NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 821 of 3051

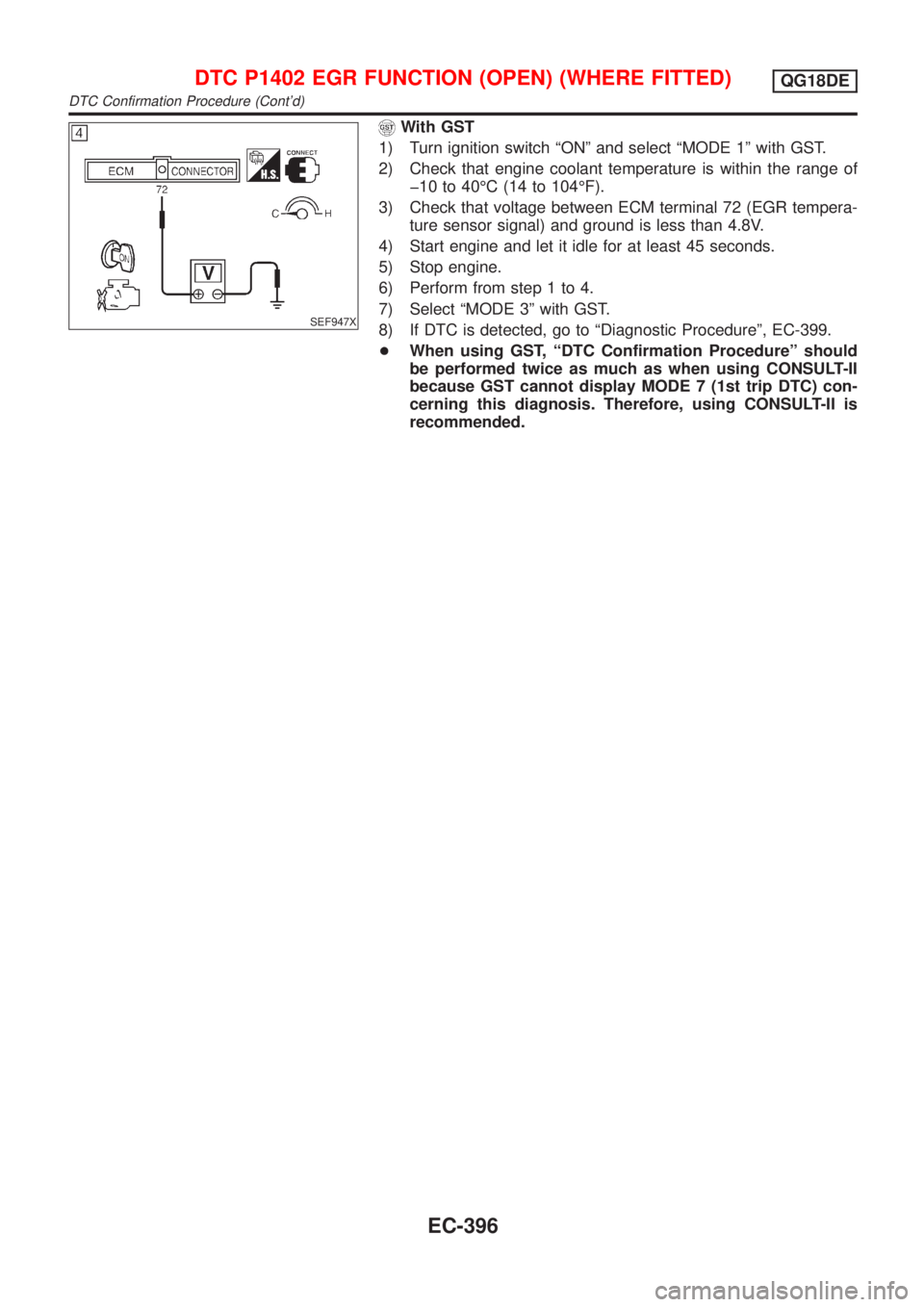

SEF947X

With GST

1) Turn ignition switch ªONº and select ªMODE 1º with GST.

2) Check that engine coolant temperature is within the range of

þ10 to 40ÉC (14 to 104ÉF).

3) Check that voltage between ECM terminal 72 (EGR tempera-

ture sensor signal) and ground is less than 4.8V.

4) Start engine and let it idle for at least 45 seconds.

5) Stop engine.

6) Perform from step 1 to 4.

7) Select ªMODE 3º with GST.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-399.

+When using GST, ªDTC Confirmation Procedureº should

be performed twice as much as when using CONSULT-II

because GST cannot display MODE 7 (1st trip DTC) con-

cerning this diagnosis. Therefore, using CONSULT-II is

recommended.

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG18DE

DTC Confirmation Procedure (Cont'd)

EC-396

Page 822 of 3051

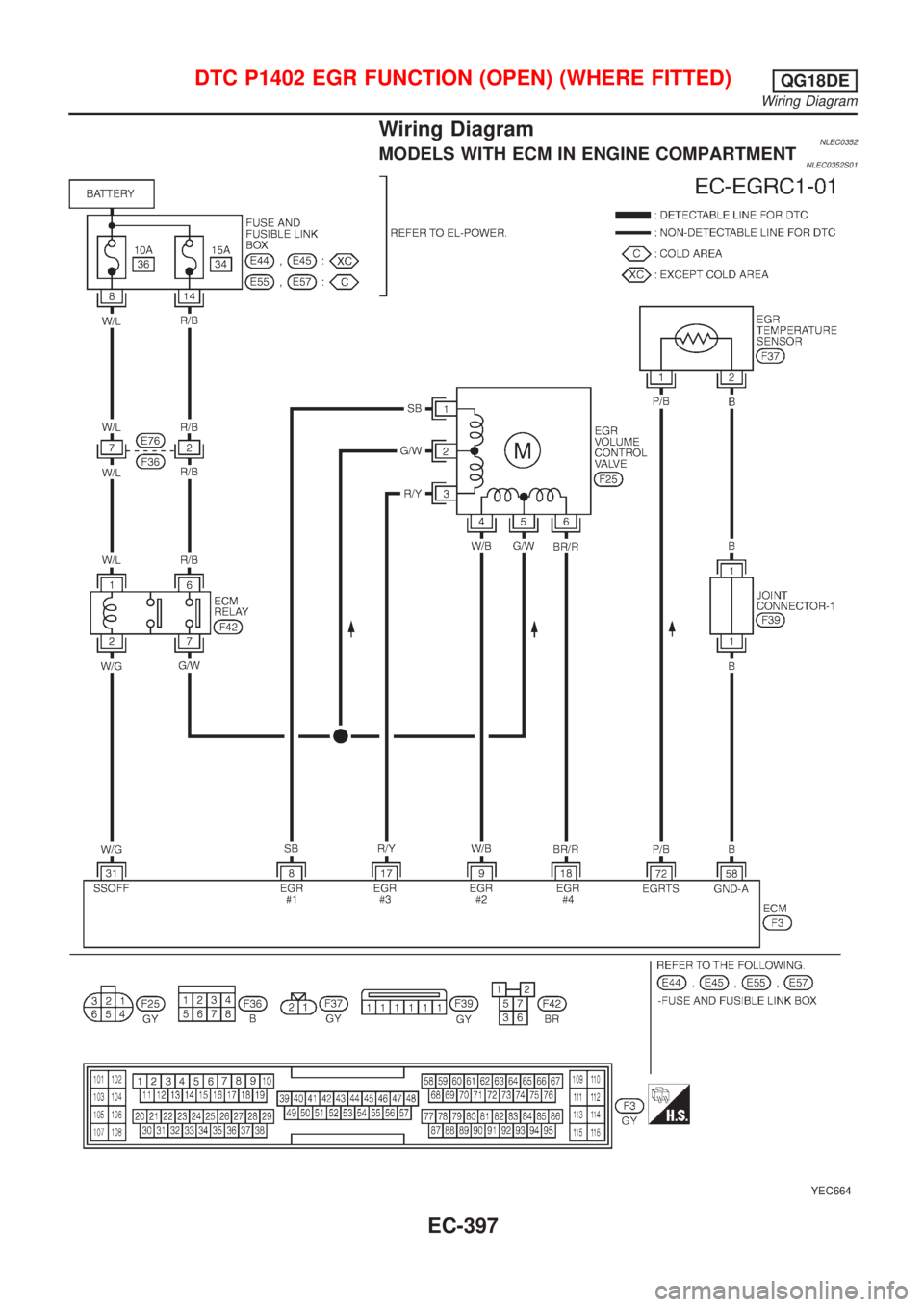

Wiring DiagramNLEC0352MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0352S01

YEC664

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG18DE

Wiring Diagram

EC-397

Page 823 of 3051

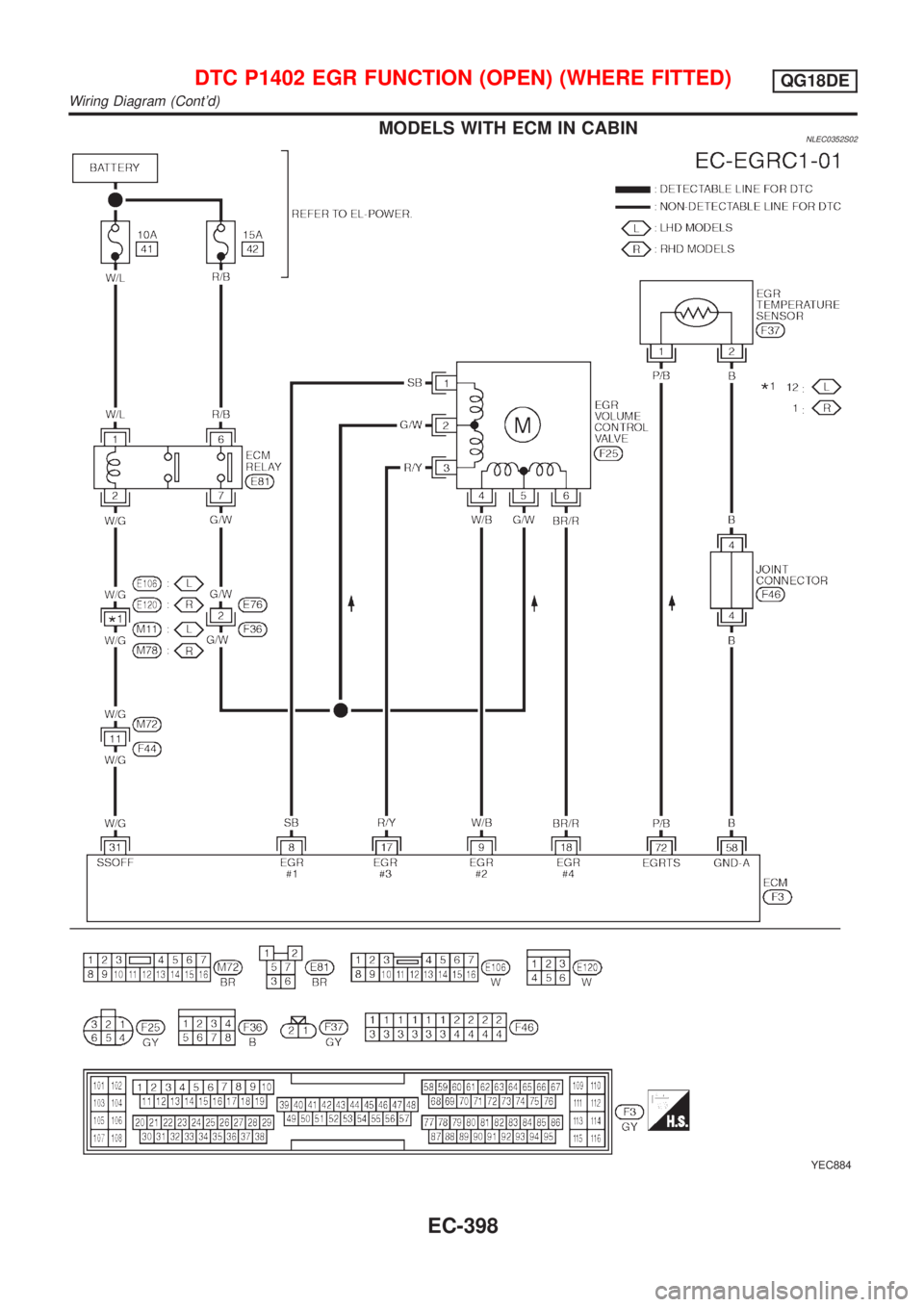

MODELS WITH ECM IN CABINNLEC0352S02

YEC884

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG18DE

Wiring Diagram (Cont'd)

EC-398

Page 824 of 3051

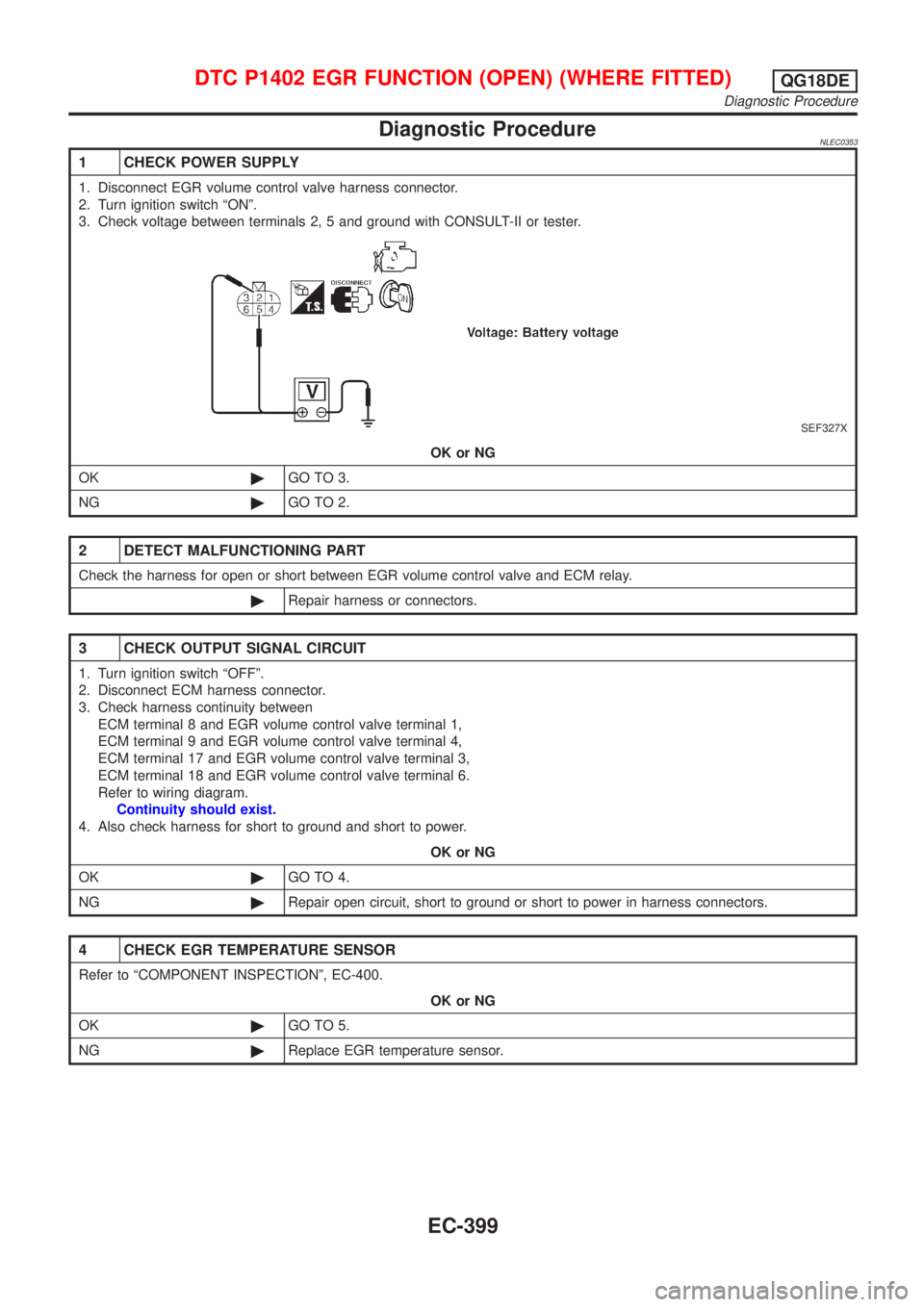

Diagnostic ProcedureNLEC0353

1 CHECK POWER SUPPLY

1. Disconnect EGR volume control valve harness connector.

2. Turn ignition switch ªONº.

3. Check voltage between terminals 2, 5 and ground with CONSULT-II or tester.

SEF327X

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the harness for open or short between EGR volume control valve and ECM relay.

©Repair harness or connectors.

3 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM terminal 8 and EGR volume control valve terminal 1,

ECM terminal 9 and EGR volume control valve terminal 4,

ECM terminal 17 and EGR volume control valve terminal 3,

ECM terminal 18 and EGR volume control valve terminal 6.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit, short to ground or short to power in harness connectors.

4 CHECK EGR TEMPERATURE SENSOR

Refer to ªCOMPONENT INSPECTIONº, EC-400.

OK or NG

OK©GO TO 5.

NG©Replace EGR temperature sensor.

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG18DE

Diagnostic Procedure

EC-399

Page 825 of 3051

5 CHECK EGR VOLUME CONTROL VALVE

Refer to ªCOMPONENT INSPECTIONº, EC-400.

OK or NG

OK©GO TO 6.

NG©Replace EGR volume control valve.

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

SEF611Y

SEF068XA

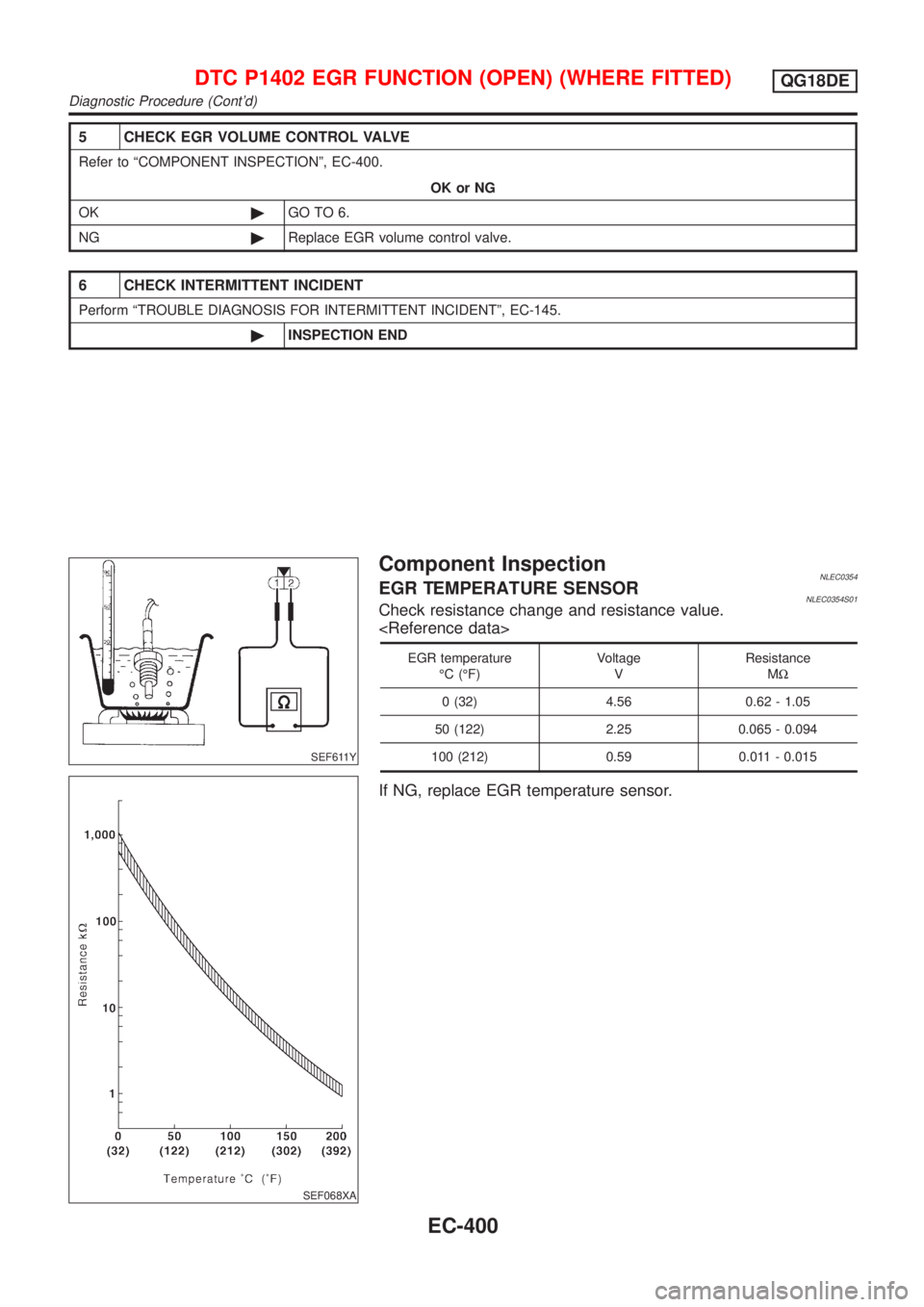

Component InspectionNLEC0354EGR TEMPERATURE SENSORNLEC0354S01Check resistance change and resistance value.

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

If NG, replace EGR temperature sensor.

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG18DE

Diagnostic Procedure (Cont'd)

EC-400

Page 826 of 3051

SEF069X

SEF783Z

SEF015Y

SEF560W

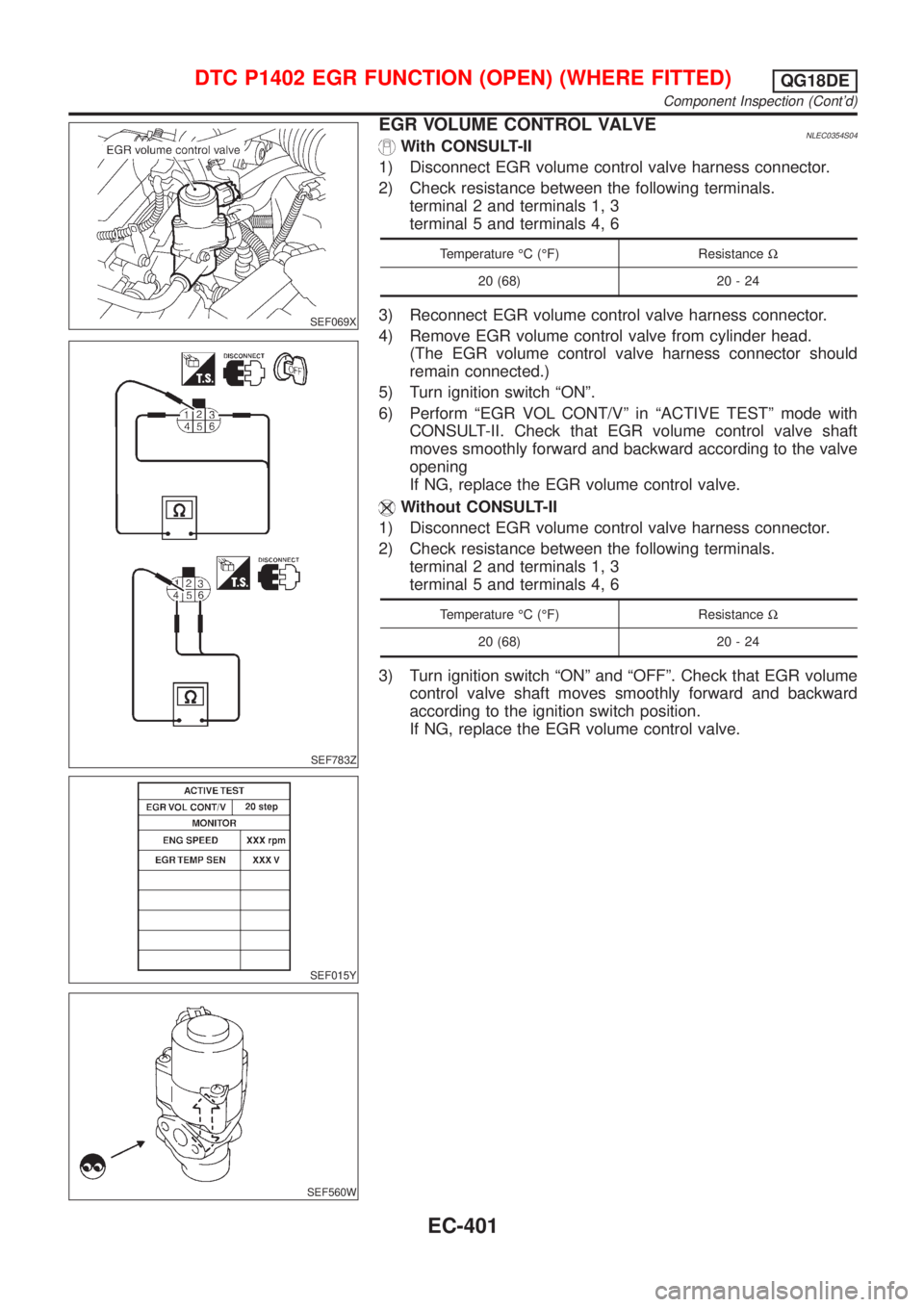

EGR VOLUME CONTROL VALVENLEC0354S04With CONSULT-II

1) Disconnect EGR volume control valve harness connector.

2) Check resistance between the following terminals.

terminal 2 and terminals 1, 3

terminal 5 and terminals 4, 6

Temperature ÉC (ÉF) ResistanceW

20 (68) 20 - 24

3) Reconnect EGR volume control valve harness connector.

4) Remove EGR volume control valve from cylinder head.

(The EGR volume control valve harness connector should

remain connected.)

5) Turn ignition switch ªONº.

6) Perform ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT-II. Check that EGR volume control valve shaft

moves smoothly forward and backward according to the valve

opening

If NG, replace the EGR volume control valve.

Without CONSULT-II

1) Disconnect EGR volume control valve harness connector.

2) Check resistance between the following terminals.

terminal 2 and terminals 1, 3

terminal 5 and terminals 4, 6

Temperature ÉC (ÉF) ResistanceW

20 (68) 20 - 24

3) Turn ignition switch ªONº and ªOFFº. Check that EGR volume

control valve shaft moves smoothly forward and backward

according to the ignition switch position.

If NG, replace the EGR volume control valve.

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG18DE

Component Inspection (Cont'd)

EC-401

Page 827 of 3051

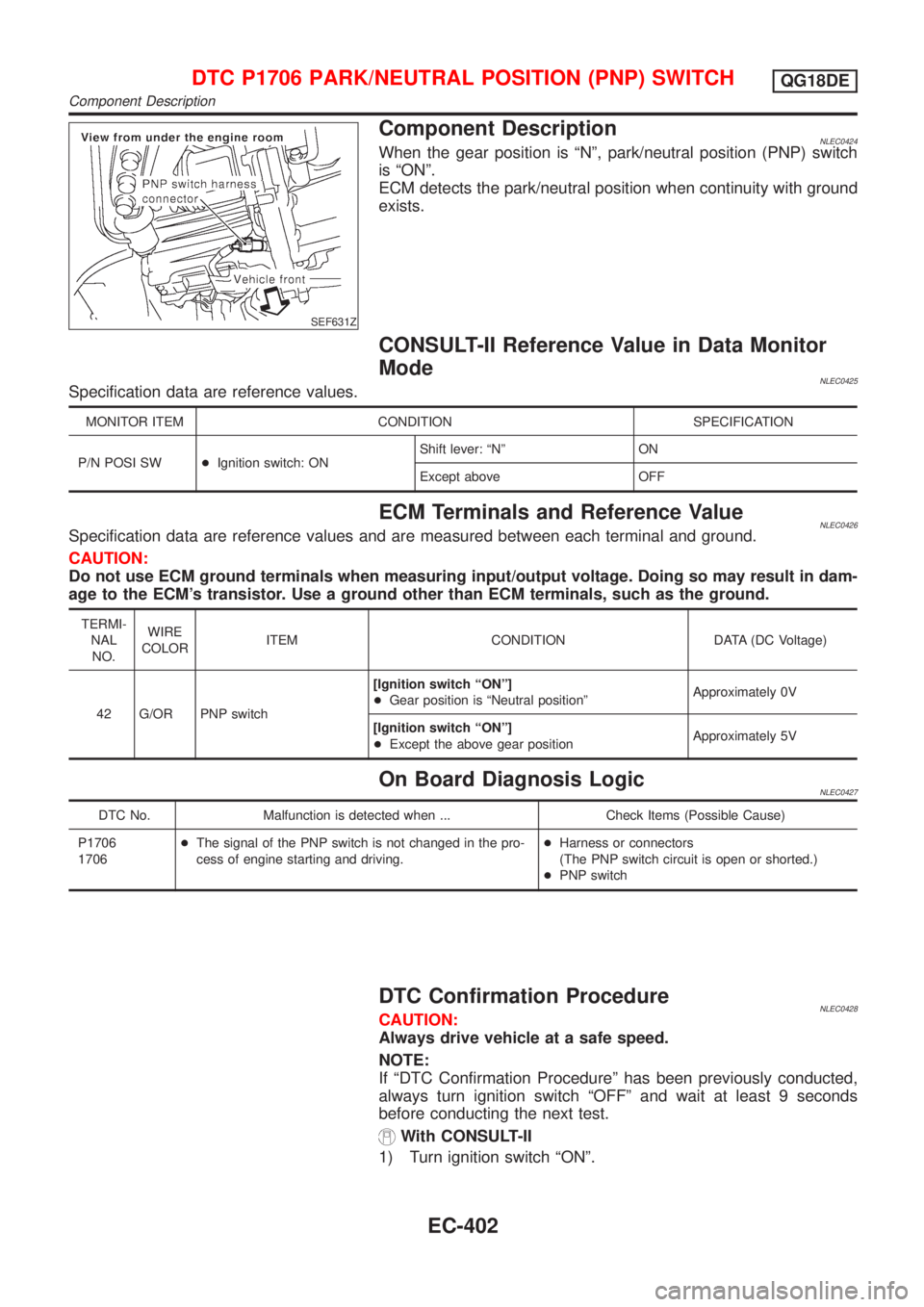

SEF631Z

Component DescriptionNLEC0424When the gear position is ªNº, park/neutral position (PNP) switch

is ªONº.

ECM detects the park/neutral position when continuity with ground

exists.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0425Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW+Ignition switch: ONShift lever: ªNº ON

Except above OFF

ECM Terminals and Reference ValueNLEC0426Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 G/OR PNP switch[Ignition switch ªONº]

+Gear position is ªNeutral positionºApproximately 0V

[Ignition switch ªONº]

+Except the above gear positionApproximately 5V

On Board Diagnosis LogicNLEC0427

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1706

1706+The signal of the PNP switch is not changed in the pro-

cess of engine starting and driving.+Harness or connectors

(The PNP switch circuit is open or shorted.)

+PNP switch

DTC Confirmation ProcedureNLEC0428CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG18DE

Component Description

EC-402

Page 828 of 3051

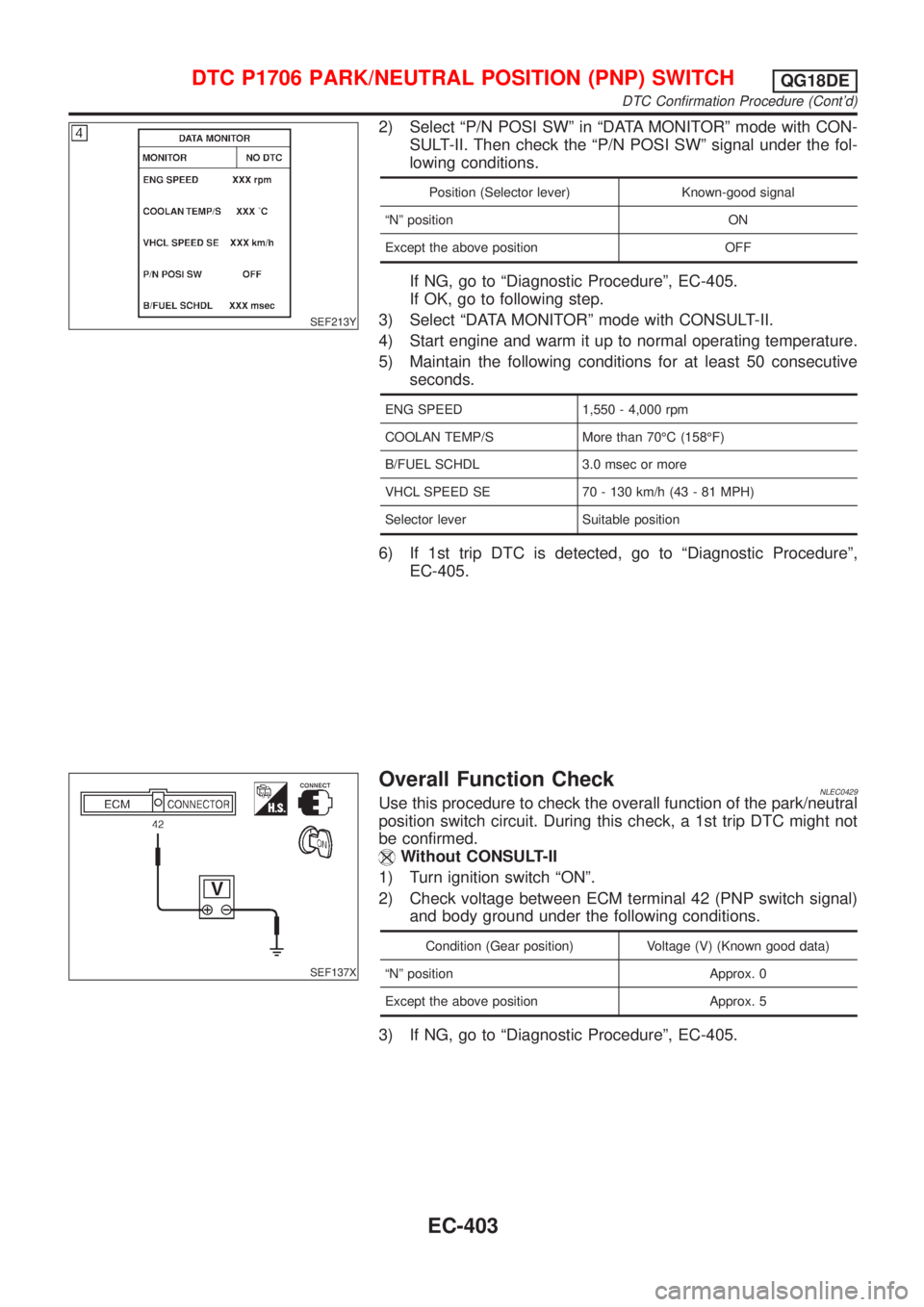

SEF213Y

2) Select ªP/N POSI SWº in ªDATA MONITORº mode with CON-

SULT-II. Then check the ªP/N POSI SWº signal under the fol-

lowing conditions.

Position (Selector lever) Known-good signal

ªNº position ON

Except the above position OFF

If NG, go to ªDiagnostic Procedureº, EC-405.

If OK, go to following step.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Start engine and warm it up to normal operating temperature.

5) Maintain the following conditions for at least 50 consecutive

seconds.

ENG SPEED 1,550 - 4,000 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 3.0 msec or more

VHCL SPEED SE 70 - 130 km/h (43 - 81 MPH)

Selector lever Suitable position

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-405.

SEF137X

Overall Function CheckNLEC0429Use this procedure to check the overall function of the park/neutral

position switch circuit. During this check, a 1st trip DTC might not

be confirmed.

Without CONSULT-II

1) Turn ignition switch ªONº.

2) Check voltage between ECM terminal 42 (PNP switch signal)

and body ground under the following conditions.

Condition (Gear position) Voltage (V) (Known good data)

ªNº position Approx. 0

Except the above position Approx. 5

3) If NG, go to ªDiagnostic Procedureº, EC-405.

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG18DE

DTC Confirmation Procedure (Cont'd)

EC-403

Page 829 of 3051

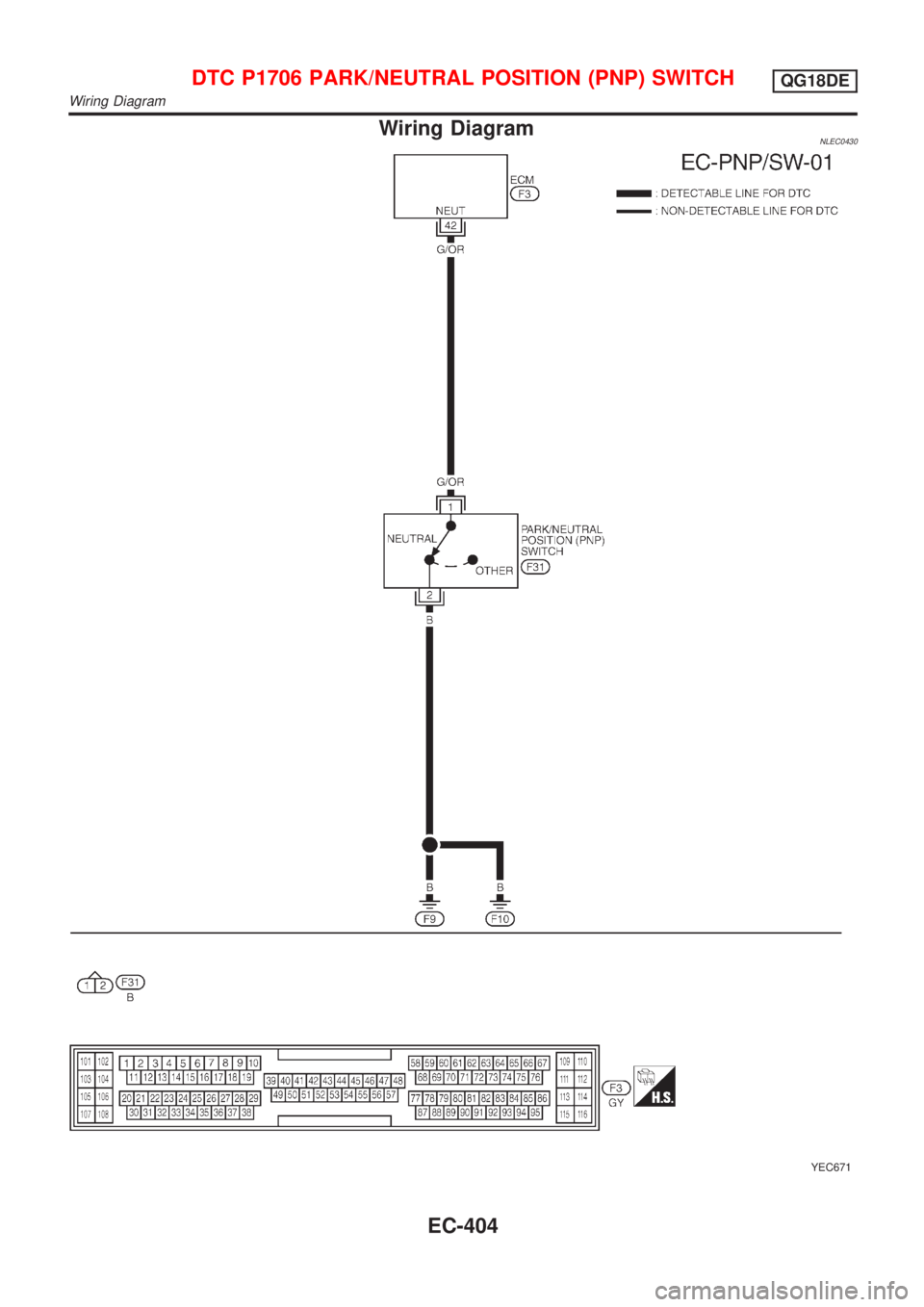

Wiring DiagramNLEC0430

YEC671

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG18DE

Wiring Diagram

EC-404

Page 830 of 3051

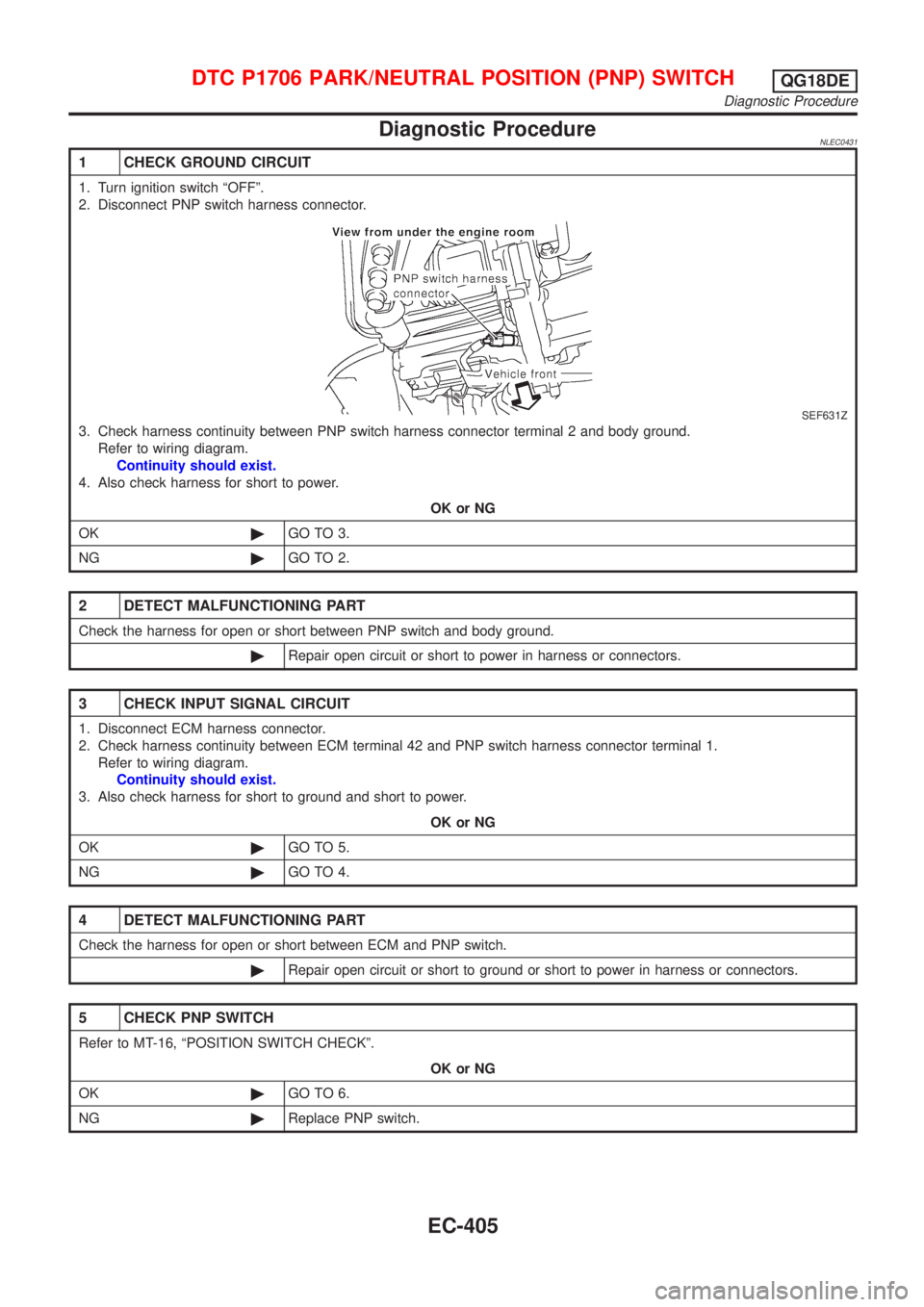

Diagnostic ProcedureNLEC0431

1 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect PNP switch harness connector.

SEF631Z

3. Check harness continuity between PNP switch harness connector terminal 2 and body ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the harness for open or short between PNP switch and body ground.

©Repair open circuit or short to power in harness or connectors.

3 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 42 and PNP switch harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and PNP switch.

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK PNP SWITCH

Refer to MT-16, ªPOSITION SWITCH CHECKº.

OK or NG

OK©GO TO 6.

NG©Replace PNP switch.

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG18DE

Diagnostic Procedure

EC-405