heater NISSAN ALMERA TINO 2001 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1175 of 3051

Diagnostic ProcedureNLEC1461

1 CHECK POWER SUPPLY

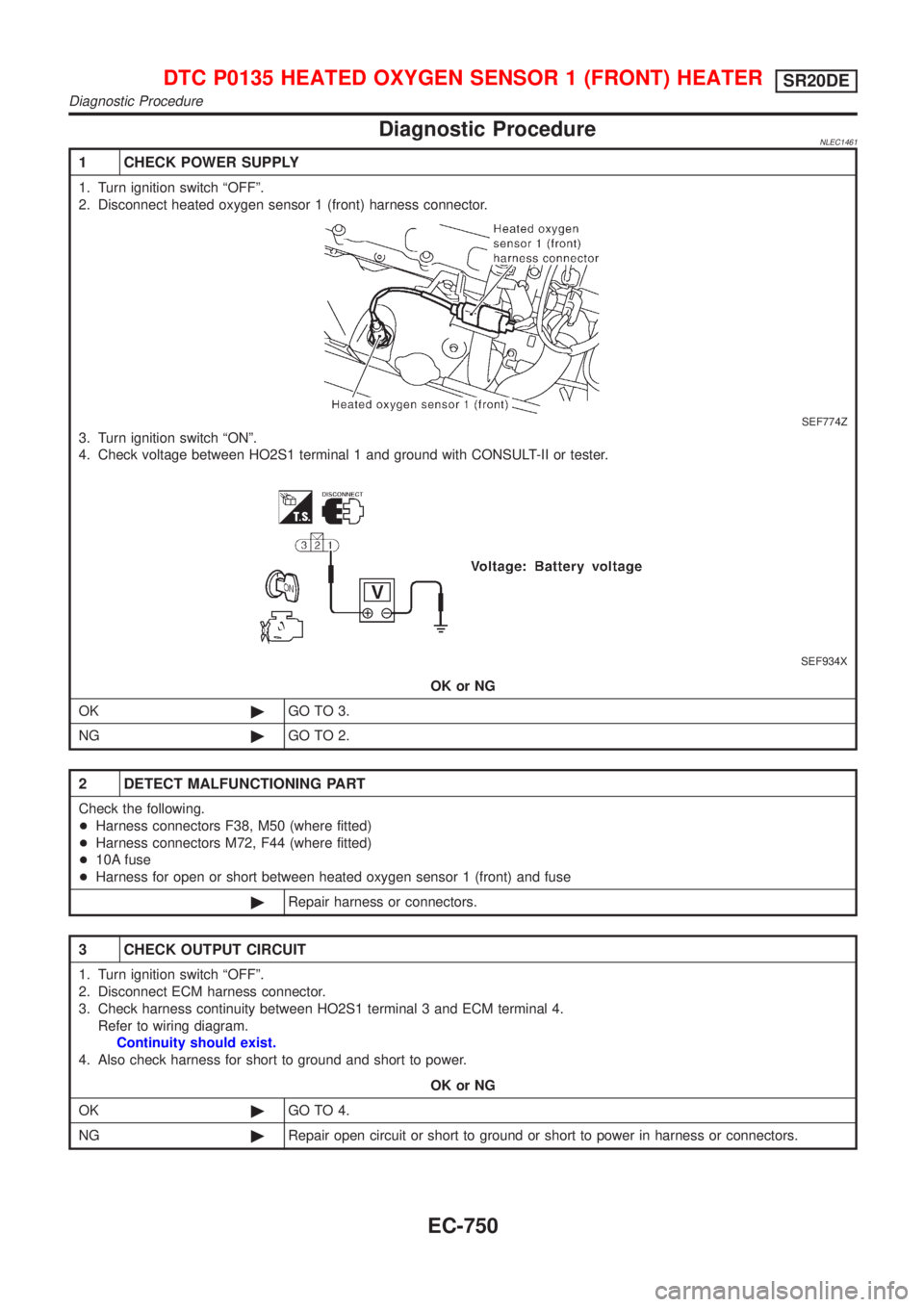

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 1 (front) harness connector.

SEF774Z

3. Turn ignition switch ªONº.

4. Check voltage between HO2S1 terminal 1 and ground with CONSULT-II or tester.

SEF934X

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F38, M50 (where fitted)

+Harness connectors M72, F44 (where fitted)

+10A fuse

+Harness for open or short between heated oxygen sensor 1 (front) and fuse

©Repair harness or connectors.

3 CHECK OUTPUT CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between HO2S1 terminal 3 and ECM terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERSR20DE

Diagnostic Procedure

EC-750

Page 1176 of 3051

4 CHECK HEATED OXYGEN SENSOR 1 HEATER (FRONT)

Refer to ªComponent Inspectionº, EC-751.

OK or NG

OK©GO TO 5.

NG©Replace heated oxygen sensor 1 (front).

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-670.

©INSPECTION END

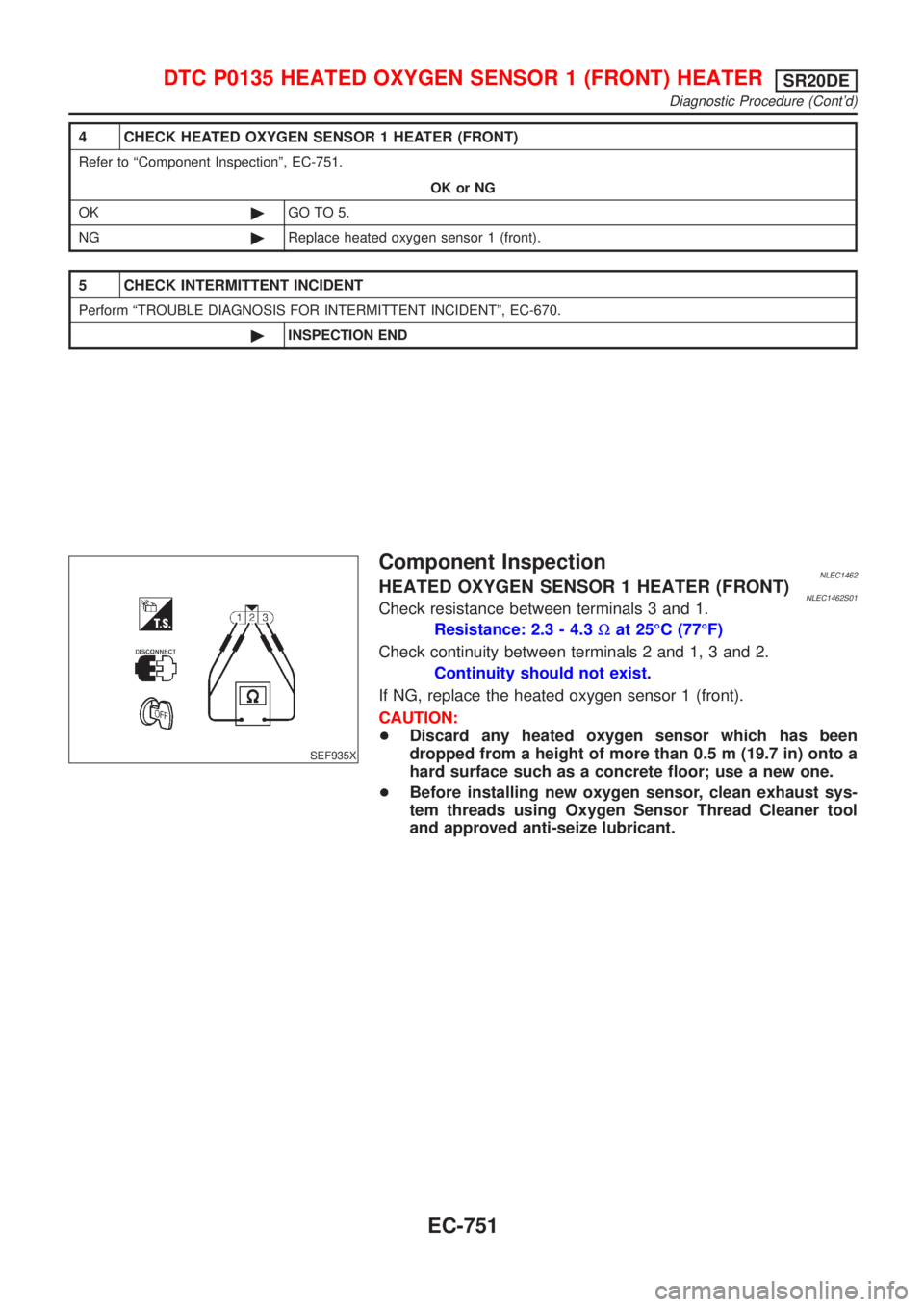

SEF935X

Component InspectionNLEC1462HEATED OXYGEN SENSOR 1 HEATER (FRONT)NLEC1462S01Check resistance between terminals 3 and 1.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

Check continuity between terminals 2 and 1, 3 and 2.

Continuity should not exist.

If NG, replace the heated oxygen sensor 1 (front).

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERSR20DE

Diagnostic Procedure (Cont'd)

EC-751

Page 1211 of 3051

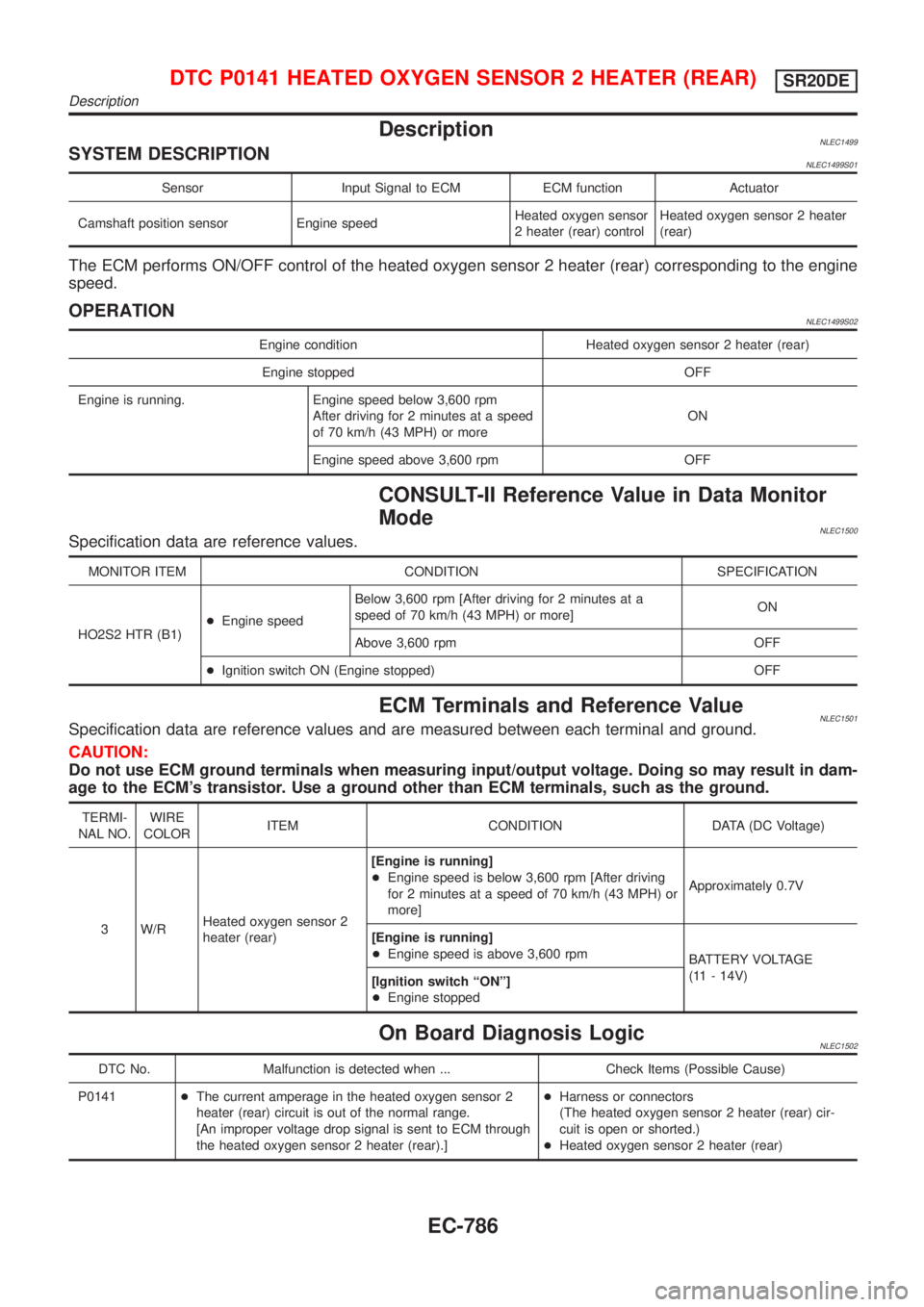

DescriptionNLEC1499SYSTEM DESCRIPTIONNLEC1499S01

Sensor Input Signal to ECM ECM function Actuator

Camshaft position sensor Engine speedHeated oxygen sensor

2 heater (rear) controlHeated oxygen sensor 2 heater

(rear)

The ECM performs ON/OFF control of the heated oxygen sensor 2 heater (rear) corresponding to the engine

speed.

OPERATIONNLEC1499S02

Engine condition Heated oxygen sensor 2 heater (rear)

Engine stopped OFF

Engine is running. Engine speed below 3,600 rpm

After driving for 2 minutes at a speed

of 70 km/h (43 MPH) or moreON

Engine speed above 3,600 rpm OFF

CONSULT-II Reference Value in Data Monitor

Mode

NLEC1500Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 HTR (B1)+Engine speedBelow 3,600 rpm [After driving for 2 minutes at a

speed of 70 km/h (43 MPH) or more]ON

Above 3,600 rpm OFF

+Ignition switch ON (Engine stopped) OFF

ECM Terminals and Reference ValueNLEC1501Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

3 W/RHeated oxygen sensor 2

heater (rear)[Engine is running]

+Engine speed is below 3,600 rpm [After driving

for 2 minutes at a speed of 70 km/h (43 MPH) or

more]Approximately 0.7V

[Engine is running]

+Engine speed is above 3,600 rpm

BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

+Engine stopped

On Board Diagnosis LogicNLEC1502

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0141+The current amperage in the heated oxygen sensor 2

heater (rear) circuit is out of the normal range.

[An improper voltage drop signal is sent to ECM through

the heated oxygen sensor 2 heater (rear).]+Harness or connectors

(The heated oxygen sensor 2 heater (rear) cir-

cuit is open or shorted.)

+Heated oxygen sensor 2 heater (rear)

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

Description

EC-786

Page 1212 of 3051

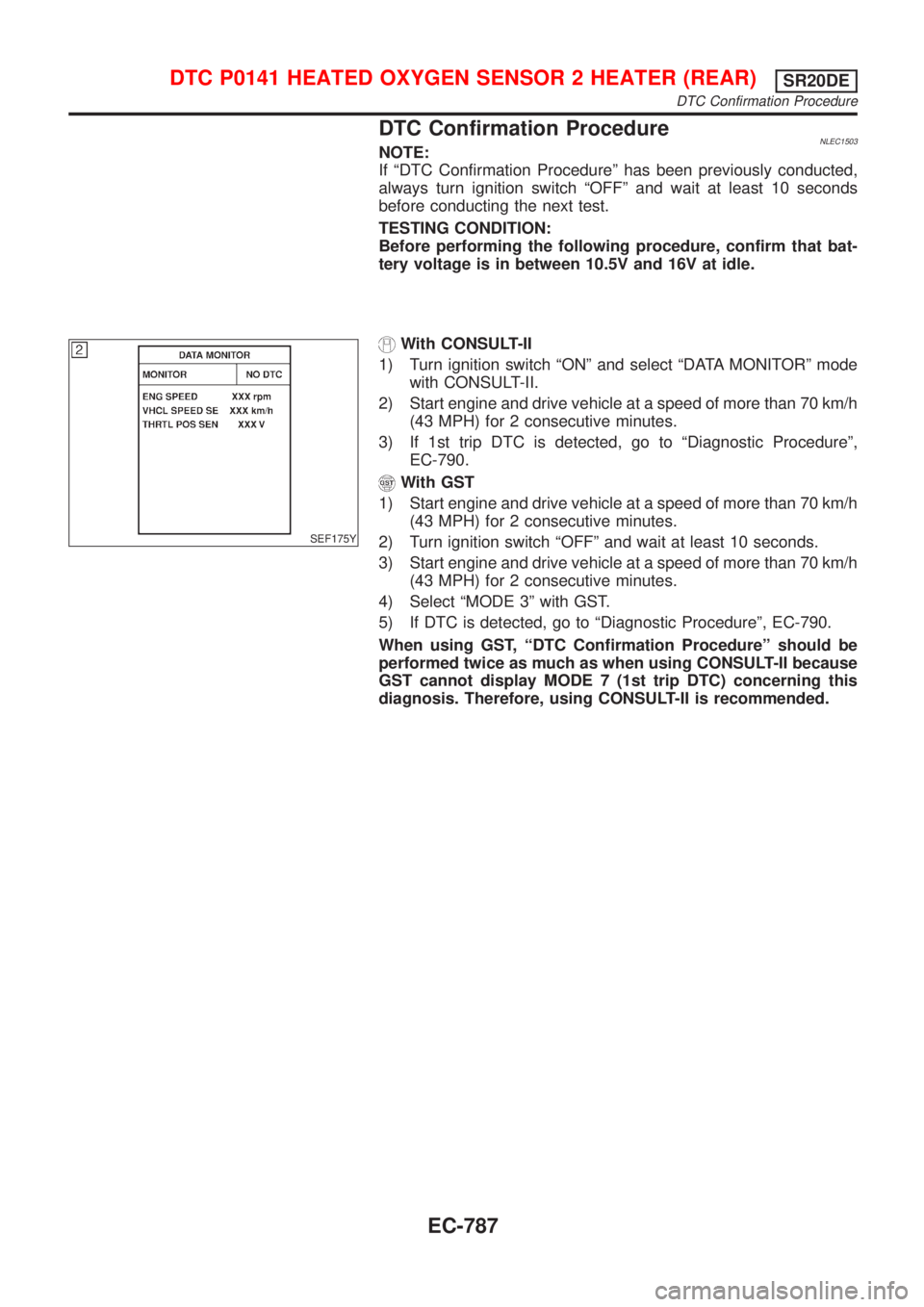

DTC Confirmation ProcedureNLEC1503NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is in between 10.5V and 16V at idle.

SEF175Y

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-790.

With GST

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

4) Select ªMODE 3º with GST.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-790.

When using GST, ªDTC Confirmation Procedureº should be

performed twice as much as when using CONSULT-II because

GST cannot display MODE 7 (1st trip DTC) concerning this

diagnosis. Therefore, using CONSULT-II is recommended.

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

DTC Confirmation Procedure

EC-787

Page 1213 of 3051

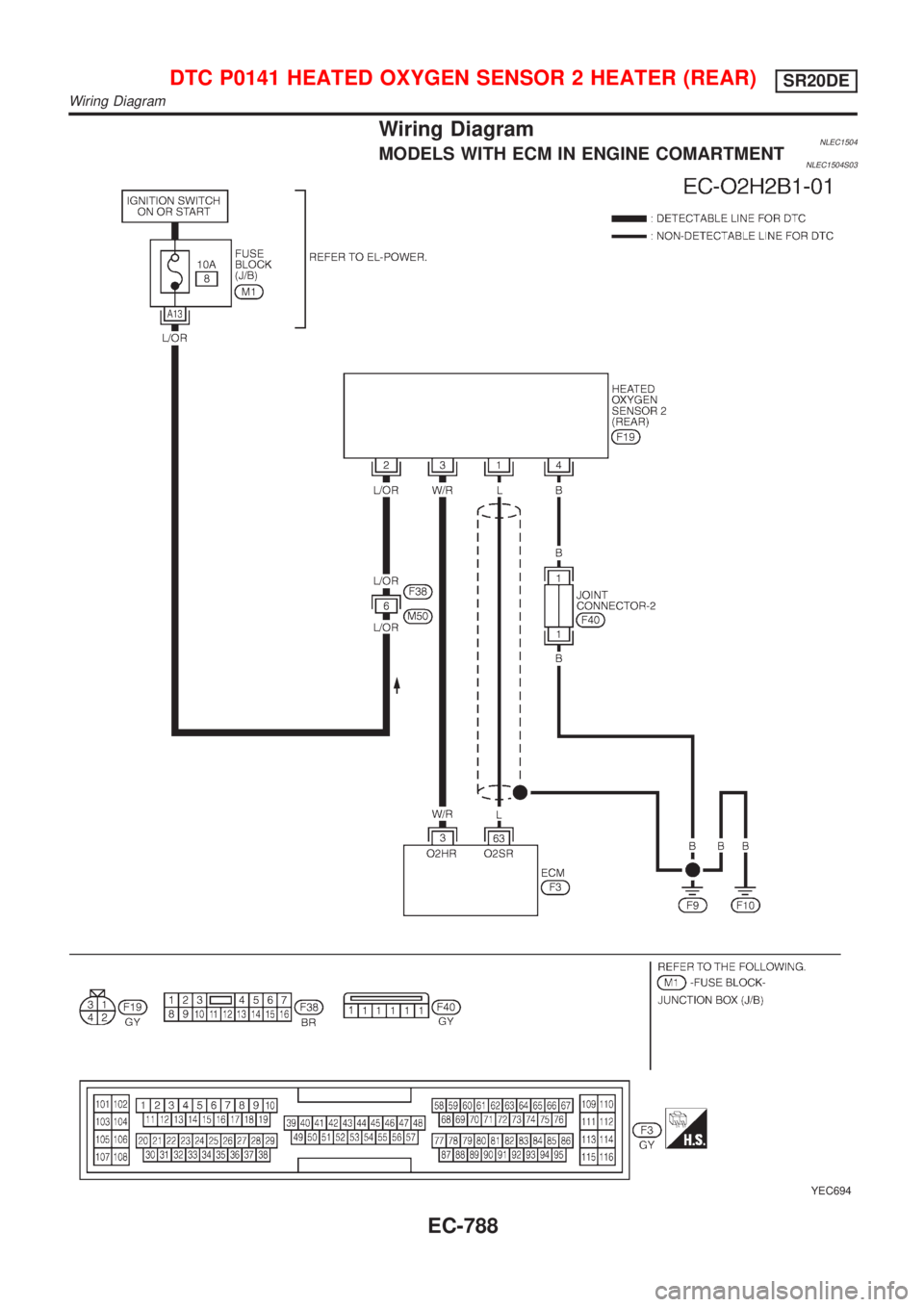

Wiring DiagramNLEC1504MODELS WITH ECM IN ENGINE COMARTMENTNLEC1504S03

YEC694

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

Wiring Diagram

EC-788

Page 1214 of 3051

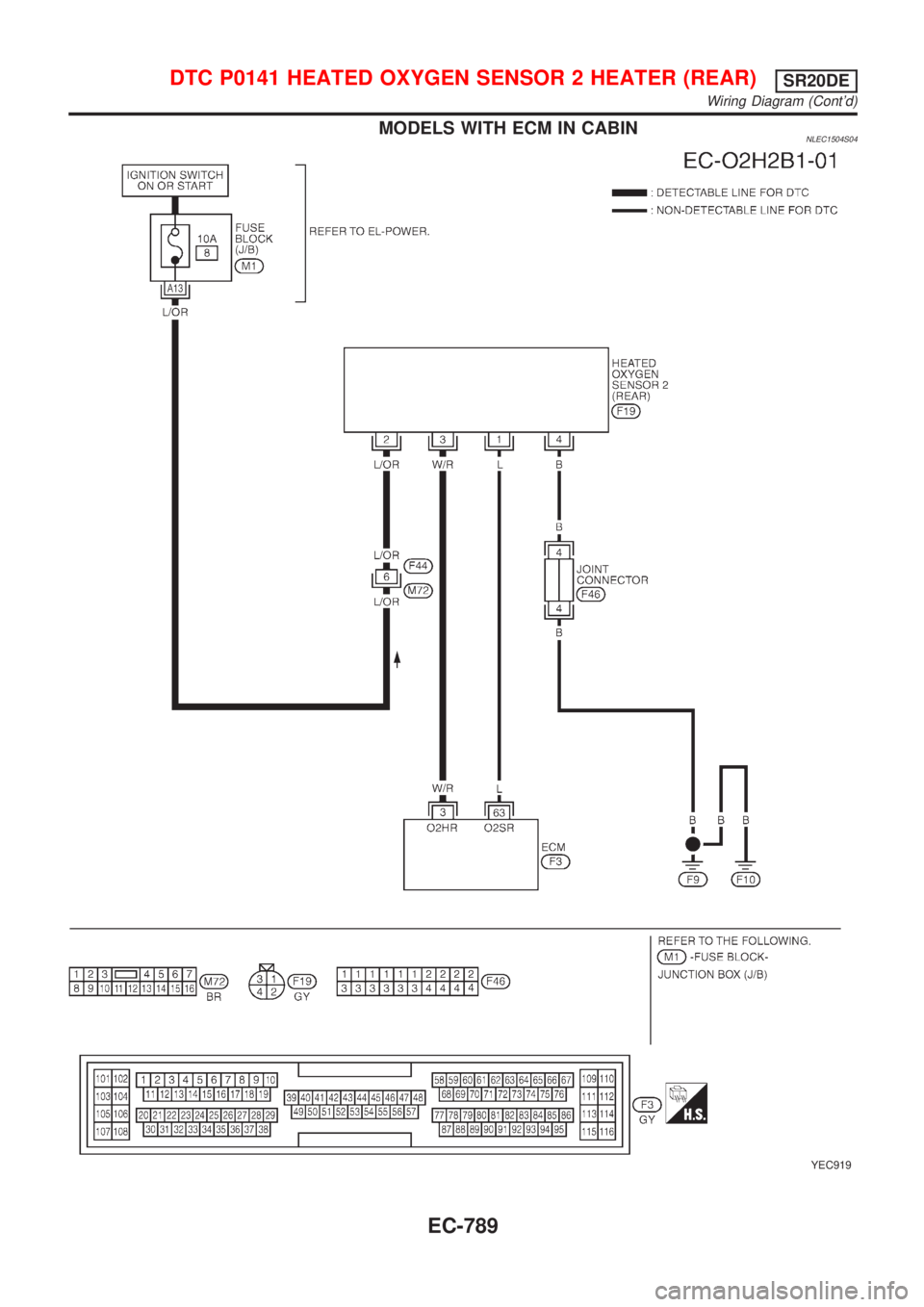

MODELS WITH ECM IN CABINNLEC1504S04

YEC919

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

Wiring Diagram (Cont'd)

EC-789

Page 1215 of 3051

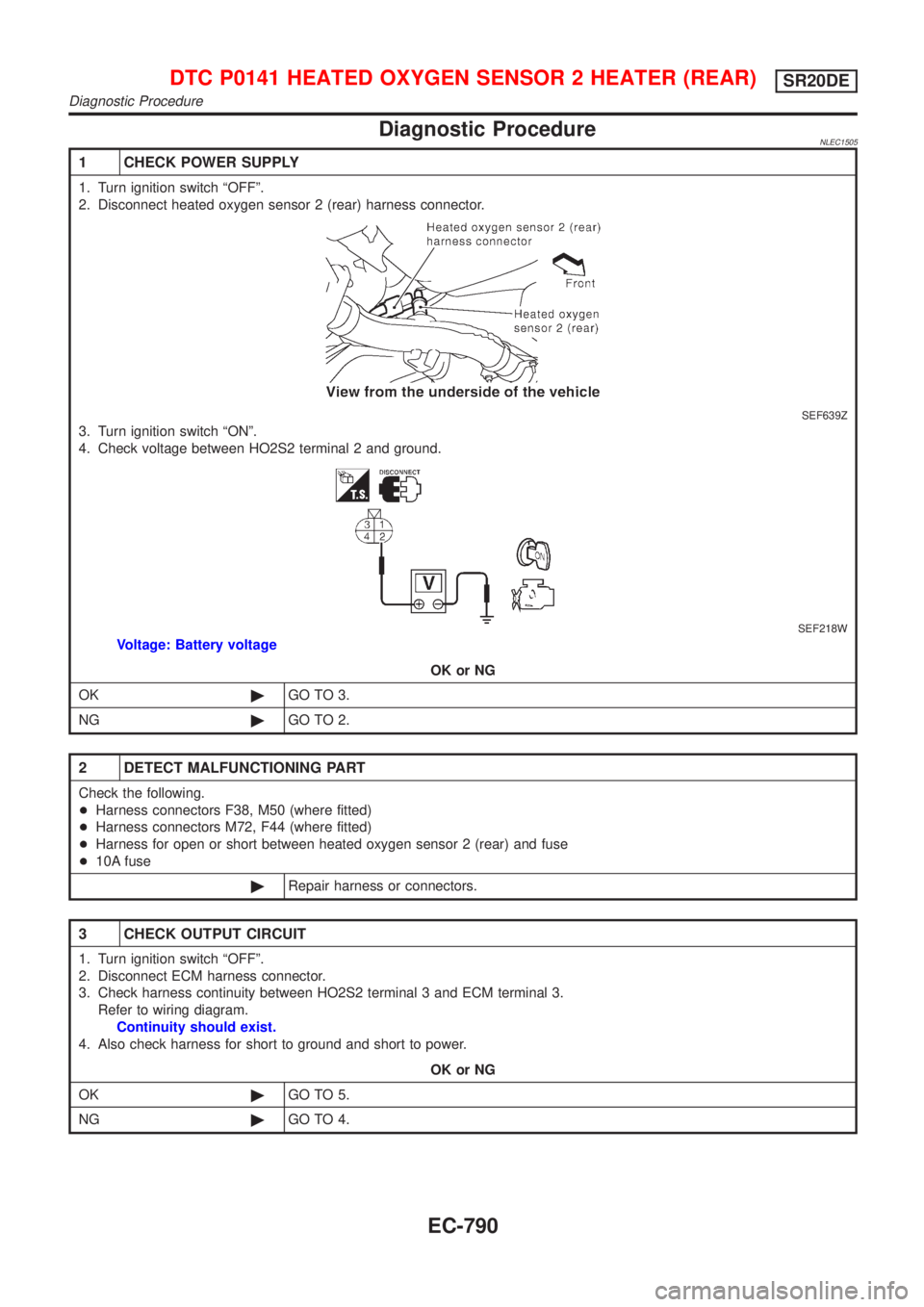

Diagnostic ProcedureNLEC1505

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 2 (rear) harness connector.

SEF639Z

3. Turn ignition switch ªONº.

4. Check voltage between HO2S2 terminal 2 and ground.

SEF218W

Voltage: Battery voltage

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F38, M50 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between heated oxygen sensor 2 (rear) and fuse

+10A fuse

©Repair harness or connectors.

3 CHECK OUTPUT CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between HO2S2 terminal 3 and ECM terminal 3.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

Diagnostic Procedure

EC-790

Page 1216 of 3051

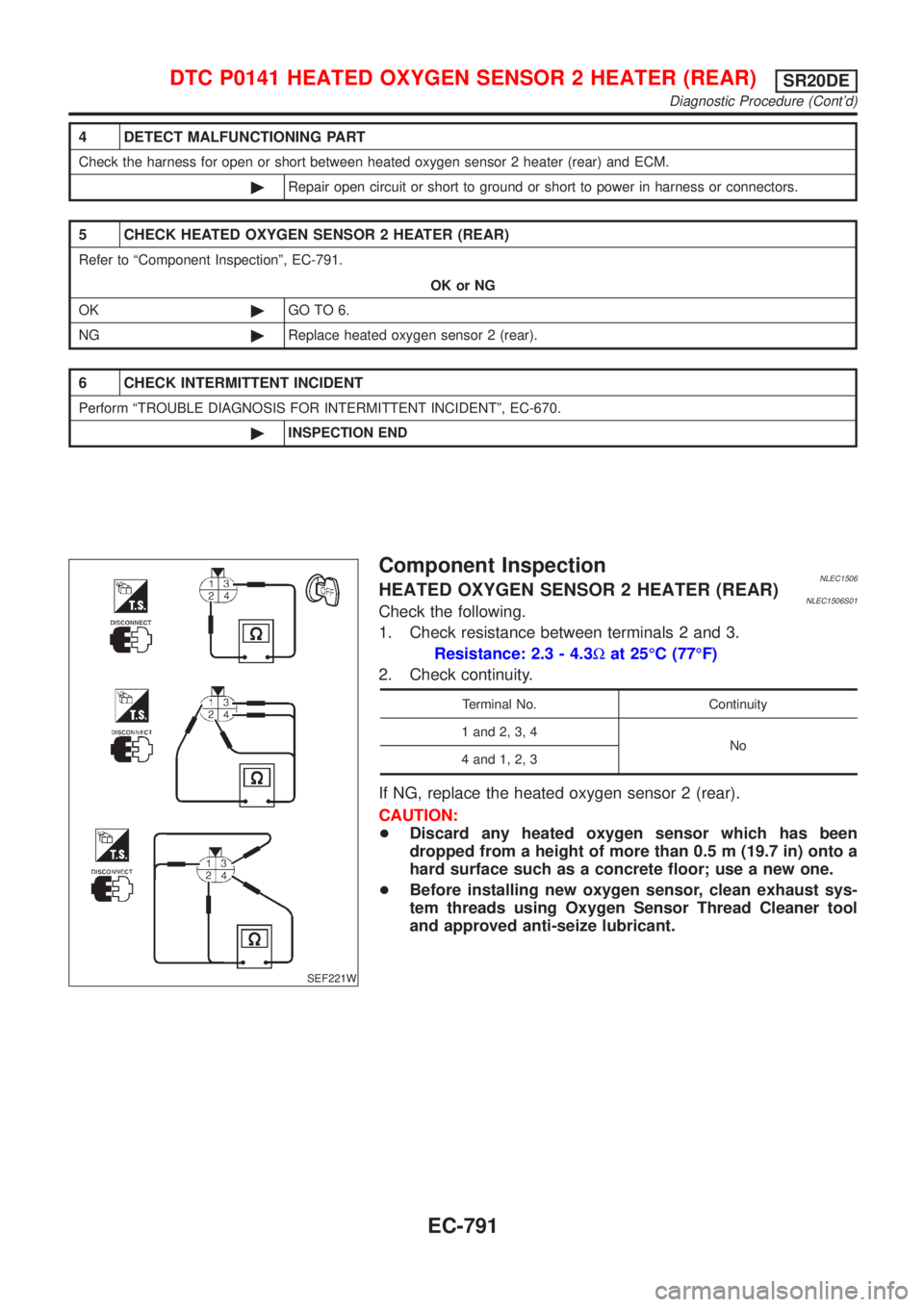

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between heated oxygen sensor 2 heater (rear) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK HEATED OXYGEN SENSOR 2 HEATER (REAR)

Refer to ªComponent Inspectionº, EC-791.

OK or NG

OK©GO TO 6.

NG©Replace heated oxygen sensor 2 (rear).

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-670.

©INSPECTION END

SEF221W

Component InspectionNLEC1506HEATED OXYGEN SENSOR 2 HEATER (REAR)NLEC1506S01Check the following.

1. Check resistance between terminals 2 and 3.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

2. Check continuity.

Terminal No. Continuity

1 and 2, 3, 4

No

4 and 1, 2, 3

If NG, replace the heated oxygen sensor 2 (rear).

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

Diagnostic Procedure (Cont'd)

EC-791

Page 1376 of 3051

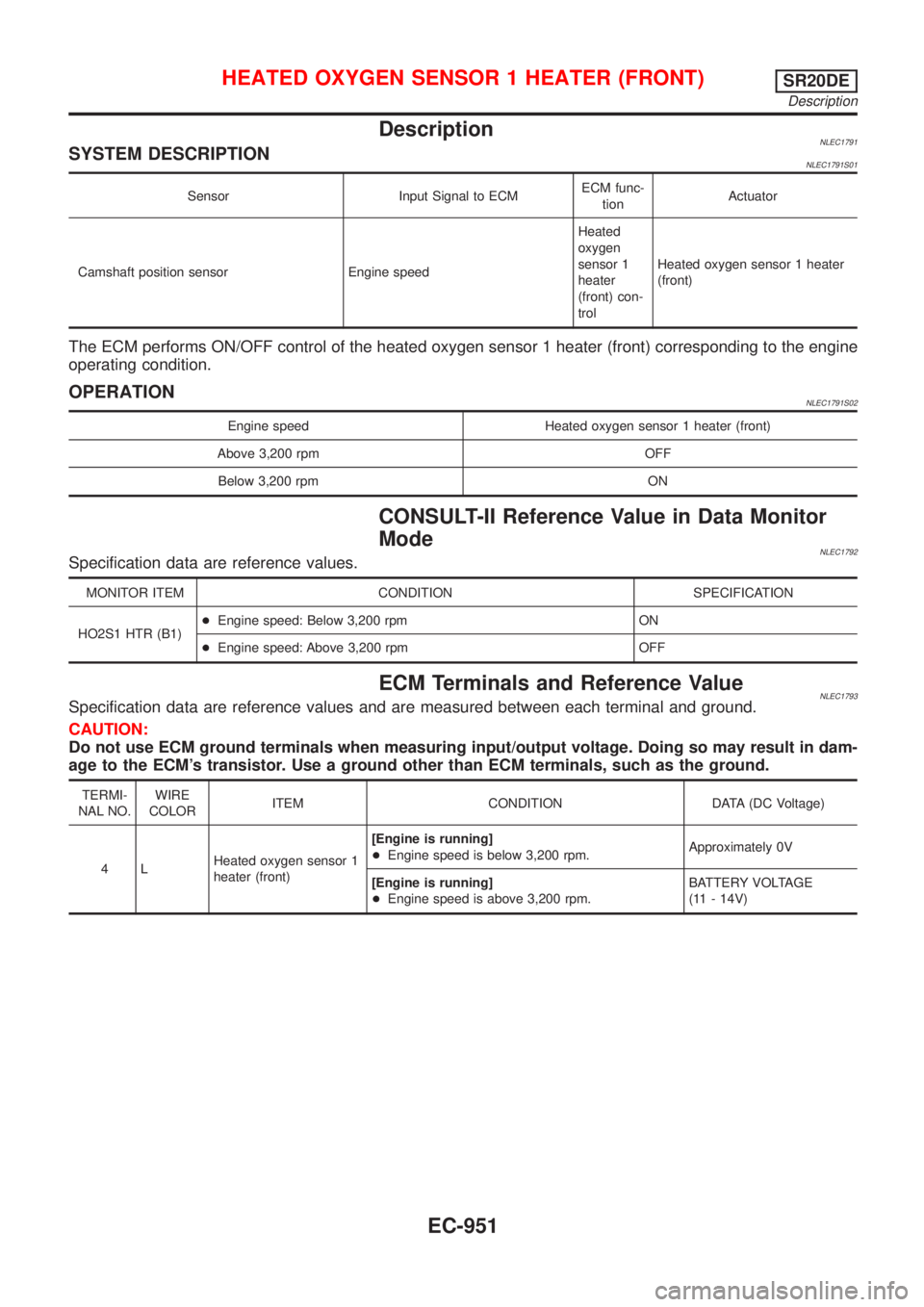

DescriptionNLEC1791SYSTEM DESCRIPTIONNLEC1791S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor Engine speedHeated

oxygen

sensor 1

heater

(front) con-

trolHeated oxygen sensor 1 heater

(front)

The ECM performs ON/OFF control of the heated oxygen sensor 1 heater (front) corresponding to the engine

operating condition.

OPERATIONNLEC1791S02

Engine speed Heated oxygen sensor 1 heater (front)

Above 3,200 rpm OFF

Below 3,200 rpm ON

CONSULT-II Reference Value in Data Monitor

Mode

NLEC1792Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S1 HTR (B1)+Engine speed: Below 3,200 rpm ON

+Engine speed: Above 3,200 rpm OFF

ECM Terminals and Reference ValueNLEC1793Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

4LHeated oxygen sensor 1

heater (front)[Engine is running]

+Engine speed is below 3,200 rpm.Approximately 0V

[Engine is running]

+Engine speed is above 3,200 rpm.BATTERY VOLTAGE

(11 - 14V)

HEATED OXYGEN SENSOR 1 HEATER (FRONT)SR20DE

Description

EC-951

Page 1377 of 3051

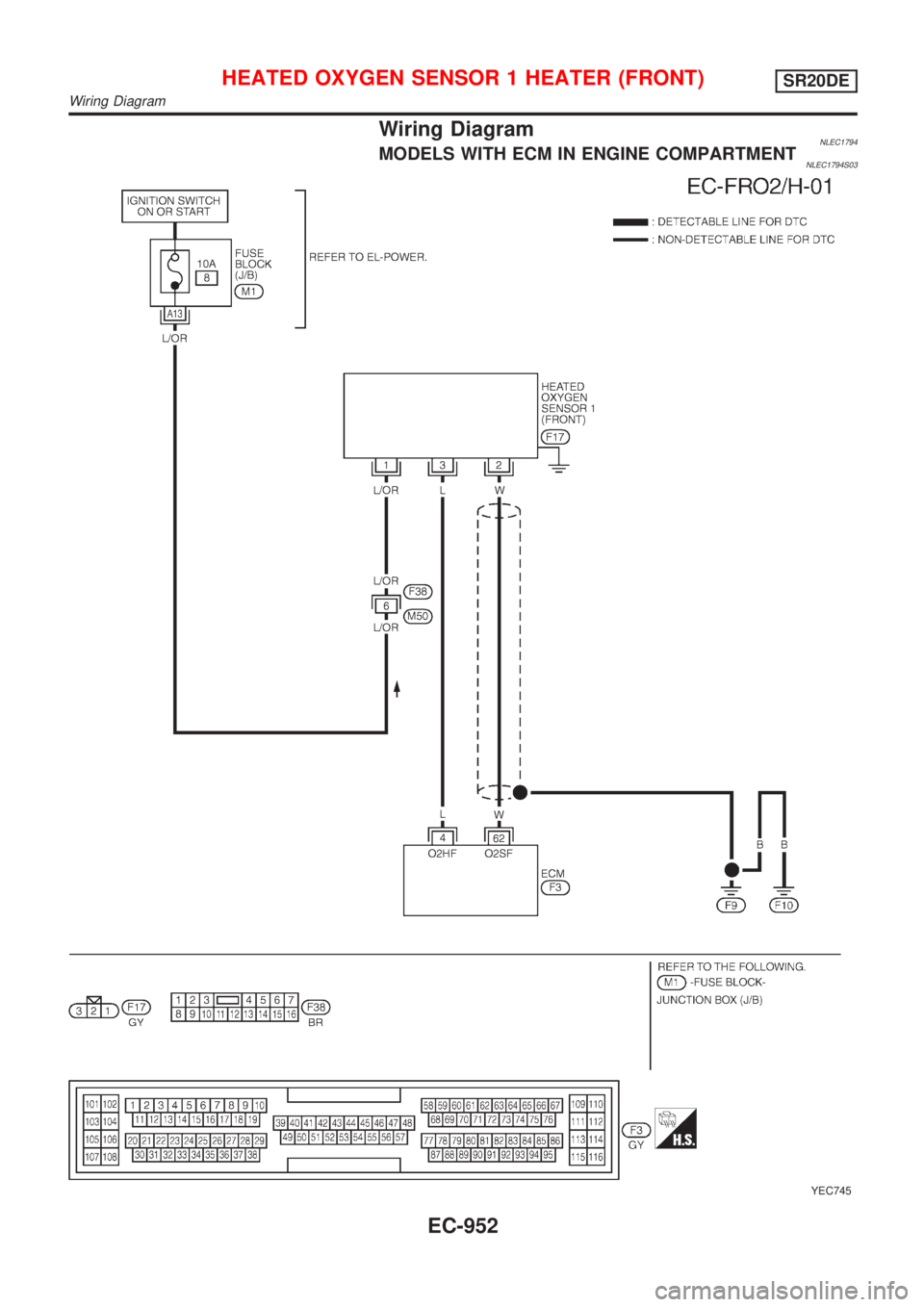

Wiring DiagramNLEC1794MODELS WITH ECM IN ENGINE COMPARTMENTNLEC1794S03

YEC745

HEATED OXYGEN SENSOR 1 HEATER (FRONT)SR20DE

Wiring Diagram

EC-952