sensor NISSAN LATIO 2009 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 693 of 4331

BL-232< SERVICE INFORMATION >

VEHICLE SECURITY (T

HEFT WARNING) SYSTEM

13 V Instrument panel an-

tenna (+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

14 LG Instrument panel an-

tenna (-) signal

15 L Front console antenna

(+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

16 P Front console antenna

(-) signal

17 W Rear bumper antenna

(+) signal

LOCK Press back door request switch.

18 B Rear bumper antenna

(-) signal

19 V Front outside antenna

LH (+) signal

LOCK Press door request switch LH.

20 P Front outside antenna

LH (-) signal

22 *2

BR Key interlock solenoid — With Intelligent Key present or mechanical

key in ignition cylinder, press "PUSH" but-

ton on ignition cylinder. Battery voltage

Other than above 0

23 LG Back door open output — Back door open (switch closed) 0

Back door closed (switch open) 5

24 V Back door opener

switch —Press and hold back door switch. 0

Other than above 5

25 L Front door request

switch RH —Press front door request switch RH. 0

Other than above 5

26 SB Stop lamp switch — Depress brake pedal Battery voltage

Other than above 0

27 W Ignition knob switch — Press ignition switch. Battery voltage

Release ignition switch. 0

28 Y Unlock sensor

(driver side) —Door (driver si

de) is locked. 5

Door (driver side ) is unlocked. 0

Terminal

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions PIIB5502J

PIIB5502J

SIIA1910J

SIIA1910J

Page 841 of 4331

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

ABS

SERVICE INFORMATION .. ..........................

2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Brake System .............................. ......2

Precaution for Brake Cont rol .....................................3

Precaution for CAN System ................................ ......3

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool .................................... ......4

SYSTEM DESCRIPTION ................................ .....5

System Component ............................................. ......5

ABS Function ...................................................... ......5

EBD Function ...................................................... ......5

Fail-Safe Function ............................................... ......5

Hydraulic Circuit Diagram .........................................6

CAN COMMUNICATION ................................ .....7

System Description ............................................. ......7

TROUBLE DIAGNOSIS ................................. .....8

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........... .............................................

8

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

11

Schematic ........................................................... ....12

Wiring Diagram - ABS - ... ........................................13 Basic Inspection ..................................................

....16

Warning Lamp and Indicator Timing .................... ....17

Control Unit Input/Output Signal Standard .......... ....17

CONSULT-III Function ( ABS) ..................................18

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS ................................................. 24

Wheel Sensor System ......................................... ....24

ABS Control Unit Inspection ................................ ....25

Solenoid Valve System Inspection ...................... ....25

Actuator Motor, Motor Re lay, and Circuit Inspec-

tion ....................................................................... ....

26

ABS Control Unit Power and Ground Systems In-

spection ............................................................... ....

27

CAN Communication System Inspection ............. ....28

TROUBLE DIAGNOSES FOR SYMPTOMS ..... 29

ABS Works Frequently ........................................ ....29

Unexpected Pedal Action .................................... ....29

Long Stopping Distance ...................................... ....30

ABS Does Not Work ............................................ ....30

Pedal Vibration or ABS Op eration Noise .................30

WHEEL SENSORS ........................................... 32

Removal and Installation ..................................... ....32

SENSOR ROTOR .............................................. 34

Removal and Installation ..................................... ....34

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) .................................................................. 35

Removal and Installation ..................................... ....35

Page 842 of 4331

![NISSAN LATIO 2009 Service Manual Online BRC-2< SERVICE INFORMATION >

[ABS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784402

The NISSAN LATIO 2009 Service Manual Online BRC-2< SERVICE INFORMATION >

[ABS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784402

The](/img/5/57359/w960_57359-841.png)

BRC-2< SERVICE INFORMATION >

[ABS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784402

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution for Brake System INFOID:0000000004307251

CAUTION:

• Refer to MA-14 for recommended brake fluid.

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• To clean or wash all parts of master cylin der and disc brake caliper, use clean brake fluid.

• Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic sys-

tem.

• Use flare nut wrench when re moving and installing brake

tube.

• If a brake fluid leak is found, the part must be disassembled

without fail. Then it has to be replaced with a new one if a

defect exists.

• Turn the ignition switch OFF an d remove the connector of the

ABS actuator and electric unit (c ontrol unit) or the battery ter-

minal before performing the work.

• Always torque brake lines when installing.

• Burnish the brake contact surf aces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage. Refer to BR-32, " Brake Burnishing Proce-

dure " .

WARNING:

• Clean brake pads and shoes with a waste cloth, then wipe with a dust collector. SBR686C

Page 851 of 4331

BRC

N

O P

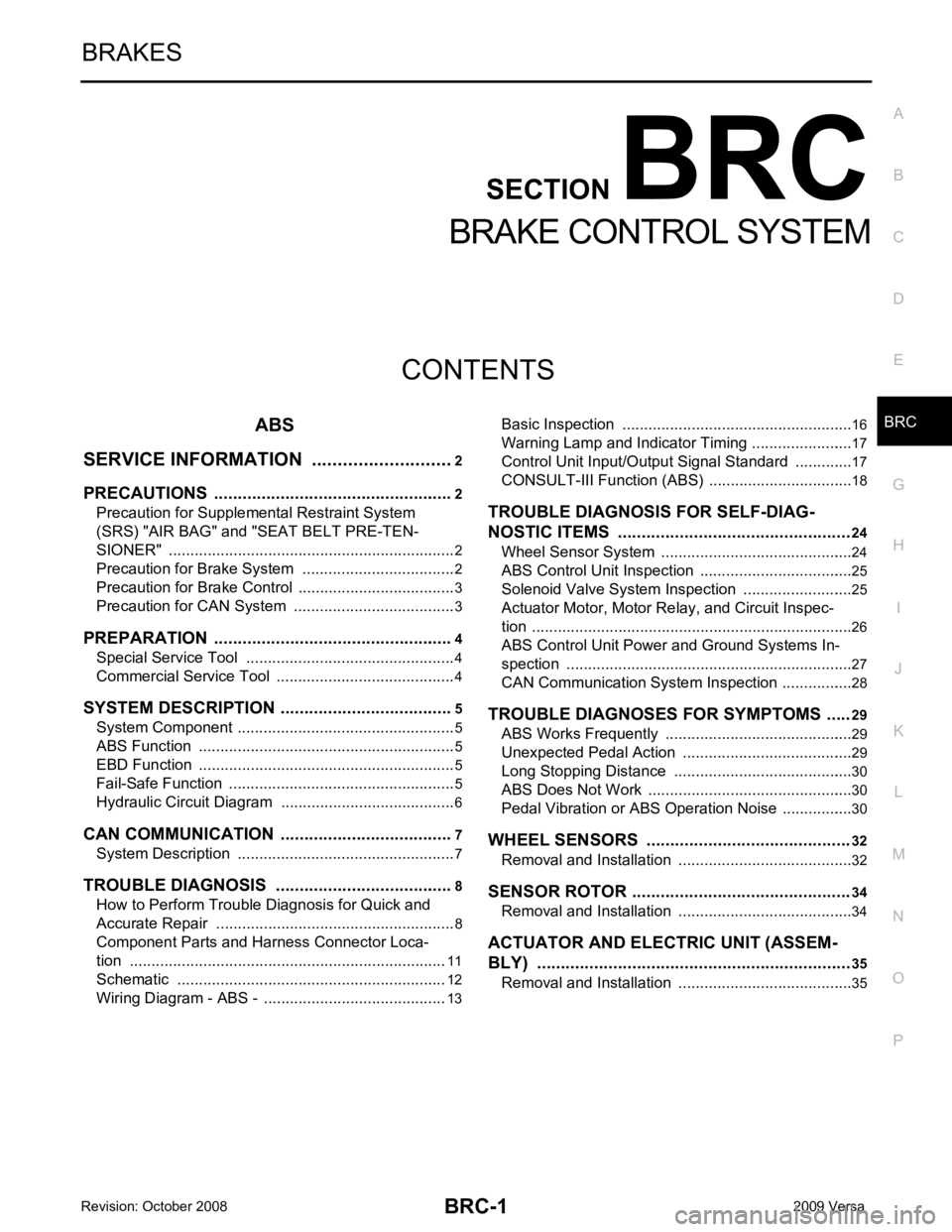

Component Parts and Har

ness Connector Location INFOID:0000000004307263

1. Front wheel sensor LH E51

RH E52 2. Rear wheel sensor

LH B123

RH B124 3. ABS actuator and electric unit (con-

trol unit) E33

4. Combination meter M24

Page 858 of 4331

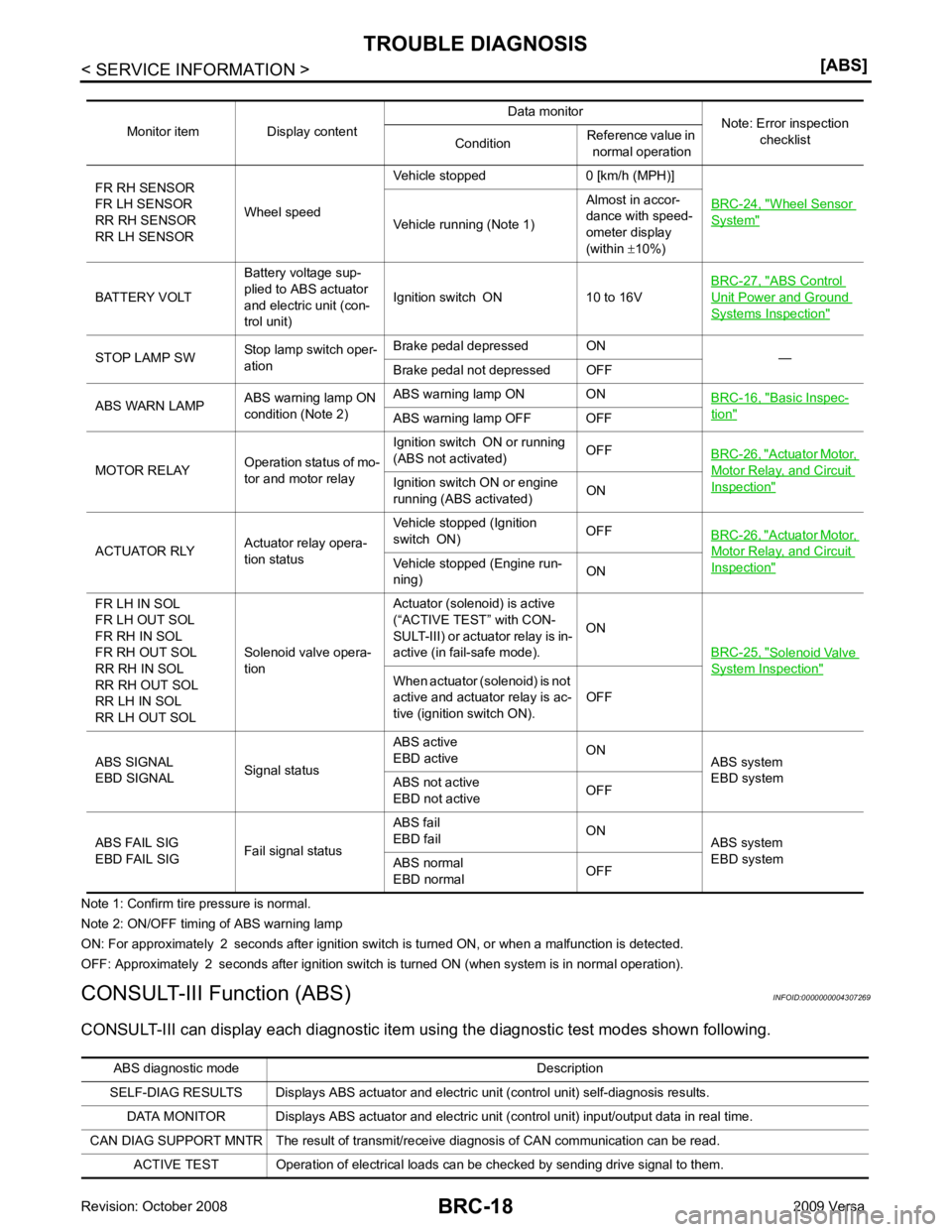

Wheel Sensor

System "

Vehicle running (Note 1)

Almost in accor-

dance with speed-

ometer display

(within ±10%)

BATTERY VOLT Battery voltage sup-

plied to ABS actuator

and electric unit (con-

trol unit) Ignition switch ON 10 to 16V

BRC-27, " ABS Control

Unit Power and Ground

Systems Inspection "

STOP LAMP SW

Stop lamp switch oper-

ation Brake pedal depressed ON

—

Brake pedal not depressed OFF

ABS WARN LAMP ABS warning lamp ON

condition (Note 2) ABS warning lamp ON ON

BRC-16, " Basic Inspec-

tion "

ABS warning lamp OFF OFF

MOTOR RELAY Operation status of mo-

tor and motor relay Ignition switch ON or running

(ABS not activated) OFF

BRC-26, " Actuator Motor,

Motor Relay, and Circuit

Inspection "Ignition switch ON or engine

running (ABS activated) ON

ACTUATOR RLY Actuator relay opera-

tion status Vehicle stopped (Ignition

switch ON) OFF

BRC-26, " Actuator Motor,

Motor Relay, and Circuit

Inspection "Vehicle stopped (Engine run-

ning) ON

FR LH IN SOL

FR LH OUT SOL

FR RH IN SOL

FR RH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOL Solenoid valve opera-

tion Actuator (solenoid) is active

(“ACTIVE TEST” with CON-

SULT-III) or actuator relay is in-

active (in fail-safe mode). ON

BRC-25, " Solenoid Valve

System Inspection "

When actuator (solenoid) is not

active and actuator relay is ac-

tive (ignition switch ON). OFF

ABS SIGNAL

EBD SIGNAL Signal statusABS active

EBD active ON

ABS system

EBD system

ABS not active

EBD not active OFF

ABS FAIL SIG

EBD FAIL SIG Fail signal statusABS fail

EBD fail ON

ABS system

EBD system

ABS normal

EBD normal OFFABS diagnostic mo

de Description

SELF-DIAG RESULTS Displays ABS actuator and electric unit (control unit) self-diagnosis results.

DATA MONITOR Displays ABS actuator and electric unit (control unit) input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Page 859 of 4331

BRC

N

O P

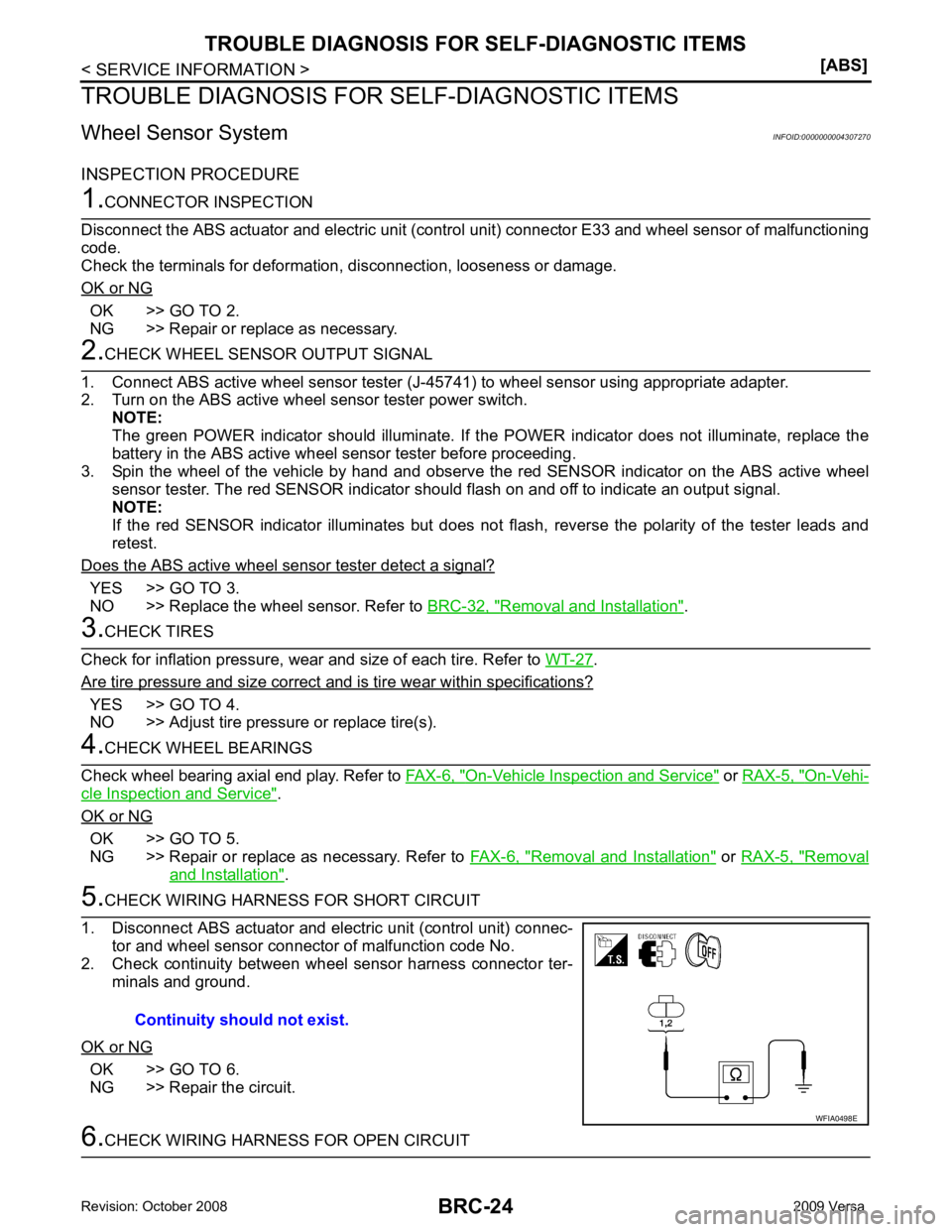

SELF-DIAGNOSIS

Description If an error is detected in the system, the ABS warning lamp will turn on. In this case, perform self-diagnosis as

follows:

Operation Procedure 1. Turn ignition switch OFF.

2. Connect CONSULT-III to the data link connector.

3. Turn ignition switch ON.

4. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

5. After stopping the vehicle, with the engine running, t ouch “ABS”, “SELF-DIAG RESULTS” in order on the

CONSULT-III screen.

6. The self-diagnostic results are displayed. (If nece ssary, the self-diagnostic results can be printed out by

touching “PRINT”.)

• When “NO DTC IS DETECTED” is displayed, check the ABS warning lamp.

7. Conduct the appropriate inspection from the display item list, and repair or replace the malfunctioning

component.

8. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

CAUTION:

• When a wheel sensor “short-circuit” is detected, if the vehicle is not driven at 30 km/h (19 MPH)

for at least 1 minute, the ABS warn ing lamp will not turn off even if the malfunction is repaired.

9. Turn ignition switch OFF to prepare for erasing the memory.

10. Start the engine and touch “ABS”, “SELF-DIAG RESU LTS”, “ERASE” in order on the CONSULT-III screen

to erase the error memory.

If “ABS” is not indicated, go to GI-36, " CONSULT-III Data Link Connector (DLC) Circuit " .

CAUTION:

If the error memory is not erased, re -conduct the operation from step 5.

11. For the final inspection, drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute and

confirm that the ABS warning lamp is off.

Display Item List FUNCTION TEST Conducted by CONSULT-III in

stead of a technician to determine whether each sy stem is "OK" or "NG".

ECU PART NUMBER ABS actuator and electric unit (control unit) part number can be read.

ABS diagnostic mode Description

Page 860 of 4331

![NISSAN LATIO 2009 Service Manual Online Wheel Sensor

System " (Note 1)

RR LH SENSOR-1

[C1102] Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104] Circuit of fron NISSAN LATIO 2009 Service Manual Online Wheel Sensor

System " (Note 1)

RR LH SENSOR-1

[C1102] Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104] Circuit of fron](/img/5/57359/w960_57359-859.png)

Wheel Sensor

System " (Note 1)

RR LH SENSOR-1

[C1102] Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104] Circuit of front LH wheel sensor is open.

RR RH SENSOR-2

[C1105] When the circuit in the rear RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

RR LH SENSOR-2

[C1106] When the circuit in the rear LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR RH SENSOR-2

[C1107] When the circuit in the front RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR LH SENSOR-2

[C1108] When the circuit in the front LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

ABS SENSOR

[ABNORMAL SIGNAL]

[C1115] Wheel sensor input is abnormal.

BATTERY VOLTAGE

[ABNORMAL]

[C1109] ABS actuator and electric unit (control unit) power voltage is too

low. BRC-27, " ABS Control

Unit Power and Ground

Systems Inspection "

CONTROLLER FAILURE

[C1110] Internal malfunction of ABS actuator

and electric unit (control unit)BRC-25, " ABS Control

Unit Inspection "

PUMP MOTOR

[C1111] During actuator motor operation with ON, when actuator motor

turns OFF or when control line for actuator motor relay is open. BRC-26, " Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection "During actuator motor operation with OFF, when actuator motor

turns ON or when control line for relay is shorted to ground.

FR LH IN ABS SOL

[C1120] Circuit of front LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

BRC-25, " Solenoid Valve

System Inspection "FR LH OUT ABS SOL

[C1121] Circuit of front LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH IN ABS SOL

[C1122] Circuit of front RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH OUT ABS SOL

[C1123] Circuit of front RH OUT ABS solenoid is open or shorted, or con-

trol line is open or shorted to power supply or ground.

RR LH IN ABS SOL

[C1124] Circuit of rear LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR LH OUT ABS SOL

[C1125] Circuit of rear LH OUT ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH IN ABS SOL

[C1126] Circuit of rear RH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH OUT ABS SOL

[C1127] Circuit of rear RH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

Page 861 of 4331

BRC

N

O P

Note 1: If wheel sens

or 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power supply voltage in addition

to wheel sensor circuit check.

Note 2: If multiple malfunctions are detected including CAN communication line [U1000], perform diagnosis for CAN communication line

first.

DATA MONITOR

Operation Procedure 1. After turning OFF the ignition switch, c onnect CONSULT-III to the data link connector.

2. Touch “ABS”, “DATA MONITOR” in order on the CONSULT-III screen. If “ABS” is not indicated, go to GI-36, " CONSULT-III Data Link Connector (DLC) Circuit " .

3. Return to the SELECT MONITOR ITEM screen, and touch “ECU INPUT SIGNALS”, “MAIN SIGNALS” or

“SELECTION FROM MENU”. Refer to the following information.

4. When “START” is touched, the data monitor screen is displayed.

Display Item List MAIN RELAY

[C1114] ABS actuator relay or circuit malfunction. BRC-26, " Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection "

CAN COMM CIRCUIT

[U1000] • CAN communication line is open or shorted.

• ABS actuator and electric unit (control unit) internal malfunction

• Battery voltage for ECM is suddenly interrupted for approxi-

mately 0.5 second or more. BRC-28, " CAN Commu-

nication System Inspec-

tion " (Note 2)

Self-diagnostic item Malfunction detecting condition Check system Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR RH SENSOR

(km/h, MPH) × × × Wheel speed calculated by front RH

wheel sensor signal is displayed.

FR LH SENSOR

(km/h, MPH) × × ×

Wheel speed calculated by front LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, MPH) × × × Wheel speed calculated by rear RH

wheel sensor signal is displayed.

RR LH SENSOR

(km/h, MPH) × × × Wheel speed calculated by rear LH

wheel sensor signal is displayed.

BATTERY VOLT

(V) × × × Voltage supplied to ABS actuator

and electric unit (control unit) is dis-

played.

STOP LAMP SW

(ON/OFF) × × × Stop lamp switch (ON/OFF) status is

displayed.

ABS WARN LAMP

(ON/OFF) –

× × ABS warning lamp (ON/OFF) status

is displayed.

FR LH IN SOL

(ON/OFF) –

× × Front LH IN ABS solenoid (ON/OFF)

status is displayed.

FR LH OUT SOL

(ON/OFF) –

× × Front LH OUT ABS solenoid (ON/

OFF) status is displayed.

FR RH IN SOL

(ON/OFF) –

× × Front RH IN ABS solenoid (ON/

OFF) status is displayed.

FR RH OUT SOL

(ON/OFF) –

× × Front RH OUT ABS solenoid (ON/

OFF) status is displayed.

RR LH IN SOL

(ON/OFF) –

× × Rear LH IN ABS solenoid (ON/OFF)

status is displayed.

RR LH OUT SOL

(ON/OFF) –

× × Rear LH OUT ABS solenoid (ON/

OFF) status is displayed.

Page 864 of 4331

OK >> GO TO 2.

NG >> Repair or replace as necessary. YES >> GO TO 3.

NO >> Replace the wheel sensor. Refer to BRC-32, " Removal and Installation " .

.

Are tire pressure and size correct and is tire wear within specifications? YES >> GO TO 4.

NO >> Adjust tire pressure or replace tire(s). On-Vehicle Inspection and Service " or

RAX-5, " On-Vehi-

cle Inspection and Service " .

OK or NG OK >> GO TO 5.

NG >> Repair or replace as necessary. Refer to FAX-6, " Removal and Installation " or

RAX-5, " Removal

and Installation " .

OK >> GO TO 6.

NG >> Repair the circuit.

Page 865 of 4331

BRC

N

O P

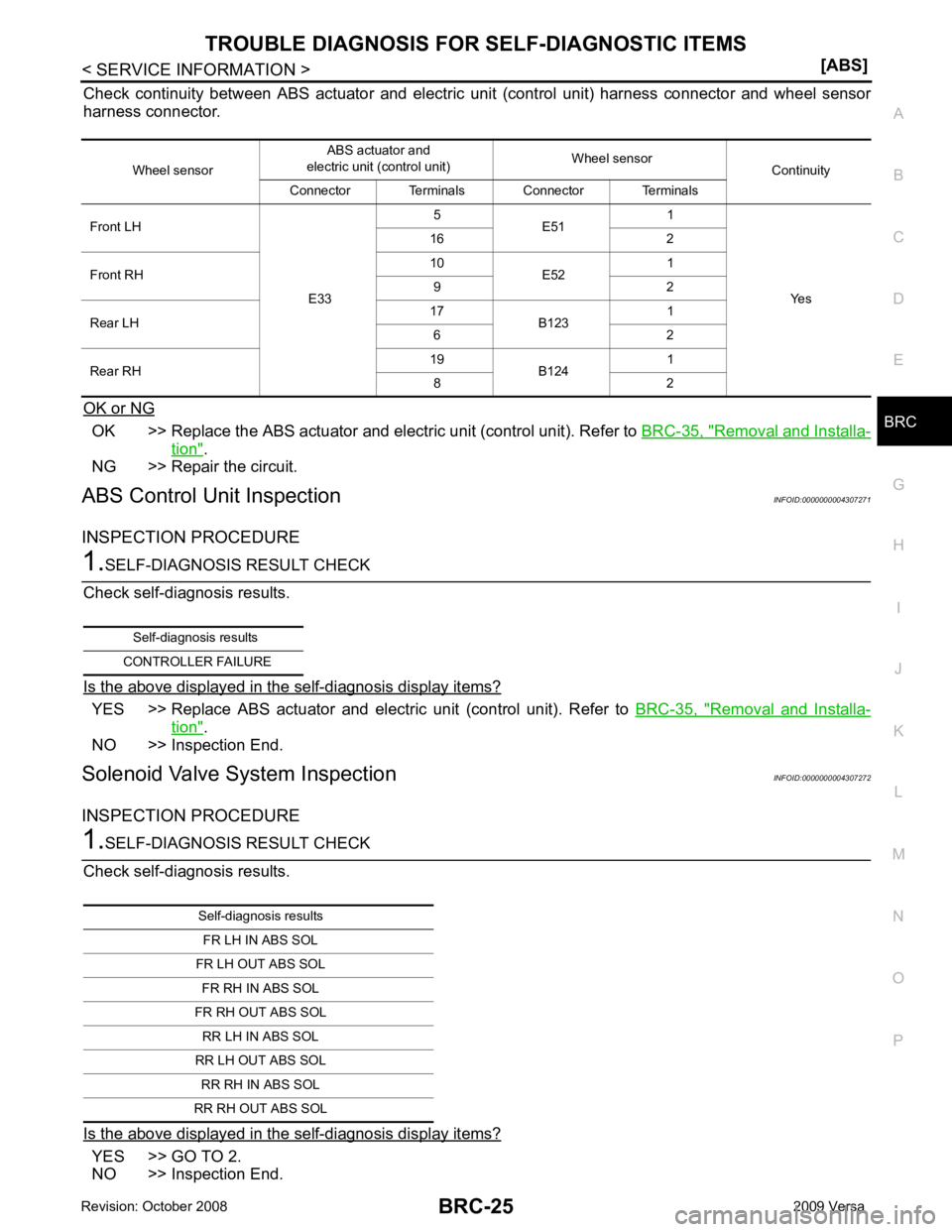

Check continuity between ABS actuator and electric

unit (control unit) harness connector and wheel sensor

harness connector.

OK or NG OK >> Replace the ABS actuator and electric unit (control unit). Refer to

BRC-35, " Removal and Installa-

tion " .

NG >> Repair the circuit.

ABS Control Unit Inspection INFOID:0000000004307271

INSPECTION PROCEDURE YES >> Replace ABS actuator and electr

ic unit (control unit). Refer to BRC-35, " Removal and Installa-

tion " .

NO >> Inspection End.

Solenoid Valve System Inspection INFOID:0000000004307272

INSPECTION PROCEDURE YES >> GO TO 2.

NO >> Inspection End. Wheel sensor

ABS actuator and

electric unit (control unit) Wheel sensor

Continuity

Connector Terminals Connector Terminals

Front LH

E335

E51 1

Yes

16 2

Front RH 10

E52 1

9 2

Rear LH 17

B123 1

6 2

Rear RH 19

B124 1

8 2 Self-diagnosis results

CONTROLLER FAILURE Self-diagnosis results

FR LH IN ABS SOL

FR LH OUT ABS SOL FR RH IN ABS SOL

FR RH OUT ABS SOL RR LH IN ABS SOL

RR LH OUT ABS SOL RR RH IN ABS SOL

RR RH OUT ABS SOL