NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: rims, hood open, steering wheel adjustment, key battery, turn signal bulb, oil change, BT-32

Page 1581 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

434 W Accelerator position sensor[Ignition switch ªONº]

+Accelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

+Accelerator pe NISSAN ALMERA TINO 2001 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

434 W Accelerator position sensor[Ignition switch ªONº]

+Accelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

+Accelerator pe](/img/5/57352/w960_57352-1580.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

434 W Accelerator position sensor[Ignition switch ªONº]

+Accelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

+Accelerator pedal fully depressed3.0 - 4.3V

435 W/GAccelerator position switch

(Idle)[Ignition switch ªONº]

+Accelerator pedal fully releasedApproximately 0V

[Ignition switch ªONº]

+Accelerator pedal depressedBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNLEC0682

DTC Malfunction is detected when ... Check Items (Possible Cause)

P0120

0403+The relation between sensor and switch signals

is not in the nomal range during the specified

accelerator positions.+Harness or connectors

(The sensor circuit is open or shorted.)

+Accelerator position sensor

+Accelerator position switch

SEF817Y

DTC Confirmation ProcedureNLEC0683WITH CONSULT-IINLEC0683S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Depress and release fully accelerator pedal slowly.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1159.

WITHOUT CONSULT-IINLEC0683S021) Turn ignition switch ªONº.

2) Depress and release fully accelerator pedal slowly.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1159.

DTC P0120 ACCEL POS SENSORYD22DDTI

ECM Terminals and Reference Value (Cont'd)

EC-1156

Page 1582 of 3051

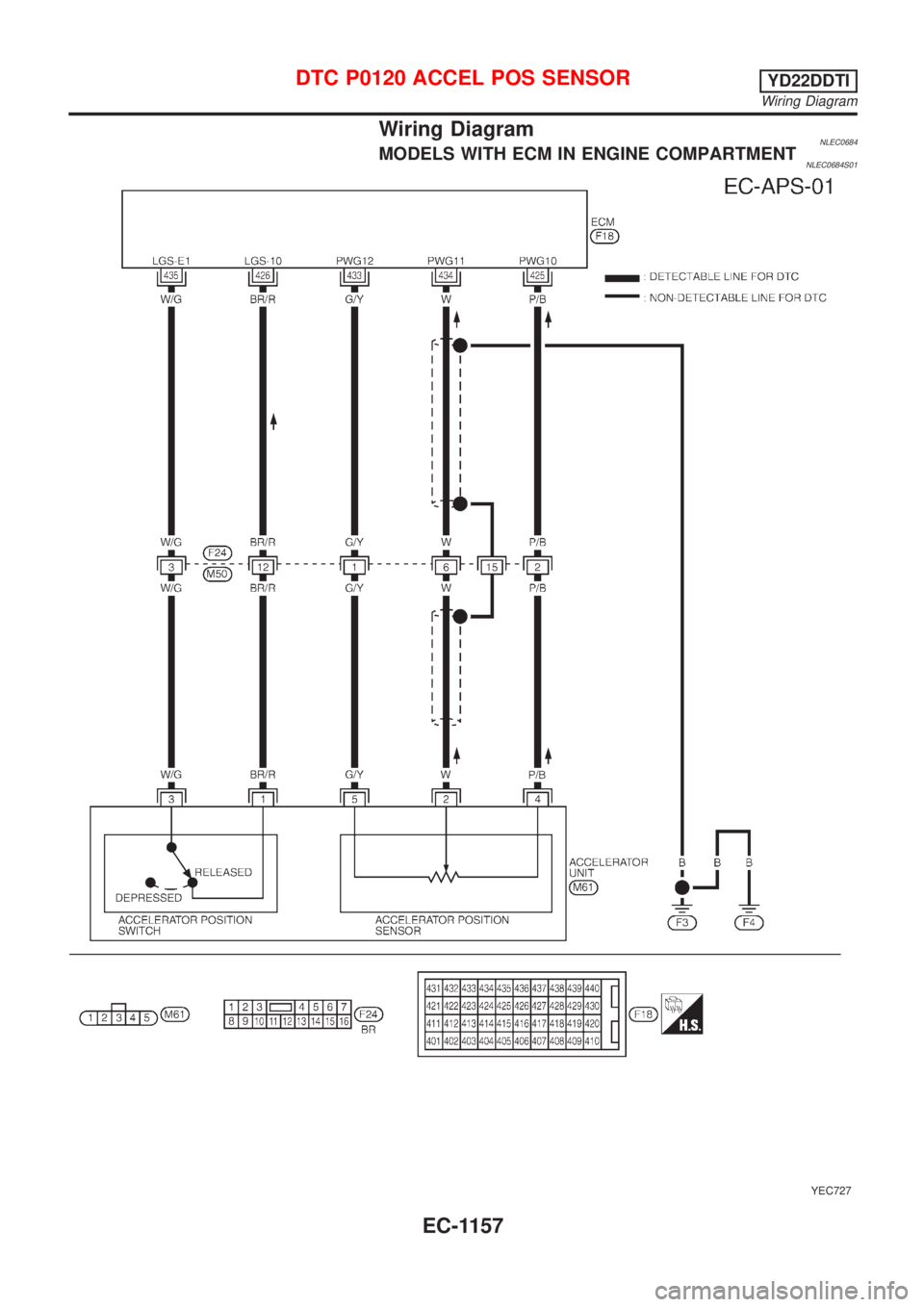

Wiring DiagramNLEC0684MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0684S01

YEC727

DTC P0120 ACCEL POS SENSORYD22DDTI

Wiring Diagram

EC-1157

Page 1583 of 3051

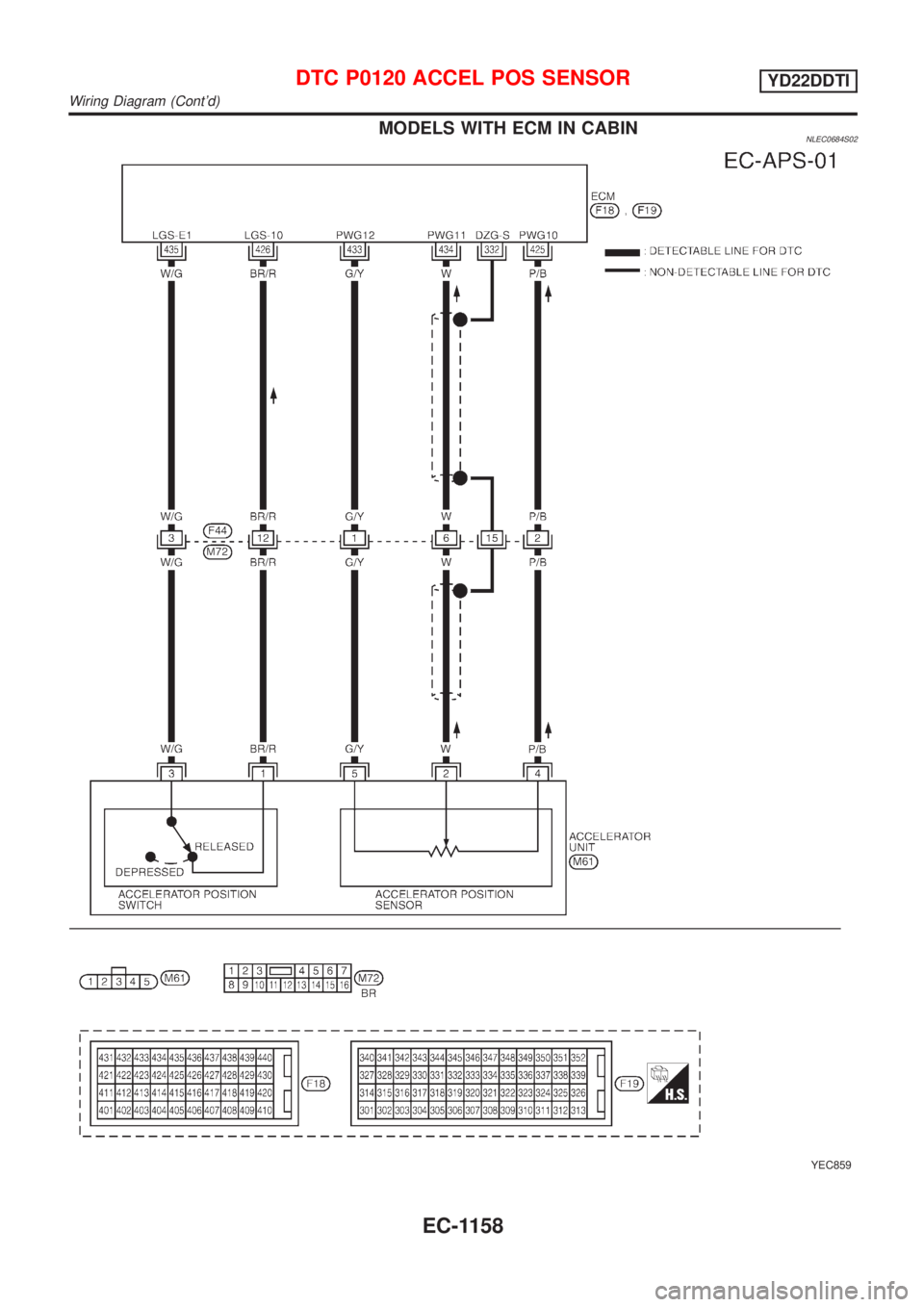

MODELS WITH ECM IN CABINNLEC0684S02

YEC859

DTC P0120 ACCEL POS SENSORYD22DDTI

Wiring Diagram (Cont'd)

EC-1158

Page 1584 of 3051

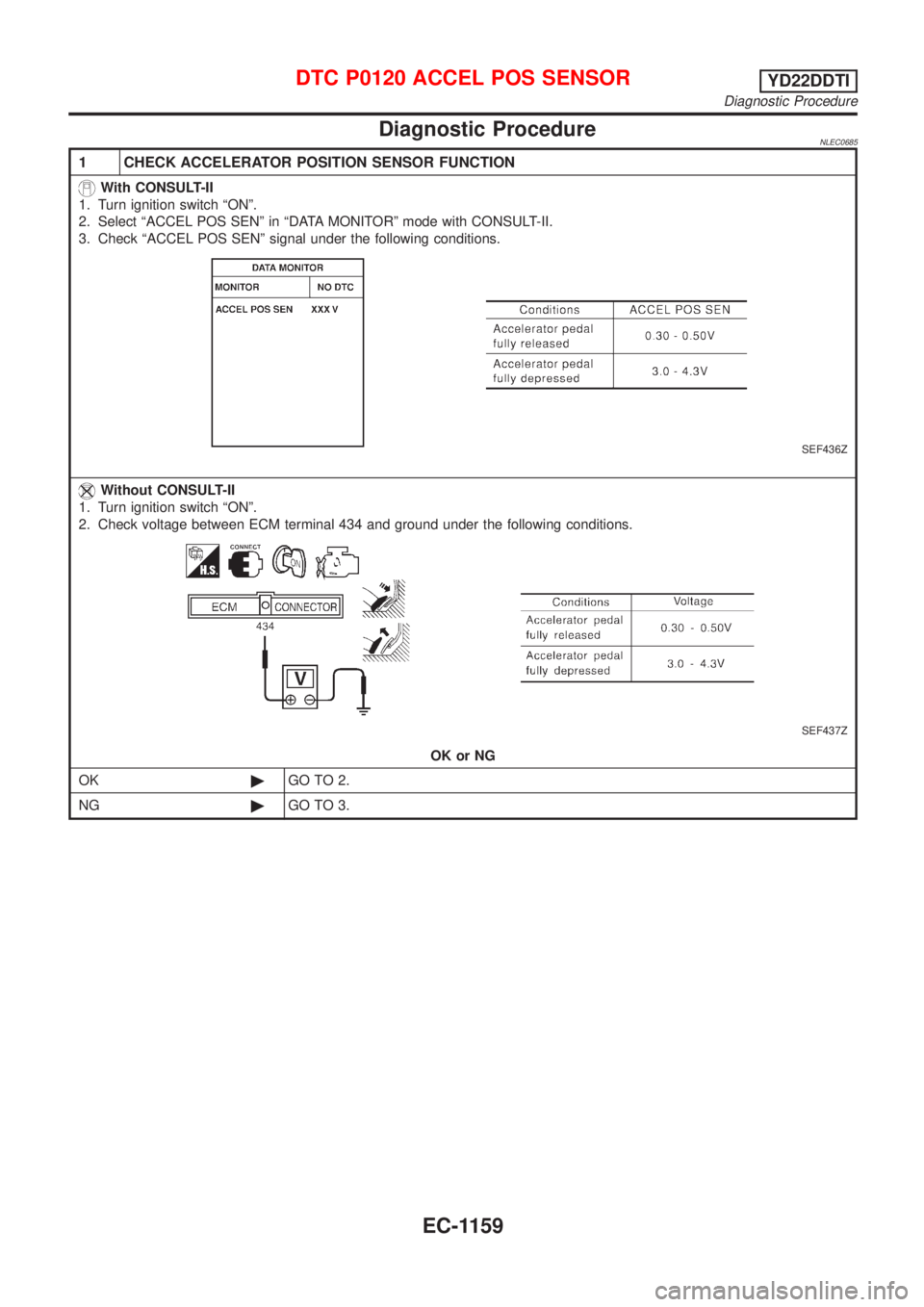

Diagnostic ProcedureNLEC0685

1 CHECK ACCELERATOR POSITION SENSOR FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªACCEL POS SENº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªACCEL POS SENº signal under the following conditions.

SEF436Z

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 434 and ground under the following conditions.

SEF437Z

OK or NG

OK©GO TO 2.

NG©GO TO 3.

DTC P0120 ACCEL POS SENSORYD22DDTI

Diagnostic Procedure

EC-1159

Page 1585 of 3051

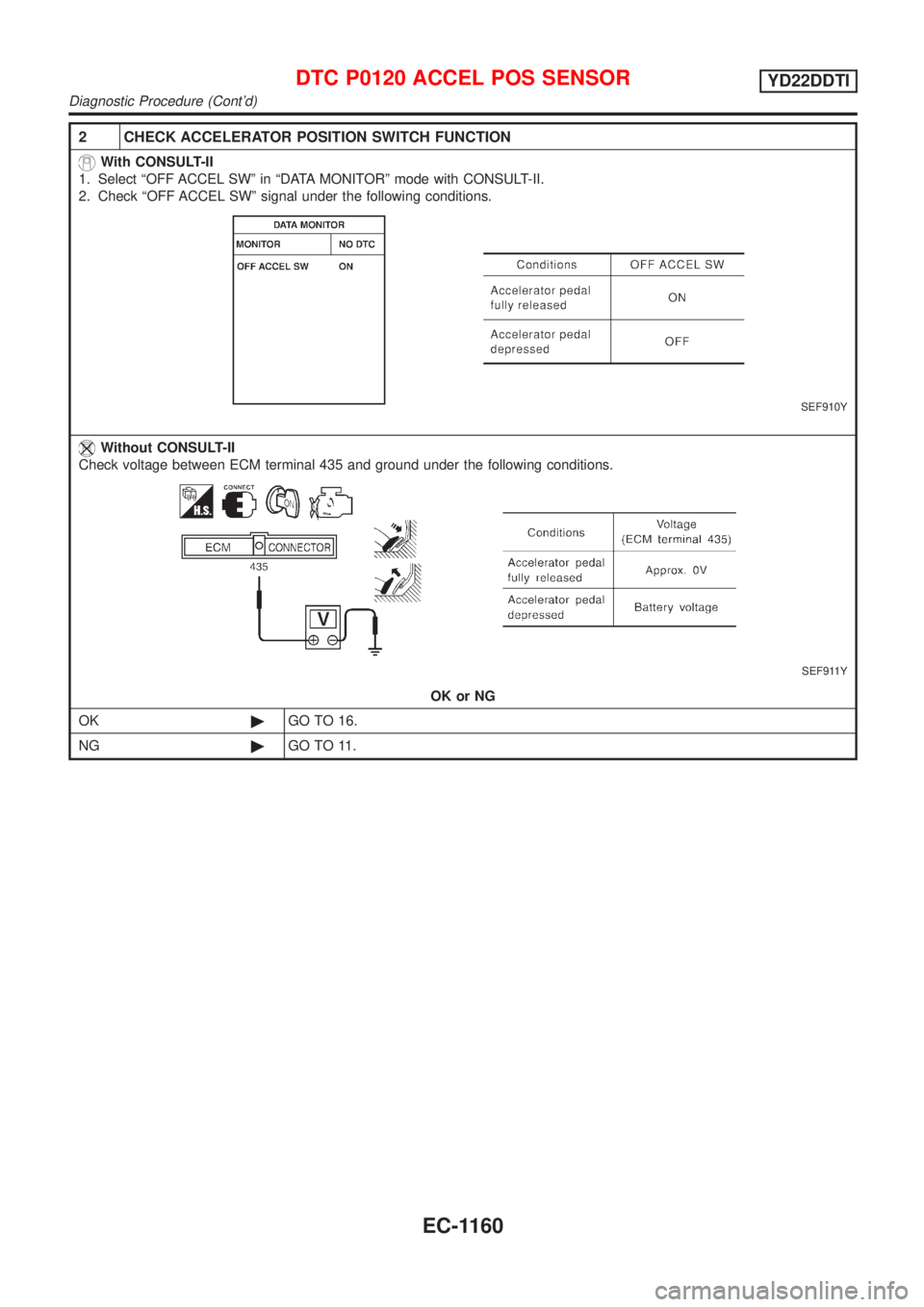

2 CHECK ACCELERATOR POSITION SWITCH FUNCTION

With CONSULT-II

1. Select ªOFF ACCEL SWº in ªDATA MONITORº mode with CONSULT-II.

2. Check ªOFF ACCEL SWº signal under the following conditions.

SEF910Y

Without CONSULT-II

Check voltage between ECM terminal 435 and ground under the following conditions.

SEF911Y

OK or NG

OK©GO TO 16.

NG©GO TO 11.

DTC P0120 ACCEL POS SENSORYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1160

Page 1586 of 3051

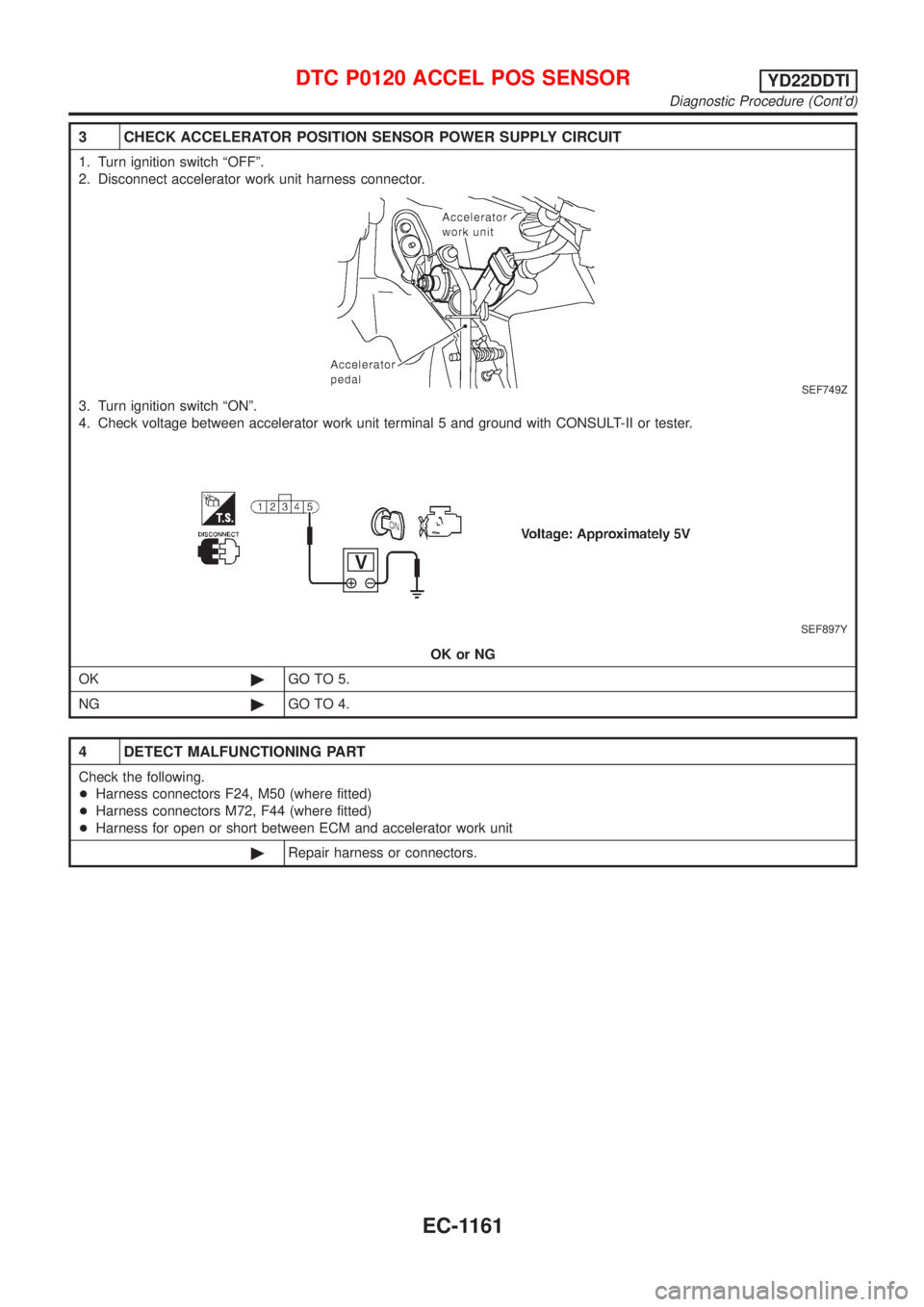

3 CHECK ACCELERATOR POSITION SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect accelerator work unit harness connector.

SEF749Z

3. Turn ignition switch ªONº.

4. Check voltage between accelerator work unit terminal 5 and ground with CONSULT-II or tester.

SEF897Y

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F24, M50 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between ECM and accelerator work unit

©Repair harness or connectors.

DTC P0120 ACCEL POS SENSORYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1161

Page 1587 of 3051

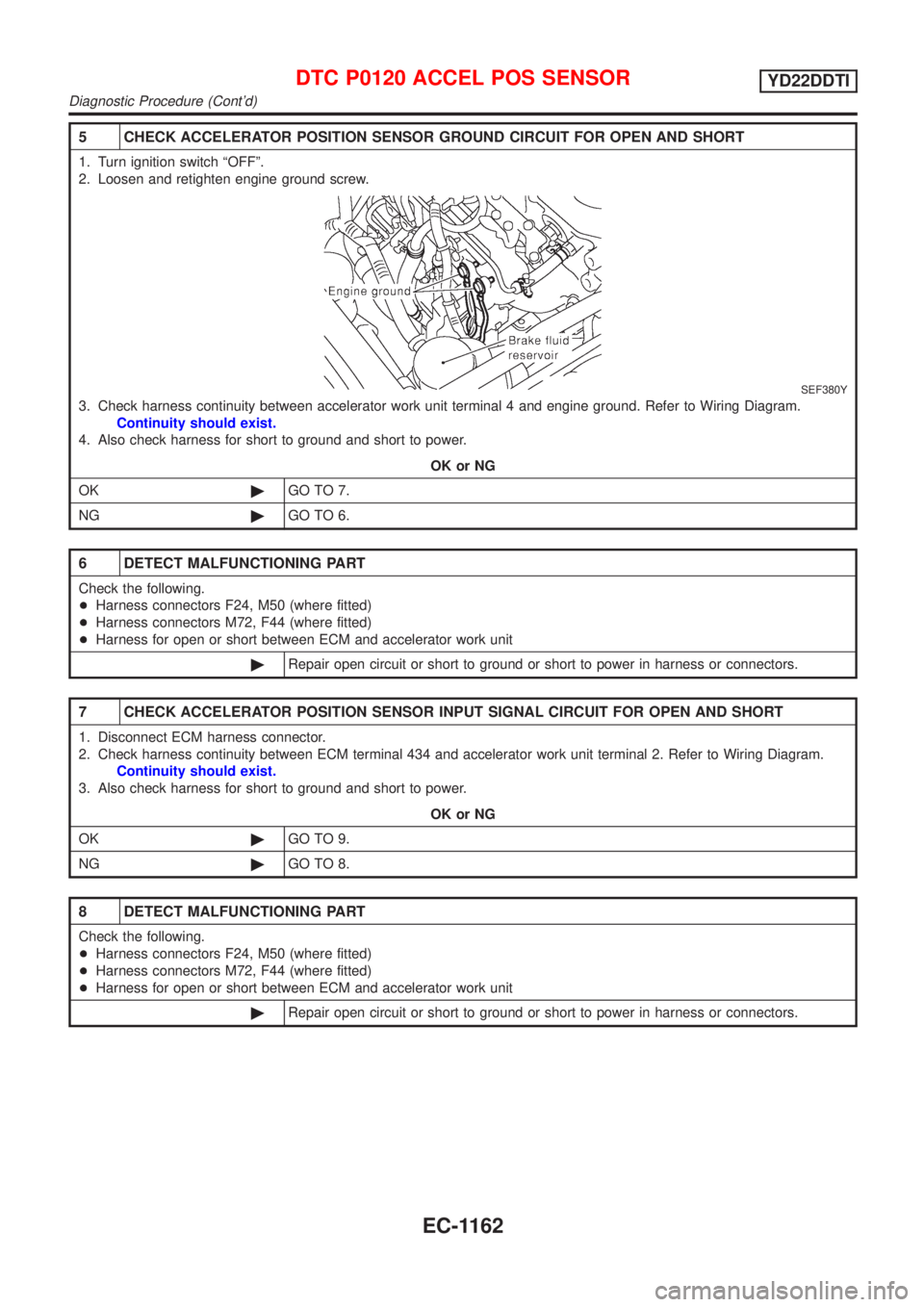

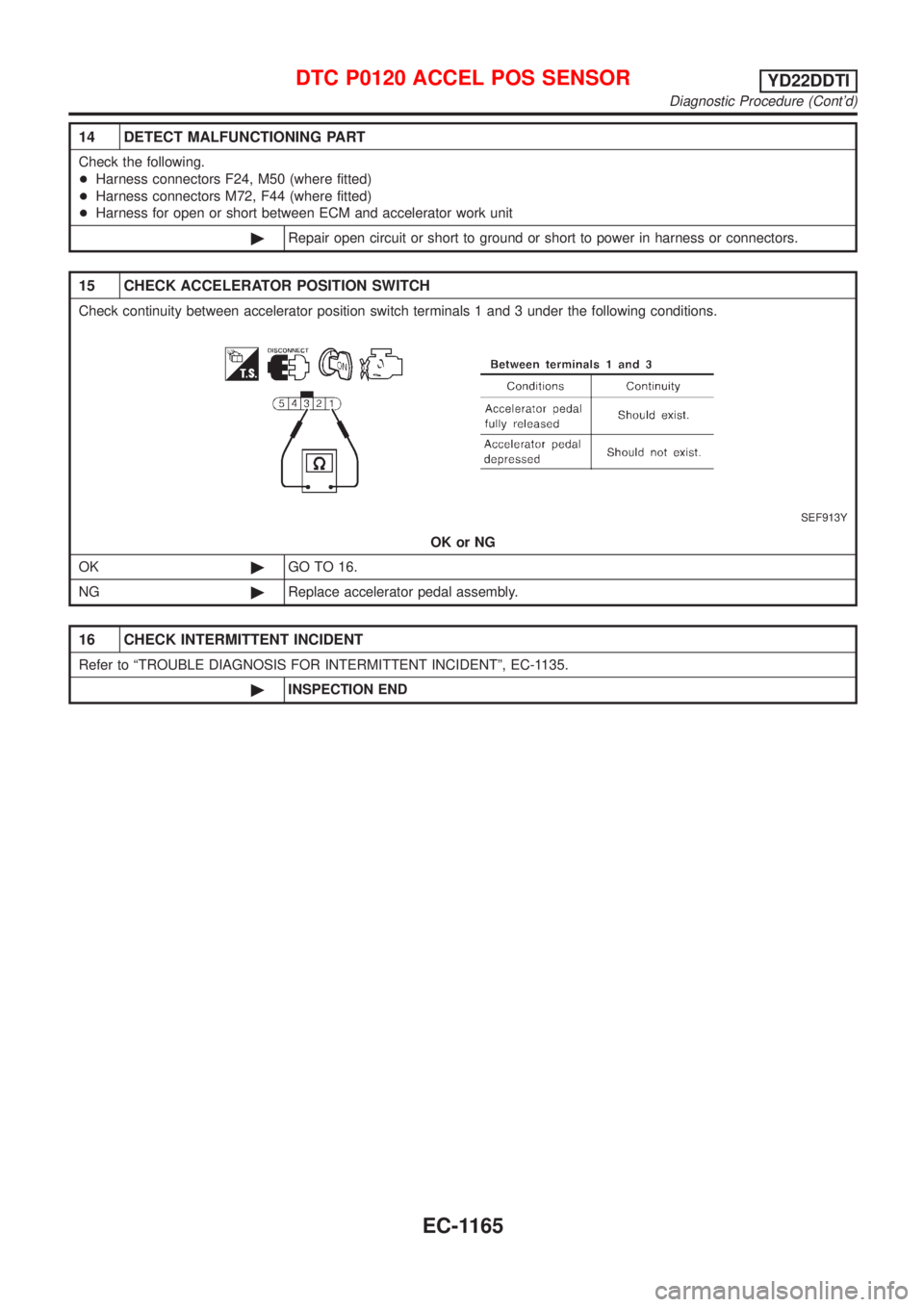

5 CHECK ACCELERATOR POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screw.

SEF380Y

3. Check harness continuity between accelerator work unit terminal 4 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F24, M50 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between ECM and accelerator work unit

©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK ACCELERATOR POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 434 and accelerator work unit terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F24, M50 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between ECM and accelerator work unit

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0120 ACCEL POS SENSORYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1162

Page 1588 of 3051

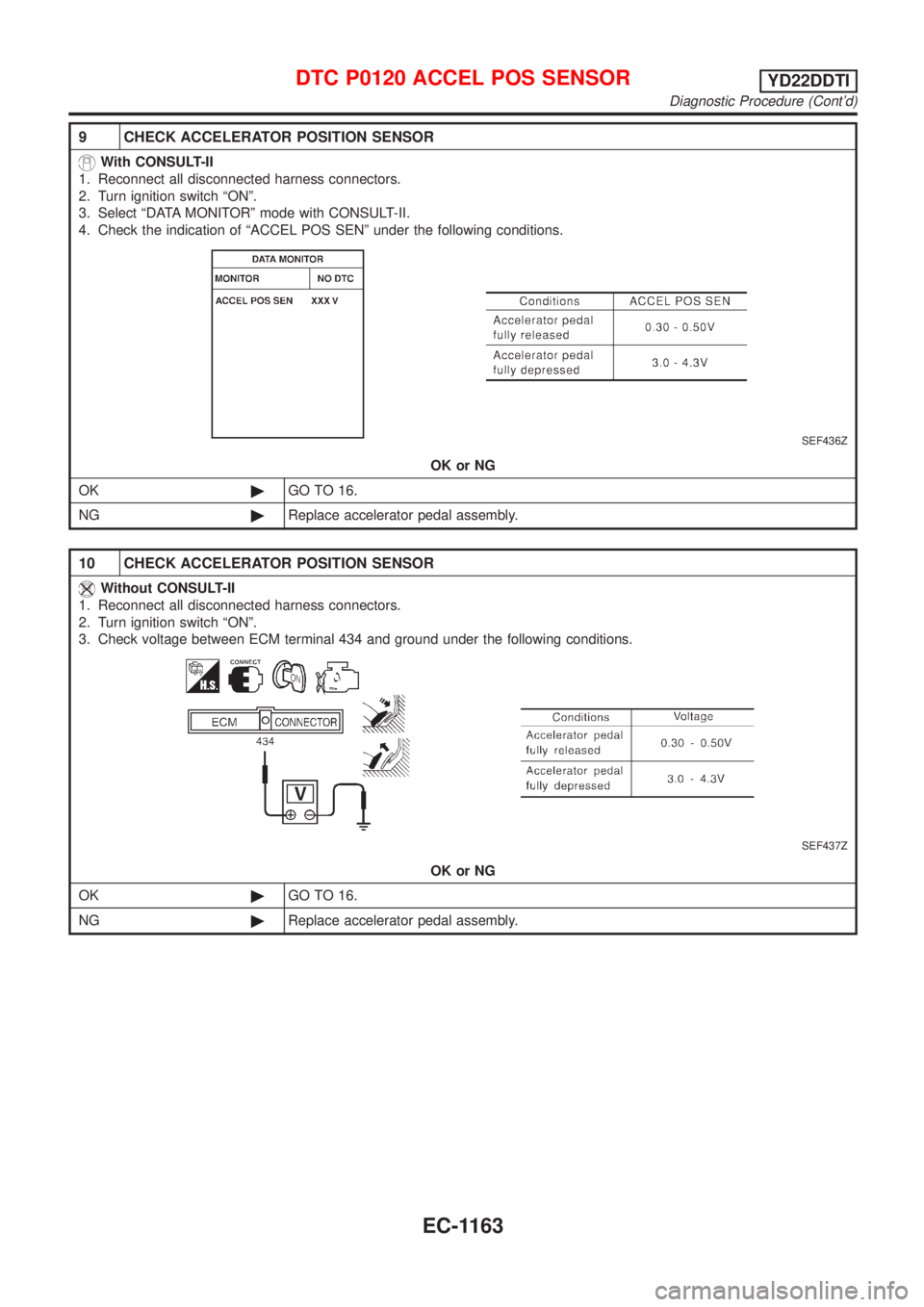

9 CHECK ACCELERATOR POSITION SENSOR

With CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Select ªDATA MONITORº mode with CONSULT-II.

4. Check the indication of ªACCEL POS SENº under the following conditions.

SEF436Z

OK or NG

OK©GO TO 16.

NG©Replace accelerator pedal assembly.

10 CHECK ACCELERATOR POSITION SENSOR

Without CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Check voltage between ECM terminal 434 and ground under the following conditions.

SEF437Z

OK or NG

OK©GO TO 16.

NG©Replace accelerator pedal assembly.

DTC P0120 ACCEL POS SENSORYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1163

Page 1589 of 3051

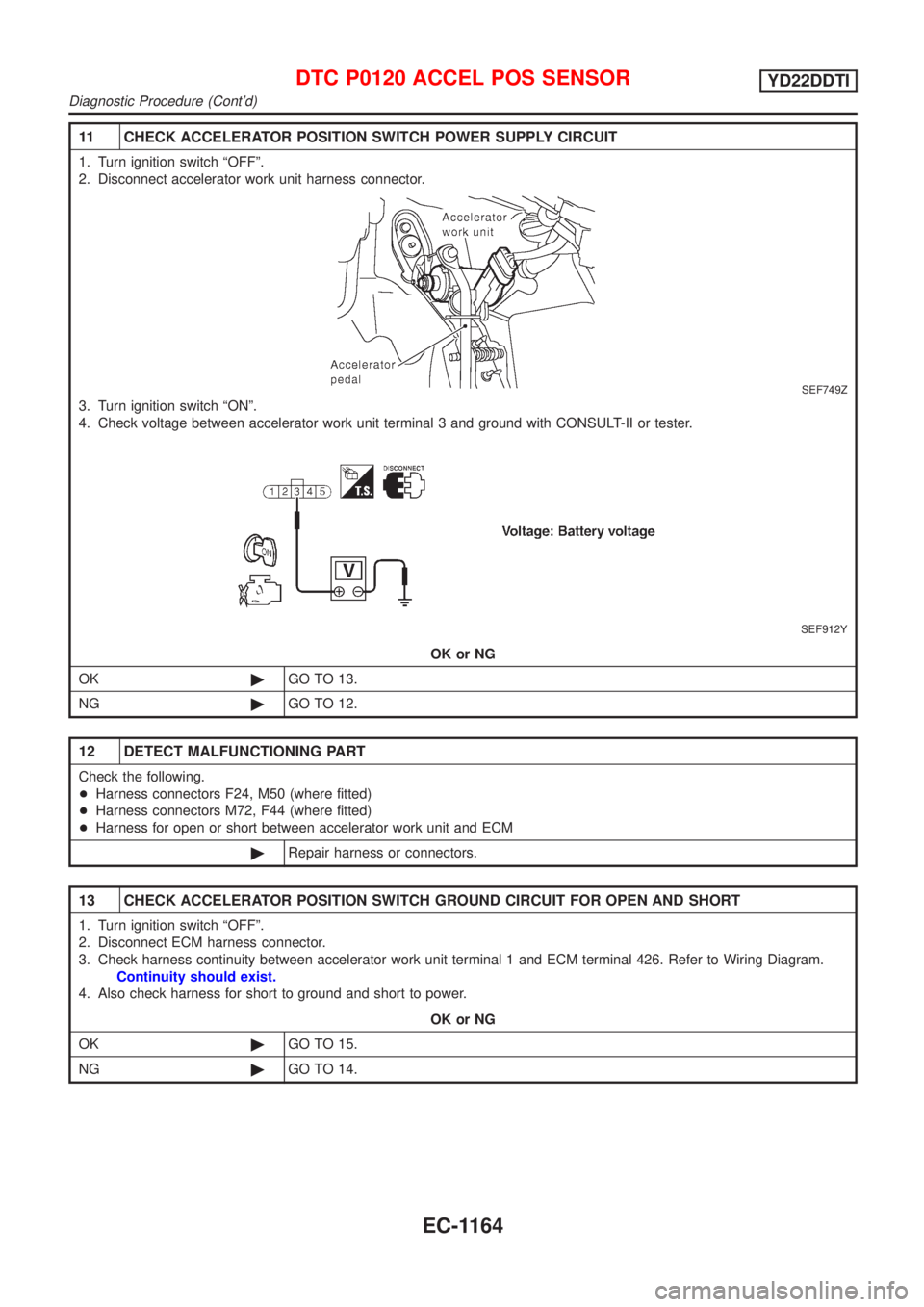

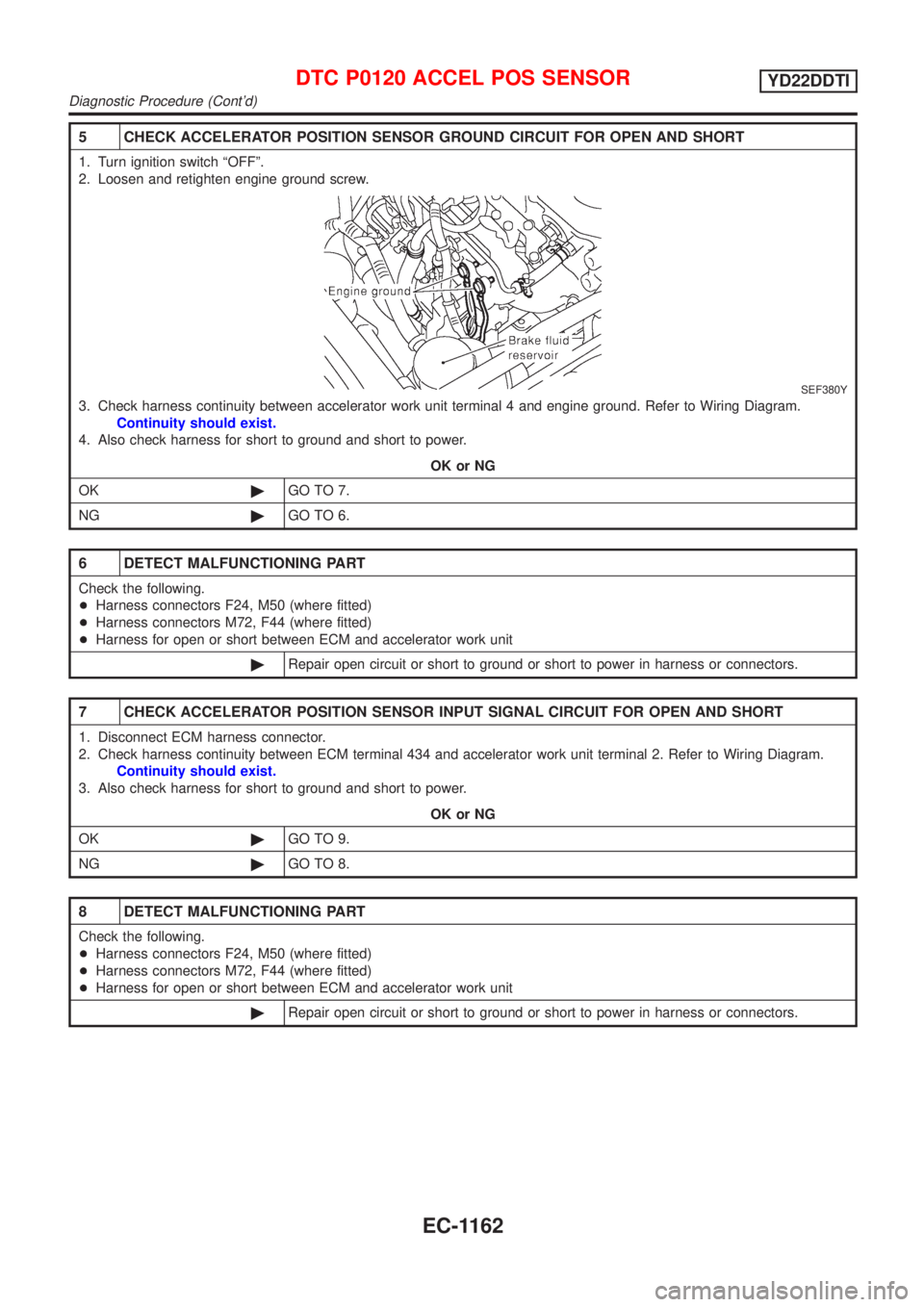

11 CHECK ACCELERATOR POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect accelerator work unit harness connector.

SEF749Z

3. Turn ignition switch ªONº.

4. Check voltage between accelerator work unit terminal 3 and ground with CONSULT-II or tester.

SEF912Y

OK or NG

OK©GO TO 13.

NG©GO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F24, M50 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between accelerator work unit and ECM

©Repair harness or connectors.

13 CHECK ACCELERATOR POSITION SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between accelerator work unit terminal 1 and ECM terminal 426. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 15.

NG©GO TO 14.

DTC P0120 ACCEL POS SENSORYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1164

Page 1590 of 3051

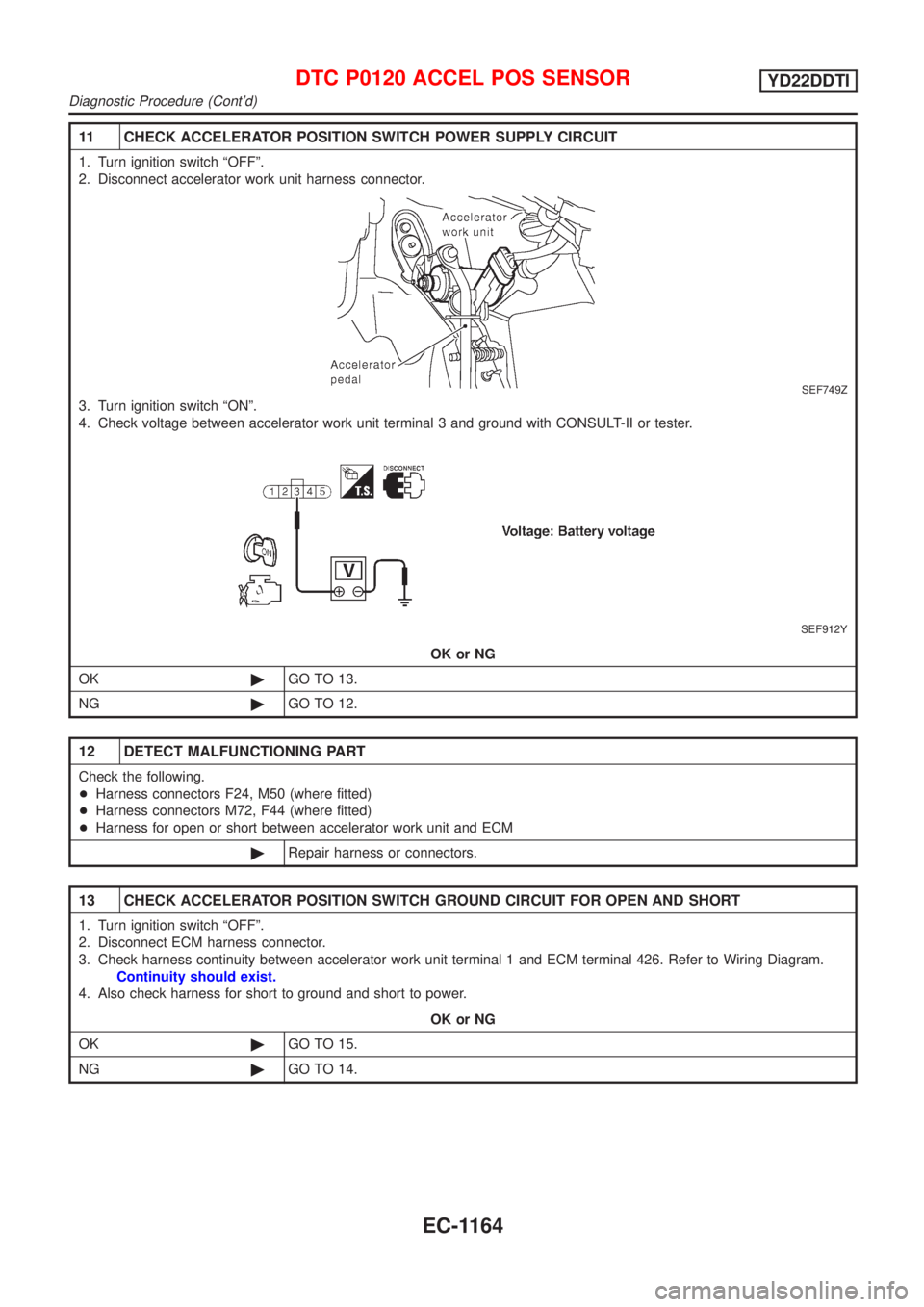

14 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F24, M50 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between ECM and accelerator work unit

©Repair open circuit or short to ground or short to power in harness or connectors.

15 CHECK ACCELERATOR POSITION SWITCH

Check continuity between accelerator position switch terminals 1 and 3 under the following conditions.

SEF913Y

OK or NG

OK©GO TO 16.

NG©Replace accelerator pedal assembly.

16 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1135.

©INSPECTION END

DTC P0120 ACCEL POS SENSORYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1165

Trending: oil pressure, fuel consumption, Trim, clock reset, oil type, wiper relay place, dead battery

![NISSAN ALMERA TINO 2001 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

434 W Accelerator position sensor[Ignition switch ªONº]

+Accelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

+Accelerator pe NISSAN ALMERA TINO 2001 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

434 W Accelerator position sensor[Ignition switch ªONº]

+Accelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

+Accelerator pe](/img/5/57352/w960_57352-1580.png)