NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 1351 of 4331

DI

N

O P

OK >> Check battery power supply circuit of combinati

on meter. If OK, replace combination meter. Refer

to IP-12, " Removal and Installation " .

NG >> Replace BCM. Refer to BCS-18, " Removal and Installation of BCM " .

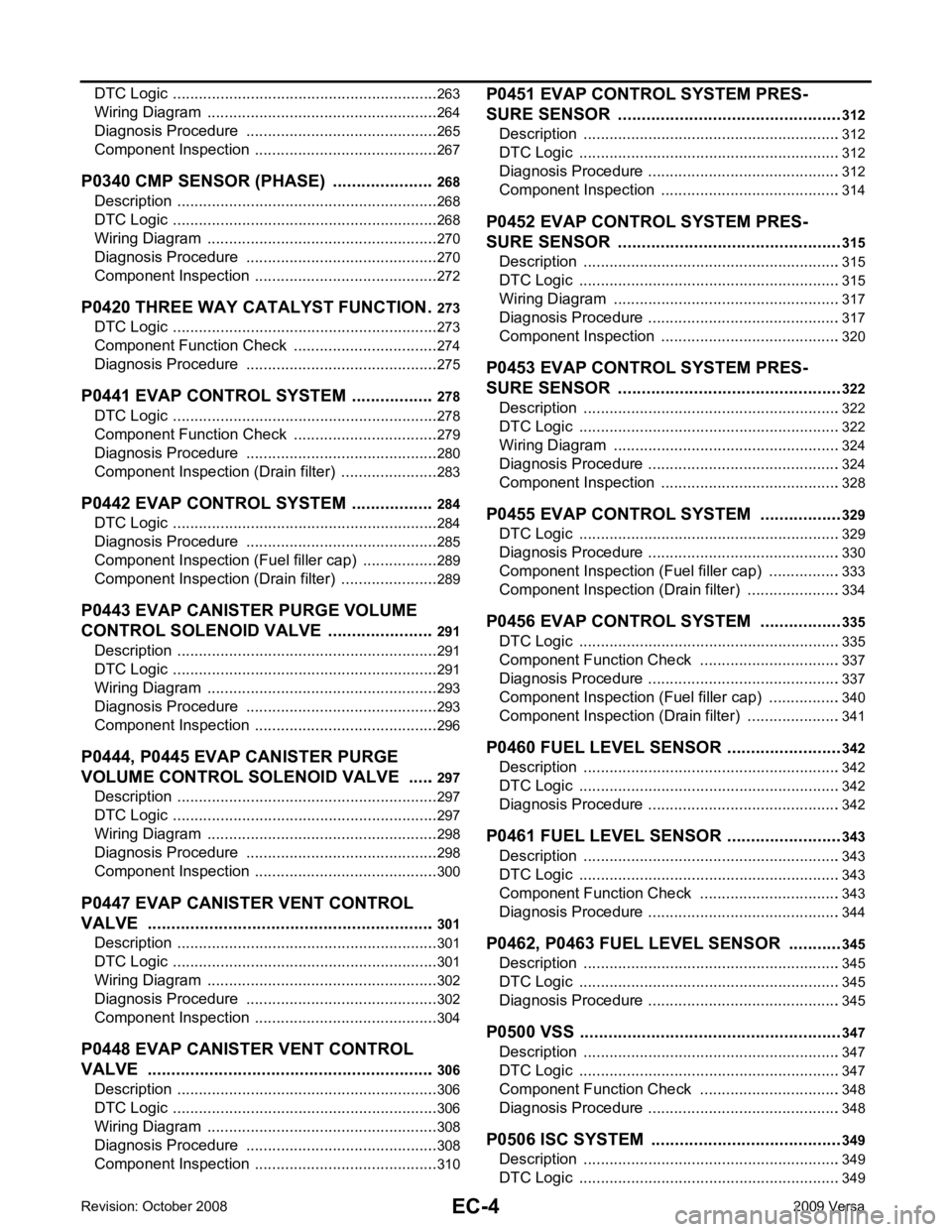

Front Door Switch LH Signal Inspection INFOID:0000000004307034OK >> Front door switch LH signal is OK. Return to

DI-47, " Trouble Diagnosis " .

NG >> GO TO 2. OK >> GO TO 3.

NG >> Repair harness or connector. Electrical Component Inspection " .

OK or NG

Page 1352 of 4331

Removal and Installation of BCM " .

NG >> Replace front door switch LH.

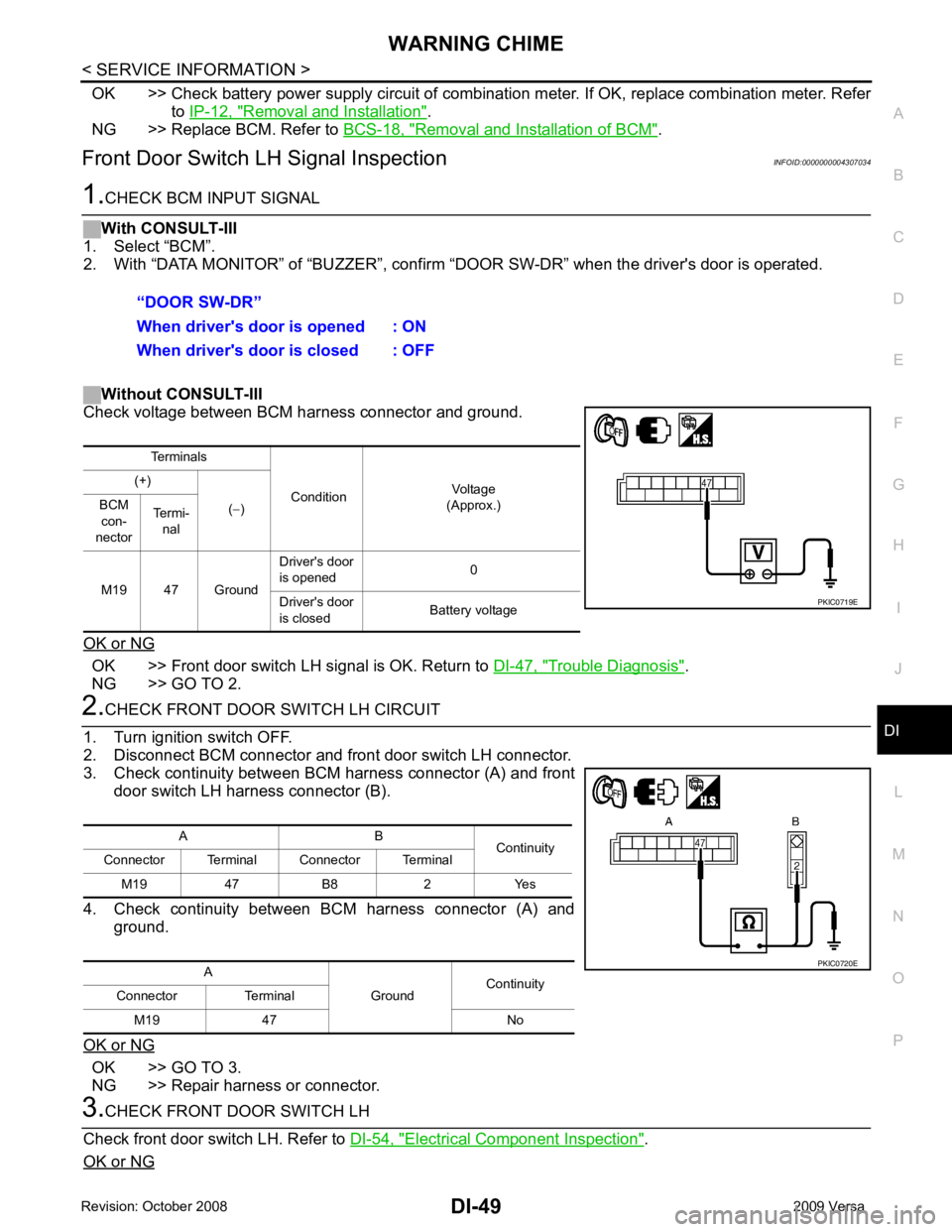

Key Switch Signal Inspection (Without Intelligent Key) INFOID:0000000004307035OK >> GO TO 2.

NG >> Be sure to repair the cause of malfunction before installing new fuse. Refer to PG-3 .

OK >> Key switch signal is OK. Return to

DI-47, " Trouble Diag-

nosis " .

NG >> GO TO 3. OK >> GO TO 4.

NG >> Replace key switch and key lock solenoid.

Page 1353 of 4331

DI

N

O P

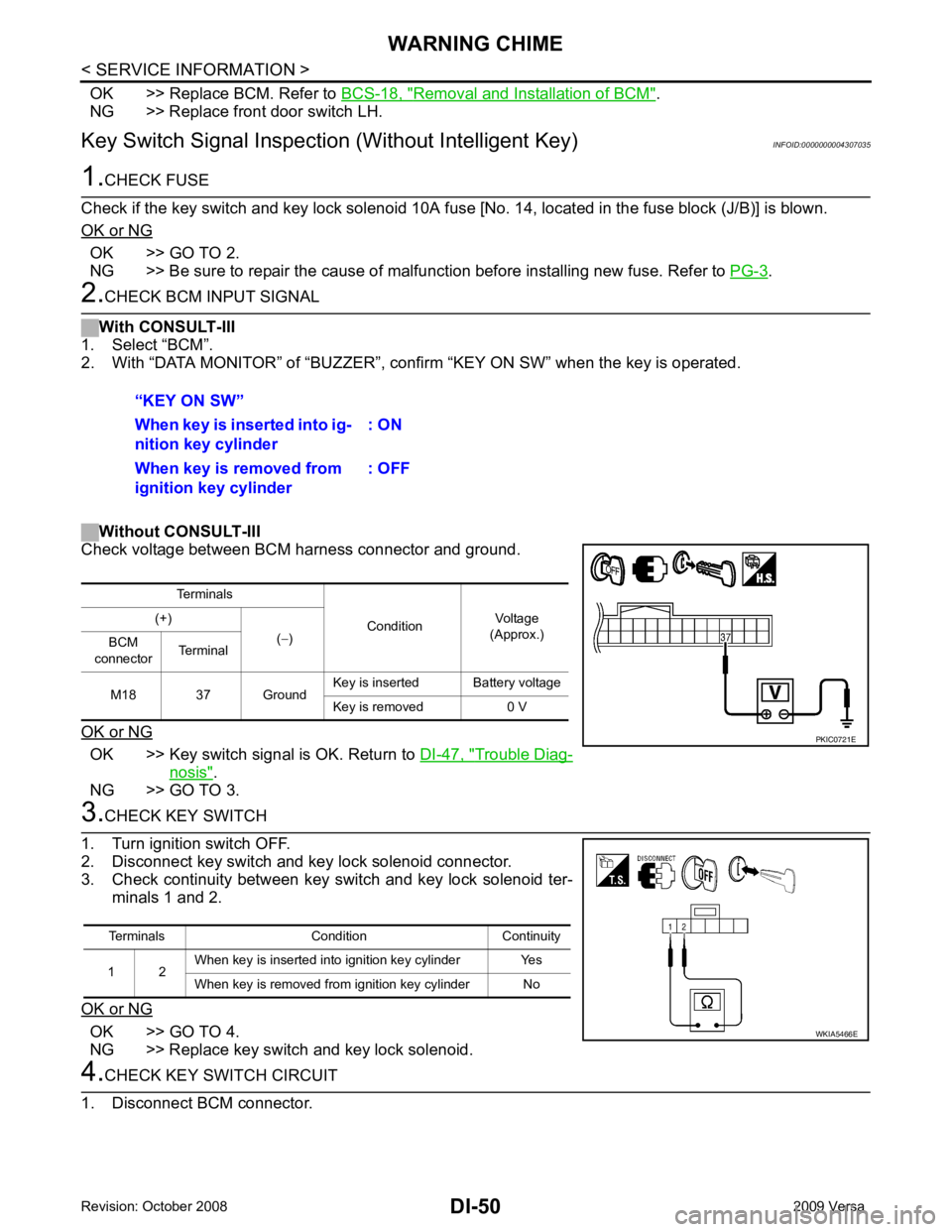

2. Check continuity between BCM harness connector (A) and key

switch and key lock solenoid harness connector (B).

3. Check continuity between BCM harness connector (A) and ground.

OK or NG OK >> GO TO 5.

NG >> Repair harness or connector. OK >> Replace BCM. Refer to

BCS-18, " Removal and Installa-

tion of BCM " .

NG >> Repair harness or connector.

Key Switch and Ignition Knob Switch Signal Inspection (With Intelligent Key, When Me-

chanical Key Is Used) INFOID:0000000004307036OK >> GO TO 2.

NG >> Be sure to repair the cause of malfunction before installing new fuse. Refer to PG-3 .

Page 1354 of 4331

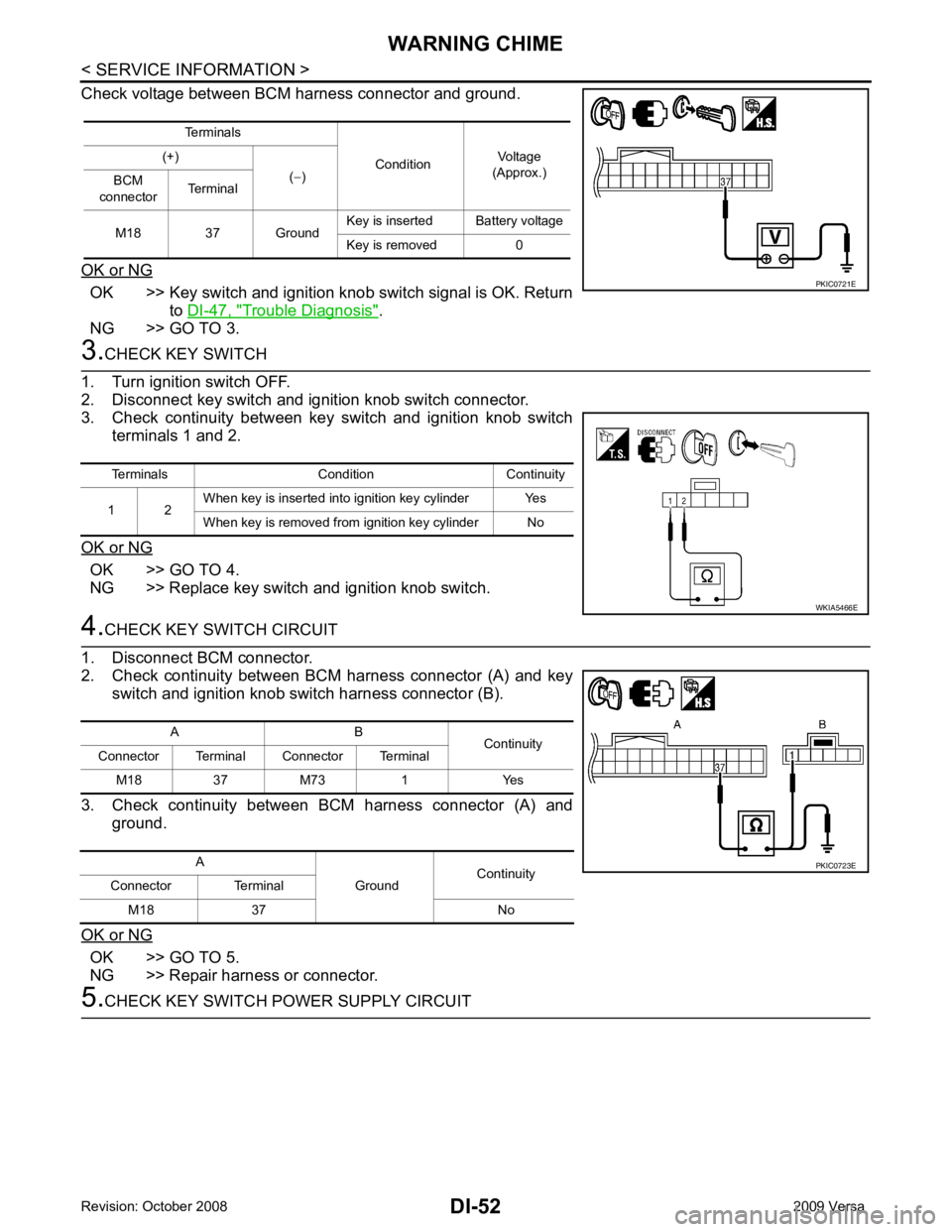

DI-52< SERVICE INFORMATION >

WARNING CHIME

Check voltage between BCM harness connector and ground.

OK or NG OK >> Key switch and ignition knob switch signal is OK. Return

to DI-47, " Trouble Diagnosis " .

NG >> GO TO 3. 3.

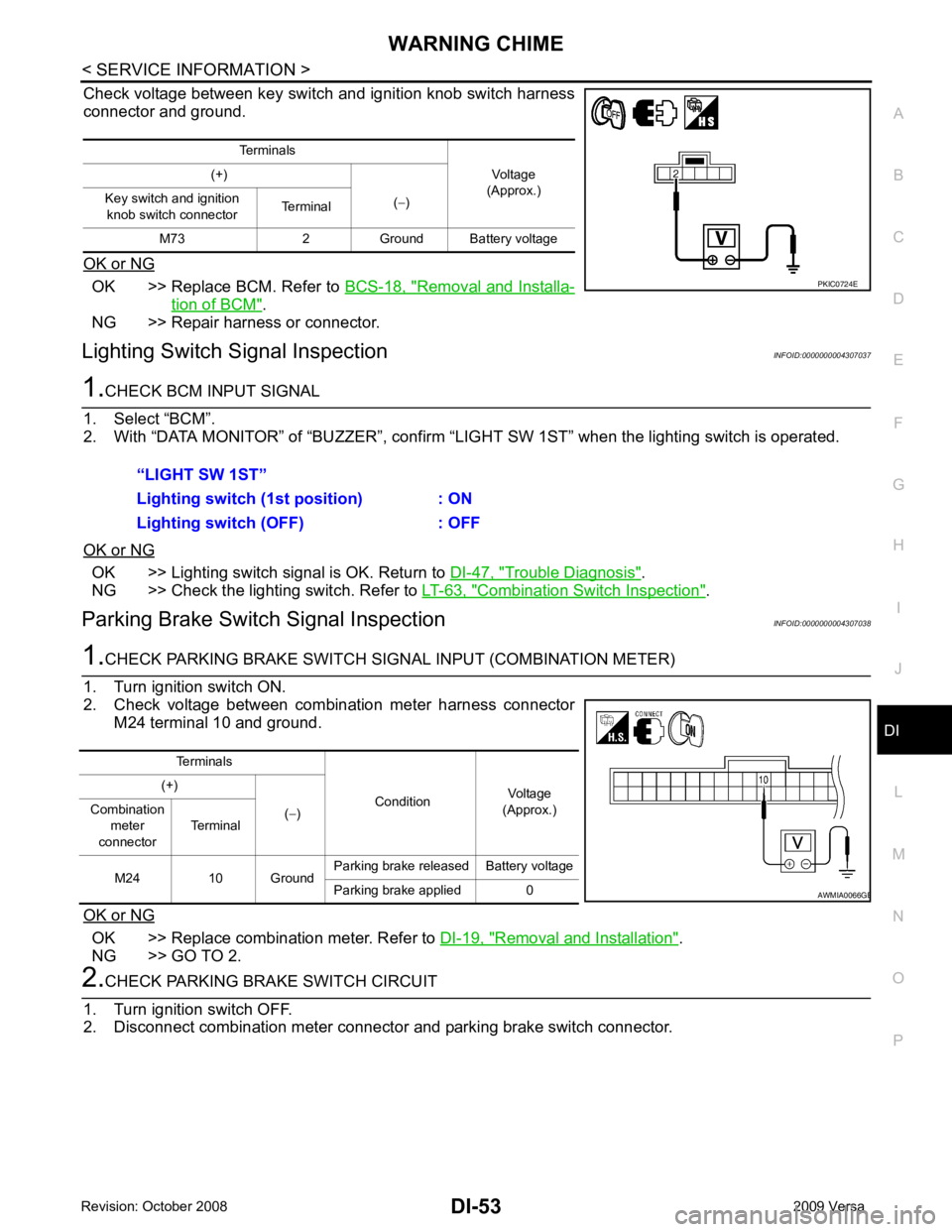

CHECK KEY SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch and ignition knob switch connector.

3. Check continuity between key switch and ignition knob switch

terminals 1 and 2.

OK or NG OK >> GO TO 4.

NG >> Replace key switch and ignition knob switch. 4.

CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector (A) and key switch and ignition knob switch harness connector (B).

3. Check continuity between BCM harness connector (A) and ground.

OK or NG OK >> GO TO 5.

NG >> Repair harness or connector. 5.

CHECK KEY SWITCH PO WER SUPPLY CIRCUIT

Terminals

ConditionVoltage

(Approx.)

(+)

(− )

BCM

connector Terminal

M18 37 Ground Key is inserted Battery voltage

Key is removed 0 PKIC0721E

Terminals Condition Continuity

1 2 When key is inserted into ignition key cylinder Yes

When key is removed from ignition key cylinder No WKIA5466E

A B

Continuity

Connector Terminal Connector Terminal

M18 37 M73 1 Yes

A GroundContinuity

Connector Terminal

M18 37 No PKIC0723E

Page 1355 of 4331

DI

N

O P

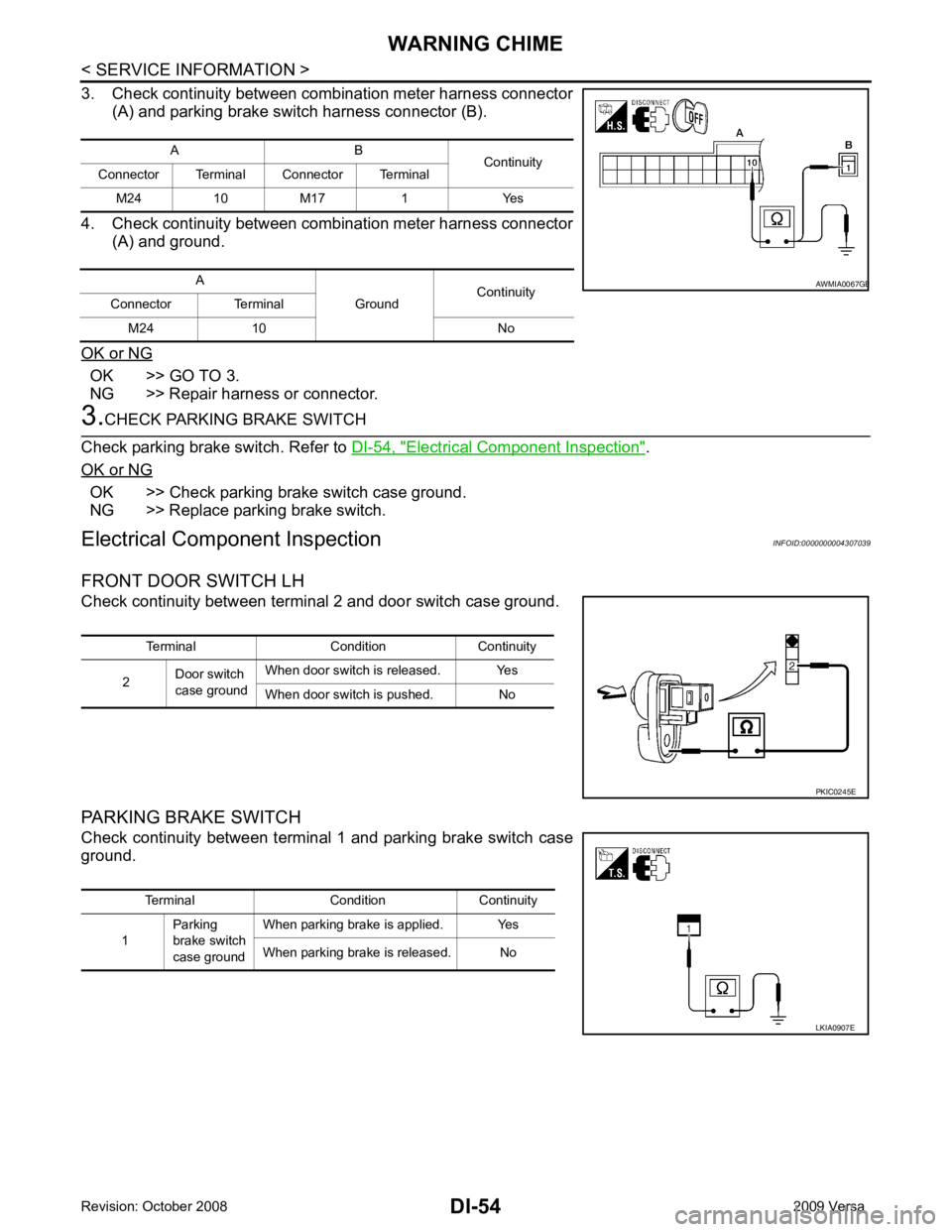

Check voltage between key switch and ignition knob switch harness

connector and ground.

OK or NG OK >> Replace BCM. Refer to

BCS-18, " Removal and Installa-

tion of BCM " .

NG >> Repair harness or connector.

Lighting Switch Signal Inspection INFOID:0000000004307037OK >> Lighting switch signal is OK. Return to

DI-47, " Trouble Diagnosis " .

NG >> Check the lighting switch. Refer to LT-63, " Combination Switch Inspection " .

Parking Brake Switch Signal Inspection INFOID:0000000004307038OK >> Replace combination meter. Refer to

DI-19, " Removal and Installation " .

NG >> GO TO 2. B

Page 1356 of 4331

OK >> GO TO 3.

NG >> Repair harness or connector. Electrical Component Inspection " .

OK or NG OK >> Check parking brake switch case ground.

NG >> Replace parking brake switch.

Electrical Component Inspection INFOID:0000000004307039

FRONT DOOR SWITCH LH

Check continuity between terminal 2 and door switch case ground.

PARKING BRAKE SWITCH

Check continuity between terminal 1 and parking brake switch case

ground. A B

Continuity

Connector Terminal Connector Terminal

M24 10 M17 1 Yes

A GroundContinuity

Connector Terminal

M24 10 No B

Page 1357 of 4331

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

HR16DE

BASIC INSPECTION ....... ............................

22

DIAGNOSIS AND REPAIR WORK FLOW .... ....22

Work Flow ........................................................... ....22

Diagnostic Work Sheet ........................................ ....25

INSPECTION AND ADJUSTMENT ................ ....26

BASIC INSPECTION ......... ........................................26

BASIC INSPECTION : Spec ial Repair Require-

ment .................................................................... ....

26

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

29

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ............................ ....

29

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

29

IDLE SPEED .......................................................... ....30

IDLE SPEED : Description ........................ ..............30

IDLE SPEED : Special R epair Requirement ...........30

IGNITION TIMING .................................................. ....30

IGNITION TIMING : Description .......................... ....30

IGNITION TIMING : Special Repair Requirement ....30

VIN REGISTRATION ............................................. ....30

VIN REGISTRATION : Description ..................... ....30

VIN REGISTRATION : Special Repair Require-

ment .................................................................... ....

31

ACCELERATOR PEDAL RE LEASED POSITION

LEARNING ............................................................ ....

31

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Description ..................................... ....

31

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement .......... ....

31

THROTTLE VALVE CLO SED POSITION LEARN-

ING ......................................................................... ....

31 THROTTLE VALVE CLOSED POSITION

LEARNING : Description ..................................... ....

31

THROTTLE VALVE CLOSED POSITION

LEARNING : Special Repai r Requirement ..............

31

IDLE AIR VOLUME LEARNING ............................ ....31

IDLE AIR VOLUME LEARNI NG : Description .........31

IDLE AIR VOLUME LEARNI NG : Special Repair

Requirement ........................................................ ....

32

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ................................................................... ....

33

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Description ............................................ ....

33

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement ................. ....

33

FUNCTION DIAGNOSIS .. ............................35

ENGINE CONTRO L SYSTEM .......................... 35

System Diagram ................................................. ....35

System Description .............................................. ....36

Component Parts Location ................................ ....36

Component Description ....................................... ....40

MULTIPORT FUEL INJECTION SYSTEM ....... 42

System Diagram ................................................. ....42

System Description .............................................. ....42

Component Parts Location ................................ ....45

Component Description ....................................... ....49

ELECTRIC IGNITI ON SYSTEM ........................ 51

System Diagram ................................................. ....51

System Description .............................................. ....51

Component Parts Location ................................ ....52

Component Description ....................................... ....56

AIR CONDITIONING CUT CONTROL .............. 58

System Diagram .................................................. ....58

System Description .............................................. ....58

Component Parts Location ................................ ....59

Component Description ....................................... ....63

Page 1358 of 4331

Page 1359 of 4331

EC

A

N

O P

P0122, P0123 TP SENSOR ...........................

..171

Description .......................................................... ..171

DTC Logic ........................................................... ..171

Wiring Diagram ................................................... ..172

Diagnosis Procedure ........................................... ..172

Component Inspection ........................................ ..174

Special Repair Requirem ent .................................174

P0125 ECT SENSOR ..................................... ..175

Description .......................................................... ..175

DTC Logic ........................................................... ..175

Diagnosis Procedure ........................................... ..176

Component Inspection ........................................ ..176

P0127 IAT SENSOR ....................................... ..178

Description .......................................................... ..178

DTC Logic ........................................................... ..178

Diagnosis Procedure ........................................... ..179

Component Inspection ........................................ ..179

P0128 THERMOSTAT FUNCTION ................ ..180

DTC Logic ........................................................... ..180

Diagnosis Procedure ........................................... ..180

Component Inspection ........................................ ..181

P0130 A/F SENSOR 1 .................................... ..182

Description .......................................................... ..182

DTC Logic ........................................................... ..182

Component Function Check ................................ ..183

Wiring Diagram ................................................... ..185

Diagnosis Procedure ........................................... ..185

P0131 A/F SENSOR 1 .................................... ..188

Description .......................................................... ..188

DTC Logic ........................................................... ..188

Wiring Diagram ................................................... ..190

Diagnosis Procedure ........................................... ..190

P0132 A/F SENSOR 1 .................................... ..193

Description .......................................................... ..193

DTC Logic ........................................................... ..193

Wiring Diagram ................................................... ..195

Diagnosis Procedure ........................................... ..195

P0133 A/F SENSOR 1 .................................... ..198

Description .......................................................... ..198

DTC Logic ........................................................... ..198

Wiring Diagram ................................................... ..200

Diagnosis Procedure ........................................... ..201

P0137 HO2S2 ................................................. ..204

Description .......................................................... ..204

DTC Logic ........................................................... ..204

Component Function Check ................................ ..205

Wiring Diagram ................................................... ..207

Diagnosis Procedure ........................................... ..207

Component Inspection ........................................ ..209

P0138 HO2S2 ................................................. ..212

Description .......................................................... ..212

DTC Logic ........................................................... ..212 Component Function Check ................................

..213

Wiring Diagram .................................................... ..215

Diagnosis Procedure ........................................... ..215

Component Inspection ......................................... ..218

P0139 HO2S2 .................................................. 221

Description ........................................................... ..221

DTC Logic ............................................................ ..221

Component Function Check ................................ ..222

Wiring Diagram .................................................... ..224

Diagnosis Procedure ........................................... ..224

Component Inspection ......................................... ..226

P0171 FUEL INJECTION SYSTEM FUNC-

TION ................................................................ 229

DTC Logic ............................................................ ..229

Wiring Diagram .................................................... ..231

Diagnosis Procedure ........................................... ..231

P0172 FUEL INJECTION SYSTEM FUNC-

TION ................................................................ 235

DTC Logic ............................................................ ..235

Wiring Diagram .................................................... ..237

Diagnosis Procedure ........................................... ..237

P0181 FTT SENSOR ....................................... 240

Description ........................................................... ..240

DTC Logic ............................................................ ..240

Wiring Diagram .................................................... ..242

Diagnosis Procedure ........................................... ..242

Component Inspection ......................................... ..244

P0182, P0183 FTT SENSOR .......................... 245

Description ........................................................... ..245

DTC Logic ............................................................ ..245

Wiring Diagram .................................................... ..246

Diagnosis Procedure ........................................... ..246

Component Inspection ......................................... ..248

P0222, P0223 TP SENSOR ............................ 249

Description ........................................................... ..249

DTC Logic ............................................................ ..249

Wiring Diagram .................................................... ..250

Diagnosis Procedure ........................................... ..250

Component Inspection ......................................... ..252

Special Repair Requiremen t ..................................252

P0300, P0301, P0302, P0303, P0304 MIS-

FIRE ................................................................. 253

DTC Logic ............................................................ ..253

Diagnosis Procedure ........................................... ..254

P0327, P0328 KS ............................................ 259

Description ........................................................... ..259

DTC Logic ............................................................ ..259

Wiring Diagram .................................................... ..260

Diagnosis Procedure ........................................... ..260

Component Inspection ......................................... ..261

P0335 CKP SENSOR (POS) ........................... 263

Description ........................................................... ..263

Page 1360 of 4331