stop start NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 24 of 230

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

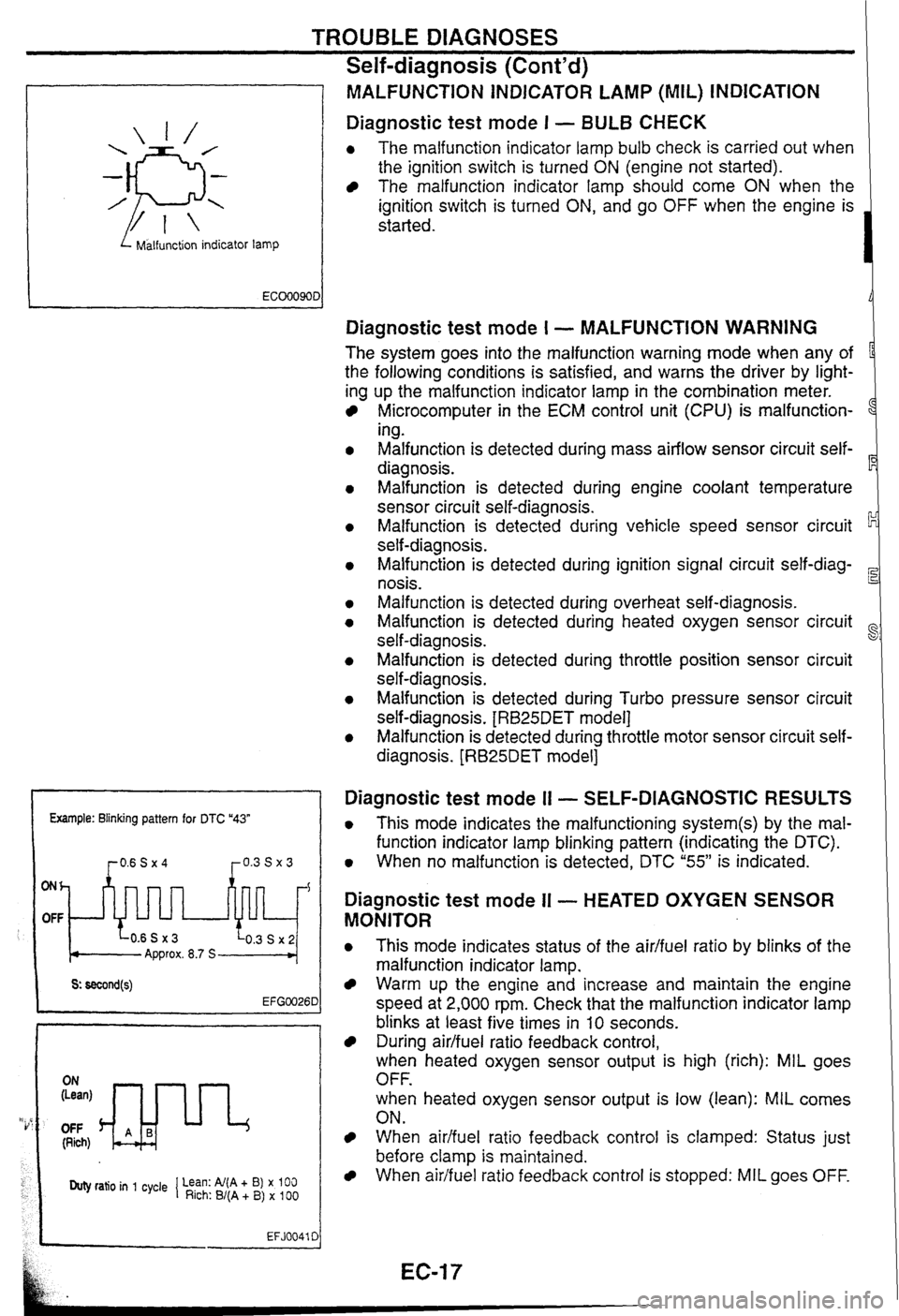

I Malfunction indicator lamp

MALFUNCTiON INDICATOR LAMP (MIL) INDICATION

Diagnostic test mode I - BULB CHECK

0 The malfunction indicator lamp bulb check is carried out when

the ignition switch is turned

ON (engine not started).

The malfunction indicator lamp should come ON when the

ignition switch is turned

ON, and go OFF when the engine is

started.

Example: Blinking pattern for DTC "43"

ONh

OFF

Approx. 8.7 S

OFF (Rich)

Duty ratio in 1 cycle 1 Lean: Al(A + B) x 100 Rich: B/(A + B) x 100

EFJ0041 C

Diagnostic test mode I - MALFUNCTION WARNING

The system goes into the malfunction warning mode when any of

the following conditions is satisfied, and warns the driver by light-

ing up the malfunction indicator lamp in the combination meter.

Microcomputer in the ECM control unit (CPU) is malfunction-

1

ing.

Malfunction is detected during mass airflow sensor circuit self-

diagnosis.

Malfunction is detected during engine coolant temperature

sensor circuit self-diagnosis.

Malfunction is detected during vehicle speed sensor circuit

self-diagnosis.

Malfunction is detected during ignition signal circuit

self-diag-

nosis.

Malfunction is detected during overheat self-diagnosis.

Malfunction is detected during heated oxygen sensor circuit

self-diagnosis.

~alfunsion is detected during throttle position sensor circuit

self-diagnosis.

Malfunction is detected during Turbo pressure sensor circuit

self-diagnosis.

[RB25DET model]

Malfunction is detected during throttle motor sensor circuit self-

diagnosis.

[RB25DET model]

Diagnostic test mode I1 - SELF-DIAGNOSTIC RESULTS

0 This mode indicates the malfunctioning system(s) by the mal-

function indicator lamp blinking pattern (indicating the DTC).

0 When no malfunction is detected, DTC "55" is indicated.

Diagnostic test mode II - HEATED OXYGEN SENSOR

MONITOR

0 This mode indicates status of the aidfuel ratio by blinks of the

malfunction indicator lamp.

Warm up the engine and increase and maintain the engine

speed at 2,000 rpm. Check that the malfunction indicator lamp

blinks at least five times in

10 seconds.

During airlfuel ratio feedback control,

when heated oxygen sensor output is high (rich): MIL goes

OFF.

when heated oxygen sensor output is low (lean):

MIL comes

ON.

When aidfuel ratio feedback control is clamped: Status just

before clamp

is maintained.

When airifuel ratio feedback control is stopped: MIL goes OFF.

Page 27 of 230

TROUBLE DIAGNOSES

CONSULT (Cont'd)

FUNCTION

Self-diagnostic results Diagnostic test mode

Work support

Self-diagnostic resuits can

be read and

erased quickly. Function

A technician can adjust some devices faster

and more accurately by following indications

on CONSULT.

Data monitor

Active test

WORK SUPPORT MODE

Input/Output data in the ECM can be read.

CONSULT drives some actuators apart from

the

ECM's and

also shifts some parameters in

a specified range.

Conducted

by CONSULT instead of a techni-

Function test

ECM part number

WORK ITEM I CONDITION I USAGE

cian to determine whether each system is

"OK" or

"NG".

ECM part number can be read.

THRTL

POS SEN ADJ CHECK THE THROTTLE POSITION SENSOR SIGNAL.

ADJUST IT TO THE SPECIFIED VALUE

BY ROTATING

THE SENSOR BODY UNDER THE FOLLOWING CONDI-

TIONS.

0 IGN SW "ONn

0 ENG NOT RUNNING When adjusting

throttle position

sensor initial position

I ACC PEDAL NOT PRESSED 1 I

IACV-AAC VALVE ADJ I SET ENGINE SPEED AT THE SPECIFIED VALUE UNDER I 1 THE FOLLOWING CONDITIONS.

ENGINE WARMED UP

When releasing fuel pressure I

from fuel line

FUEL

PRESSURE RELEASE

0 NO-LOAD

FUEL PUMP WILL STOP BY TOUCHING "START"

DURING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.

i J

Page 29 of 230

![NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES

CONSULT (Contd)

DATA MONITOR MODE

ECM input

signals

Monitored item

[Unit] Main

signals Remarks

Description

lndicates the engine speed computed

from the POS signal (l NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES

CONSULT (Contd)

DATA MONITOR MODE

ECM input

signals

Monitored item

[Unit] Main

signals Remarks

Description

lndicates the engine speed computed

from the POS signal (l](/img/5/57354/w960_57354-28.png)

TROUBLE DIAGNOSES

CONSULT (Cont'd)

DATA MONITOR MODE

ECM input

signals

Monitored item

[Unit] Main

signals Remarks

Description

lndicates the engine speed computed

from the POS signal (lo signal) of the

camshaft position sensor.

When the engine is stopped, a certain

value is indicated.

When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine coolant

temperature determined by the ECM is

displayed.

The signai voltage of the mass air flow

0 sensor is displayed.

The engine coolant temperature (deter-

mined by the signal voltage of the engine

0 coolant temperature sensor) is displayed.

-

MAS AIRiFL SE [V]

The signal voltage of the oxygen sensor

is displayed.

02

SEN [V]'

0 After turning ON the ignition switch, "RICH" is displayed until air-fuel mixture

ratio feedback control begins.

When the air-fuel ratio feedback is

clamped, the value just before the clamp-

ing is displayed continuously.

MiR

F/C MNT*

[RICH/LEAN] Display of oxygen sensor signal during

air-fuel ratio feedback control:

RICH

... means the mixture became

"rich", and control is being affected

toward a leaner mixture.

LEAN

... means the mixture became

"lean", and control is being affected

toward

a rich mixture.

The vehicle speed computed from the

vehicle speed sensor signal is displayed. VHCL SPEED SE [krn/h] or [mph]

The power supply voltage of ECM is dis-

played. I BATTERY VOLT [V]

THRTL POS SEN [V] The throttle position sensor signal volt-

age is displayed.

Throttle motor sensor output voltage Approx. 4.6V THRTL POS SE2 [V] 0 RB25DET

TURBO BOOST

SENSOR

RB25DET

Turbo pressure sensor output voltage 0 Approx. 2.7V

Indicates [ON/OFF] condition from the After starting the engine, [OFF] is dis-

0 starter signal. played regardless of the starter signal.

lndicates [ON/OFF] condition from the 0 throttle position sensor signal.

-

START SIGNAL

[ON/OFF]

CLSD THUP SW

[0

N/O

FF]

0 lndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner sianal. AIR COND SIG

[ON/OFF]

lndicates [ON/OFFj condition from the

parldneutral position switch signal.

PiN

POSl SW [ONIOFF)

PW/ST SIGNAL

[ONIOFF]

LOAD SIGNAL

[ON/OFF]

lndicates [ON/OFfl condition from the

electrical load signal

andlor lighting

switch.

ON ... rear defogger is operating.

OFF ... rear defogger is not operating.

NOTE: Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically. *: Models with three way catalyst.

Page 33 of 230

TROUBLE DIAGNOSES t i

CONSULT (Cont'd) i

FUNCTION TEST MODE

CHECK ITEM (REMEDY)

FUNCTION

TEST

ITEM JUDGEMENT

CONDITION

lgnition switch: ON

(Engine stopped)

Displays the results of on board

diagnostic system.

SELF-DIAG

RESULTS Objective

system

--

ignition switch: ON

(Engine stopped)

Throttle position sensor circuit is

tested when throttle is opened and

closed fully. ("IDLE POSITION" is

the test item name for the vehicles

in which idle is selected by throttle

position sensor.) Harness and connector

Throttle position sensor (Closed

throttle position)

Throttle position sensor (Closed

throttle position) adjustment

Throttle linkage

Venfy operation in DATA

MONITOR mode.

Throttle

valve:

opened OFF

ON

CLOSED THROTTLE

POSl Throttle valve:

closed

lgnition switch: ON

(Engine stopped)

Throttle position sensor circuit is

tested when throttle is opened and

closed fully.

Harness and connector

Throttle position sensor

Throttle position sensor

adjustment

Throttle linkage

Verify operation in DATA

MONITOR mode.

Range

(Throttle

valve fully opened

- Throttle valve

fully closed) More

than 3.0V THROTTLE POSl

SEN CKT

lgnition switch: ON

(Engine stopped)

Neutral position switch circuit is

tested when shift lever is

manipulated.

lgnition switch: ON

(Engine stopped)

Fuel pump circuit is tested by

checking the pulsation in fuel

pressure when fuel tube is

pinched. Out of

N/P

positions OFF

Harness

and connector

Neutral position switch

Linkage adjustment

PARWNEUT POSl SW CKT

In

N/P positions

Harness and connector

Fuel pump

Fuel pump relay

Fuel filter clogging

Fuel level

There

is pressure pulsation on

the fuel feed hose.

FUEL PUMP

CIRCUIT

--

The valve timing control system is

diagnosed by checking for

operating sound of the solenoid

valve.

lgnition switch: ON

(Engine stopped)

Cooling fan circuit is tested when

cooling fan is rotated.

VALVE

TIMING

SN

CKT

Harness and connector

Cooling fan motor

Cooling fan relay

COOLING

FAN

CIRCUIT RB25DE, RB25DET

The cooling fan rotates and

stops every

3 seconds.

lgnition switch: ON -+ START

Start signal circuit is tested when

engine is started by operating the

starter. Battery voltage and water

temperature before cranking, and

average battery voltage, mass air

flow sensor output voltage and

cranking speed during cranking

are displayed.

Harness and connector

lgnition switch

START

SIGNAL

CIRCUIT Start

signal: OFF 3 ON

Page 84 of 230

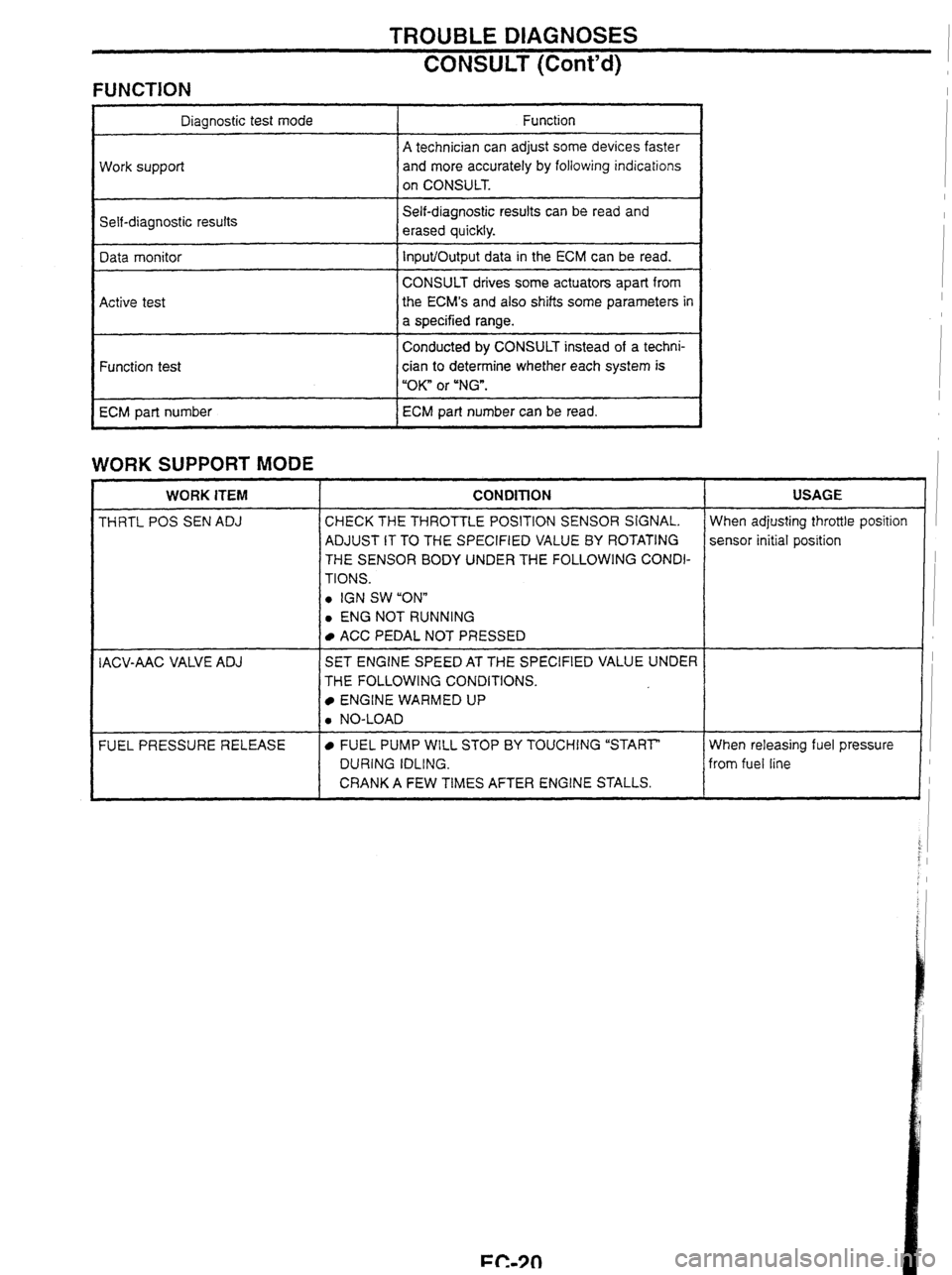

ANTI-LOCK BRAKE SYSTEM

ABS control unit connector

Terminal No.

Control Unit InputlOutput Signal Specifications

USING CIRCUIT TESTER

To perform the following inspection, the ignition switch should be

turned

ON with ABS control unit connector and actuator connector

properly connected.

Item Specifications*l

Battery Ignition switch ON: Battery voltage (Approx. 12V)

Brake pedal is depressed: Battery voltage (Approx. 12V)

Stop lamp signal

Brake pedal is not depressed: Less than approx.

2V

ABS motor is running

ABS motor relay (in

CONSULT active test mode): Less than approx.

2V

ABS motor is stopped: Battery voltage (Approx.

12V)

Actuator relay is activated (with engine running): Less than approx. 2V

Actuator relay Actuator

relay is not activated (with fail-safe function activated and engine

not running): Battery voltage (Approx. 12V)

Actuator relay is activated (with engine running): Battery voltage (Approx.

Actuator relay 1 2V)

monitor Actuator

relay is not activated (with fail-safe function activated and engine

not running): Approx. OV

Front

right inlet

Actuator is activated (in CONSULT active test mode), or actuator relay is

solenoid not activated (with fail-safe function activated and engine not running):

Rear inlet solenoid Approx. OV

Front

left inlet Actuator

is not activated and actuator relay is activated (with vehicle

solenoid stopped

and engine running): Battery voltage (Approx. 12V)

ABS motor is running (in CONSULT active test mode): Battery voltage

ABS motor monitor (Approx. 12V)

ABS motor is stopped (with ignition switch

ON): Approx. OV

ABS warning lamp

ON'2:

Approx. OV

ABS warning lamp

ABS warning lamp

OFF'2:

Battery voltage (Approx. 12V)

Front right wheel

sensor Wheels are turning (Approx. 30

krn/h)*3: Pulse generates.

Front: Approx. 200

Hz

sensor

Rear: Approx. 400 Hz

Front right outlet

Actuator is activated (in CONSULT active test mode), or actuator relay is

not activated (with fail-safe function activated and engine not running):

Rear outlet

sole-

Approx. OV

I lUlU / Actuator is not activated and actuator relay is activated (with vehicle Front left Outlet stopped and engine running): Battery voltage (Approx. 12V)

solenoid

'1:e

to

tooen

a connector terminal when

using a circuit tester for inspection. Control

I

unit

power

supply circuit

ST

Stop lamp switch

and circuit

ABS motor, motor

R8

relay and circuit

ABS actuator relay

and circuit

pL

ABS warning lamp

and circuit, ABS

actuator relay

SD monitor circuit

ABS solenoid and

circuit

ABS motor monitor

circuit

ABS warning lamp

and circuit

Wheel sensors and circuit

ABS solenoid and

circuit

'2: ABS warning lamp ON: When the ignition switch is turned ON (before starting the engine) or a malfunction is detected ABS warning lamp OFF: One second after the ignition switch is turned ON (with the system in normal condition) *3: Tire pressure must be in accordance with specification.

Page 85 of 230

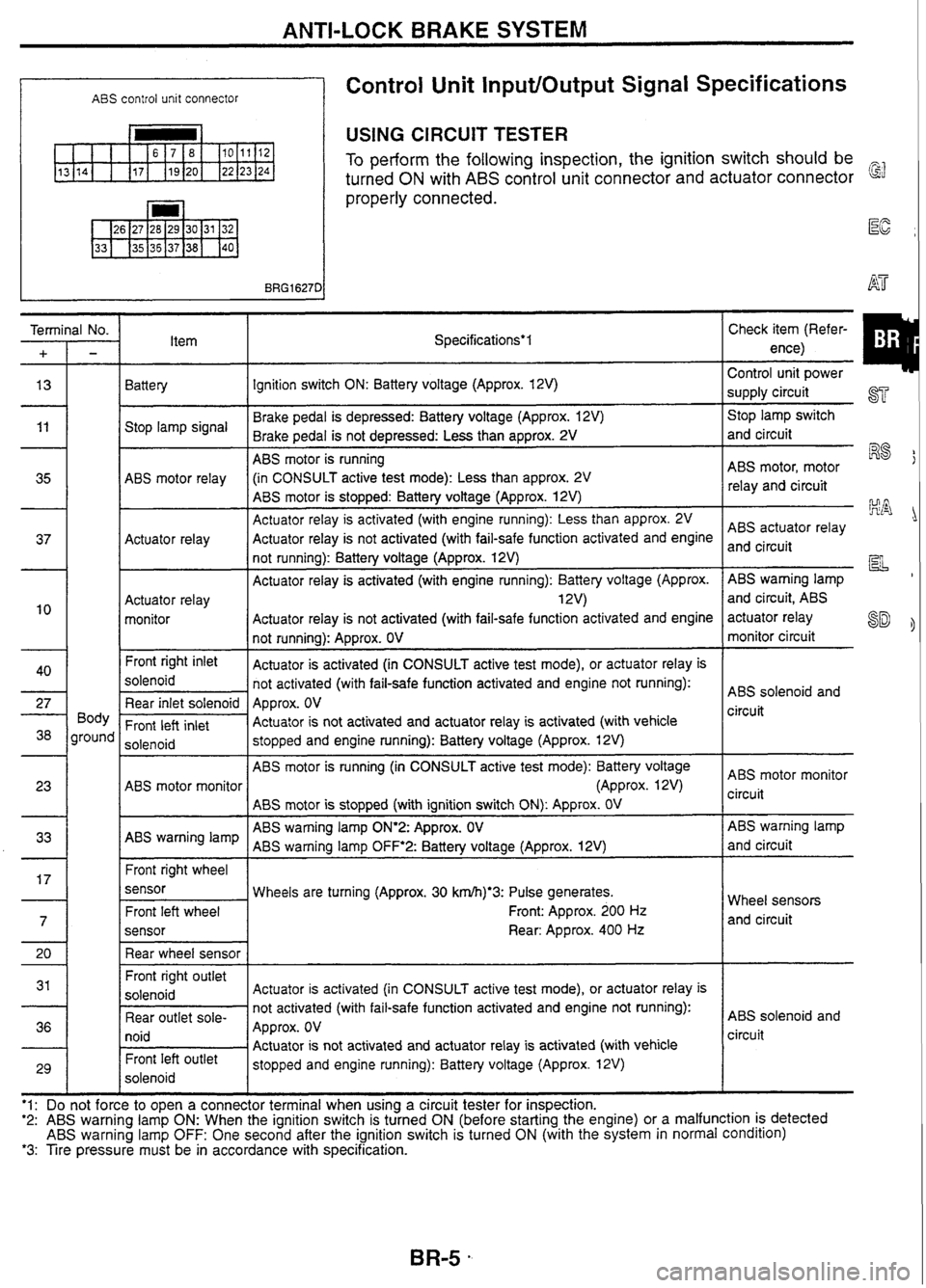

ANTI-LOCK BRAKE SYSTEM

Control Unit InputfOutput Signal Specifications

(Cont'd)

USING CONSULT

Indicated are the control unit computed data. If the output circuit (harness) should be open or short-

circuited, correct values may be displayed.

Check item (Reference)

Data monitor

Display Condition

Monitor

item

Specifications

Vehicle is stationary.

I 0 kdh

FR RH SENSOR

FR LH SENSOR

RR SENSOR

[kdh]

Virtually the same speed

as speedometer (within

+I 0%)

Wheel sensor and circuit

Wheel speed

Vehicle is

drivem'l

Brake pedal is

depressed. Stop lamp switch and

circuit

STOP

LAMP SW

[ON-OFF] Brake pedal status

Brake pedal is not

depressed. OFF

-- --

Actuator (solenoid)

is

activated (at CONSULT

active test),

or

actuator relay is not

activated (with fail-safe

function activated and

engine not running).

FR

RH IN SOL

FR

LH IN SOL

REAR IN SOL

[ON-OFF]

ABS solenoid and circuit

Solenoid status

FR RH OUT SOL

FR

LH OUT SOL

REAR OUT SOL

[ON-OFF]

-- -- - -- -

Actuator (solenoid) is not

activated and actuator

relay is activated (with

vehicle stopped and

engine running).

Actuator relay is acti-

vated (with engine run-

ning).

Actuator relay is not acti-

vated (with fail-safe

function activated and

engine not running).

ABS actuator relay and

circuit

OFF

ON

OFF

ACTUATOR

RLY

[ON-OFF] Actuator

relay status

Motor relay and motor

are activated (at CON-

SULT active test). ABS

motor, motor relay,

and circuit

MOTOR

RLY

[ON-OFF] Motor

relay and motor

status Motor relay and motor

are not activated. OFF

ABS warning lamp and

circuit

- -

Waming lamp ON'2 1 ON

WARNING LAMP

[ON-OFF] ABS

warning lamp sta-

tus

Power supply voltage

provided for control unit -- -

Warning lamp OFF'2 1 OFF

Control unit power sup-

ply circuit - -

BAlTERY VOLT [V] Ignition switch

ON

'1: Tire pressure must be in accordance with specification. "2: ABS warning lamp ON: When the ignition switch is turned ON (before starting the engine) or a malfunction is detected ABS warning lamp OFF: One second after the ignition switch is turned ON (with the system in normal condition)

Page 87 of 230

ANTI-LOCK BRAKE SYSTEM

CONSULT

CONTROL UNIT PART NUMBER

The part number that is shown on the control unit label and CON-

SULT 47850 AAOOO

- SELF-DIAGNOSIS PROCEDURE

Coliect information on the concern from the customer, and then

perform basic inspections.

Turn ignition switch

OFF and connect CONSULT connector to

data link connector for CONSULT on the vehicle.

Start engine and drive vehicle at approx.

30 km/b for approx.

1 minute.

Stop vehicle and touch "START",

"ABS" and "SELF-DIAG

RESULTS" sequentially on the CONSULT screen with engine

running.

If "START" is touched immediately after engine is started

or ignition switch is turned on,

"ABS" may not be dis-

played on "SELECT

SYSTEM" screen. To display "ABS",

repeat the self-diagnosis procedure from the beginning.

Self-diagnosis results are displayed on the screen. (Touch

"PRINT" to print out the self-diagnosis results, if necessary.)

If

"NO FAIL" is displayed, inspect ABS warning lamp. Refer to

the previous page.

Perform appropriate inspection from the self-diagnostic results

mode and repair or replace faulty parts.

Start engine and drive vehicle at approx. 30

km/b for approx.

1 minute.

Recheck to ensure that there is no other malfunction.

Turn ignition switch OFF to prepare for erasing the trouble

stored in memory.

Start engine and touch "START",

"ABS", "SELF-DIAG

RESULTS" and "ERASE" sequentially on the CONSULT

screen to erase the trouble stored in memory.

If the trouble stored in memory is not erased, repeat step

6.

10. Drive vehicle at approx. 30 km/h for approx. 1 minute and then

confirm that ABS warning lamp is

off.

Page 89 of 230

![NISSAN GT-R 1998 Service Manual

ANTI-LOCK BRAKE SYSTEM

CONSULT (Contd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnost NISSAN GT-R 1998 Service Manual

ANTI-LOCK BRAKE SYSTEM

CONSULT (Contd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnost](/img/5/57354/w960_57354-88.png)

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnostic

item is detected when

...

Control unit,

control

unit

power supply

and ground

circuit

Check item

ABS control unit battery voltage

is abnormally high.

ABS control unit battery voltage is abnormally low.

. ABS MOTOR

[LOCK FAILURE] Control

unit

power supply

circuit ABS motor speed is abnormally low. AES motor,

motor relay

and circuit

1 I

'1 : ABS warning lamp turns on if a wheel or wheels spin for I0 to 80 seconds (depending on the wheel speed) with the vehicle

stuck in snow. ice, or mud. This is a normal condition.

'2: After repairing short-circuited sensor, turning ignition switch ON lights up ABS warning lamp. Check that ABS warning lamp

turns

off when the vehicle is driven at approx. 30 krnh for approx. 1 minute as shown in the self-diagnosis procedure. NOTE: If "ABSn is not displayed on "SELECT SYSTEM" screen, check ABS control unit and data link connector circuit, and make sure

of the CONSULT card number.

DATA MONITOR PROCEDURE

Refer to CONSULT Instruction Manual for details on data

monitor function.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector for CON-

SULT.

3. Turn ignition switch ON.

4. Touch "START' on CONSULT screen.

5. Touch "ABS" on CONSULT screen.

If "START" is touched immediately after engine is started

or ignition switch is turned on,

"ABS" may not be dis-

played on "SELECT SYSTEM" screen. To display "ABS",

repeat the data monitor procedure from the beginning.

6. Touch "DATA MONITORn.

7. Touch "SETTING" to set recording condition.

8. Touch "AUTO TRIG", "LONG TIME" and then "ENTER".

9. Return to "SELECT MONITOR ITEM" screen and touch "CIU

INPUT ITEM", "ALL SIGNALS" or 'SELECTION FROM

MENU". Refer to "DATA MONITOR MODE" on the next page.

10. Touch "START'.

11. Display data monitor.

12. If necessary, sequentially touch "REC START, "REC STOP",

"DATA DISPLAY", "NUMBER PRINT' and "PRINT' to print out

the data.

Page 90 of 230

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd)

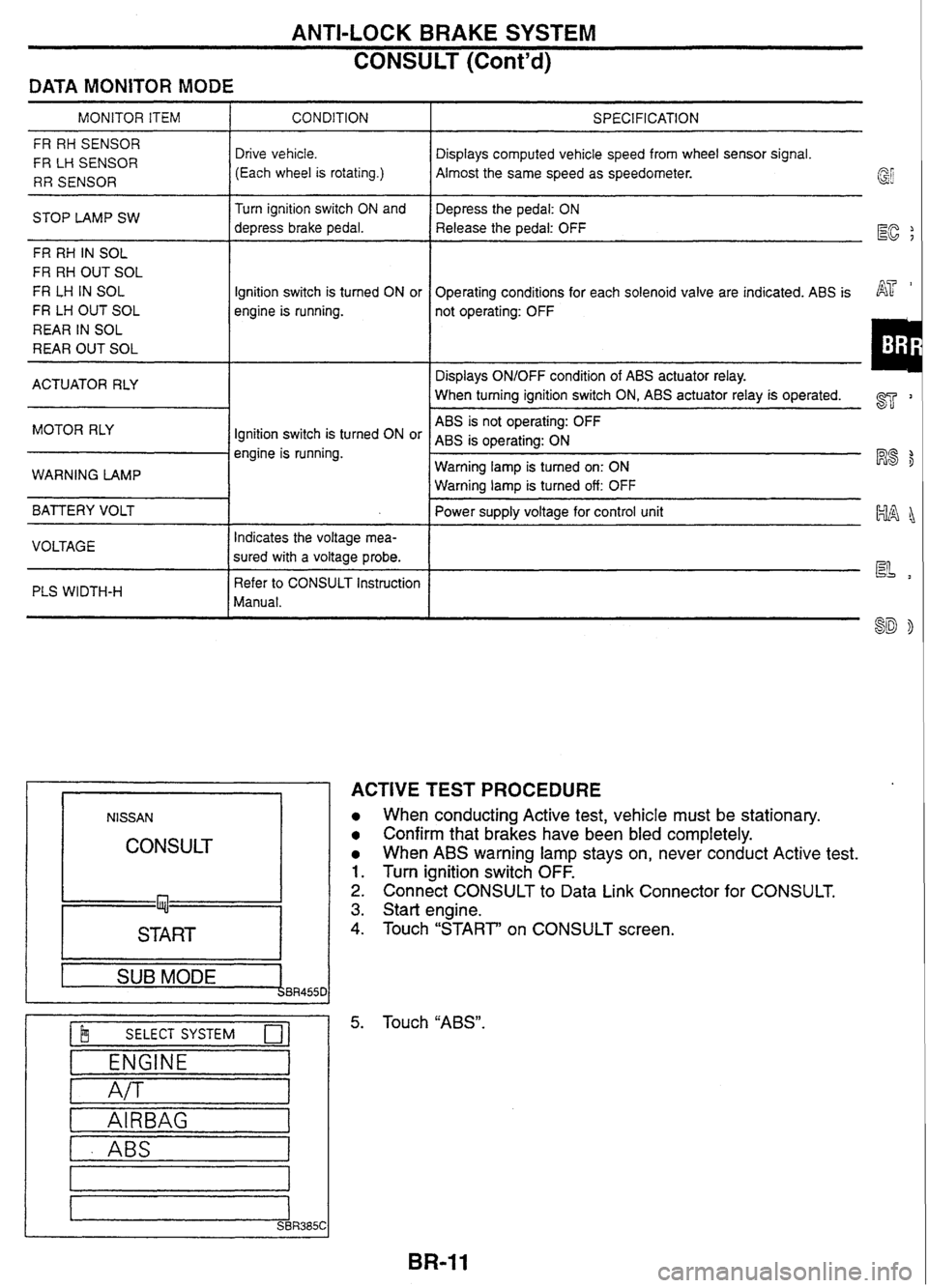

DATA MONITOR MODE

MONITOR ITEM I CONDITION

FR RH SENSOR

FR

LH SENSOR

RR SENSOR Drive vehicle.

(Each wheel is rotating.)

STOP LAMP SW Turn

ignition switch ON and

depress brake pedal.

FR RH

IN SOL

FR RH OUT SOL

FR

LH IN SOL

FR LH OUT SOL

REAR IN SOL

REAR OUT SOL Ignition

switch is turned ON or

engine is running.

ACTUATOR RLY

MOTOR RLY

Ignition switch is turned ON or

engine is running.

WARNING LAMP

BATTERY VOLT

I

VOLTAGE Indicates

the voltage mea-

sured with a voltage probe.

PLS WIDTH-H

I

Refer to CONSULT Instruction

Manual.

NlSSAN

CONSULT

START I --

1 SUB MODE BR455C

$ SELECT SYSTEM 0-

ENGINE

A/T

I - ABS I

SPECIFICATION

Displays computed vehicle speed from wheel sensor signal.

Almost the same speed as speedometer.

Depress the pedal: ON

Release the pedal: OFF

EC ;

Operating conditions for each solenoid valve are indicated. ABS is AT '

not operating: OFF

Displays ON/OFF condition of ABS actuator relay.

When turning ignition switch ON,

ABS actuator relay

is operated. 2

ABS is not operating: OFF

ABS

is operating: ON

Warning lamp is turned on: ON

R8 $

Warning lamp is turned off: OFF

Power supply voltage for control unit

~~~~

ACTIVE TEST PROCEDURE

When conducting Active test, vehicle must be stationary.

Confirm that brakes have been bled completely.

When ABS warning lamp stays on, never conduct Active test.

Turn ignition switch OFF.

Connect CONSULT to Data Link Connector for CONSULT.

Start engine.

Touch "START' on CONSULT screen.

Touch

"ABS".

Page 91 of 230

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd)

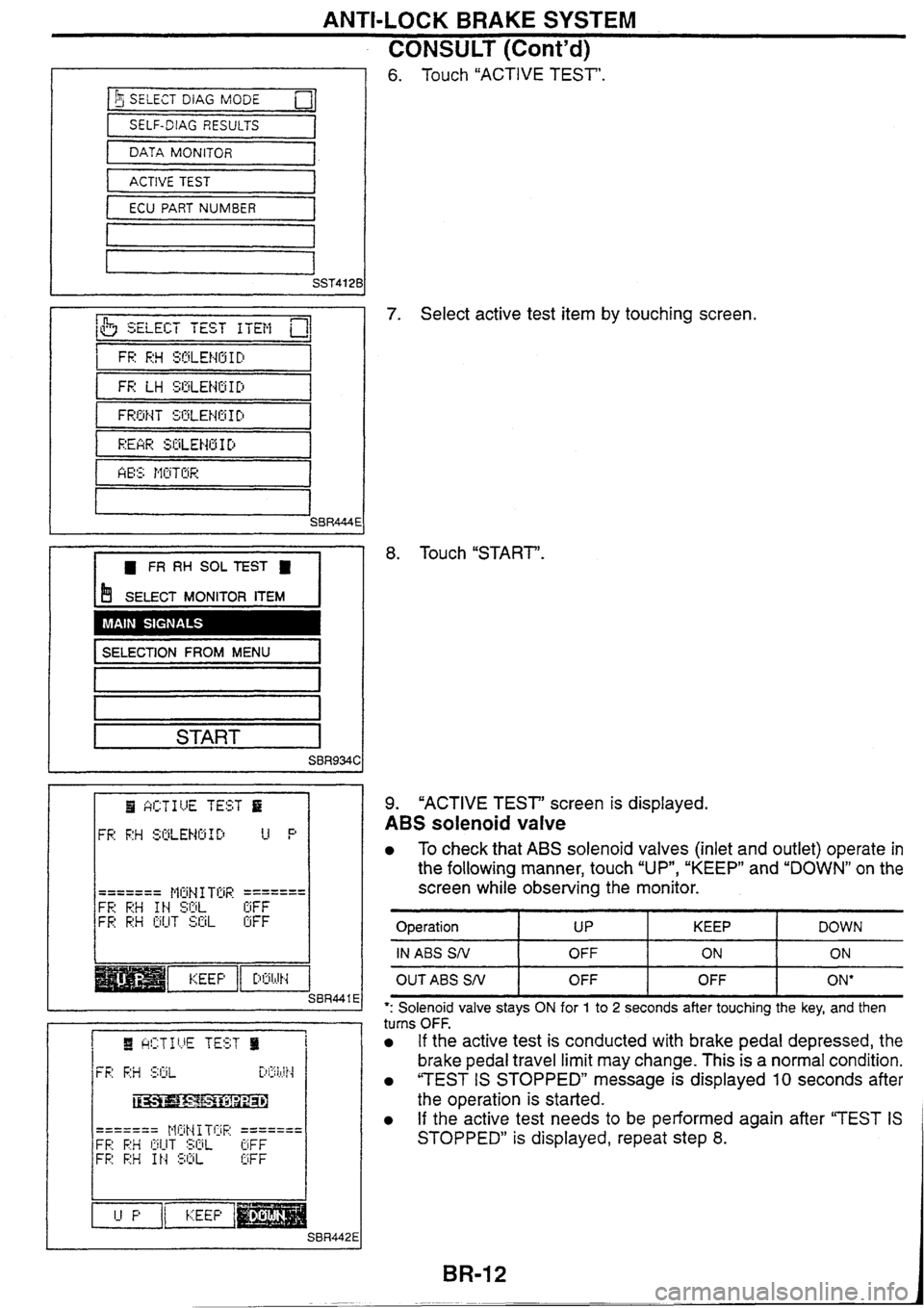

I b~ SELECT DiAG MODE 01 r SELF-DIAG RESULTS

DATA MONITOR

ACTIVE TEST

ECU

PART NUMBER I

FR RH SOL TEST

I 1 !!! SELECT MONITOR ITEM I I

I I SELECTION FROM MENU I I

I I START 1

6. Touch "ACTIVE TEST'.

7. Select active test item by touching screen.

8. Touch "START'.

9. "ACTIVE TEST" screen is displayed.

ABS solenoid valve

To check that ABS solenoid valves (inlet and outlet) operate in

the following manner, touch

"UP*, "KEEP" and "DOWN" on the

screen while observing the monitor.

Operation I UP I KEEP ( DOWN

IN ABS SN I OFF 1 ON I ON

OUTABS SN I OFF I OFF I ON*

*: Solenoid valve stays ON for 1 to 2 seconds after touching the key, and then

turns OFF.

If the active test is conducted with brake pedal depressed, the

brake pedal travel limit may change. This is a normal condition.

"TEST IS STOPPED" message is displayed 10 seconds after

the operation is started.

If the active test needs to be performed again after "TEST IS

STOPPED" is displayed, repeat step 8.