NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 781 of 3051

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between throttle position switch and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

5 ADJUST THROTTLE POSITION SWITCH IDLE POSITION

Perform Basic Inspection, EC-99.

©GO TO 6.

6 CHECK CLOSED THROTTLE POSITION SWITCH

Refer to ªComponent Inspectionº, EC-356.

OK or NG

OK©GO TO 7.

NG©Replace throttle position switch.

7 CHECK THROTTLE POSITION SENSOR

Refer to ªComponent Inspectionº, EC-182.

OK or NG

OK©GO TO 8.

NG©Replace throttle position sensor.

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

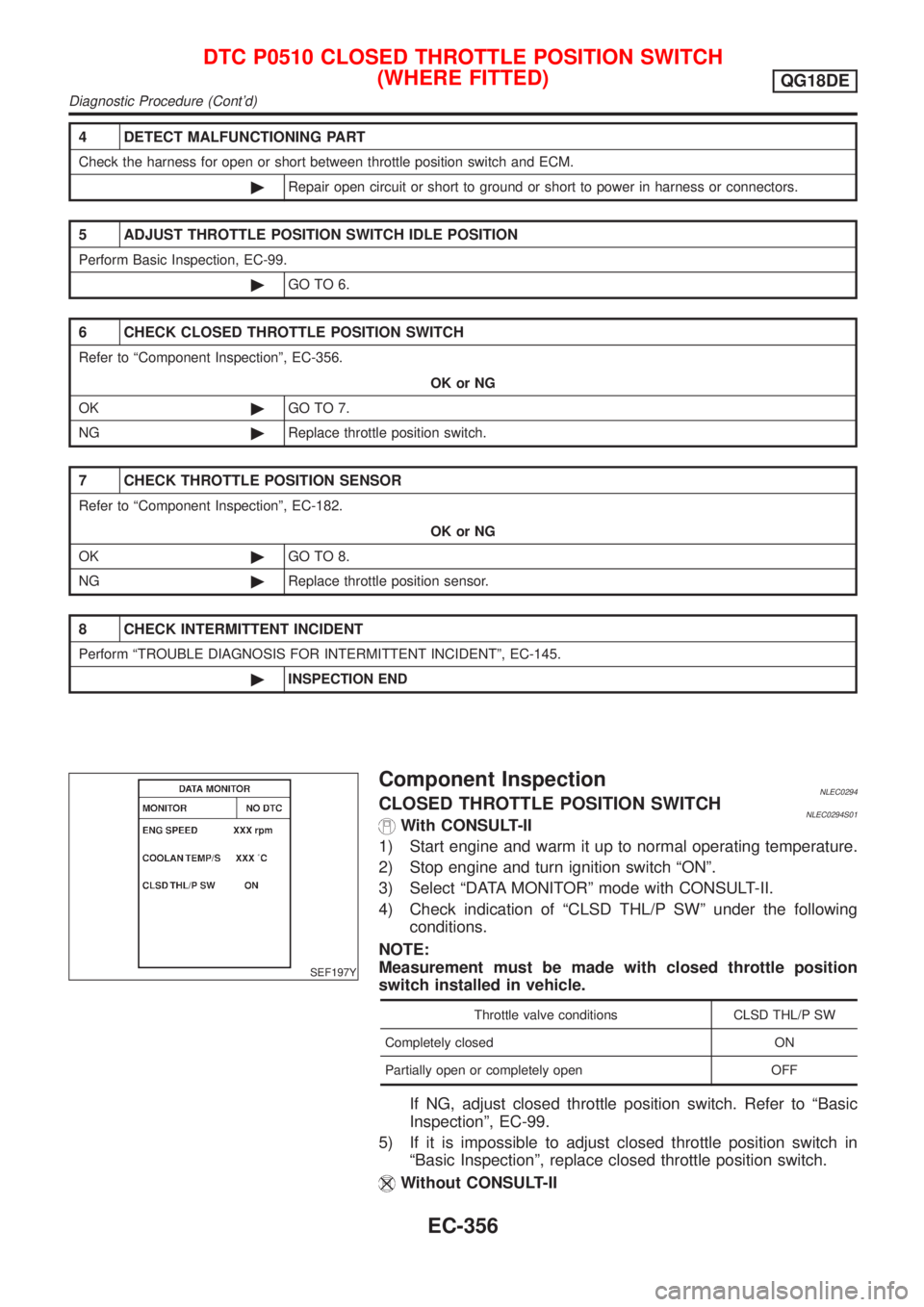

SEF197Y

Component InspectionNLEC0294CLOSED THROTTLE POSITION SWITCHNLEC0294S01With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Stop engine and turn ignition switch ªONº.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Check indication of ªCLSD THL/P SWº under the following

conditions.

NOTE:

Measurement must be made with closed throttle position

switch installed in vehicle.

Throttle valve conditions CLSD THL/P SW

Completely closed ON

Partially open or completely open OFF

If NG, adjust closed throttle position switch. Refer to ªBasic

Inspectionº, EC-99.

5) If it is impossible to adjust closed throttle position switch in

ªBasic Inspectionº, replace closed throttle position switch.

Without CONSULT-II

DTC P0510 CLOSED THROTTLE POSITION SWITCH

(WHERE FITTED)

QG18DE

Diagnostic Procedure (Cont'd)

EC-356

Page 782 of 3051

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº.

3) Disconnect throttle position switch harness connector.

4) Check continuity between terminals 4 and 5 under the follow-

ing conditions. Refer to wiring diagram.

NOTE:

Continuity measurement must be made with closed throttle

position switch installed in vehicle.

Throttle valve conditions Continuity

Completely closed Yes

Partially open or completely open No

If NG, adjust closed throttle position switch. Refer to ªBasic

Inspectionº, EC-99.

5) If it is impossible to adjust closed throttle position switch in

ªBasic Inspectionº, replace closed throttle position switch.

DTC P0510 CLOSED THROTTLE POSITION SWITCH

(WHERE FITTED)

QG18DE

Component Inspection (Cont'd)

EC-357

Page 783 of 3051

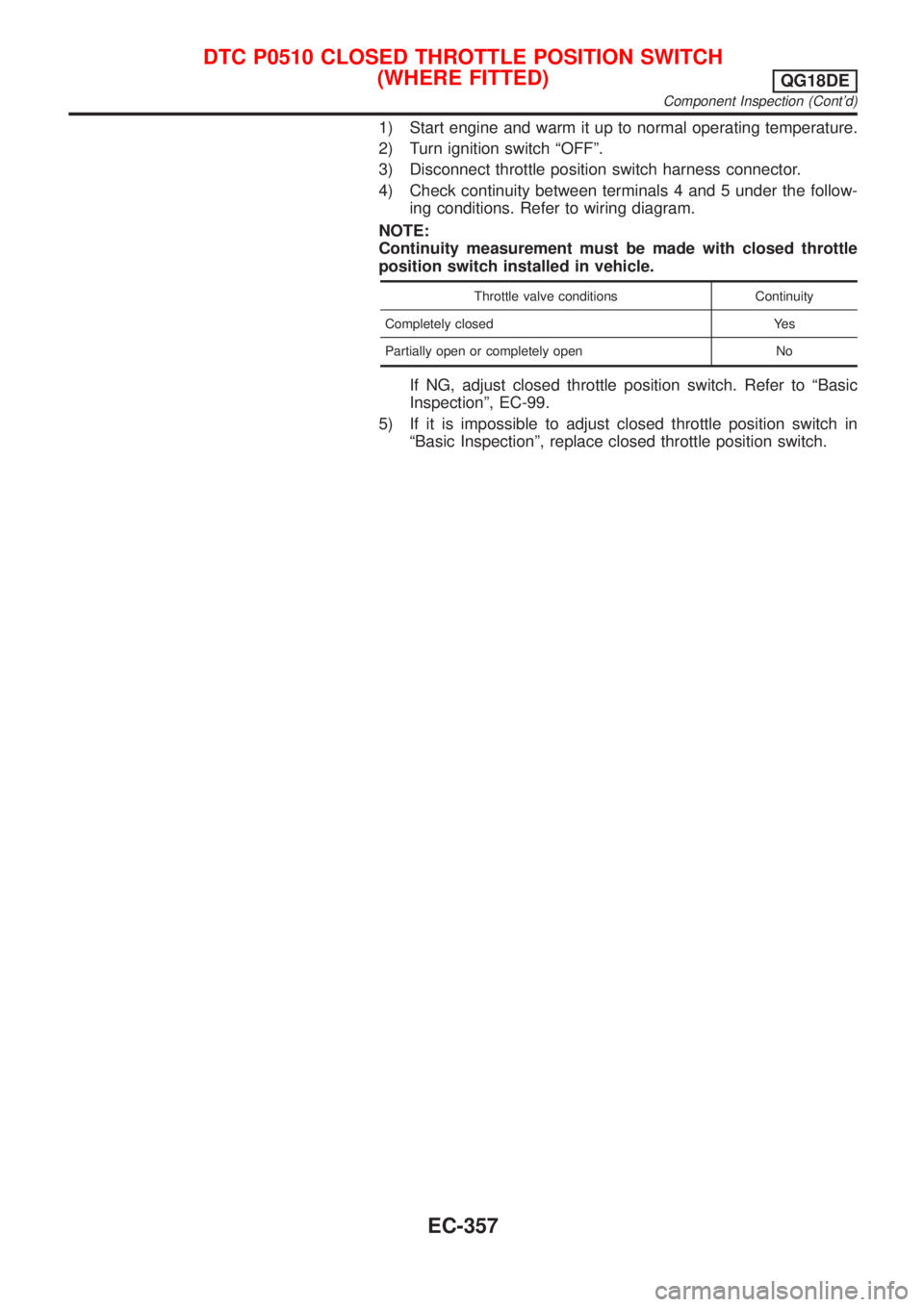

SEF093X

Component DescriptionNLEC0295The ECM consists of a microcomputer, and connectors for signal

input and output and for power supply. The ECM controls the

engine.

On Board Diagnosis LogicNLEC0296

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0605

0605+ECM calculation function is malfunctioning.+ECM

SEF058Y

DTC Confirmation ProcedureNLEC0297NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine.

4) Run engine for at least 1 second at idle speed.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-359.

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P0605 ECMQG18DE

Component Description

EC-358

Page 784 of 3051

Diagnostic Procedure=NLEC0298

1 INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº.

See EC-358.

5. Is the 1st trip DTC P0605 displayed again?

With GST

1. Turn ignition switch ªONº.

2. Select MODE 4 with GST.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº.

See EC-358.

5. Is the 1st trip DTC P0605 displayed again?

YesorNo

Ye s©GO TO 2.

No©INSPECTION END

2 REPLACE ECM

1. Replace ECM.

2. Perform initialization of NATS (NISSAN ANTI-THEFT SYSTEM) system and registration of all NATS ignition key IDs.

Refer to ªNATS (NISSAN ANTI-THEFT SYSTEM)º, EC-72.

3. Perform ªIdle Air Volume Learningº, EC-57,

Is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©INSPECTION END

INCMP©Follow the construction of ªIdle Air Volume Learningº.

DTC P0605 ECMQG18DE

Diagnostic Procedure

EC-359

Page 785 of 3051

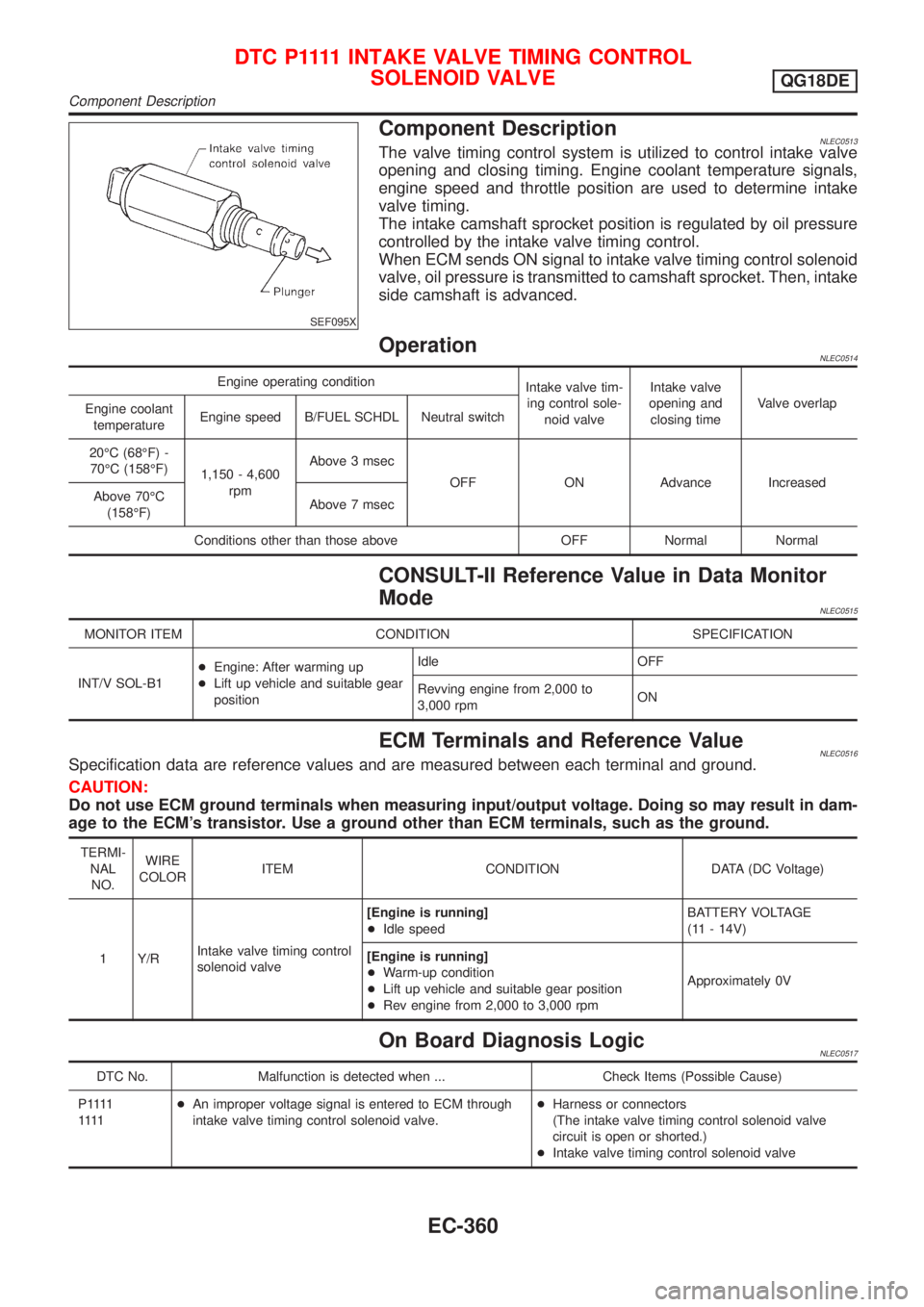

SEF095X

Component DescriptionNLEC0513The valve timing control system is utilized to control intake valve

opening and closing timing. Engine coolant temperature signals,

engine speed and throttle position are used to determine intake

valve timing.

The intake camshaft sprocket position is regulated by oil pressure

controlled by the intake valve timing control.

When ECM sends ON signal to intake valve timing control solenoid

valve, oil pressure is transmitted to camshaft sprocket. Then, intake

side camshaft is advanced.

OperationNLEC0514

Engine operating condition

Intake valve tim-

ing control sole-

noid valveIntake valve

opening and

closing timeValve overlap

Engine coolant

temperatureEngine speed B/FUEL SCHDL Neutral switch

20ÉC (68ÉF) -

70ÉC (158ÉF)

1,150 - 4,600

rpmAbove 3 msec

OFF ON Advance Increased

Above 70ÉC

(158ÉF)Above 7 msec

Conditions other than those above OFF Normal Normal

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0515

MONITOR ITEM CONDITION SPECIFICATION

INT/V SOL-B1+Engine: After warming up

+Lift up vehicle and suitable gear

positionIdle OFF

Revving engine from 2,000 to

3,000 rpmON

ECM Terminals and Reference ValueNLEC0516Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

1 Y/RIntake valve timing control

solenoid valve[Engine is running]

+Idle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Warm-up condition

+Lift up vehicle and suitable gear position

+Rev engine from 2,000 to 3,000 rpmApproximately 0V

On Board Diagnosis LogicNLEC0517

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P 1111

1111+An improper voltage signal is entered to ECM through

intake valve timing control solenoid valve.+Harness or connectors

(The intake valve timing control solenoid valve

circuit is open or shorted.)

+Intake valve timing control solenoid valve

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE

QG18DE

Component Description

EC-360

Page 786 of 3051

SEF608Y

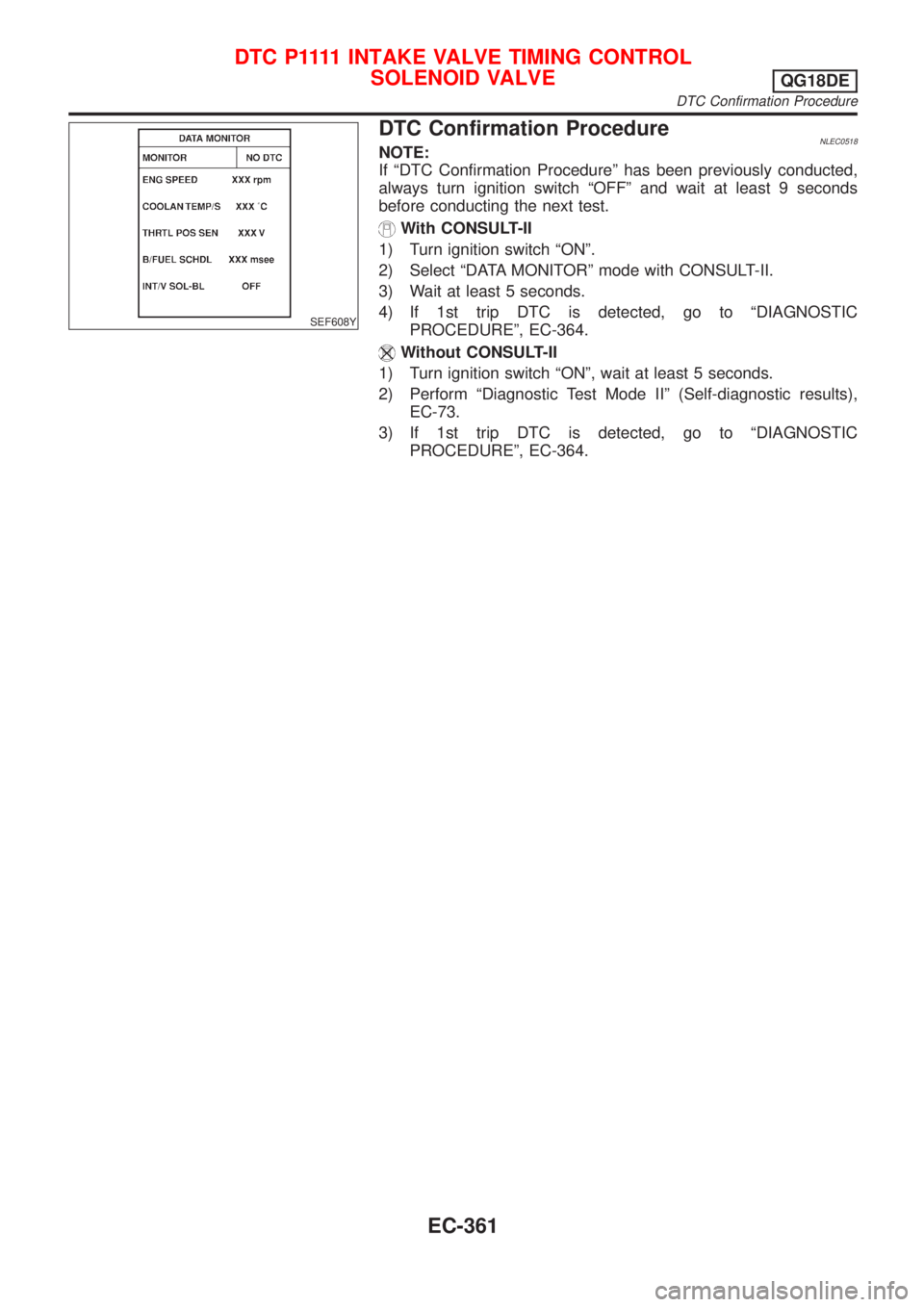

DTC Confirmation ProcedureNLEC0518NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDIAGNOSTIC

PROCEDUREº, EC-364.

Without CONSULT-II

1) Turn ignition switch ªONº, wait at least 5 seconds.

2) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results),

EC-73.

3) If 1st trip DTC is detected, go to ªDIAGNOSTIC

PROCEDUREº, EC-364.

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE

QG18DE

DTC Confirmation Procedure

EC-361

Page 787 of 3051

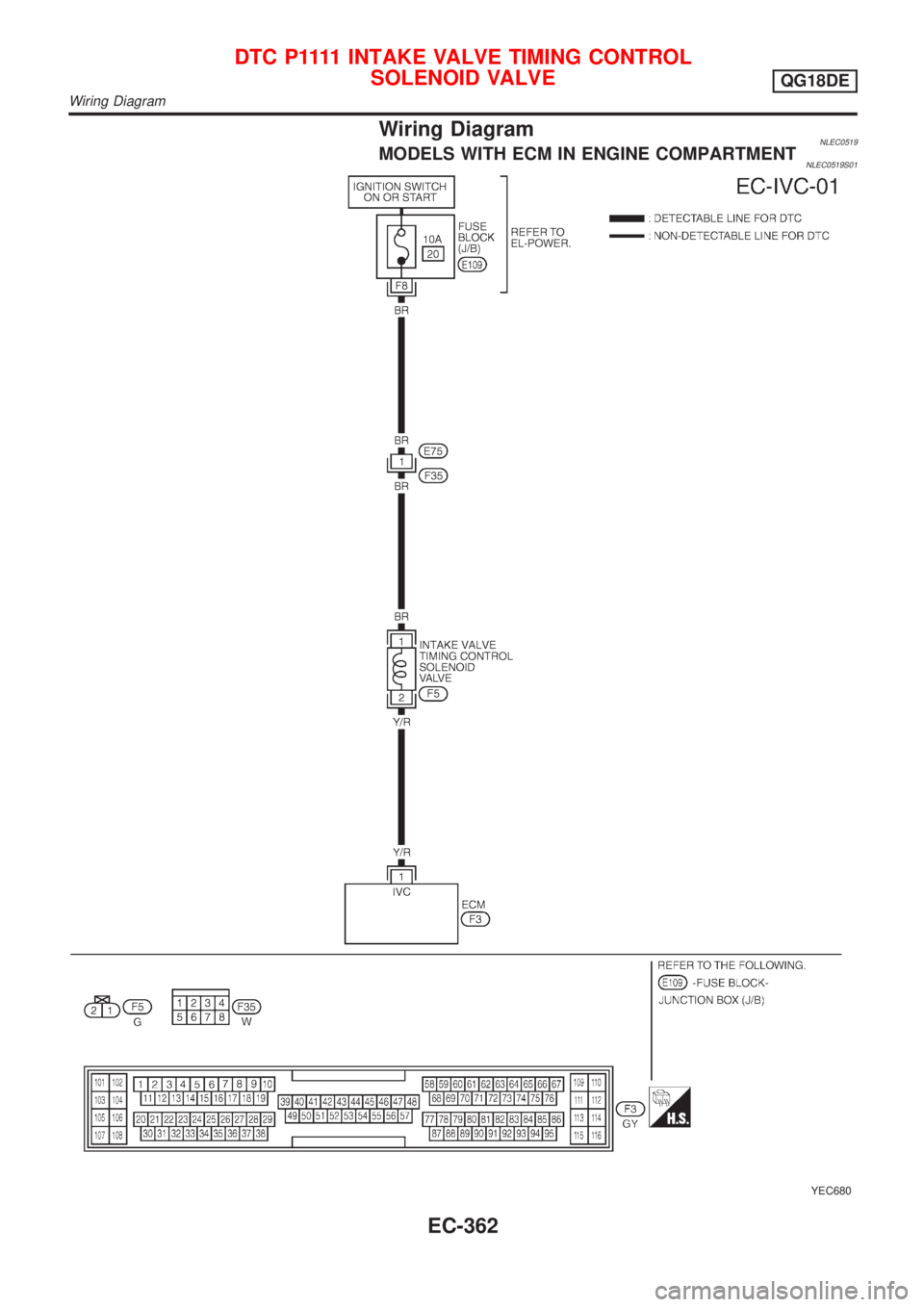

Wiring DiagramNLEC0519MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0519S01

YEC680

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE

QG18DE

Wiring Diagram

EC-362

Page 788 of 3051

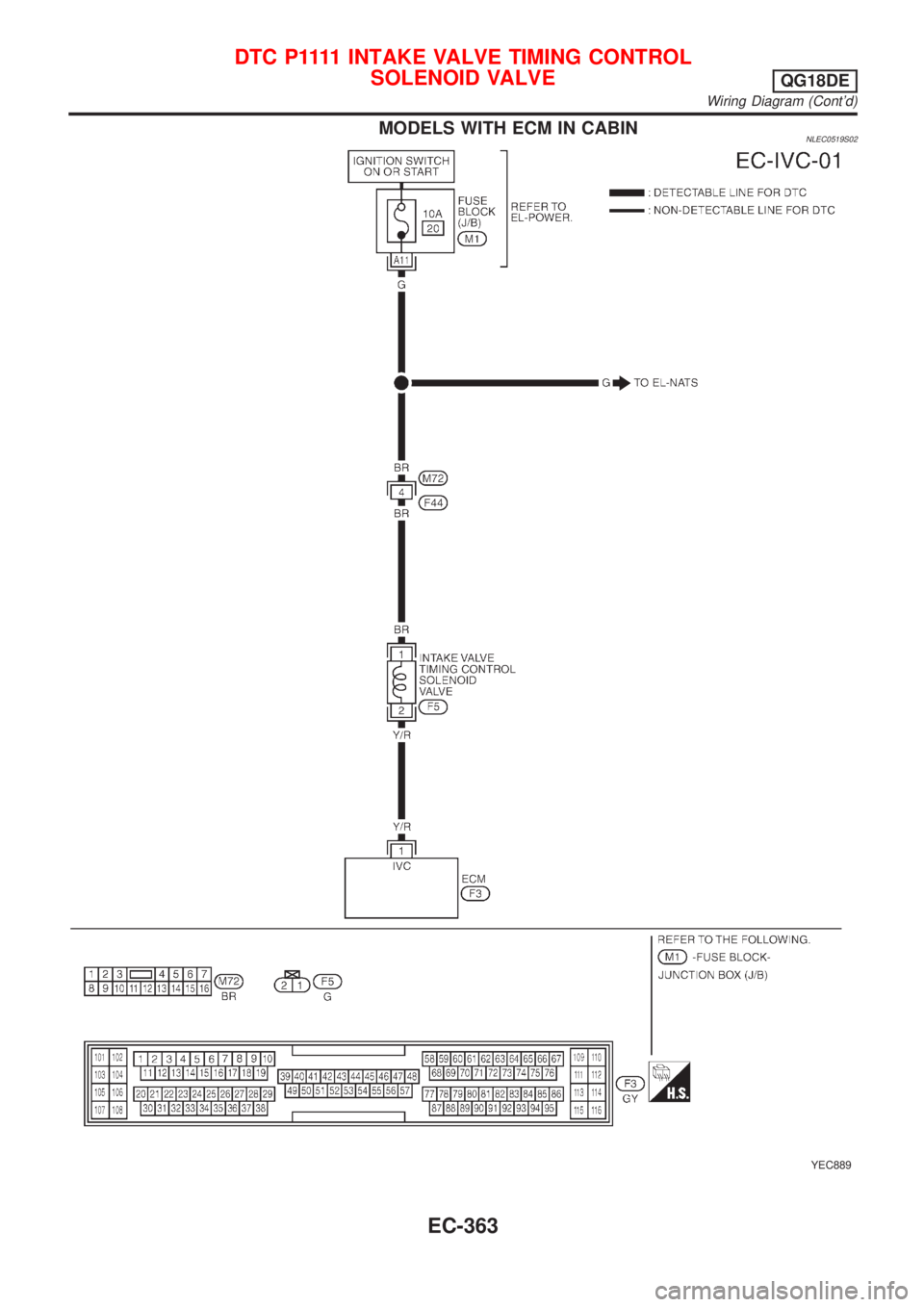

MODELS WITH ECM IN CABINNLEC0519S02

YEC889

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE

QG18DE

Wiring Diagram (Cont'd)

EC-363

Page 789 of 3051

Diagnostic ProcedureNLEC0520

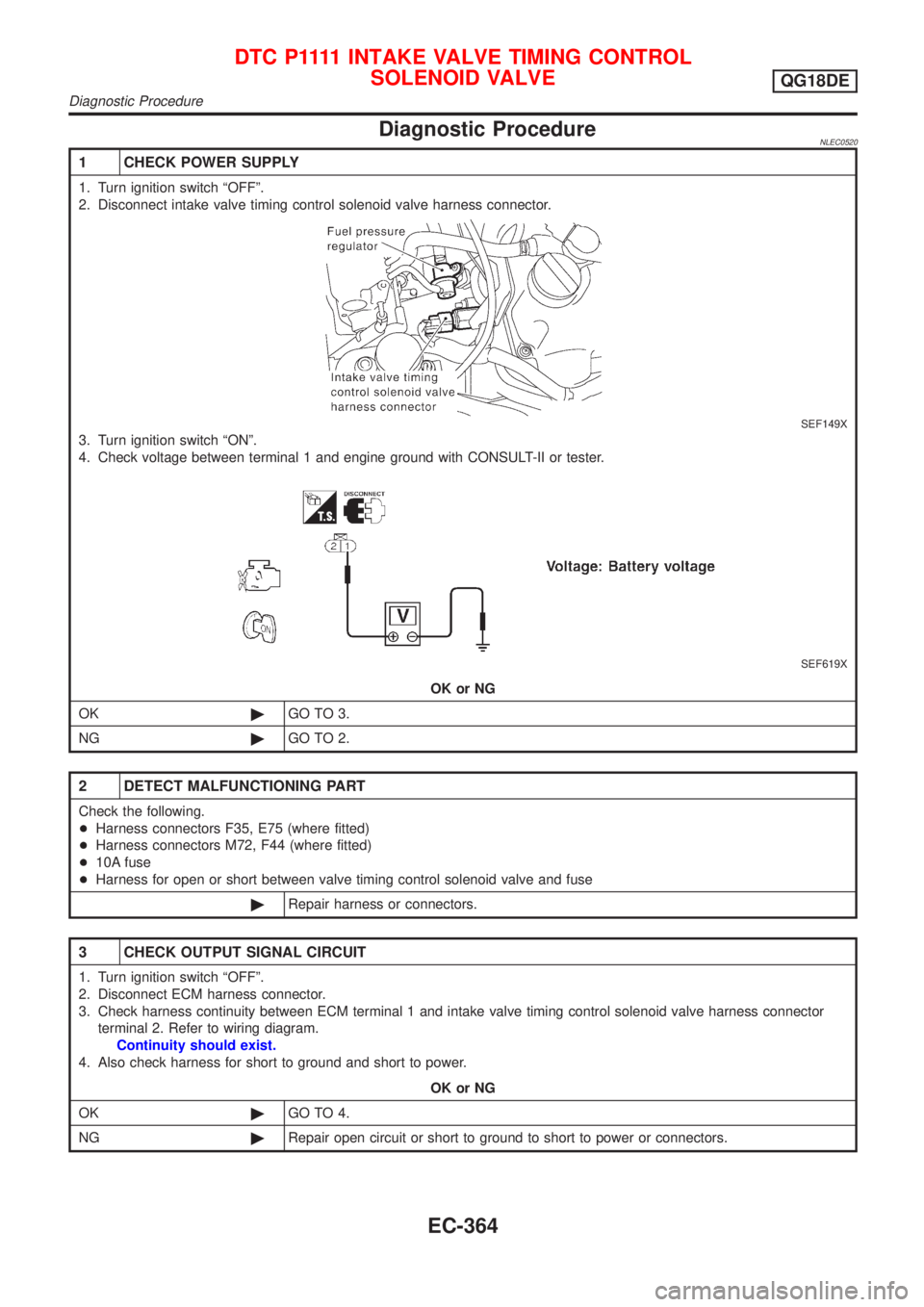

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect intake valve timing control solenoid valve harness connector.

SEF149X

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and engine ground with CONSULT-II or tester.

SEF619X

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F35, E75 (where fitted)

+Harness connectors M72, F44 (where fitted)

+10A fuse

+Harness for open or short between valve timing control solenoid valve and fuse

©Repair harness or connectors.

3 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 1 and intake valve timing control solenoid valve harness connector

terminal 2. Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground to short to power or connectors.

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE

QG18DE

Diagnostic Procedure

EC-364

Page 790 of 3051

4 CHECK VALVE TIMING CONTROL SOLENOID VALVE

Refer to ªComponent Inspectionº, EC-365.

OK or NG

OK©GO TO 5.

NG©Replace valve timing control solenoid valve.

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

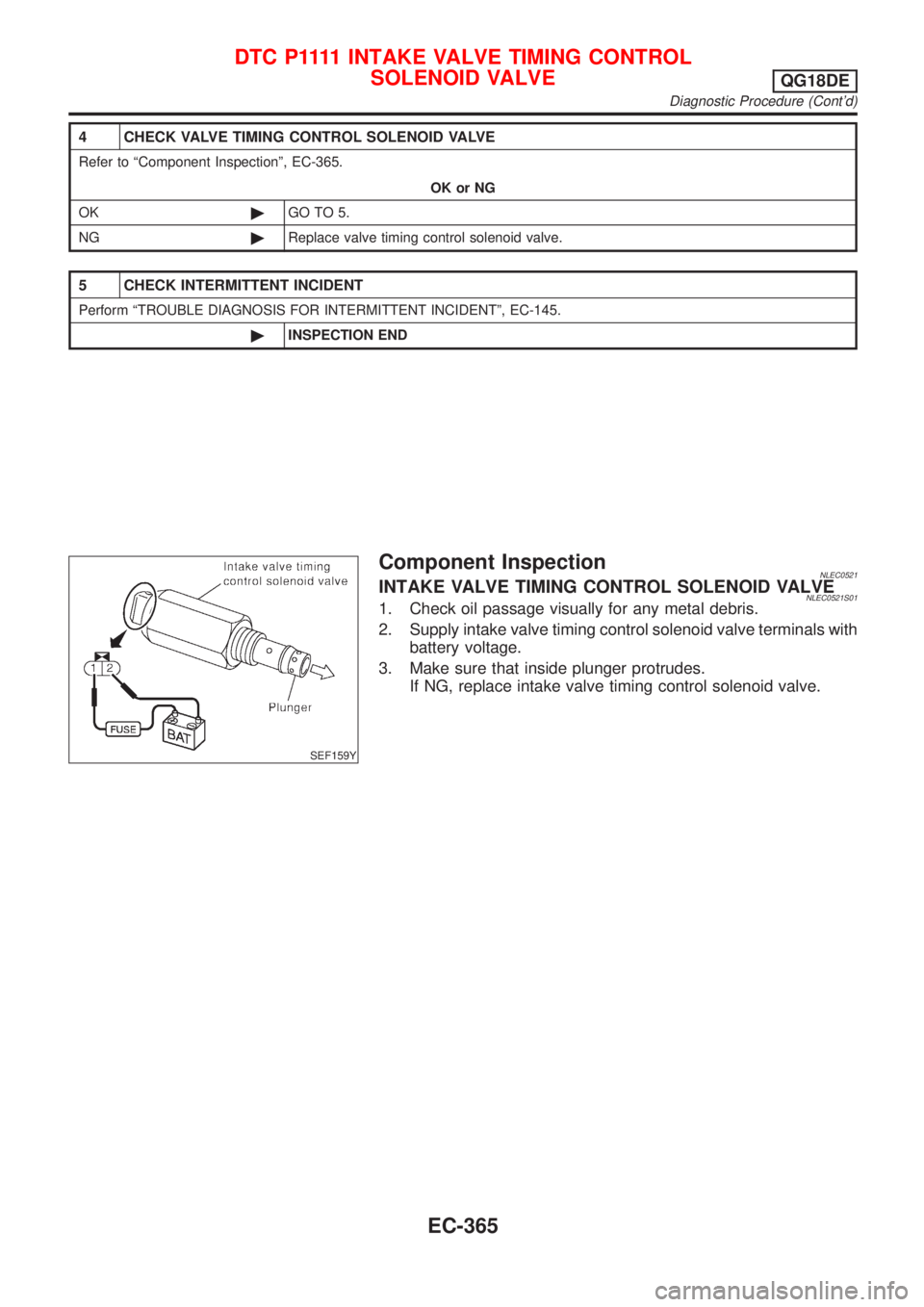

SEF159Y

Component InspectionNLEC0521INTAKE VALVE TIMING CONTROL SOLENOID VALVENLEC0521S011. Check oil passage visually for any metal debris.

2. Supply intake valve timing control solenoid valve terminals with

battery voltage.

3. Make sure that inside plunger protrudes.

If NG, replace intake valve timing control solenoid valve.

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE

QG18DE

Diagnostic Procedure (Cont'd)

EC-365