NISSAN LATIO 2009 Service Repair Manual

LATIO 2009

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57359/w960_57359-0.png

NISSAN LATIO 2009 Service Repair Manual

Trending: key fob battery, fuel pump, windshield wipers, gas type, flat tire, width, height

Page 331 of 4331

SCIA7045E

Output Shaft " .

Standard clearance and allowable limit: Refer to AT-378, " Bearing Retainer " .

Page 332 of 4331

REPAIR FOR COMPONENT PARTS

AT-327

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

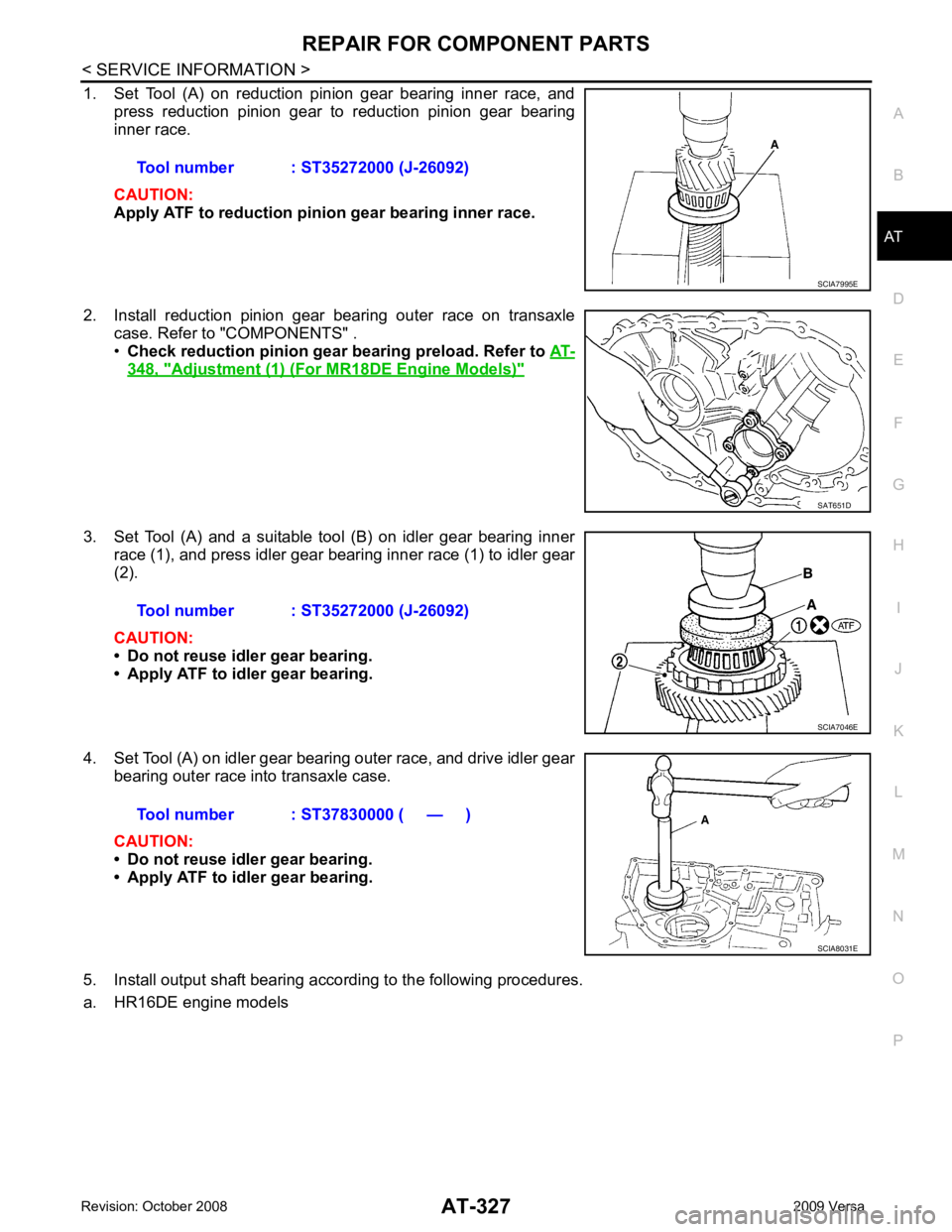

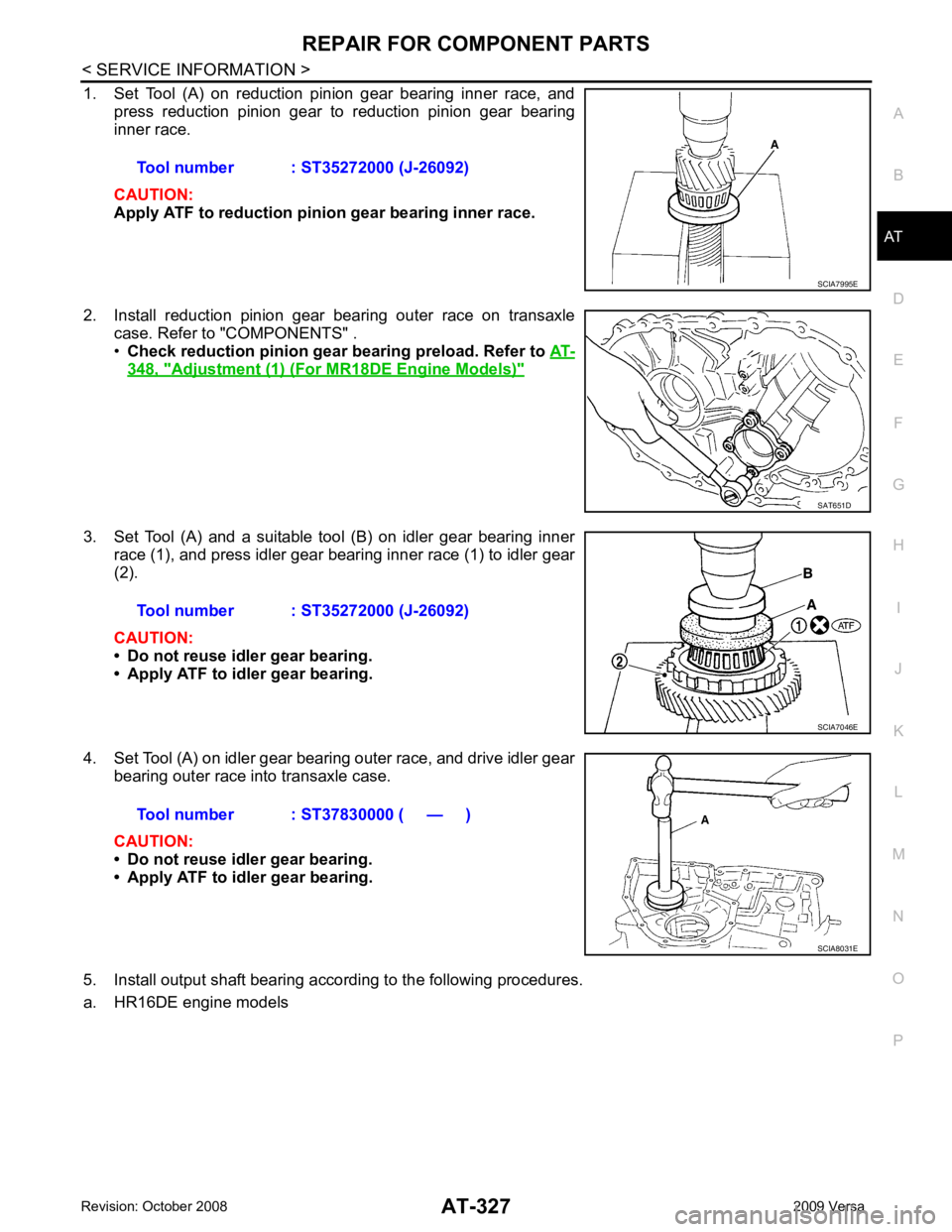

1. Set Tool (A) on reduction pinion gear bearing inner race, and

press reduction pinion gear to reduction pinion gear bearing

inner race.

CAUTION:

Apply ATF to reduction pinion gear bearing inner race.

2. Install reduction pinion gear bearing outer race on transaxle case. Refer to "COMPONENTS" .

• Check reduction pinion gear b earing preload. Refer to AT-348, " Adjustment (1) (For MR18DE Engine Models) "

3. Set Tool (A) and a suitable tool (B) on idler gear bearing inner

race (1), and press idler gear bearing inner race (1) to idler gear

(2).

CAUTION:

• Do not reuse idler gear bearing.

• Apply ATF to idler gear bearing.

4. Set Tool (A) on idler gear bearing outer race, and drive idler gear bearing outer race into transaxle case.

CAUTION:

• Do not reuse idler gear bearing.

• Apply ATF to idler gear bearing.

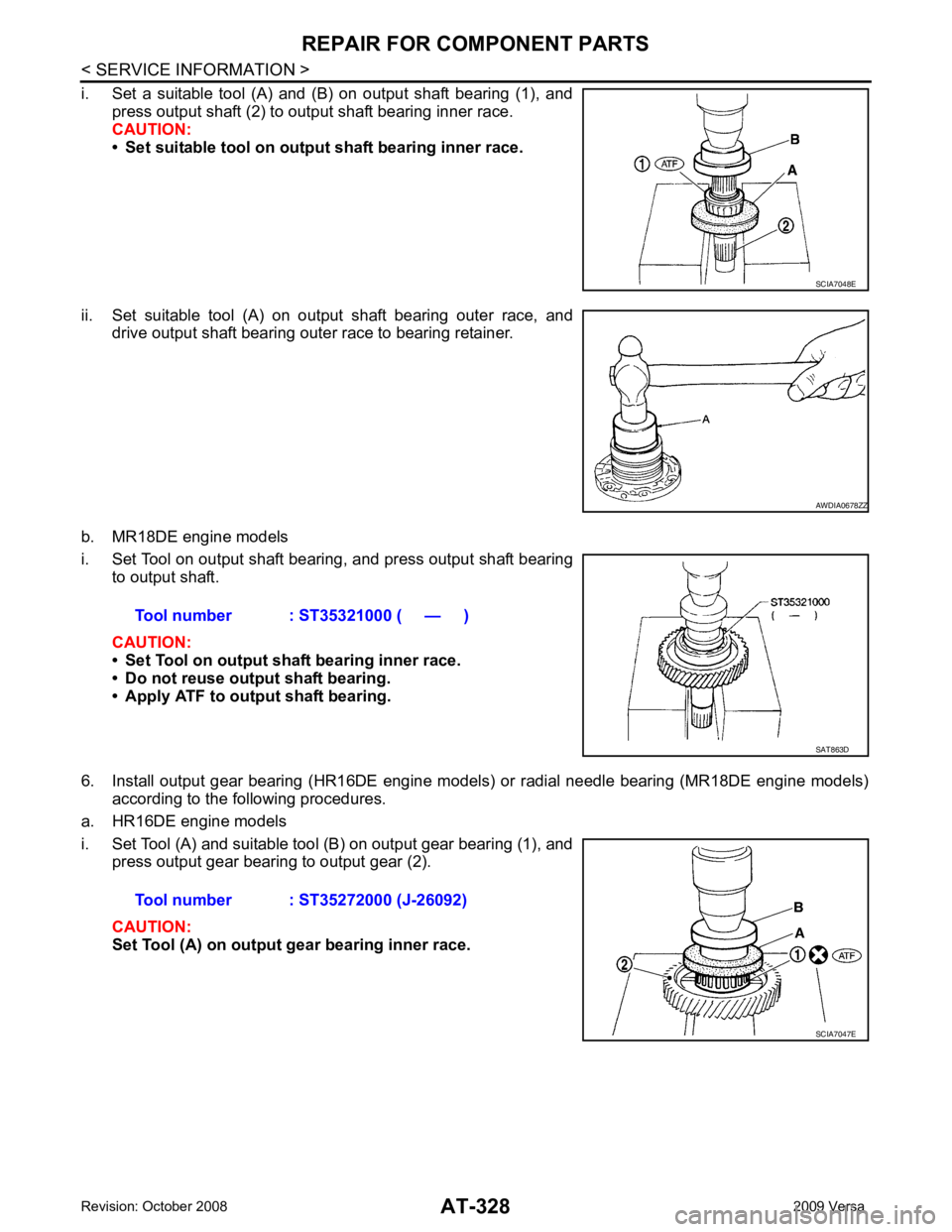

5. Install output shaft bearing according to the following procedures.

a. HR16DE engine models Tool number : ST35272000 (J-26092) SCIA7995E

SAT651D

Tool number : ST35272000 (J-26092)

SCIA7046E

Tool number : ST37830000 ( — )

SCIA8031E

Page 333 of 4331

Page 334 of 4331

AT

N

O P

ii. Set Tool on output gear bearing outer race, and drive output

gear bearing outer race to bearing retainer.

b. MR18DE engine models

i. Set drift [commercial service tool] on radial needle bearing, and press radial needle bearing into bearing retainer.

ii. Install snap ring to bearing retainer using suitable tool.

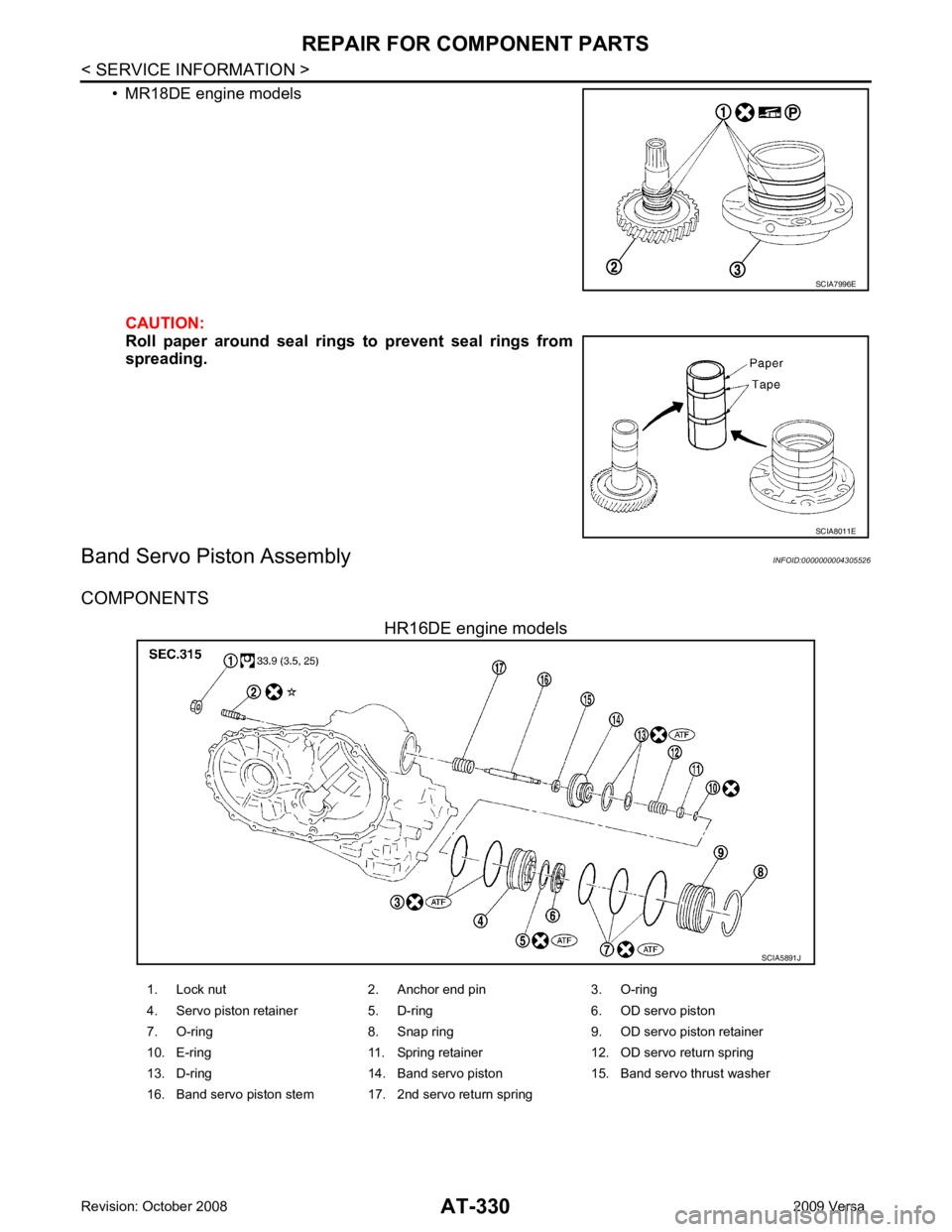

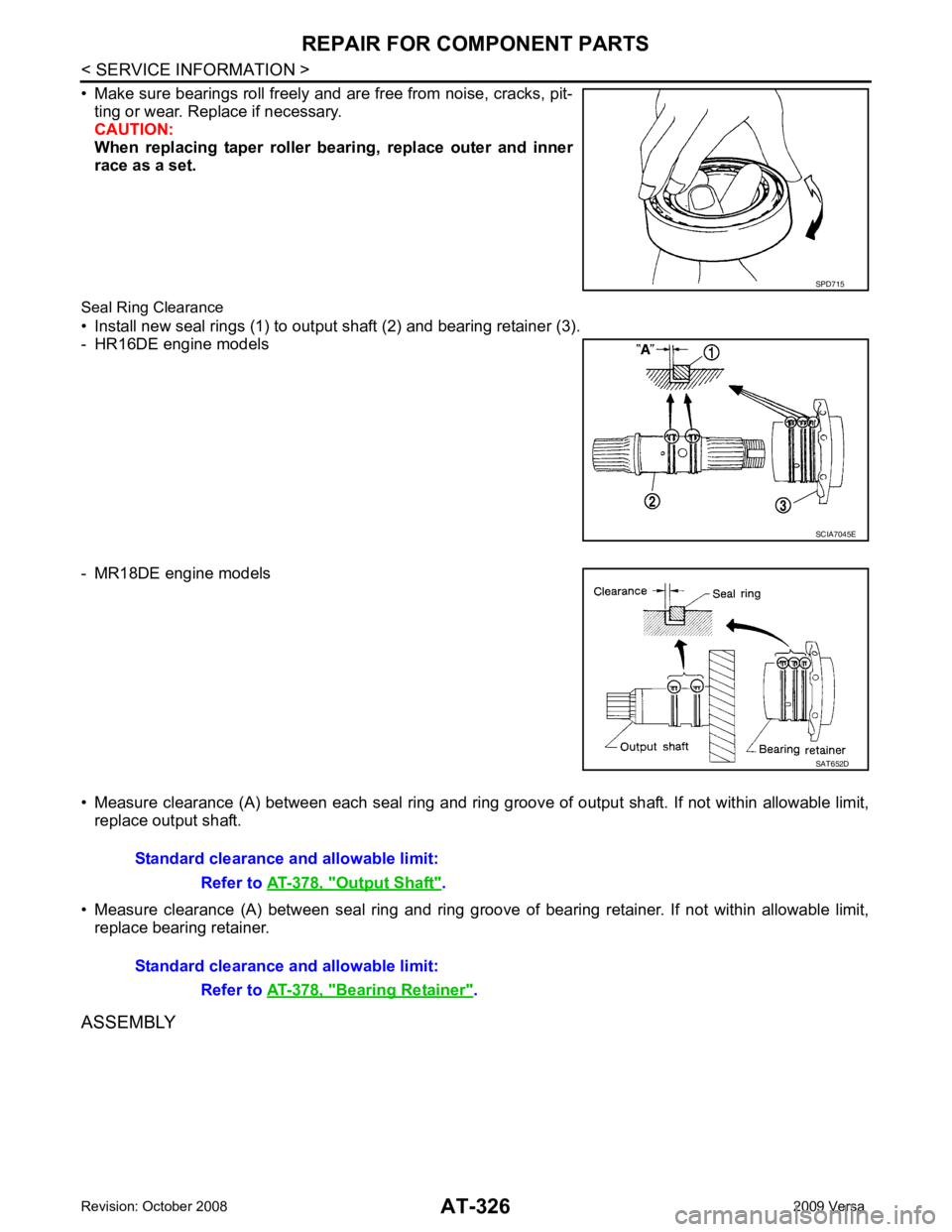

7. After packing ring grooves with petroleum jelly, carefully install new seal rings (1) on output shaft (2) and bearing retainer (3).

• HR16DE engine models Tool number : ST33400001 (J-26082) SAT658D

SAT659D

Page 335 of 4331

Page 336 of 4331

AT

N

O P

MR18DE engine models

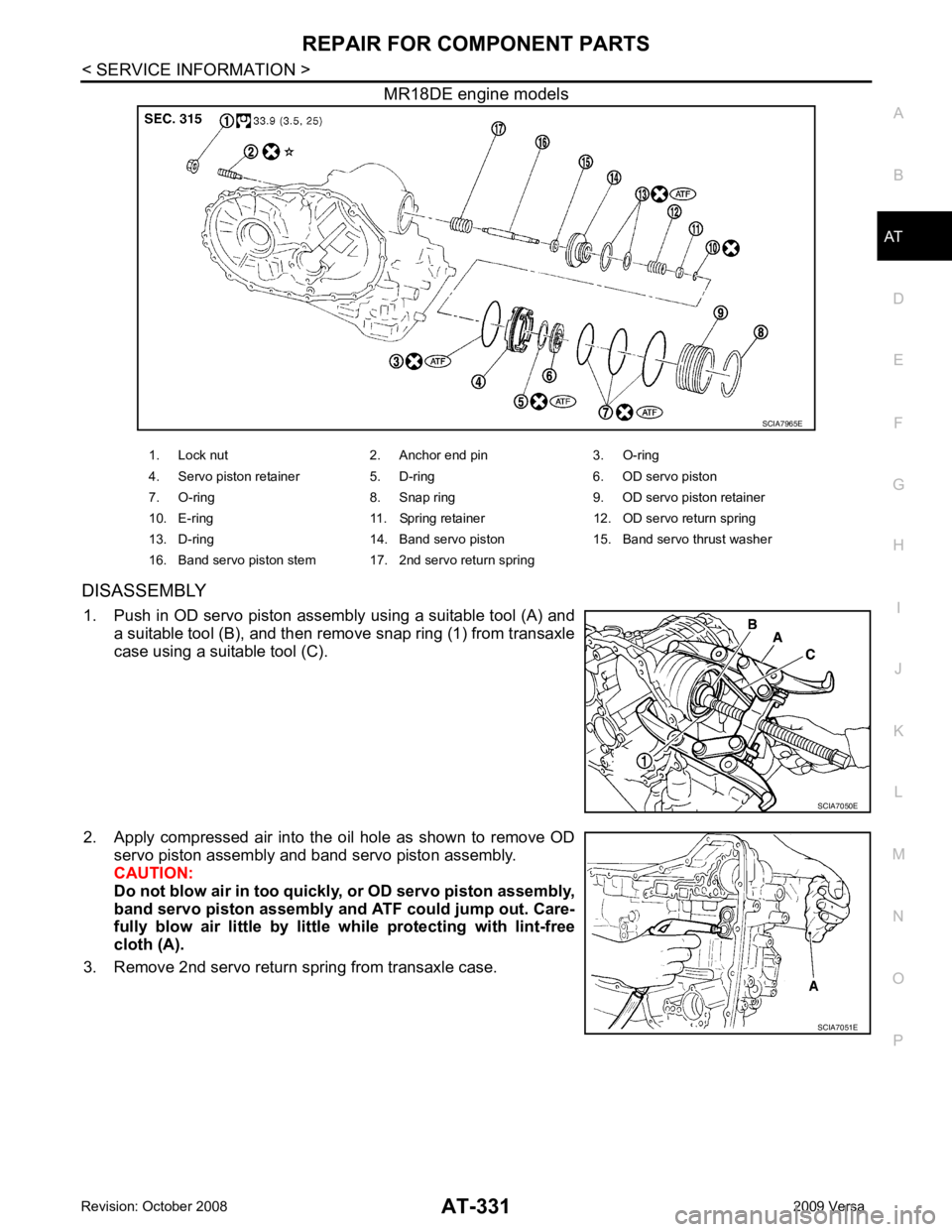

DISASSEMBLY 1. Push in OD servo piston assembly using a suitable tool (A) and a suitable tool (B), and then remove snap ring (1) from transaxle

case using a suitable tool (C).

2. Apply compressed air into the oil hole as shown to remove OD servo piston assembly and band servo piston assembly.

CAUTION:

Do not blow air in too quickl y, or OD servo piston assembly,

band servo piston assembly and ATF could jump out. Care-

fully blow air little by littl e while protecting with lint-free

cloth (A).

3. Remove 2nd servo return spring from transaxle case. SCIA7051E

Page 337 of 4331

SCIA7053E

SCIA6492J

SCIA4336E

Page 338 of 4331

AT

N

O P

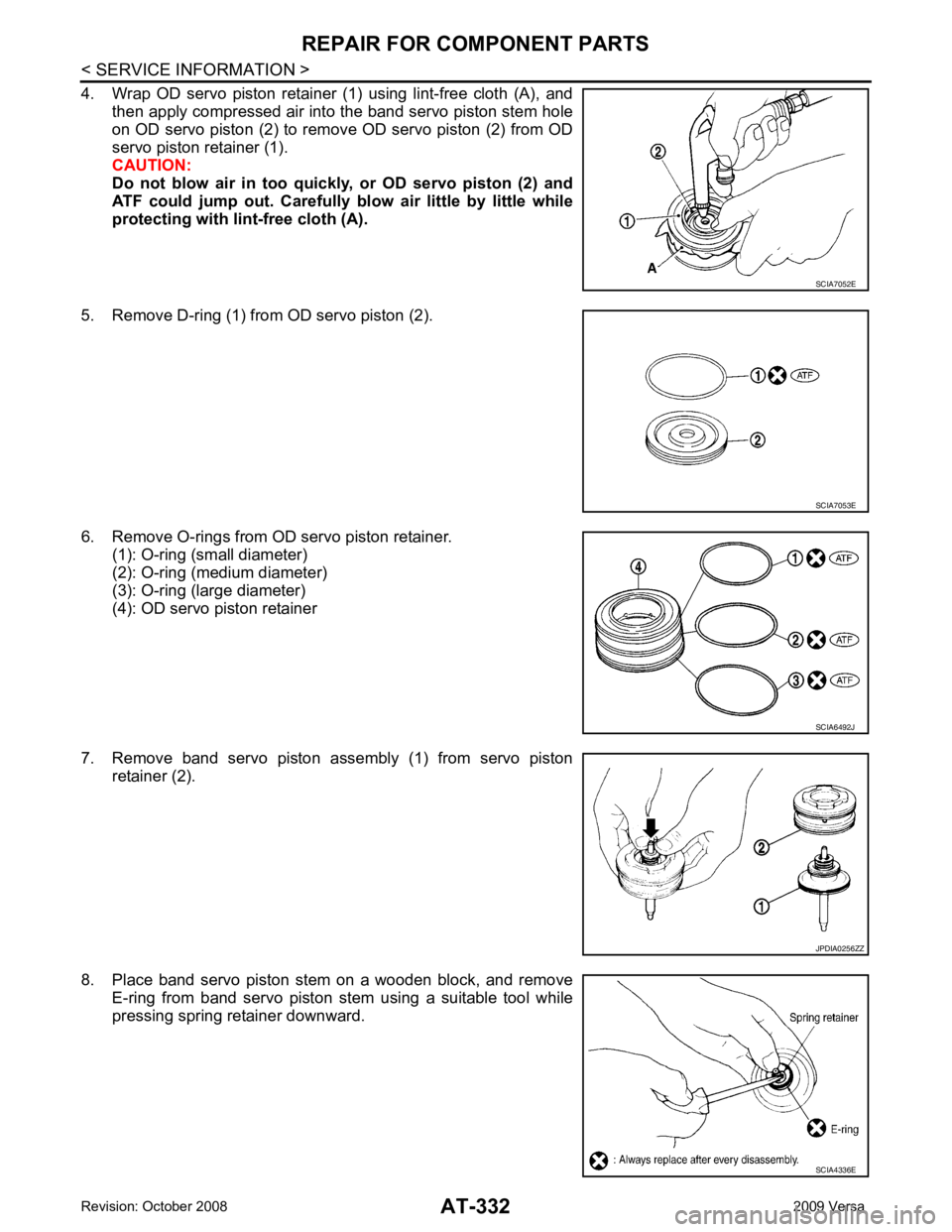

9. Remove spring retainer (1), OD servo return spring (2), band

servo piston (3) and band servo thrust washer (4) from band

servo piston stem (5).

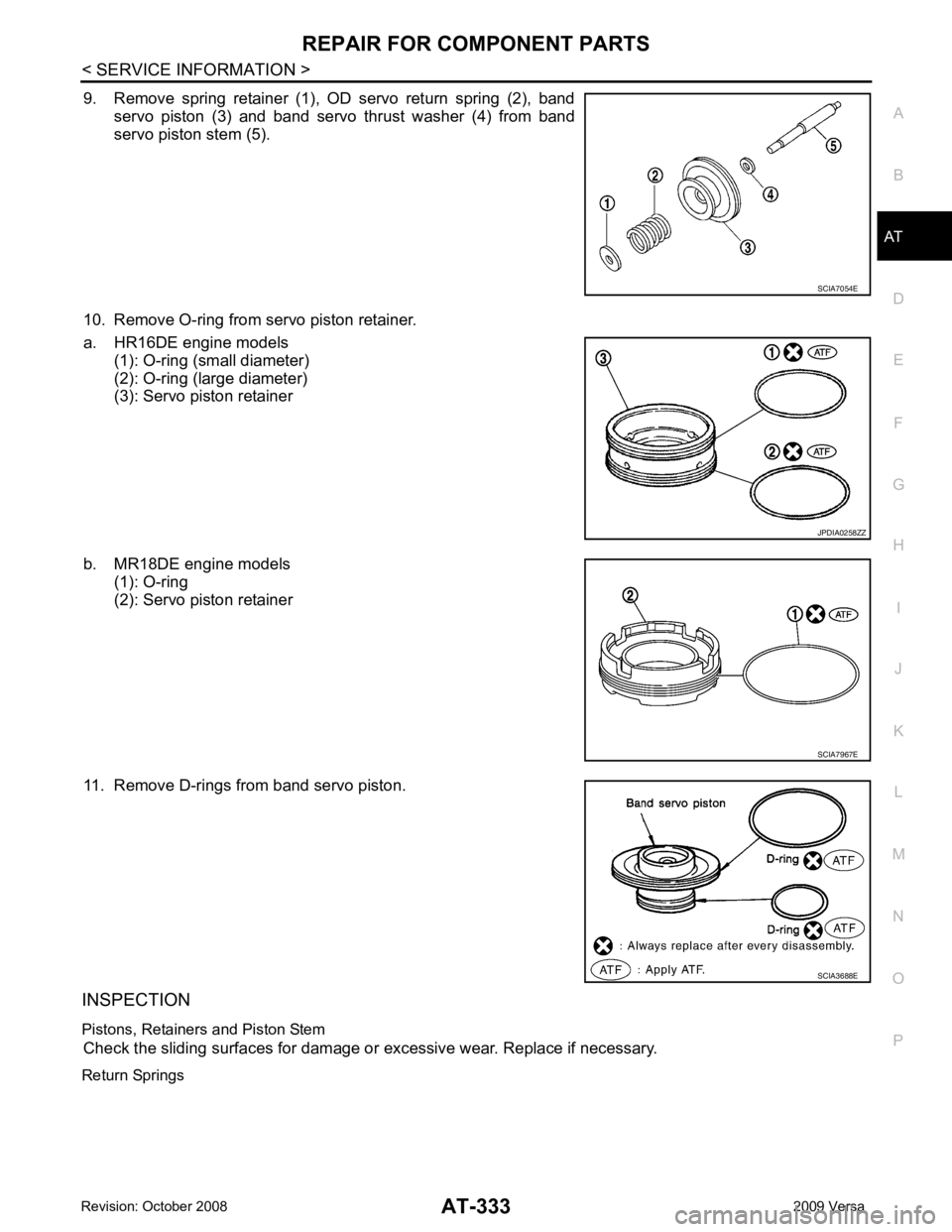

10. Remove O-ring from servo piston retainer.

a. HR16DE engine models (1): O-ring (small diameter)

(2): O-ring (large diameter)

(3): Servo piston retainer

b. MR18DE engine models (1): O-ring

(2): Servo piston retainer

11. Remove D-rings from band servo piston.

INSPECTION

Pistons, Retainers and Piston Stem Check the sliding surfaces for damage or excessive wear. Replace if necessary.

Return Springs JPDIA0258ZZ

SCIA7967E

SCIA3688E

Page 339 of 4331

AT-334< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

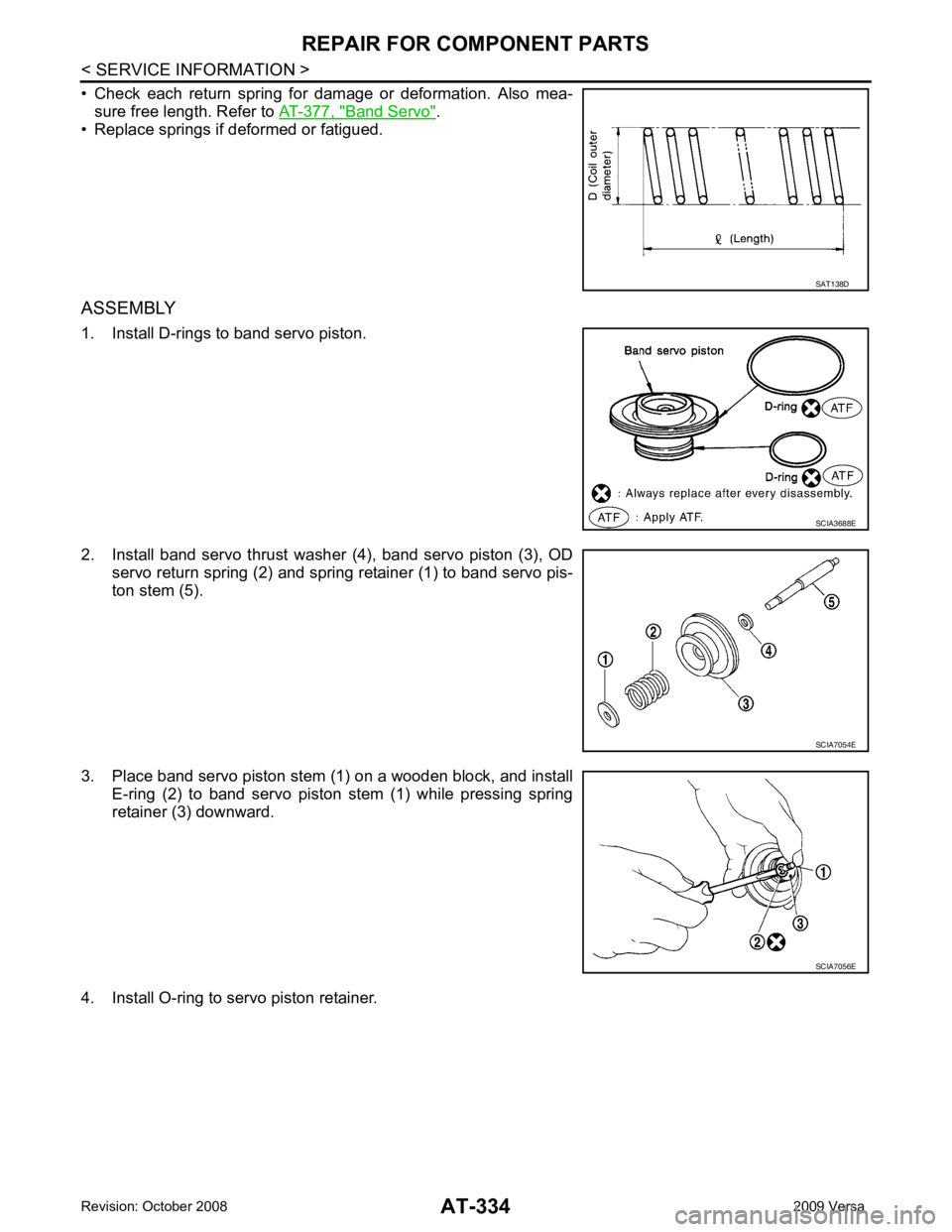

• Check each return spring for damage or deformation. Also mea- sure free length. Refer to AT-377, " Band Servo " .

• Replace springs if deformed or fatigued.

ASSEMBLY

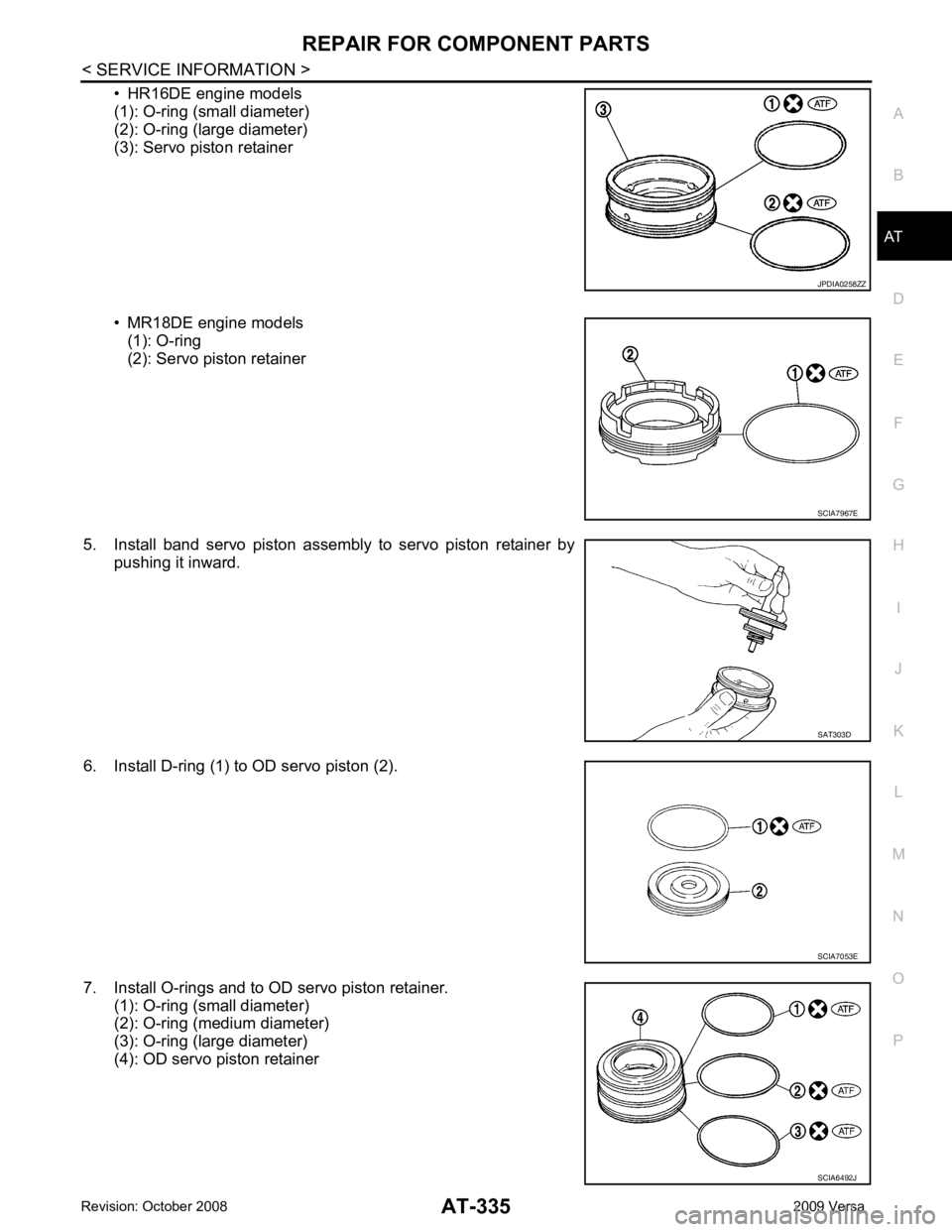

1. Install D-rings to band servo piston.

2. Install band servo thrust washer (4), band servo piston (3), OD servo return spring (2) and spring retainer (1) to band servo pis-

ton stem (5).

3. Place band servo piston stem (1) on a wooden block, and install E-ring (2) to band servo piston stem (1) while pressing spring

retainer (3) downward.

4. Install O-ring to servo piston retainer. SAT138D

SCIA3688E

SCIA7054E

SCIA7056E

Page 340 of 4331

REPAIR FOR COMPONENT PARTS

AT-335

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

• HR16DE engine models

(1): O-ring (small diameter)

(2): O-ring (large diameter)

(3): Servo piston retainer

• MR18DE engine models (1): O-ring

(2): Servo piston retainer

5. Install band servo piston assembly to servo piston retainer by pushing it inward.

6. Install D-ring (1) to OD servo piston (2).

7. Install O-rings and to OD servo piston retainer. (1): O-ring (small diameter)

(2): O-ring (medium diameter)

(3): O-ring (large diameter)

(4): OD servo piston retainer JPDIA0258ZZ

SCIA7967E

SAT303D

SCIA7053E

SCIA6492J

Trending: immobilizer, engine oil capacity, boot, clutch, coolant level, wiper blades, seat memory

![NISSAN LATIO 2009 Service Repair Manual AT

N

O P

ii. Set Tool on output gear bearing outer race, and drive output

gear bearing outer race to bearing retainer.

b. MR18DE engine models

i. Set drift [commercial service tool] on radia NISSAN LATIO 2009 Service Repair Manual AT

N

O P

ii. Set Tool on output gear bearing outer race, and drive output

gear bearing outer race to bearing retainer.

b. MR18DE engine models

i. Set drift [commercial service tool] on radia](/img/5/57359/w960_57359-333.png)