NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: spare tire, change language, airbag, maintenance schedule, remove seats, brake sensor, run flat

Page 1591 of 3051

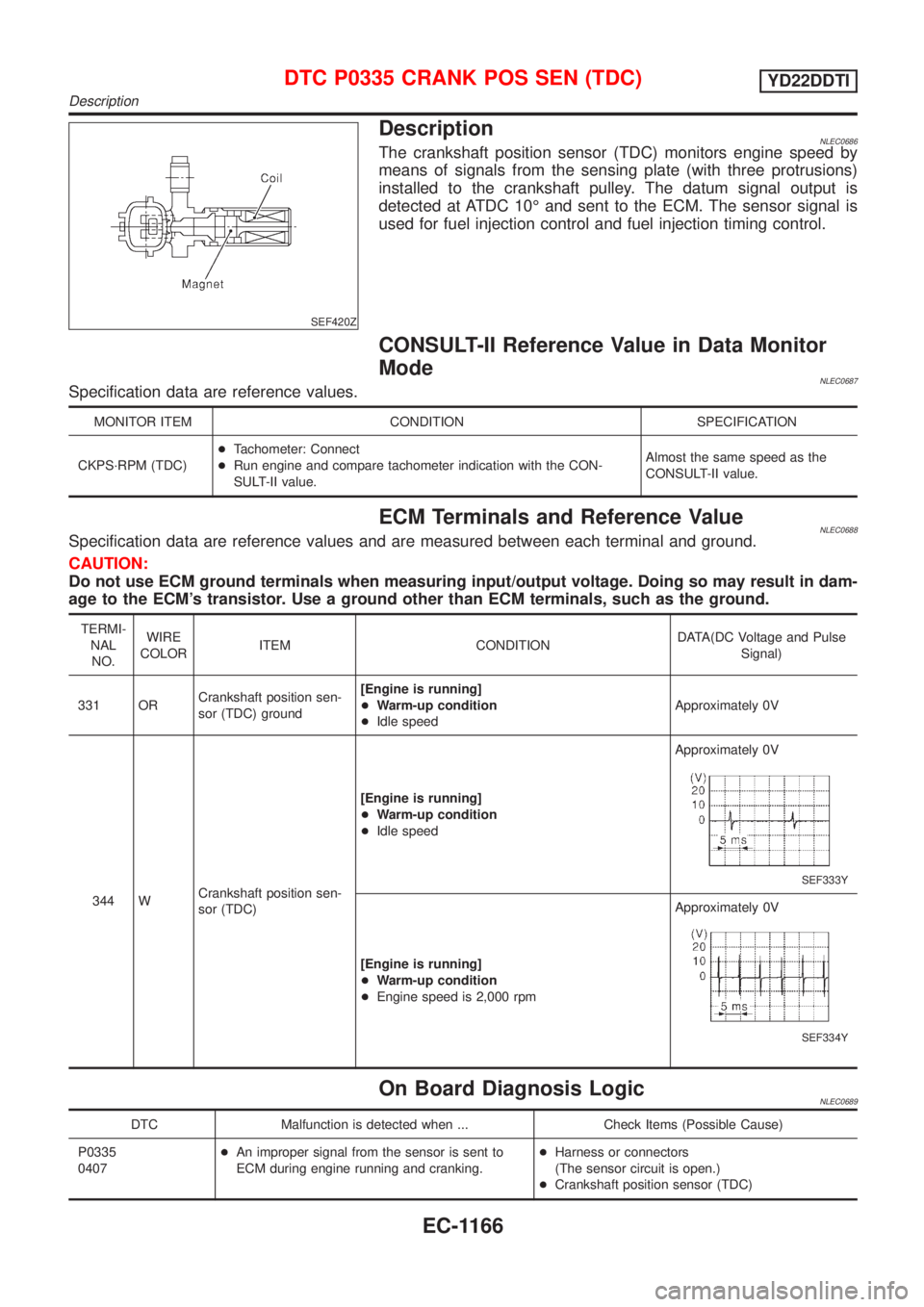

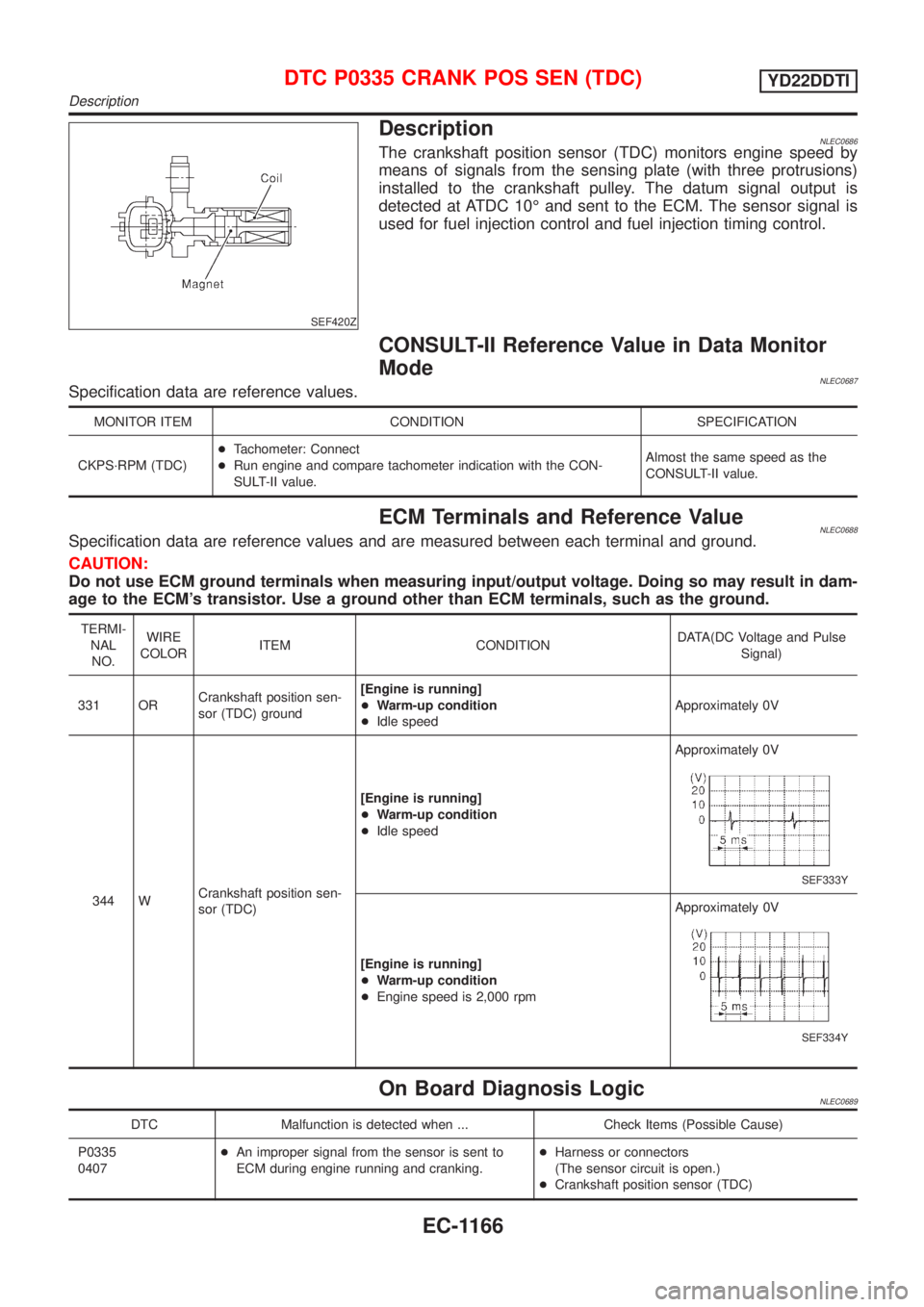

SEF420Z

DescriptionNLEC0686The crankshaft position sensor (TDC) monitors engine speed by

means of signals from the sensing plate (with three protrusions)

installed to the crankshaft pulley. The datum signal output is

detected at ATDC 10É and sent to the ECM. The sensor signal is

used for fuel injection control and fuel injection timing control.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0687Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPS´RPM (TDC)+Tachometer: Connect

+Run engine and compare tachometer indication with the CON-

SULT-II value.Almost the same speed as the

CONSULT-II value.

ECM Terminals and Reference ValueNLEC0688Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA(DC Voltage and Pulse

Signal)

331 ORCrankshaft position sen-

sor (TDC) ground[Engine is running]

+Warm-up condition

+Idle speedApproximately 0V

344 WCrankshaft position sen-

sor (TDC)[Engine is running]

+Warm-up condition

+Idle speedApproximately 0V

SEF333Y

[Engine is running]

+Warm-up condition

+Engine speed is 2,000 rpmApproximately 0V

SEF334Y

On Board Diagnosis LogicNLEC0689

DTC Malfunction is detected when ... Check Items (Possible Cause)

P0335

0407+An improper signal from the sensor is sent to

ECM during engine running and cranking.+Harness or connectors

(The sensor circuit is open.)

+Crankshaft position sensor (TDC)

DTC P0335 CRANK POS SEN (TDC)YD22DDTI

Description

EC-1166

Page 1592 of 3051

SEF817Y

DTC Confirmation ProcedureNLEC0690Before performing the following procedure, confirm that bat-

tery voltage is more than 10V.

WITH CONSULT-IINLEC0690S011) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1169.

WITHOUT CONSULT-IINLEC0690S021) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle speed.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1169.

DTC P0335 CRANK POS SEN (TDC)YD22DDTI

DTC Confirmation Procedure

EC-1167

Page 1593 of 3051

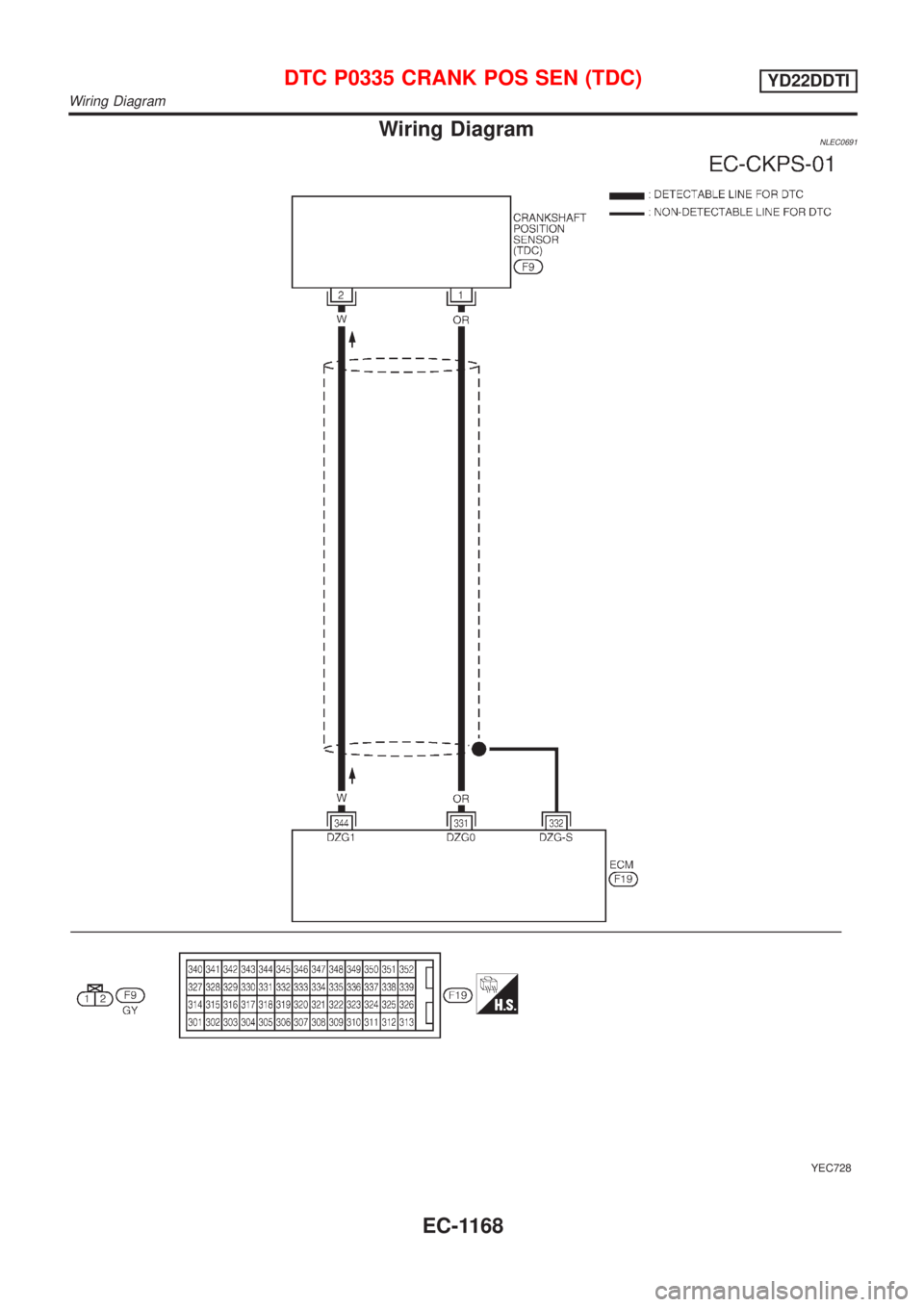

Wiring DiagramNLEC0691

YEC728

DTC P0335 CRANK POS SEN (TDC)YD22DDTI

Wiring Diagram

EC-1168

Page 1594 of 3051

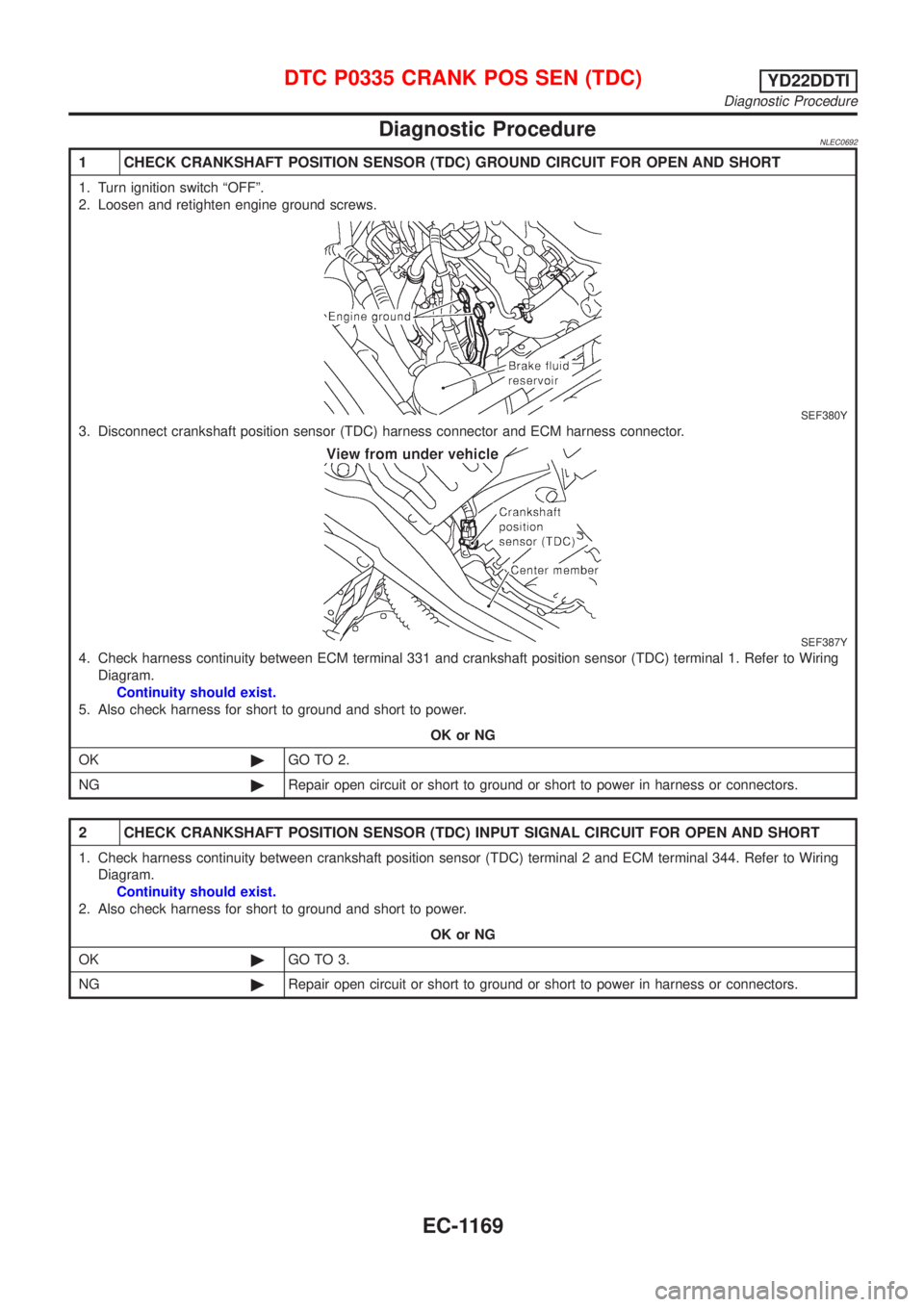

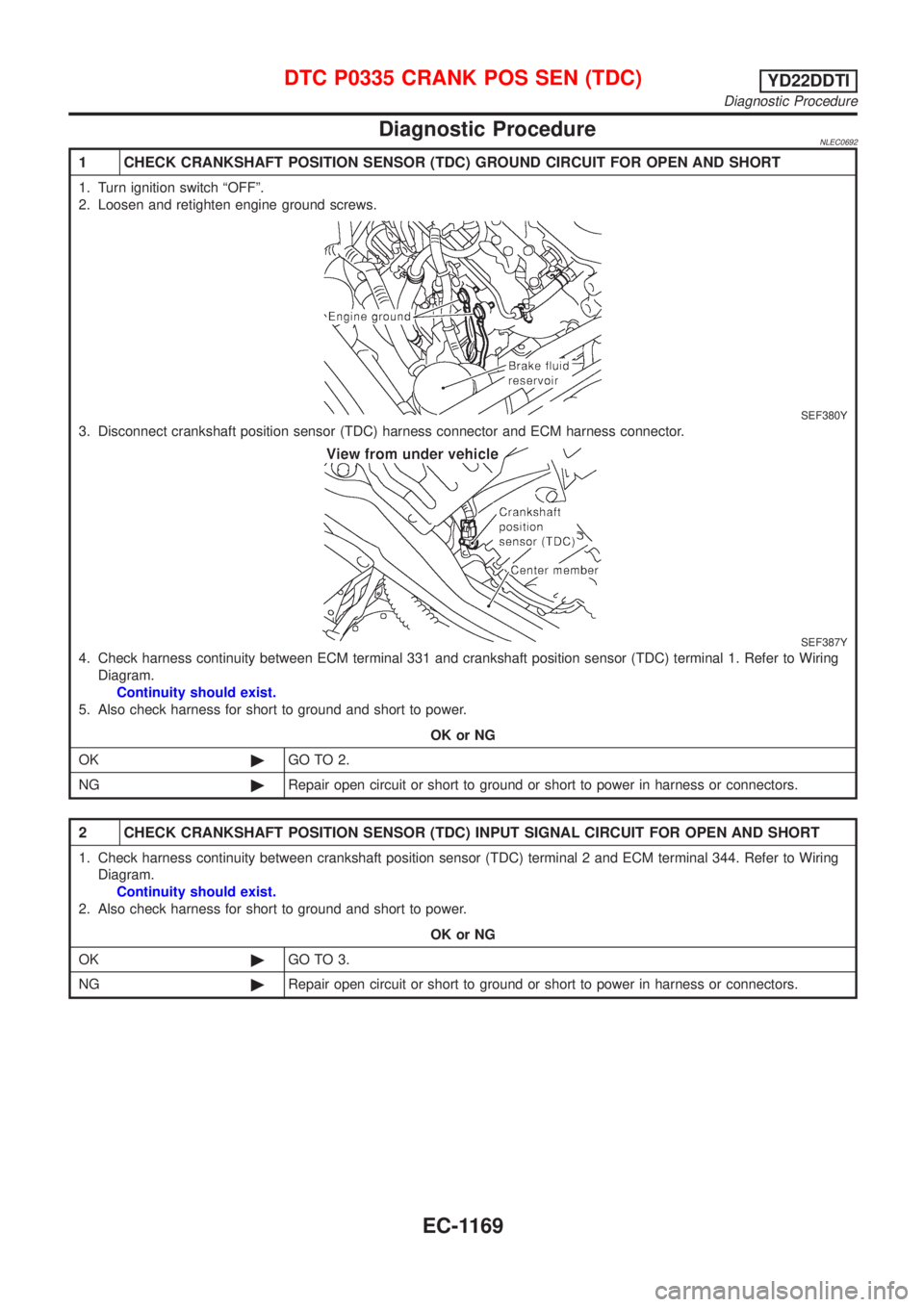

Diagnostic ProcedureNLEC0692

1 CHECK CRANKSHAFT POSITION SENSOR (TDC) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF380Y

3. Disconnect crankshaft position sensor (TDC) harness connector and ECM harness connector.

SEF387Y

4. Check harness continuity between ECM terminal 331 and crankshaft position sensor (TDC) terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 2.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

2 CHECK CRANKSHAFT POSITION SENSOR (TDC) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between crankshaft position sensor (TDC) terminal 2 and ECM terminal 344. Refer to Wiring

Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0335 CRANK POS SEN (TDC)YD22DDTI

Diagnostic Procedure

EC-1169

Page 1595 of 3051

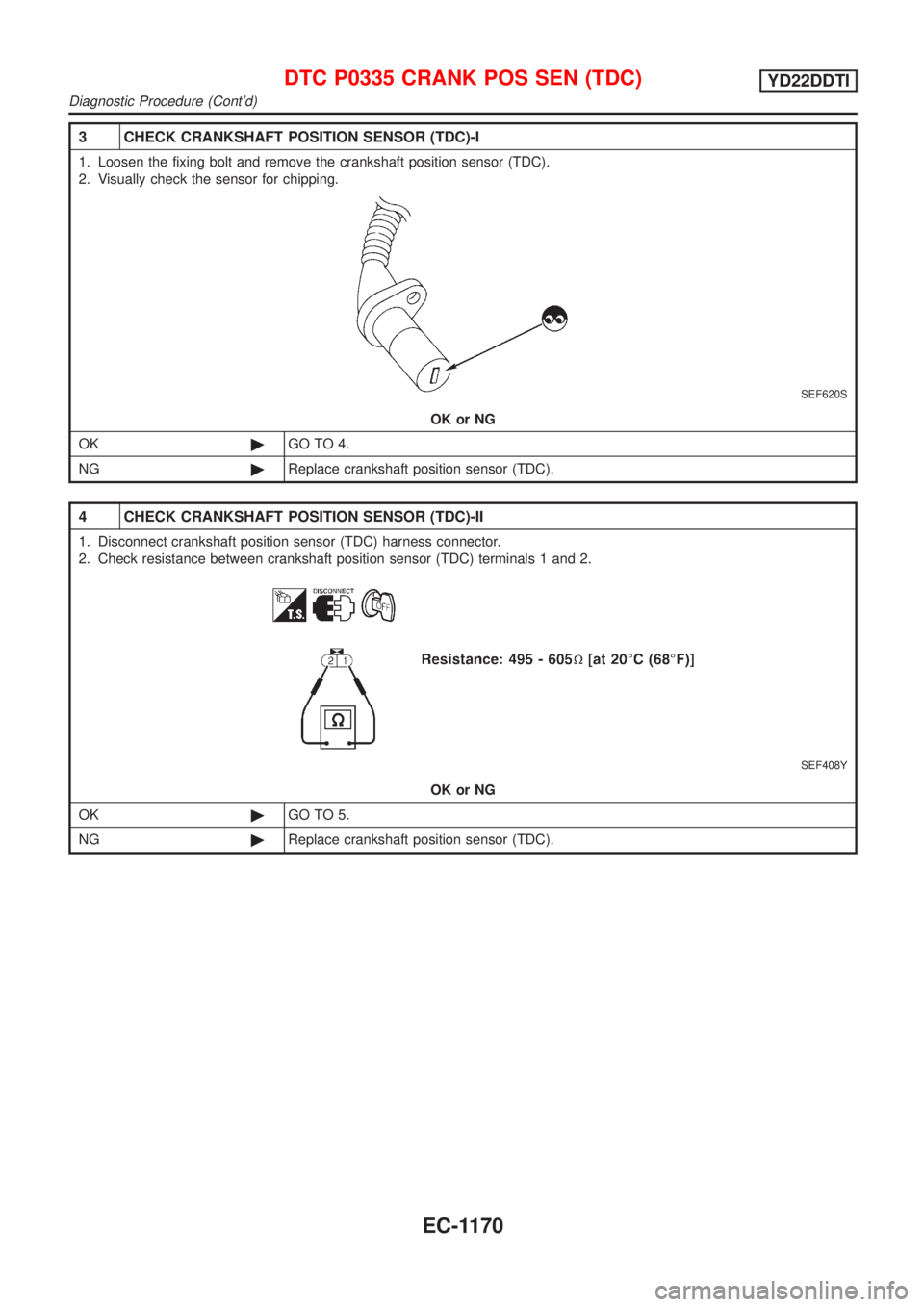

3 CHECK CRANKSHAFT POSITION SENSOR (TDC)-I

1. Loosen the fixing bolt and remove the crankshaft position sensor (TDC).

2. Visually check the sensor for chipping.

SEF620S

OK or NG

OK©GO TO 4.

NG©Replace crankshaft position sensor (TDC).

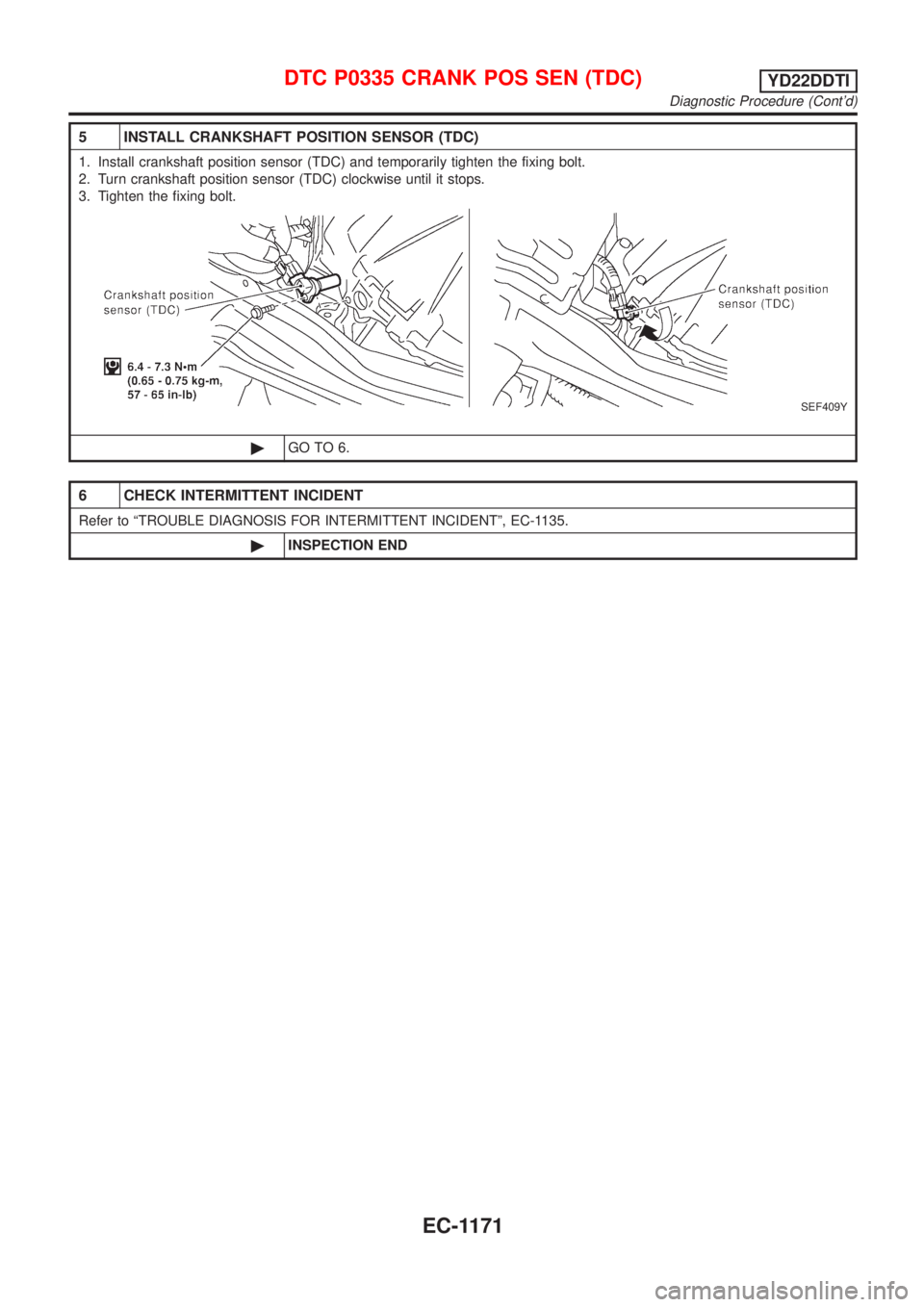

4 CHECK CRANKSHAFT POSITION SENSOR (TDC)-II

1. Disconnect crankshaft position sensor (TDC) harness connector.

2. Check resistance between crankshaft position sensor (TDC) terminals 1 and 2.

SEF408Y

OK or NG

OK©GO TO 5.

NG©Replace crankshaft position sensor (TDC).

DTC P0335 CRANK POS SEN (TDC)YD22DDTI

Diagnostic Procedure (Cont'd)

EC-1170

Page 1596 of 3051

5 INSTALL CRANKSHAFT POSITION SENSOR (TDC)

1. Install crankshaft position sensor (TDC) and temporarily tighten the fixing bolt.

2. Turn crankshaft position sensor (TDC) clockwise until it stops.

3. Tighten the fixing bolt.

SEF409Y

©GO TO 6.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1135.

©INSPECTION END

DTC P0335 CRANK POS SEN (TDC)YD22DDTI

Diagnostic Procedure (Cont'd)

EC-1171

Page 1597 of 3051

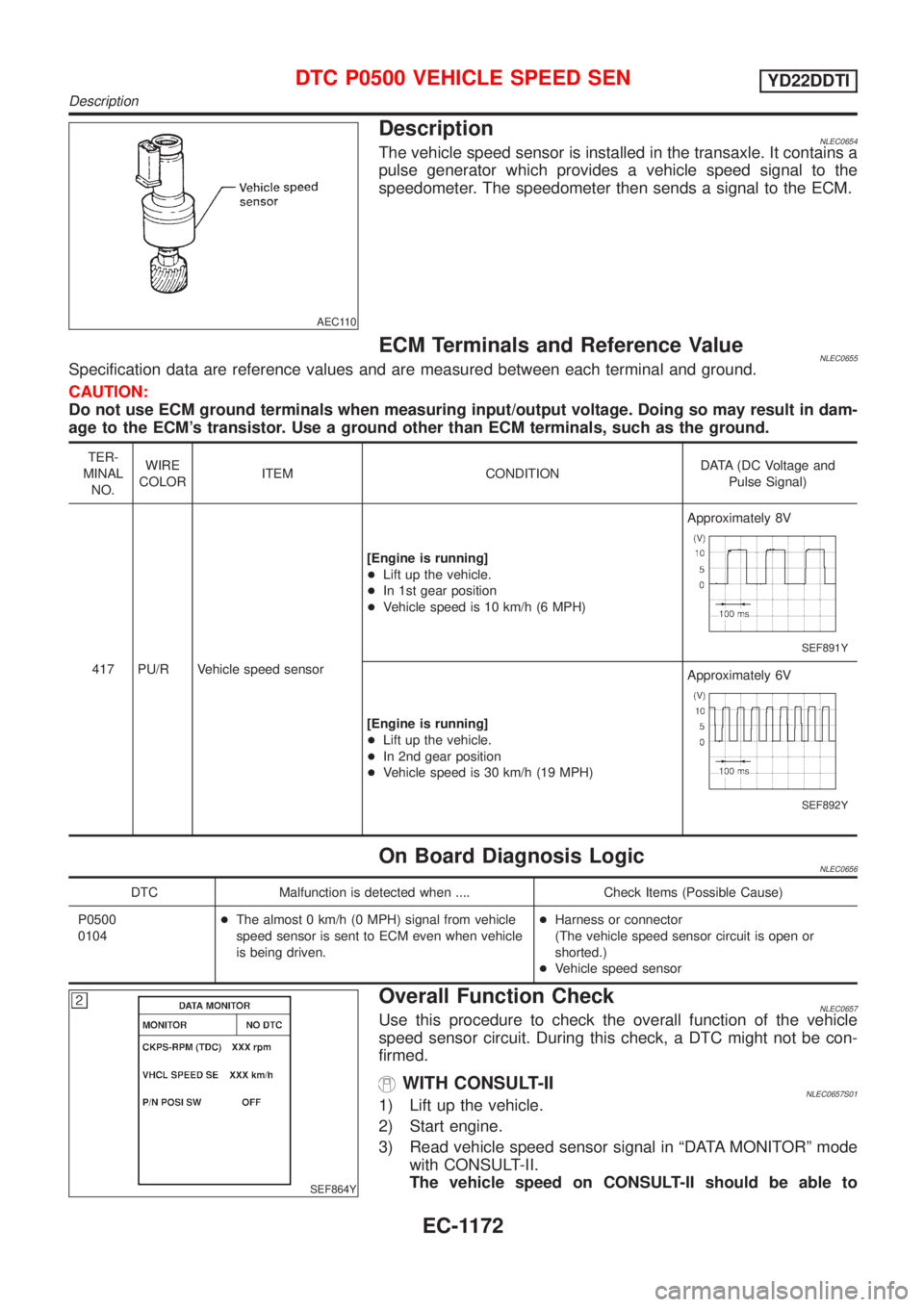

AEC110

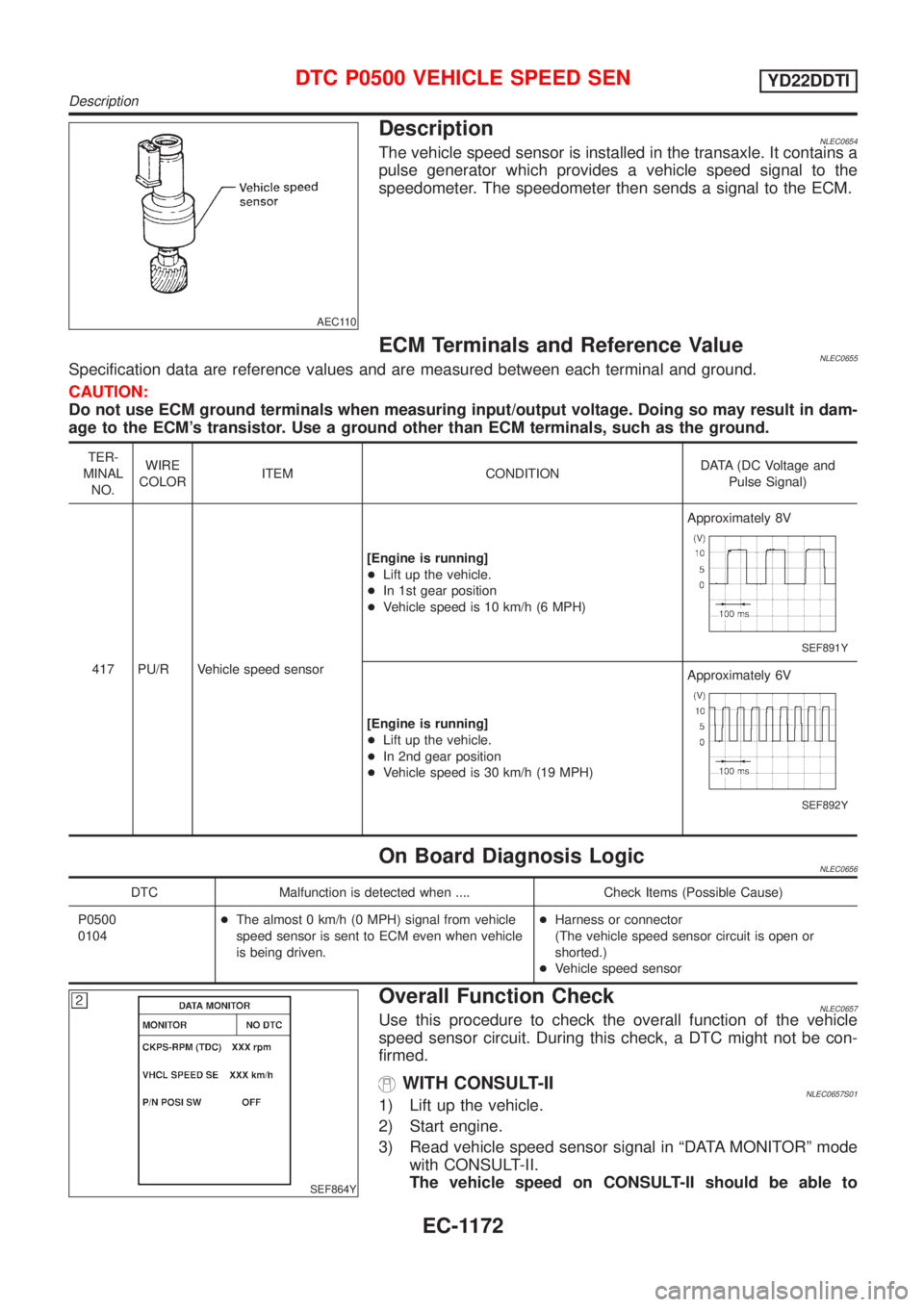

DescriptionNLEC0654The vehicle speed sensor is installed in the transaxle. It contains a

pulse generator which provides a vehicle speed signal to the

speedometer. The speedometer then sends a signal to the ECM.

ECM Terminals and Reference ValueNLEC0655Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

417 PU/R Vehicle speed sensor[Engine is running]

+Lift up the vehicle.

+In 1st gear position

+Vehicle speed is 10 km/h (6 MPH)Approximately 8V

SEF891Y

[Engine is running]

+Lift up the vehicle.

+In 2nd gear position

+Vehicle speed is 30 km/h (19 MPH)Approximately 6V

SEF892Y

On Board Diagnosis LogicNLEC0656

DTC Malfunction is detected when .... Check Items (Possible Cause)

P0500

0104+The almost 0 km/h (0 MPH) signal from vehicle

speed sensor is sent to ECM even when vehicle

is being driven.+Harness or connector

(The vehicle speed sensor circuit is open or

shorted.)

+Vehicle speed sensor

SEF864Y

Overall Function CheckNLEC0657Use this procedure to check the overall function of the vehicle

speed sensor circuit. During this check, a DTC might not be con-

firmed.

WITH CONSULT-IINLEC0657S011) Lift up the vehicle.

2) Start engine.

3) Read vehicle speed sensor signal in ªDATA MONITORº mode

with CONSULT-II.

The vehicle speed on CONSULT-II should be able to

DTC P0500 VEHICLE SPEED SENYD22DDTI

Description

EC-1172

Page 1598 of 3051

exceed 10 km/h (6 MPH) when rotating wheels with suit-

able gear position.

4) If NG, go to ªDiagnostic Procedureº, EC-1176.

WITHOUT CONSULT-IINLEC0657S021) Lift up the vehicle.

2) Start engine.

3) Read the voltage signal for the vehicle speed sensor with an

oscilloscope. Refer to ªECM Terminals and Reference Valueº,

EC-1172.

4) Verify that the oscilloscope screen shows the signal wave as

shown at ªECM Terminals and Reference Valueº, EC-1172.

5) If NG, go to ªDiagnostic Procedureº, EC-1176.

DTC P0500 VEHICLE SPEED SENYD22DDTI

Overall Function Check (Cont'd)

EC-1173

Page 1599 of 3051

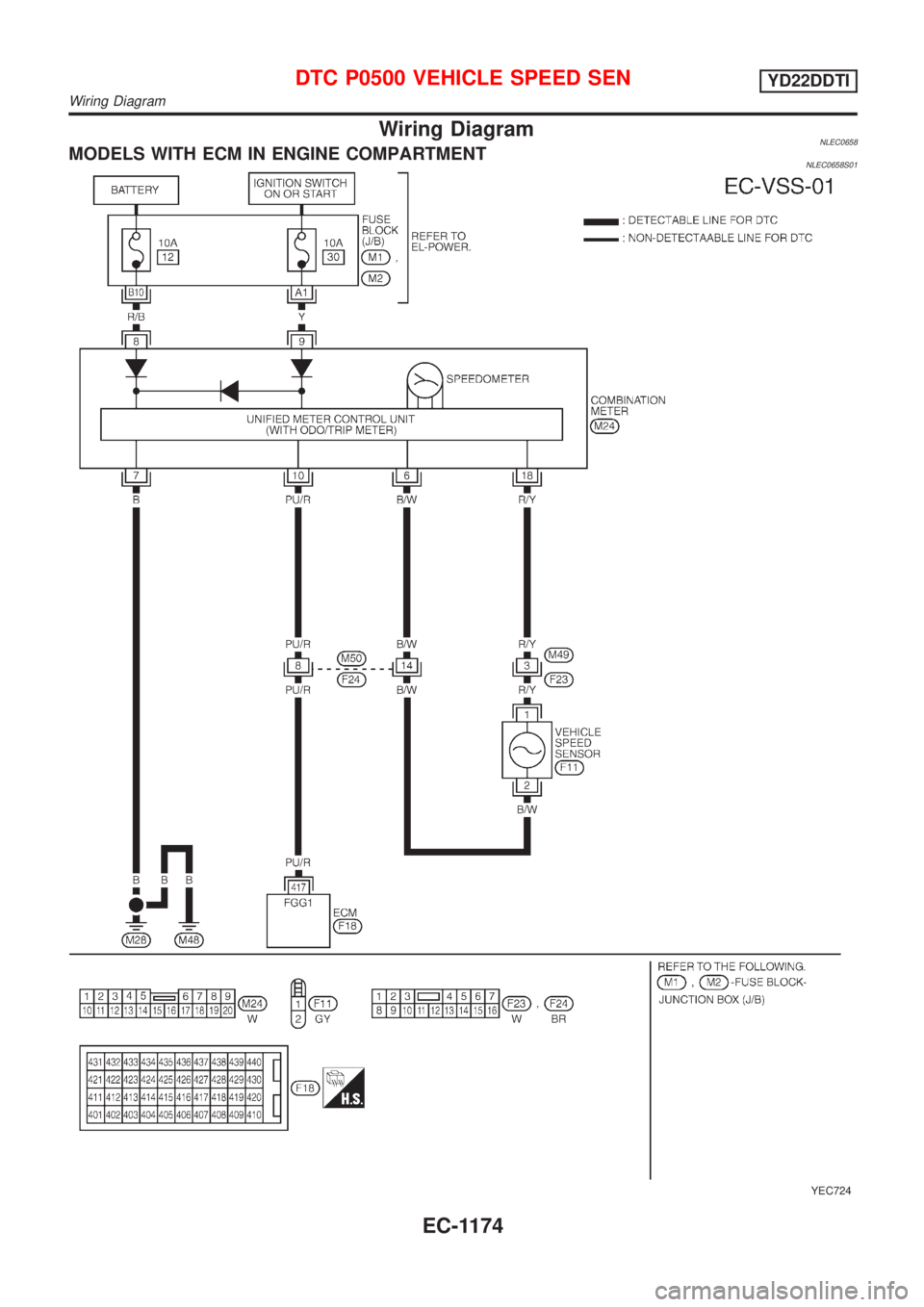

Wiring DiagramNLEC0658MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0658S01

YEC724

DTC P0500 VEHICLE SPEED SENYD22DDTI

Wiring Diagram

EC-1174

Page 1600 of 3051

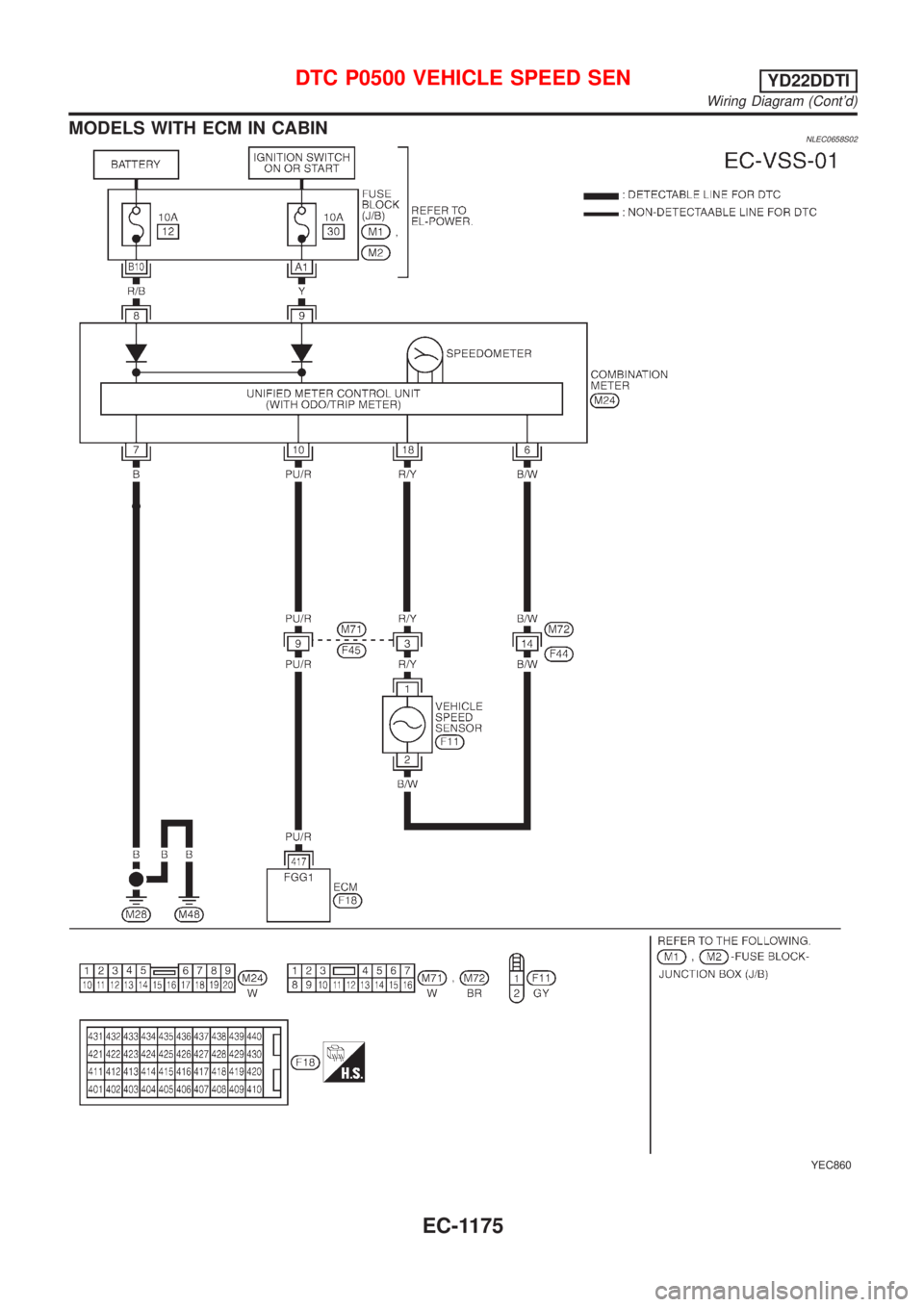

MODELS WITH ECM IN CABINNLEC0658S02

YEC860

DTC P0500 VEHICLE SPEED SENYD22DDTI

Wiring Diagram (Cont'd)

EC-1175

Trending: low beam, wheel bolt torque, automatic transmission fluid, maintenance schedule, radiator, octane, battery replacement