NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1051 of 3051

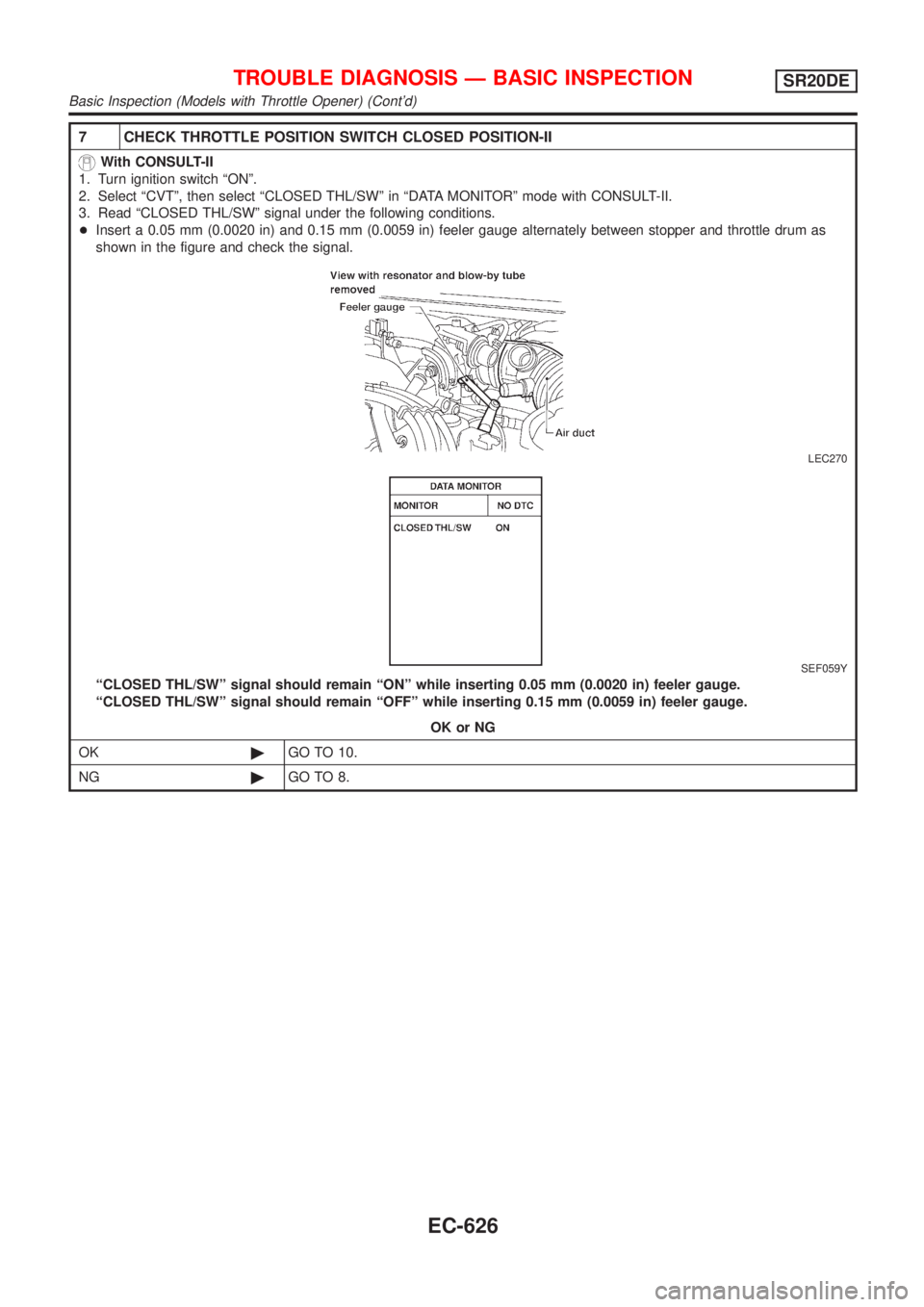

7 CHECK THROTTLE POSITION SWITCH CLOSED POSITION-II

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªCVTº, then select ªCLOSED THL/SWº in ªDATA MONITORº mode with CONSULT-II.

3. Read ªCLOSED THL/SWº signal under the following conditions.

+Insert a 0.05 mm (0.0020 in) and 0.15 mm (0.0059 in) feeler gauge alternately between stopper and throttle drum as

shown in the figure and check the signal.

LEC270

SEF059Y

ªCLOSED THL/SWº signal should remain ªONº while inserting 0.05 mm (0.0020 in) feeler gauge.

ªCLOSED THL/SWº signal should remain ªOFFº while inserting 0.15 mm (0.0059 in) feeler gauge.

OK or NG

OK©GO TO 10.

NG©GO TO 8.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-626

Page 1052 of 3051

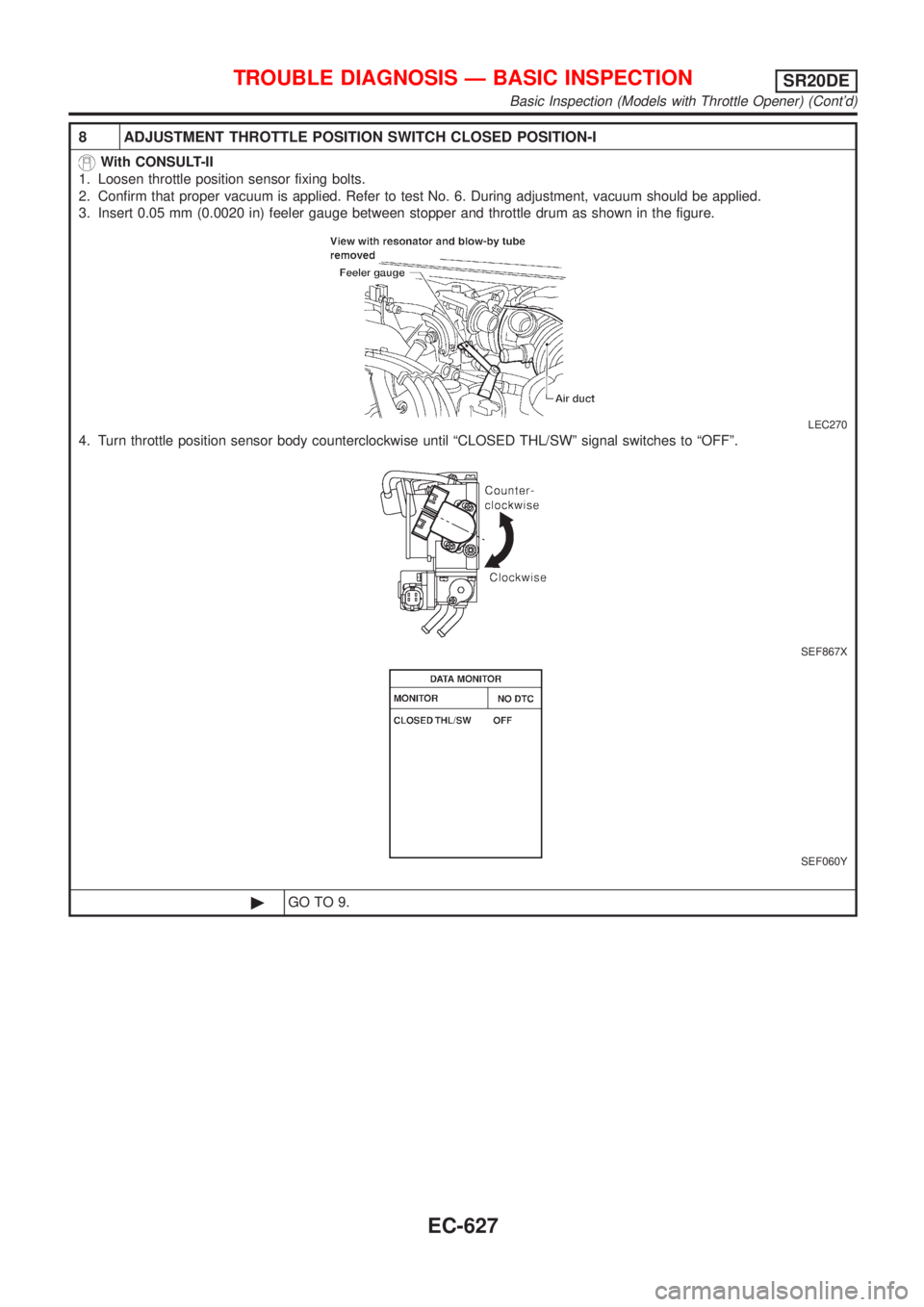

8 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-I

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Confirm that proper vacuum is applied. Refer to test No. 6. During adjustment, vacuum should be applied.

3. Insert 0.05 mm (0.0020 in) feeler gauge between stopper and throttle drum as shown in the figure.

LEC270

4. Turn throttle position sensor body counterclockwise until ªCLOSED THL/SWº signal switches to ªOFFº.

SEF867X

SEF060Y

©GO TO 9.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-627

Page 1053 of 3051

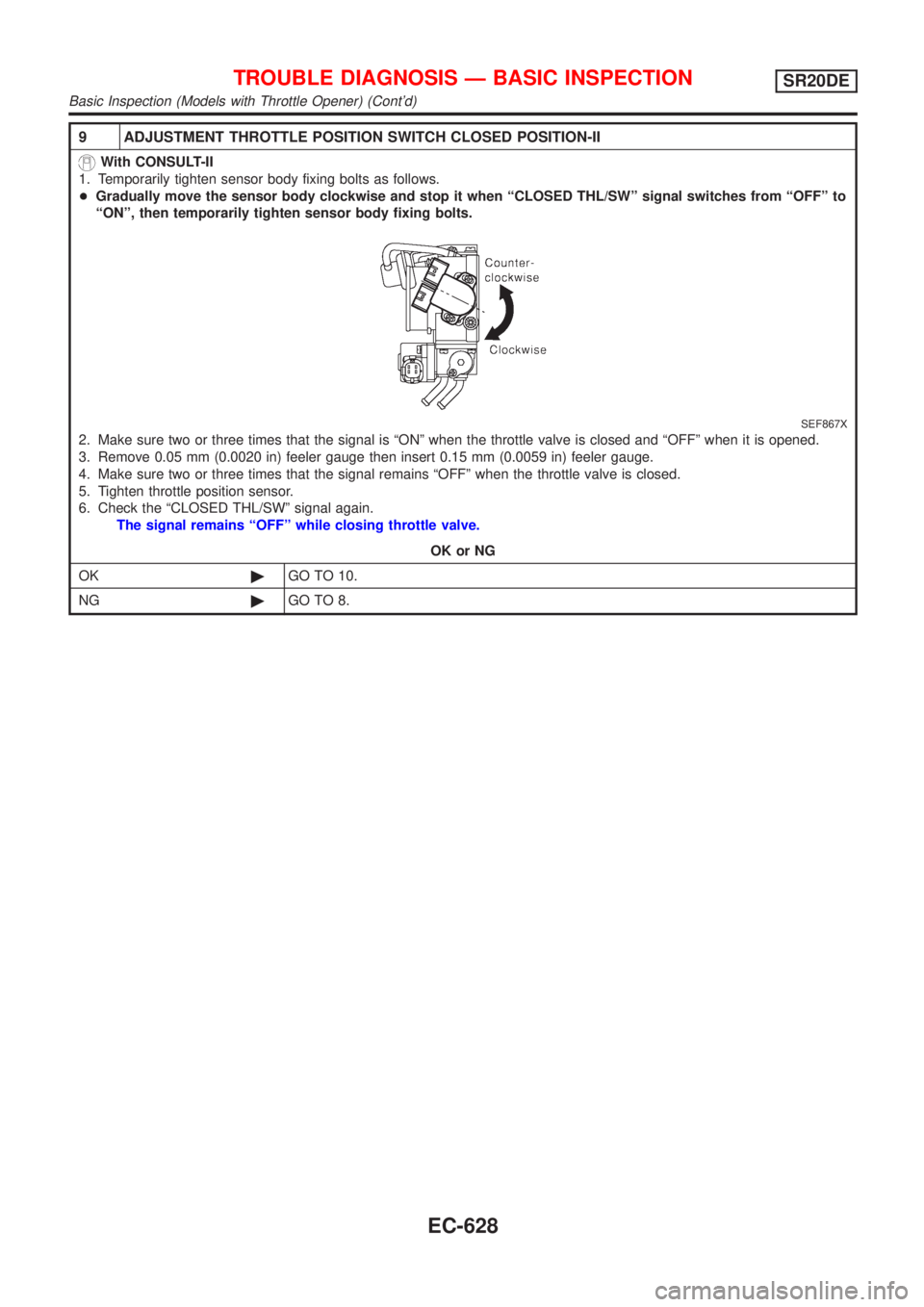

9 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-II

With CONSULT-II

1. Temporarily tighten sensor body fixing bolts as follows.

+Gradually move the sensor body clockwise and stop it when ªCLOSED THL/SWº signal switches from ªOFFº to

ªONº, then temporarily tighten sensor body fixing bolts.

SEF867X

2. Make sure two or three times that the signal is ªONº when the throttle valve is closed and ªOFFº when it is opened.

3. Remove 0.05 mm (0.0020 in) feeler gauge then insert 0.15 mm (0.0059 in) feeler gauge.

4. Make sure two or three times that the signal remains ªOFFº when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the ªCLOSED THL/SWº signal again.

The signal remains ªOFFº while closing throttle valve.

OK or NG

OK©GO TO 10.

NG©GO TO 8.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-628

Page 1054 of 3051

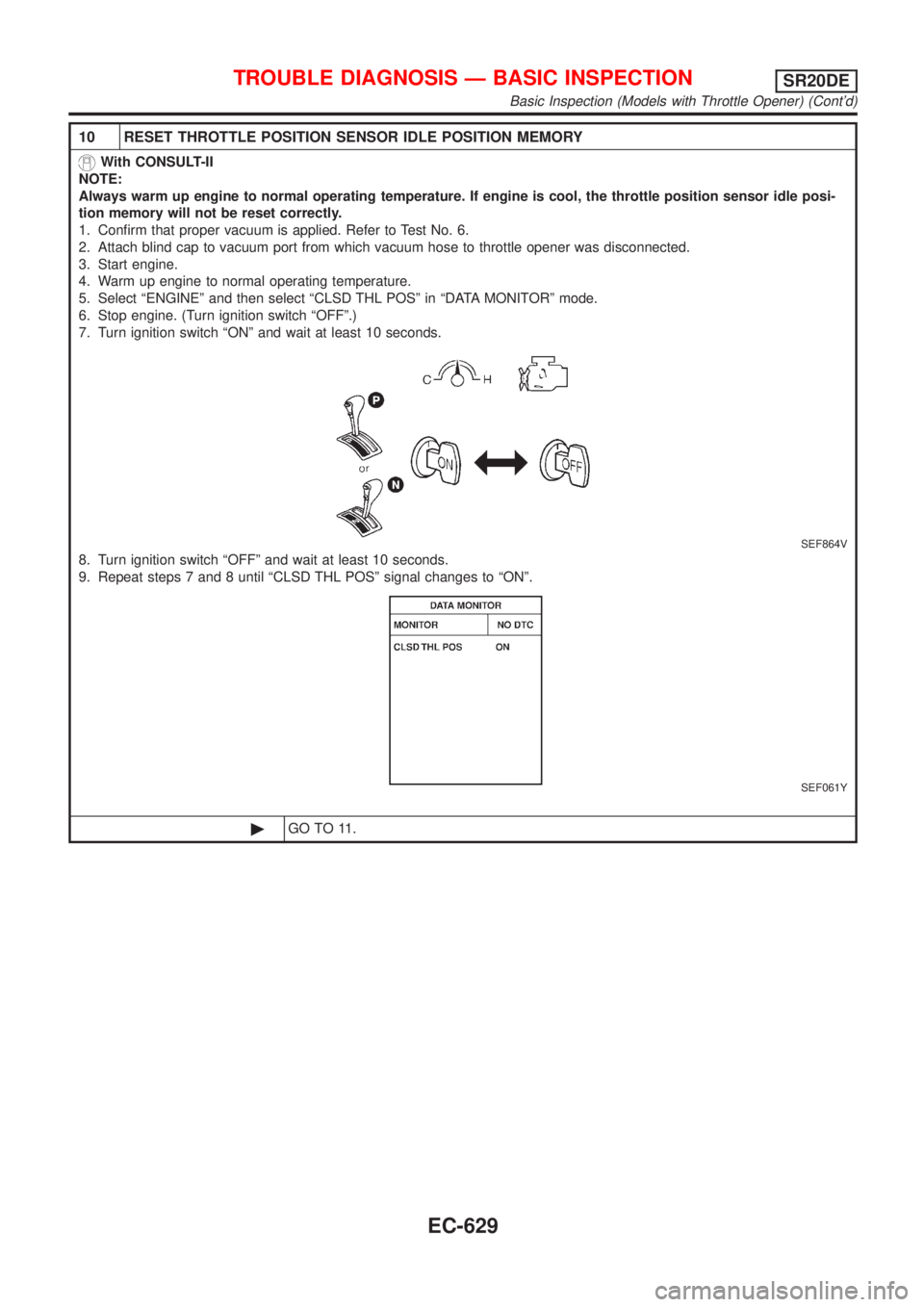

10 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Confirm that proper vacuum is applied. Refer to Test No. 6.

2. Attach blind cap to vacuum port from which vacuum hose to throttle opener was disconnected.

3. Start engine.

4. Warm up engine to normal operating temperature.

5. Select ªENGINEº and then select ªCLSD THL POSº in ªDATA MONITORº mode.

6. Stop engine. (Turn ignition switch ªOFFº.)

7. Turn ignition switch ªONº and wait at least 10 seconds.

SEF864V

8. Turn ignition switch ªOFFº and wait at least 10 seconds.

9. Repeat steps 7 and 8 until ªCLSD THL POSº signal changes to ªONº.

SEF061Y

©GO TO 11.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-629

Page 1055 of 3051

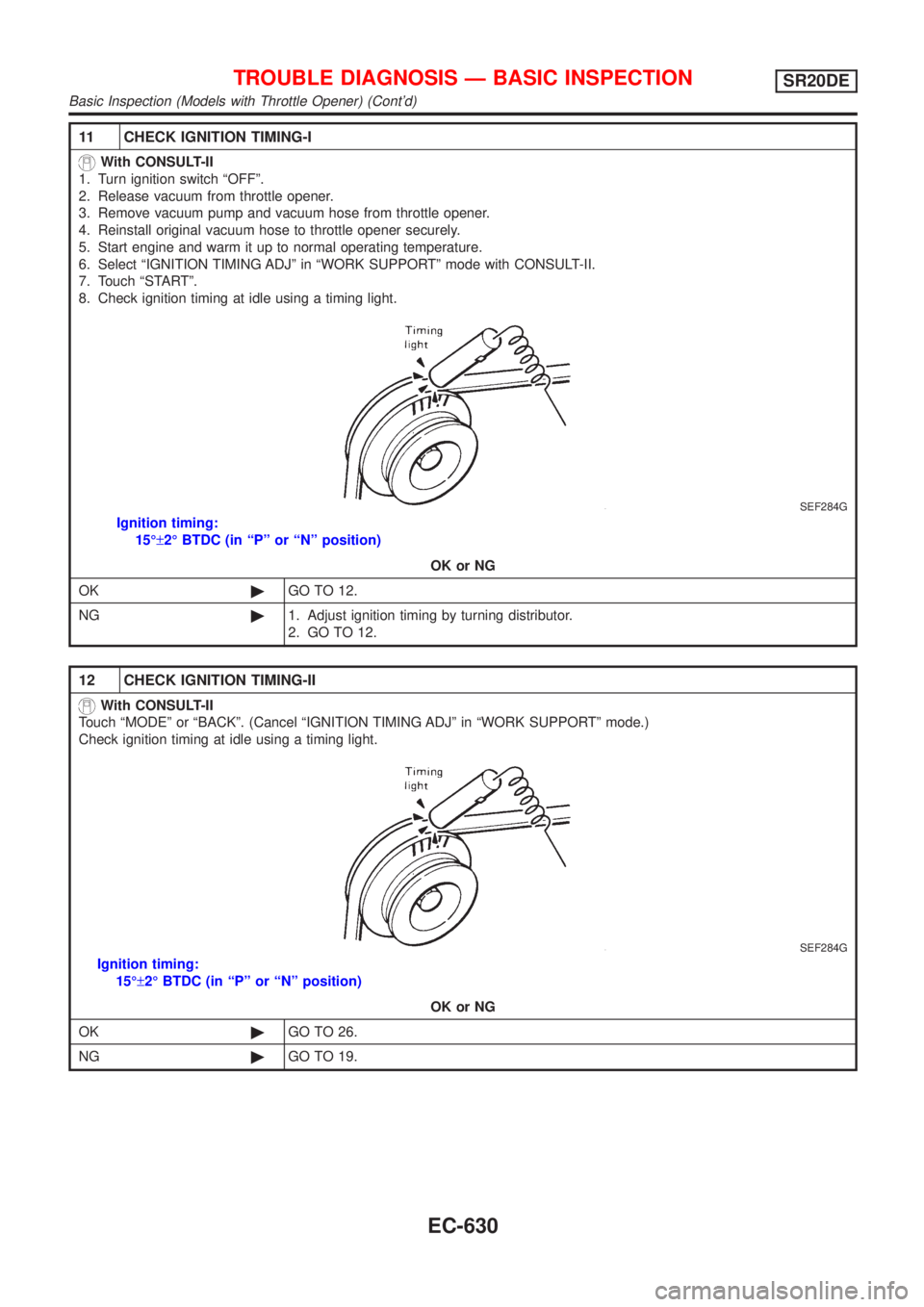

11 CHECK IGNITION TIMING-I

With CONSULT-II

1. Turn ignition switch ªOFFº.

2. Release vacuum from throttle opener.

3. Remove vacuum pump and vacuum hose from throttle opener.

4. Reinstall original vacuum hose to throttle opener securely.

5. Start engine and warm it up to normal operating temperature.

6. Select ªIGNITION TIMING ADJº in ªWORK SUPPORTº mode with CONSULT-II.

7. Touch ªSTARTº.

8. Check ignition timing at idle using a timing light.

SEF284G

Ignition timing:

15ɱ2É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 12.

NG©1. Adjust ignition timing by turning distributor.

2. GO TO 12.

12 CHECK IGNITION TIMING-II

With CONSULT-II

Touch ªMODEº or ªBACKº. (Cancel ªIGNITION TIMING ADJº in ªWORK SUPPORTº mode.)

Check ignition timing at idle using a timing light.

SEF284G

Ignition timing:

15ɱ2É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 26.

NG©GO TO 19.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-630

Page 1056 of 3051

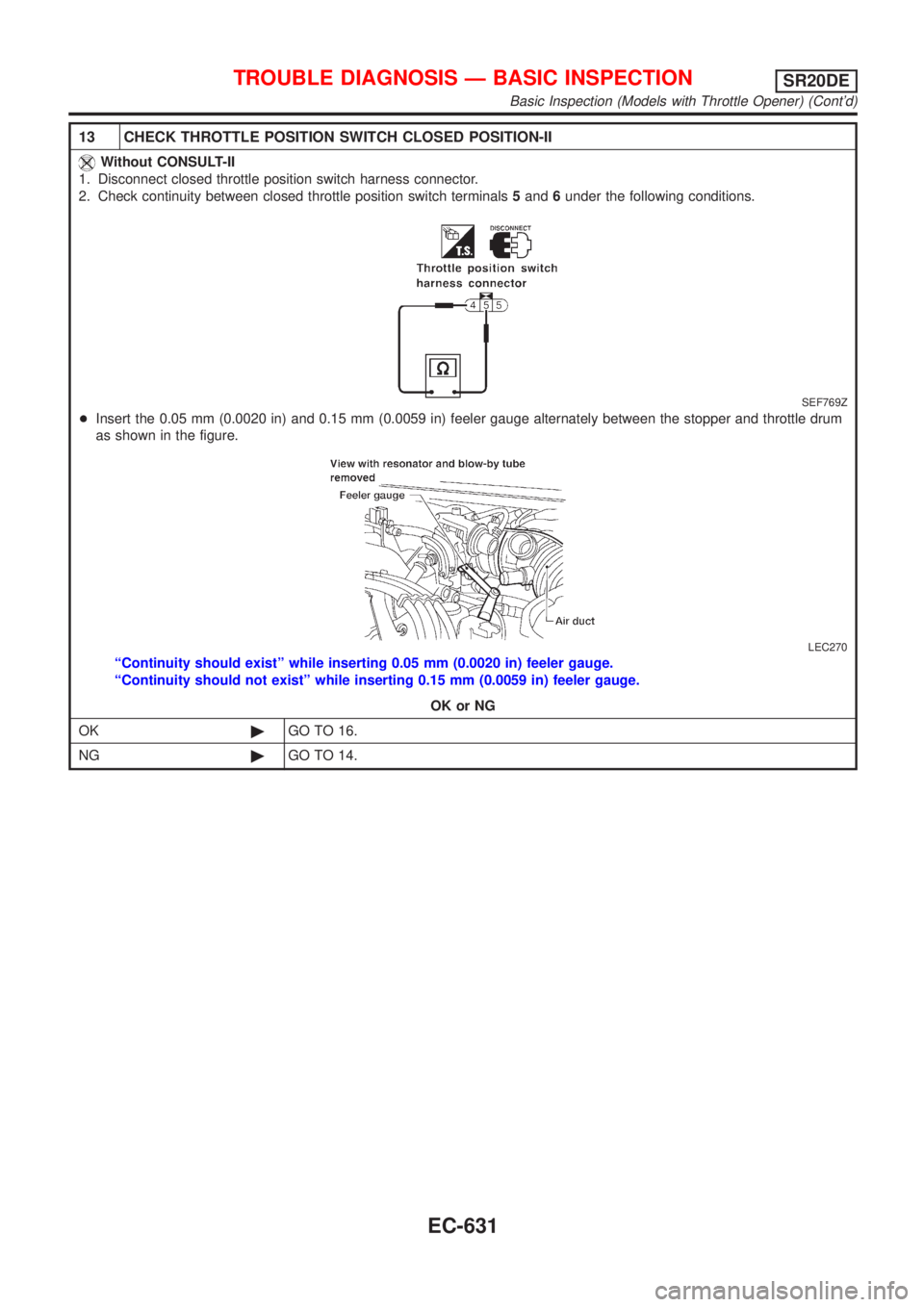

13 CHECK THROTTLE POSITION SWITCH CLOSED POSITION-II

Without CONSULT-II

1. Disconnect closed throttle position switch harness connector.

2. Check continuity between closed throttle position switch terminals5and6under the following conditions.

SEF769Z

+Insert the 0.05 mm (0.0020 in) and 0.15 mm (0.0059 in) feeler gauge alternately between the stopper and throttle drum

as shown in the figure.

LEC270

ªContinuity should existº while inserting 0.05 mm (0.0020 in) feeler gauge.

ªContinuity should not existº while inserting 0.15 mm (0.0059 in) feeler gauge.

OK or NG

OK©GO TO 16.

NG©GO TO 14.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-631

Page 1057 of 3051

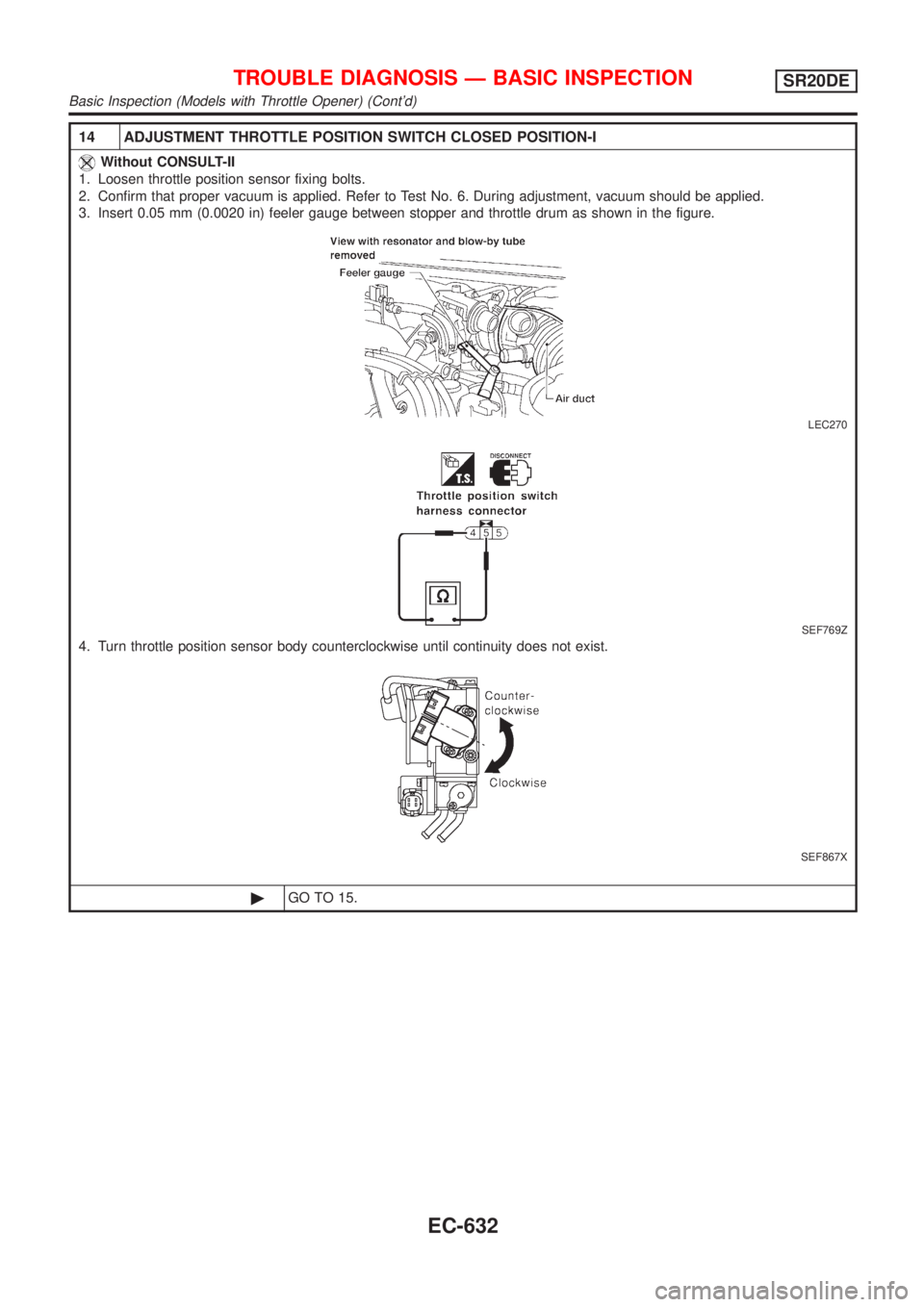

14 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-I

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Confirm that proper vacuum is applied. Refer to Test No. 6. During adjustment, vacuum should be applied.

3. Insert 0.05 mm (0.0020 in) feeler gauge between stopper and throttle drum as shown in the figure.

LEC270

SEF769Z

4. Turn throttle position sensor body counterclockwise until continuity does not exist.

SEF867X

©GO TO 15.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-632

Page 1058 of 3051

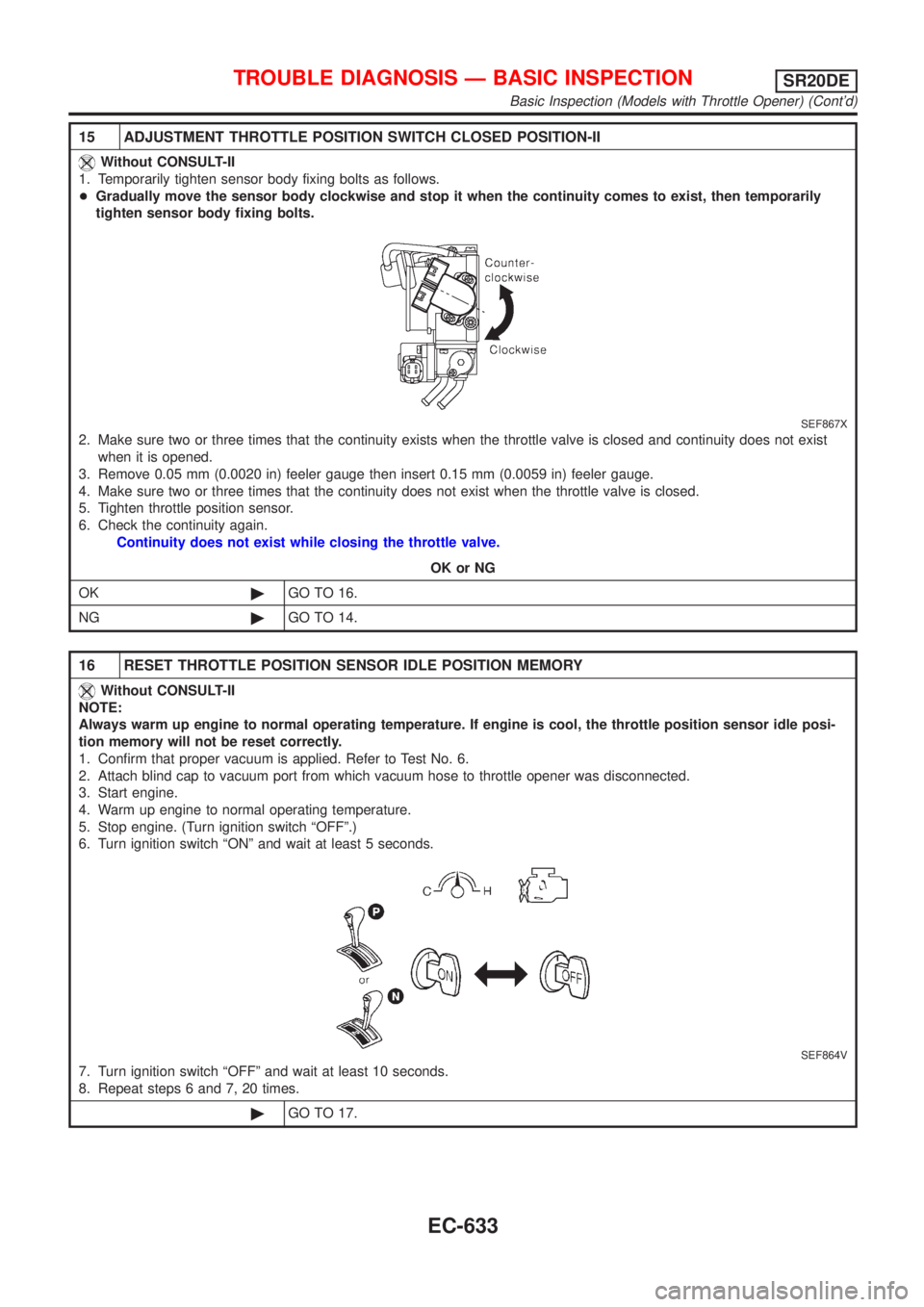

15 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-II

Without CONSULT-II

1. Temporarily tighten sensor body fixing bolts as follows.

+Gradually move the sensor body clockwise and stop it when the continuity comes to exist, then temporarily

tighten sensor body fixing bolts.

SEF867X

2. Make sure two or three times that the continuity exists when the throttle valve is closed and continuity does not exist

when it is opened.

3. Remove 0.05 mm (0.0020 in) feeler gauge then insert 0.15 mm (0.0059 in) feeler gauge.

4. Make sure two or three times that the continuity does not exist when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the continuity again.

Continuity does not exist while closing the throttle valve.

OK or NG

OK©GO TO 16.

NG©GO TO 14.

16 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Confirm that proper vacuum is applied. Refer to Test No. 6.

2. Attach blind cap to vacuum port from which vacuum hose to throttle opener was disconnected.

3. Start engine.

4. Warm up engine to normal operating temperature.

5. Stop engine. (Turn ignition switch ªOFFº.)

6. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

7. Turn ignition switch ªOFFº and wait at least 10 seconds.

8. Repeat steps 6 and 7, 20 times.

©GO TO 17.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-633

Page 1059 of 3051

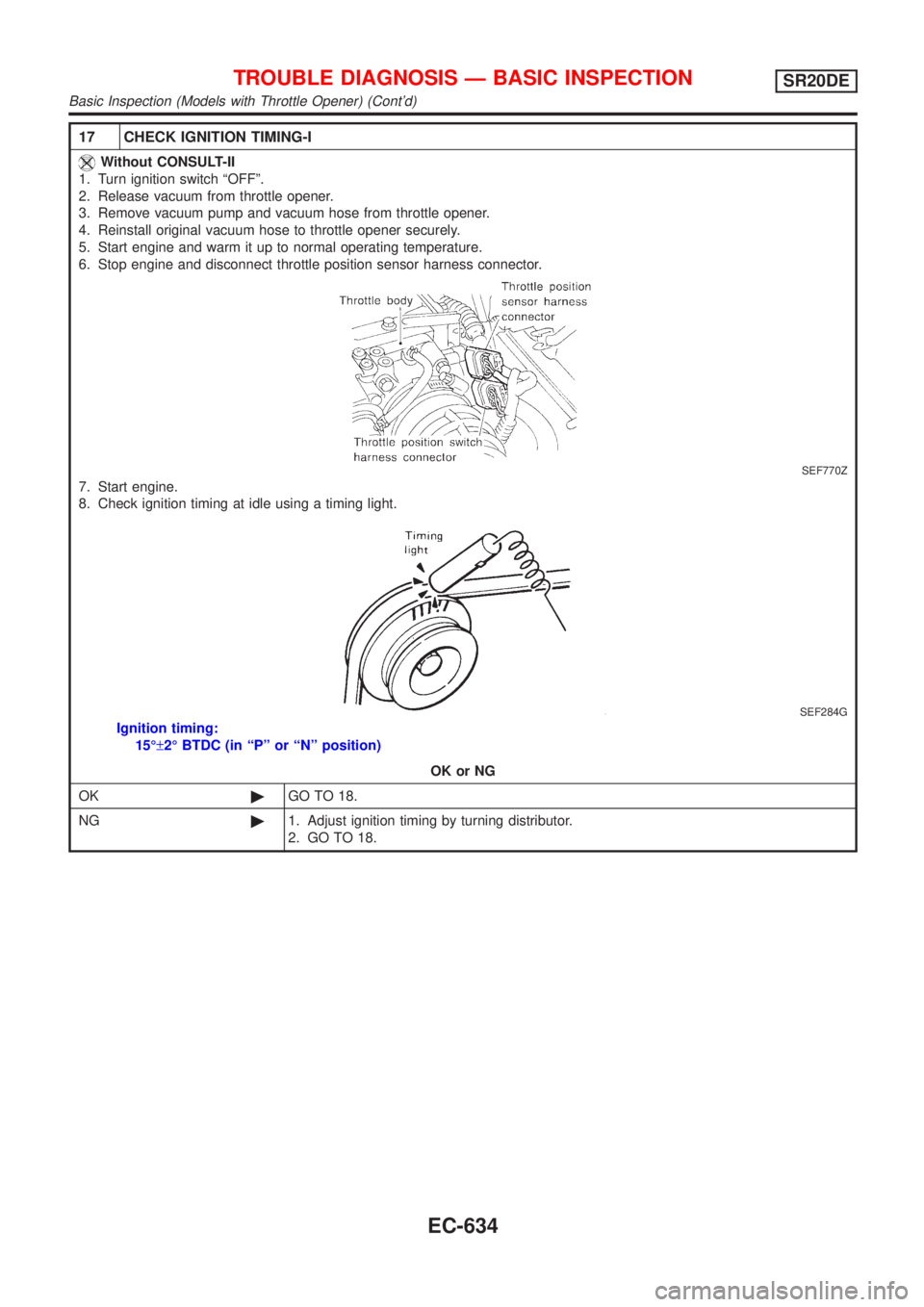

17 CHECK IGNITION TIMING-I

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Release vacuum from throttle opener.

3. Remove vacuum pump and vacuum hose from throttle opener.

4. Reinstall original vacuum hose to throttle opener securely.

5. Start engine and warm it up to normal operating temperature.

6. Stop engine and disconnect throttle position sensor harness connector.

SEF770Z

7. Start engine.

8. Check ignition timing at idle using a timing light.

SEF284G

Ignition timing:

15ɱ2É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 18.

NG©1. Adjust ignition timing by turning distributor.

2. GO TO 18.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-634

Page 1060 of 3051

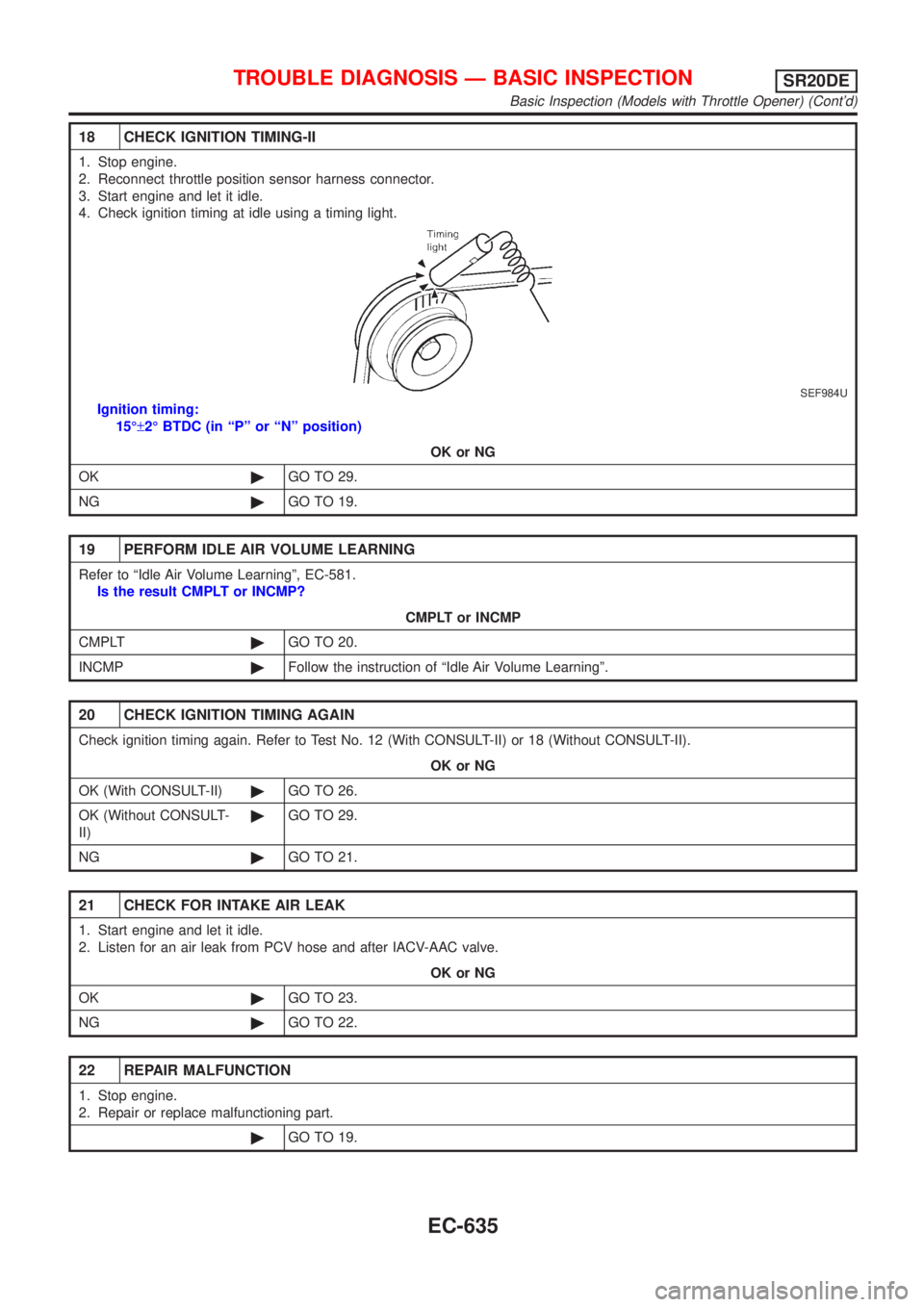

18 CHECK IGNITION TIMING-II

1. Stop engine.

2. Reconnect throttle position sensor harness connector.

3. Start engine and let it idle.

4. Check ignition timing at idle using a timing light.

SEF984U

Ignition timing:

15ɱ2É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 29.

NG©GO TO 19.

19 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-581.

Is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 20.

INCMP©Follow the instruction of ªIdle Air Volume Learningº.

20 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 12 (With CONSULT-II) or 18 (Without CONSULT-II).

OK or NG

OK (With CONSULT-II)©GO TO 26.

OK (Without CONSULT-

II)©GO TO 29.

NG©GO TO 21.

21 CHECK FOR INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an air leak from PCV hose and after IACV-AAC valve.

OK or NG

OK©GO TO 23.

NG©GO TO 22.

22 REPAIR MALFUNCTION

1. Stop engine.

2. Repair or replace malfunctioning part.

©GO TO 19.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Models with Throttle Opener) (Cont'd)

EC-635