NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 531 of 3051

14 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Confirm that proper vacuum is applied. Refer to Test No. 10.

2. Attach blind cap to vacuum port from which vacuum hose to throttle opener was disconnected.

3. Start engine.

4. Warm up engine to normal operating temperature.

5. Select ªTP SW/TP SEN IDLE POSI ADJº in ªWORK SUPPORTº mode.

6. Stop engine. (Turn ignition switch ªOFFº.)

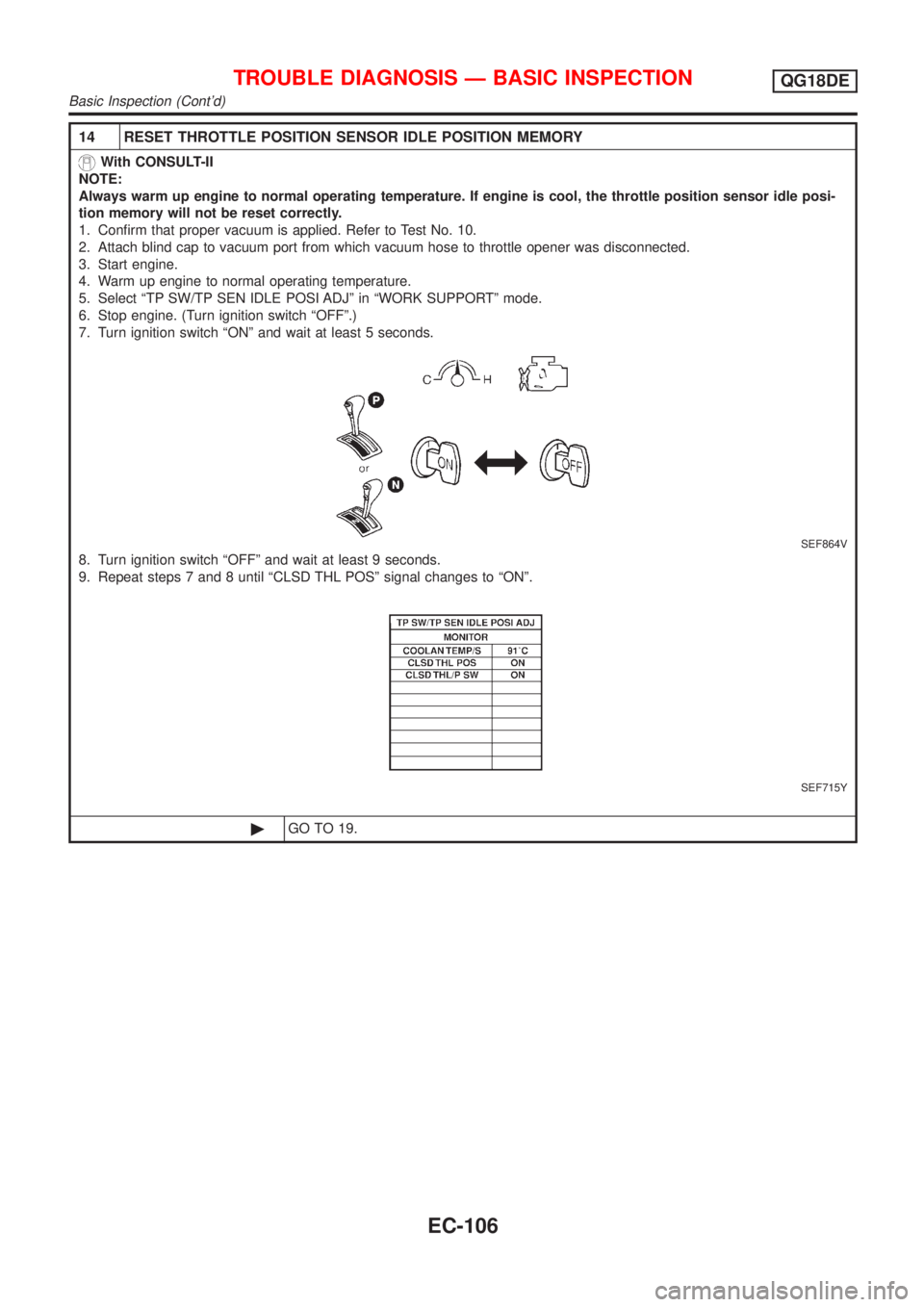

7. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

8. Turn ignition switch ªOFFº and wait at least 9 seconds.

9. Repeat steps 7 and 8 until ªCLSD THL POSº signal changes to ªONº.

SEF715Y

©GO TO 19.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-106

Page 532 of 3051

15 CHECK THROTTLE POSITION SWITCH CLOSED POSITION-II

Without CONSULT-II

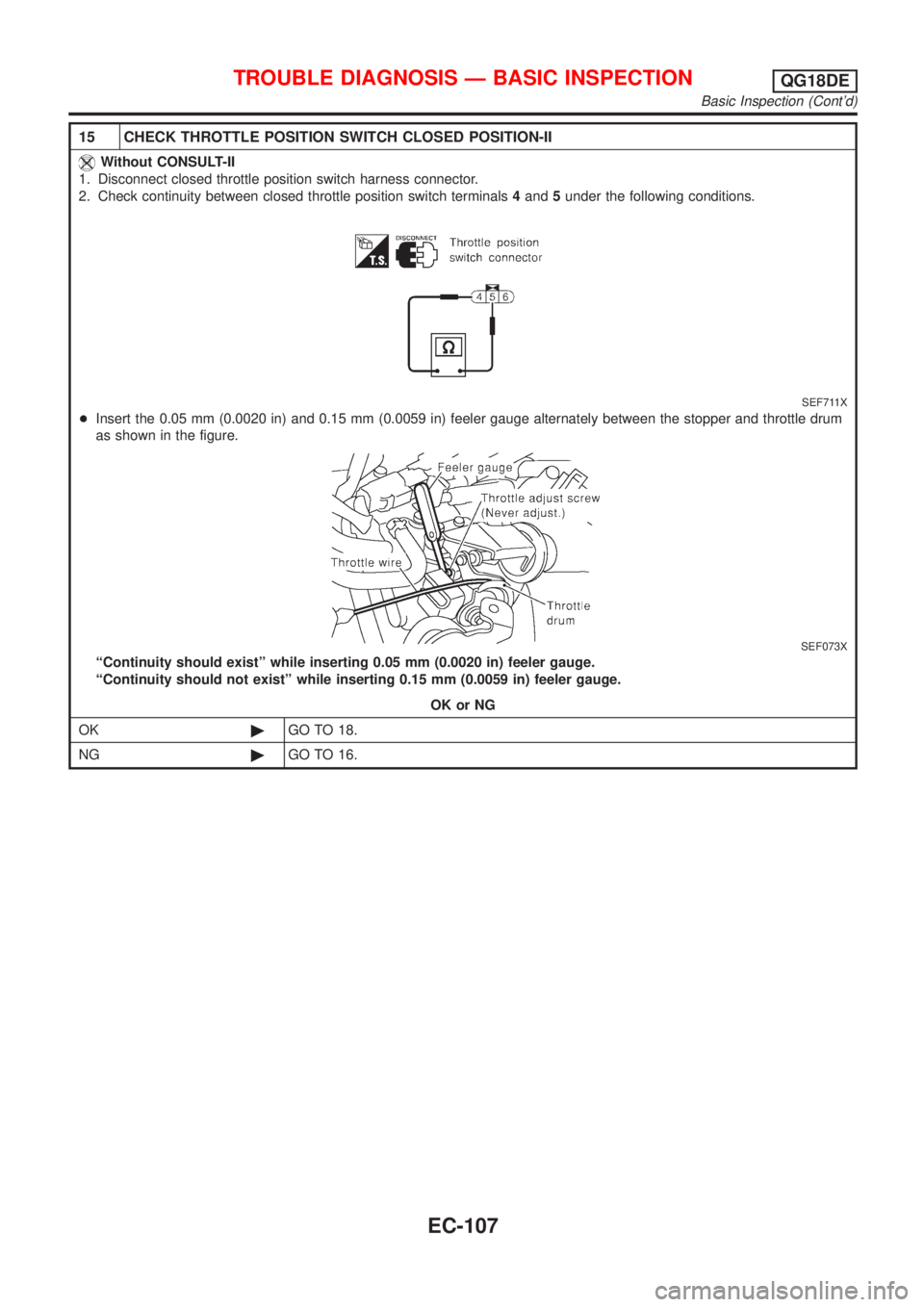

1. Disconnect closed throttle position switch harness connector.

2. Check continuity between closed throttle position switch terminals4and5under the following conditions.

SEF711X

+Insert the 0.05 mm (0.0020 in) and 0.15 mm (0.0059 in) feeler gauge alternately between the stopper and throttle drum

as shown in the figure.

SEF073X

ªContinuity should existº while inserting 0.05 mm (0.0020 in) feeler gauge.

ªContinuity should not existº while inserting 0.15 mm (0.0059 in) feeler gauge.

OK or NG

OK©GO TO 18.

NG©GO TO 16.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-107

Page 533 of 3051

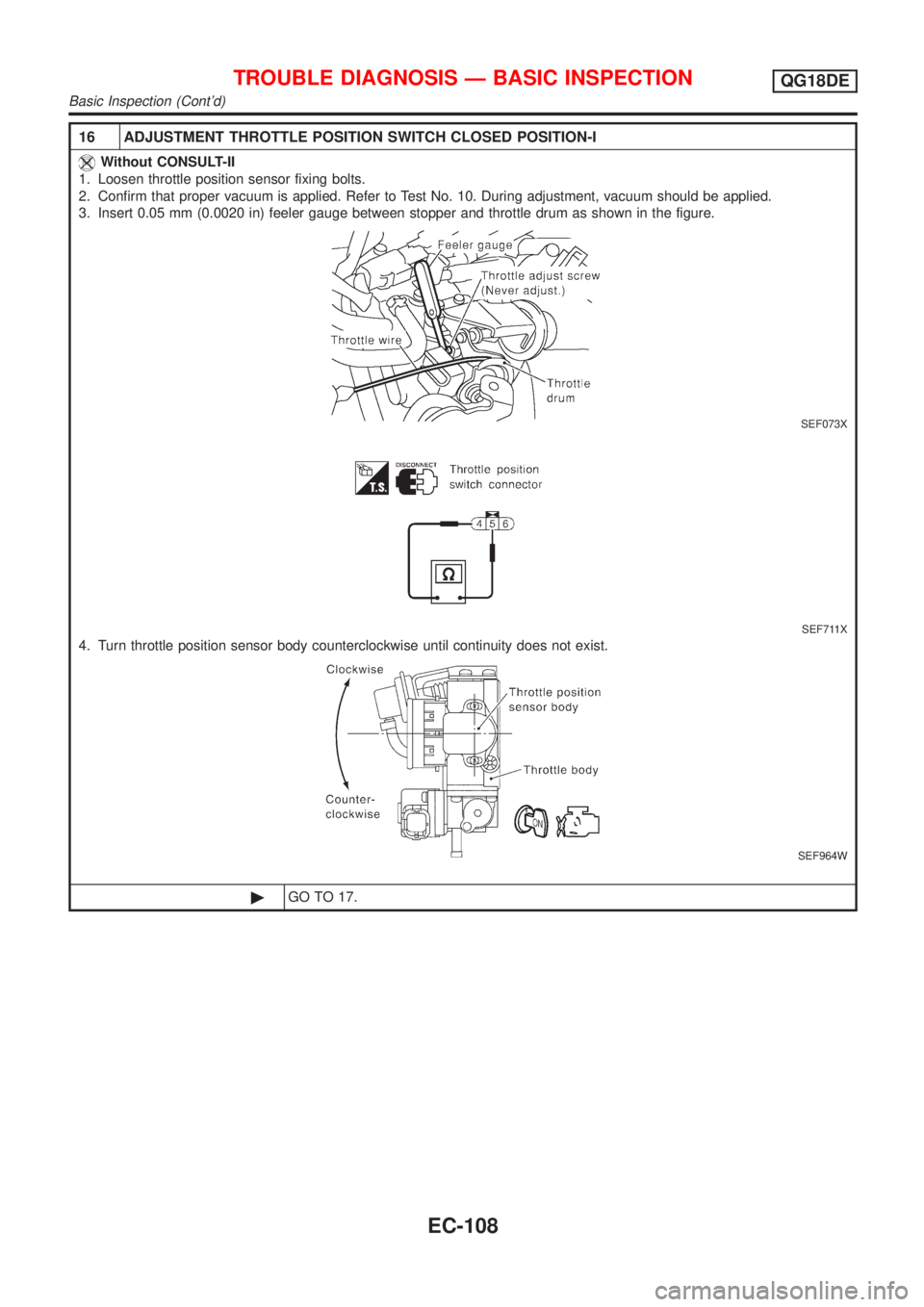

16 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-I

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Confirm that proper vacuum is applied. Refer to Test No. 10. During adjustment, vacuum should be applied.

3. Insert 0.05 mm (0.0020 in) feeler gauge between stopper and throttle drum as shown in the figure.

SEF073X

SEF711X

4. Turn throttle position sensor body counterclockwise until continuity does not exist.

SEF964W

©GO TO 17.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-108

Page 534 of 3051

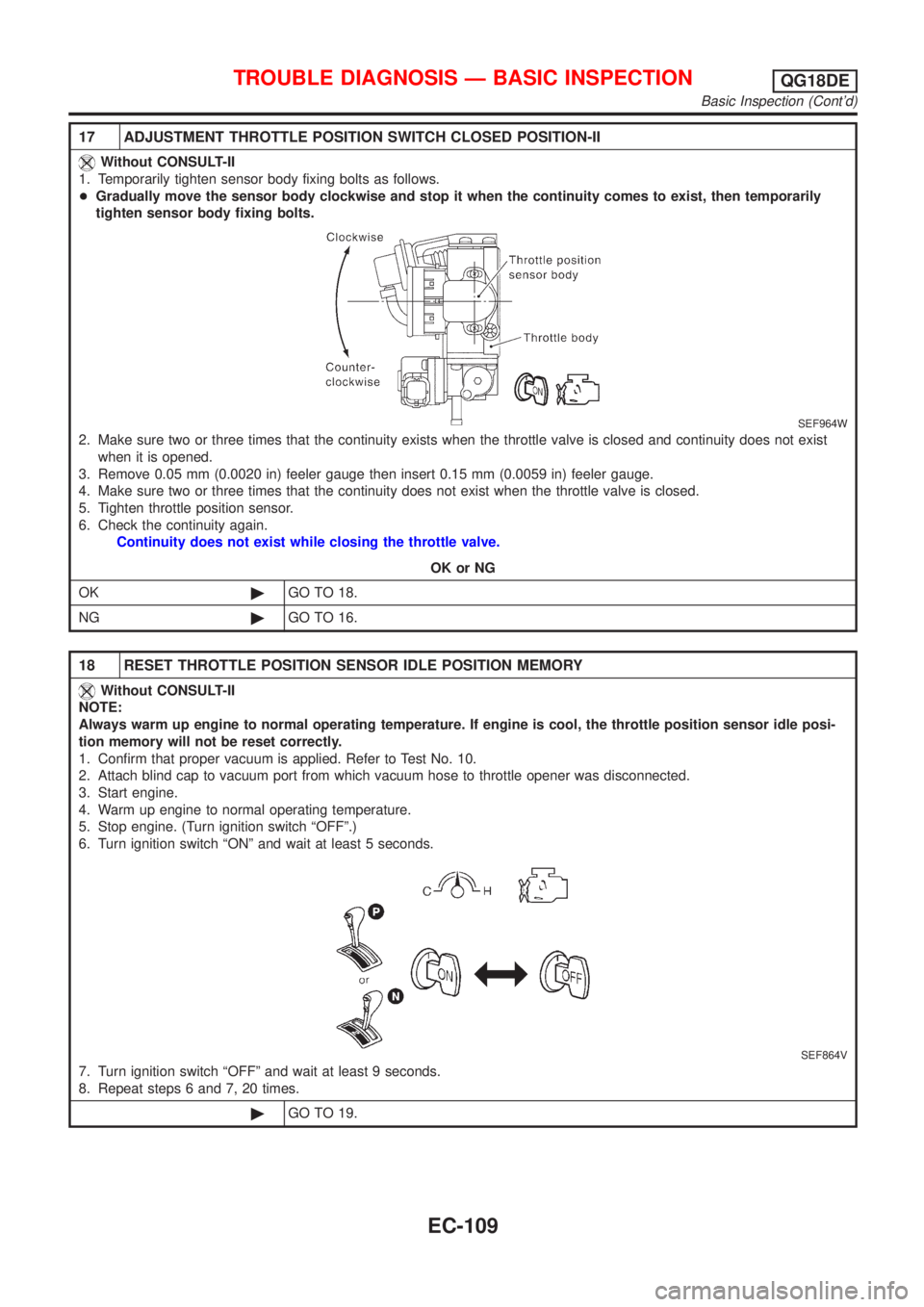

17 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-II

Without CONSULT-II

1. Temporarily tighten sensor body fixing bolts as follows.

+Gradually move the sensor body clockwise and stop it when the continuity comes to exist, then temporarily

tighten sensor body fixing bolts.

SEF964W

2. Make sure two or three times that the continuity exists when the throttle valve is closed and continuity does not exist

when it is opened.

3. Remove 0.05 mm (0.0020 in) feeler gauge then insert 0.15 mm (0.0059 in) feeler gauge.

4. Make sure two or three times that the continuity does not exist when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the continuity again.

Continuity does not exist while closing the throttle valve.

OK or NG

OK©GO TO 18.

NG©GO TO 16.

18 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Confirm that proper vacuum is applied. Refer to Test No. 10.

2. Attach blind cap to vacuum port from which vacuum hose to throttle opener was disconnected.

3. Start engine.

4. Warm up engine to normal operating temperature.

5. Stop engine. (Turn ignition switch ªOFFº.)

6. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

7. Turn ignition switch ªOFFº and wait at least 9 seconds.

8. Repeat steps 6 and 7, 20 times.

©GO TO 19.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-109

Page 535 of 3051

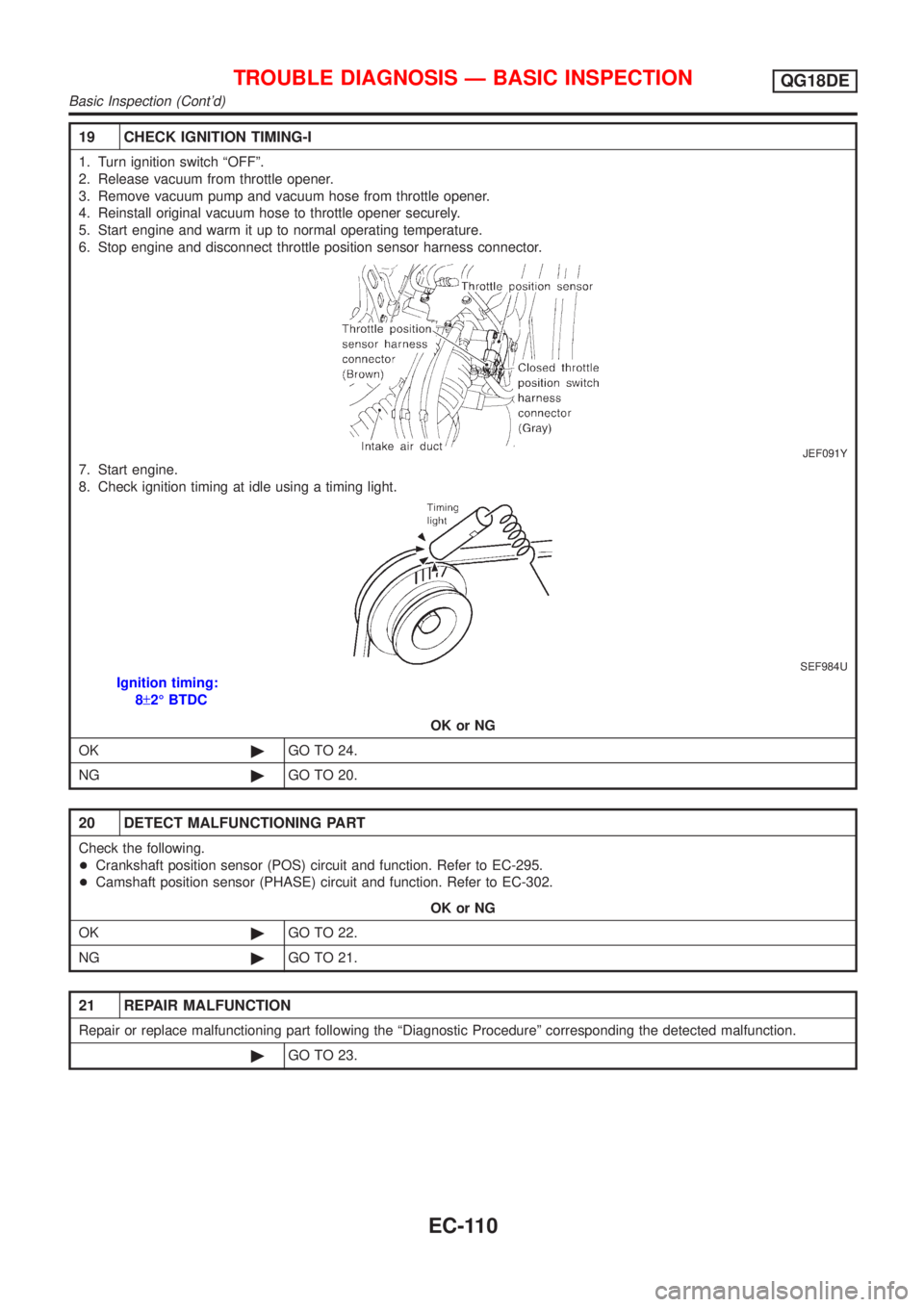

19 CHECK IGNITION TIMING-I

1. Turn ignition switch ªOFFº.

2. Release vacuum from throttle opener.

3. Remove vacuum pump and vacuum hose from throttle opener.

4. Reinstall original vacuum hose to throttle opener securely.

5. Start engine and warm it up to normal operating temperature.

6. Stop engine and disconnect throttle position sensor harness connector.

JEF091Y

7. Start engine.

8. Check ignition timing at idle using a timing light.

SEF984U

Ignition timing:

8±2É BTDC

OK or NG

OK©GO TO 24.

NG©GO TO 20.

20 DETECT MALFUNCTIONING PART

Check the following.

+Crankshaft position sensor (POS) circuit and function. Refer to EC-295.

+Camshaft position sensor (PHASE) circuit and function. Refer to EC-302.

OK or NG

OK©GO TO 22.

NG©GO TO 21.

21 REPAIR MALFUNCTION

Repair or replace malfunctioning part following the ªDiagnostic Procedureº corresponding the detected malfunction.

©GO TO 23.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-110

Page 536 of 3051

22 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of a problem, but this is rarely

the case.)

2. Perform initialization of NATS system and registration of all NATS ignition key IDs. Refer to ªNATS (Nissan Anti-Theft

System)º, EC-72.

©GO TO 23.

23 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 19.

INCMP©Follow the construction of ªIdle Air Volume Leaningº.

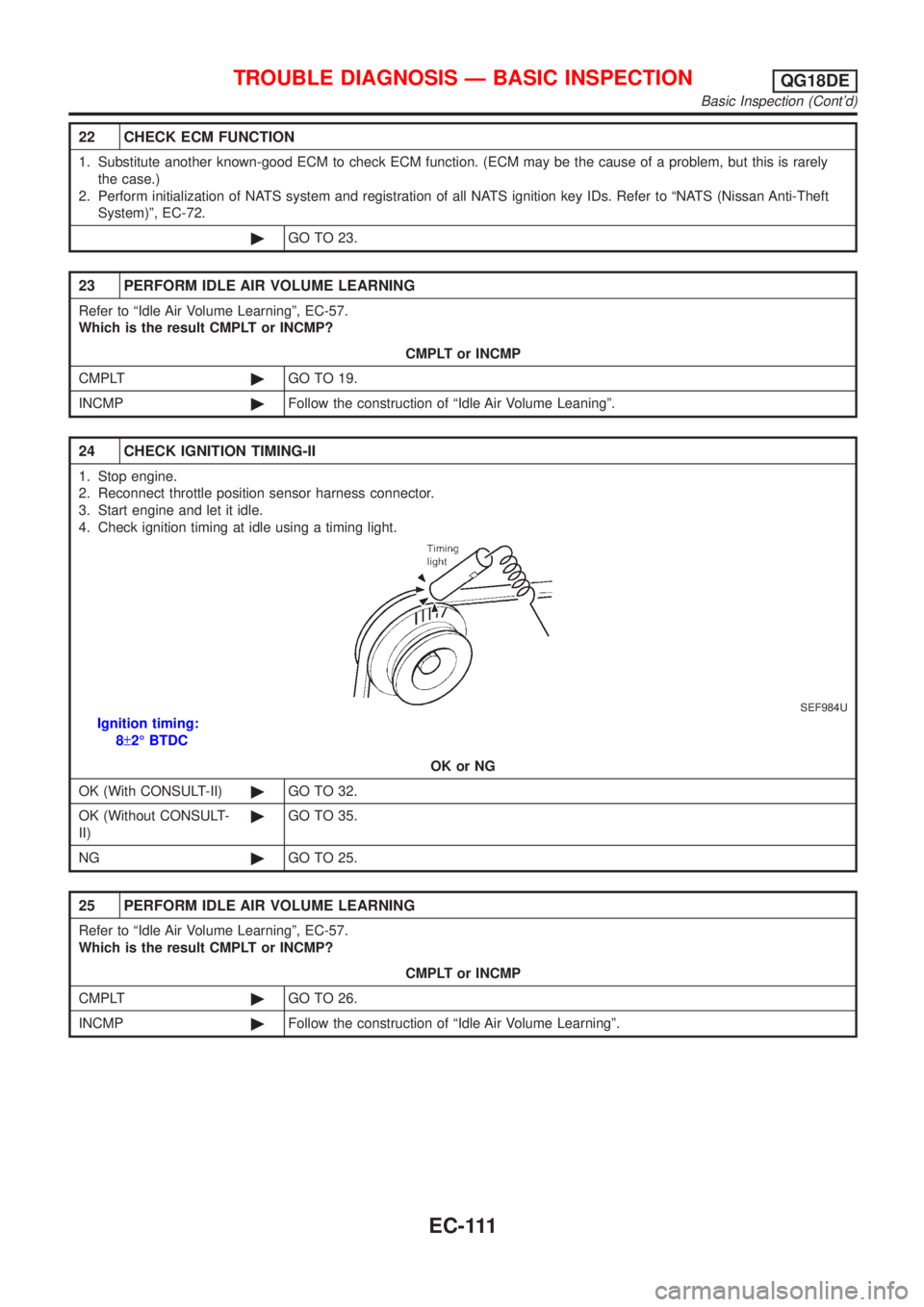

24 CHECK IGNITION TIMING-II

1. Stop engine.

2. Reconnect throttle position sensor harness connector.

3. Start engine and let it idle.

4. Check ignition timing at idle using a timing light.

SEF984U

Ignition timing:

8±2É BTDC

OK or NG

OK (With CONSULT-II)©GO TO 32.

OK (Without CONSULT-

II)©GO TO 35.

NG©GO TO 25.

25 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 26.

INCMP©Follow the construction of ªIdle Air Volume Learningº.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-111

Page 537 of 3051

26 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 24.

OK or NG

OK (With CONSULT-II)©GO TO 32.

OK (Without CONSULT-

II)©GO TO 35.

NG©GO TO 27.

27 CHECK FOR INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an air leak from PCV hose and after IACV-AAC valve.

OK or NG

OK©GO TO 29.

NG©GO TO 28.

28 REPAIR MALFUNCTION

1. Stop engine.

2. Repair or replace malfunctioning part.

©GO TO 25.

29 DETECT MALFUNCTIONING PART

Check the IACV-AAC valve circuit and function. Refer to EC-343.

OK or NG

OK©GO TO 31.

NG©GO TO 30.

30 REPAIR MALFUNCTION

Repair or replace malfunction part following the ªDiagnostic Procedureº corresponding the detected malfunction.

©GO TO 25.

31 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function.

(ECM may be the cause of a problem, but this is rarely the case.)

2. Perform initialization of NATS system and registration of NATS ignition key IDs. Refer to ªNATS (Nissan Anti-Theft

System)º, EC-72.

©GO TO 25.

32 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode.

3. Check idle speed.

700±50 rpm

OK or NG

OK©GO TO 38.

NG©GO TO 33.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-112

Page 538 of 3051

33 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 34.

INCMP©Follow the construction of ªIdle Air Volume Learningº.

34 CHECK TARGET IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

700±50 rpm

OK or NG

OK©GO TO 38.

NG©GO TO 27.

35 CHECK TARGET IDLE SPEED

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

700±50 rpm

OK or NG

OK©GO TO 38.

NG©GO TO 36.

36 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 37.

INCMP©Follow the construction of ªIdle Air Volume Learningº.

37 CHECK TARGET IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

700±50 rpm

OK or NG

OK©GO TO 38.

NG©GO TO 27.

38 ERASE UNNECESSARY DTC

After this inspection, unnecessary DTC No. might be displayed.

Erase the stored memory in ECM.

Refer to ªHow to Erase Emission-related Diagnostic Informationº, EC-69.

©INSPECTION END

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-113

Page 539 of 3051

MODELS WITHOUT THROTTLE POSITION SWITCH AND

THROTTLE OPENER

NLEC0564S02Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

+Headlamp switch is OFF,

On vehicle equipped with daytime light system, set lighting

switch to the 1st position to light only small lamps.

+Air conditioner switch is OFF,

+Rear window defogger switch is OFF,

+Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or a current need for scheduled

maintenance.

2. Open engine hood and check the following:

+Harness connectors for improper connections

+Vacuum hoses for splits, kinks and improper connections

+Wiring for improper connections, pinches and cuts

+Air cleaner clogging

+Hoses and ducts for leaks

SEF983U

©GO TO 2.

2 CHECK THROTTLE DRUM OPERATION-I

Confirm that throttle drum is in contact with the stopper.

OK or NG

OK (with CONSULT-II)©GO TO 5.

OK (without CONSULT-

II)©GO TO 8.

NG©GO TO 3.

3 CHECK ACCELERATOR WIRE INSTALLATION

Check accelerator wire for slack.

OK or NG

OK©GO TO 4.

NG©Adjust accelerator wire. Refer to FE section, ªAdjusting Accelerator Wireº.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-114

Page 540 of 3051

4 CHECK THROTTLE VALVE OPERATION

1. Remove intake air ducts.

2. Check throttle valve operation when moving throttle drum by hand.

OK or NG

OK©Retighten the throttle drum fixing nuts.

NG©Clean the throttle body and throttle valve.

5 CHECK CLOSED THROTTLE POSITION SWITCH IDLE POSITION

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Select ªTHRTL POS SENº and ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

5. Make sure that ªTHRTL POS SENº indicates 0.35 to 0.65V, and ªCLSD THL POSº indicates ªONº. (Accelerator pedal is

fully released).

NEF238A

OK or NG

OK©GO TO 11.

NG©GO TO 6.

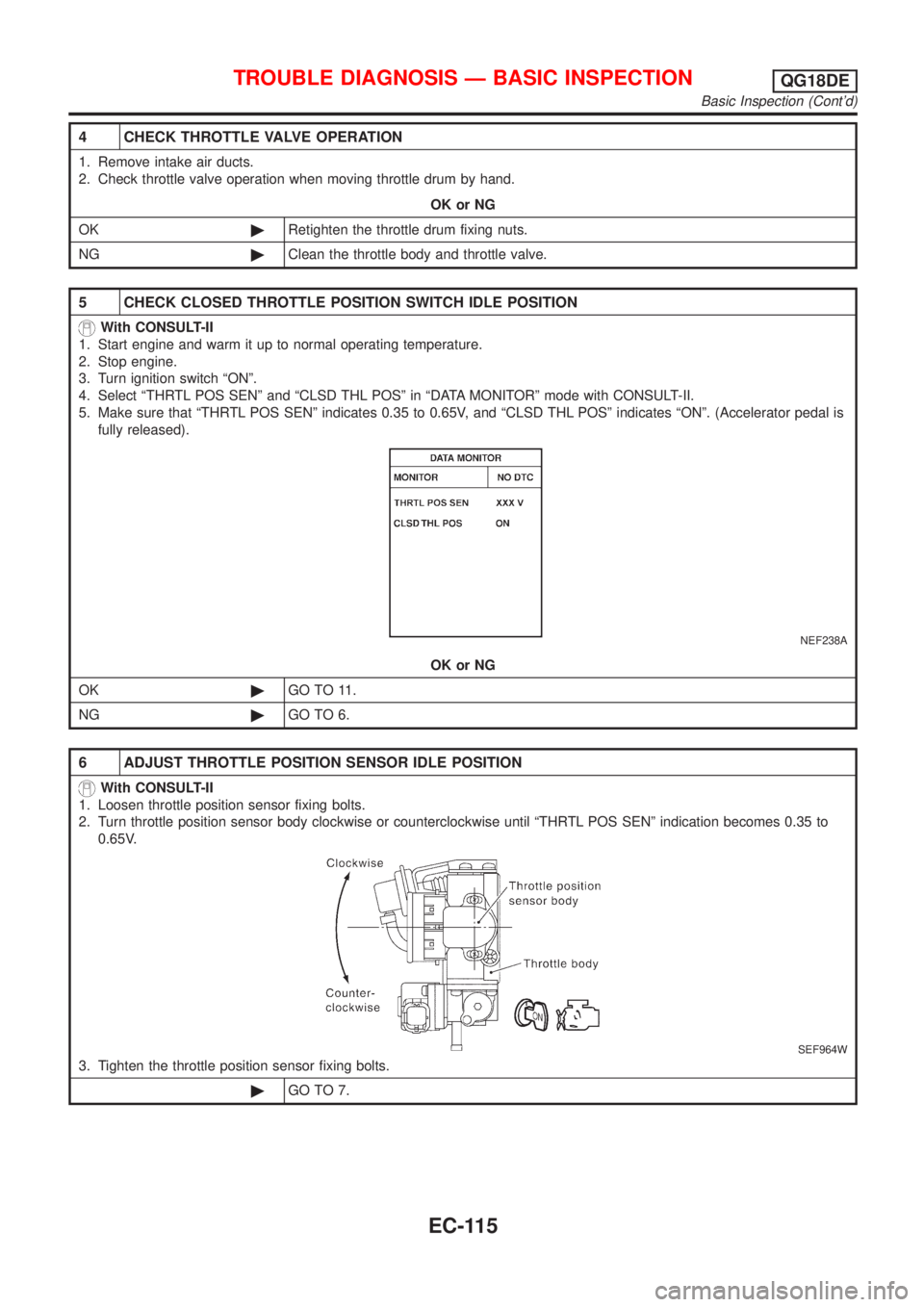

6 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until ªTHRTL POS SENº indication becomes 0.35 to

0.65V.

SEF964W

3. Tighten the throttle position sensor fixing bolts.

©GO TO 7.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG18DE

Basic Inspection (Cont'd)

EC-115