NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 271 of 3051

SBR892

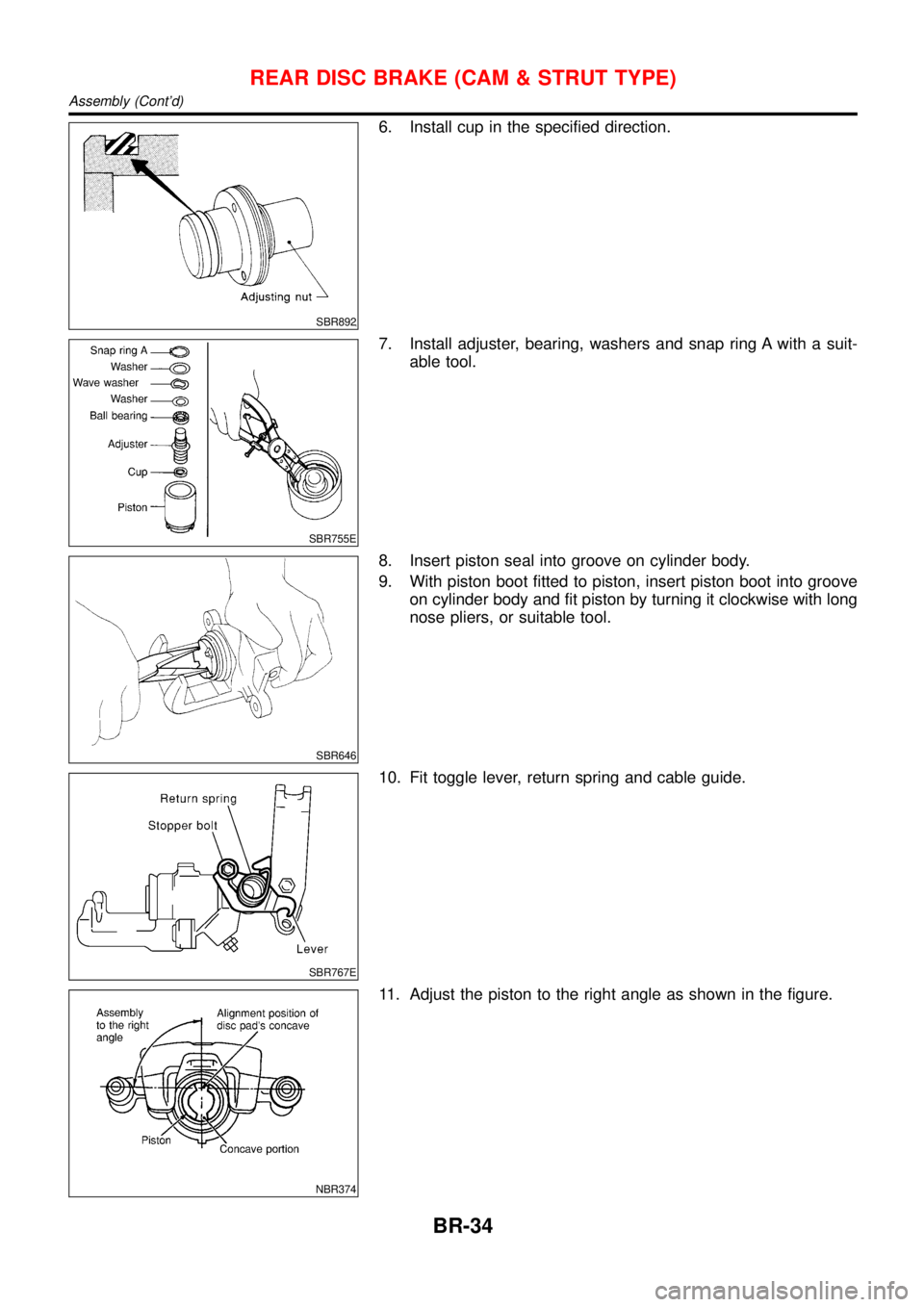

6. Install cup in the specified direction.

SBR755E

7. Install adjuster, bearing, washers and snap ring A with a suit-

able tool.

SBR646

8. Insert piston seal into groove on cylinder body.

9. With piston boot fitted to piston, insert piston boot into groove

on cylinder body and fit piston by turning it clockwise with long

nose pliers, or suitable tool.

SBR767E

10. Fit toggle lever, return spring and cable guide.

NBR374

11. Adjust the piston to the right angle as shown in the figure.

REAR DISC BRAKE (CAM & STRUT TYPE)

Assembly (Cont’d)

BR-34

Page 272 of 3051

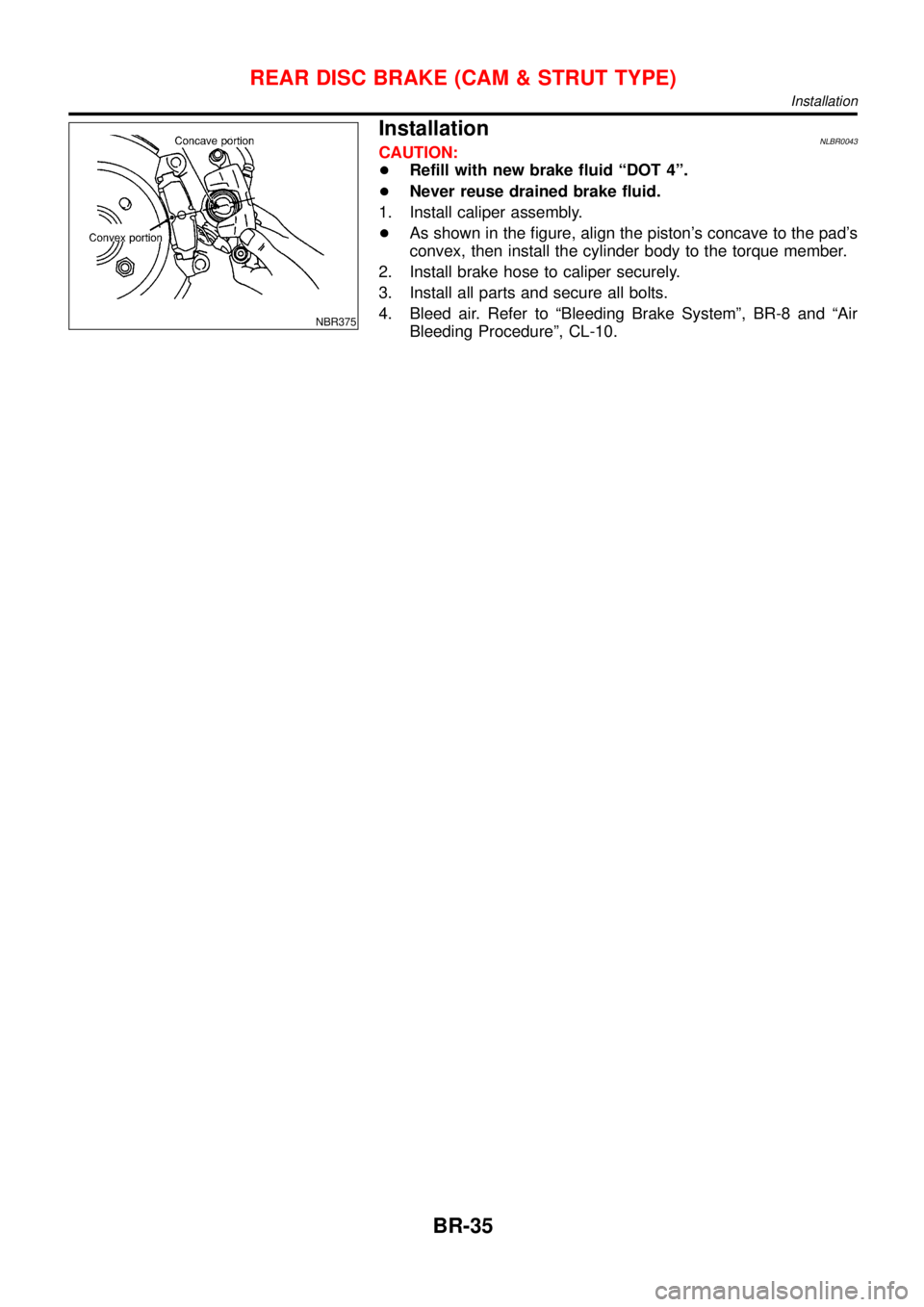

NBR375

InstallationNLBR0043CAUTION:

+Refill with new brake fluid“DOT 4”.

+Never reuse drained brake fluid.

1. Install caliper assembly.

+As shown in the figure, align the piston’s concave to the pad’s

convex, then install the cylinder body to the torque member.

2. Install brake hose to caliper securely.

3. Install all parts and secure all bolts.

4. Bleed air. Refer to“Bleeding Brake System”, BR-8 and“Air

Bleeding Procedure”, CL-10.

REAR DISC BRAKE (CAM & STRUT TYPE)

Installation

BR-35

Page 273 of 3051

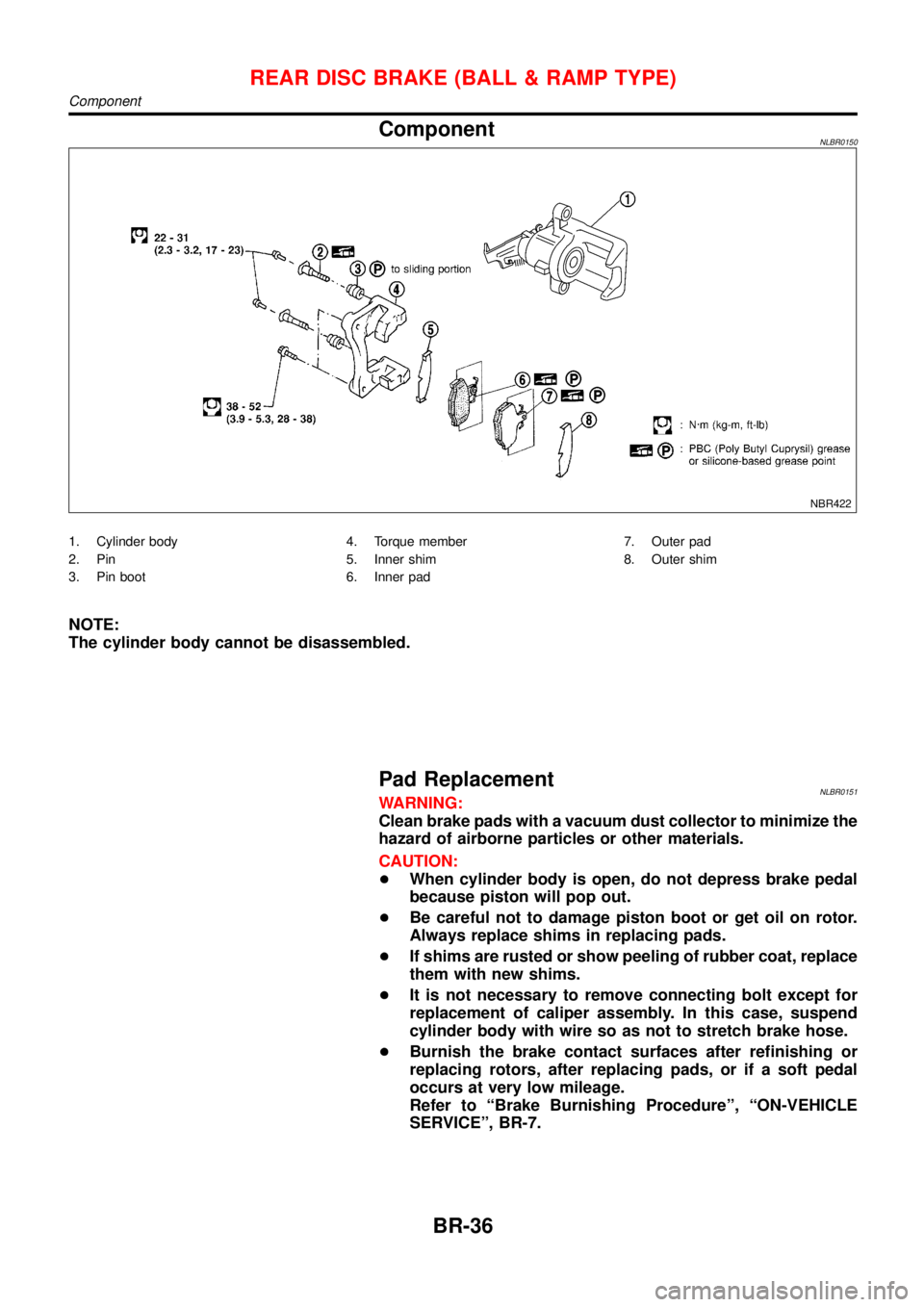

ComponentNLBR0150

NBR422

1. Cylinder body

2. Pin

3. Pin boot4. Torque member

5. Inner shim

6. Inner pad7. Outer pad

8. Outer shim

NOTE:

The cylinder body cannot be disassembled.

Pad ReplacementNLBR0151WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

+When cylinder body is open, do not depress brake pedal

because piston will pop out.

+Be careful not to damage piston boot or get oil on rotor.

Always replace shims in replacing pads.

+If shims are rusted or show peeling of rubber coat, replace

them with new shims.

+It is not necessary to remove connecting bolt except for

replacement of caliper assembly. In this case, suspend

cylinder body with wire so as not to stretch brake hose.

+Burnish the brake contact surfaces after refinishing or

replacing rotors, after replacing pads, or if a soft pedal

occurs at very low mileage.

Refer to“Brake Burnishing Procedure”,“ON-VEHICLE

SERVICE”, BR-7.

REAR DISC BRAKE (BALL & RAMP TYPE)

Component

BR-36

Page 274 of 3051

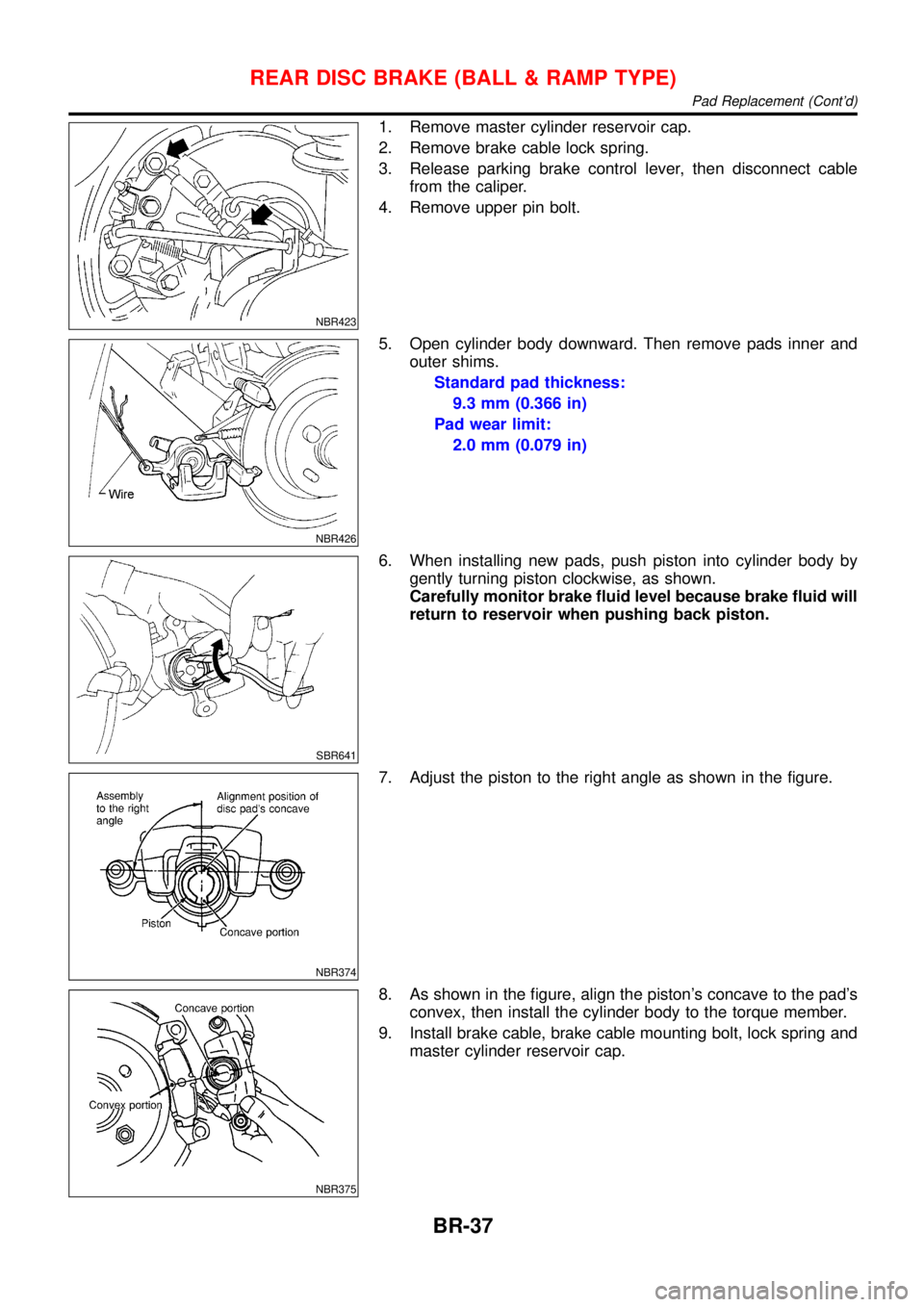

NBR423

1. Remove master cylinder reservoir cap.

2. Remove brake cable lock spring.

3. Release parking brake control lever, then disconnect cable

from the caliper.

4. Remove upper pin bolt.

NBR426

5. Open cylinder body downward. Then remove pads inner and

outer shims.

Standard pad thickness:

9.3 mm (0.366 in)

Pad wear limit:

2.0 mm (0.079 in)

SBR641

6. When installing new pads, push piston into cylinder body by

gently turning piston clockwise, as shown.

Carefully monitor brake fluid level because brake fluid will

return to reservoir when pushing back piston.

NBR374

7. Adjust the piston to the right angle as shown in the figure.

NBR375

8. As shown in the figure, align the piston’s concave to the pad’s

convex, then install the cylinder body to the torque member.

9. Install brake cable, brake cable mounting bolt, lock spring and

master cylinder reservoir cap.

REAR DISC BRAKE (BALL & RAMP TYPE)

Pad Replacement (Cont’d)

BR-37

Page 275 of 3051

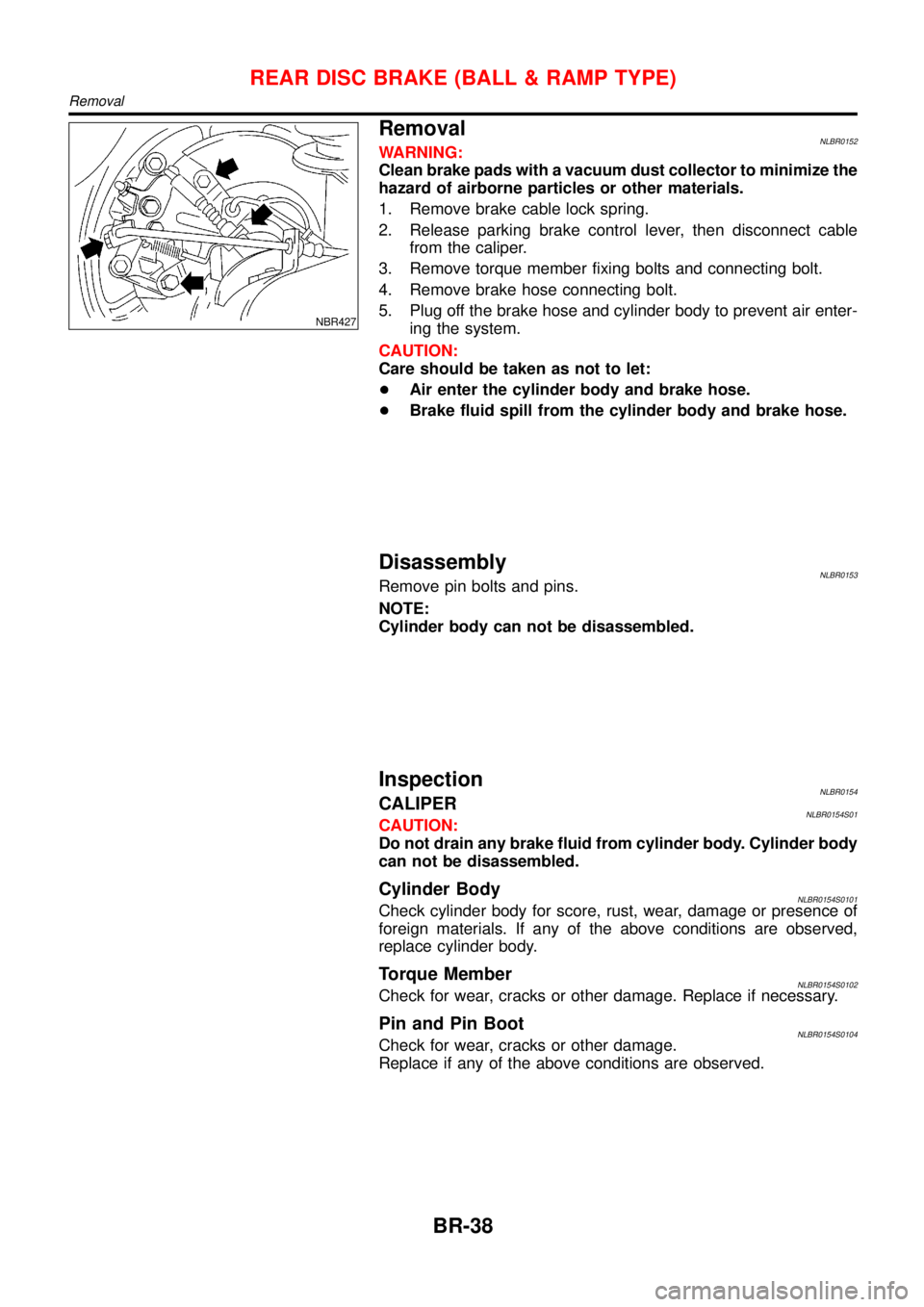

NBR427

RemovalNLBR0152WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

1. Remove brake cable lock spring.

2. Release parking brake control lever, then disconnect cable

from the caliper.

3. Remove torque member fixing bolts and connecting bolt.

4. Remove brake hose connecting bolt.

5. Plug off the brake hose and cylinder body to prevent air enter-

ing the system.

CAUTION:

Care should be taken as not to let:

+Air enter the cylinder body and brake hose.

+Brake fluid spill from the cylinder body and brake hose.

DisassemblyNLBR0153Remove pin bolts and pins.

NOTE:

Cylinder body can not be disassembled.

InspectionNLBR0154CALIPERNLBR0154S01CAUTION:

Do not drain any brake fluid from cylinder body. Cylinder body

can not be disassembled.

Cylinder BodyNLBR0154S0101Check cylinder body for score, rust, wear, damage or presence of

foreign materials. If any of the above conditions are observed,

replace cylinder body.

Torque MemberNLBR0154S0102Check for wear, cracks or other damage. Replace if necessary.

Pin and Pin BootNLBR0154S0104Check for wear, cracks or other damage.

Replace if any of the above conditions are observed.

REAR DISC BRAKE (BALL & RAMP TYPE)

Removal

BR-38

Page 276 of 3051

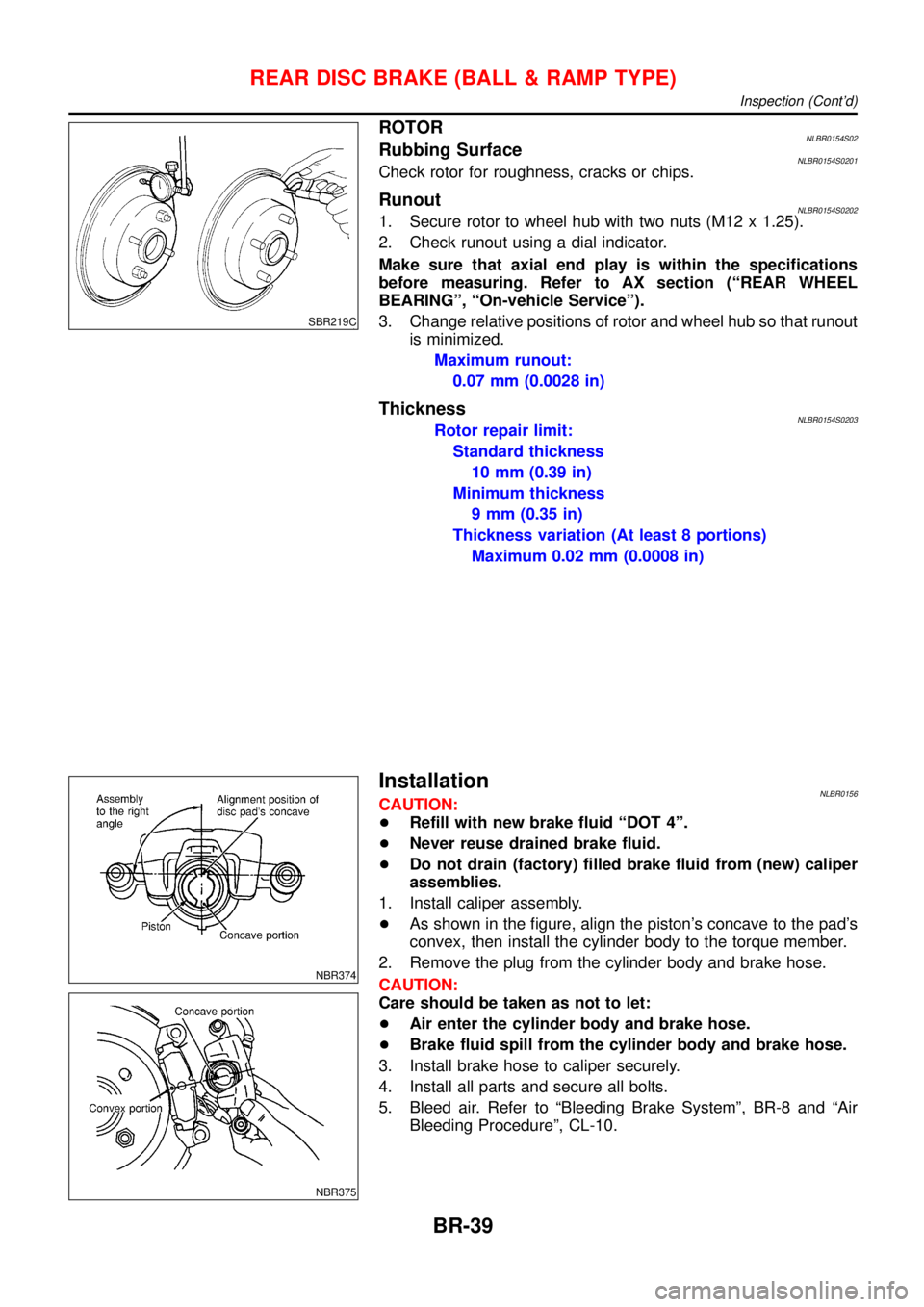

SBR219C

ROTORNLBR0154S02Rubbing SurfaceNLBR0154S0201Check rotor for roughness, cracks or chips.

RunoutNLBR0154S02021. Secure rotor to wheel hub with two nuts (M12 x 1.25).

2. Check runout using a dial indicator.

Make sure that axial end play is within the specifications

before measuring. Refer to AX section (“REAR WHEEL

BEARING”,“On-vehicle Service”).

3. Change relative positions of rotor and wheel hub so that runout

is minimized.

Maximum runout:

0.07 mm (0.0028 in)

ThicknessNLBR0154S0203Rotor repair limit:

Standard thickness

10 mm (0.39 in)

Minimum thickness

9 mm (0.35 in)

Thickness variation (At least 8 portions)

Maximum 0.02 mm (0.0008 in)

NBR374

NBR375

InstallationNLBR0156CAUTION:

+Refill with new brake fluid“DOT 4”.

+Never reuse drained brake fluid.

+Do not drain (factory) filled brake fluid from (new) caliper

assemblies.

1. Install caliper assembly.

+As shown in the figure, align the piston’s concave to the pad’s

convex, then install the cylinder body to the torque member.

2. Remove the plug from the cylinder body and brake hose.

CAUTION:

Care should be taken as not to let:

+Air enter the cylinder body and brake hose.

+Brake fluid spill from the cylinder body and brake hose.

3. Install brake hose to caliper securely.

4. Install all parts and secure all bolts.

5. Bleed air. Refer to“Bleeding Brake System”, BR-8 and“Air

Bleeding Procedure”, CL-10.

REAR DISC BRAKE (BALL & RAMP TYPE)

Inspection (Cont’d)

BR-39

Page 277 of 3051

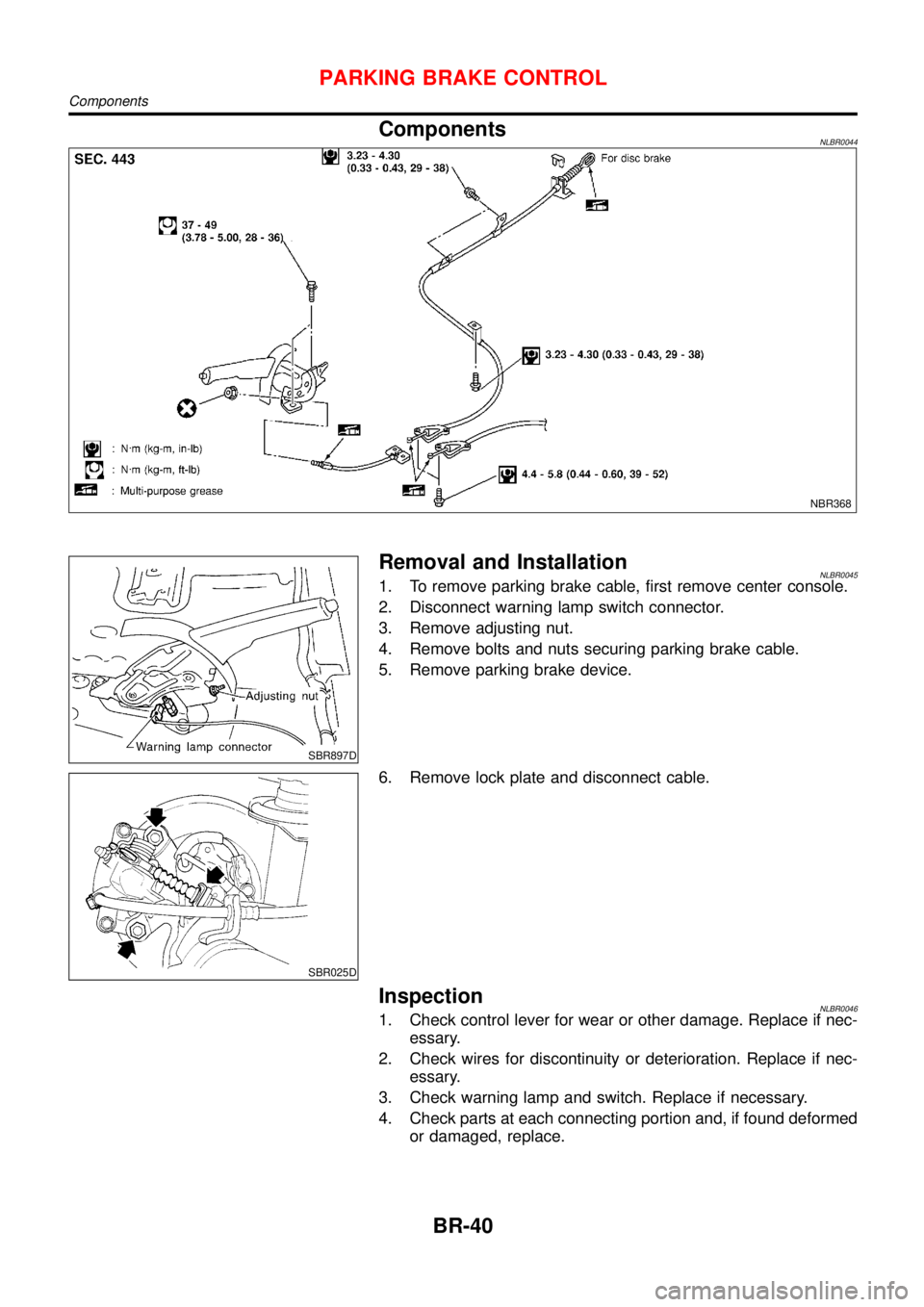

ComponentsNLBR0044

NBR368

SBR897D

Removal and InstallationNLBR00451. To remove parking brake cable, first remove center console.

2. Disconnect warning lamp switch connector.

3. Remove adjusting nut.

4. Remove bolts and nuts securing parking brake cable.

5. Remove parking brake device.

SBR025D

6. Remove lock plate and disconnect cable.

InspectionNLBR00461. Check control lever for wear or other damage. Replace if nec-

essary.

2. Check wires for discontinuity or deterioration. Replace if nec-

essary.

3. Check warning lamp and switch. Replace if necessary.

4. Check parts at each connecting portion and, if found deformed

or damaged, replace.

PARKING BRAKE CONTROL

Components

BR-40

Page 278 of 3051

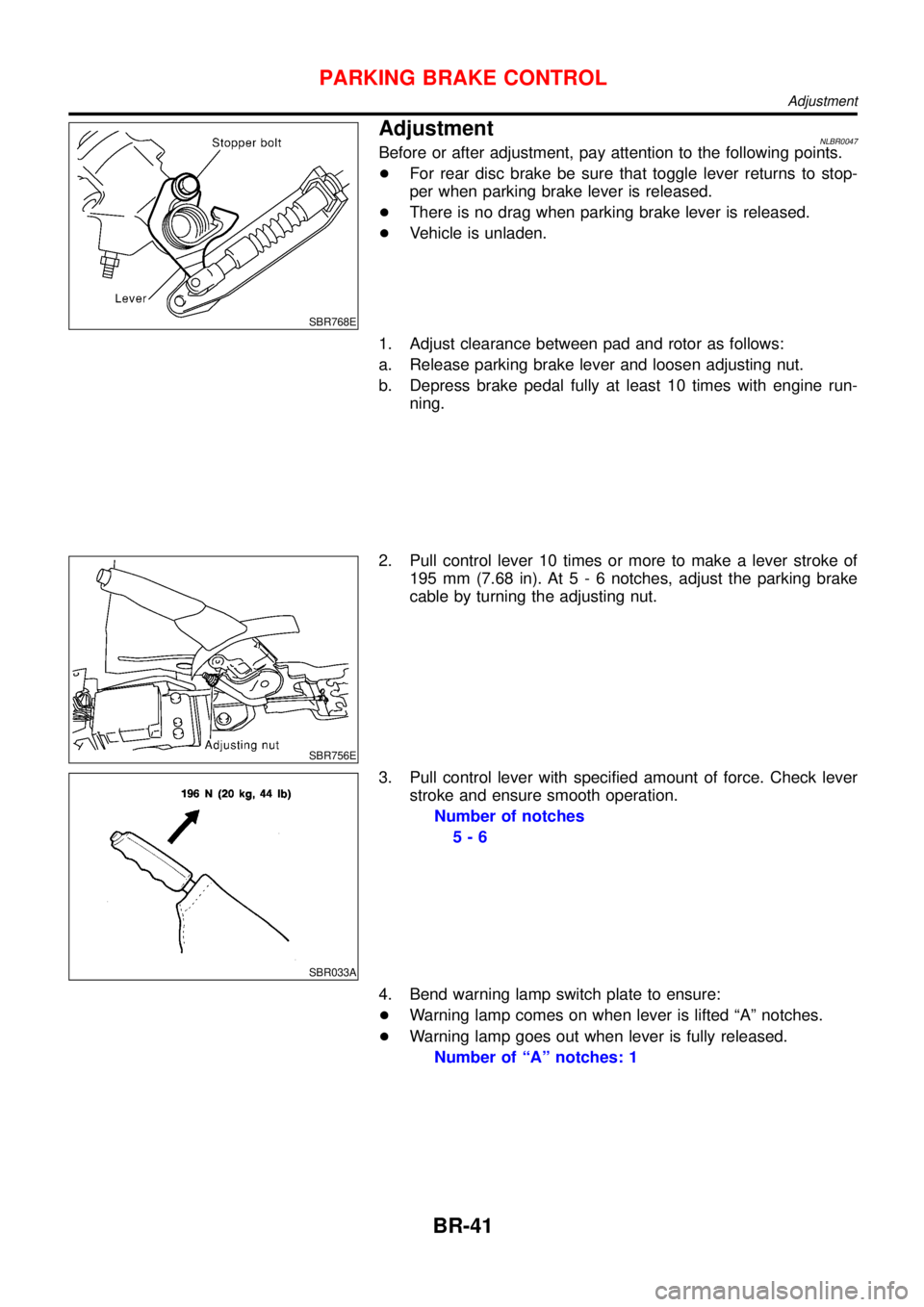

SBR768E

AdjustmentNLBR0047Before or after adjustment, pay attention to the following points.

+For rear disc brake be sure that toggle lever returns to stop-

per when parking brake lever is released.

+There is no drag when parking brake lever is released.

+Vehicle is unladen.

1. Adjust clearance between pad and rotor as follows:

a. Release parking brake lever and loosen adjusting nut.

b. Depress brake pedal fully at least 10 times with engine run-

ning.

SBR756E

2. Pull control lever 10 times or more to make a lever stroke of

195 mm (7.68 in). At5-6notches, adjust the parking brake

cable by turning the adjusting nut.

SBR033A

3. Pull control lever with specified amount of force. Check lever

stroke and ensure smooth operation.

Number of notches

5-6

4. Bend warning lamp switch plate to ensure:

+Warning lamp comes on when lever is lifted“A”notches.

+Warning lamp goes out when lever is fully released.

Number of“A”notches: 1

PARKING BRAKE CONTROL

Adjustment

BR-41

Page 279 of 3051

PurposeNLBR0082The ABS consists of electronic and hydraulic components. It allows to control the braking force so that lock-

ing of the wheels can be avoided.

The ABS:

1) Ensures proper tracking performance through steering wheel operation.

2) Enables obstacles to be avoided through steering wheel operation.

3) Ensures vehicle stability by preventing flat spins.

ABS (Anti-Lock Brake System) OperationNLBR0083+When the vehicle speed is less than 10 km/h (6 MPH) this system does not work.

+The Anti-Lock Brake System (ABS) has self-test capabilities. The system turns on the ABS warning lamp

for 1 second after turning the ignition switch ON. The system performs another test the first time the vehicle

reaches 6 km/h (4 MPH). A mechanical noise may be heard as the ABS performs a self-test. This is a

normal part of the self-test feature. If a malfunction is found during this check, the ABS warning lamp will

come on.

+During ABS operation, a mechanical noise may be heard. This is a normal condition.

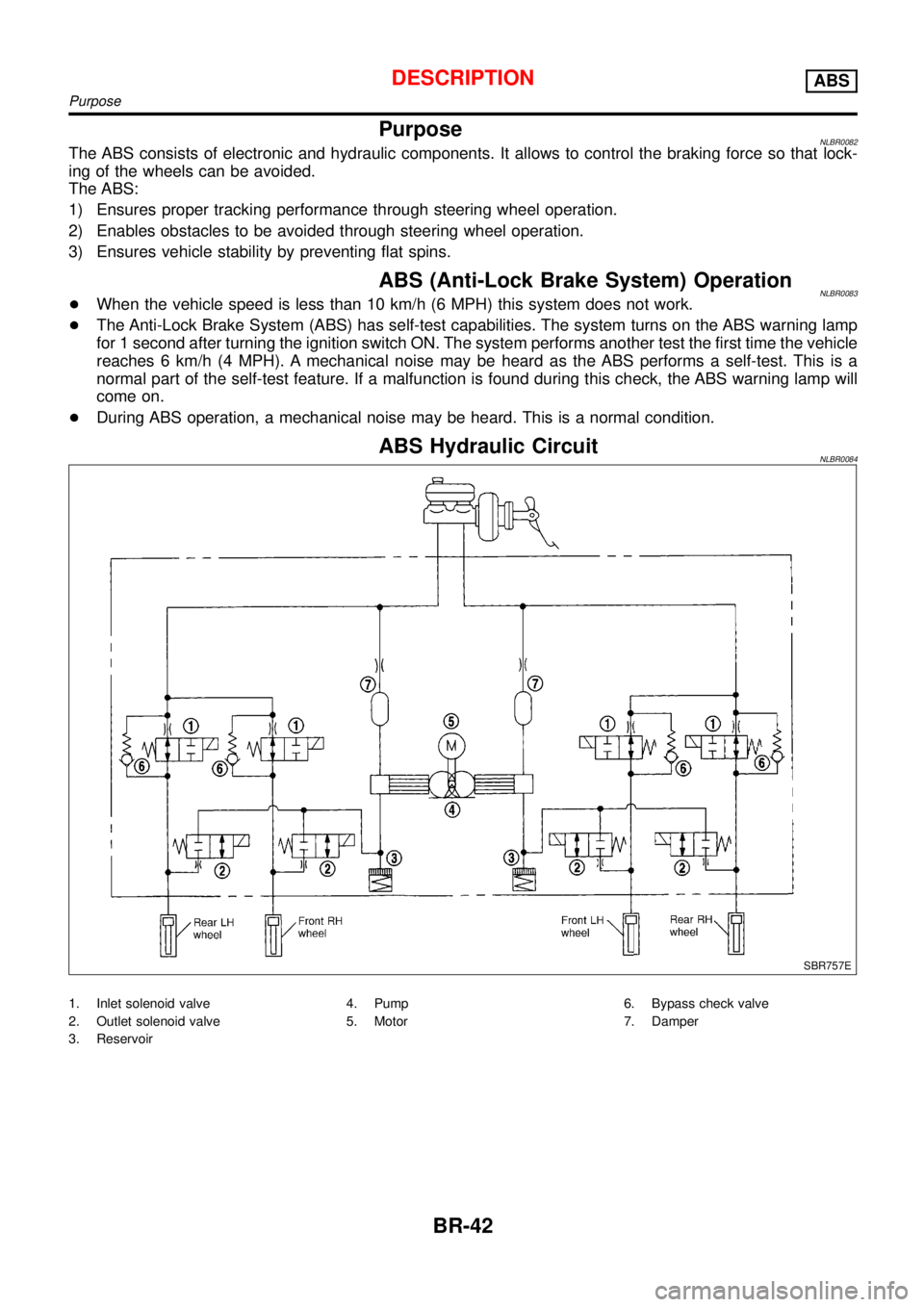

ABS Hydraulic CircuitNLBR0084

SBR757E

1. Inlet solenoid valve

2. Outlet solenoid valve

3. Reservoir4. Pump

5. Motor6. Bypass check valve

7. Damper

DESCRIPTIONABS

Purpose

BR-42

Page 280 of 3051

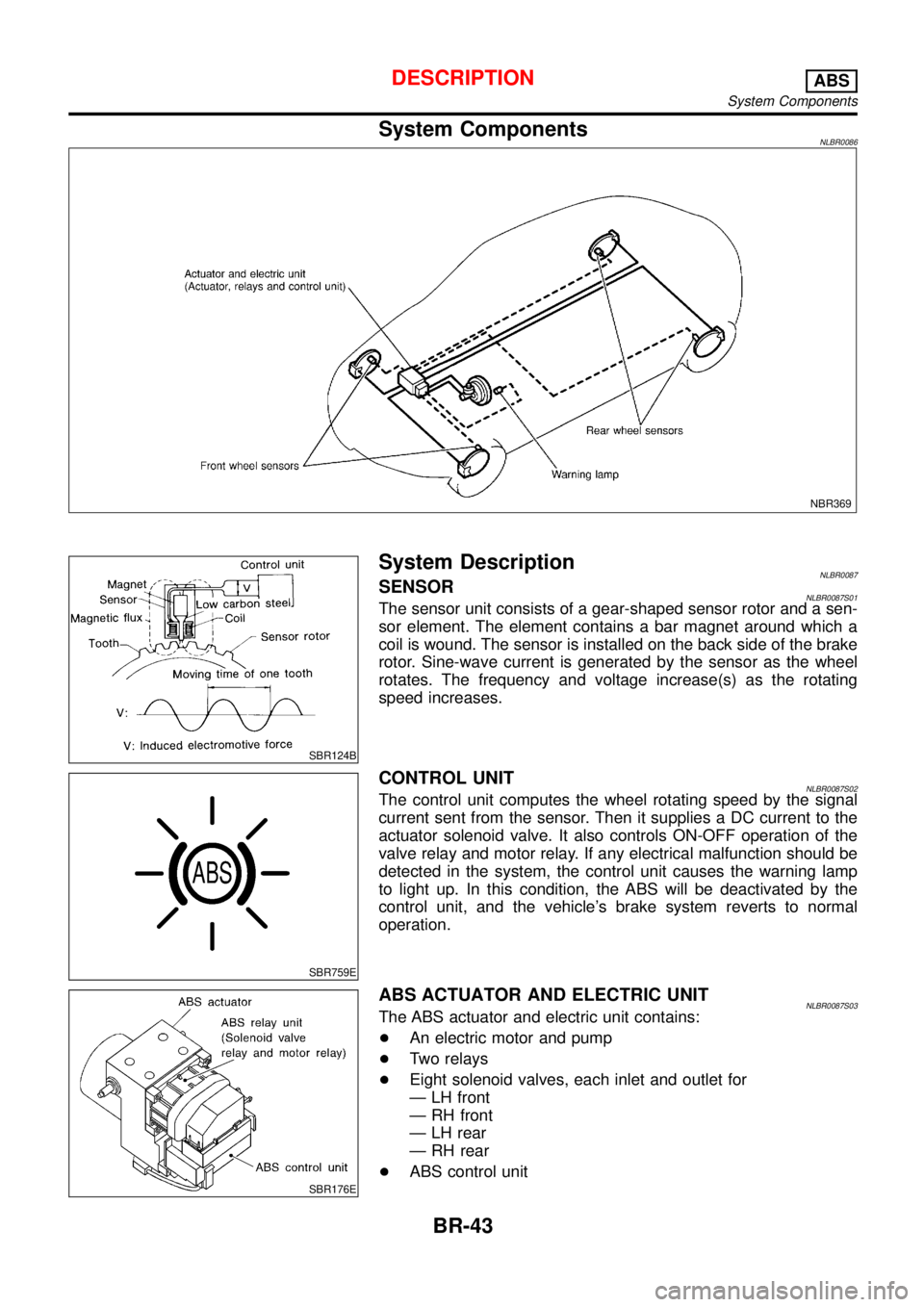

System ComponentsNLBR0086

NBR369

SBR124B

System DescriptionNLBR0087SENSORNLBR0087S01The sensor unit consists of a gear-shaped sensor rotor and a sen-

sor element. The element contains a bar magnet around which a

coil is wound. The sensor is installed on the back side of the brake

rotor. Sine-wave current is generated by the sensor as the wheel

rotates. The frequency and voltage increase(s) as the rotating

speed increases.

SBR759E

CONTROL UNITNLBR0087S02The control unit computes the wheel rotating speed by the signal

current sent from the sensor. Then it supplies a DC current to the

actuator solenoid valve. It also controls ON-OFF operation of the

valve relay and motor relay. If any electrical malfunction should be

detected in the system, the control unit causes the warning lamp

to light up. In this condition, the ABS will be deactivated by the

control unit, and the vehicle’s brake system reverts to normal

operation.

SBR176E

ABS ACTUATOR AND ELECTRIC UNITNLBR0087S03The ABS actuator and electric unit contains:

+An electric motor and pump

+Two relays

+Eight solenoid valves, each inlet and outlet for

—LH front

—RH front

—LH rear

—RH rear

+ABS control unit

DESCRIPTIONABS

System Components

BR-43