NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 1681 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-325

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK CONNECTOR

1. Disco NISSAN LATIO 2009 Service Repair Manual P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-325

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK CONNECTOR

1. Disco](/img/5/57359/w960_57359-1680.png)

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-325

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check sensor harness connector for water.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness connector. 3.

CHECK EVAP CONTROL SYS TEM PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check the voltage between EVAP control system pressure sen- sor harness connector and ground.

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 4. 4.

CHECK EVAP CONTROL SYS TEM PRESSURE SENSOR POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EVAP control syst em pressure sensor harness connector and ECM har-

ness connector.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5. 5.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors B102, M13

• Harness connectors M69, E7

• Harness connectors E8, F8

• Harness for open or short between EVAP c ontrol system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors. 6.

CHECK SENSOR POWER SUPPLY CIRCUIT

Check harness for short to power and short to ground, between the following terminals.

Water should not exist.

EVAP control system pressure sensor Ground Voltage

Connector Terminal

B104 3 Ground Approx. 5 V PBIB0138E

EVAP control system pressure sensor ECM

Continuity

Connector Terminal Connector Terminal

B104 3 F11 76 Existed

Page 1682 of 4331

YES >> GO TO 7.

NO >> Repair short to ground or short to power in harness or connectors. Component Inspection " .)

• Refrigerant pressure sensor (Refer to EC-458, " Diagnosis Procedure " .)

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace malfunctioning component. Component Inspection " .

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 9. Special Repair Requirement " .

>> INSPECTION END

10. CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR GROUND CIRCUIT FOR OPEN ANDYES >> GO TO 12.

NO >> GO TO 11. EVAP control system pressure sensor ECM

Continuity

Connector Terminal Connector Terminal

B104 1 F11 51 Existed

Page 1683 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-327

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

12.

CHECK EVAP CONTROL SYSTEM PRESSURE SENS OR INPUT SIGNAL CIRCUIT FOR OPEN ANDSHORT

NISSAN LATIO 2009 Service Repair Manual P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-327

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

12.

CHECK EVAP CONTROL SYSTEM PRESSURE SENS OR INPUT SIGNAL CIRCUIT FOR OPEN ANDSHORT](/img/5/57359/w960_57359-1682.png)

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-327

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

12.

CHECK EVAP CONTROL SYSTEM PRESSURE SENS OR INPUT SIGNAL CIRCUIT FOR OPEN ANDSHORT

1. Check the continuity between EVAP control syst em pressure sensor harness connector and ECM har-

ness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 14.

NO >> GO TO 13. 13.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors B102, M13

• Harness connectors M69, E7

• Harness connectors E8, F8

• Harness for open or short between EVAP c ontrol system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors. 14.

CHECK RUBBER TUBE

1. Disconnect rubber tube connected to EV AP canister vent control valve.

2. Check the rubber tube for clogging.

Is the inspection result normal? YES >> GO TO 15.

NO >> Clean the rubber tube using an air blower, repair or replace rubber tube. 15.

CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-304, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 16.

NO >> Replace EVAP canister vent control valve. 16.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-328, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 17.

NO >> Replace EVAP control system pressure sensor. 17.

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Check if water will drain from the EVAP canister.

Does water drain from EVAP canister? YES >> GO TO 18.

NO >> GO TO 20. EVAP control system pressure sensor ECM

Continuity

Connector Terminal Connector Terminal

B104 2 F11 42 Existed PBIB1213E

Page 1684 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-328< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR 18.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pres NISSAN LATIO 2009 Service Repair Manual EC-328< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR 18.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pres](/img/5/57359/w960_57359-1683.png)

EC-328< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR 18.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 1.9 kg (4.2 lb).

Is the inspection result normal? YES >> GO TO 15.

NO >> GO TO 14. 19.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. 20.

CHECK INTERMITTENT INCIDENT

Refer to EC-120, " Diagnosis Procedure " .

>> INSPECTION END

Component Inspection INFOID:00000000047804521.

CHECK EVAP CONTROL SY STEM PRESSURE SENSOR

1. Turn ignition switch OFF.

2. Remove EVAP control system pressure sensor wit h its harness connector connected from EVAP canister.

Always replace O-ring with a new one.

3. Install a vacuum pump to EVAP control system pressure sensor.

4. Turn ignition switch ON and check output voltage between ECM

harness connector and ground under the following conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

• Do not apply below -93.3 kPa (-0.952 kg/cm 2

, -13.53 psi) or pressure over 101.3 kPa (1.033 kg/

cm 2

, 14.69 psi).

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EVAP control system pressure sensor ECM Condition

[Applied vacuum kPa

(kg/cm 2

, psi) Voltage

Connector Terminal

F11 42

(EVAP control system

pressure sensor signal) Not applied 1.8 - 4.8 V

-26.7 (-0.272, -3.87) 2.1 to 2.5 V lower

than above value PBIB3314E

Page 1685 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0455 EVAP CONTROL SYSTEM

EC-329

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0455 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780203

DTC DETECTION LOGIC This diagnosis detects NISSAN LATIO 2009 Service Repair Manual P0455 EVAP CONTROL SYSTEM

EC-329

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0455 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780203

DTC DETECTION LOGIC This diagnosis detects](/img/5/57359/w960_57359-1684.png)

P0455 EVAP CONTROL SYSTEM

EC-329

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0455 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780203

DTC DETECTION LOGIC This diagnosis detects a very large leak (fuel filler cap fell off etc.) in EVAP system between the fuel tank and

EVAP canister purge volume control solenoid valve.

CAUTION:

• Use only a genuine NISSAN fuel filler cap as a replacemen t. If an incorrect fuel filler cap is used, the

MIL may come on.

• If the fuel filler cap is not tigh tened properly, the MIL may come on.

• Use only a genuine NISSAN rubber tube as a replacement.

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0455 EVAP control system

gross leak detected EVAP control system has a very large leak such

as fuel filler cap fell off, EVAP control system

does not operate properly. • Fuel filler cap remains open or fails to

close.

• Incorrect fuel tank vacuum relief valve

• Incorrect fuel filler cap used

• Foreign matter caught in fuel filler cap.

• Leak is in line between intake manifold

and EVAP canister purge volume control

solenoid valve.

• Foreign matter caught in EVAP canister

vent control valve.

• EVAP canister or fuel tank leaks

• EVAP purge line (pipe and rubber tube)

leaks

• EVAP purge line rubber tube bent.

• Loose or disconnected rubber tube

• EVAP canister vent control valve and the circuit

• EVAP canister purge volume control so-

lenoid valve and the circuit

• Fuel tank temperature sensor

• O-ring of EVAP canister vent control

valve is missing or damaged.

• EVAP control system pressure sensor

• Refueling EVAP vapor cut valve

• ORVR system leaks

• Drain filter PBIB1026E

Page 1686 of 4331

YES >> GO TO 2.

NO >> GO TO 4. BASIC INSPECTION : Special Repair Requirement " .

Which is displayed on CONSULT-III screen? OK >> INSPECTION END

NG >> GO TO 3. P0455 >> Go to

EC-330, " Diagnosis Procedure " .

P0442 >> Go to EC-285, " Diagnosis Procedure " .

How to Set SRT Code " before driving

vehicle.

1. Start engine.

2. Drive vehicle according to DRIVING PATTERN.

3. Stop vehicle.

4. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

5. Check 1st trip DTC.

Is 1st trip DTC detected? YES-1 >> P0455: Go to

EC-330, " Diagnosis Procedure " .

YES-2 >> P0442: Go to EC-285, " Diagnosis Procedure " .

YES-3 >> P0441: Go to EC-280, " Diagnosis Procedure " .

NO >> INSPECTION END

Diagnosis Procedure INFOID:0000000004780204

Page 1687 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0455 EVAP CONTROL SYSTEM

EC-331

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

Is the inspection res NISSAN LATIO 2009 Service Repair Manual P0455 EVAP CONTROL SYSTEM

EC-331

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

Is the inspection res](/img/5/57359/w960_57359-1686.png)

P0455 EVAP CONTROL SYSTEM

EC-331

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace with genuine NISSAN fuel filler cap. 2.

CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened properly by rotating the cap clockwise.

Is the inspection result normal? YES >> GO TO 3.

NO >> Open fuel filler cap, then clean cap and fuel fi ller neck threads using air blower. Then retighten

until ratcheting sound is heard. 3.

CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4. 4.

CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-333, " Component Inspection (Fuel filler cap) " .

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace fuel filler cap with a genuine one. 5.

CHECK EVAP PURGE LINE

Check EVAP purge line (pipe, rubber tube, fuel tank and EVAP canister) for cracks, improper connection or

disconnection.

Refer to EC-74, " System Description " .

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or reconnect the hose. 6.

CLEAN EVAP PURGE LINE

Clean EVAP purge line (pipe and rubber tube) using air blower.

>> GO TO 7. 7.

CHECK DRAIN FILTER

Refer to EC-334, " Component Inspection (Drain filter) " .

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace drain filter. 8.

CHECK EVAP CANISTER VENT CONTROL VALVE

Check the following.

• EVAP canister vent control valve is installed properly.

Refer to EC-502, " Exploded View " .

• EVAP canister vent control valve. Refer to EC-304, " Component Inspection " . SEF915U

Page 1688 of 4331

YES >> GO TO 9.

NO >> Repair or replace EVAP cani ster vent control valve and O-ring.Inspection " .

Is there any leak in EVAP line? YES >> Repair or replace.

NO-1 >> With CONSULT-III: GO TO 10.

NO-2 >> Without CONSULT-III: GO TO 11. YES >> GO TO 13.

NO >> GO TO 12. YES >> GO TO 14.

NO >> GO TO 12. System Description " .

Is the inspection result normal? YES-1 >> With CONSULT-III: GO TO 13.

YES-2 >> Without CONSULT-III: GO TO 14.

NO >> Repair or reconnect the hose. YES >> GO TO 15.

NO >> GO TO 14. Component Inspection " .

Is the inspection result normal? YES >> GO TO 15.Vacuum should exist.

Vacuum should exist.

Page 1689 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0455 EVAP CONTROL SYSTEM

EC-333

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

NO >> Replace EVAP canister purge volume control solenoid valve. 15.

CHECK FUEL TANK TEMPERATURE SENSO NISSAN LATIO 2009 Service Repair Manual P0455 EVAP CONTROL SYSTEM

EC-333

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

NO >> Replace EVAP canister purge volume control solenoid valve. 15.

CHECK FUEL TANK TEMPERATURE SENSO](/img/5/57359/w960_57359-1688.png)

P0455 EVAP CONTROL SYSTEM

EC-333

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

NO >> Replace EVAP canister purge volume control solenoid valve. 15.

CHECK FUEL TANK TEMPERATURE SENSOR

Refer to EC-244, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 16.

NO >> Replace fuel level sensor unit. 16.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-314, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 17.

NO >> Replace EVAP control system pressure sensor. 17.

CHECK EVAP/ORVR LINE

Check EVAP/ORVR line between EVAP canister and fuel tank for clogging, kink, looseness and improper con-

nection. For location, refer to EC-450, " Description " .

Is the inspection result normal? YES >> GO TO 18.

NO >> Repair or replace hoses and tubes. 18.

CHECK RECIRCULATION LINE

Check recirculation line between fuel filler tube and fuel tank for clogging, kink, cracks, looseness and

improper connection.

Is the inspection result normal? YES >> GO TO 19.

NO >> Repair or replace hose, tube or fuel filler tube. 19.

CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-453, " Component Inspection (Refueling EVAP vapor cut valve) " .

Is the inspection result normal? YES >> GO TO 20.

NO >> Replace refueling EVAP vapor cut valve with fuel tank. 20.

CHECK INTERMITTENT INCIDENT

Refer to EC-120, " Diagnosis Procedure " .

>> INSPECTION END

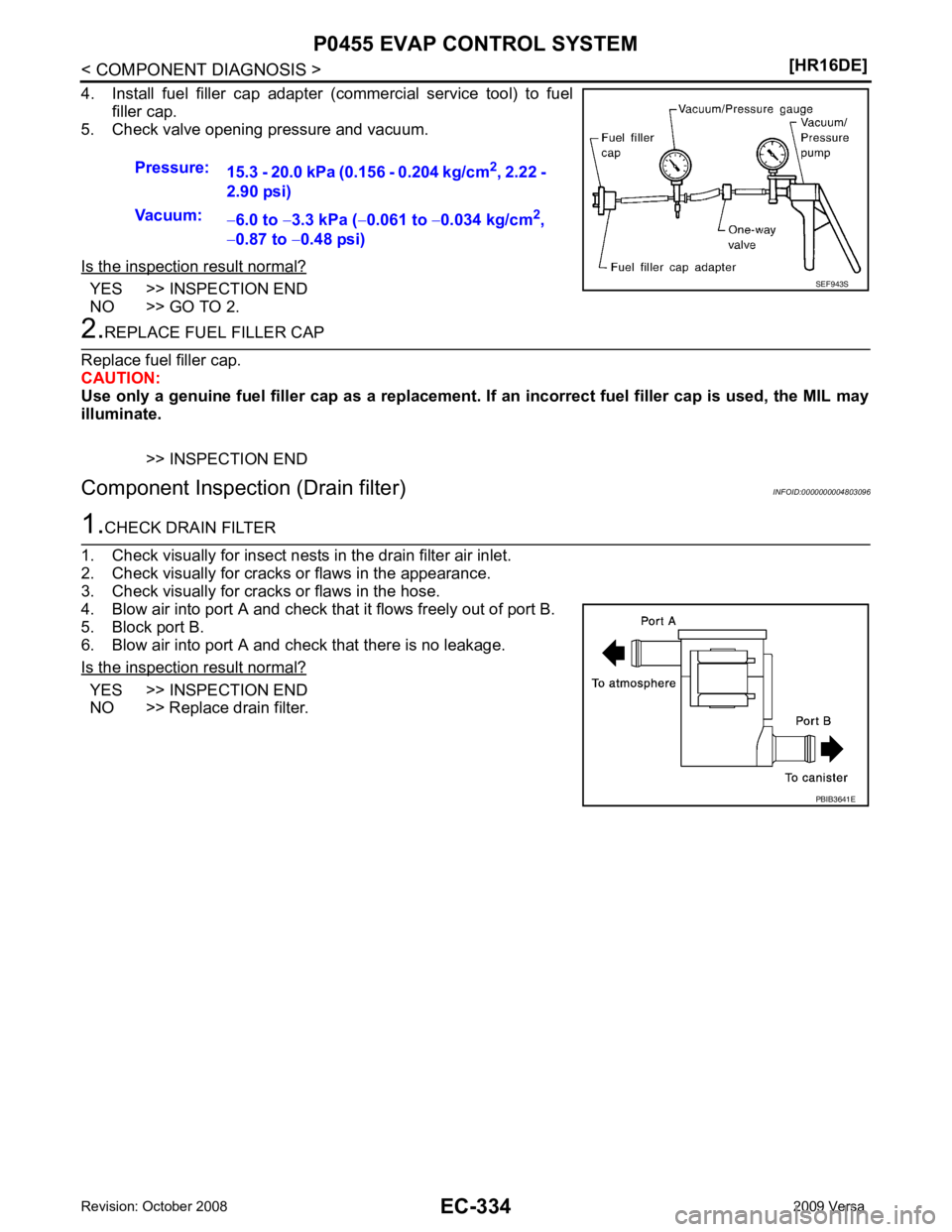

Component Inspection (Fuel filler cap) INFOID:00000000048031171.

CHECK FUEL FILLER CAP

1. Turn ignition switch OFF.

2. Remove fuel filler cap.

3. Wipe clean valve housing. SEF445Y

Page 1690 of 4331

YES >> INSPECTION END

NO >> GO TO 2. YES >> INSPECTION END

NO >> Replace drain filter. Pressure:

15.3 - 20.0 kPa (0.156 - 0.204 kg/cm 2

, 2.22 -

2.90 psi)

Vacuum: −6.0 to −3.3 kPa ( −0.061 to −0.034 kg/cm 2

,

− 0.87 to −0.48 psi)