NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 371 of 4331

AT-366< SERVICE INFORMATION >

ASSEMBLY

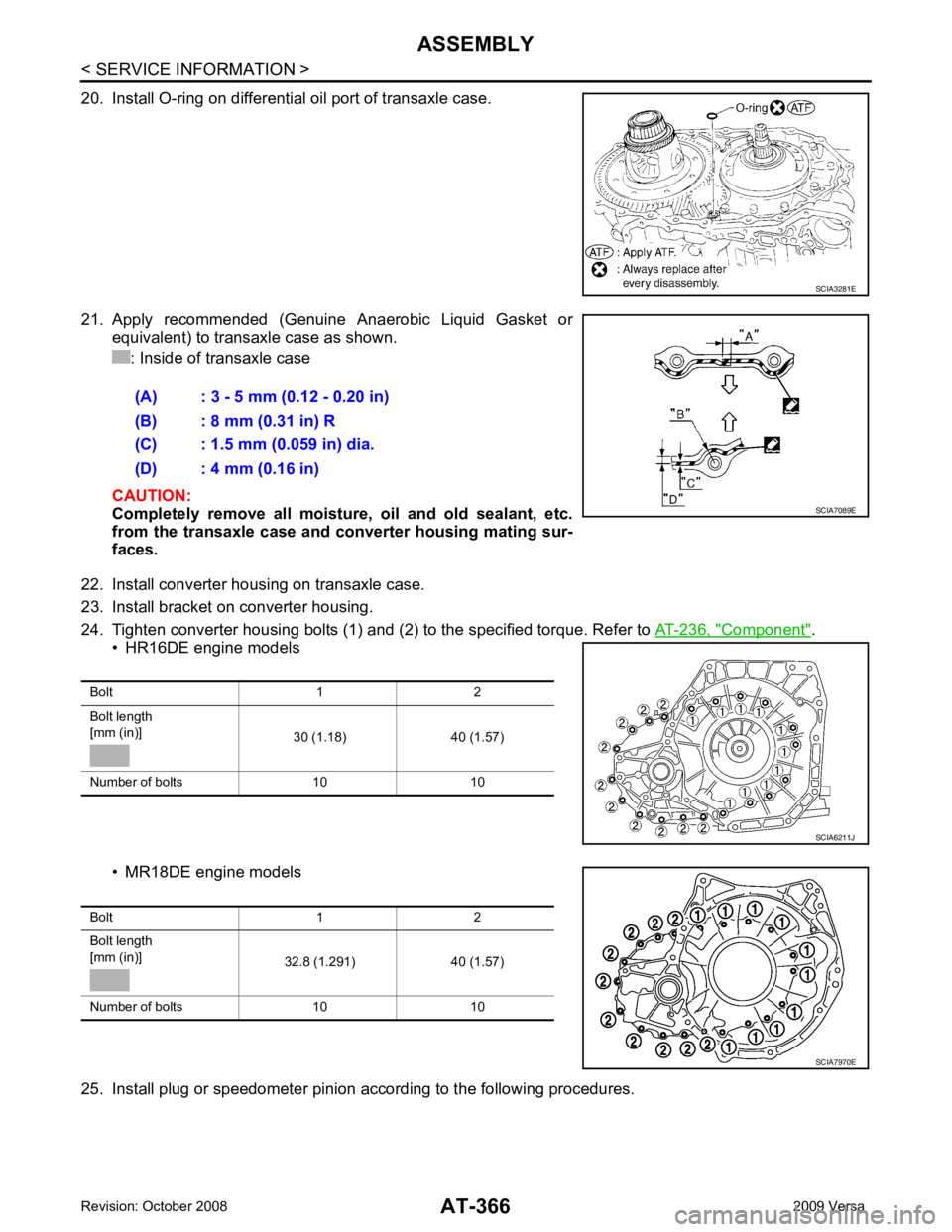

20. Install O-ring on differential oil port of transaxle case.

21. Apply recommended (Genuine Anaerobic Liquid Gasket or equivalent) to transaxle case as shown.

: Inside of transaxle case

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transaxle case and converter housing mating sur-

faces.

22. Install converter housing on transaxle case.

23. Install bracket on converter housing.

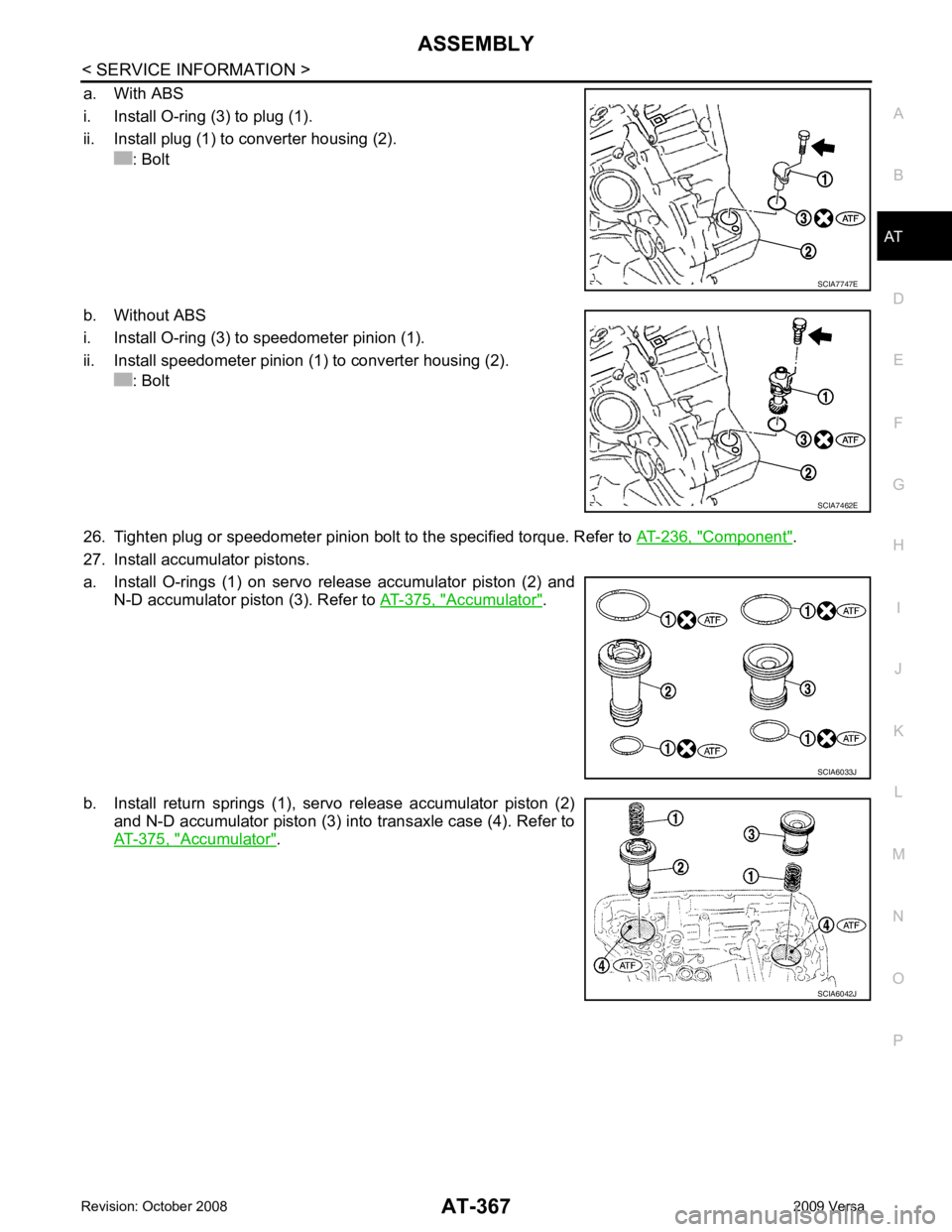

24. Tighten converter housing bolts (1) and (2) to the specified torque. Refer to AT-236, " Component " .

• HR16DE engine models

• MR18DE engine models

25. Install plug or speedometer pinion according to the following procedures. SCIA3281E

(A) : 3 - 5 mm (0.12 - 0.20 in)

(B) : 8 mm (0.31 in) R

(C) : 1.5 mm (0.059 in) dia.

(D) : 4 mm (0.16 in) SCIA7089E

Bolt 1 2

Bolt length

[mm (in)] 30 (1.18) 40 (1.57)

Number of bolts 10 10 SCIA6211J

Bolt 1 2

Bolt length

[mm (in)] 32.8 (1.291) 40 (1.57)

Number of bolts 10 10 SCIA7970E

Page 372 of 4331

ASSEMBLY

AT-367

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

a. With ABS

i. Install O-ring (3) to plug (1).

ii. Install plug (1) to converter housing (2). : Bolt

b. Without ABS

i. Install O-ring (3) to speedometer pinion (1).

ii. Install speedometer pinion (1) to converter housing (2). : Bolt

26. Tighten plug or speedometer pinion bolt to the specified torque. Refer to AT-236, " Component " .

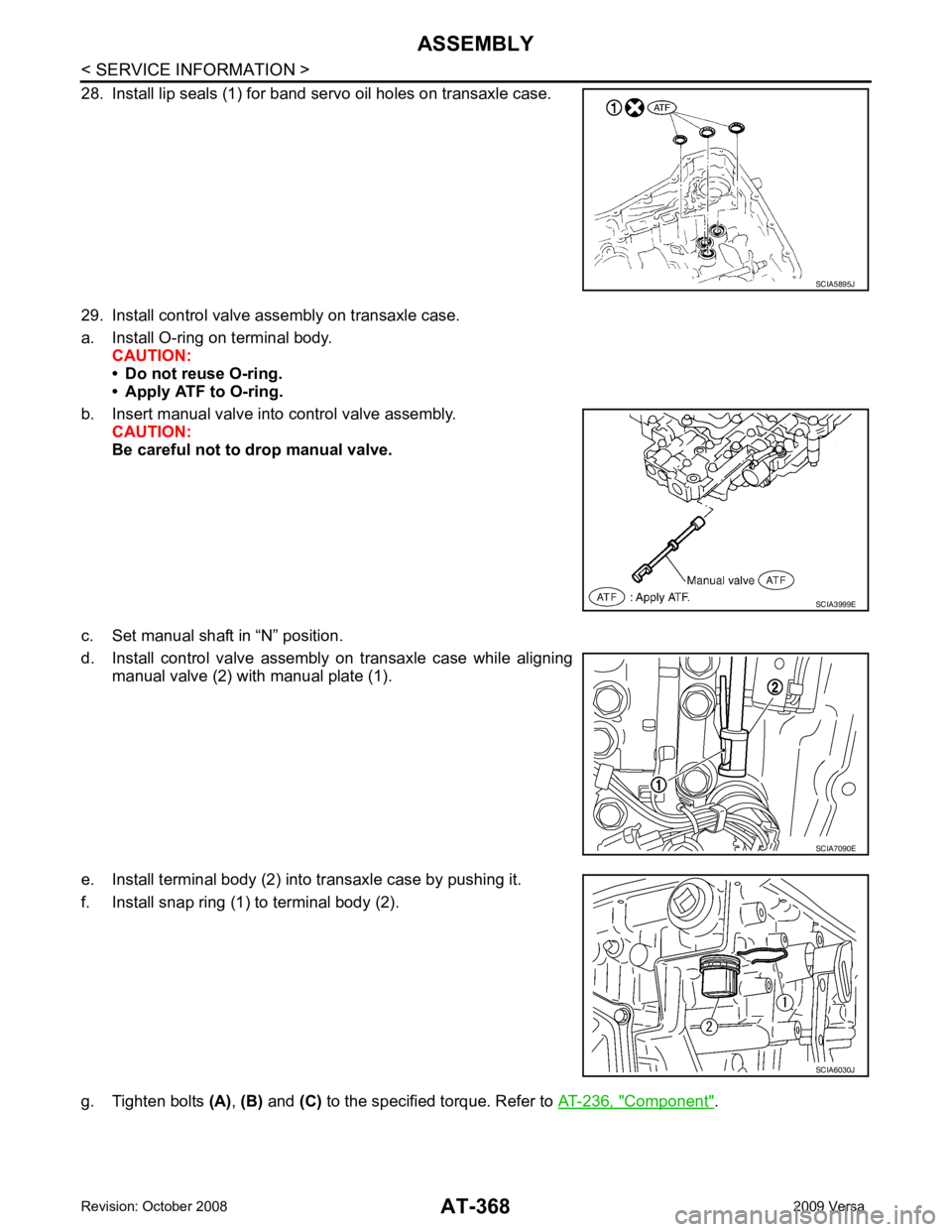

27. Install accumulator pistons.

a. Install O-rings (1) on servo release accumulator piston (2) and N-D accumulator piston (3). Refer to AT-375, " Accumulator " .

b. Install return springs (1), servo release accumulator piston (2) and N-D accumulator piston (3) into transaxle case (4). Refer to

AT-375, " Accumulator " . SCIA7747E

SCIA7462E

SCIA6033J

SCIA6042J

Page 373 of 4331

AT-368< SERVICE INFORMATION >

ASSEMBLY

28. Install lip seals (1) for band servo oil holes on transaxle case.

29. Install control valve assembly on transaxle case.

a. Install O-ring on terminal body. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

b. Insert manual valve into control valve assembly. CAUTION:

Be careful not to drop manual valve.

c. Set manual shaft in “N” position.

d. Install control valve assembly on transaxle case while aligning manual valve (2) with manual plate (1).

e. Install terminal body (2) into transaxle case by pushing it.

f. Install snap ring (1) to terminal body (2).

g. Tighten bolts (A), (B) and (C) to the specified torque. Refer to AT-236, " Component " . SCIA5895J

SCIA3999E

SCIA7090E

SCIA6030J

Page 374 of 4331

AT

N

O P

Bolt length, number and location:

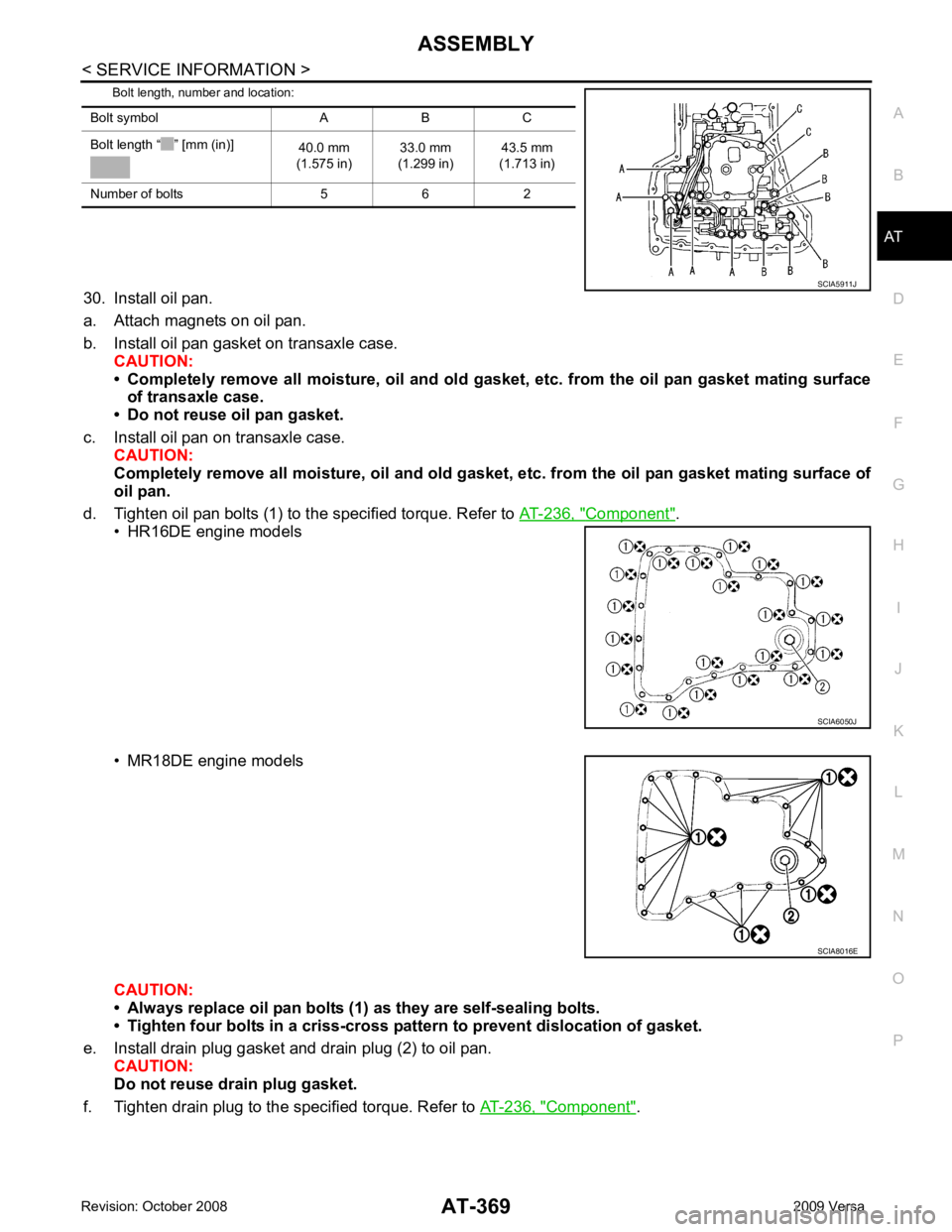

30. Install oil pan.

a. Attach magnets on oil pan.

b. Install oil pan gasket on transaxle case. CAUTION:

• Completely remove all moisture, oil and old gasket , etc. from the oil pan gasket mating surface

of transaxle case.

• Do not reuse oil pan gasket.

c. Install oil pan on transaxle case. CAUTION:

Completely remove all moisture, oil and old gasket , etc. from the oil pan gasket mating surface of

oil pan.

d. Tighten oil pan bolts (1) to the specified torque. Refer to AT-236, " Component " .

• HR16DE engine models

• MR18DE engine models

CAUTION:

• Always replace oil pan bolts (1) as they are self-sealing bolts.

• Tighten four bolts in a criss-cross pattern to prevent dislocation of gasket.

e. Install drain plug gasket and drain plug (2) to oil pan. CAUTION:

Do not reuse drain plug gasket.

f. Tighten drain plug to the specified torque. Refer to AT-236, " Component " .

Bolt symbol A B C

Bolt length “ ” [mm (in)] 40.0 mm

(1.575 in) 33.0 mm

(1.299 in) 43.5 mm

(1.713 in)

Number of bolts 5 6 2 SCIA6050J

Page 375 of 4331

AT-370< SERVICE INFORMATION >

ASSEMBLY

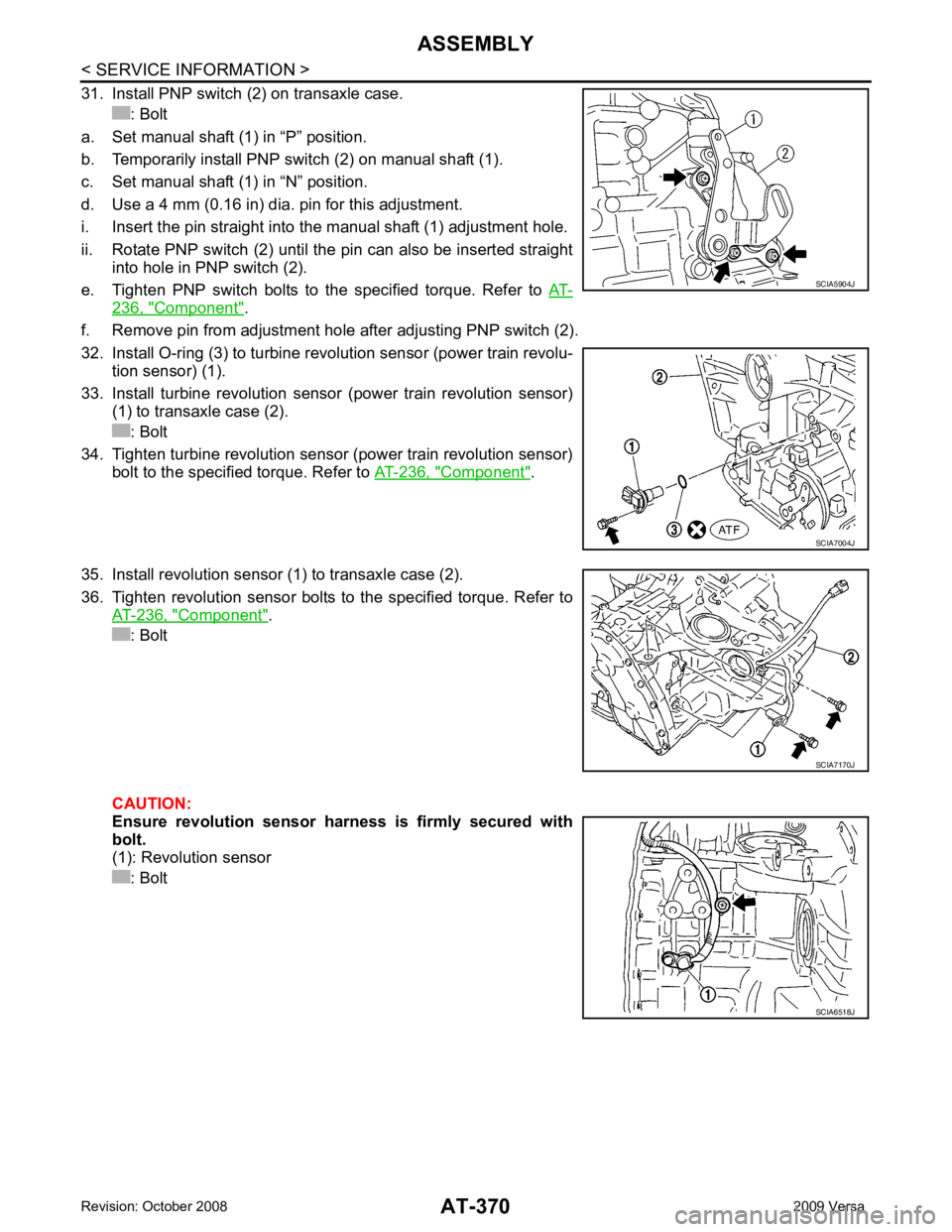

31. Install PNP switch (2) on transaxle case. : Bolt

a. Set manual shaft (1) in “P” position.

b. Temporarily install PNP switch (2) on manual shaft (1).

c. Set manual shaft (1) in “N” position.

d. Use a 4 mm (0.16 in) dia. pin for this adjustment.

i. Insert the pin straight into the manual shaft (1) adjustment hole.

ii. Rotate PNP switch (2) until the pin can also be inserted straight into hole in PNP switch (2).

e. Tighten PNP switch bolts to the specified torque. Refer to AT-236, " Component " .

f. Remove pin from adjustment hole after adjusting PNP switch (2).

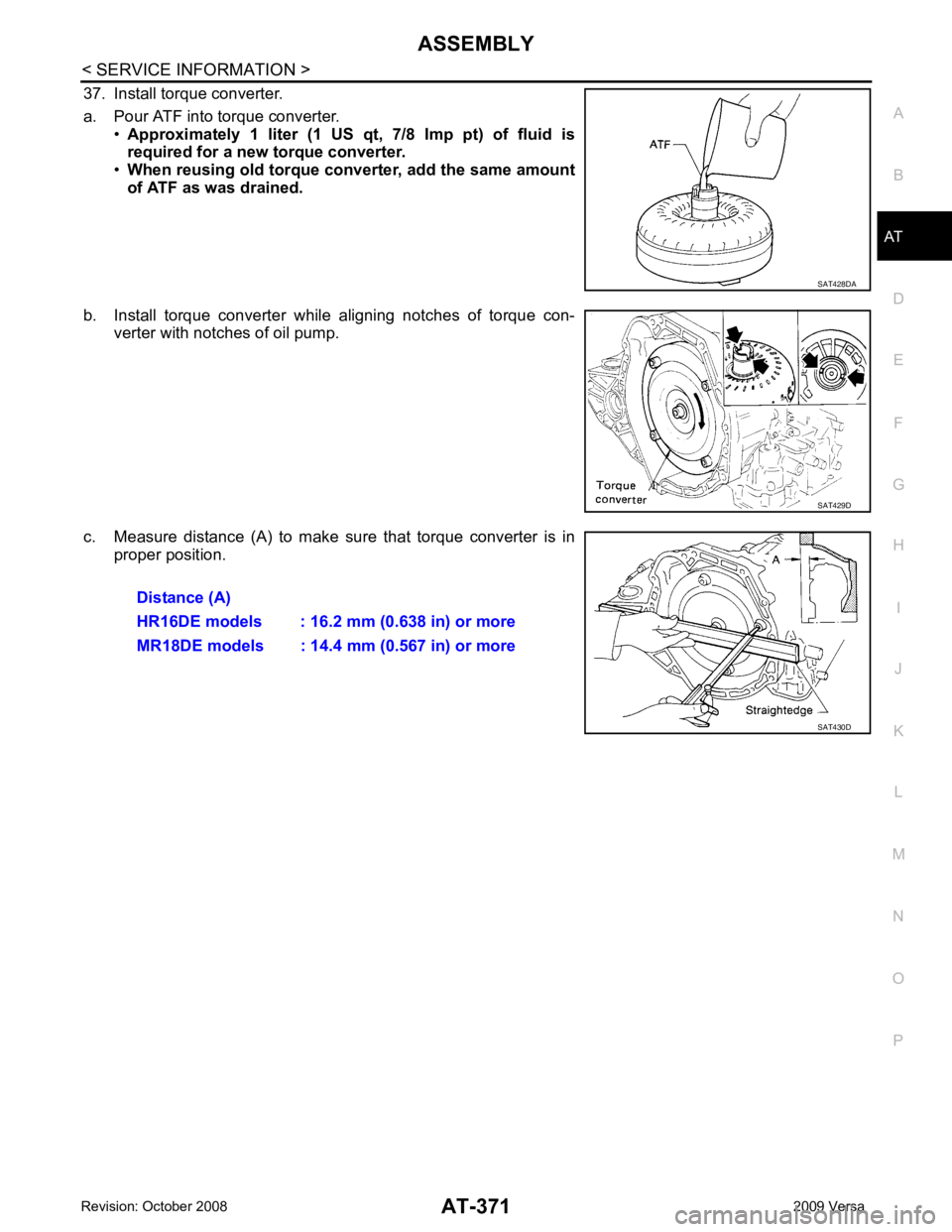

32. Install O-ring (3) to turbine revolution sensor (power train revolu- tion sensor) (1).

33. Install turbine revolution sensor (power train revolution sensor) (1) to transaxle case (2).

: Bolt

34. Tighten turbine revolution sensor (power train revolution sensor) bolt to the specified torque. Refer to AT-236, " Component " .

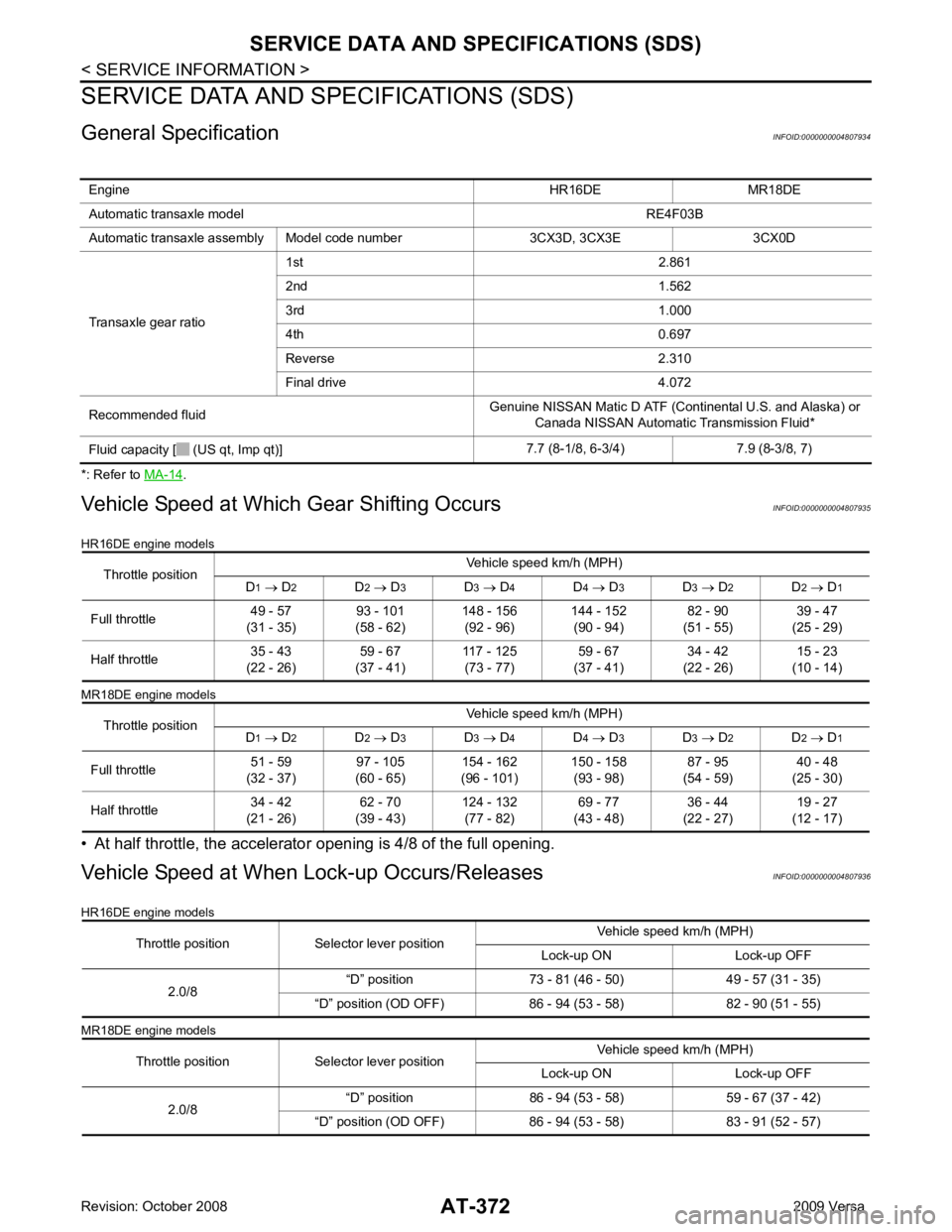

35. Install revolution sensor (1) to transaxle case (2).

36. Tighten revolution sensor bolts to the specified torque. Refer to AT-236, " Component " .

: Bolt

CAUTION:

Ensure revolution sensor harness is firmly secured with

bolt.

(1): Revolution sensor

: Bolt SCIA5904J

SCIA7004J

SCIA7170J

SCIA6518J

Page 376 of 4331

AT

N

O P

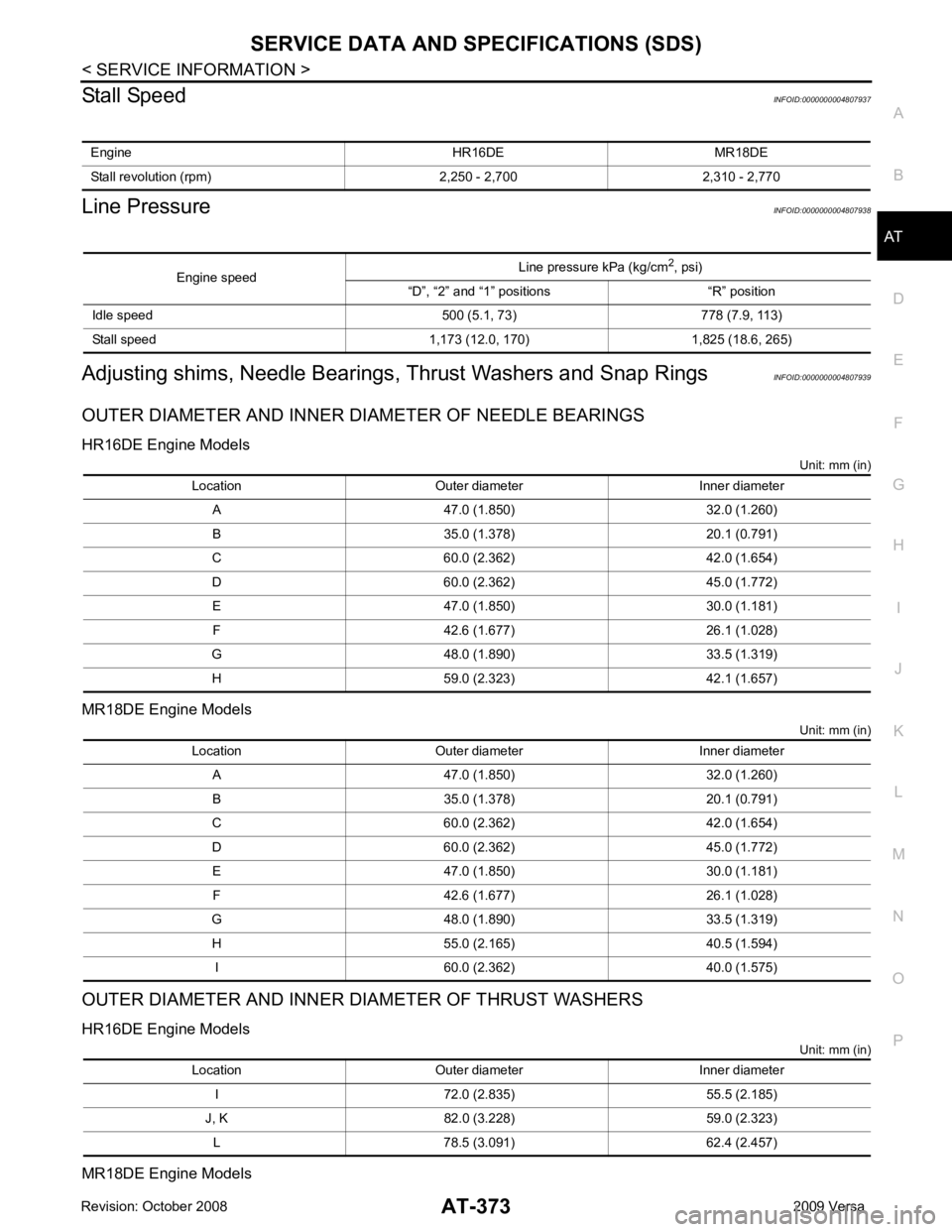

37. Install torque converter.

a. Pour ATF into torque converter. •Approximately 1 liter (1 US qt, 7/8 Imp pt) of fluid is

required for a new torque converter.

• When reusing old torque co nverter, add the same amount

of ATF as was drained.

b. Install torque converter while aligning notches of torque con- verter with notches of oil pump.

c. Measure distance (A) to make sure that torque converter is in proper position. SAT429D

Page 377 of 4331

.

Vehicle Speed at Which Gear Shifting Occurs INFOID:0000000004807935

HR16DE engine models

MR18DE engine models

• At half throttle, the accelerator opening is 4/8 of the full opening.

Vehicle Speed at When Lock-up Occurs/Releases INFOID:0000000004807936

HR16DE engine models

MR18DE engine models Engine

HR16DE MR18DE

Automatic transaxle model RE4F03B

Automatic transaxle assembly Model code number 3CX3D, 3CX3E 3CX0D

Transaxle gear ratio 1st 2.861

2nd 1.562

3rd 1.000

4th 0.697

Reverse 2.310

Final drive 4.072

Recommended fluid Genuine NISSAN Matic D ATF (Conti

nental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid*

Fluid capacity [ (US qt, Imp qt)] 7.7 (8-1/8, 6-3/4) 7.9 (8-3/8, 7)Throttle position

Vehicle speed km/h (MPH)

D 1

→ D 2 D2 → D 3 D3 → D 4 D4 → D 3 D3 → D 2 D2 → D 1

Full throttle 49 - 57

(31 - 35) 93 - 101

(58 - 62) 148 - 156

(92 - 96) 144 - 152

(90 - 94) 82 - 90

(51 - 55) 39 - 47

(25 - 29)

Half throttle 35 - 43

(22 - 26) 59 - 67

(37 - 41) 117 - 125

(73 - 77) 59 - 67

(37 - 41) 34 - 42

(22 - 26) 15 - 23

(10 - 14)

Throttle position Vehicle speed km/h (MPH)

D 1 → D 2 D2 → D 3 D3 → D 4 D4 → D 3 D3 → D 2 D2 → D 1

Full throttle 51 - 59

(32 - 37) 97 - 105

(60 - 65) 154 - 162

(96 - 101) 150 - 158

(93 - 98) 87 - 95

(54 - 59) 40 - 48

(25 - 30)

Half throttle 34 - 42

(21 - 26) 62 - 70

(39 - 43) 124 - 132

(77 - 82) 69 - 77

(43 - 48) 36 - 44

(22 - 27) 19 - 27

(12 - 17) Throttle position Selector lever position

Vehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

2.0/8 “D” position 73 - 81 (46

- 50) 49 - 57 (31 - 35)

“D” position (OD OFF) 86 - 94 (53 - 58) 82 - 90 (51 - 55)

Throttle position Selector lever position Vehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

2.0/8 “D” position 86 - 94 (53

- 58) 59 - 67 (37 - 42)

“D” position (OD OFF) 86 - 94 (53 - 58) 83 - 91 (52 - 57)

Page 378 of 4331

AT

N

O P

Stall Speed

INFOID:0000000004807937

Line Pressure INFOID:0000000004807938

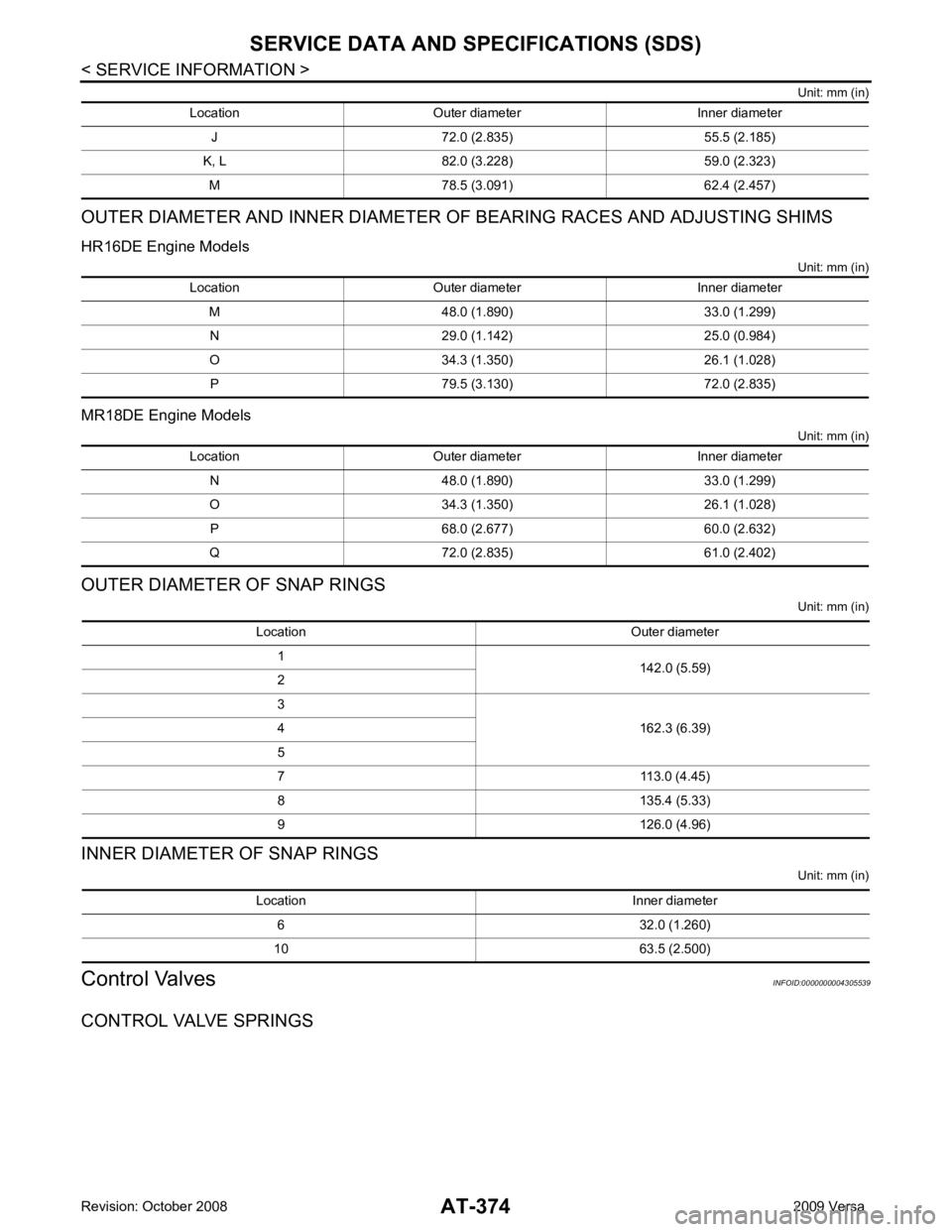

Adjusting shims, Needle Bearings , Thrust Washers and Snap Rings INFOID:0000000004807939

OUTER DIAMETER AND INNER DIAMETER OF NEEDLE BEARINGS

HR16DE Engine Models Unit: mm (in)

MR18DE Engine Models Unit: mm (in)

OUTER DIAMETER AND INNER DIAMETER OF THRUST WASHERS

HR16DE Engine Models Unit: mm (in)

MR18DE Engine Models Engine HR16DE MR18DE

Stall revolution (rpm) 2,250 - 2,700 2,310 - 2,770 Engine speed

Line pressure kPa (kg/cm

2

, psi)

“D”, “2” and “1” positions “R” position

Idle speed 500 (5.1, 73) 778 (7.9, 113)

Stall speed 1,173 (12.0, 170) 1,825 (18.6, 265) Location Outer diameter Inner diameter

A 47.0 (1.850) 32.0 (1.260)

B 35.0 (1.378) 20.1 (0.791)

C 60.0 (2.362) 42.0 (1.654)

D 60.0 (2.362) 45.0 (1.772) E 47.0 (1.850) 30.0 (1.181)F 42.6 (1.677) 26.1 (1.028)

G 48.0 (1.890) 33.5 (1.319) H 59.0 (2.323) 42.1 (1.657) Location Outer diameter Inner diameter

A 47.0 (1.850) 32.0 (1.260)

B 35.0 (1.378) 20.1 (0.791)

C 60.0 (2.362) 42.0 (1.654)

D 60.0 (2.362) 45.0 (1.772) E 47.0 (1.850) 30.0 (1.181)F 42.6 (1.677) 26.1 (1.028)

G 48.0 (1.890) 33.5 (1.319) H 55.0 (2.165) 40.5 (1.594) I 60.0 (2.362) 40.0 (1.575) Location Outer diameter Inner diameter

I 72.0 (2.835) 55.5 (2.185)

J, K 82.0 (3.228) 59.0 (2.323) L 78.5 (3.091) 62.4 (2.457)

Page 379 of 4331

Location Outer diameter Inner diameter

M 48.0 (1.890) 33.0 (1.299)N 29.0 (1.142) 25.0 (0.984)

O 34.3 (1.350) 26.1 (1.028) P 79.5 (3.130) 72.0 (2.835) Location Outer diameter Inner diameter

N 48.0 (1.890) 33.0 (1.299)

O 34.3 (1.350) 26.1 (1.028) P 68.0 (2.677) 60.0 (2.632)

Q 72.0 (2.835) 61.0 (2.402) Location Outer diameter

1 142.0 (5.59)

2

3 162.3 (6.39)

4

5

7 113.0 (4.45)

8 135.4 (5.33)

9 126.0 (4.96) Location Inner diameter

6 32.0 (1.260)

10 63.5 (2.500)

Page 380 of 4331

AT

N

O P

Unit: mm (in)

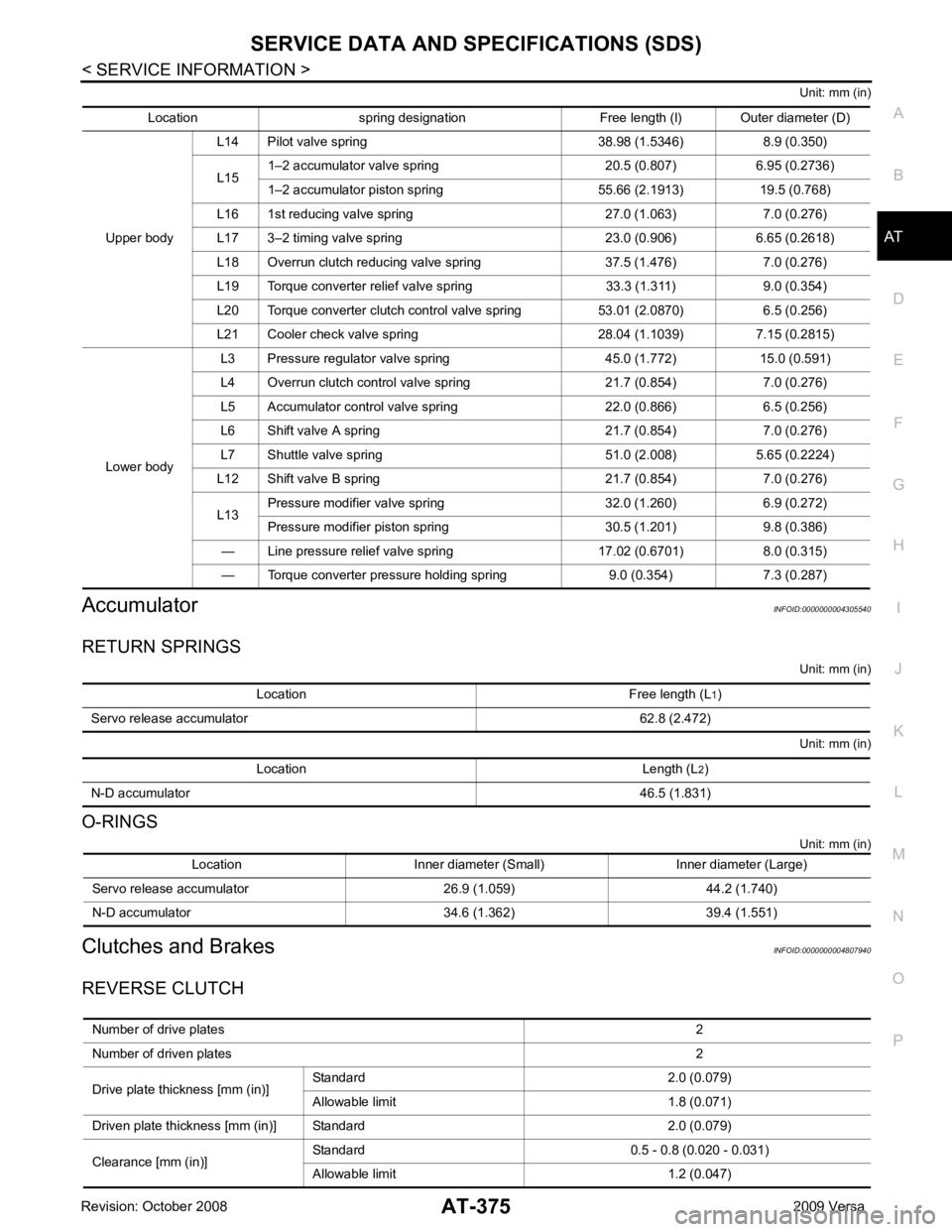

Accumulator INFOID:0000000004305540

RETURN SPRINGS Unit: mm (in)

Unit: mm (in)

O-RINGS Unit: mm (in)

Clutches and Brakes INFOID:0000000004807940

REVERSE CLUTCH Location spring designation Free length (l) Outer diameter (D)

Upper body L14 Pilot valve spring 38.98 (1.5346) 8.9 (0.350)

L15 1–2 accumulator valve spring 20.5 (0.807) 6.95 (0.2736)

1–2 accumulator piston spring 55.66 (2.1913) 19.5 (0.768)

L16 1st reducing valve spring 27.0 (1.063) 7.0 (0.276)

L17 3–2 timing valve spring 23.0 (0.906) 6.65 (0.2618)

L18 Overrun clutch reducing valve spring 37.5 (1.476) 7.0 (0.276)

L19 Torque converter relief valve spring 33.3 (1.311) 9.0 (0.354)

L20 Torque converter clutch control valve spring 53.01 (2.0870) 6.5 (0.256)

L21 Cooler check valve spring 28.04 (1.1039) 7.15 (0.2815)

Lower body L3 Pressure regulator valve sp

ring 45.0 (1.772) 15.0 (0.591)

L4 Overrun clutch control valve spring 21.7 (0.854) 7.0 (0.276)

L5 Accumulator control valve spring 22.0 (0.866) 6.5 (0.256)

L6 Shift valve A spring 21.7 (0.854) 7.0 (0.276)

L7 Shuttle valve spring 51.0 (2.008) 5.65 (0.2224)

L12 Shift valve B spring 21.7 (0.854) 7.0 (0.276)

L13 Pressure modifier valve spring 32.0 (1.260) 6.9 (0.272)

Pressure modifier piston spring 30.5 (1.201) 9.8 (0.386)

— Line pressure relief valve spring 17.02 (0.6701) 8.0 (0.315)

— Torque converter pressure holding spring 9.0 (0.354) 7.3 (0.287) Location Free length (L

1)

Servo release accumulator 62.8 (2.472) Location Length (L

2)

N-D accumulator 46.5 (1.831)Location Inner diameter (Small) Inner diameter (Large)

Servo release accumulator 26.9 (1.059) 44.2 (1.740)

N-D accumulator 34.6 (1.362) 39.4 (1.551) Number of drive plates

2

Number of driven plates 2

Drive plate thickness [mm (in)] Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard 0.5 - 0.8 (0.020 - 0.031)

Allowable limit 1.2 (0.047)