NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 1671 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-315

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0452 EVAP CONTROL SYST

EM PRESSURE SENSOR

Description INFOID:0000000004780195

The EV NISSAN LATIO 2009 Service Repair Manual P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-315

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0452 EVAP CONTROL SYST

EM PRESSURE SENSOR

Description INFOID:0000000004780195

The EV](/img/5/57359/w960_57359-1670.png)

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-315

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0452 EVAP CONTROL SYST

EM PRESSURE SENSOR

Description INFOID:0000000004780195

The EVAP control system pressure sensor detects pressure in the

purge line. The sensor output voltage to the ECM increases as pres-

sure increases.

DTC Logic INFOID:0000000004780196

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Always perform test at a temperature of 5 °C (41 °F) or more.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Select “DATA MONITOR” mode with CONSULT-III.

5. Make sure that “FUEL T/TMP SE” indication is more than 0 °C (32 °F).

6. Start engine and wait at least 20 seconds.

7. Check 1st trip DTC.

With GST

1. Start engine and warm it up to normal operating temperature. PBIB3370E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0452 EVAP control system

pressure sensor low input An excessively low voltage from the sensor is

sent to ECM. • Harness or connectors

(EVAP control system pressure sensor

circuit is open or shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.)

(Accelerator pedal position sensor circuit

is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

• EVAP control system pressure sensor

• Crankshaft position sensor (POS)

• Accelerator pedal position sensor

• Refrigerant pressure sensor

Page 1672 of 4331

YES >> Go to

EC-317, " Diagnosis Procedure " .

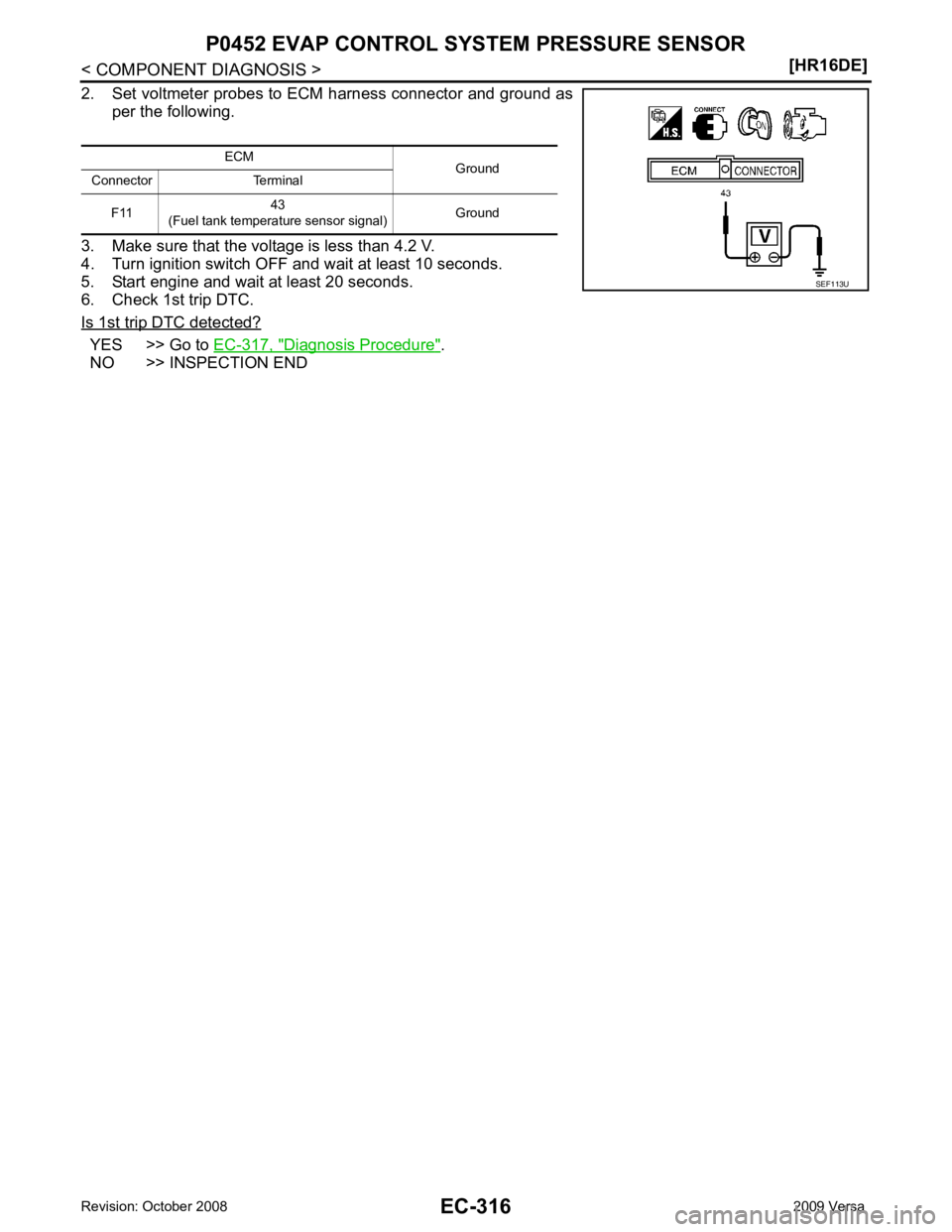

NO >> INSPECTION END ECM

Ground

Connector Terminal

F11 43

(Fuel tank temperature sensor signal) Ground

Page 1673 of 4331

EC

NP

O

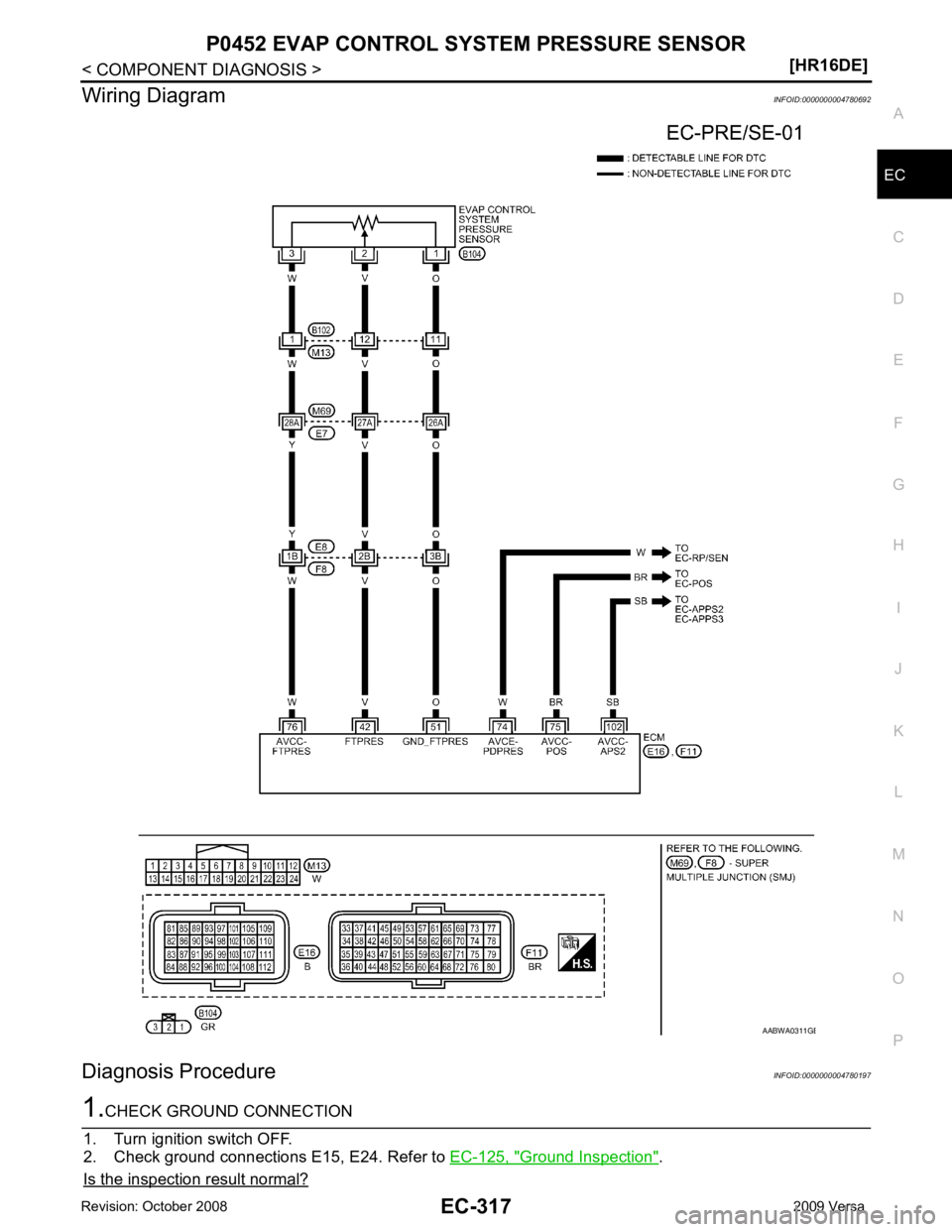

Wiring Diagram

INFOID:0000000004780692

Diagnosis Procedure INFOID:0000000004780197Ground Inspection " .

Is the inspection result normal? B

Page 1674 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-318< COMPONENT DIAGNOSIS >

[HR16DE]

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK CONNECTOR

1. Disconnect EVAP control system pressur NISSAN LATIO 2009 Service Repair Manual EC-318< COMPONENT DIAGNOSIS >

[HR16DE]

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK CONNECTOR

1. Disconnect EVAP control system pressur](/img/5/57359/w960_57359-1673.png)

EC-318< COMPONENT DIAGNOSIS >

[HR16DE]

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check sensor harness connector for water.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness connector. 3.

CHECK EVAP CONTROL SYST EM PRESSURE SENSOR POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check the voltage between EVAP control system pressure sen- sor harness connector and ground.

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 4. 4.

CHECK EVAP CONTROL SYST EM PRESSURE SENSOR POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EVAP control system pressure sensor harness connector and ECM har-

ness connector.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5. 5.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors B102, M13

• Harness connectors M69, E7

• Harness connectors E8, F8

• Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors. 6.

CHECK SENSOR POWER SUPPLY CIRCUIT

Check harness for short to power and short to ground, between the following terminals. Water should not exist.

EVAP control system pressure sensor Ground Voltage

Connector Terminal

B104 3 Ground Approx. 5 V PBIB0138E

EVAP control system pressure sensor ECM

Continuity

Connector Terminal Connector Terminal

B104 3 F11 76 Existed

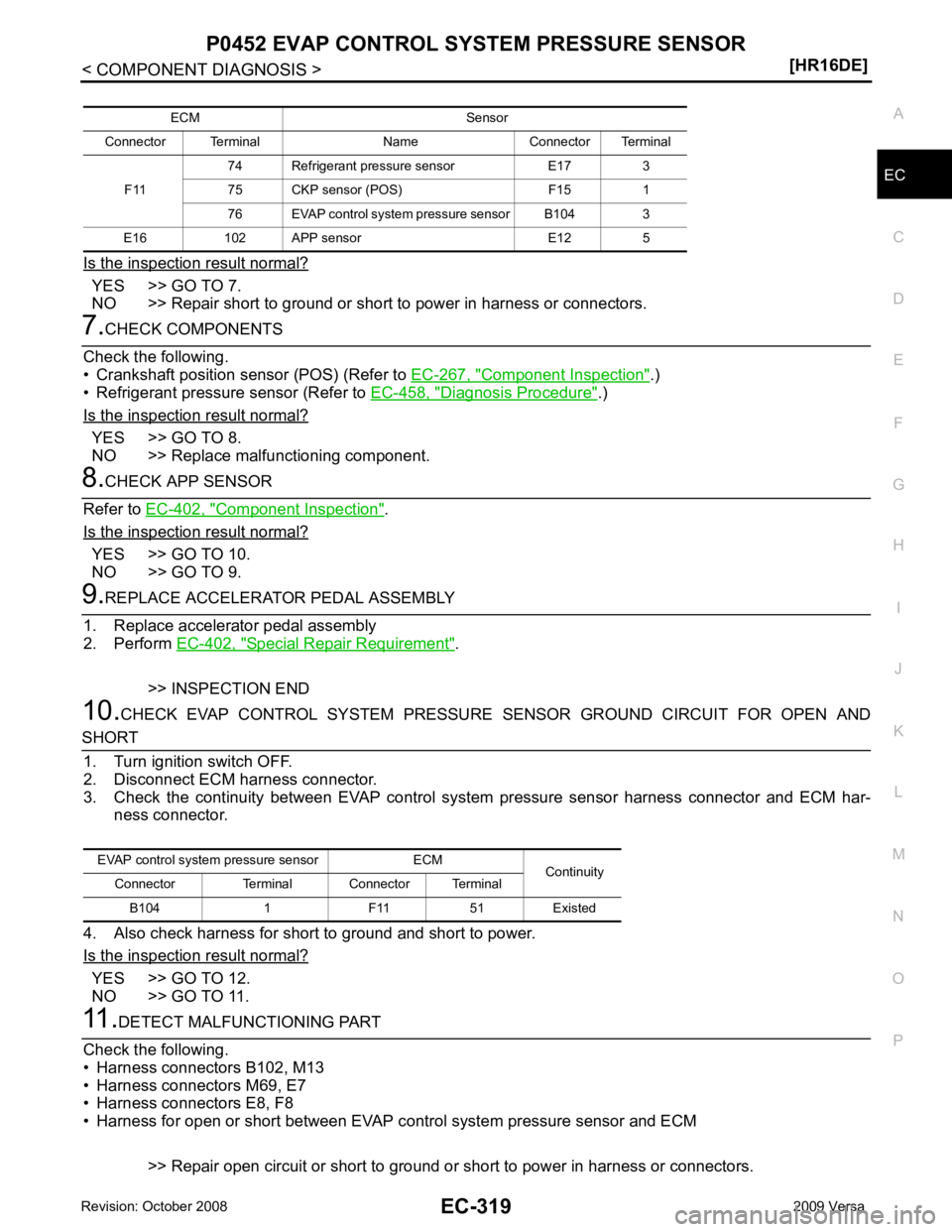

Page 1675 of 4331

EC

NP

O

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair short to ground or short to power in harness or connectors. Component Inspection " .)

• Refrigerant pressure sensor (Refer to EC-458, " Diagnosis Procedure " .)

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace malfunctioning component. Component Inspection " .

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 9. Special Repair Requirement " .

>> INSPECTION END

10. CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR GROUND CIRCUIT FOR OPEN ANDYES >> GO TO 12.

NO >> GO TO 11. EVAP control system pressure sensor ECM

Continuity

Connector Terminal Connector Terminal

B104 1 F11 51 Existed

Page 1676 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-320< COMPONENT DIAGNOSIS >

[HR16DE]

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

12. CHECK EVAP CONTROL SYSTEM PRESSURE SEN SOR INPUT SIGNAL CIRCUIT FOR OPEN ANDSHORT

1. Check the continuity betwee NISSAN LATIO 2009 Service Repair Manual EC-320< COMPONENT DIAGNOSIS >

[HR16DE]

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

12. CHECK EVAP CONTROL SYSTEM PRESSURE SEN SOR INPUT SIGNAL CIRCUIT FOR OPEN ANDSHORT

1. Check the continuity betwee](/img/5/57359/w960_57359-1675.png)

EC-320< COMPONENT DIAGNOSIS >

[HR16DE]

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

12. CHECK EVAP CONTROL SYSTEM PRESSURE SEN SOR INPUT SIGNAL CIRCUIT FOR OPEN ANDSHORT

1. Check the continuity between EVAP control system pressure sensor harness connector and ECM har- ness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 14.

NO >> GO TO 13. 13.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors B102, M13

• Harness connectors M69, E7

• Harness connectors E8, F8

• Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors. 14.

CHECK EVAP CONTROL SYS TEM PRESSURE SENSOR

Refer to EC-320, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 15.

NO >> Replace EVAP control system pressure sensor. 15.

CHECK INTERMITTENT INCIDENT

Refer to EC-120, " Diagnosis Procedure " .

>> INSPECTION END

Component Inspection INFOID:00000000047804511.

CHECK EVAP CONTROL SY STEM PRESSURE SENSOR

1. Turn ignition switch OFF.

2. Remove EVAP control system pressure sensor wit h its harness connector connected from EVAP canister.

Always replace O-ring with a new one.

3. Install a vacuum pump to EVAP control system pressure sensor.

4. Turn ignition switch ON and check output voltage between ECM harness connector and ground under the following conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

• Do not apply below -93.3 kPa (-0.952 kg/cm 2

, -13.53 psi) or pressure over 101.3 kPa (1.033 kg/

cm 2

, 14.69 psi).

Is the inspection result normal? EVAP control system pressure sensor ECM

Continuity

Connector Terminal Connector Terminal

B104 2 F11 42 Existed ECM Condition

[Applied vacuum kPa

(kg/cm 2

, psi) Voltage

Connector Terminal

F11 42

(EVAP control system

pressure sensor signal) Not applied 1.8 - 4.8 V

-26.7 (-0.272, -3.87) 2.1 to 2.5 V lower

than above value PBIB3314E

Page 1677 of 4331

EC

NP

O

YES >> INSPECTION END

NO >> Replace EVAP control system pressure sensor

Page 1678 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-322< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

Description INFOID:0000000004780199

The EVAP control system pressure s e NISSAN LATIO 2009 Service Repair Manual EC-322< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

Description INFOID:0000000004780199

The EVAP control system pressure s e](/img/5/57359/w960_57359-1677.png)

EC-322< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

Description INFOID:0000000004780199

The EVAP control system pressure s ensor detects pressure in the

purge line. The sensor output voltage to the ECM increases as pres-

sure increases.

DTC Logic INFOID:0000000004780200

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Always perform test at a temperature of 5 °C (41 °F) or more.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Select “DATA MONITOR” mode with CONSULT-III.

5. Make sure that “FUEL T/TMP SE” indication is more than 0°C (32 °F).

6. Start engine and wait at least 20 seconds.

7. Check 1st trip DTC.

With GST

1. Start engine and warm it up to normal operating temperature. PBIB3370E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0453 EVAP control system pres-

sure sensor high input An excessively high voltage from the sensor

is sent to ECM. • Harness or connectors

(EVAP control system pressure sensor

circuit is open or shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.]

(Accelerator pedal circuit is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

• EVAP control system pressure sensor

• Crankshaft position sensor (POS)

• Accelerator pedal position sensor

• Refrigerant pressure sensor

• EVAP canister vent control valve

• EVAP canister

• Rubber hose from EVAP canister vent control valve to vehicle frame

Page 1679 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-323

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Set voltmeter probes to ECM harness connector and ground as

per the following.

3. NISSAN LATIO 2009 Service Repair Manual P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-323

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Set voltmeter probes to ECM harness connector and ground as

per the following.

3.](/img/5/57359/w960_57359-1678.png)

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-323

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

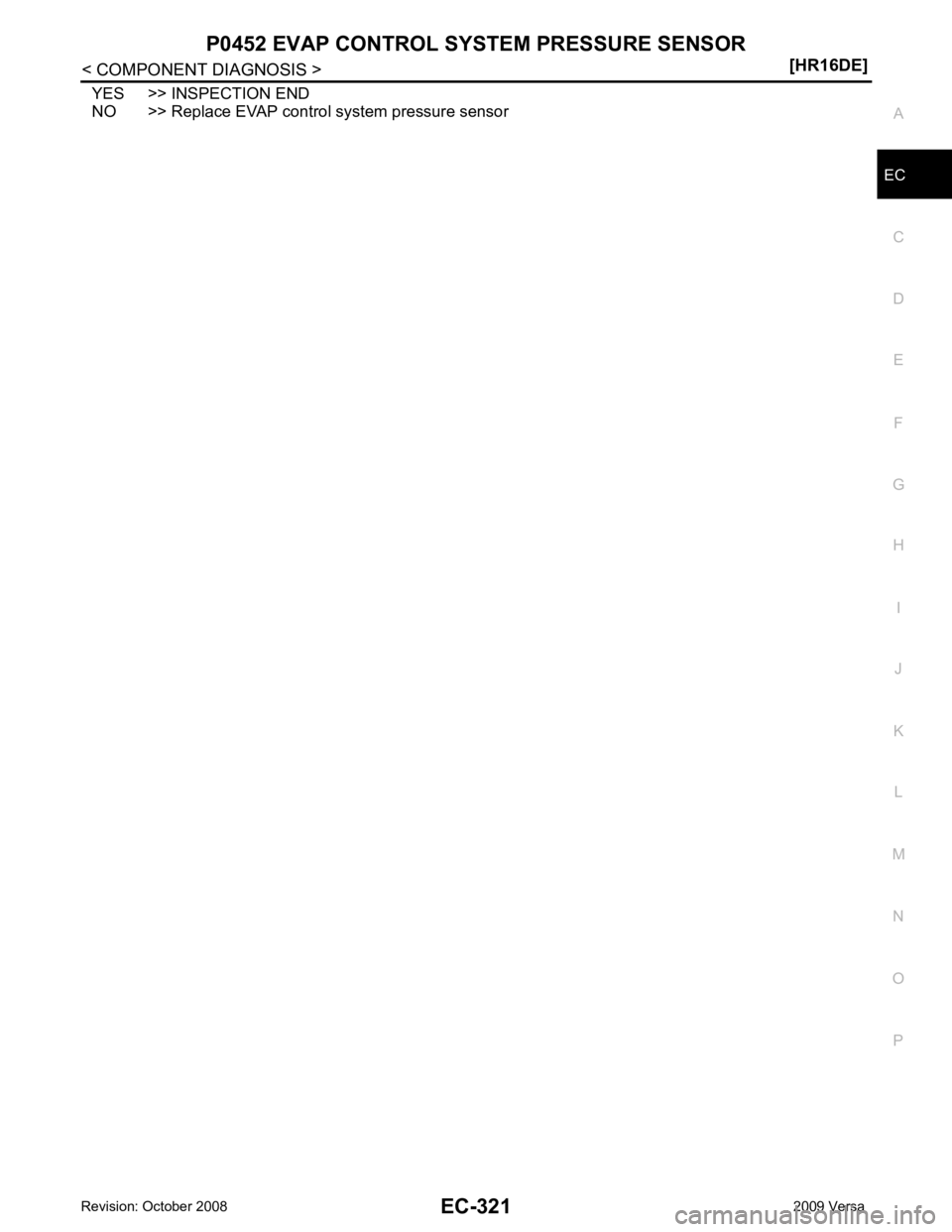

2. Set voltmeter probes to ECM harness connector and ground as

per the following.

3. Make sure that the voltage is less than 4.2 V.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and wait at least 20 seconds.

6. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to

EC-324, " Diagnosis Procedure " .

NO >> INSPECTION END ECM

Ground

Connector Terminal

F11 43

(Fuel tank temperature sensor signal) Ground SEF113U

Page 1680 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-324< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

Wiring Diagram INFOID:0000000004780721

Diagnosis Procedure INFOID:00000000047802011.

CHECK GROUND CONNECTION

1. Turn ig NISSAN LATIO 2009 Service Repair Manual EC-324< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

Wiring Diagram INFOID:0000000004780721

Diagnosis Procedure INFOID:00000000047802011.

CHECK GROUND CONNECTION

1. Turn ig](/img/5/57359/w960_57359-1679.png)

EC-324< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

Wiring Diagram INFOID:0000000004780721

Diagnosis Procedure INFOID:00000000047802011.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connections E15, E24. Refer to EC-125, " Ground Inspection " .

Is the inspection result normal? AABWA0311G B