NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: manual transmission, oil viscosity, fuel cap release, jacking points, oil, jump cable, brake

Page 801 of 3051

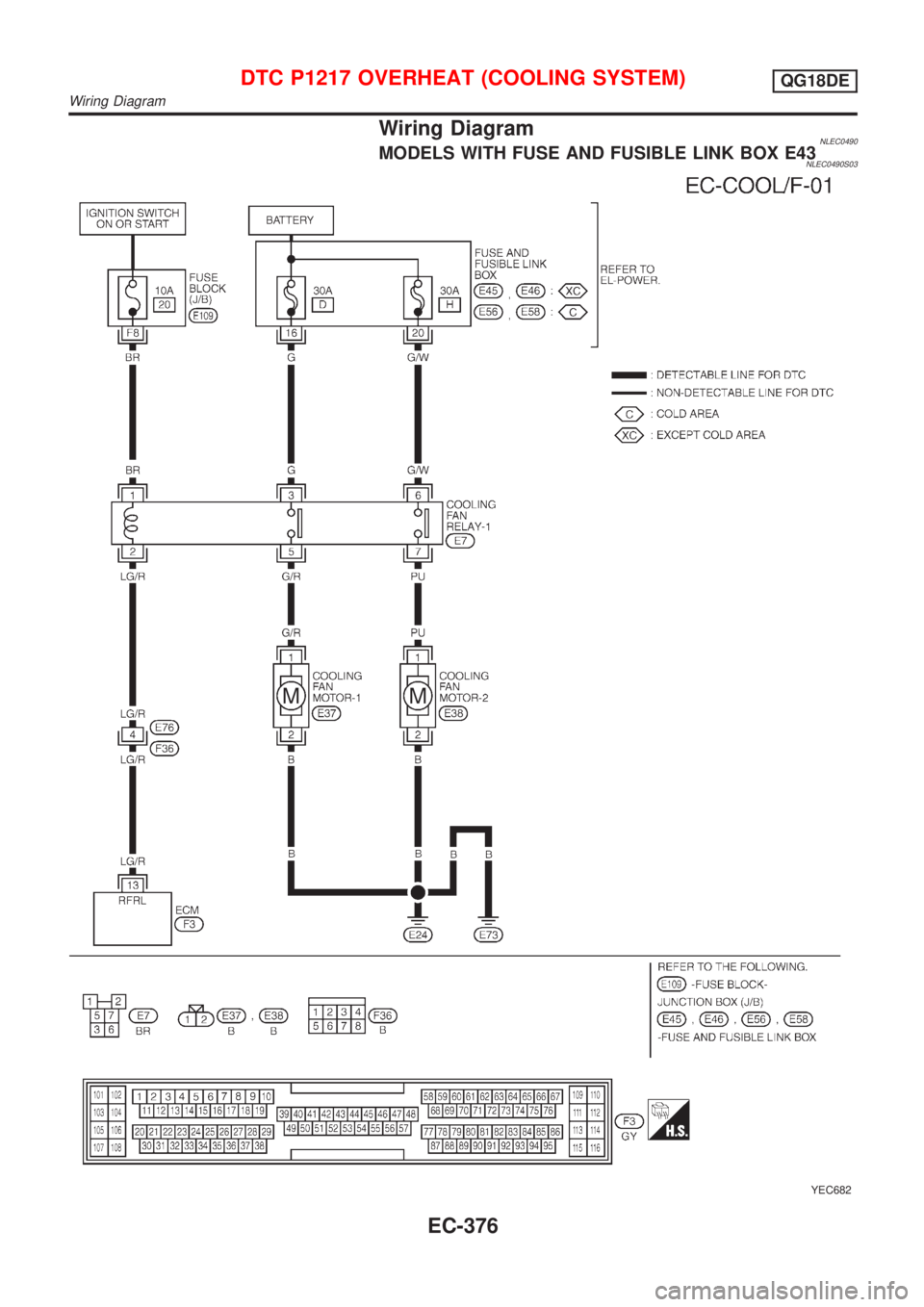

Wiring DiagramNLEC0490MODELS WITH FUSE AND FUSIBLE LINK BOX E43NLEC0490S03

YEC682

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Wiring Diagram

EC-376

Page 802 of 3051

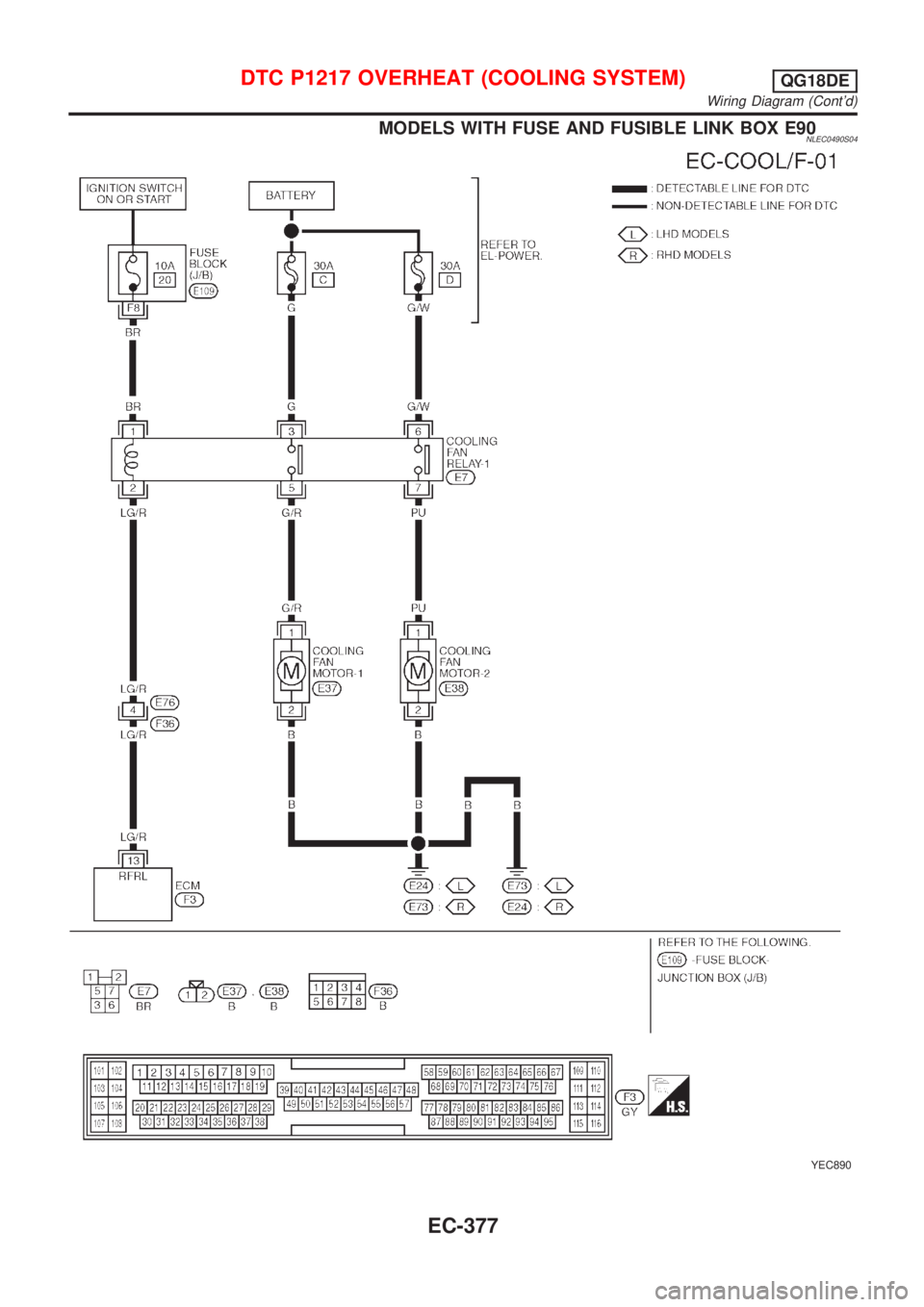

MODELS WITH FUSE AND FUSIBLE LINK BOX E90NLEC0490S04

YEC890

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Wiring Diagram (Cont'd)

EC-377

Page 803 of 3051

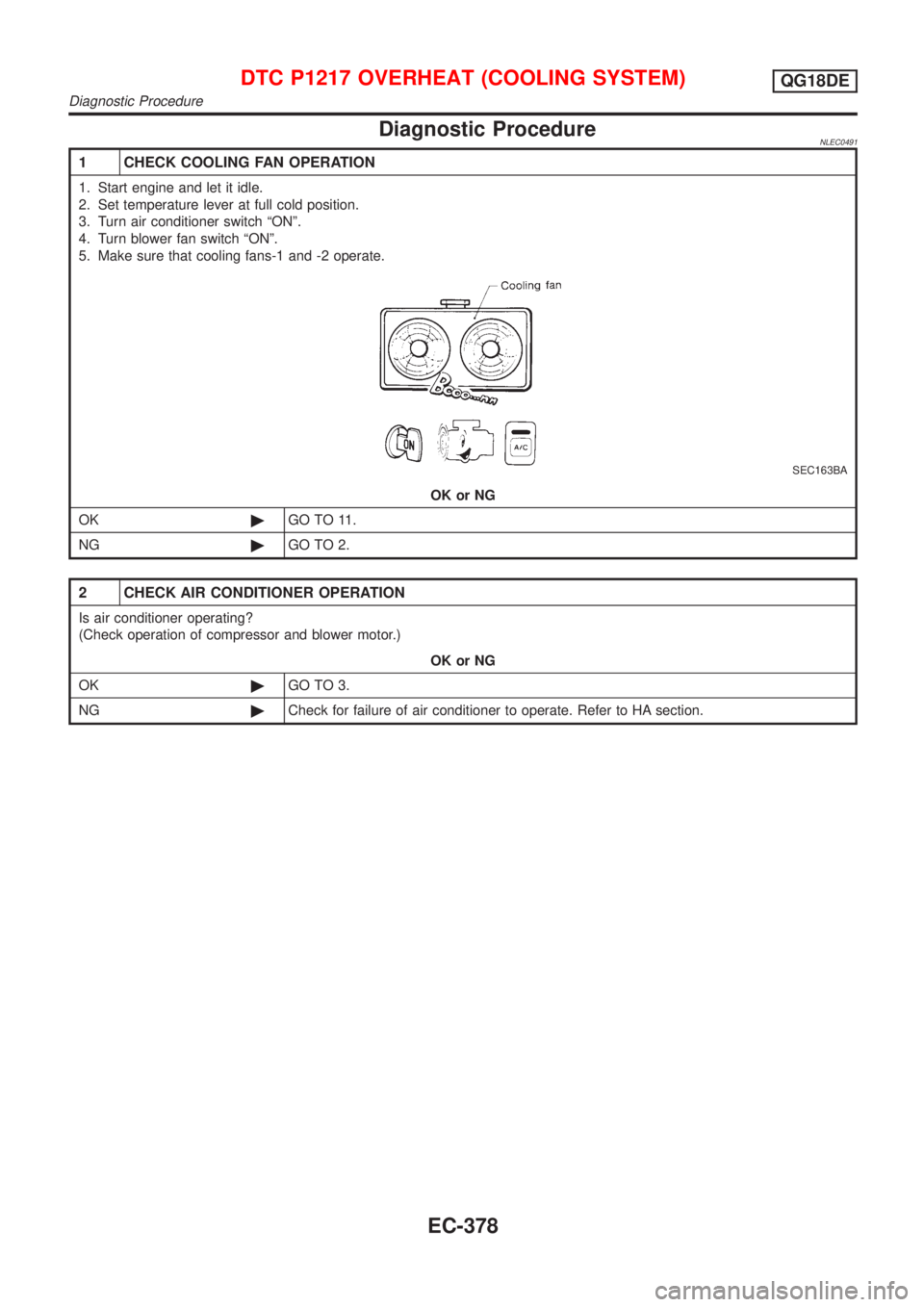

Diagnostic ProcedureNLEC0491

1 CHECK COOLING FAN OPERATION

1. Start engine and let it idle.

2. Set temperature lever at full cold position.

3. Turn air conditioner switch ªONº.

4. Turn blower fan switch ªONº.

5. Make sure that cooling fans-1 and -2 operate.

SEC163BA

OK or NG

OK©GO TO 11.

NG©GO TO 2.

2 CHECK AIR CONDITIONER OPERATION

Is air conditioner operating?

(Check operation of compressor and blower motor.)

OK or NG

OK©GO TO 3.

NG©Check for failure of air conditioner to operate. Refer to HA section.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Diagnostic Procedure

EC-378

Page 804 of 3051

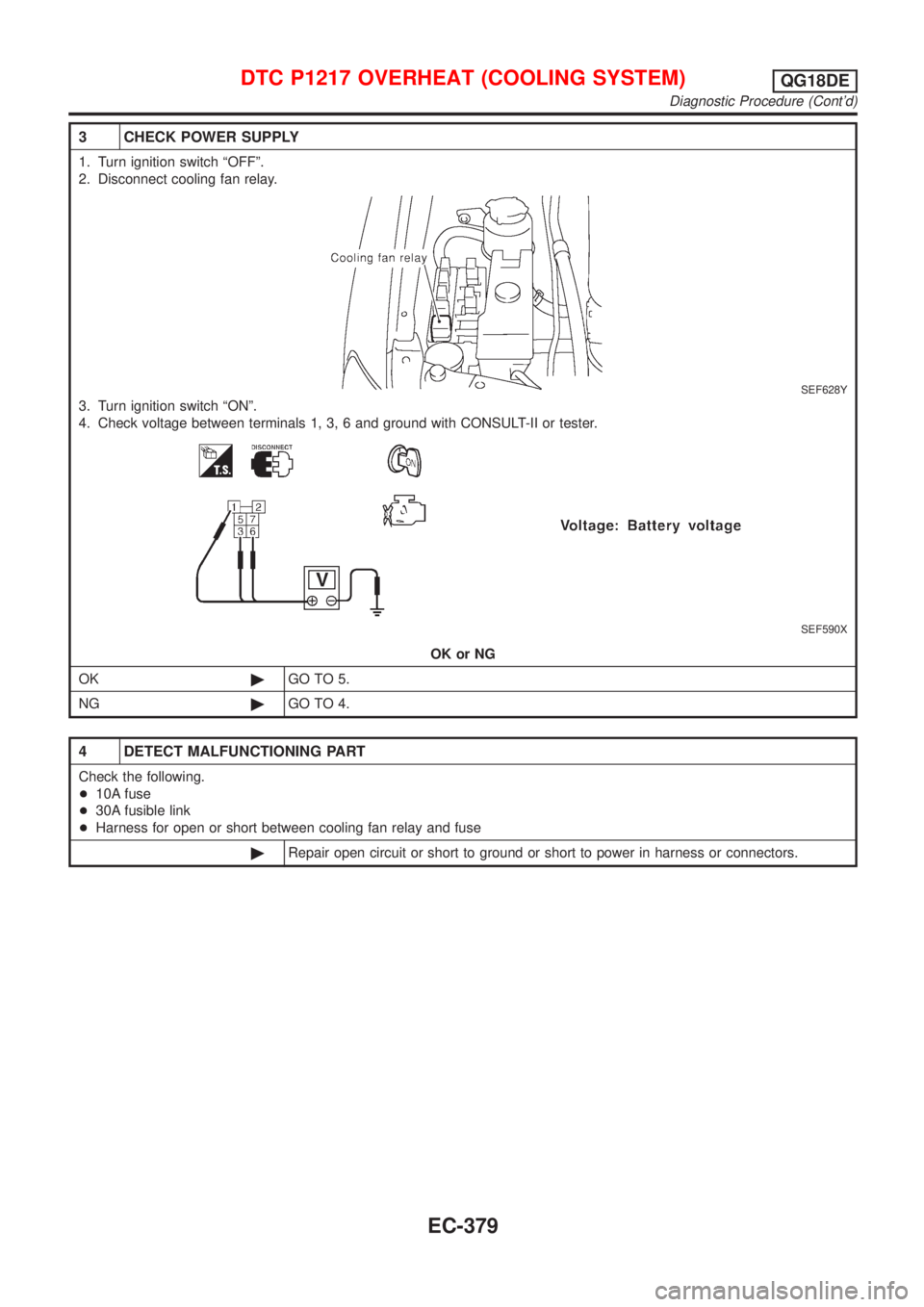

3 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay.

SEF628Y

3. Turn ignition switch ªONº.

4. Check voltage between terminals 1, 3, 6 and ground with CONSULT-II or tester.

SEF590X

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+10A fuse

+30A fusible link

+Harness for open or short between cooling fan relay and fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Diagnostic Procedure (Cont'd)

EC-379

Page 805 of 3051

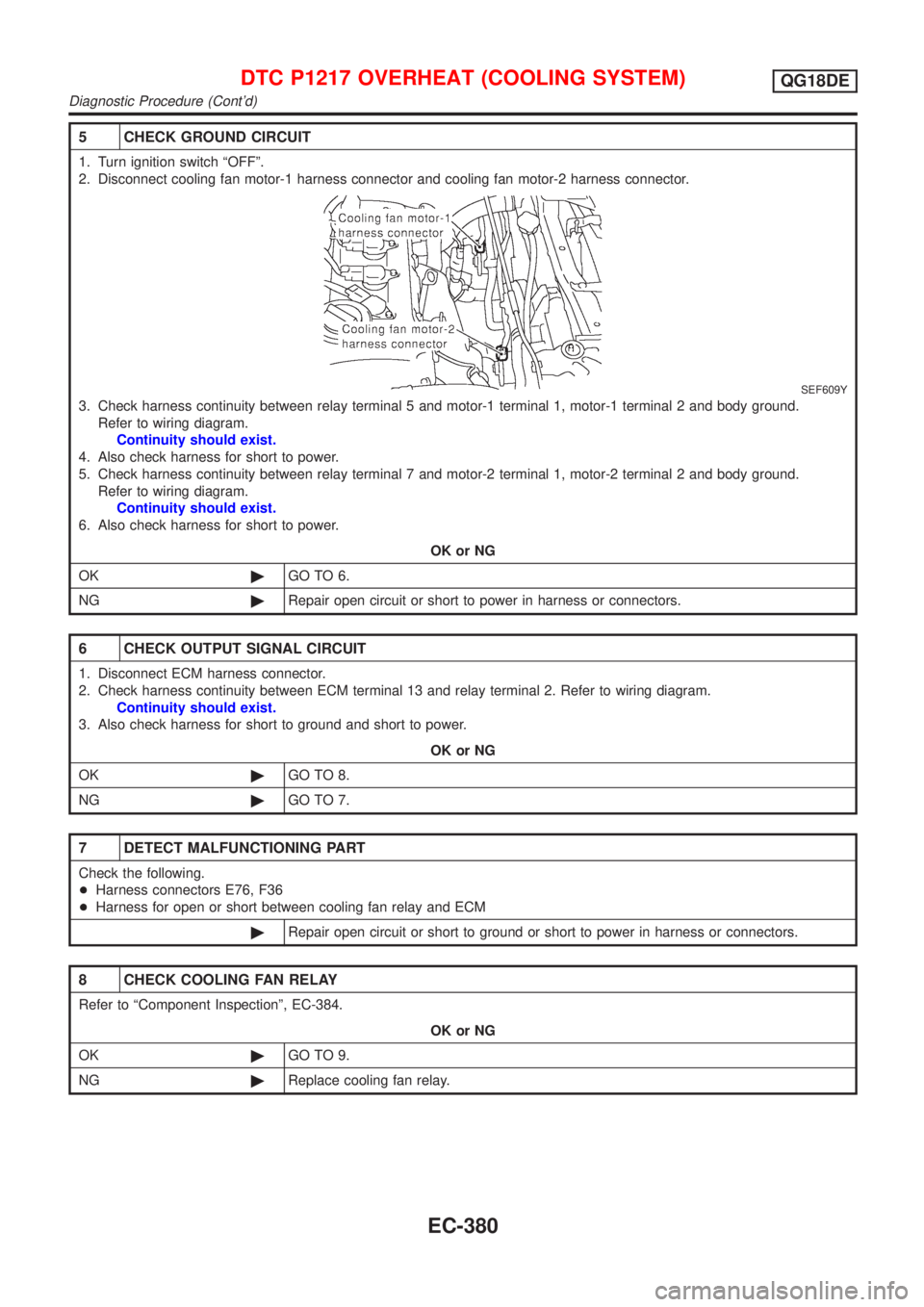

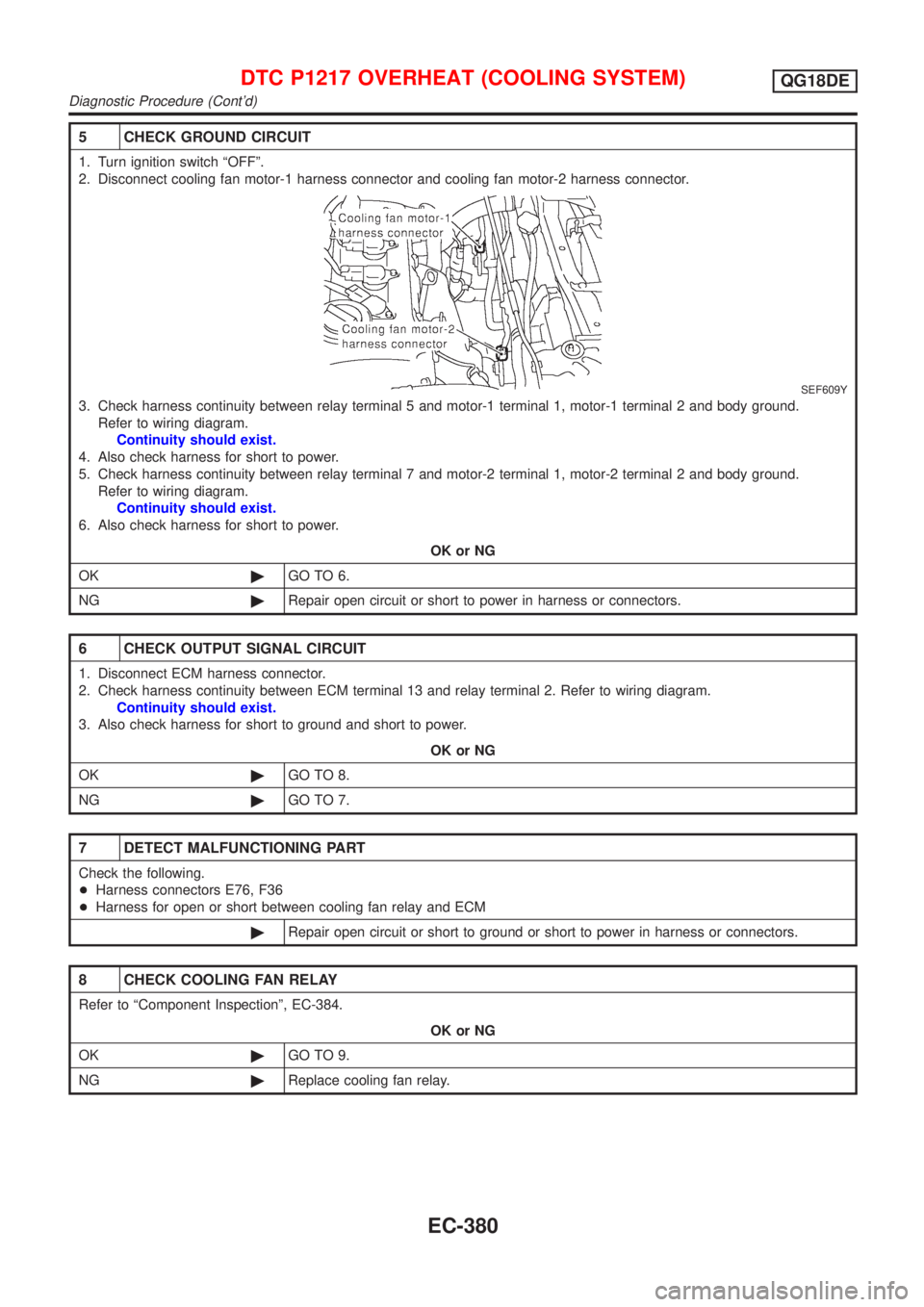

5 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan motor-1 harness connector and cooling fan motor-2 harness connector.

SEF609Y

3. Check harness continuity between relay terminal 5 and motor-1 terminal 1, motor-1 terminal 2 and body ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to power.

5. Check harness continuity between relay terminal 7 and motor-2 terminal 1, motor-2 terminal 2 and body ground.

Refer to wiring diagram.

Continuity should exist.

6. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to power in harness or connectors.

6 CHECK OUTPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 13 and relay terminal 2. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E76, F36

+Harness for open or short between cooling fan relay and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK COOLING FAN RELAY

Refer to ªComponent Inspectionº, EC-384.

OK or NG

OK©GO TO 9.

NG©Replace cooling fan relay.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Diagnostic Procedure (Cont'd)

EC-380

Page 806 of 3051

9 CHECK COOLING FAN MOTORS-1 AND -2

Refer to ªComponent Inspectionº, EC-384.

OK or NG

OK©GO TO 10.

NG©Replace cooling fan motors.

10 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

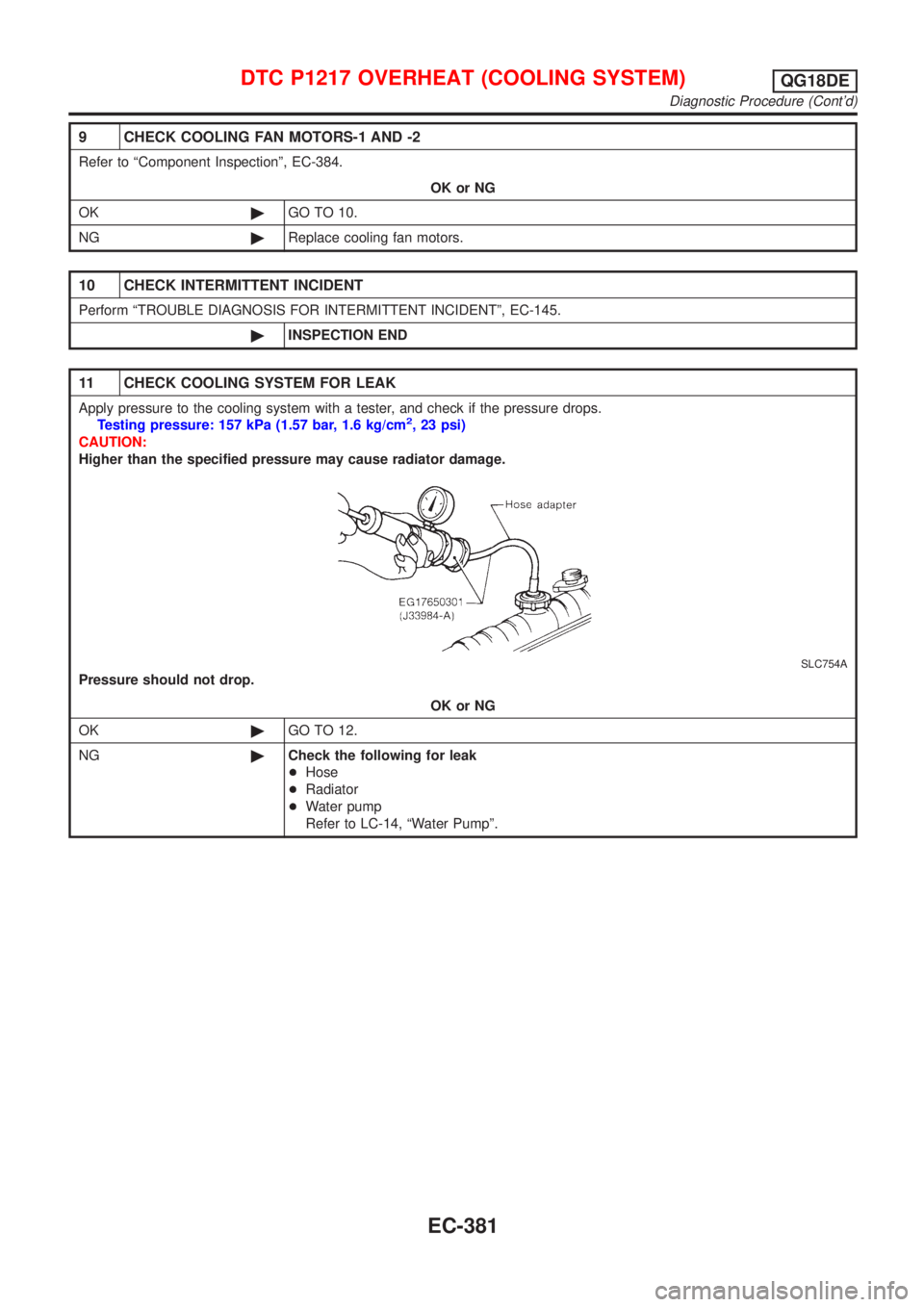

11 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK©GO TO 12.

NG©Check the following for leak

+Hose

+Radiator

+Water pump

Refer to LC-14, ªWater Pumpº.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Diagnostic Procedure (Cont'd)

EC-381

Page 807 of 3051

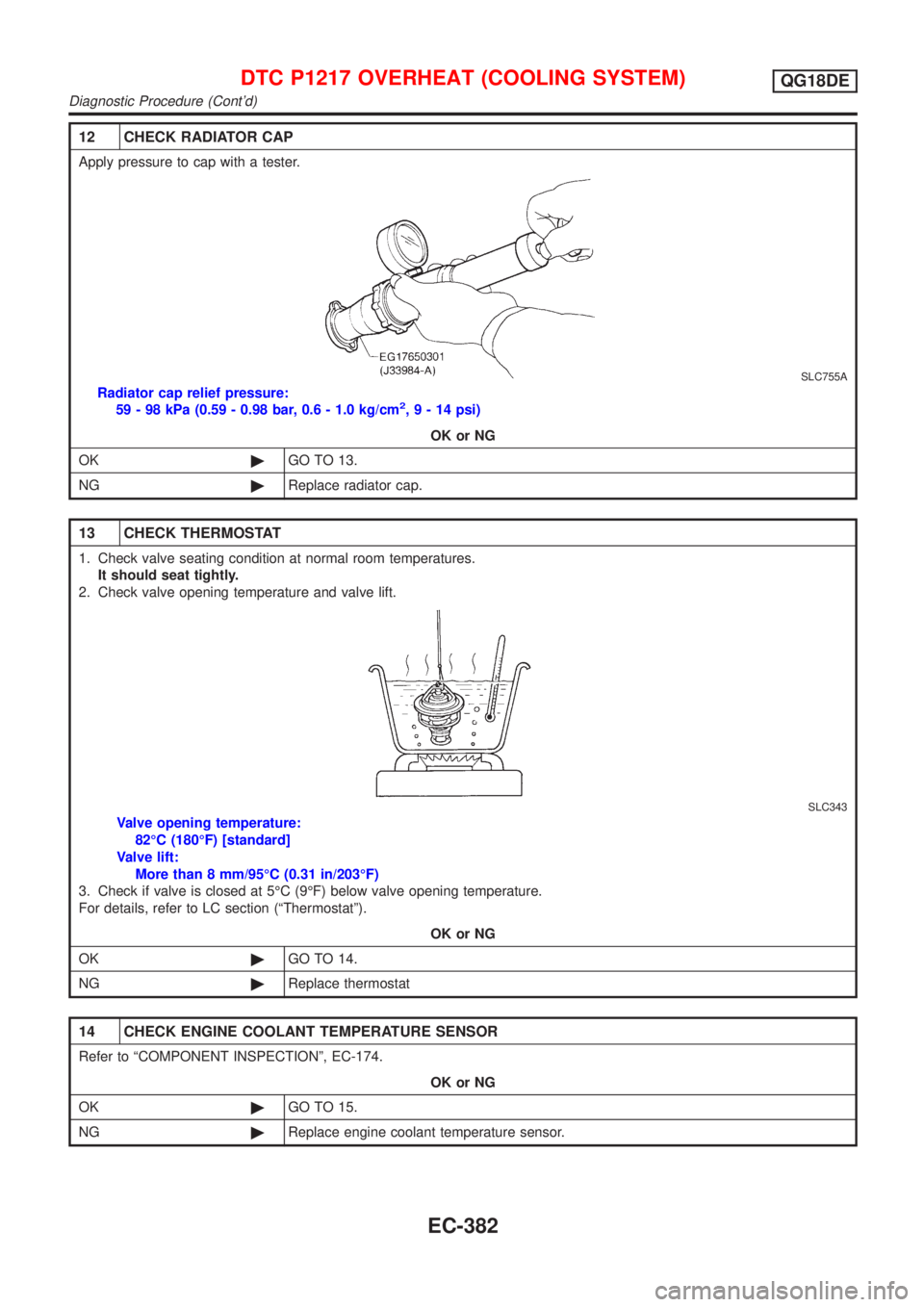

12 CHECK RADIATOR CAP

Apply pressure to cap with a tester.

SLC755A

Radiator cap relief pressure:

59 - 98 kPa (0.59 - 0.98 bar, 0.6 - 1.0 kg/cm2,9-14psi)

OK or NG

OK©GO TO 13.

NG©Replace radiator cap.

13 CHECK THERMOSTAT

1. Check valve seating condition at normal room temperatures.

It should seat tightly.

2. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

82ÉC (180ÉF) [standard]

Valve lift:

More than 8 mm/95ÉC (0.31 in/203ÉF)

3. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature.

For details, refer to LC section (ªThermostatº).

OK or NG

OK©GO TO 14.

NG©Replace thermostat

14 CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to ªCOMPONENT INSPECTIONº, EC-174.

OK or NG

OK©GO TO 15.

NG©Replace engine coolant temperature sensor.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Diagnostic Procedure (Cont'd)

EC-382

Page 808 of 3051

15 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-384.

©INSPECTION END

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Diagnostic Procedure (Cont'd)

EC-383

Page 809 of 3051

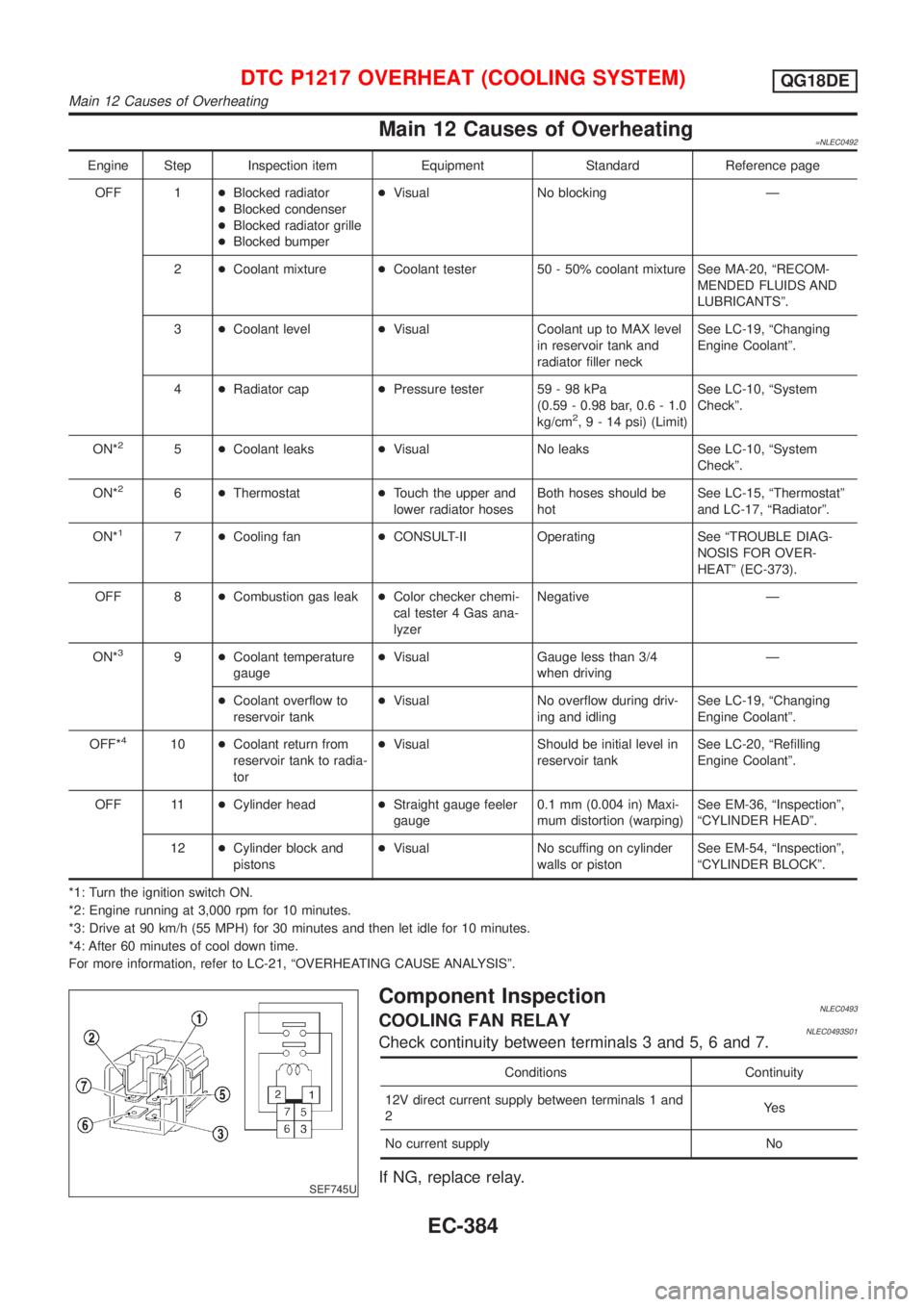

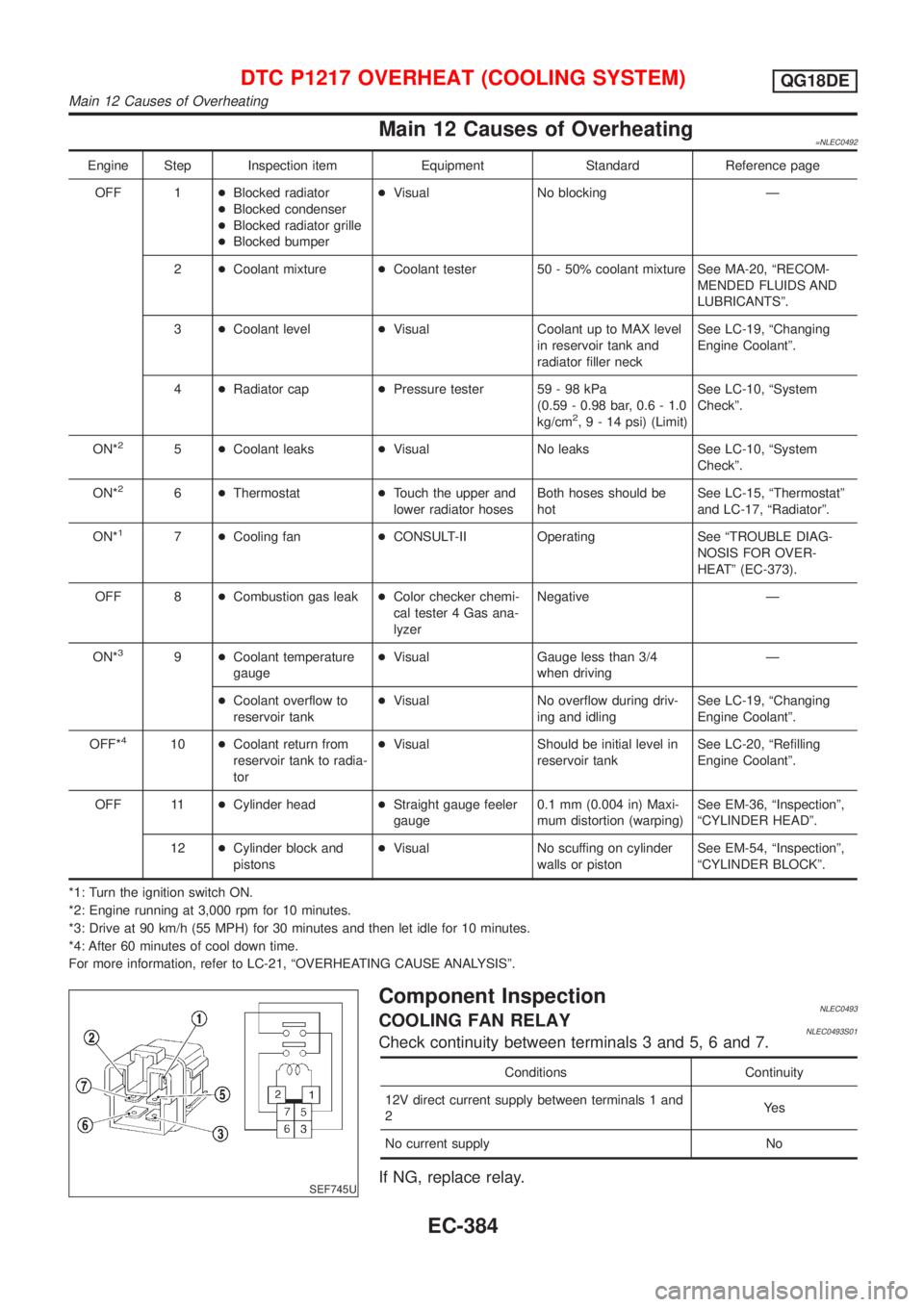

Main 12 Causes of Overheating=NLEC0492

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 50 - 50% coolant mixture See MA-20, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee LC-19, ªChanging

Engine Coolantº.

4+Radiator cap+Pressure tester 59 - 98 kPa

(0.59 - 0.98 bar, 0.6 - 1.0

kg/cm

2,9-14psi) (Limit)See LC-10, ªSystem

Checkº.

ON*

25+Coolant leaks+Visual No leaks See LC-10, ªSystem

Checkº.

ON*

26+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-15, ªThermostatº

and LC-17, ªRadiatorº.

ON*

17+Cooling fan+CONSULT-II Operating See ªTROUBLE DIAG-

NOSIS FOR OVER-

HEATº (EC-373).

OFF 8+Combustion gas leak+Color checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to

reservoir tank+Visual No overflow during driv-

ing and idlingSee LC-19, ªChanging

Engine Coolantº.

OFF*

410+Coolant return from

reservoir tank to radia-

tor+Visual Should be initial level in

reservoir tankSee LC-20, ªRefilling

Engine Coolantº.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM-36, ªInspectionº,

ªCYLINDER HEADº.

12+Cylinder block and

pistons+Visual No scuffing on cylinder

walls or pistonSee EM-54, ªInspectionº,

ªCYLINDER BLOCKº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC-21, ªOVERHEATING CAUSE ANALYSISº.

SEF745U

Component InspectionNLEC0493COOLING FAN RELAYNLEC0493S01Check continuity between terminals 3 and 5, 6 and 7.

Conditions Continuity

12V direct current supply between terminals 1 and

2Ye s

No current supply No

If NG, replace relay.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Main 12 Causes of Overheating

EC-384

Page 810 of 3051

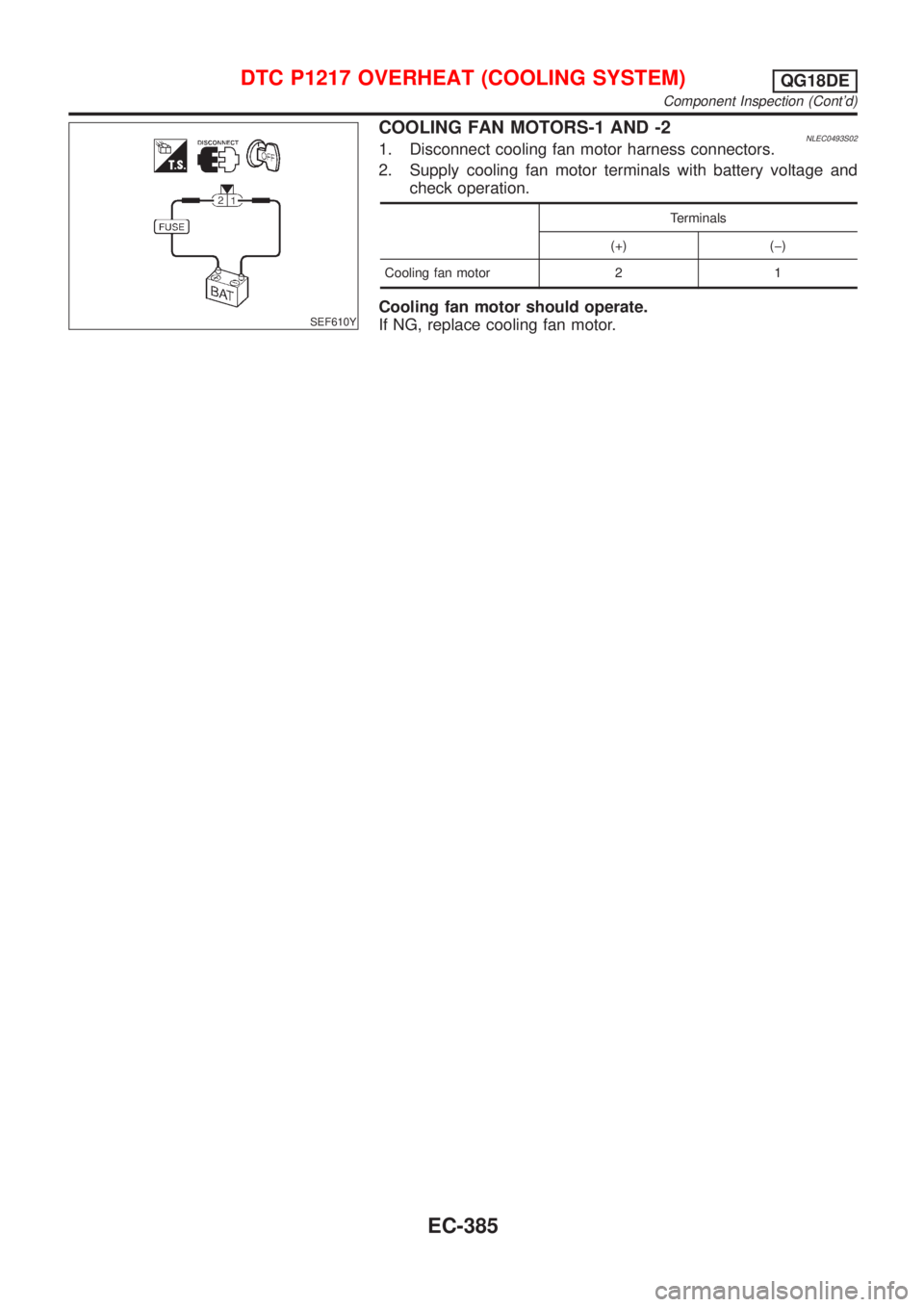

SEF610Y

COOLING FAN MOTORS-1 AND -2NLEC0493S021. Disconnect cooling fan motor harness connectors.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Terminals

(+) (þ)

Cooling fan motor 2 1

Cooling fan motor should operate.

If NG, replace cooling fan motor.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Component Inspection (Cont'd)

EC-385

Trending: exhaust manifold, brake, phone, refrigerant type, center console, brake sensor, fuel pump