NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1091 of 3051

DescriptionNLEC1748The specification (SP) value indicates the tolerance of the value that is displayed in ªDATA MONITOR (SPEC)º

mode of CONSULT-II during normal operation of the Engine Control System. When the value in ªDATA MONI-

TOR (SPEC)º mode is within the SP value, the Engine Control System is confirmed OK. When the value in

ªDATA MONITOR (SPEC)º mode is NOT within the SP value, the Engine Control System may have one or

more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

+B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board cor-

rection)

+A/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

+MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionNLEC1749+Vehicle driven distance: More than 5,000 km (3,107 miles)

+Barometric pressure: 98.3 - 104.3 kPa (0.983 - 1.043 bar, 1.003 - 1.064 kg/cm2, 14.25 - 15.12 psi)

+Atmospheric temperature: 20 - 30ÉC (68 - 86ÉF)

+Engine coolant temperature: 75 - 95ÉC (167 - 203ÉF)

+Transmission: Warmed-up*1

+Electrical load: Not applied*2

+Engine speed: Idle

*1: For after the engine is warmed up to normal operating temperature, drive vehicle until ªFLUID TEMP SEº

(CVT fluid temperature sensor signal) indicates less than 0.9V.

*2: Rear window defogger switch, air conditioner switch, lighting switch are ªOFFº. Cooling fans are not oper-

ating. Steering wheel is straight ahead.

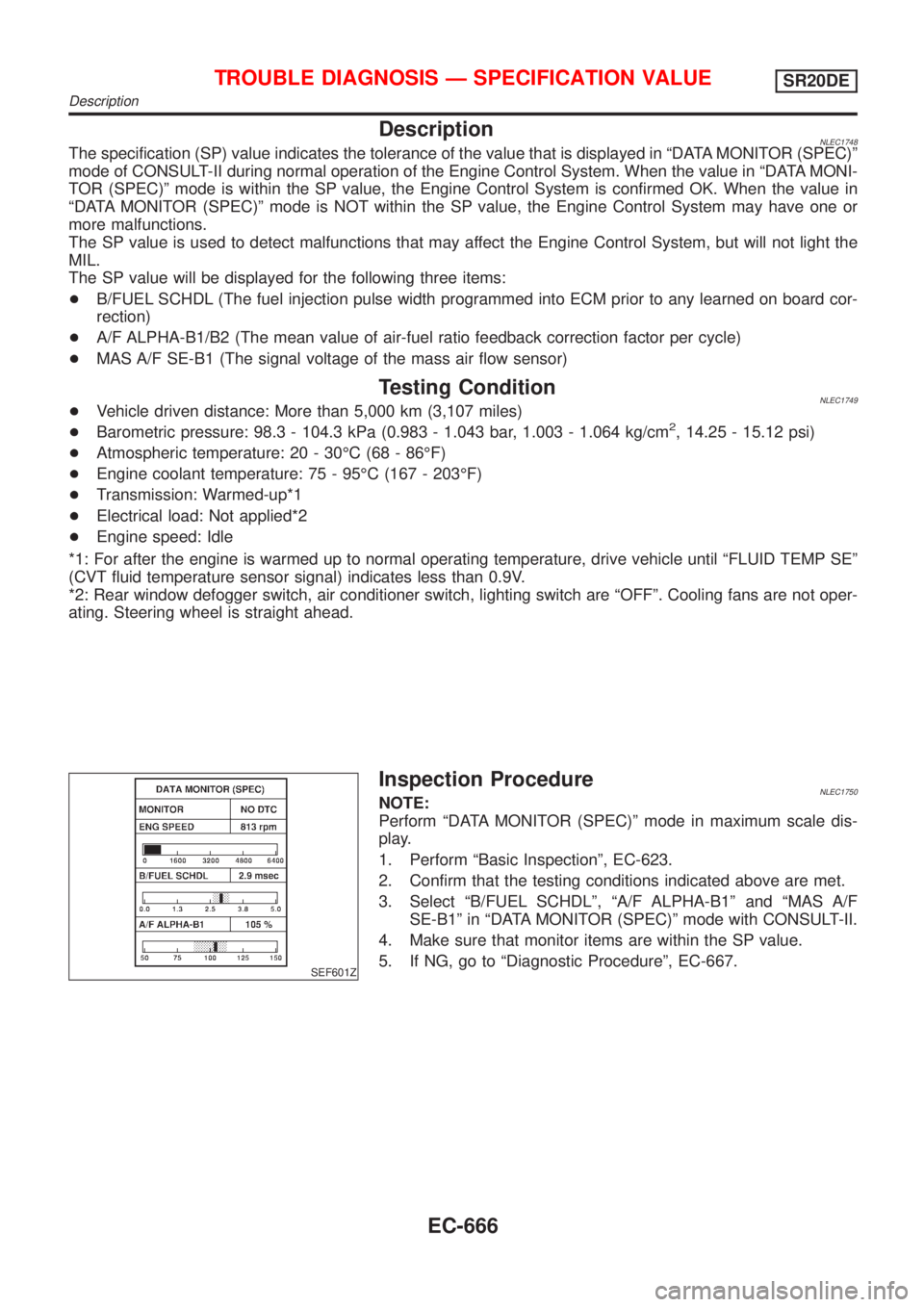

SEF601Z

Inspection ProcedureNLEC1750NOTE:

Perform ªDATA MONITOR (SPEC)º mode in maximum scale dis-

play.

1. Perform ªBasic Inspectionº, EC-623.

2. Confirm that the testing conditions indicated above are met.

3. Select ªB/FUEL SCHDLº, ªA/F ALPHA-B1º and ªMAS A/F

SE-B1º in ªDATA MONITOR (SPEC)º mode with CONSULT-II.

4. Make sure that monitor items are within the SP value.

5. If NG, go to ªDiagnostic Procedureº, EC-667.

TROUBLE DIAGNOSIS Ð SPECIFICATION VALUESR20DE

Description

EC-666

Page 1092 of 3051

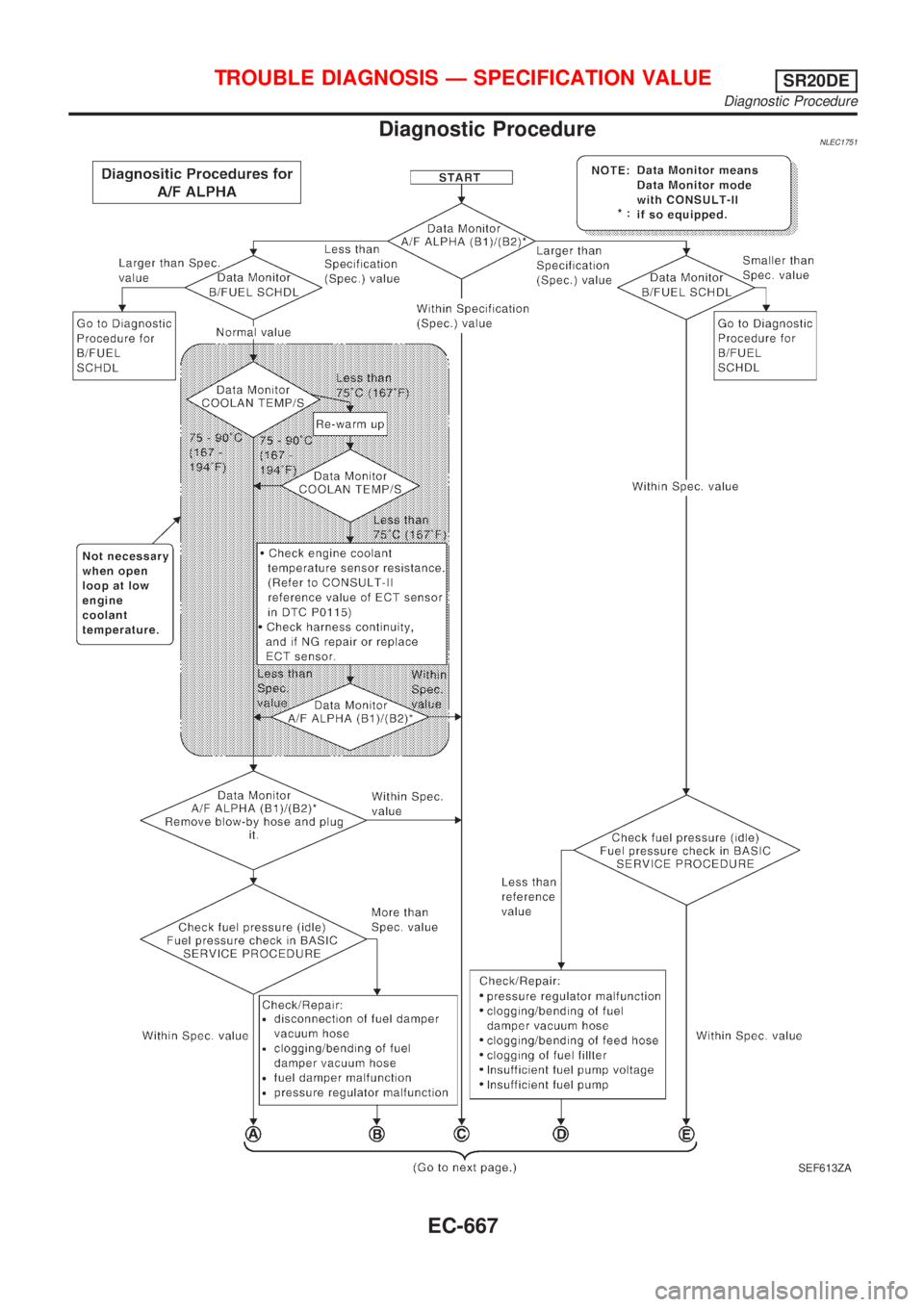

Diagnostic ProcedureNLEC1751

SEF613ZA

TROUBLE DIAGNOSIS Ð SPECIFICATION VALUESR20DE

Diagnostic Procedure

EC-667

Page 1093 of 3051

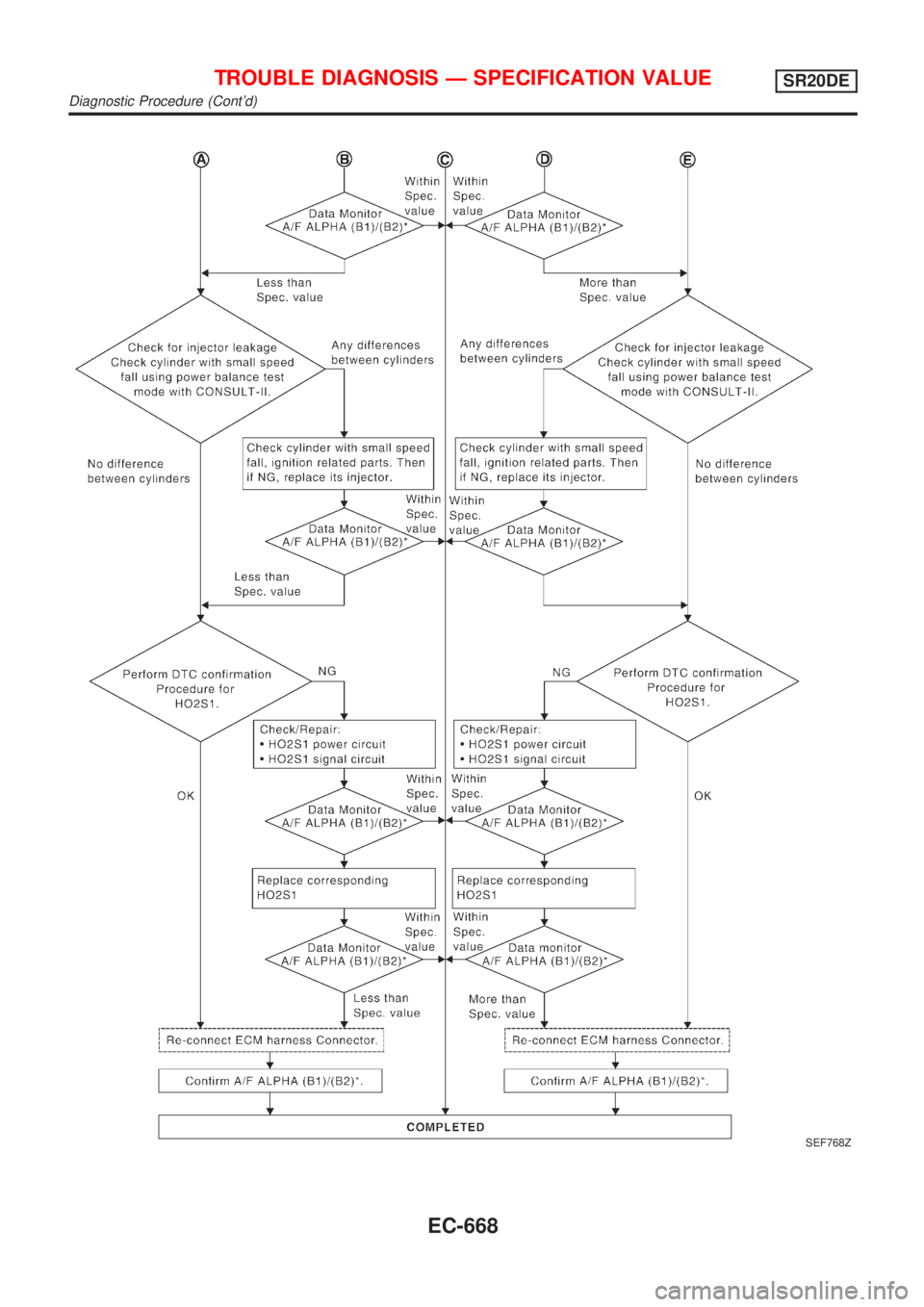

SEF768Z

TROUBLE DIAGNOSIS Ð SPECIFICATION VALUESR20DE

Diagnostic Procedure (Cont'd)

EC-668

Page 1094 of 3051

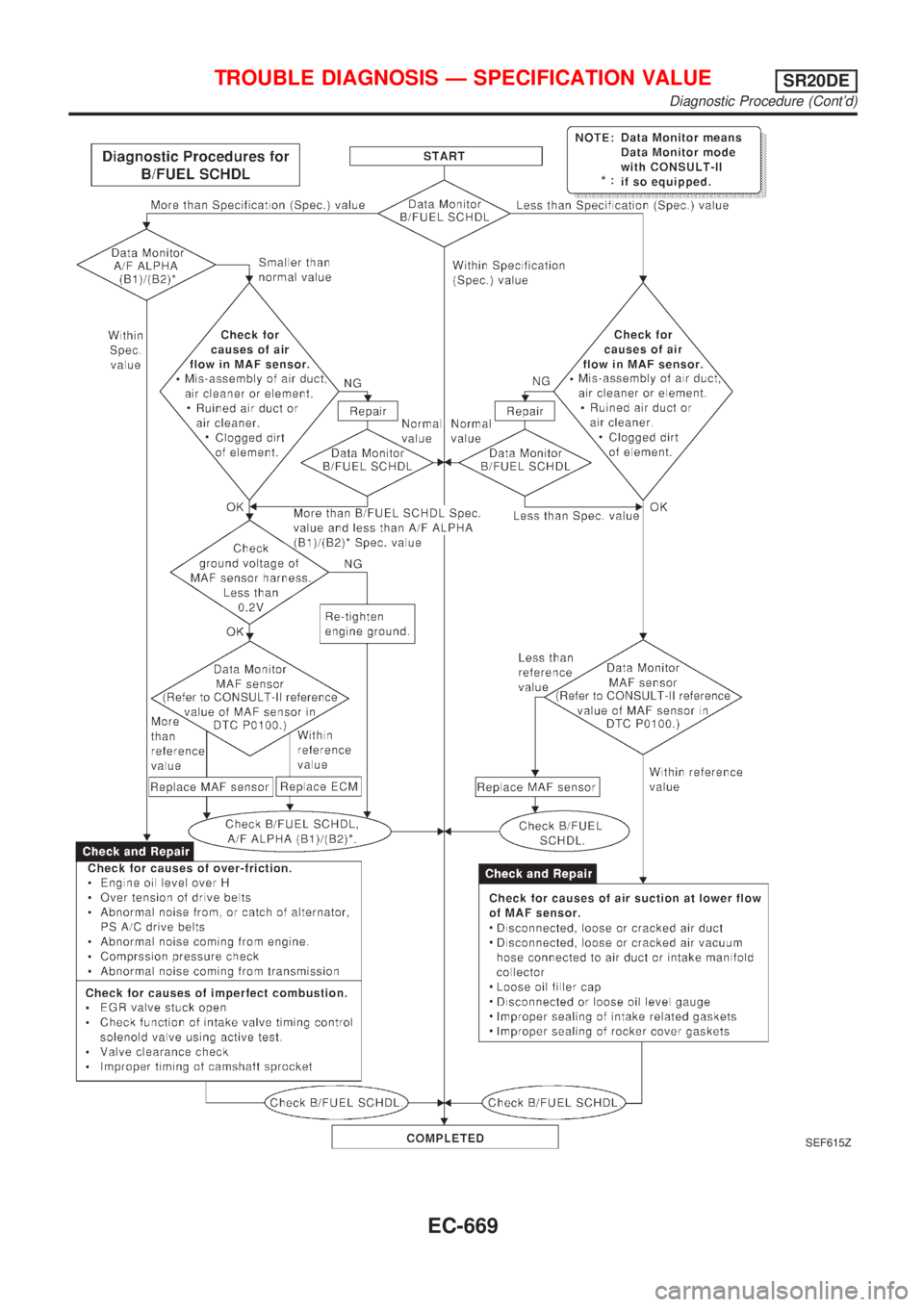

SEF615Z

TROUBLE DIAGNOSIS Ð SPECIFICATION VALUESR20DE

Diagnostic Procedure (Cont'd)

EC-669

Page 1095 of 3051

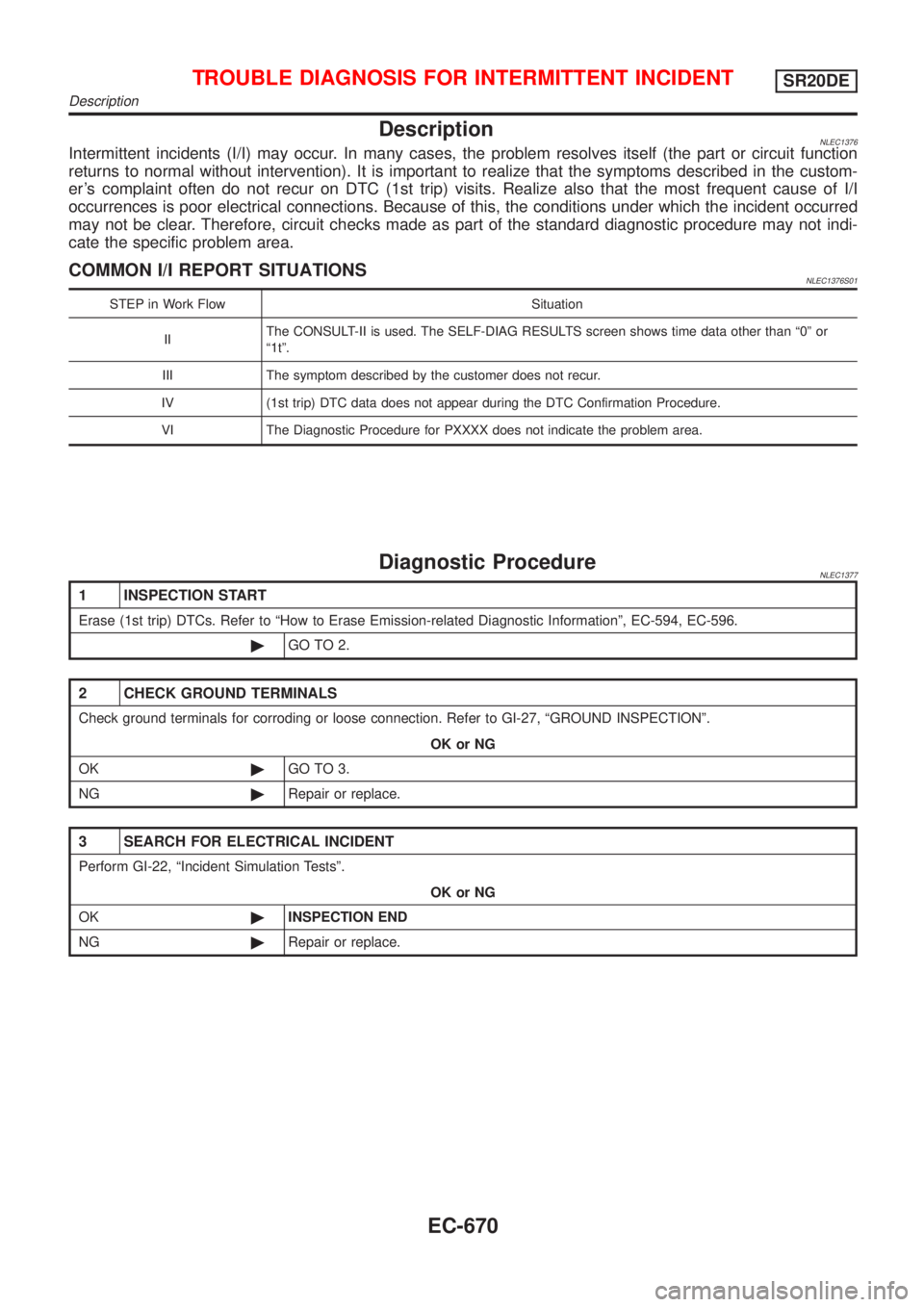

DescriptionNLEC1376Intermittent incidents (I/I) may occur. In many cases, the problem resolves itself (the part or circuit function

returns to normal without intervention). It is important to realize that the symptoms described in the custom-

er's complaint often do not recur on DTC (1st trip) visits. Realize also that the most frequent cause of I/I

occurrences is poor electrical connections. Because of this, the conditions under which the incident occurred

may not be clear. Therefore, circuit checks made as part of the standard diagnostic procedure may not indi-

cate the specific problem area.

COMMON I/I REPORT SITUATIONSNLEC1376S01

STEP in Work Flow Situation

IIThe CONSULT-II is used. The SELF-DIAG RESULTS screen shows time data other than ª0º or

ª1tº.

III The symptom described by the customer does not recur.

IV (1st trip) DTC data does not appear during the DTC Confirmation Procedure.

VI The Diagnostic Procedure for PXXXX does not indicate the problem area.

Diagnostic ProcedureNLEC1377

1 INSPECTION START

Erase (1st trip) DTCs. Refer to ªHow to Erase Emission-related Diagnostic Informationº, EC-594, EC-596.

©GO TO 2.

2 CHECK GROUND TERMINALS

Check ground terminals for corroding or loose connection. Refer to GI-27, ªGROUND INSPECTIONº.

OK or NG

OK©GO TO 3.

NG©Repair or replace.

3 SEARCH FOR ELECTRICAL INCIDENT

Perform GI-22, ªIncident Simulation Testsº.

OK or NG

OK©INSPECTION END

NG©Repair or replace.

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTSR20DE

Description

EC-670

Page 1096 of 3051

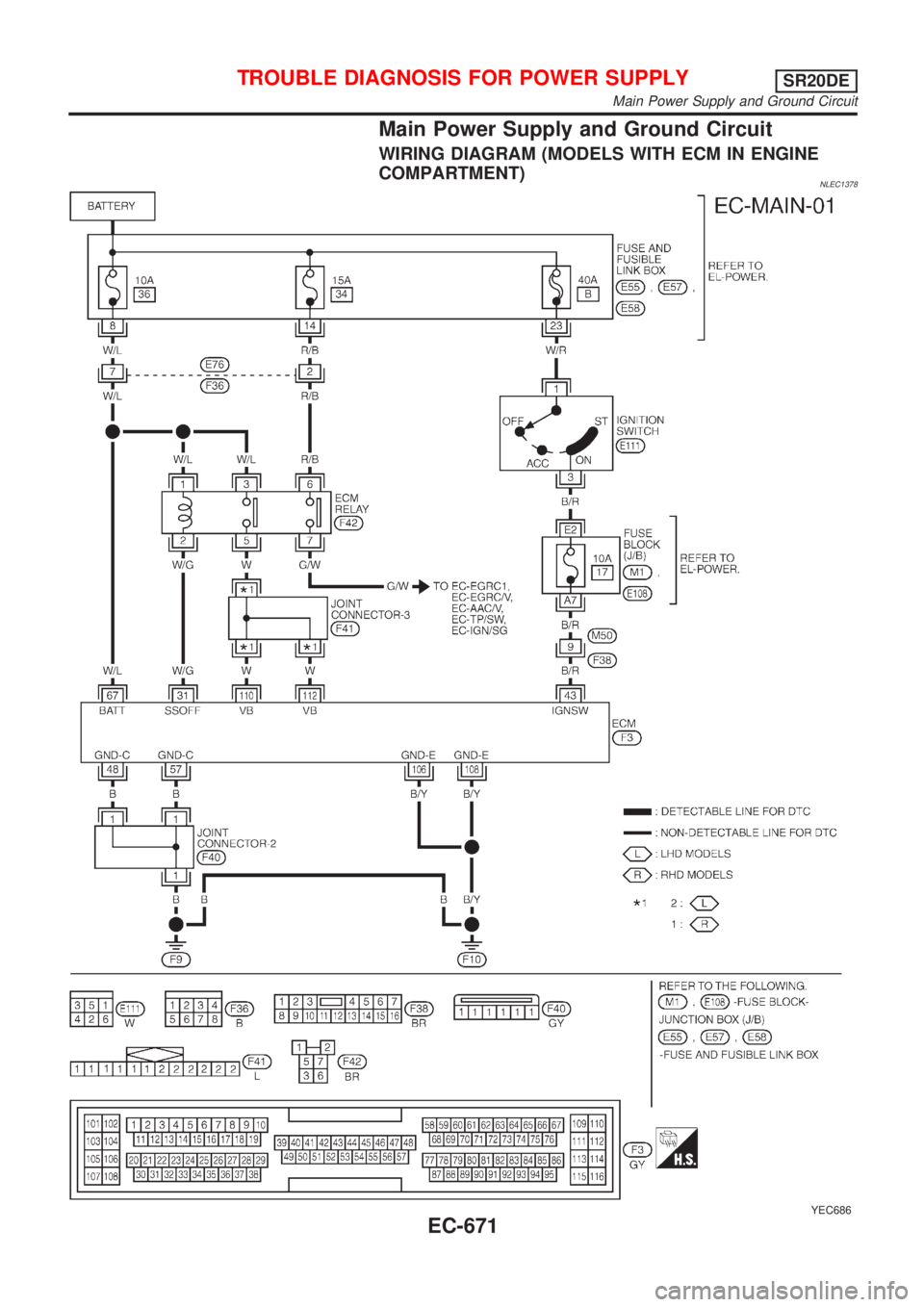

Main Power Supply and Ground Circuit

WIRING DIAGRAM (MODELS WITH ECM IN ENGINE

COMPARTMENT)

NLEC1378

YEC686

TROUBLE DIAGNOSIS FOR POWER SUPPLYSR20DE

Main Power Supply and Ground Circuit

EC-671

Page 1097 of 3051

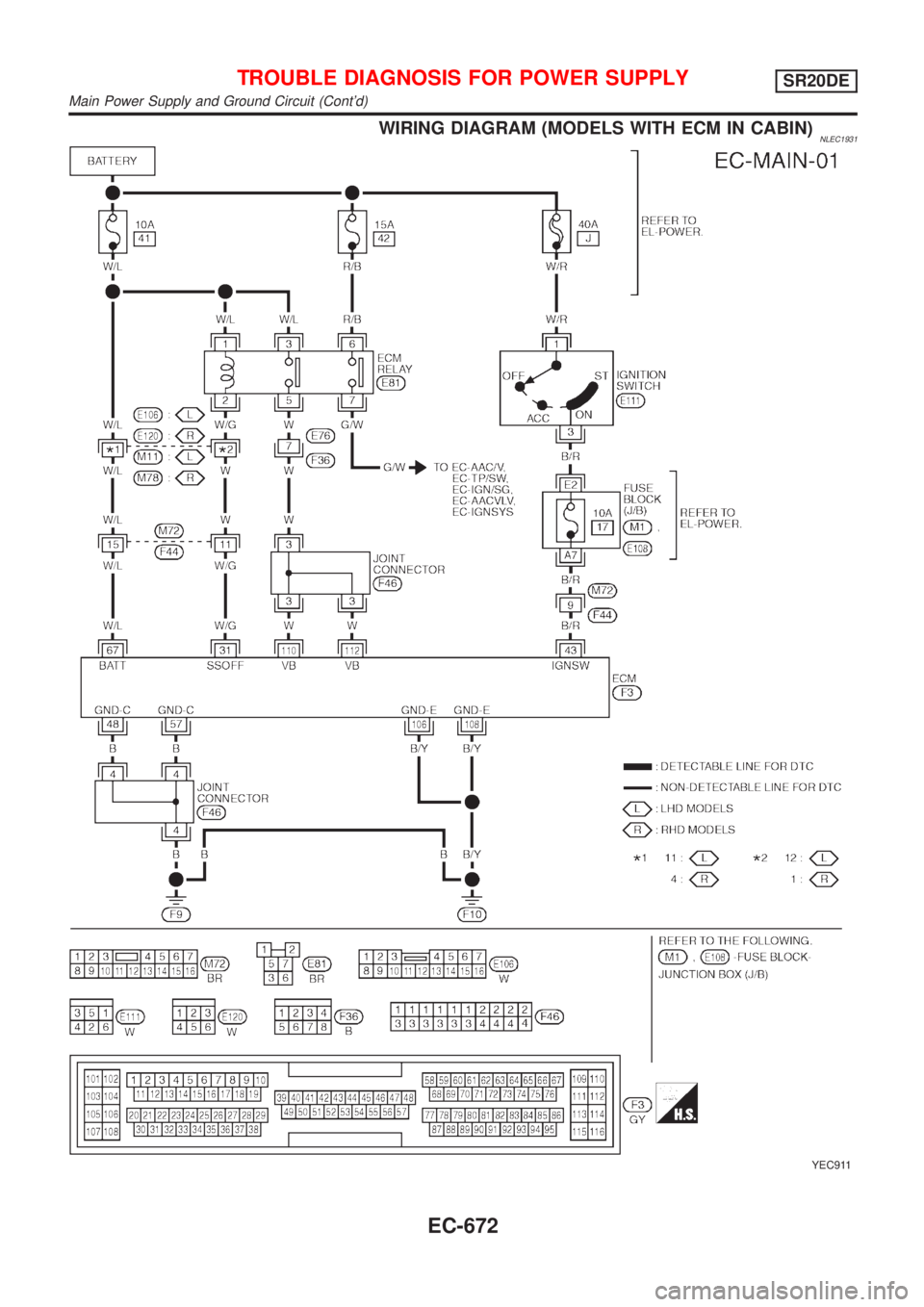

WIRING DIAGRAM (MODELS WITH ECM IN CABIN)NLEC1931

YEC911

TROUBLE DIAGNOSIS FOR POWER SUPPLYSR20DE

Main Power Supply and Ground Circuit (Cont'd)

EC-672

Page 1098 of 3051

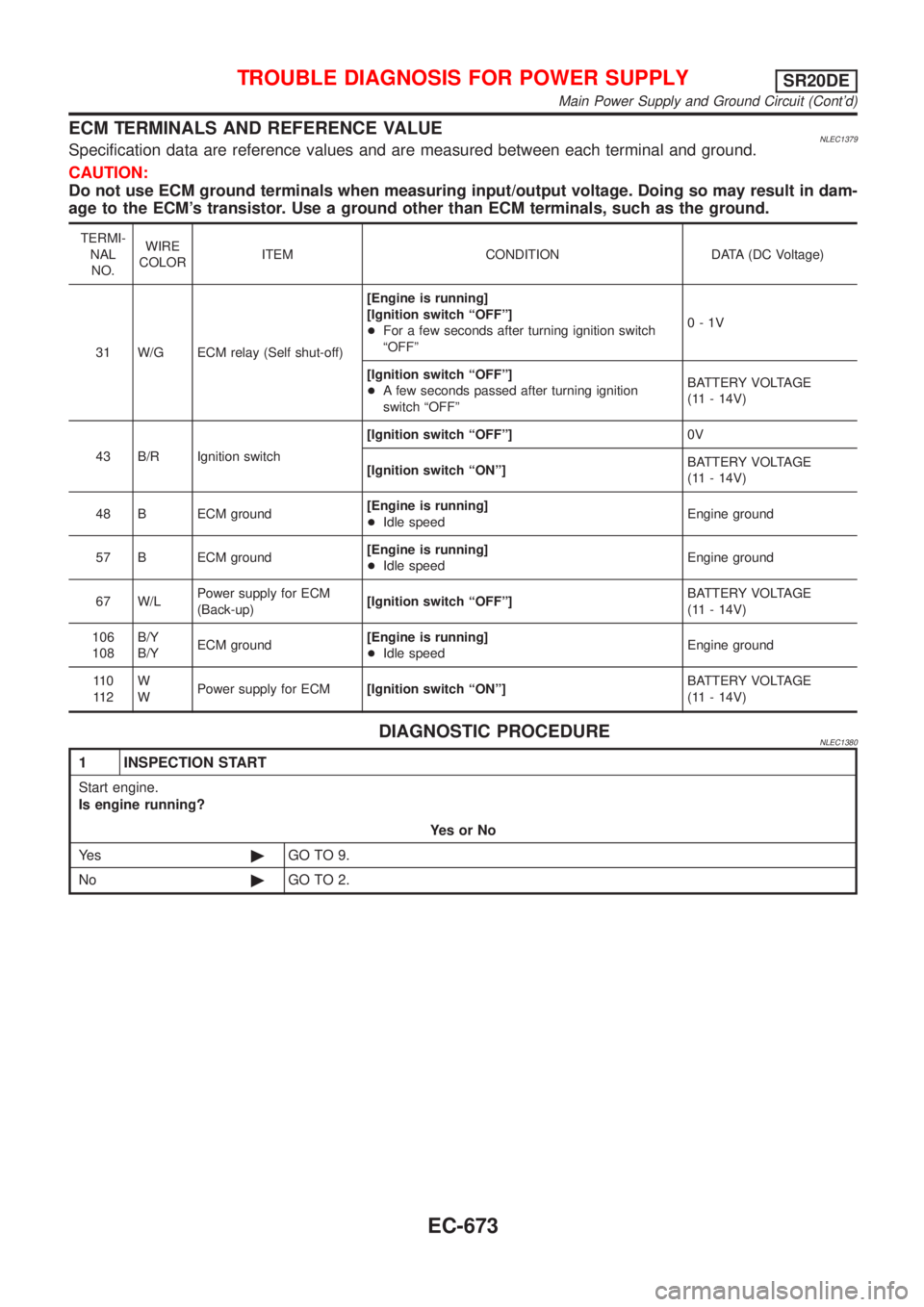

ECM TERMINALS AND REFERENCE VALUENLEC1379Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

31 W/G ECM relay (Self shut-off)[Engine is running]

[Ignition switch ªOFFº]

+For a few seconds after turning ignition switch

ªOFFº0-1V

[Ignition switch ªOFFº]

+A few seconds passed after turning ignition

switch ªOFFºBATTERY VOLTAGE

(11 - 14V)

43 B/R Ignition switch[Ignition switch ªOFFº]0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

48 B ECM ground[Engine is running]

+Idle speedEngine ground

57 B ECM ground[Engine is running]

+Idle speedEngine ground

67 W/LPower supply for ECM

(Back-up)[Ignition switch ªOFFº]BATTERY VOLTAGE

(11 - 14V)

106

108B/Y

B/YECM ground[Engine is running]

+Idle speedEngine ground

11 0

11 2W

WPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

DIAGNOSTIC PROCEDURENLEC1380

1 INSPECTION START

Start engine.

Is engine running?

YesorNo

Ye s©GO TO 9.

No©GO TO 2.

TROUBLE DIAGNOSIS FOR POWER SUPPLYSR20DE

Main Power Supply and Ground Circuit (Cont'd)

EC-673

Page 1099 of 3051

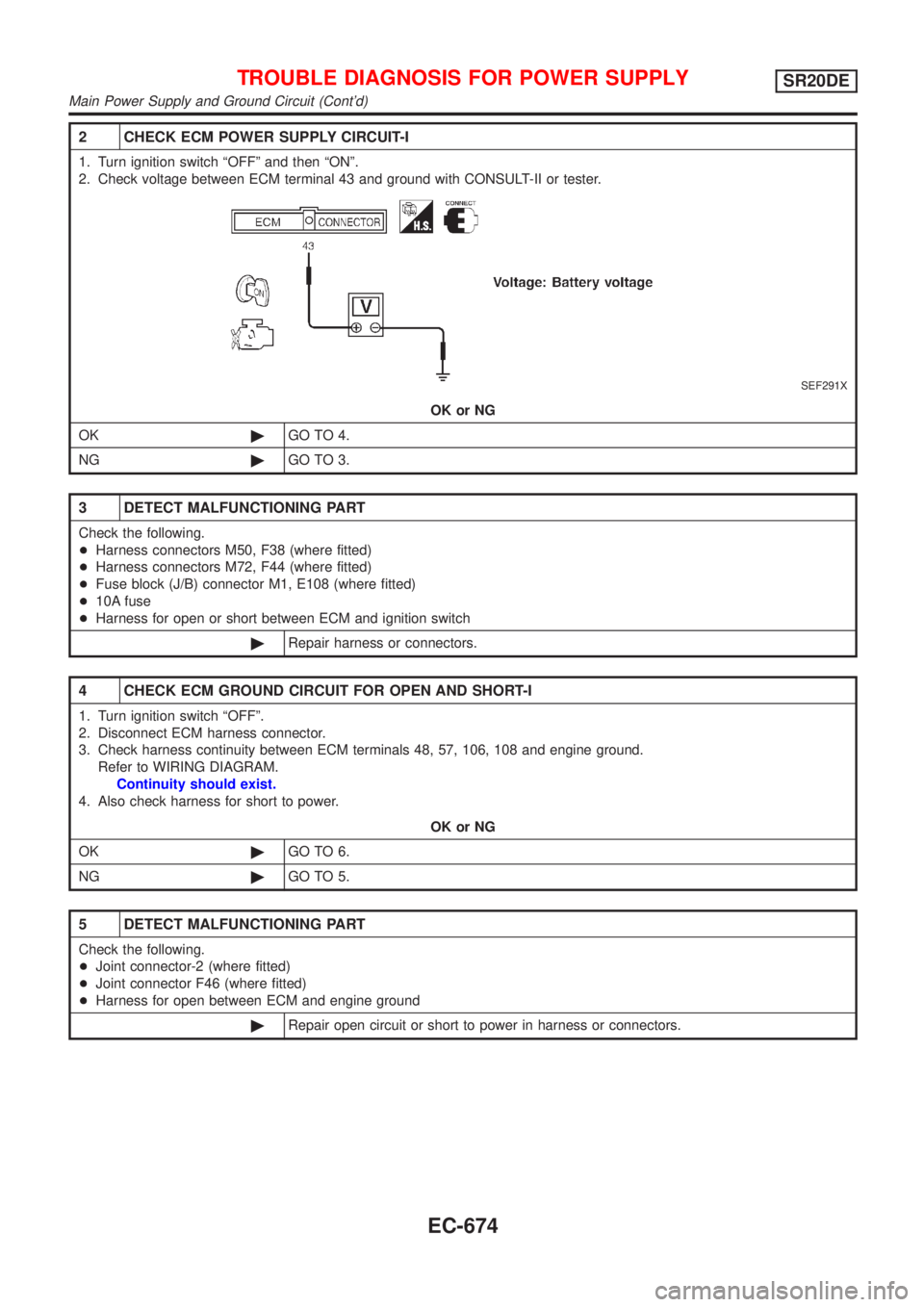

2 CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between ECM terminal 43 and ground with CONSULT-II or tester.

SEF291X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F38 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Fuse block (J/B) connector M1, E108 (where fitted)

+10A fuse

+Harness for open or short between ECM and ignition switch

©Repair harness or connectors.

4 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-2 (where fitted)

+Joint connector F46 (where fitted)

+Harness for open between ECM and engine ground

©Repair open circuit or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYSR20DE

Main Power Supply and Ground Circuit (Cont'd)

EC-674

Page 1100 of 3051

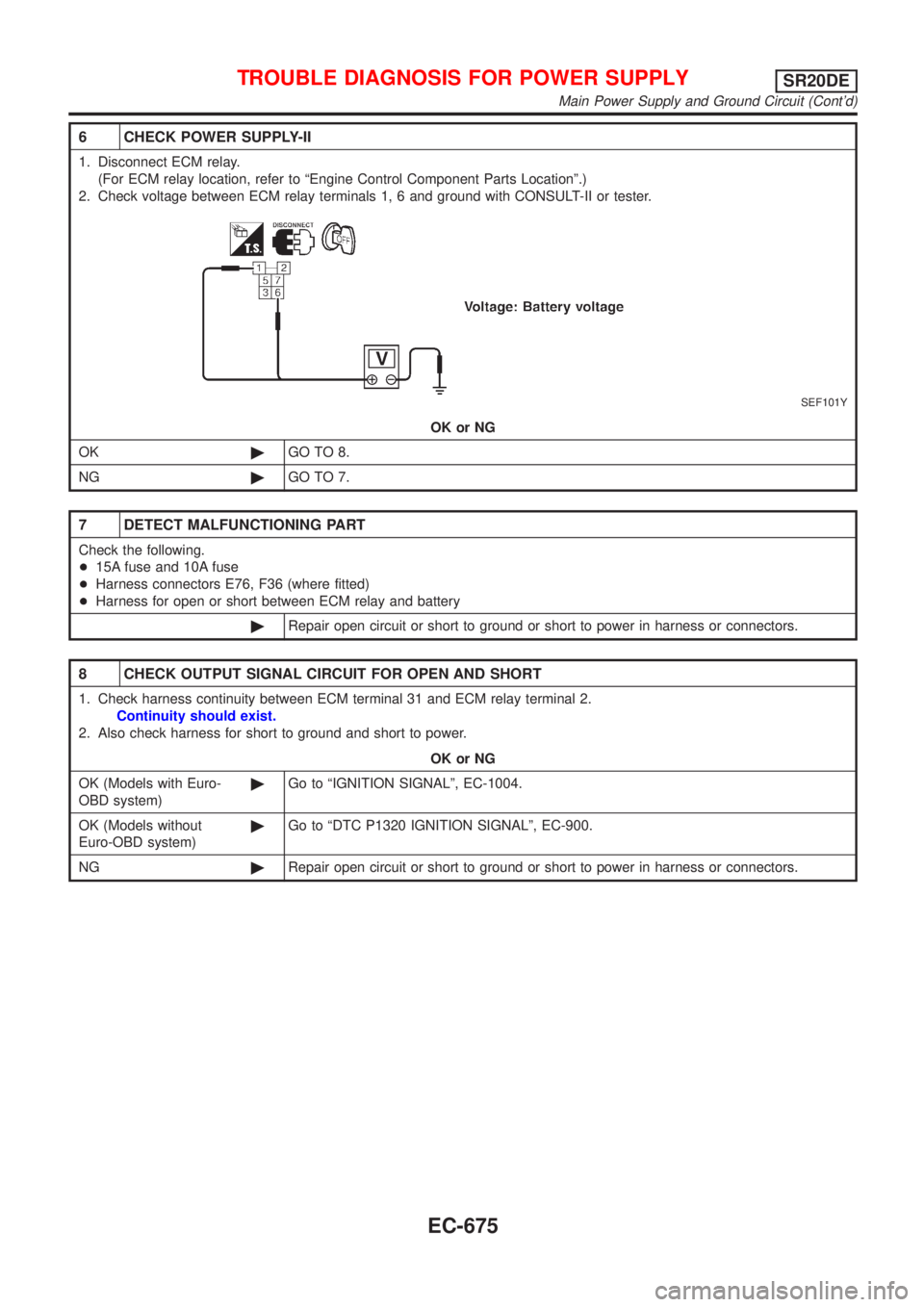

6 CHECK POWER SUPPLY-II

1. Disconnect ECM relay.

(For ECM relay location, refer to ªEngine Control Component Parts Locationº.)

2. Check voltage between ECM relay terminals 1, 6 and ground with CONSULT-II or tester.

SEF101Y

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+15A fuse and 10A fuse

+Harness connectors E76, F36 (where fitted)

+Harness for open or short between ECM relay and battery

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 31 and ECM relay terminal 2.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK (Models with Euro-

OBD system)©Go to ªIGNITION SIGNALº, EC-1004.

OK (Models without

Euro-OBD system)©Go to ªDTC P1320 IGNITION SIGNALº, EC-900.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYSR20DE

Main Power Supply and Ground Circuit (Cont'd)

EC-675