engine NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 149 of 230

FULLY AUTOMATIC AIR CONDITIONER

System Description

The fully automatic air conditioner system utilizes sensors to detect the in-vehicle temperature, ambient

temperature, temperature of air passing through the evaporator, and

sunload. The detected values are

compared with the temperature adjustment dial setting, and calculated by the microcomputer within the

automatic amplifier. The air inlet and outlet temperatures and airflow rate are adjusted in order to main-

@ tain the in-vehicle temperature.

When an abnormal pressure occurs within the cooler cycle [gauge pressure: approx.

2.7 MPa (28 kg/

cm2G)

or higher; or approx. 0.18

MPa

(1.8

kg/cm2-G)

or lower] the refrigerant pressure sensor operates,

Ec

and stops the compressor.

The

ECM turns off the air conditioner relay, and stops the compressor during engine high load.

The blower fan motor utilizes

a brushless motor, and controls the airflow with a built-in IC that recognizes AT

the driver signal (pulse) from the automatic amplifier.

Step-motor type actuators are employed for intake door, mode door, and air mix door. They are rotated in

response to the signal (pulse) step quantity transmitted from the automatic amplifier to control the target

BR

door position.

Page 150 of 230

FULLY AUTOMATIC AIR CONDlTlONER

Component Parts Location

Intake door actua:or

,

Sunload sensor

Controller

B&wer temperature sensor

fan motor

@ Radiator core lower support I

Front defros!er grille (left)

1 ,?efros:er gnlie (left) t I

0 Blower fan motor relay

Engine room, right relay box I / Air conditioner relay I

Blower and cooling unit

I Blower fan motor

? Ar condlboner relay

@ Refrigerant

pressure sensor @ Compressor @ Ambtent sensor

a Liquid tank I @ Englne room. front left

I

Blower and cooling unit

lnta Instrument panel, center I

7 IJj Cluster

lid A 0 Fuse block, rear face 1

Page 154 of 230

FULLY AUTOMATIC AIR CONDITIONER

Performance Test

PROCEDURE

Connect the manifold gauge to the vehicle side cooler cycle (service valve).

Attach a psychrometer to the recirculation air inlet port of the blower and cooling unit (below the glove box);

and attach a dry-bulb thermometer to the right side of the center ventilator grille.

Start and

warm up the engine.

After warming up the engine, check that the engine speed has reached the standard idle speed.

After pressing the AUTO switch, operate the fan switch, mode switch (air outlet switch),

REG switch, tem-

perature adjustment dial and switch; and satisfy the following conditions.

Fan speed: 4th

Air inlet: Recirculation

Air outlet: Ventilator (VENT)

Temperature setting:

18°C

Completely open the hood and all door windows, and close all doors.

Maintain these conditions until the cooler cycle stabilizes. (Approx.

10 minutes)

Maintain the engine speed at idle.

Measure the recirculation inlet temperature and humidity, outlet temperature, and cooler cycle high- and

low-pressures. Compare and judge the values with the "AMBIENT AIR TEMPERATURE AND PRESSURE

CHARACTERISTICS and "INTAKE AIR TEMPERATURE AND DISCHARGE AIR TEMPERATURE CHAR-

ACTERISTICS.

Page 157 of 230

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis by Self-diagnosis Function

There are 5 steps in the self-diagnosis: to check for any sensor failure, and to check that a given control sig-

nal is transmitted to each output device.

Diagnosis

content

- - -

Diagnostic

item

i Step I I Step 2 - - - - - - - --

Each sensor check

Indicator lamp check

Display segments Ambient sensor

0 Indicator lamp In-vehicle sensor

lntake air tempera-

ture sensor

Sunload sensor Step

3

Each

actuator check

and reset check display for each

sen-

lntake door actuator

Air mix door actua-

tor Mode door actuator

lntake door actuator

Air mix door actua-

tor

Mode door actuator

Blower fan motor

Compressor

Air purifier (only

when connected)

Ambient sensor

In-vehicle sensor

lntake air tempera-

ture sensor

SELF-DIAGNOSIS OPERATION PROCEDURE R8

Switching to self-diagnosis mode

Turn the temperature adjustment dial all the way to the left.

Start the engine with the ignition switch from OFF position. Within 10 seconds, press and hold the OFF

switch for more than approx. 5 seconds, to start the self-diagnosis step 1.

Self-diagnosis completion EL

a Turn the ignition switch OFF.

Turn the AUTO switch ON.

Switching between self-diagnosis steps

Use the temperature adjustment dial to switch between self-diagnosis steps 1 to 5.

Temperature adjustment dial (turn clockwise): Step

1-5

Temperature adjustment dial (turn counterclockwise): Step

5- 1

a Refer to "SELF-DIAGNOSIS DISPLAY ITEM" for the diagnosis contents of each step.

Page 161 of 230

FULLY AUTOMATIC AIR CONDITIONER

Magnet Clutch System Check

MAGNET CLUTCH

Disconnect the compressor connector. Apply approx. 12V to the compressor to check the magnet clutch

operation.

/;sn

AIR CONDITIONER RELAY QJg

Remove the air conditioner relay. Apply approx. 12V between the air conditioner relay terminals No. 1 and

2. Check the relay operation sound. Ec Check the continuity between terminals No. 3 and 5.

REFRIGERANT CHARGE AMOUNT AT

Connect the manifold gauge to the vehicle side service valve.

Check that the lower pressure side (gauge pressure) is more than approx. 0.1 8 MPa (1.8 kg/cm2.G). BR

ECM

Start the engine, and short-circuit the ECM terminal No. 14 to the ground. Check the magnet clutch operation.

INTAKE AIR TEMPERATURE SENSOR

Start the engine, and short-circuit the intake air temperature sensor terminal No. 1 to the ground. Check the Rs

maanet clutch o~eration.

Blower Fan Motor System Check

BLOWER FAN MOTOR

Disconnect the blower fan motor connector. Short-circuit the blower fan motor terminals No. 2 and 5 to El!, (

the ground. Apply approx. 12V to the terminal No. 6, and check the motor operation.

Connect the blower fan motor connector. Turn the ignition switch to the ON position, and change the fan sD

switch from 1st to 4th. Check the blower fan motor terminal No. 5 with an oscilloscope. When the termi-

nal No.

5 is normal according to the following table and the fan airflow does not change, this indicates a

faulty blower fan motor.

When the terminal No.

5 results differ from the following table and the fan airflow does not change, this

indicates either a faulty harness between the blower fan motor and automatic amplifier, or a faulty auto-

matic amplifier.

Page 163 of 230

FULLY AUTOMATIC AIR CONDITIONER

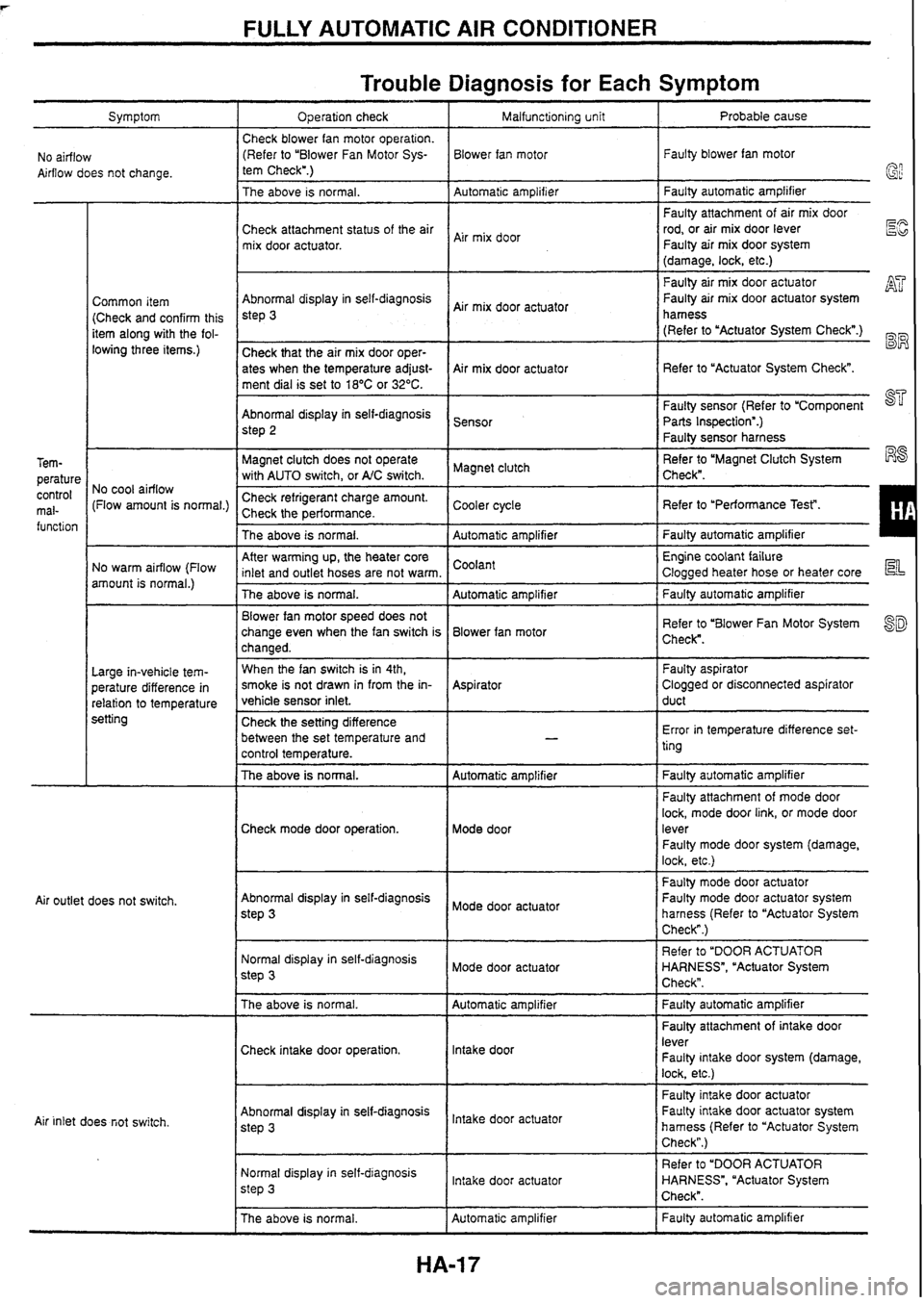

Symptom

Trouble Diagnosis for Each Symptom

No airflow

Airflow does not change. Operation check

Check blower fan motor operation. (Refer to "Blower Fan Motor Sys-

tem Check".)

The above is normal.

I Automatic amolifier 1 Faultv automatic amplifier

Faulty attachment of air mix door

rod, or air mix door lever

Faulty air mix door system

ElG

(damage, lock, etc.)

Malfunctioning unit

Blower fan motor Probable cause

Faulty blower fan motor

Check attachment status of the air

mix door actuator.

Common item (Check and confirm this

item along with the fol-

lowing three items.)

Air mix door

Abnormal display in self-diagnosis

step

3

Check that the air mix door oper-

ates when the temperature

adjust-

ment dial is set to

18OC or 32°C.

Faulty sensor (Refer to 'Component a

Parts Inspection".)

Faulty sensor harness

Air

mix door actuator

Air mix door actuator

Abnormal display in self-diagnosis

step 2

Magnet clutch does not operate

Magnet clutch Refer

to 'Magnet Clutch System R8

with AUTO switch, or A/C switch. Check".

I Faulty

air mix door actuator

Faulty air mix door actuator system AT

hamess

(Refer to "Actuator System Check".)

BW

Refer to "Actuator System Check".

@'i?

Sensor

Tem- perature

control mal-

function No

cool airflow

(Flow amount is normal.)

ngeranr

cnarge

amounr.

( Cooler cycle 2 ~erformance. I Refer to 'Performance Test". I

The above is normal. I Automatic amolifier 1 Faulty automatic amplifier I

After warming up, the heater core

inlet and outlet hoses are not warm. 1 Coolant I

Engine coolant failure

Clogged heater hose or heater core

No warm airflow

(Flow

amount is normal.)

The above is normal. Automatic amplifier

1 Faulty automatic amplifier

Blower fan motor speed does not

change even when the fan switch is Blower fan motor

changed. Refer

to "Blower Fan Motor System

Check".

I

When the fan switch is in 4th, Faulty aspirator

smoke is not drawn in from the

in-

Aspirator Clogged

or disconnected aspirator

vehicle sensor inlet. duct

Large

in-vehicle tem-

perature difference in

relation to temperature

setting Check the setting difference

between the set temperature and

control temperature. Error

in temperature difference set-

ting

- The above isnormal.- Automatic amplifier Faulty automatic amplifier

Faulty attachment of mode door

lock, mode door link, or mode door

Check mode door operation. Mode door lever

Faulty mode door system (damage,

lock, etc.)

Faulty mode door actuator

Abnormal display in self-diagnosis Faulty mode door actuator system

step

3 Mode door actuator

harness (Refer to "Actuator System

Check".)

Air

outlet does not switch.

Normal display in self-diagnosis

Mode door actuator

step

3

Refer to "DOOR ACTUATOR

HARNESS", "Actuator System

Check".

The above is normal.

I Automatic amplifier I Faulty automatic amplifier - - I I Faulty attachment of intake door

Check intake door operation. lntake

door lever

Faulty intake door system (damage,

lock, etc.)

~aulG intake door actuator

Faulty intake door actuator system

hamess (Refer to "Actuator System

Check".)

Abnormal

display in self-diagnosis

door step 3 Air inlet does fiot switch.

Normal display in self-diagnosis

lntake door actuator

step

3

Refer to "DOOR ACTUATOR

HARNESS", "Actuator System

Check".

I I The above is normal. I Automatic amplifier I Faulty automatic amplifier

Page 189 of 230

COMBINATION METER

Trouble Diagnoses (Cont'd)

VEHICLE SPEED INPUT SIGNAL DIAGNOSIS

I Connector

WARNING LAMP CHECK Does ABS warning lamp remain ON with

ignition switch ON?

ABS I

Perform ABS self-diagnosis

and check faulty circuit.

Refer to

BR section ("ABS

SYSTEMn).

Continuity exists.

Terminal No. 19 and ground:

No continuity

. -- I I

HARNESS CHECK ' Disconnect ABS control unit connector

(TK24)

and meter connector (TK20

Brown).

Terminals No. 19 - 24:

OK

El f

Meter control unit connector on vehicle

NG+'

I - = 'ELF0970D

El

@EM

Meter control unit connector on vehicle rn

rm-1 ffee

1

L / - - -

ELFo971D -

ABS control unit to meter

harness is faulty.

Meter control unit

is faulty. VEHICLE SPEED INPUT SIGNAL

CHECK 1 Connect meter connector (TK20 Brown). Terminal No. 19 and around:

'2

" Approx. 9V

OK

r9 v

VEHICLE SPEED INPUT SIGNAL

CHECK 2 Connect ABS control unit connector

(TK24).

Start the engine and drive the vehicle. Terminal No. 19 and ground:

Specification

Refer to "Combination Meter InpuffOutput

Signal Specificationsn on the next page.

OK

Meter control unit is faulty.

5' Pelform ABS self-diagnosis and check faulty circuit.

Refer to BR section ("ABS

SYSTEMn).

Page 190 of 230

COMBINATION METER

Combination Meter

InputlOutput Signal

Specifications

Terminal No. Measuring condition

Signal name

Ignition switch Operation or condition

Disconnect ECM connector. Approx.

8 - 10V

At 2.000 rprn: Approx. 3.OV

IVI

15

10

5 0

ELF0973D

Tachometer drive

signal

Engine is idling or running at

!,000 rpm. RB25DET

At ~dling: Approx. 7.2V At 2.000 rprn: Approx. 72V

(VI

(VI ST

15 I5 10 10

5 5

0 0

RS

ELF0974D RA

Refer to "Component Parts Inspection" (EL-27).

Approx. 12V I

-uel gauge signal

OFF With TCS

Vehicle speed: Approx. 40 km

(VI

15 10 5 0 -5 -1 0 -1 5

A Veh~cle Speed Approx 60 kmh

Body

lrounc

Speedometer is in operation.

Vehicle speed is approx.

10 kmh.)

Vehicle speed is approx.

i0 kmh.)

e speed

inpi

Without

TCS Vehcle speed: Approx. 40 k

IV!

15 10 5 0

h Vehicle speed: Approx. 60 kmh (V) 15 10

5

0

ELF0376D

-

-

;peedometer is not in opera-

on.

hermal

transmitte

iignal Refer

to "Component Parts Inspection"

(EL-27)

gnition power sup

'IY Approx. 12V

Approx. 4.8V or OV

Vehicle speed is approx. 40 kwh: Approx. 2.4V (Vi d!!!!!!!!!] ,

rehicle speed sign 2 pulses) ipeedometer

is in operation.

Vehicle speed is approx.

0 kmm.)

Voltage the

part

of the indicates the value checked with an )gue circuit tester

Page 192 of 230

COMBINATION METER

Component Parts Inspection (Cont'd)

Fuel gauge unit harness

connector

Lower side

<

I

I

I

(Full) Lead switch

harness connector

on fuel gauge unit

h L Upper side

Harness connec:or on lead sw~lch

With fuel

T/f Without fuel

Lower side

(Empty)

FUEL GAUGE UNIT

Remove fuel gauge unit from the vehicle.

Check the gauge resistance on the gauge with the fuel gauge

at Empty and then Full.

SD

LEAD SWITCH

Remove fuel gauge unit from the vehicle.

Check continuity between terminals on the lead switches in the

tank.

Terminal No.

1-3

Termina! No. I Condition I Continuity

Float position

Full

Empty

THERMAL

TRANSMITER

Resistance R

Approx. 6 max.

Approx. 80 min.

5 - 7 6-7

0 When the engine has warmed up to approx. 80°C, measure

resistance between thermal transmitter and body ground.

Specification: Approx. 76 - 90Q

There is no continuity when approx. 26 of fuel is left in the sub fuel tank.

With fuel

Without fuel Yes

No

Page 193 of 230

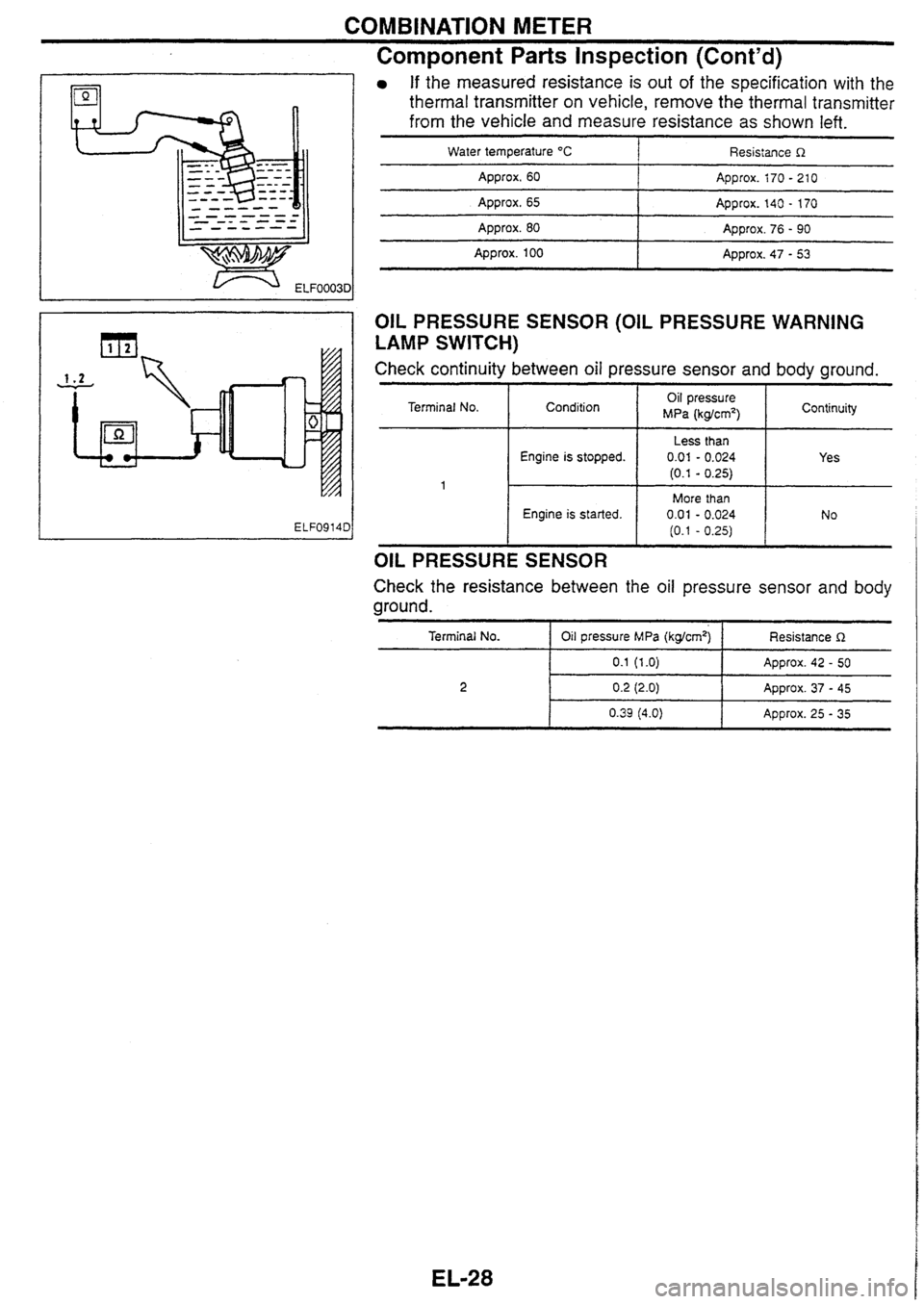

COMBINATION METER

Component Parts Inspection (Cont'd)

If the measured resistance is out of the specification with the

thermal transmitter on vehicle, remove the thermal transmitter

from the vehicle and measure resistance as

shown left.

Water temperature "C 1 Resistance R

Approx. 60 I Approx. i70 - 21 0

Approx. 65 I Approx. 140 - 170

Approx. 80 I Approx. 76 - 90

I

- - -- Appro~. 100 Approx. 47 - 53

OIL PRESSURE SENSOR (OIL PRESSURE WARNING

LAMP SWITCH)

Check continuity between oil pressure sensor and body ground.

Terminal No.

OIL PRESSURE SENSOR

Engine is stopped.

Engine is started.

Check the resistance between the oil pressure sensor and body

ground.

Condition

Terminal No.

I Oil pressure MPa (kgkmq-1 Resistance R

Oil pressure

MPa (kg/cm2) 1 Continuity

Less than

0.01 - 0.024

(0.1 - 0.25)

More than 0.01 - 0.024

(0.1 - 0.25)

0.2 (2.0) Approx. 37 - 45

Yes

No