sensor NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 1609 of 4331

EC

NP

O

P0300, P0301, P0302, P0303, P0304 MISFIRE

DTC Logic INFOID:0000000004780152

DTC DETECTION LOGIC When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary , ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage) On the 1st trip , when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration) For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

light when the misfire is detected on a second trip. Du ring this condition, the ECM monitors the CKP sen-

sor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC CONFIRMATION PROCEDURE YES >> Go to

EC-254, " Diagnosis Procedure " .

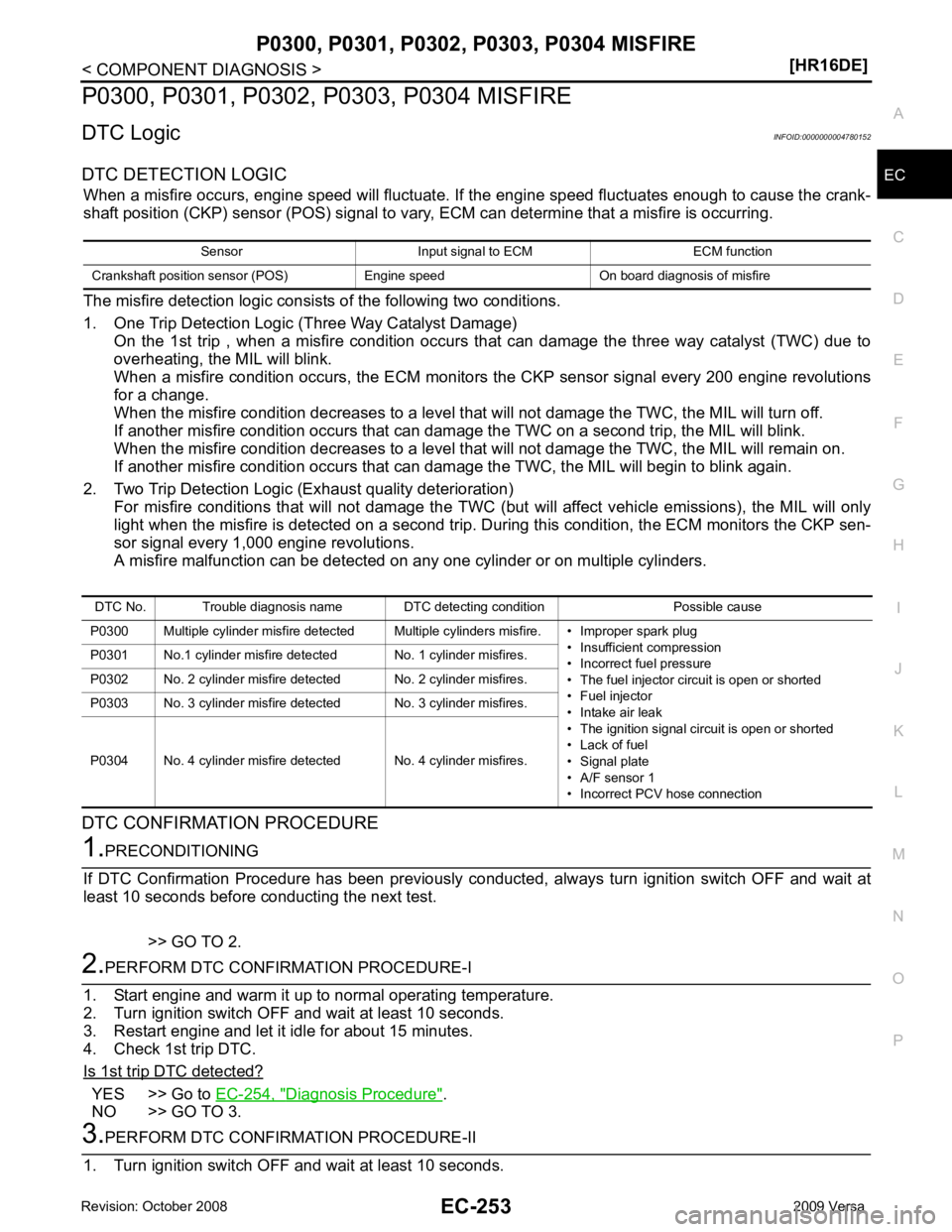

NO >> GO TO 3. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300 Multiple cylinder misfire detected Multiple cylinders misfire. • Improper spark plug • Insufficient compression

• Incorrect fuel pressure

• The fuel injector circuit is open or shorted

• Fuel injector

• Intake air leak

• The ignition signal circuit is open or shorted

• Lack of fuel

• Signal plate

• A/F sensor 1

• Incorrect PCV hose connection

P0301 No.1 cylinder misfire detected No. 1 cylinder misfires.

P0302 No. 2 cylinder misfire detected No. 2 cylinder misfires.

P0303 No. 3 cylinder misfire detected No. 3 cylinder misfires.

P0304 No. 4 cylinder misfire detected No. 4 cylinder misfires.

Page 1613 of 4331

EC

NP

O

5. Check the continuity between A/F sensor 1

harness connector and ground, or ECM harness connector

and ground.

6. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 14.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. Component Inspection " .

Is the inspection result normal? YES >> GO TO 15.

NO >> Replace A/F sensor 1. Mass Air Flow Sensor " .

With GST

Check mass air flow sensor signal in Service $01 with GST.

For specification, refer to EC-504, " Mass Air Flow Sensor " .

Is the measurement value within the specification?YES >> GO TO 16.

NO >> Check connectors for rusted terminals or loose c onnections in the mass air flow sensor circuit or

ground. Refer to EC-148, " DTC Logic " .

Symptom Table " .

Is the inspection result normal? YES >> GO TO 17.

NO >> Repair or replace. Diagnosis Description " .

>> GO TO 18.

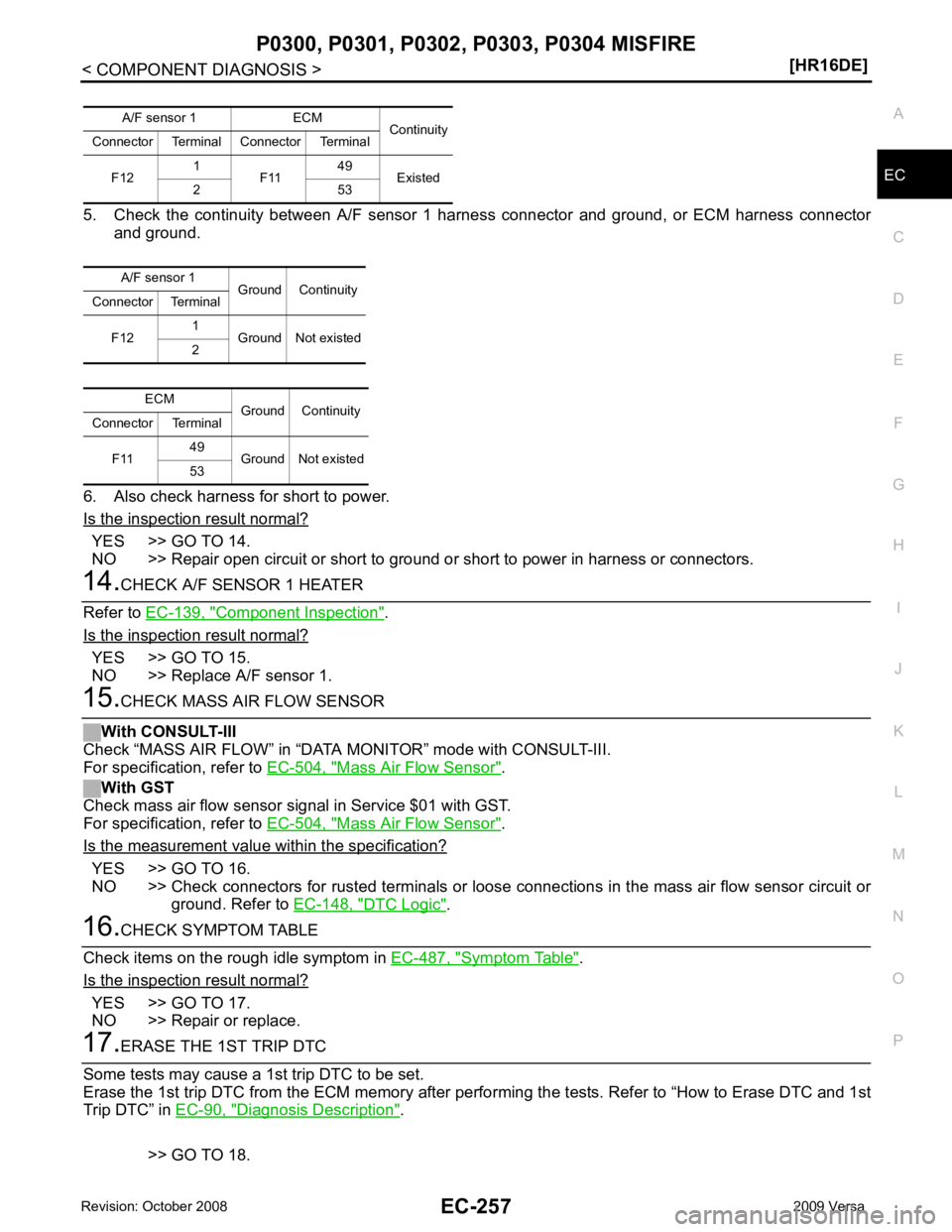

A/F sensor 1 ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

2 53

A/F sensor 1 Ground Continuity

Connector Terminal

F12 1

Ground Not existed

2

ECM Ground Continuity

Connector Terminal

F11 49

Ground Not existed

53

Page 1615 of 4331

EC

NP

O

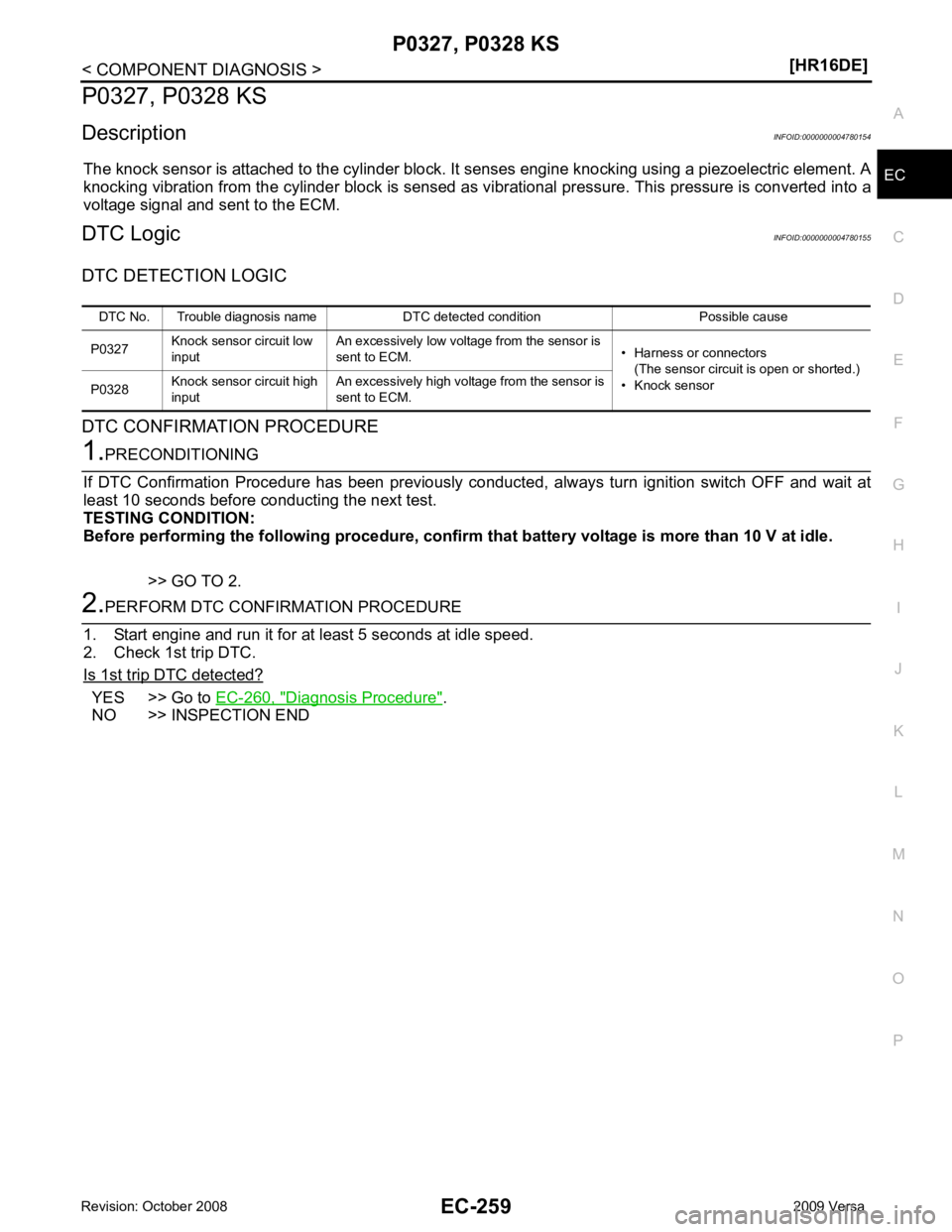

P0327, P0328 KS

Description INFOID:0000000004780154

The knock sensor is attached to the cylinder block. It senses engine knocking using a piezoelectric element. A

knocking vibration from the cylinder blo ck is sensed as vibrational pressure. This pressure is converted into a

voltage signal and sent to the ECM.

DTC Logic INFOID:0000000004780155

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE YES >> Go to

EC-260, " Diagnosis Procedure " .

NO >> INSPECTION END DTC No. Trouble diagnosis name DTC detected condition Possible cause

P0327 Knock sensor circuit low

input An excessively low voltage from the sensor is

sent to ECM. • Harness or connectors

(The sensor circuit is open or shorted.)

• Knock sensor

P0328 Knock sensor circuit high

input An excessively high voltage from the sensor is

sent to ECM.

Page 1617 of 4331

EC

NP

O

YES >> GO TO 2.

NO >> Repair or replace ground connection. YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. Component Inspection " .

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace knock sensor. Diagnosis Procedure " .

>> INSPECTION END

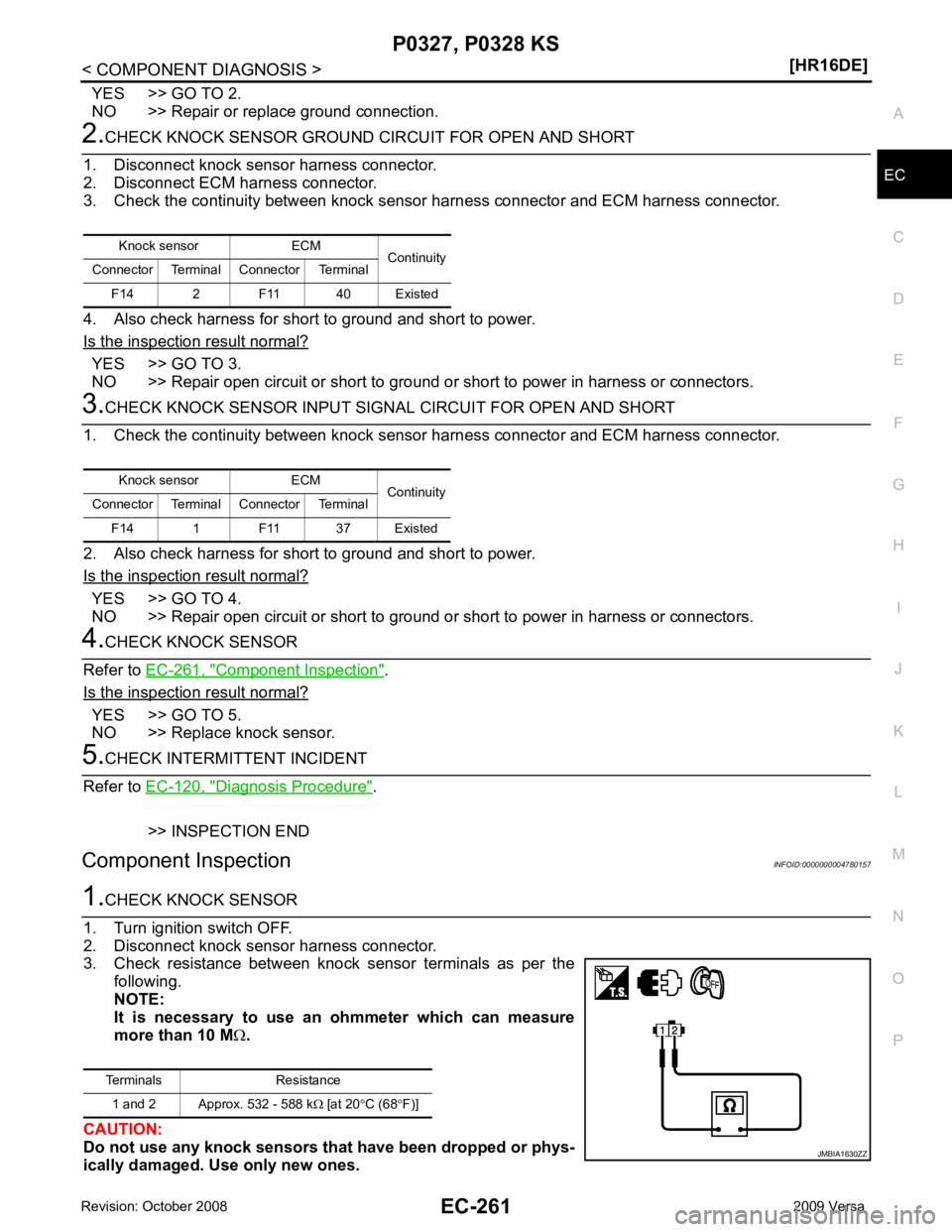

Component Inspection INFOID:0000000004780157Knock sensor ECM

Continuity

Connector Terminal Connector Terminal

F14 1 F11 37 Existed Terminals Resistance

1 and 2 Approx. 532 - 588 k Ω [at 20 °C (68 °F)]

Page 1618 of 4331

YES >> INSPECTION END

NO >> Replace knock sensor.

Page 1619 of 4331

EC

NP

O

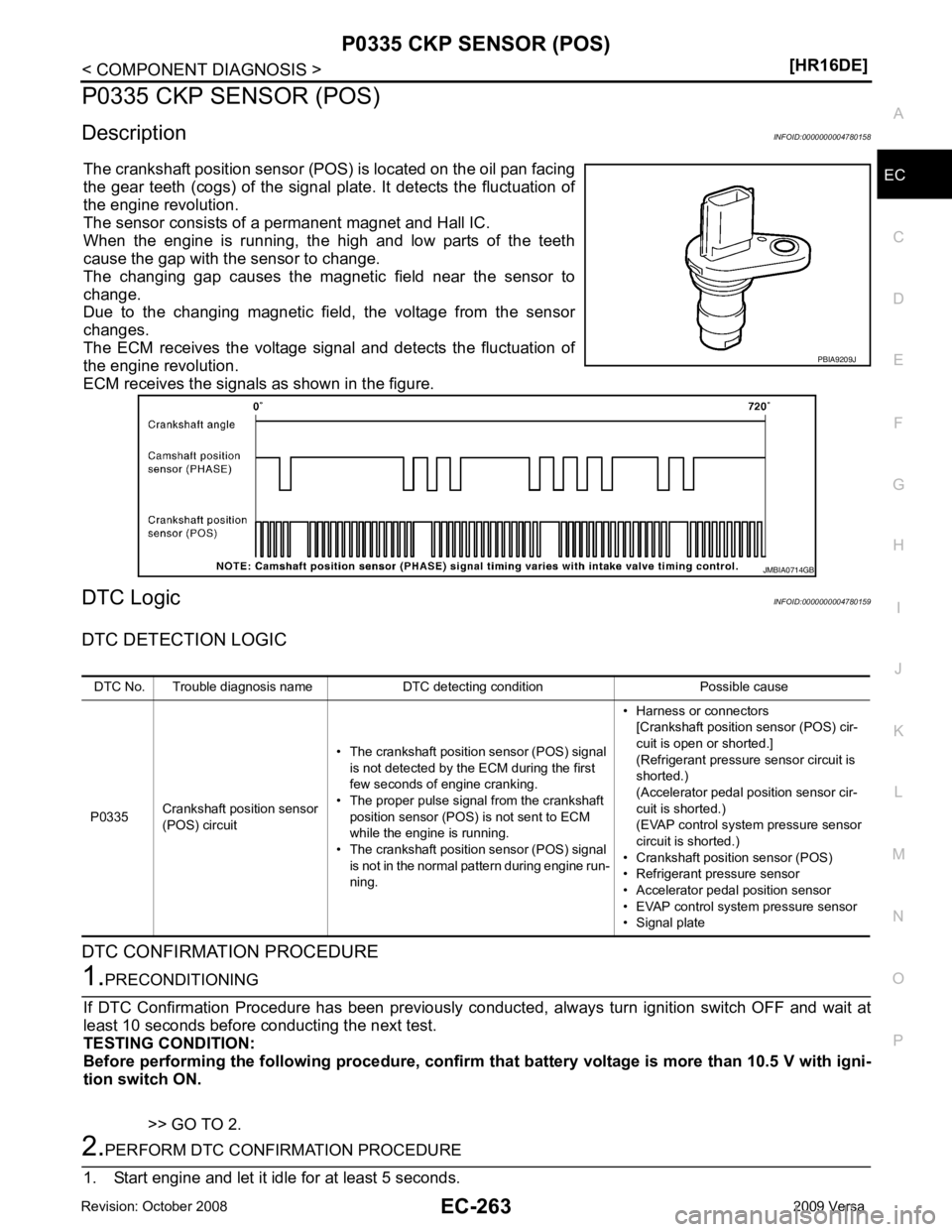

P0335 CKP SENSOR (POS)

Description INFOID:0000000004780158

The crankshaft position sensor (POS ) is located on the oil pan facing

the gear teeth (cogs) of the signal pl ate. It detects the fluctuation of

the engine revolution.

The sensor consists of a permanent magnet and Hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnet ic field near the sensor to

change.

Due to the changing magnetic fiel d, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

the engine revolution.

ECM receives the signals as shown in the figure.

DTC Logic INFOID:0000000004780159

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

Page 1621 of 4331

EC

NP

O

Diagnosis Procedure

INFOID:0000000004780160Ground Inspection " .

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection. YES >> GO TO 8.

NO >> GO TO 3. YES >> GO TO 4.

NO >> Repair open circuit. YES >> GO TO 5.

NO >> Repair short to ground or short to power in harness or connectors. Diagnosis Procedure " .)

• EVAP control system pressure sensor (Refer to EC-314, " Component Inspection " .)

Is the inspection result normal? ECM Sensor

Connector Terminal Name Connector Terminal

F11 74 Refrigerant pressure sensor E17 3

75 CKP sensor (POS) F15 1

76 EVAP control system pressure sensor B104 3

E16 102 APP sensor E12 5

Page 1622 of 4331

Component Inspection " .

Is the inspection result normal? YES >> GO TO 12.

NO >> GO TO 7. Special Repair Requirement " .

>> INSPECTION END YES >> GO TO 9.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. YES >> GO TO 10.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. Component Inspection " .

Is the inspection result normal? YES >> GO TO 11.

NO >> Replace crankshaft position sensor (POS). YES >> GO TO 12.

NO >> Replace the signal plate. Diagnosis Procedure " .

CKP sensor (POS) ECM

Continuity

Connector Terminal Connector Terminal

F15 2 F11 62 Existed CKP sensor (POS) ECM

Continuity

Connector Terminal Connector Terminal

F15 3 F11 61 Existed

Page 1623 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0335 CKP SENSOR (POS)

EC-267

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

>> INSPECTION END

Component Inspection INFOID:00000000047801611.

CHECK CRANKSHAFT POSI TION SENSOR (POS)- NISSAN LATIO 2009 Service Repair Manual P0335 CKP SENSOR (POS)

EC-267

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

>> INSPECTION END

Component Inspection INFOID:00000000047801611.

CHECK CRANKSHAFT POSI TION SENSOR (POS)-](/img/5/57359/w960_57359-1622.png)

P0335 CKP SENSOR (POS)

EC-267

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

>> INSPECTION END

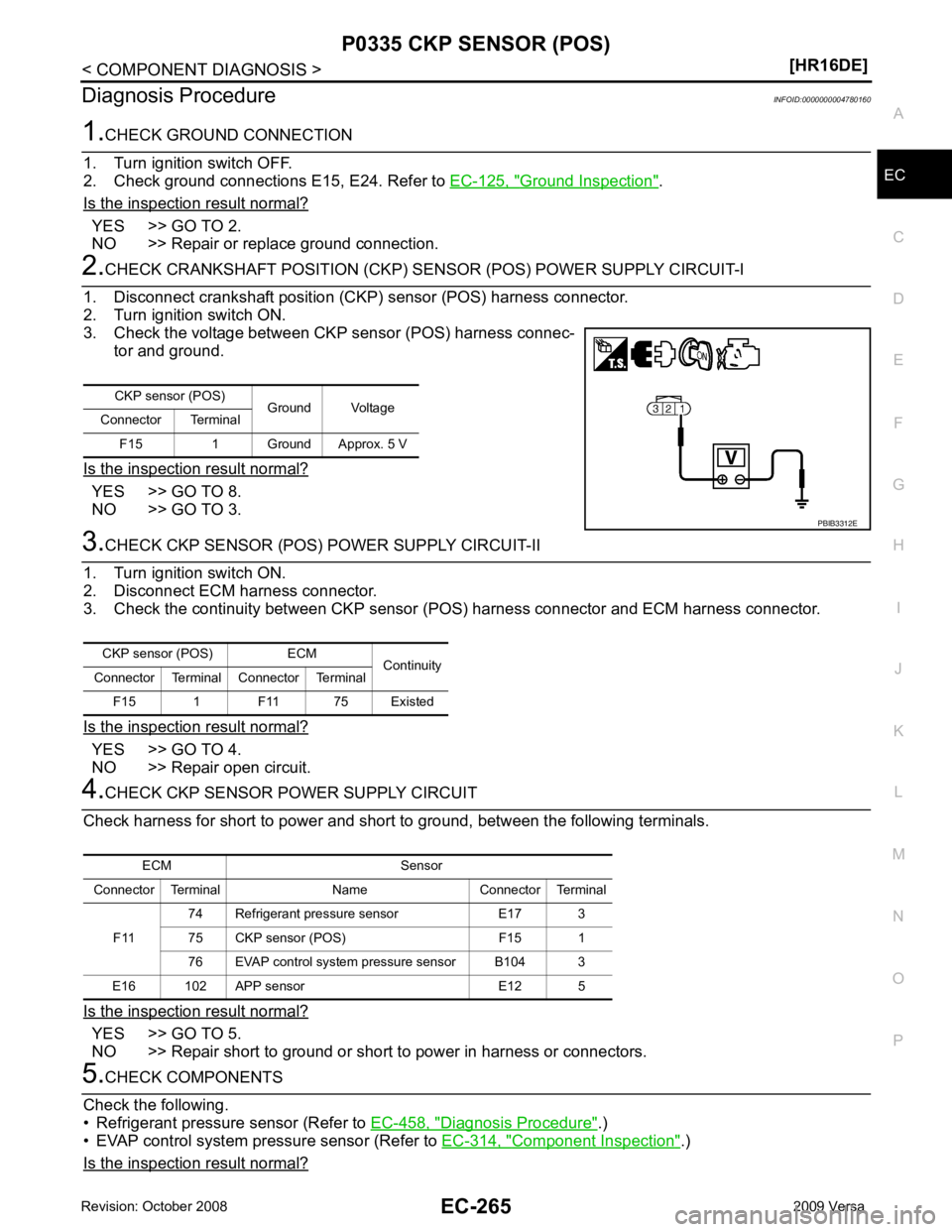

Component Inspection INFOID:00000000047801611.

CHECK CRANKSHAFT POSI TION SENSOR (POS)-I

1. Turn ignition switch OFF.

2. Loosen the fixing bolt of the sensor.

3. Disconnect crankshaft position sensor (POS) harness connector.

4. Remove the sensor.

5. Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace crankshaft position sensor (POS). 2.

CHECK CRANKSHAFT POSITI ON SENSOR (POS)-II

Check resistance between crankshaft position sensor (POS) termi-

nals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace crankshaft position sensor (POS). PBIA9209J

Terminals (Polarity) Resistance [

Ω at 25 °C (77 °F)]

1 (+) - 2 (-) Except 0 or ∞

1 (+) - 3 (-)

2 (+) - 3 (-) PBIA9584J

Page 1624 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-268< COMPONENT DIAGNOSIS >

[HR16DE]

P0340 CMP SENSOR (PHASE)

P0340 CMP SENSOR (PHASE)

Description INFOID:0000000004780162

The camshaft position sensor (P HASE) senses the retraction of

cams NISSAN LATIO 2009 Service Repair Manual EC-268< COMPONENT DIAGNOSIS >

[HR16DE]

P0340 CMP SENSOR (PHASE)

P0340 CMP SENSOR (PHASE)

Description INFOID:0000000004780162

The camshaft position sensor (P HASE) senses the retraction of

cams](/img/5/57359/w960_57359-1623.png)

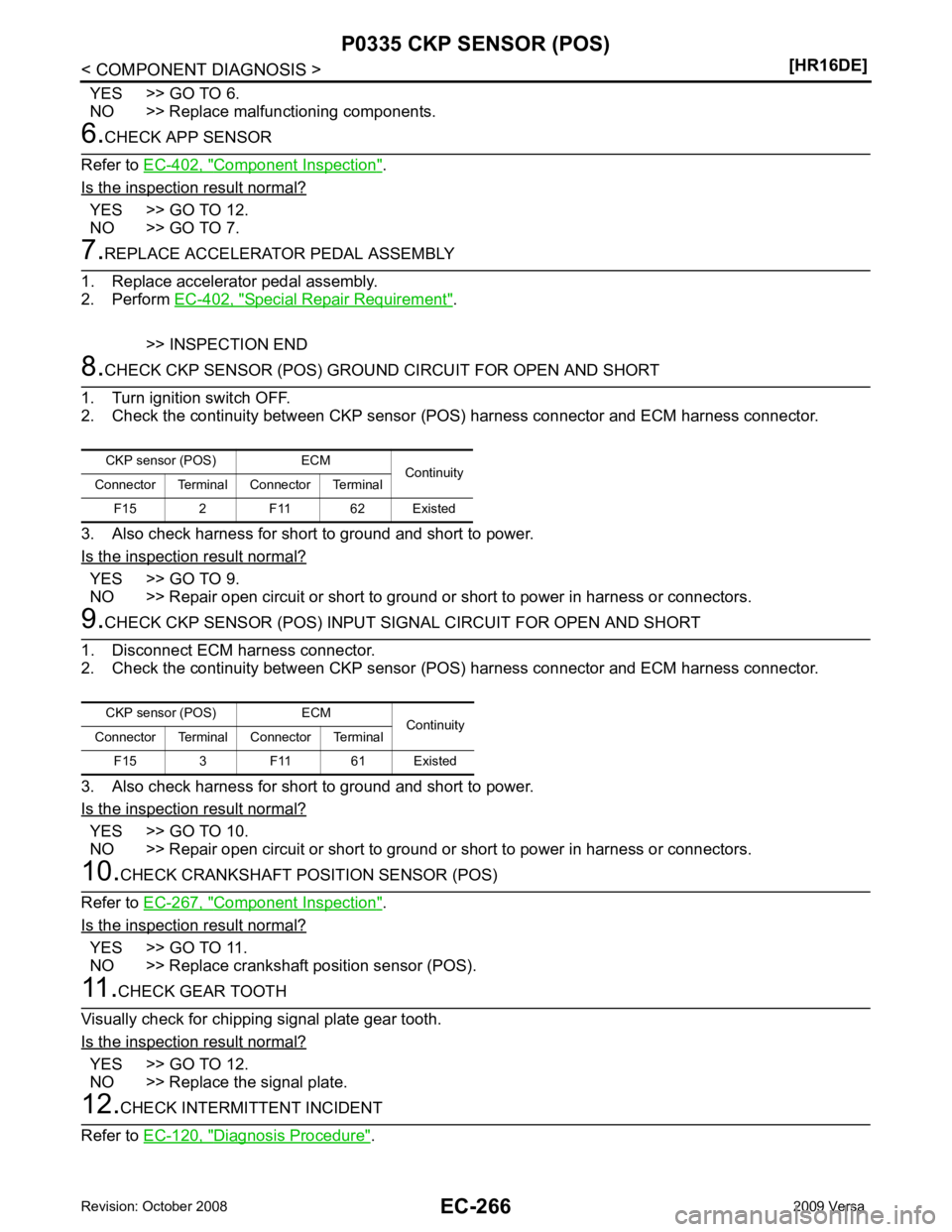

EC-268< COMPONENT DIAGNOSIS >

[HR16DE]

P0340 CMP SENSOR (PHASE)

P0340 CMP SENSOR (PHASE)

Description INFOID:0000000004780162

The camshaft position sensor (P HASE) senses the retraction of

camshaft (INT) to identify a particular cylinder. The camshaft position

sensor (PHASE) senses the piston position.

When the crankshaft position sensor (POS) system becomes inoper-

ative, the camshaft position sensor (PHASE) provides various con-

trols of engine parts instead, utilizing timing of cylinder identification

signals.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause

the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor changes.

ECM receives the signals as shown in the figure.

DTC Logic INFOID:0000000004780163

DTC DETECTION LOGIC

NOTE:

If DTC P0340 is displayed with DTC P0643, first pe rform the trouble diagnosis for DTC P0643. Refer to

EC-358, " DTC Logic " .

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V with igni-

tion switch ON.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE-I

1. Start engine and let it idle for at least 5 seconds. If engine does not start, crank engine for at least 2 seconds.

2. Check 1st trip DTC. PBIA9875J

JMBIA0714GB

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0340 Camshaft position sensor

(PHASE) circuit • The cylinder No. signal is not sent to ECM for

the first few seconds during engine cranking.

• The cylinder No. signal is not sent to ECM during engine running.

• The cylinder No. signal is not in the normal pattern during engine running. • Harness or connectors

(The sensor circuit is open or shorted)

• Camshaft position sensor (PHASE)

• Camshaft (INT)

• Starter motor

• Starting system circuit

• Dead (Weak) battery