NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1601 of 3051

Diagnostic ProcedureNLEC0659

1 CHECK VEHICLE SPEED SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and combination meter harness connector.

3. Check harness continuity between ECM terminal 417 and combination meter terminal 10. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F24 (where fitted)

+Harness connectors M71, F45 (where fitted)

+Harness for open or short between ECM and combination meter

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK SPEEDOMETER FUNCTION

Make sure that speedometer functions properly.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 CHECK SPEEDOMETER CIRCUIT FOR OPEN AND SHORT

Check the following.

+Harness connectors M50, F24 (where fitted)

+Harness connectors M49, F23 (where fitted)

+Harness connectors M71, F45 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between combination meter and vehicle speed sensor

OK or NG

OK©Check vehicle speed sensor and combination meter. Refer to EL section.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1135.

©INSPECTION END

DTC P0500 VEHICLE SPEED SENYD22DDTI

Diagnostic Procedure

EC-1176

Page 1602 of 3051

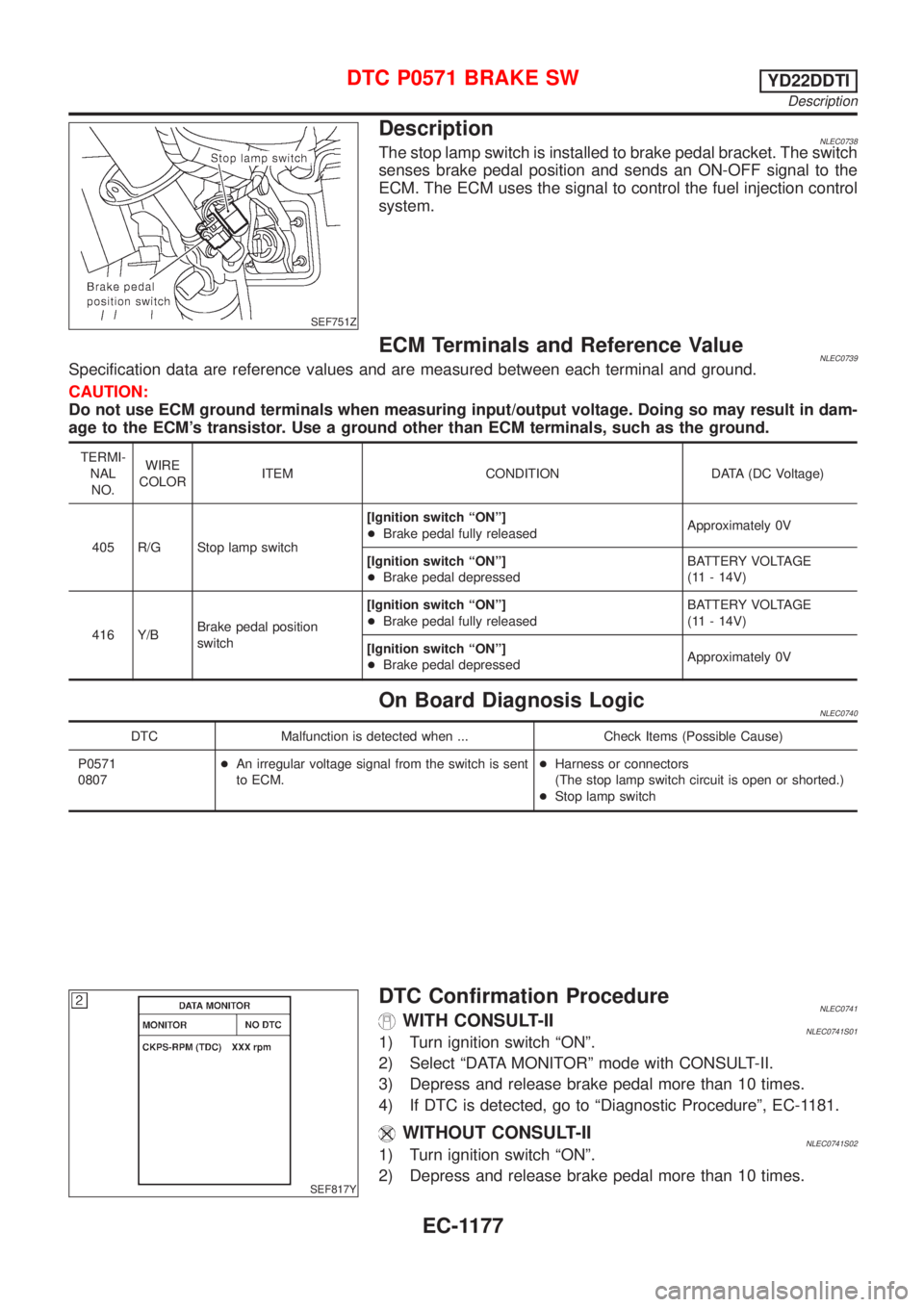

SEF751Z

DescriptionNLEC0738The stop lamp switch is installed to brake pedal bracket. The switch

senses brake pedal position and sends an ON-OFF signal to the

ECM. The ECM uses the signal to control the fuel injection control

system.

ECM Terminals and Reference ValueNLEC0739Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

405 R/G Stop lamp switch[Ignition switch ªONº]

+Brake pedal fully releasedApproximately 0V

[Ignition switch ªONº]

+Brake pedal depressedBATTERY VOLTAGE

(11 - 14V)

416 Y/BBrake pedal position

switch[Ignition switch ªONº]

+Brake pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

+Brake pedal depressedApproximately 0V

On Board Diagnosis LogicNLEC0740

DTC Malfunction is detected when ... Check Items (Possible Cause)

P0571

0807+An irregular voltage signal from the switch is sent

to ECM.+Harness or connectors

(The stop lamp switch circuit is open or shorted.)

+Stop lamp switch

SEF817Y

DTC Confirmation ProcedureNLEC0741WITH CONSULT-IINLEC0741S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Depress and release brake pedal more than 10 times.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1181.

WITHOUT CONSULT-IINLEC0741S021) Turn ignition switch ªONº.

2) Depress and release brake pedal more than 10 times.

DTC P0571 BRAKE SWYD22DDTI

Description

EC-1177

Page 1603 of 3051

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1181.

DTC P0571 BRAKE SWYD22DDTI

DTC Confirmation Procedure (Cont'd)

EC-1178

Page 1604 of 3051

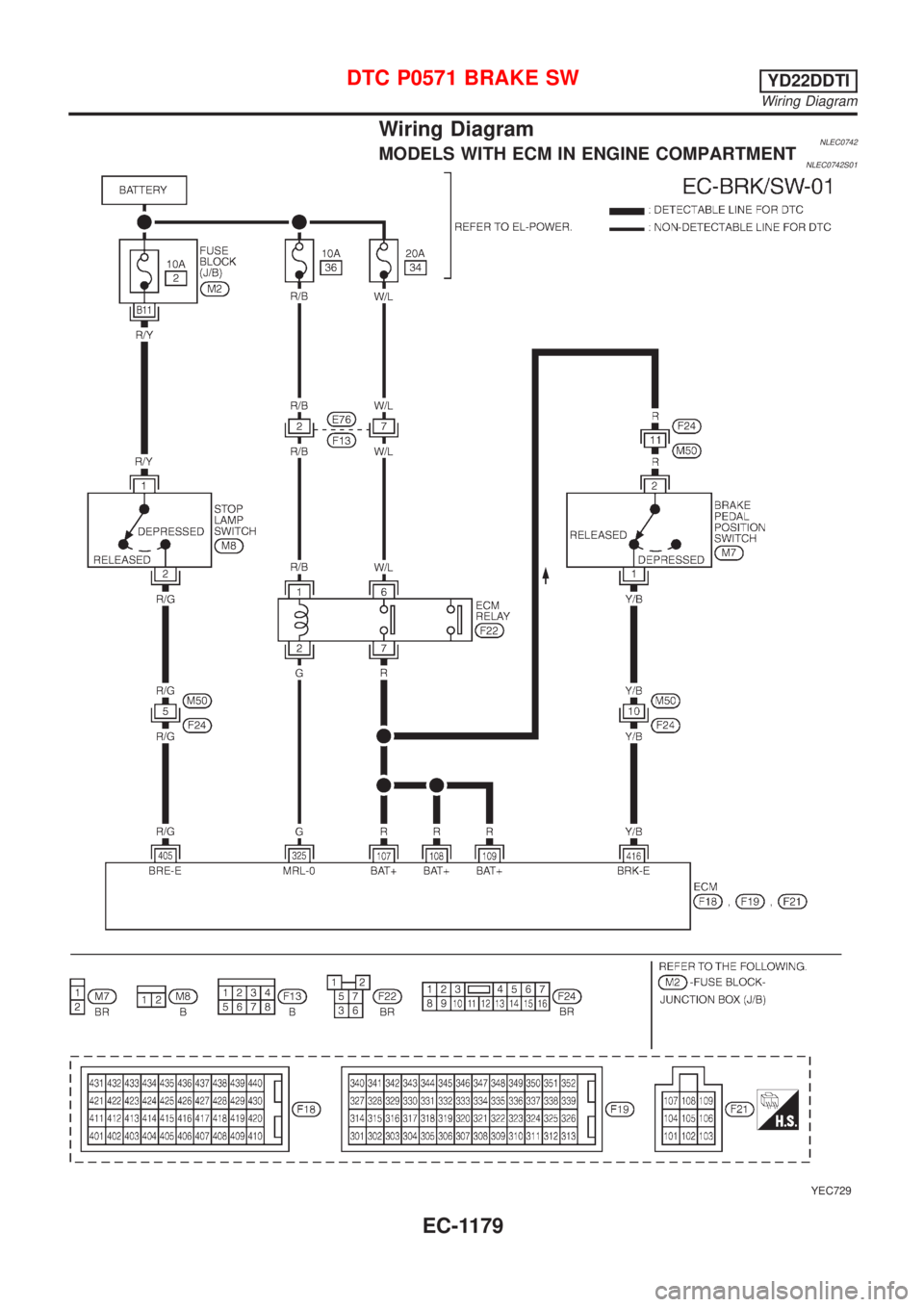

Wiring DiagramNLEC0742MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0742S01

YEC729

DTC P0571 BRAKE SWYD22DDTI

Wiring Diagram

EC-1179

Page 1605 of 3051

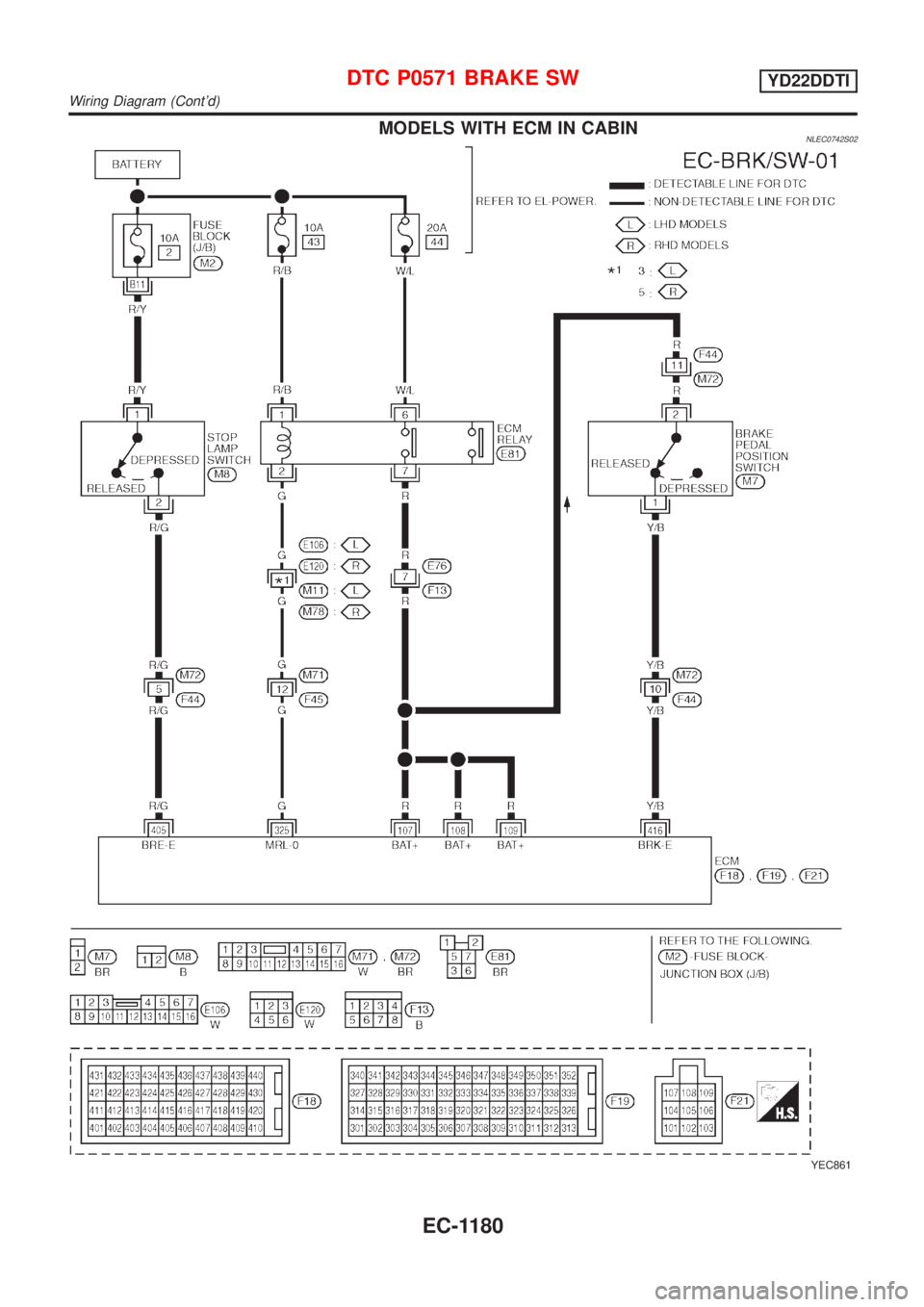

MODELS WITH ECM IN CABINNLEC0742S02

YEC861

DTC P0571 BRAKE SWYD22DDTI

Wiring Diagram (Cont'd)

EC-1180

Page 1606 of 3051

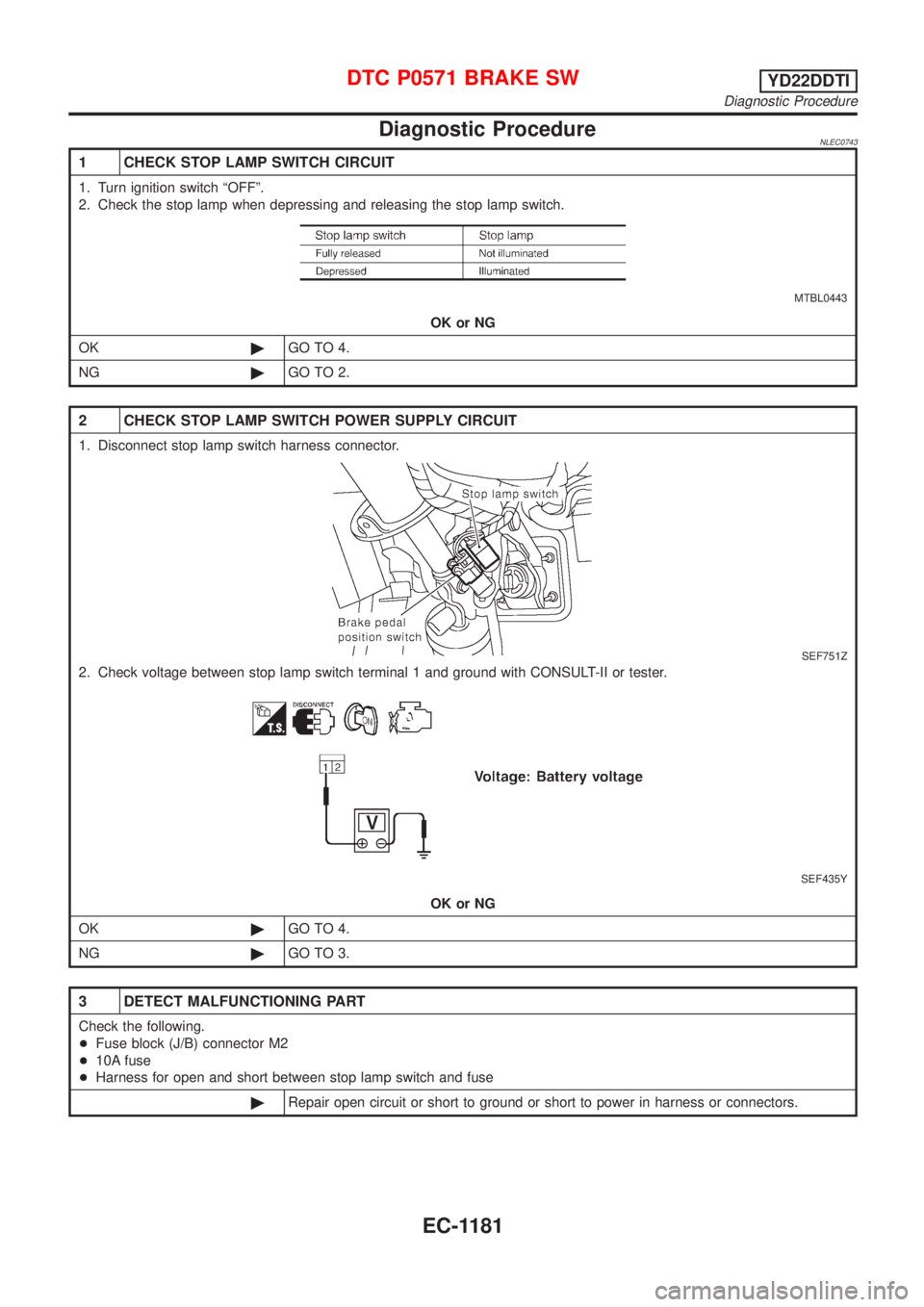

Diagnostic ProcedureNLEC0743

1 CHECK STOP LAMP SWITCH CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check the stop lamp when depressing and releasing the stop lamp switch.

MTBL0443

OK or NG

OK©GO TO 4.

NG©GO TO 2.

2 CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Disconnect stop lamp switch harness connector.

SEF751Z

2. Check voltage between stop lamp switch terminal 1 and ground with CONSULT-II or tester.

SEF435Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open and short between stop lamp switch and fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0571 BRAKE SWYD22DDTI

Diagnostic Procedure

EC-1181

Page 1607 of 3051

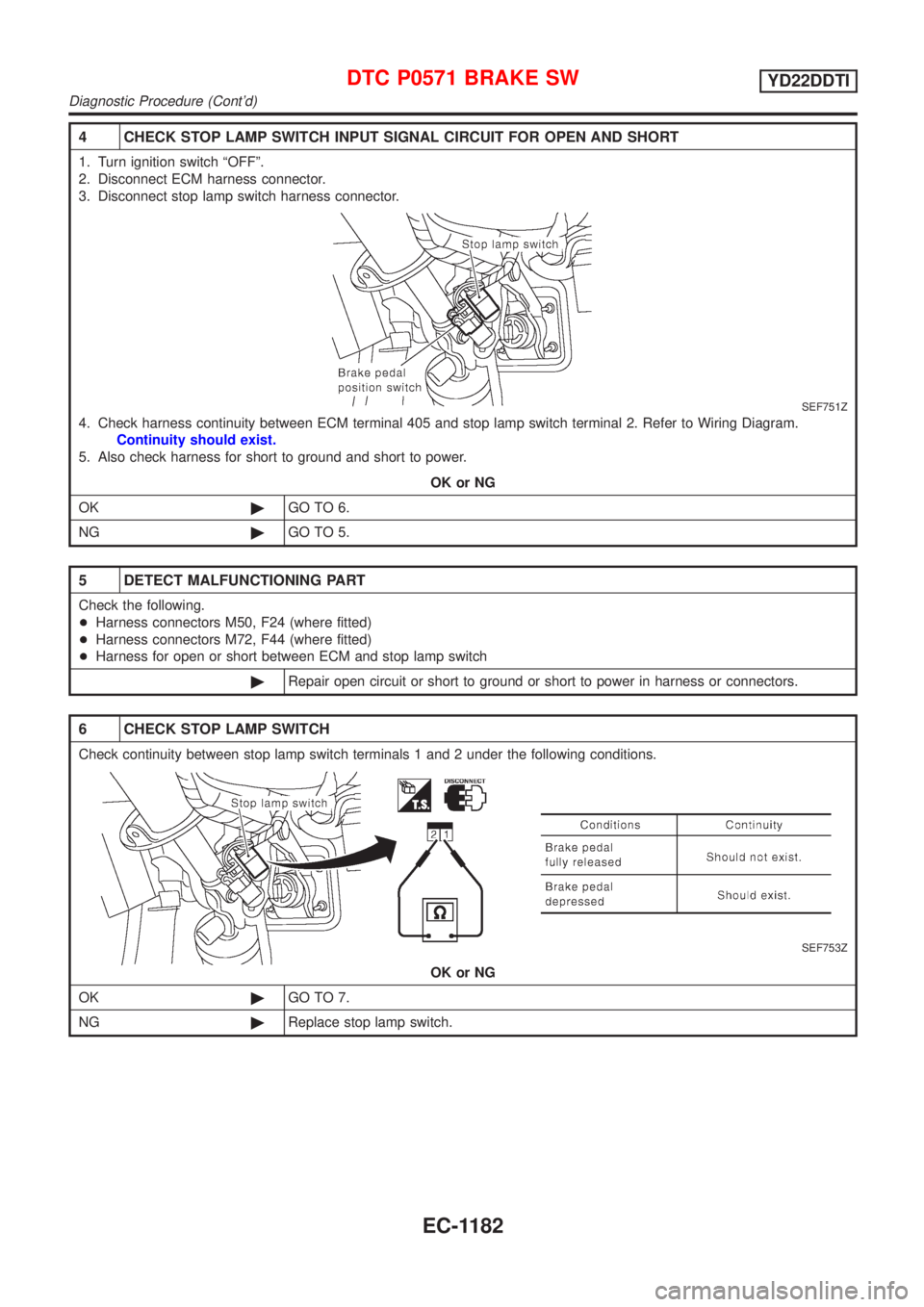

4 CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Disconnect stop lamp switch harness connector.

SEF751Z

4. Check harness continuity between ECM terminal 405 and stop lamp switch terminal 2. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F24 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between ECM and stop lamp switch

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK STOP LAMP SWITCH

Check continuity between stop lamp switch terminals 1 and 2 under the following conditions.

SEF753Z

OK or NG

OK©GO TO 7.

NG©Replace stop lamp switch.

DTC P0571 BRAKE SWYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1182

Page 1608 of 3051

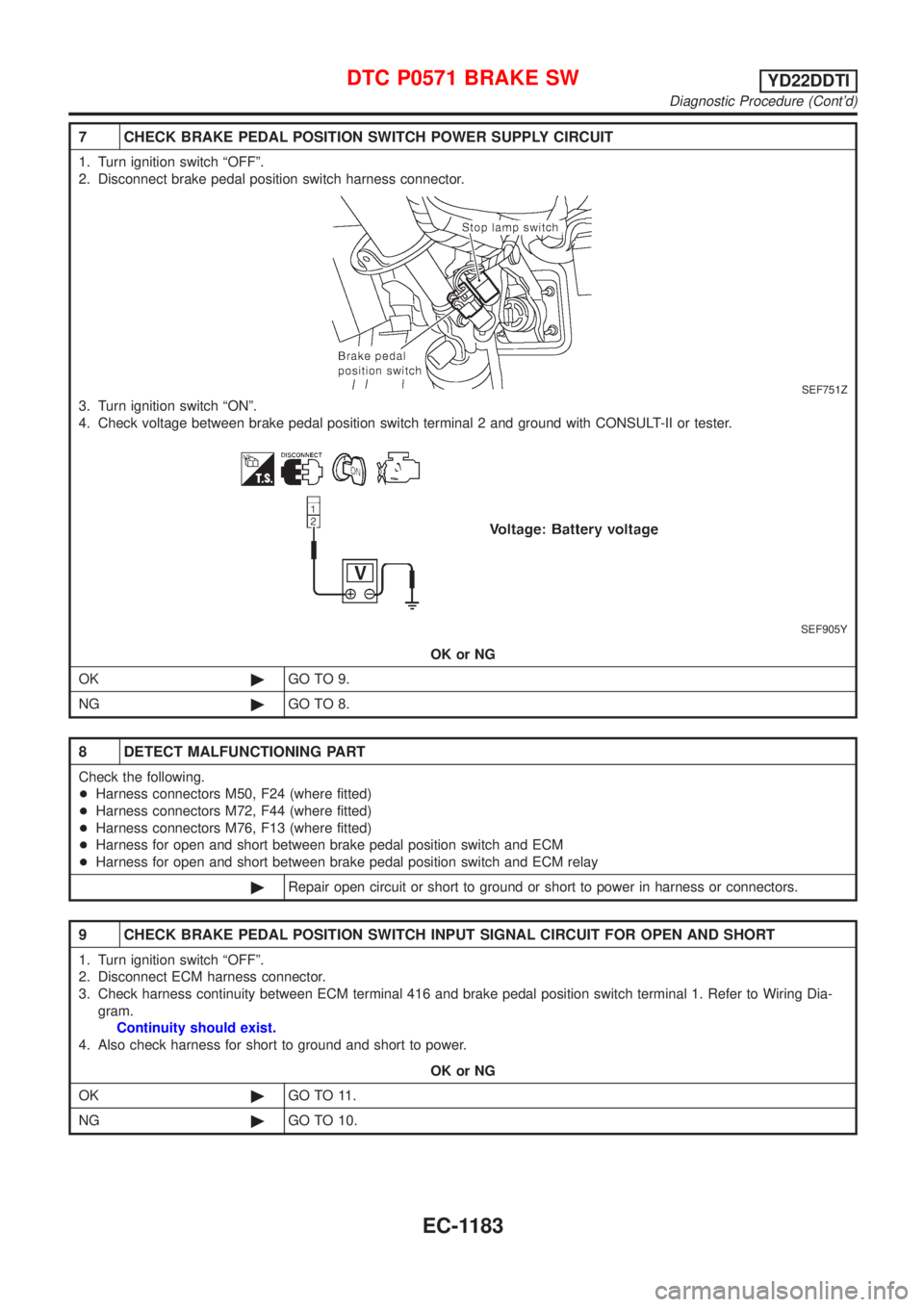

7 CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect brake pedal position switch harness connector.

SEF751Z

3. Turn ignition switch ªONº.

4. Check voltage between brake pedal position switch terminal 2 and ground with CONSULT-II or tester.

SEF905Y

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F24 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness connectors M76, F13 (where fitted)

+Harness for open and short between brake pedal position switch and ECM

+Harness for open and short between brake pedal position switch and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

9 CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 416 and brake pedal position switch terminal 1. Refer to Wiring Dia-

gram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 11.

NG©GO TO 10.

DTC P0571 BRAKE SWYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1183

Page 1609 of 3051

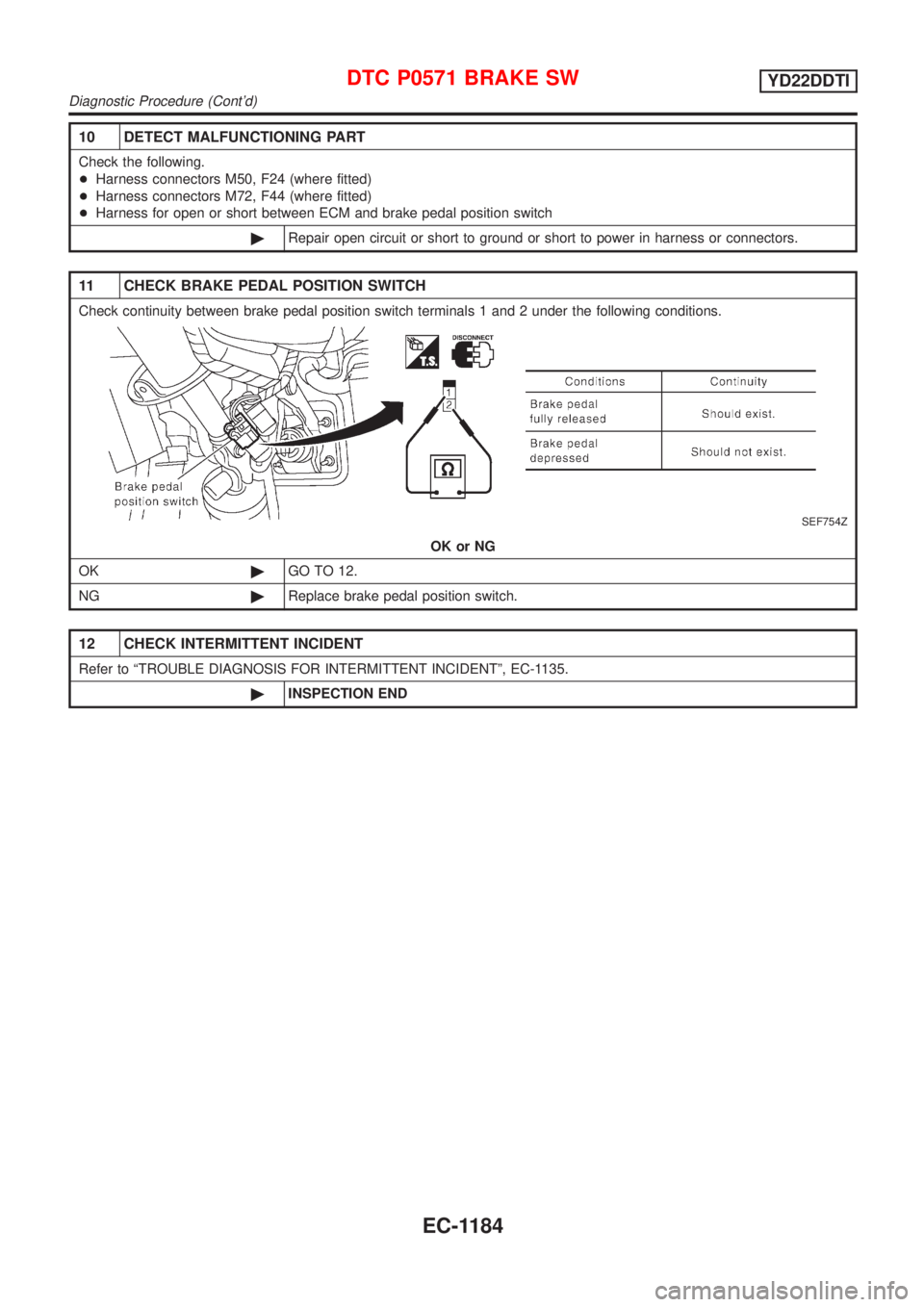

10 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F24 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between ECM and brake pedal position switch

©Repair open circuit or short to ground or short to power in harness or connectors.

11 CHECK BRAKE PEDAL POSITION SWITCH

Check continuity between brake pedal position switch terminals 1 and 2 under the following conditions.

SEF754Z

OK or NG

OK©GO TO 12.

NG©Replace brake pedal position switch.

12 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1135.

©INSPECTION END

DTC P0571 BRAKE SWYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1184

Page 1610 of 3051

SEC220B

DescriptionNLEC0734The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis LogicNLEC0735

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1107

0802+An excessively high or low voltage from the

absolute pressure sensor (built-into ECM) is sent

to ECM.+ECM

(ECCS-D control module)

SEF817Y

DTC Confirmation ProcedureNLEC0736WITH CONSULT-IINLEC0736S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1186.

WITHOUT CONSULT-IINLEC0736S021) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1186.

DTC P1107 ECM 10YD22DDTI

Description

EC-1185