overdrive NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 13 of 3189

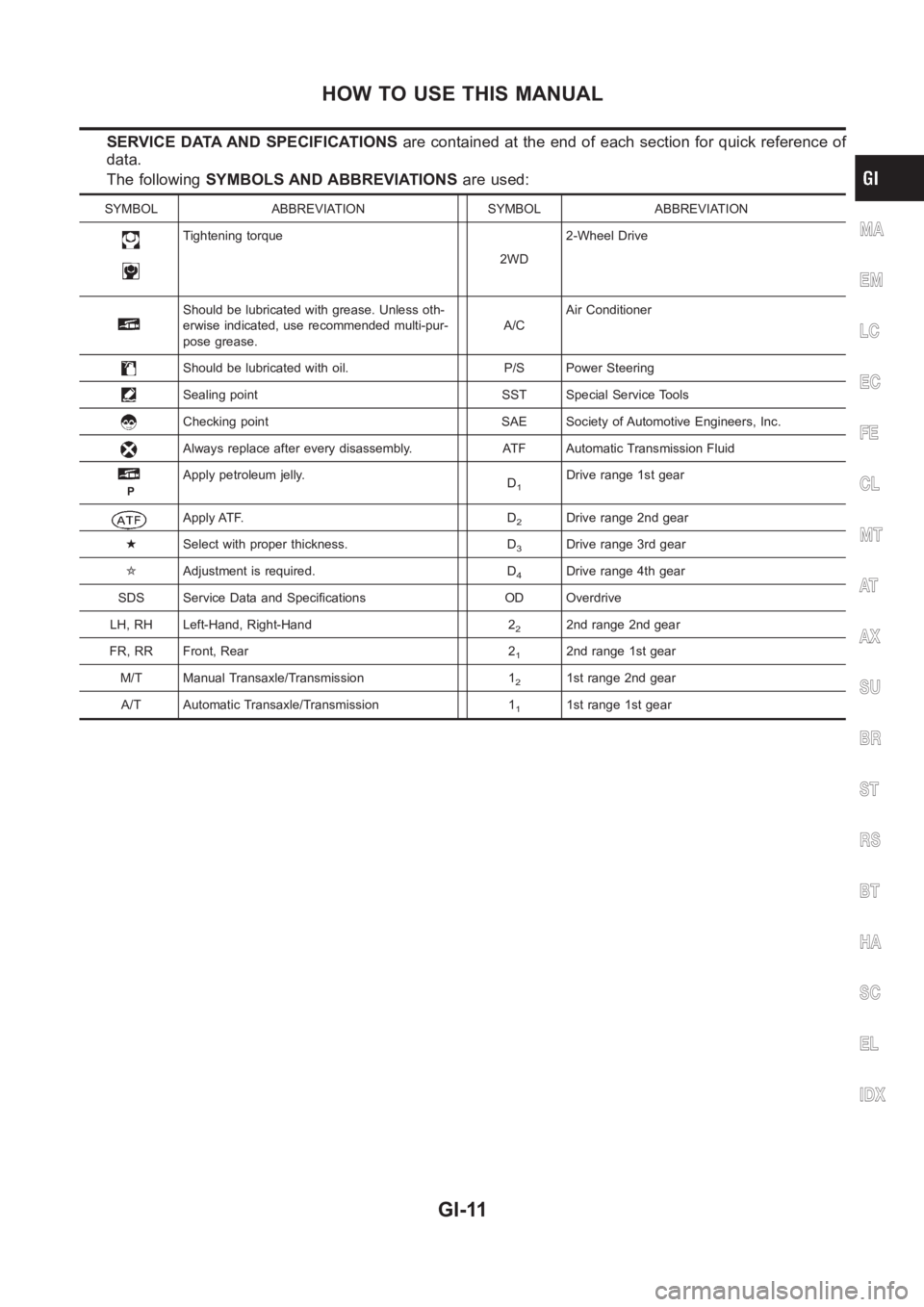

SERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

The followingSYMBOLS AND ABBREVIATIONSare used:

SYMBOL ABBREVIATION SYMBOL ABBREVIATION

Tightening torque

2WD2-Wheel Drive

Should be lubricated with grease. Unless oth-

erwise indicated, use recommended multi-pur-

pose grease.A/CAir Conditioner

Should be lubricated with oil. P/S Power Steering

Sealing point SST Special Service Tools

Checking point SAE Society of Automotive Engineers, Inc.

Always replace after every disassembly. ATF Automatic Transmission Fluid

P

Apply petroleum jelly.

D1Drive range 1st gear

Apply ATF. D2Drive range 2nd gear

★Select with proper thickness. D

3Drive range 3rd gear

✩Adjustment is required. D

4Drive range 4th gear

SDS Service Data and Specifications OD Overdrive

LH, RH Left-Hand, Right-Hand 2

22nd range 2nd gear

FR, RR Front, Rear 2

12nd range 1st gear

M/T Manual Transaxle/Transmission 1

21st range 2nd gear

A/T Automatic Transaxle/Transmission 1

11st range 1st gear

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO USE THIS MANUAL

GI-11

Page 377 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-47

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

●The time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

i NISSAN ALMERA N16 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-47

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

●The time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

i](/img/5/57350/w960_57350-376.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-47

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

●The time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

ing habits, etc.

Zone A refers to the range where the time, required for the diagnosis under normal conditions*, is the

shortest.

Zone B refers to the range where the diagnosis can still be performed if the diagnosis is not completed

within zone A.

*: Normal conditions refer to the following:

●Sea level

●Flat road

●Ambient air temperature: 20 - 30°C (68 - 86°F)

●Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30°C (68 - 86°F)], diag-

nosis may also be performed.

Pattern 1:

●The engine is started at the engine coolant temperature of −10 to 35°C (14 to 95°F)

(where the voltage between the ECM terminal 72 and ground is 3.0 - 4.3V).

●The engine must be operated at idle speed until the engine coolant temperature is greater than

70°C (158°F) (where the voltage between the ECM terminal 72 and ground is lower than 1.4V).

Pattern 2:

●When steady-state driving is performed again even after it is interrupted, each diagnosis can be con-

ducted. In this case, the time required for diagnosis may be extended.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56 MPH), then release the accelerator pedal

and keep it released for more than 10 seconds. Depress the accelerator pedal until vehicle speed is 90 km/h

(56 MPH) again.

*2: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Position for A/T Models

Set the selector lever in the “D” position with the overdrive switch turned ON.

TEST VALUE AND TEST LIMIT (GST ONLY — NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Mode 6 of ISO 15031-5.

The test value is a parameter used to determine whether a system/circuit diagnostic test is “OK” or “NG” while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

Items for which these data (test value and test limit) are displayed are the same as SRT code items.

These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be dis-

played on the GST screen.

×: Applicable —: Not applicable

SRT item Self-diagnostic test itemTest value (GST display)

Test limit Application

TID CID

CATALYST Three way catalyst function 01H 01H Max.×

HO2SHeated oxygen sensor 109H 04H Max.×

0AH 84H Min.×

0BH 04H Max.×

0CH 04H Max.×

0DH 04H Max.×

Heated oxygen sensor 219H 86H Min.×

1AH 86H Min.×

1BH 06H Max.×

1CH 06H Max.×

HO2S HTRHeated oxygen sensor 1 heater29H 08H Max.×

2AH 88H Min.×

Heated oxygen sensor 2 heater2DH 0AH Max.×

2EH 8AH Min.×

Page 1458 of 3189

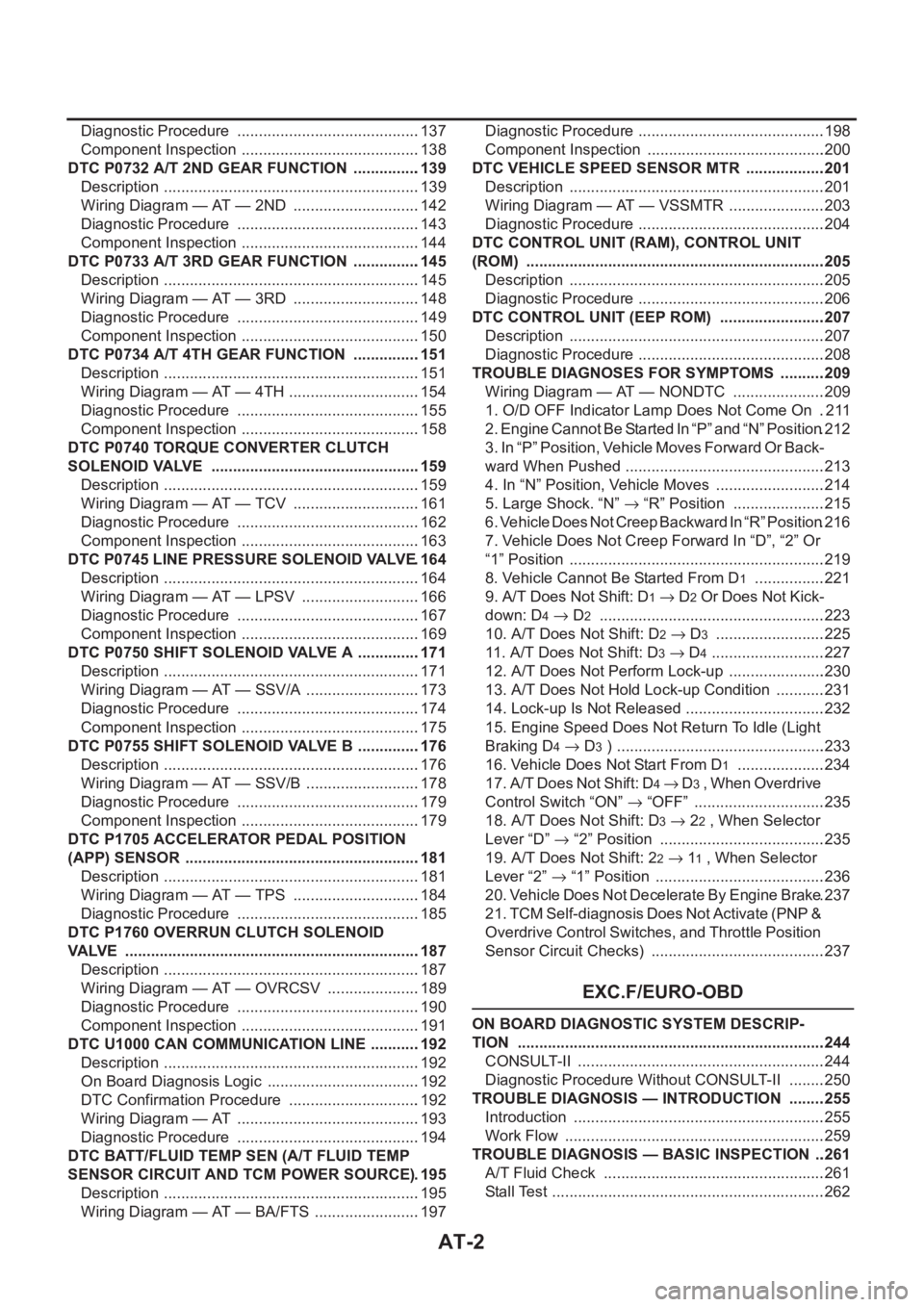

AT-2

Diagnostic Procedure ...........................................137

Component Inspection ..........................................138

DTC P0732 A/T 2ND GEAR FUNCTION ................139

Description ............................................................139

Wiring Diagram — AT — 2ND ..............................142

Diagnostic Procedure ...........................................143

Component Inspection ..........................................144

DTC P0733 A/T 3RD GEAR FUNCTION ................145

Description ............................................................145

Wiring Diagram — AT — 3RD ..............................148

Diagnostic Procedure ...........................................149

Component Inspection ..........................................150

DTC P0734 A/T 4TH GEAR FUNCTION ................151

Description ............................................................151

Wiring Diagram — AT — 4TH ...............................154

Diagnostic Procedure ...........................................155

Component Inspection ..........................................158

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE .................................................159

Description ............................................................159

Wiring Diagram — AT — TCV ..............................161

Diagnostic Procedure ...........................................162

Component Inspection ..........................................163

DTC P0745 LINE PRESSURE SOLENOID VALVE .164

Description ............................................................164

Wiring Diagram — AT — LPSV ............................166

Diagnostic Procedure ...........................................167

Component Inspection ..........................................169

DTC P0750 SHIFT SOLENOID VALVE A ...............171

Description ............................................................171

Wiring Diagram — AT — SSV/A ...........................173

Diagnostic Procedure ...........................................174

Component Inspection ..........................................175

DTC P0755 SHIFT SOLENOID VALVE B ...............176

Description ............................................................176

Wiring Diagram — AT — SSV/B ...........................178

Diagnostic Procedure ...........................................179

Component Inspection ..........................................179

DTC P1705 ACCELERATOR PEDAL POSITION

(APP) SENSOR .......................................................181

Description ............................................................181

Wiring Diagram — AT — TPS ..............................184

Diagnostic Procedure ...........................................185

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE .....................................................................187

Description ............................................................187

Wiring Diagram — AT — OVRCSV ......................189

Diagnostic Procedure ...........................................190

Component Inspection ..........................................191

DTC U1000 CAN COMMUNICATION LINE ............192

Description ............................................................192

On Board Diagnosis Logic ....................................192

DTC Confirmation Procedure ...............................192

Wiring Diagram — AT ...........................................193

Diagnostic Procedure ...........................................194

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE) .195

Description ............................................................195

Wiring Diagram — AT — BA/FTS .........................197Diagnostic Procedure ............................................198

Component Inspection ..........................................200

DTC VEHICLE SPEED SENSOR MTR ...................201

Description ............................................................201

Wiring Diagram — AT — VSSMTR .......................203

Diagnostic Procedure ............................................204

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ......................................................................205

Description ............................................................205

Diagnostic Procedure ............................................206

DTC CONTROL UNIT (EEP ROM) .........................207

Description ............................................................207

Diagnostic Procedure ............................................208

TROUBLE DIAGNOSES FOR SYMPTOMS ...........209

Wiring Diagram — AT — NONDTC ......................209

1. O/D OFF Indicator Lamp Does Not Come On ..211

2. Engine Cannot Be Started In “P” and “N” Position .212

3. In “P” Position, Vehicle Moves Forward Or Back-

ward When Pushed ...............................................213

4. In “N” Position, Vehicle Moves ..........................214

5. Large Shock. “N” → “R” Position ......................215

6. Vehicle Does Not Creep Backward In “R” Position .216

7. Vehicle Does Not Creep Forward In “D”, “2” Or

“1” Position ............................................................219

8. Vehicle Cannot Be Started From D

1 .................221

9. A/T Does Not Shift: D

1→ D2 Or Does Not Kick-

down: D

4→ D2 .....................................................223

10. A/T Does Not Shift: D

2→ D3 ..........................225

11. A/T Does Not Shift: D

3→ D4 ...........................227

12. A/T Does Not Perform Lock-up .......................230

13. A/T Does Not Hold Lock-up Condition ............231

14. Lock-up Is Not Released .................................232

15. Engine Speed Does Not Return To Idle (Light

Braking D

4→ D3 ) .................................................233

16. Vehicle Does Not Start From D

1 .....................234

17. A/T Does Not Shift: D

4→ D3 , W h e n O v e r d r i v e

Control Switch “ON” → “OFF” ...............................235

18. A/T Does Not Shift: D

3→ 22 , When Selector

Lever “D” → “2” Position .......................................235

19. A/T Does Not Shift: 2

2→ 11 , When Selector

Lever “2” → “1” Position ........................................236

20. Vehicle Does Not Decelerate By Engine Brake .237

21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position

Sensor Circuit Checks) .........................................237

EXC.F/EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION ........................................................................244

CONSULT-II ..........................................................244

Diagnostic Procedure Without CONSULT-II .........250

TROUBLE DIAGNOSIS — INTRODUCTION .........255

Introduction ...........................................................255

Work Flow .............................................................259

TROUBLE DIAGNOSIS — BASIC INSPECTION ...261

A/T Fluid Check ....................................................261

Stall Test ................................................................262

Page 1459 of 3189

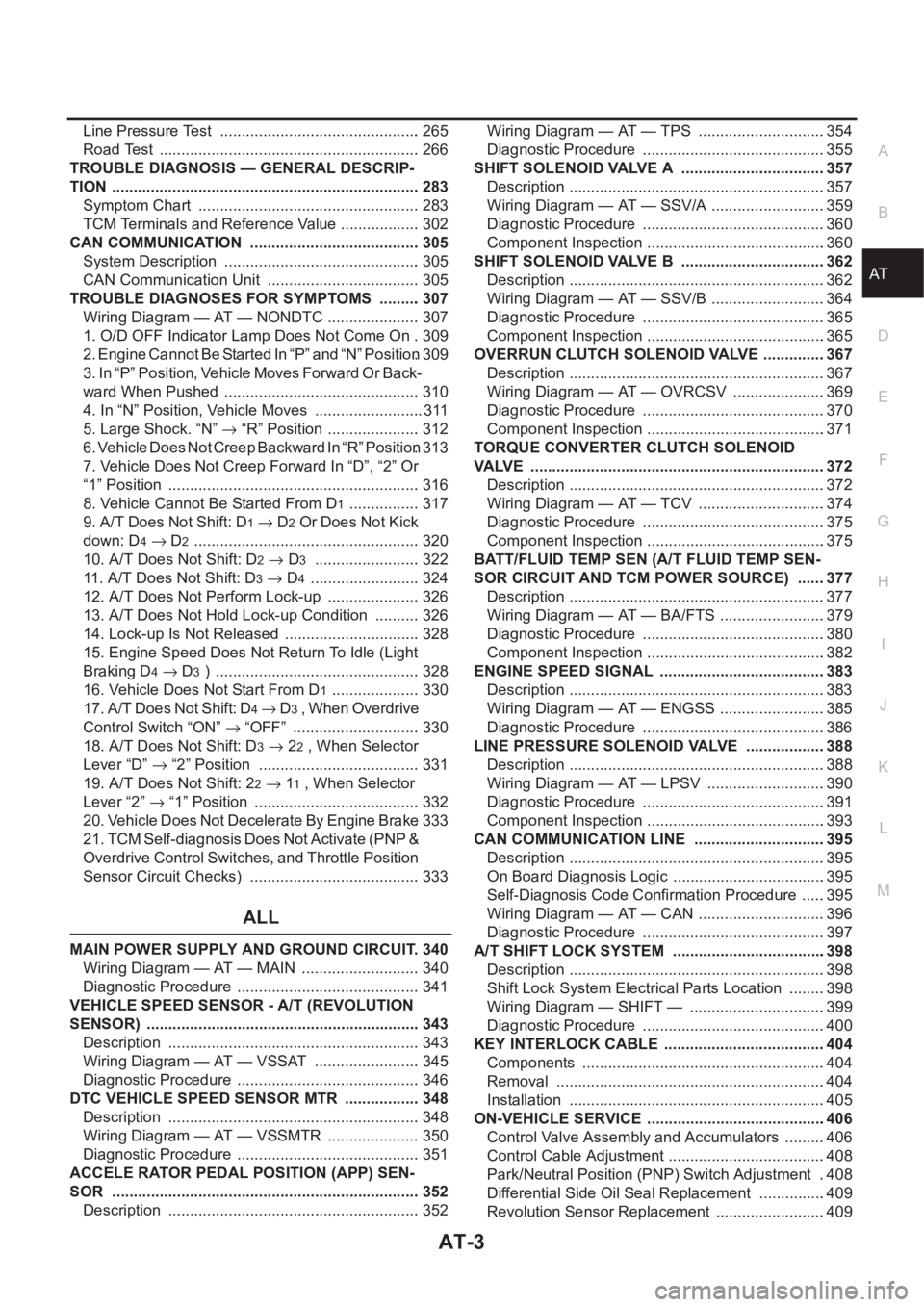

AT-3

D

E

F

G

H

I

J

K

L

MA

B

AT Line Pressure Test ............................................... 265

Road Test ............................................................. 266

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION ........................................................................ 283

Symptom Chart .................................................... 283

TCM Terminals and Reference Value ................... 302

CAN COMMUNICATION ........................................ 305

System Description .............................................. 305

CAN Communication Unit .................................... 305

TROUBLE DIAGNOSES FOR SYMPTOMS .......... 307

Wiring Diagram — AT — NONDTC ...................... 307

1. O/D OFF Indicator Lamp Does Not Come On . 309

2. Engine Cannot Be Started In “P” and “N” Position . 309

3. In “P” Position, Vehicle Moves Forward Or Back-

ward When Pushed .............................................. 310

4. In “N” Position, Vehicle Moves .......................... 311

5. Large Shock. “N” → “R” Position ...................... 312

6. Vehicle Does Not Creep Backward In “R” Position . 313

7. Vehicle Does Not Creep Forward In “D”, “2” Or

“1” Position ........................................................... 316

8. Vehicle Cannot Be Started From D

1 ................. 317

9. A/T Does Not Shift: D

1→ D2 Or Does Not Kick

down: D

4→ D2 ..................................................... 320

10. A/T Does Not Shift: D

2→ D3 ......................... 322

11. A/T Does Not Shift: D

3→ D4 .......................... 324

12. A/T Does Not Perform Lock-up ...................... 326

13. A/T Does Not Hold Lock-up Condition ........... 326

14. Lock-up Is Not Released ................................ 328

15. Engine Speed Does Not Return To Idle (Light

Braking D

4→ D3 ) ................................................ 328

16. Vehicle Does Not Start From D

1 ..................... 330

17. A/T Does Not Shift: D

4→ D3 , When Overdrive

Control Switch “ON” → “OFF” .............................. 330

18. A/T Does Not Shift: D

3→ 22 , When Selector

Lever “D” → “2” Position ...................................... 331

19. A/T Does Not Shift: 2

2→ 11 , When Selector

Lever “2” → “1” Position ....................................... 332

20. Vehicle Does Not Decelerate By Engine Brake . 333

21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position

Sensor Circuit Checks) ........................................ 333

ALL

MAIN POWER SUPPLY AND GROUND CIRCUIT . 340

Wiring Diagram — AT — MAIN ............................ 340

Diagnostic Procedure ........................................... 341

VEHICLE SPEED SENSOR - A/T (REVOLUTION

SENSOR) ................................................................ 343

Description ........................................................... 343

Wiring Diagram — AT — VSSAT ......................... 345

Diagnostic Procedure ........................................... 346

DTC VEHICLE SPEED SENSOR MTR .................. 348

Description ........................................................... 348

Wiring Diagram — AT — VSSMTR ...................... 350

Diagnostic Procedure ........................................... 351

ACCELE RATOR PEDAL POSITION (APP) SEN-

SOR ........................................................................ 352

Description ........................................................... 352Wiring Diagram — AT — TPS ..............................354

Diagnostic Procedure ...........................................355

SHIFT SOLENOID VALVE A ..................................357

Description ............................................................357

Wiring Diagram — AT — SSV/A ...........................359

Diagnostic Procedure ...........................................360

Component Inspection ..........................................360

SHIFT SOLENOID VALVE B ..................................362

Description ............................................................362

Wiring Diagram — AT — SSV/B ...........................364

Diagnostic Procedure ...........................................365

Component Inspection ..........................................365

OVERRUN CLUTCH SOLENOID VALVE ...............367

Description ............................................................367

Wiring Diagram — AT — OVRCSV ......................369

Diagnostic Procedure ...........................................370

Component Inspection ..........................................371

TORQUE CONVERTER CLUTCH SOLENOID

VALVE .....................................................................372

Description ............................................................372

Wiring Diagram — AT — TCV ..............................374

Diagnostic Procedure ...........................................375

Component Inspection ..........................................375

BATT/FLUID TEMP SEN (A/T FLUID TEMP SEN-

SOR CIRCUIT AND TCM POWER SOURCE) .......377

Description ............................................................377

Wiring Diagram — AT — BA/FTS .........................379

Diagnostic Procedure ...........................................380

Component Inspection ..........................................382

ENGINE SPEED SIGNAL .......................................383

Description ............................................................383

Wiring Diagram — AT — ENGSS .........................385

Diagnostic Procedure ...........................................386

LINE PRESSURE SOLENOID VALVE ...................388

Description ............................................................388

Wiring Diagram — AT — LPSV ............................390

Diagnostic Procedure ...........................................391

Component Inspection ..........................................393

CAN COMMUNICATION LINE ...............................395

Description ............................................................395

On Board Diagnosis Logic ....................................395

Self-Diagnosis Code Confirmation Procedure ......395

Wiring Diagram — AT — CAN ..............................396

Diagnostic Procedure ...........................................397

A/T SHIFT LOCK SYSTEM ....................................398

Description ............................................................398

Shift Lock System Electrical Parts Location .........398

Wiring Diagram — SHIFT — ................................399

Diagnostic Procedure ...........................................400

KEY INTERLOCK CABLE ......................................404

Components .........................................................404

Removal ...............................................................404

Installation ............................................................405

ON-VEHICLE SERVICE ..........................................406

Control Valve Assembly and Accumulators ..........406

Control Cable Adjustment .....................................408

Park/Neutral Position (PNP) Switch Adjustment ..408

Differential Side Oil Seal Replacement ................409

Revolution Sensor Replacement ..........................409

Page 1475 of 3189

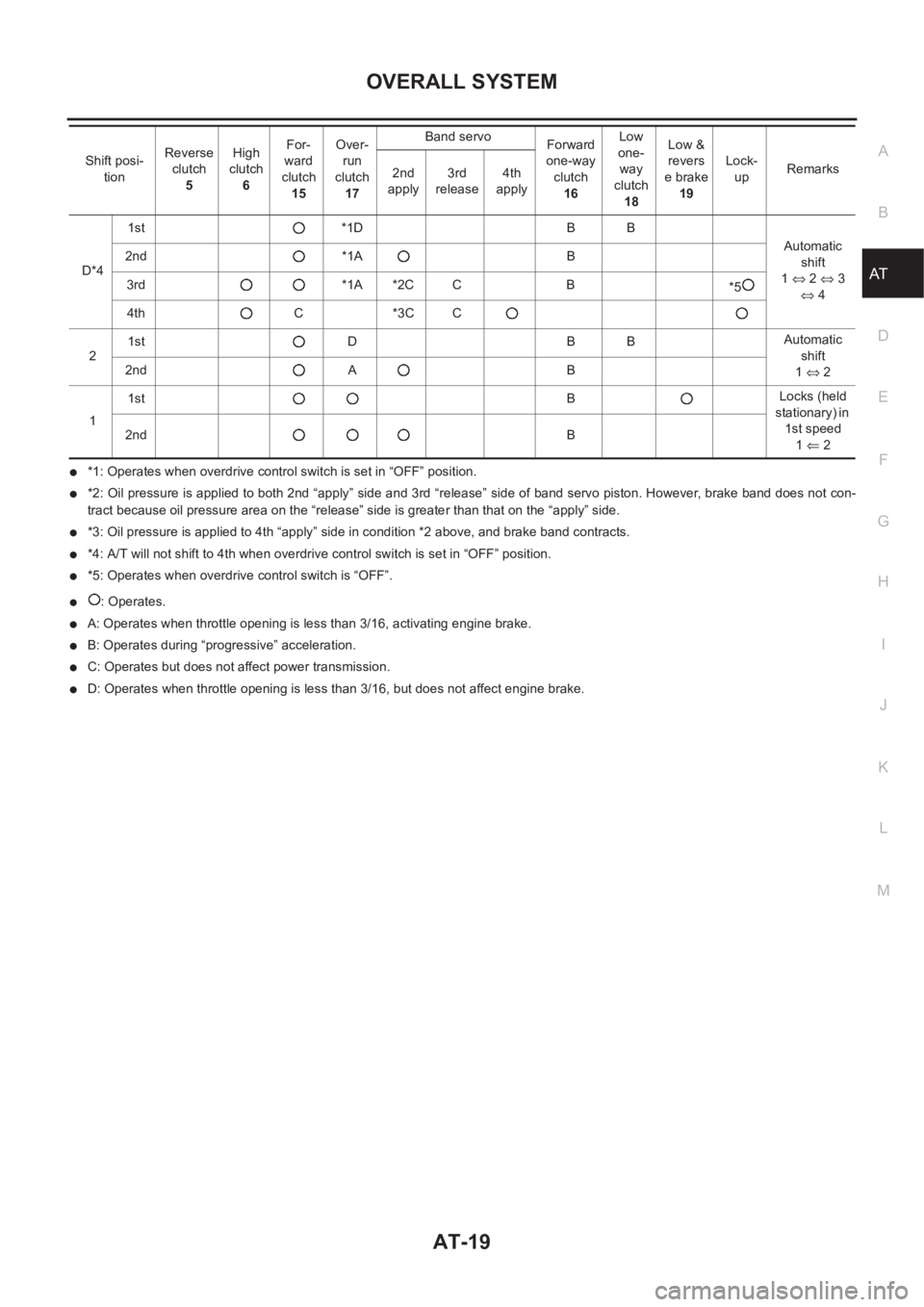

OVERALL SYSTEM

AT-19

D

E

F

G

H

I

J

K

L

MA

B

AT

●*1: Operates when overdrive control switch is set in “OFF” position.

●*2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not con-

tract because oil pressure area on the “release” side is greater than that on the “apply” side.

●*3: Oil pressure is applied to 4th “apply” side in condition *2 above, and brake band contracts.

●*4: A/T will not shift to 4th when overdrive control switch is set in “OFF” position.

●*5: Operates when overdrive control switch is “OFF”.

●: Operates.

●A: Operates when throttle opening is less than 3/16, activating engine brake.

●B: Operates during “progressive” acceleration.

●C: Operates but does not affect power transmission.

●D: Operates when throttle opening is less than 3/16, but does not affect engine brake. D*41st *1D B B

Automatic

shift

1⇔ 2 ⇔ 3

⇔ 4 2nd *1A B

3rd *1A *2C C B

*5

4th C *3C C

21st D B BAutomatic

shift

1⇔ 2 2nd A B

11stBLocks (held

stationary) in

1st speed

1⇐ 2 2ndB Shift posi-

tionReverse

clutch

5High

clutch

6For-

ward

clutch

15Over-

run

clutch

17Band servo

Forward

one-way

clutch

16Low

one-

way

clutch

18Low &

revers

e brake

19Lock-

upRemarks

2nd

apply3rd

release4th

apply

Page 1478 of 3189

AT-22

OVERALL SYSTEM

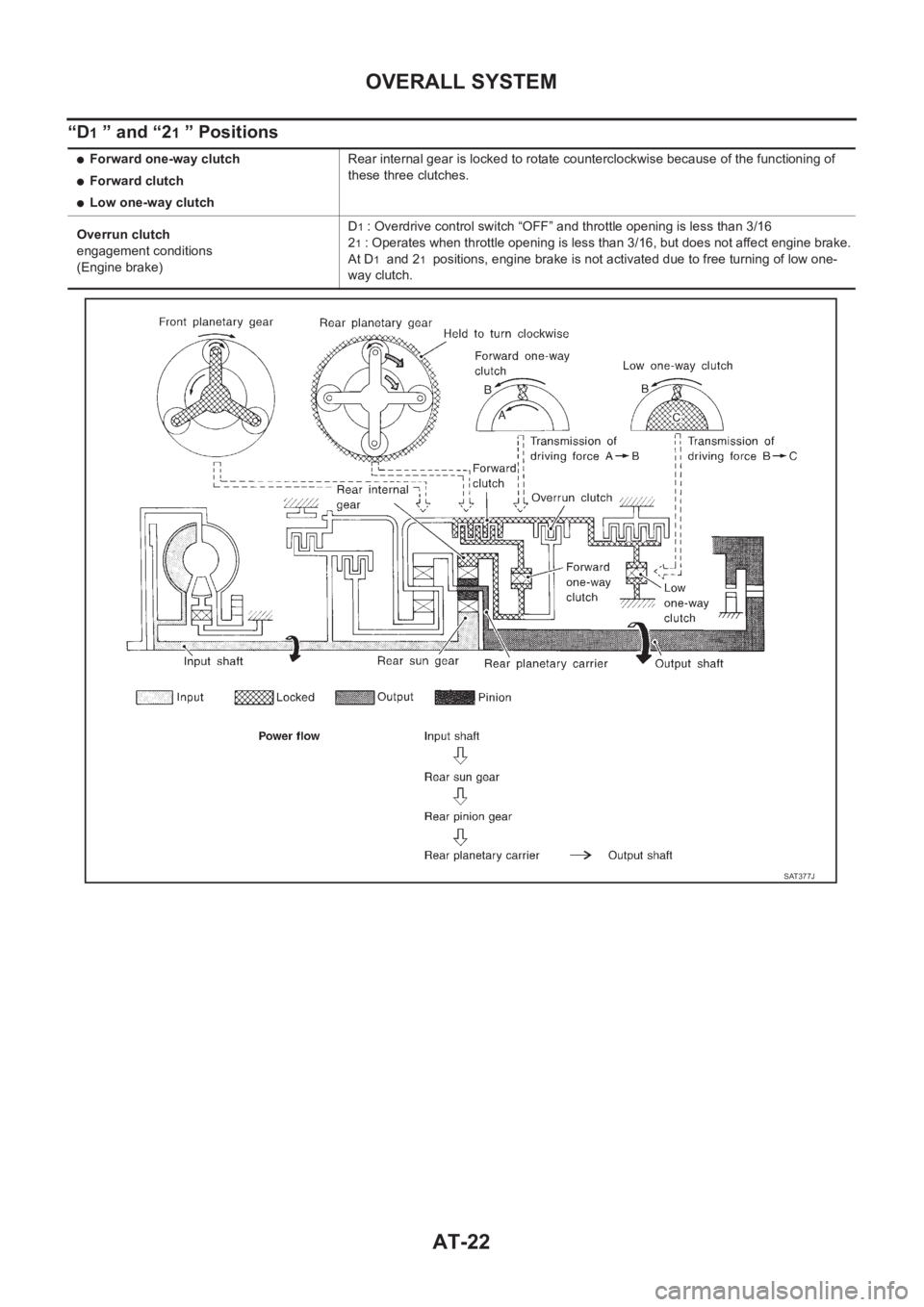

“D1 ” and “21 ” Positions

●Forward one-way clutch

●Forward clutch

●Low one-way clutchRear internal gear is locked to rotate counterclockwise because of the functioning of

these three clutches.

Overrun clutch

engagement conditions

(Engine brake)D

1 : Overdrive control switch “OFF” and throttle opening is less than 3/16

2

1 : Operates when throttle opening is less than 3/16, but does not affect engine brake.

At D

1 and 21 positions, engine brake is not activated due to free turning of low one-

way clutch.

SAT377J

Page 1479 of 3189

OVERALL SYSTEM

AT-23

D

E

F

G

H

I

J

K

L

MA

B

AT

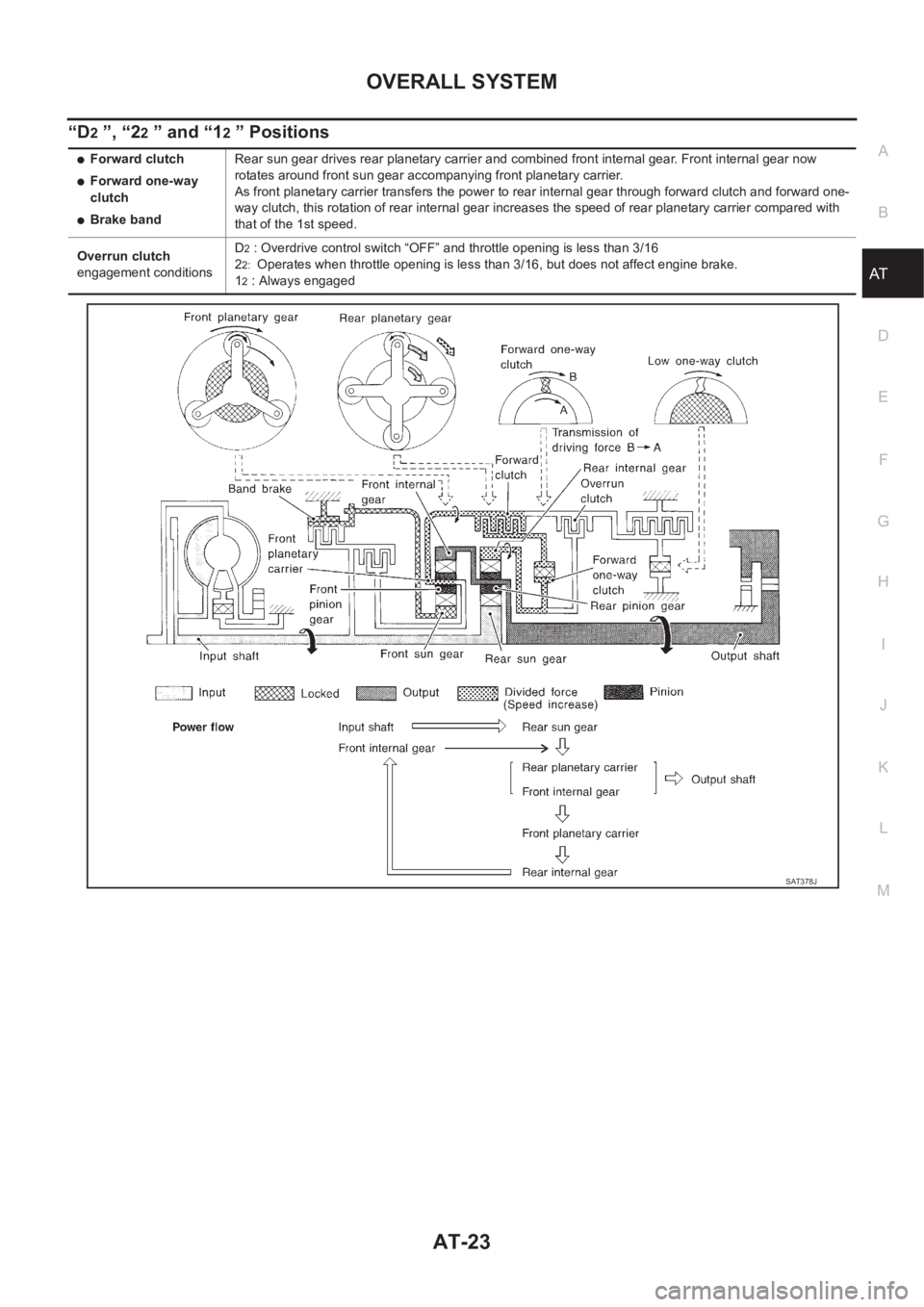

“D2 ”, “22 ” and “12 ” Positions

●Forward clutch

●Forward one-way

clutch

●Brake bandRear sun gear drives rear planetary carrier and combined front internal gear. Front internal gear now

rotates around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch and forward one-

way clutch, this rotation of rear internal gear increases the speed of rear planetary carrier compared with

that of the 1st speed.

Overrun clutch

engagement conditionsD

2 : Overdrive control switch “OFF” and throttle opening is less than 3/16

2

2: Operates when throttle opening is less than 3/16, but does not affect engine brake.

1

2 : Always engaged

SAT378J

Page 1480 of 3189

AT-24

OVERALL SYSTEM

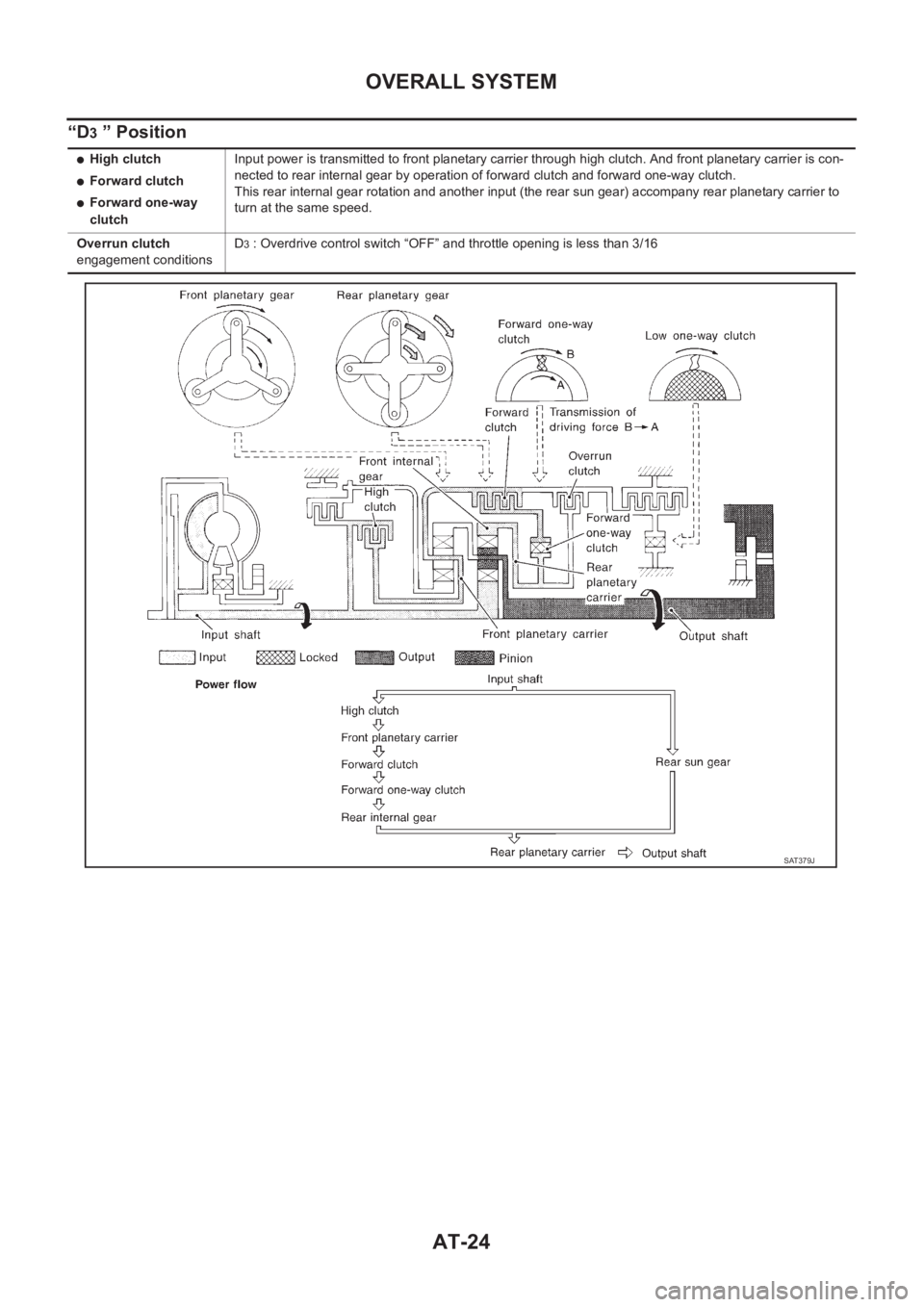

“D3 ” Position

●High clutch

●Forward clutch

●Forward one-way

clutchInput power is transmitted to front planetary carrier through high clutch. And front planetary carrier is con-

nected to rear internal gear by operation of forward clutch and forward one-way clutch.

This rear internal gear rotation and another input (the rear sun gear) accompany rear planetary carrier to

turn at the same speed.

Overrun clutch

engagement conditionsD

3 : Overdrive control switch “OFF” and throttle opening is less than 3/16

SAT379J

Page 1483 of 3189

OVERALL SYSTEM

AT-27

D

E

F

G

H

I

J

K

L

MA

B

AT

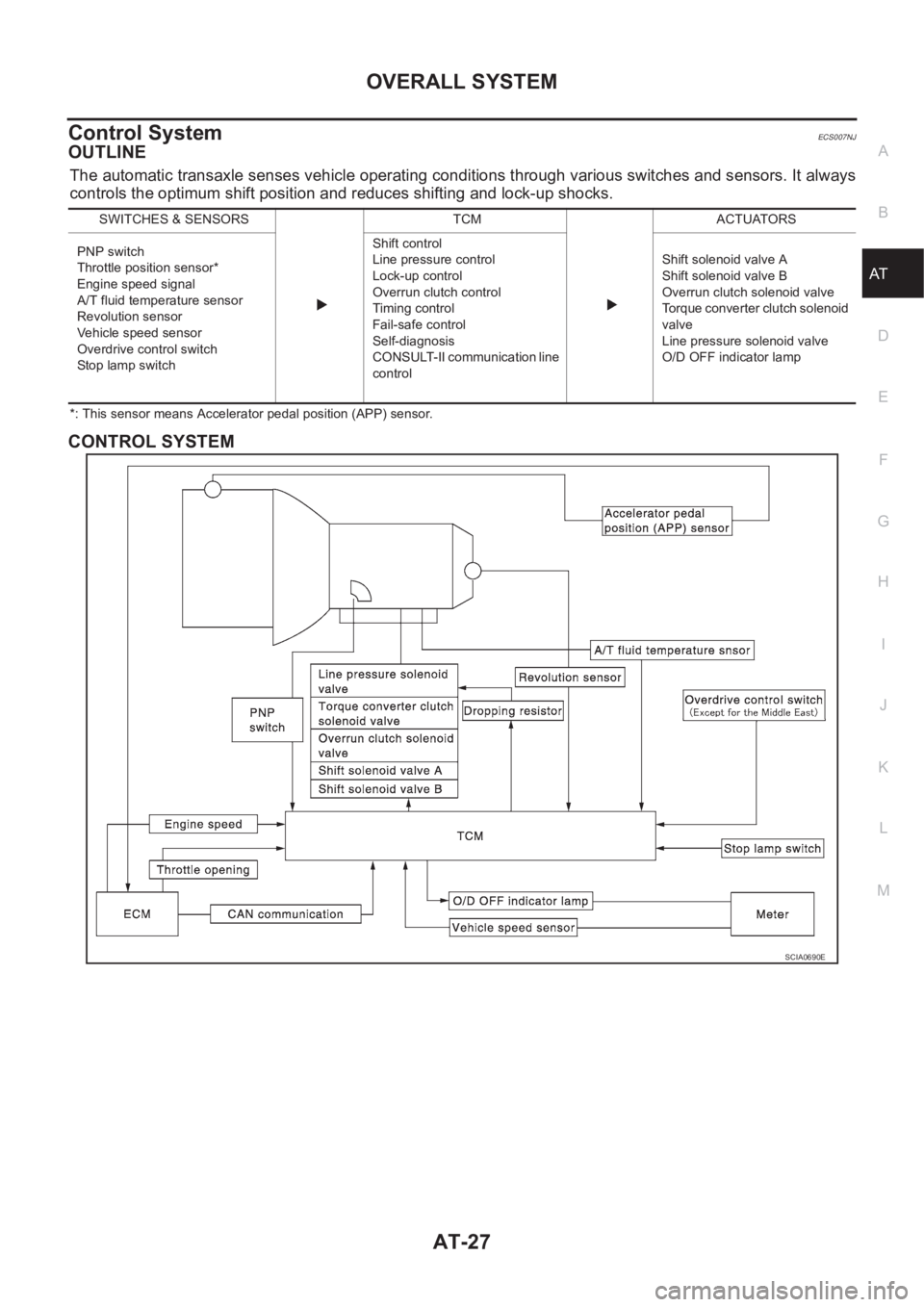

Control SystemECS007NJ

OUTLINE

The automatic transaxle senses vehicle operating conditions through various switches and sensors. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

*: This sensor means Accelerator pedal position (APP) sensor.

CONTROL SYSTEM

SWITCHES & SENSORS TCM ACTUATORS

PNP switch

Throttle position sensor*

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed sensor

Overdrive control switch

Stop lamp switchShift control

Line pressure control

Lock-up control

Overrun clutch control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

controlShift solenoid valve A

Shift solenoid valve B

Overrun clutch solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

O/D OFF indicator lamp

SCIA0690E

Page 1484 of 3189

AT-28

OVERALL SYSTEM

TCM FUNCTION

The function of the TCM is to:

●Receive input signals sent from various switches and sensors.

●Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

●Send required output signals to the respective solenoid valves.

INPUT/OUTPUT SIGNAL OF TCM

Control MechanismECS007NK

LINE PRESSURE CONTROL

TCM has various line pressure control characteristics to match the driving conditions.

An ON-OFF duty signal is sent to the line pressure solenoid valve based on TCM characteristics.

Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid valve

to accommodate engine torque. This results in smooth shift operation.

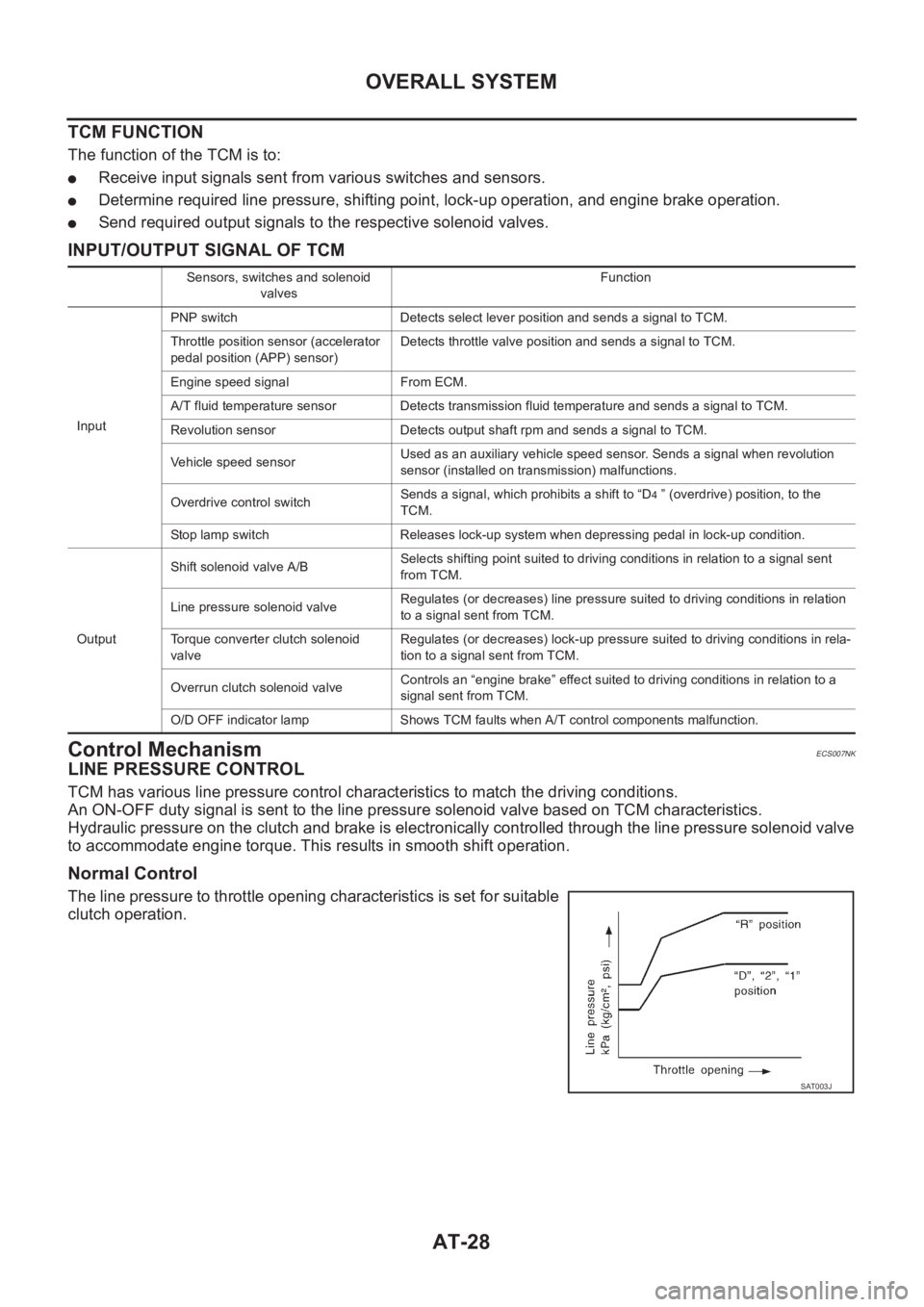

Normal Control

The line pressure to throttle opening characteristics is set for suitable

clutch operation.

Sensors, switches and solenoid

valvesFunction

InputPNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor (accelerator

pedal position (APP) sensor)Detects throttle valve position and sends a signal to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensorUsed as an auxiliary vehicle speed sensor. Sends a signal when revolution

sensor (installed on transmission) malfunctions.

Overdrive control switchSends a signal, which prohibits a shift to “D

4 ” (overdrive) position, to the

TCM.

Stop lamp switch Releases lock-up system when depressing pedal in lock-up condition.

OutputShift solenoid valve A/BSelects shifting point suited to driving conditions in relation to a signal sent

from TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in relation

to a signal sent from TCM.

Torque converter clutch solenoid

valveRegulates (or decreases) lock-up pressure suited to driving conditions in rela-

tion to a signal sent from TCM.

Overrun clutch solenoid valveControls an “engine brake” effect suited to driving conditions in relation to a

signal sent from TCM.

O/D OFF indicator lamp Shows TCM faults when A/T control components malfunction.

SAT003J