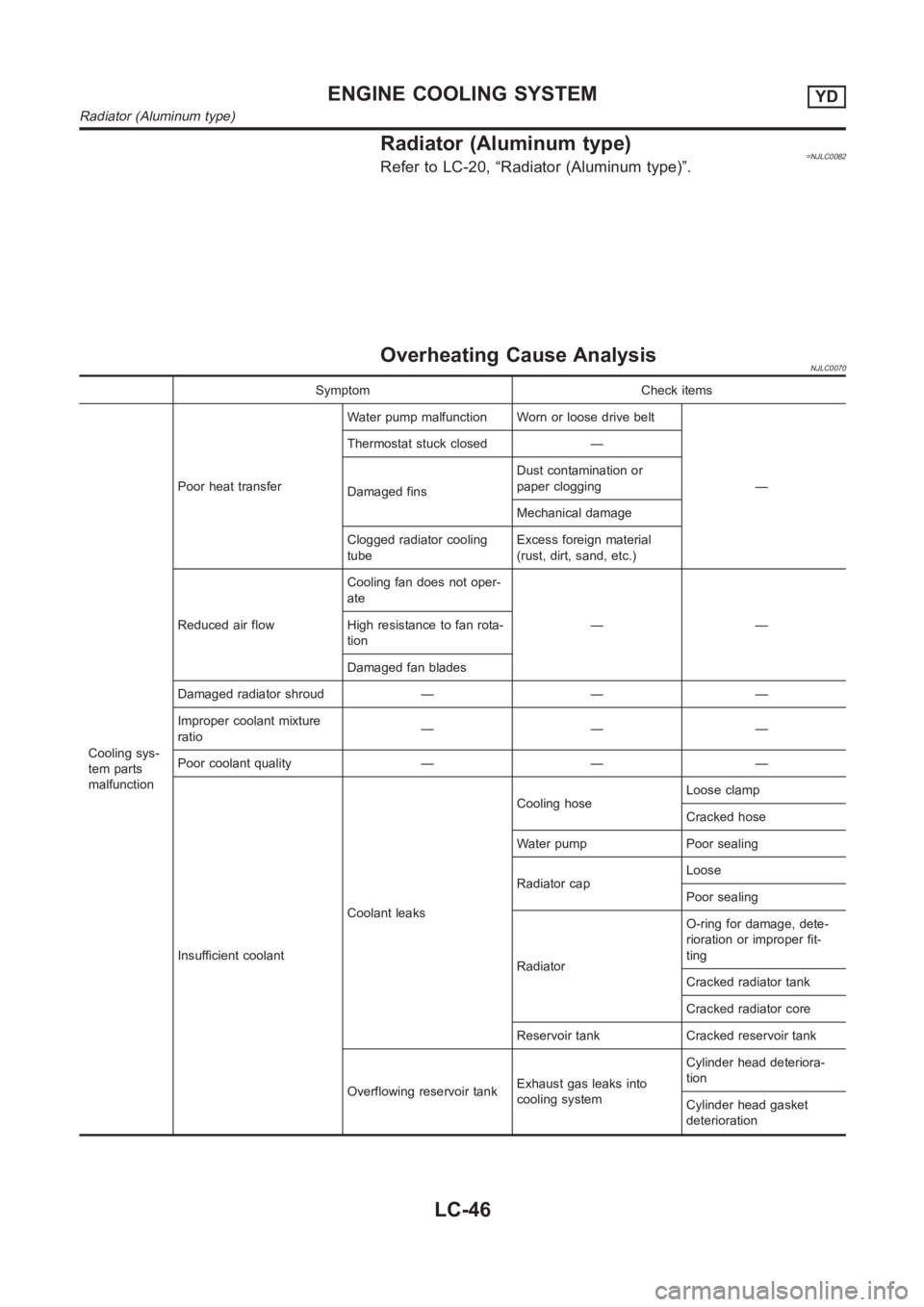

Overheating Cause AnalysisNJLC0070

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

—— High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper coolant mixture

ratio———

Poor coolant quality — — —

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, dete-

rioration or improper fit-

ting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deteriora-

tion

Cylinder head gasket

deterioration

ENGINE COOLING SYSTEMYD

Radiator (Aluminum type)

LC-46

Page 331 of 3189

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EC

ENGINE CONTROL SYSTEM

QG (WITH EURO-OBD)

INDEX FOR DTC ...................................................... 10

Alphabetical Index .................................................. 10

DTC No. Index ....................................................... 12

PRECAUTIONS ........................................................ 15

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 15

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 15

Precaution .............................................................. 15

Wiring Diagrams and Trouble Diagnosis ................ 18

PREPARATION ......................................................... 19

Special Service Tools ............................................. 19

Commercial Service Tools ...................................... 19

ENGINE CONTROL SYSTEM .................................. 21

System Diagram ..................................................... 21

Vacuum Hose Drawing ........................................... 22

System Chart ......................................................... 23

Multiport Fuel Injection (MFI) System .................... 23

Electronic Ignition (EI) System ............................... 25

Air Conditioning Cut Control ................................... 26

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 27

CAN Communication .............................................. 27

BASIC SERVICE PROCEDURE .............................. 30

Idle Speed and Ignition Timing Check .................... 30

Accelerator Pedal Released Position Learning ...... 31

Throttle Valve Closed Position Learning ................ 31

Idle Air Volume Learning ........................................ 31

Fuel Pressure Check .............................................. 34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 36

Introduction ............................................................ 36

Two Trip Detection Logic ........................................ 36

Emission-related Diagnostic Information ................ 37

NATS (Nissan Anti-theft System) ........................... 49

Malfunction Indicator (MI) ....................................... 49

OBD System Operation Chart ................................ 52

TROUBLE DIAGNOSIS ............................................ 58

Trouble Diagnosis Introduction ............................... 58DTC Inspection Priority Chart ................................. 62

Fail-safe Chart ........................................................ 63

Basic Inspection ..................................................... 65

Symptom Matrix Chart ............................................ 70

Engine Control Component Parts Location ............ 74

Circuit Diagram ....................................................... 78

ECM Harness Connector Terminal Layout ............. 80

ECM Terminals and Reference Value ..................

... 80

CONSULT-II Function ............................................. 87

Generic Scan Tool (GST) Function ......................... 97

CONSULT-II Reference Value in Data Monitor Mode

... 99

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................102

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .105

Description ............................................................105

Testing Condition ..................................................105

Inspection Procedure ............................................105

Diagnostic Procedure ...........................................106

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................109

Description ............................................................109

Diagnostic Procedure ...........................................109

POWER SUPPLY CIRCUIT FOR ECM ...................110

Wiring Diagram .....................................................110

Diagnostic Procedure ............................................111

Component Inspection ..........................................115

DTC U1000, U1001 CAN COMMUNICATION LINE .116

Description ............................................................116

On Board Diagnosis Logic ....................................116

DTC Confirmation Procedure ...............................116

Wiring Diagram .....................................................117

Diagnostic Procedure ...........................................118

DTC P0011 IVT CONTROL .....................................119

Description ............................................................119

CONSULT-II Reference Value in Data Monitor Mode

.119

On Board Diagnosis Logic ....................................120

DTC Confirmation Procedure ...............................120

Diagnostic Procedure ...........................................121

Page 335 of 3189

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA Wiring Diagram .................................................... 353

Diagnostic Procedure ........................................... 354

DTC P1706 PNP SWITCH ...................................... 356

Component Description ........................................ 356

CONSULT-II Reference Value in Data Monitor Mode

. 356

On Board Diagnosis Logic ................................... 356

DTC Confirmation Procedure ............................... 356

Overall Function Check ........................................ 357

Wiring Diagram .................................................... 358

Diagnostic Procedure ........................................... 359

DTC P1805 BRAKE SWITCH ................................ 360

Description ........................................................... 360

CONSULT-II Reference Value in Data Monitor Mode

. 360

On Board Diagnosis Logic ................................... 360

DTC Confirmation Procedure ............................... 360

Wiring Diagram .................................................... 361

Diagnostic Procedure ........................................... 362

Component Inspection ......................................... 364

IGNITION SIGNAL .................................................. 365

Component Description ........................................ 365

Wiring Diagram .................................................... 366

Diagnostic Procedure ........................................... 369

Component Inspection ......................................... 373

Removal and Installation ...................................... 374

INJECTOR CIRCUIT ............................................... 375

Component Description ........................................ 375

CONSULT-II Reference Value in Data Monitor Mode

. 375

Wiring Diagram .................................................... 376

Diagnostic Procedure ........................................... 377

Component Inspection ......................................... 380

Removal and Installation ...................................... 380

FUEL PUMP CIRCUIT ............................................ 381

Description ........................................................... 381

CONSULT-II Reference Value in Data Monitor Mode

. 381

Wiring Diagram .................................................... 382

Diagnostic Procedure ........................................... 383

Component Inspection ......................................... 385

Removal and Installation ...................................... 386

REFRIGERANT PRESSURE SENSOR ................. 387

Component Description ........................................ 387

Wiring Diagram .................................................... 388

Diagnostic Procedure ........................................... 389

Removal and Installation ...................................... 391

ELECTRICAL LOAD SIGNAL ................................ 392

Description ...................................................

........ 392

CONSULT-II Reference Value in Data Monitor Mode

. 392

Wiring Diagram .................................................... 393

Diagnostic Procedure ........................................... 394

MI & DATA LINK CONNECTORS .......................... 397

Wiring Diagram—LHD Models ............................. 397

Wiring Diagram—RHD Models ............................ 398

EVAPORATIVE EMISSION SYSTEM ..................... 399

Description ........................................................... 399

Component Inspection ......................................... 401POSITIVE CRANKCASE VENTILATION ...............402

Description ............................................................402

Component Inspection ..........................................402

SERVICE DATA AND SPECIFICATIONS (SDS) ....404

Fuel Pressure .......................................................404

Idle Speed and Ignition Timing .............................404

Calculated Load Value ..........................................404

Mass Air Flow Sensor ...........................................404

Intake Air Temperature Sensor .............................404

Engine Coolant Temperature Sensor ...................404

Heated Oxygen Sensor 1 Heater .........................404

Heated Oxygen sensor 2 Heater ..........................404

Crankshaft Position Sensor (POS) .......................404

Camshaft Position Sensor (PHASE) ....................404

Throttle Control Motor ...........................................405

Injector ..................................................................405

Fuel Pump ............................................................405

QG (WITHOUT EURO-OBD)

INDEX FOR DTC .....................................................406

Alphabetical Index ................................................406

DTC No. Index ......................................................407

PRECAUTIONS ......................................................409

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................409

On Board Diagnostic (OBD) System of Engine ....409

Precaution ............................................................409

Wiring Diagrams and Trouble Diagnosis ..............412

PREPARATION .......................................................413

Special Service Tools ...........................................413

Commercial Service Tools ....................................413

ENGINE CONTROL SYSTEM ................................415

System Diagram ...................................................415

Vacuum Hose Drawing .........................................416

System Chart ........................................................417

Multiport Fuel Injection (MFI) System ...................417

Electronic Ignition (EI) System .............................419

Air Conditioning Cut Control .................................420

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................421

CAN Communication ............................................421

BASIC SERVICE PROCEDURE .............................424

Idle Speed and Ignition Timing Check ..................424

Accelerator Pedal Released Position Learning ....425

Throttle Valve Closed Position Learning ...............425

Idle Air Volume Learning ......................................425

Fuel Pressure Check ............................................427

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........429

Introduction ...........................................................429

Two Trip Detection Logic ......................................429

Emission-related Diagnostic Information ..............429

NATS (Nissan Anti-theft System) .........................431

Malfunction Indicator (MI) .....................................432

TROUBLE DIAGNOSIS ..........................................436

Trouble Diagnosis Introduction .............................436

DTC Inspection Priority Chart ...............................440

Fail-safe Chart ......................................................441