NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 971 of 4331

CVT

N

O P

Optimize the line pressure and secondary pressure, dependi

ng on driving conditions, on the basis of the throt-

tle position, the engine speed, the primary pulley (input ) revolution speed, the secondary pulley (output) revo-

lution speed, the brake signal, the PNP switch signal, the lock-up signal, the voltage, the target gear ratio, the

fluid temperature, and the fluid pressure.

FEEDBACK CONTROL When controlling the normal fluid pressure or the sele cted fluid pressure, the secondary pressure can be set

more accurately by using the fluid pressure sensor to detect the secondary pressure and controlling the feed-

back.

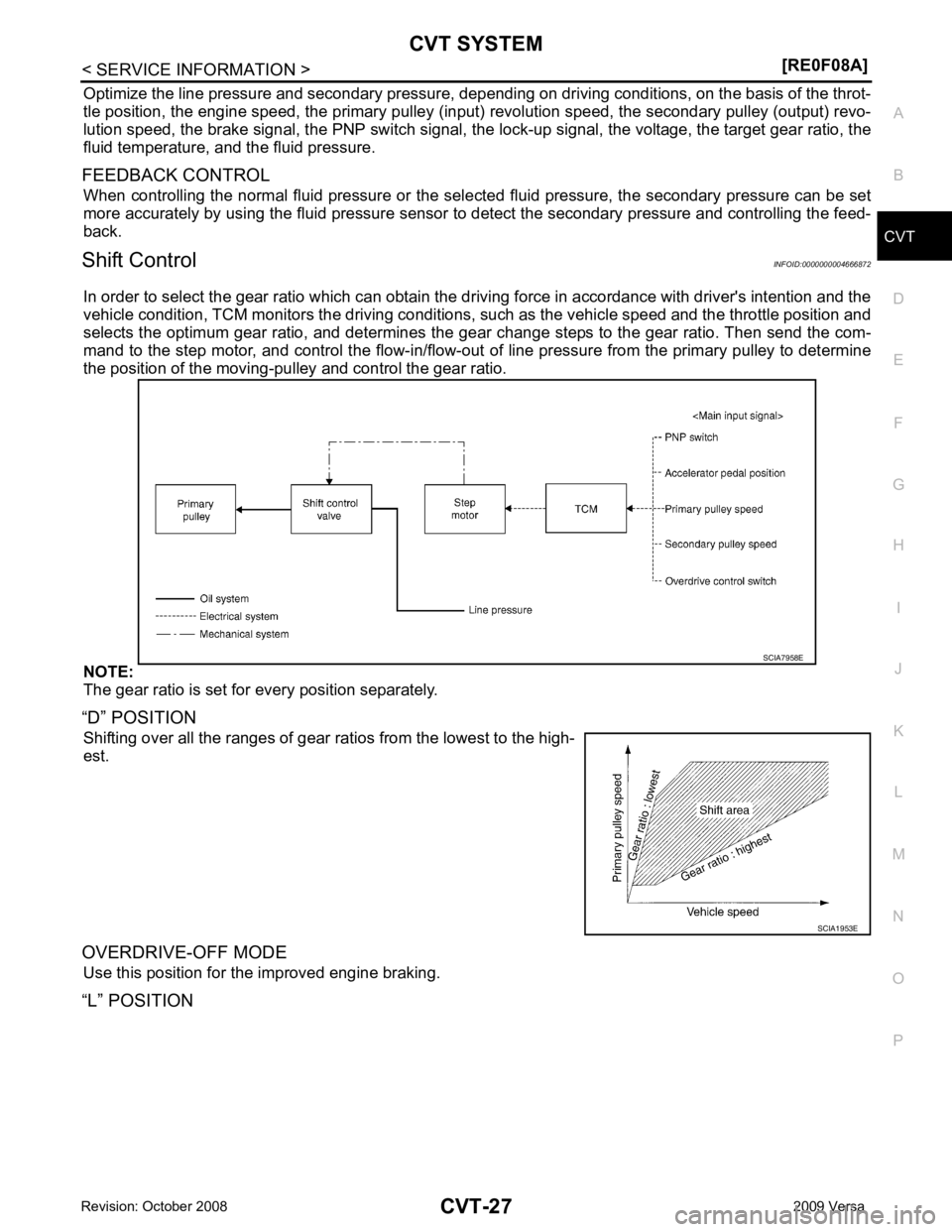

Shift Control INFOID:0000000004666872

In order to select the gear ratio which can obtain the dr iving force in accordance with driver's intention and the

vehicle condition, TCM monitors the driving conditions, such as the vehicle speed and the throttle position and

selects the optimum gear ratio, and determines the gear change steps to the gear ratio. Then send the com-

mand to the step motor, and control the flow-in/flow-out of line pressure from the primary pulley to determine

the position of the moving-pul ley and control the gear ratio.

NOTE:

The gear ratio is set for every position separately.

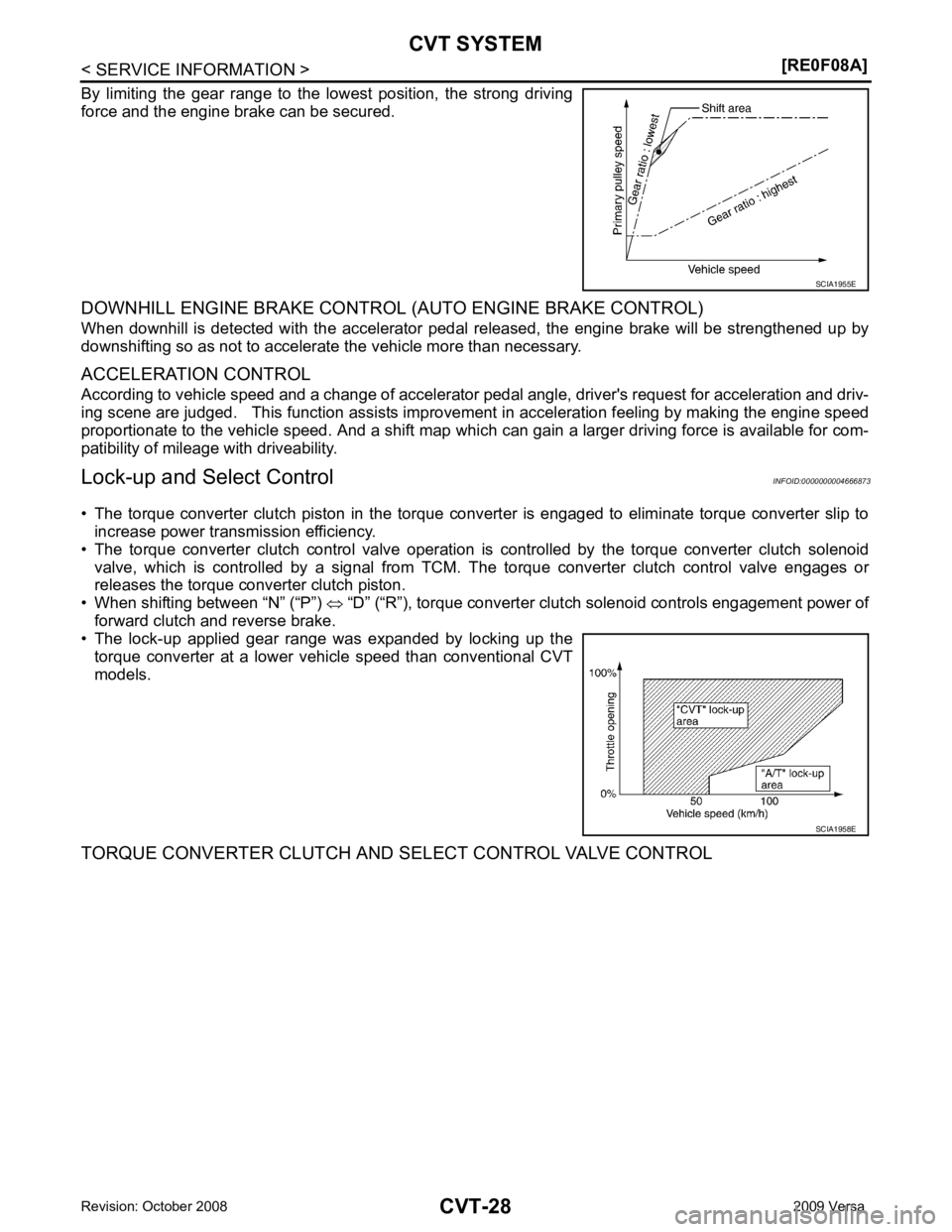

“D” POSITION Shifting over all the ranges of gear ra tios from the lowest to the high-

est.

OVERDRIVE-OFF MODE Use this position for the improved engine braking.

“L” POSITION

Page 972 of 4331

Page 973 of 4331

CVT

N

O P

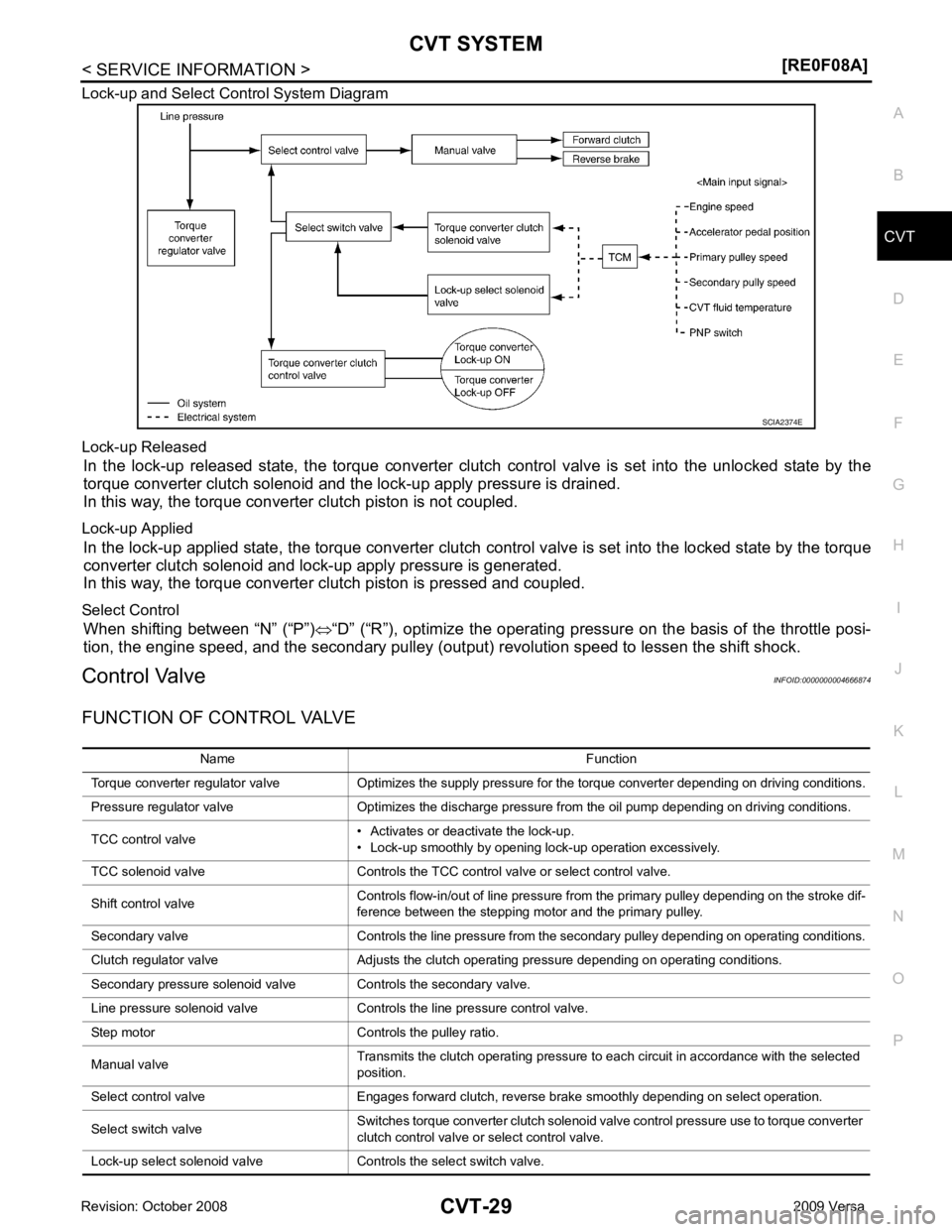

Lock-up and Select Control System Diagram

Lock-up Released In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the torque

converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

Select Control When shifting between “N” (“P”) ⇔“D” (“R”), optimize the operating pressure on the basis of the throttle posi-

tion, the engine speed, and the secondary pulley (out put) revolution speed to lessen the shift shock.

Control Valve INFOID:0000000004666874

FUNCTION OF CONTROL VALVE

Page 974 of 4331

" CONSULT-III Function (TRANSMISSION) " .

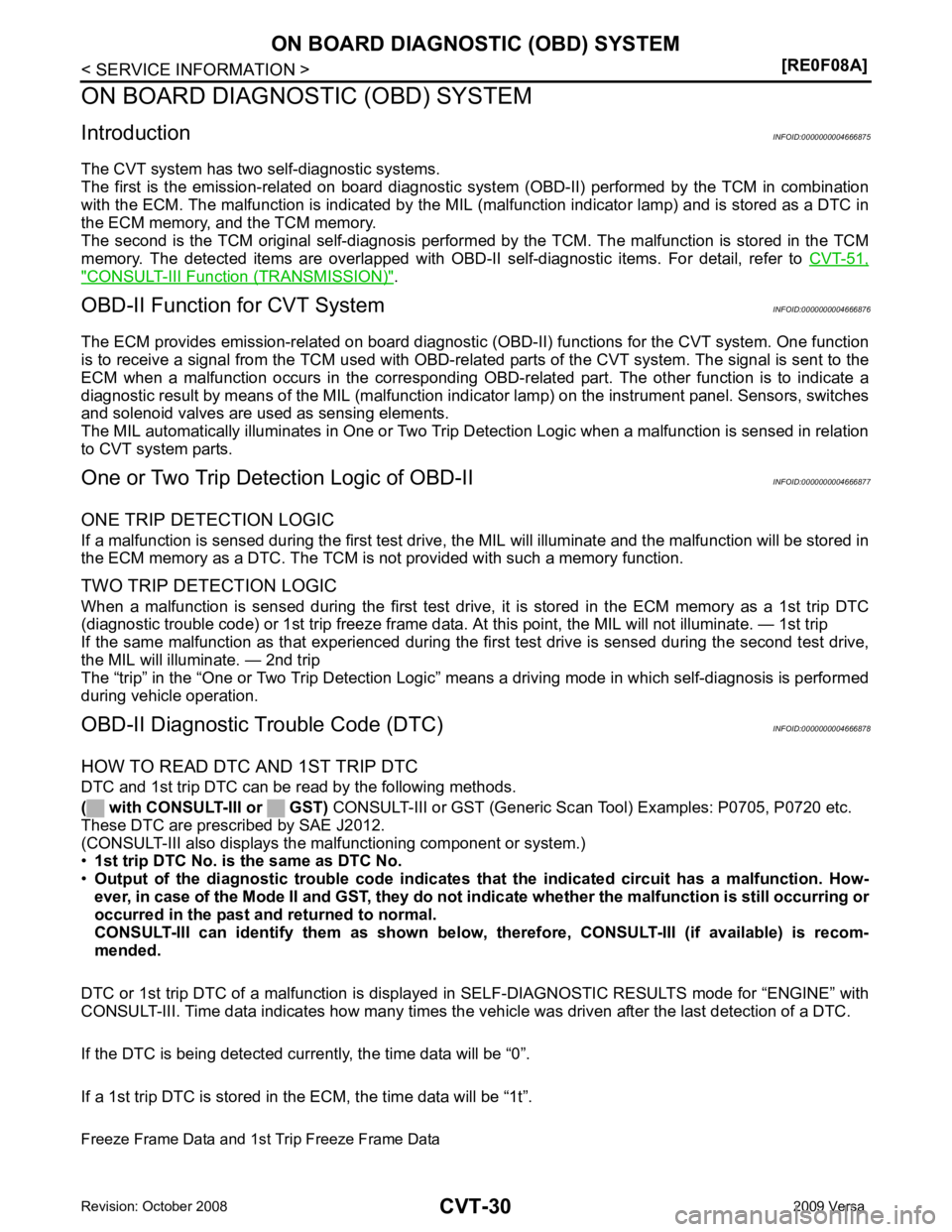

OBD-II Function for CVT System INFOID:0000000004666876

The ECM provides emission-related on board diagnostic (O BD-II) functions for the CVT system. One function

is to receive a signal from the TCM used with OBD-relat ed parts of the CVT system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indi cator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to CVT system parts.

One or Two Trip Detection Logic of OBD-II INFOID:0000000004666877

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC) INFOID:0000000004666878

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic troubl e code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”. Freeze Frame Data and 1st Trip Freeze Frame Data

Page 975 of 4331

CVT

N

O P

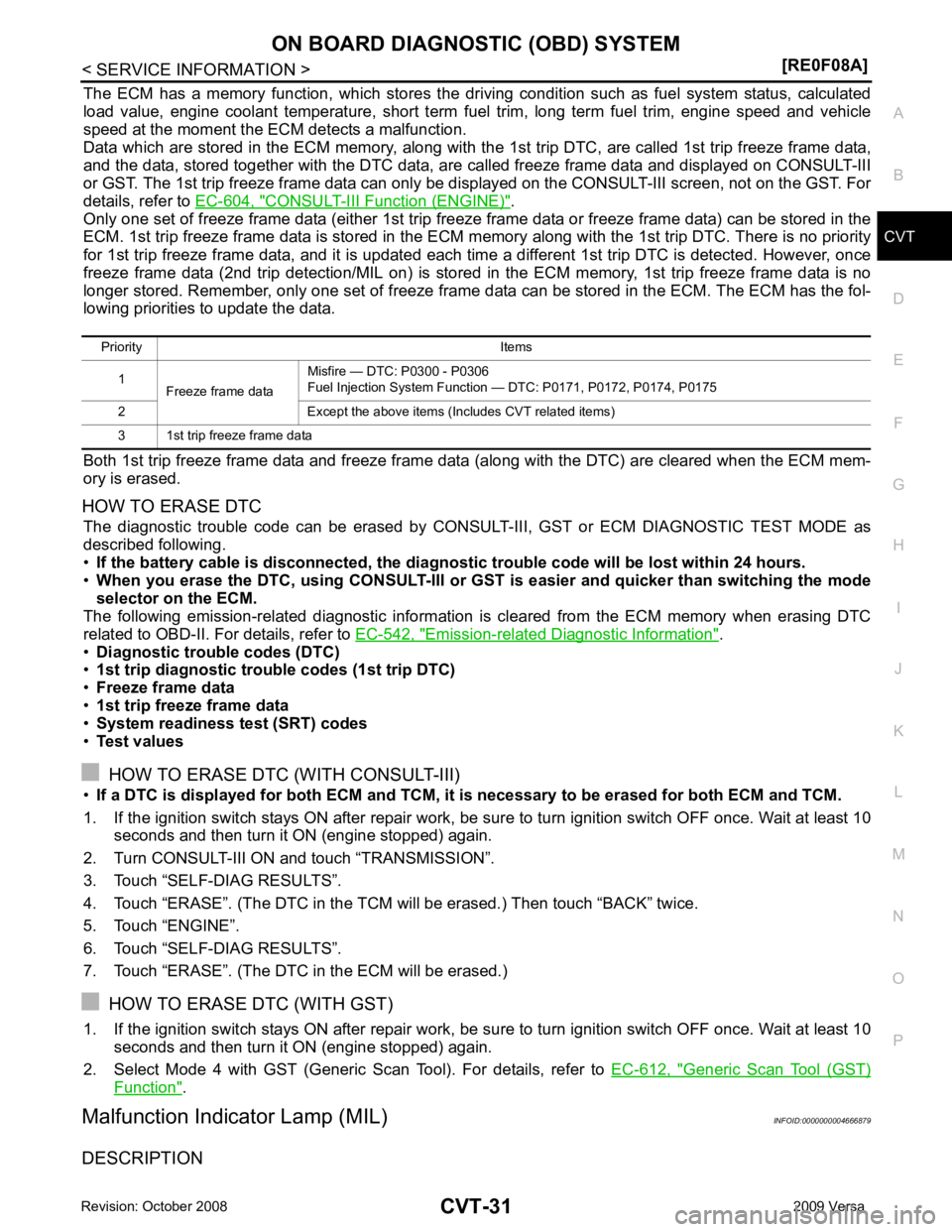

The ECM has a memory function, which stores the driv

ing condition such as fuel system status, calculated

load value, engine coolant temperature, short term f uel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-III

or GST. The 1st trip freeze frame data can only be di splayed on the CONSULT-III screen, not on the GST. For

details, refer to EC-604, " CONSULT-III Function (ENGINE) " .

Only one set of freeze frame data (either 1st trip freez e frame data or freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM me mory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data, and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame data (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC The diagnostic trouble code can be erased by CONSULT- III, GST or ECM DIAGNOSTIC TEST MODE as

described following.

• If the battery cable is disconnected, the diagnost ic trouble code will be lost within 24 hours.

• When you erase the DTC, using CONSULT-III or GS T is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-542, " Emission-related Diagnostic Information " .

• Diagnostic trouble codes (DTC)

• 1st trip diagnostic trouble codes (1st trip DTC)

• Freeze frame data

• 1st trip freeze frame data

• System readiness test (SRT) codes

• Test values

HOW TO ERASE DTC (WITH CONSULT-III)

• If a DTC is displayed for both ECM and TCM, it is necessary to be erased for both ECM and TCM.

1. If the ignition switch stays ON after repair work, be su re to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-III ON and touch “TRANSMISSION”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays ON after repair work, be su re to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Select Mode 4 with GST (Generic Scan Tool). For details, refer to EC-612, " Generic Scan Tool (GST)

Function " .

Malfunction Indicator Lamp (MIL) INFOID:0000000004666879

DESCRIPTION Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0306

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes CVT related items)

3 1st trip freeze frame data

Page 976 of 4331

![NISSAN LATIO 2009 Service Repair Manual CVT-32< SERVICE INFORMATION >

[RE0F08A]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with- out the engine NISSAN LATIO 2009 Service Repair Manual CVT-32< SERVICE INFORMATION >

[RE0F08A]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with- out the engine](/img/5/57359/w960_57359-975.png)

CVT-32< SERVICE INFORMATION >

[RE0F08A]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with- out the engine running. This is a bulb check.

• If the MIL does not light up, refer to DI-20, " Schematic " , or see

EC-1010, " Wiring Diagram " .

2. When the engine is started, the MIL should go off. If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction. SEF217U

Page 977 of 4331

CVT

N

O P

TROUBLE DIAGNOSIS

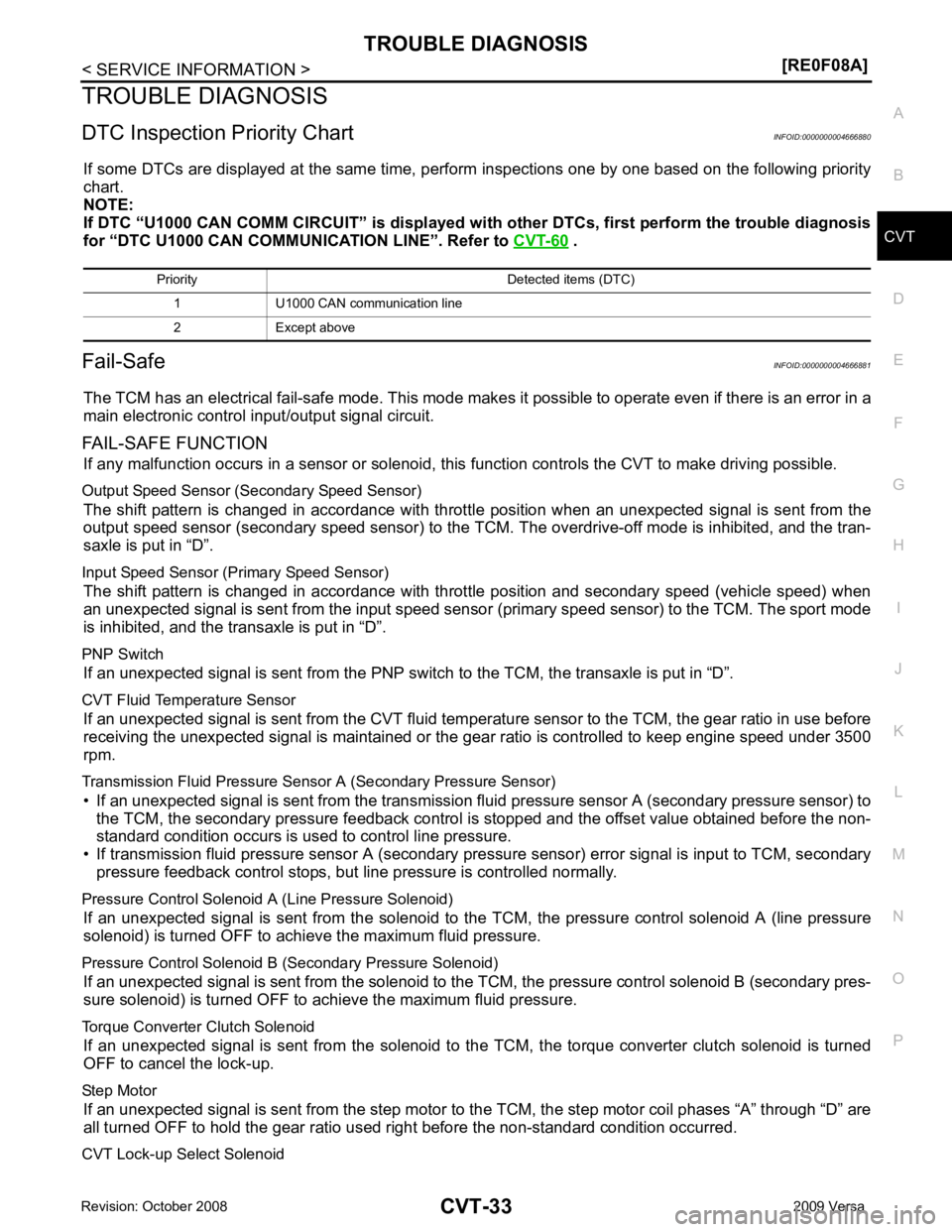

DTC Inspection Priority Chart INFOID:0000000004666880

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-60 .

Fail-Safe INFOID:0000000004666881

The TCM has an electrical fail-safe mode. This mode make s it possible to operate even if there is an error in a

main electronic control input/output signal circuit.

FAIL-SAFE FUNCTION If any malfunction occurs in a sensor or solenoid, th is function controls the CVT to make driving possible.

Output Speed Sensor (Secondary Speed Sensor) The shift pattern is changed in accordance with throttle position when an unexpected signal is sent from the

output speed sensor (secondary speed sensor) to the TCM. The overdrive-off mode is inhibited, and the tran-

saxle is put in “D”.

Input Speed Sensor (Primary Speed Sensor) The shift pattern is changed in accordance with throttle position and secondary speed (vehicle speed) when

an unexpected signal is sent from the input speed sensor (primary speed sensor) to the TCM. The sport mode

is inhibited, and the transaxle is put in “D”.

PNP Switch If an unexpected signal is sent from the PNP switch to the TCM, the transaxle is put in “D”.

CVT Fluid Temperature Sensor If an unexpected signal is sent from the CVT fluid temper ature sensor to the TCM, the gear ratio in use before

receiving the unexpected signal is maintained or the gear ratio is controlled to keep engine speed under 3500

rpm.

Transmission Fluid Pressure Sens or A (Secondary Pressure Sensor)

• If an unexpected signal is sent from the transmission fl uid pressure sensor A (secondary pressure sensor) to

the TCM, the secondary pressure feedback control is stopped and the offset value obtained before the non-

standard condition occurs is used to control line pressure.

• If transmission fluid pressure sensor A (secondary pre ssure sensor) error signal is input to TCM, secondary

pressure feedback control stops, but line pressure is controlled normally.

Pressure Control Solenoid A (Line Pressure Solenoid) If an unexpected signal is sent from the solenoid to t he TCM, the pressure control solenoid A (line pressure

solenoid) is turned OFF to achieve the maximum fluid pressure.

Pressure Control Solenoid B (Secondary Pressure Solenoid) If an unexpected signal is sent from the solenoid to t he TCM, the pressure control solenoid B (secondary pres-

sure solenoid) is turned OFF to achieve the maximum fluid pressure.

Torque Converter Clutch Solenoid If an unexpected signal is sent from the solenoid to t he TCM, the torque converter clutch solenoid is turned

OFF to cancel the lock-up.

Step Motor If an unexpected signal is sent from the step motor to the TCM, the step motor coil phases “A” through “D” are

all turned OFF to hold the gear ratio used right before the non-standard condition occurred.

CVT Lock-up Select Solenoid Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 978 of 4331

![NISSAN LATIO 2009 Service Repair Manual CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power NISSAN LATIO 2009 Service Repair Manual CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power](/img/5/57359/w960_57359-977.png)

CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power Supply (Memory Back-up)

Transaxle assembly is protected by limiting the engine torque when the memory back-up power supply (for

controlling) from the battery is not supplied to TCM. Normal statues is restored when turning the ignition switch

OFF to ON after the normal power supply.

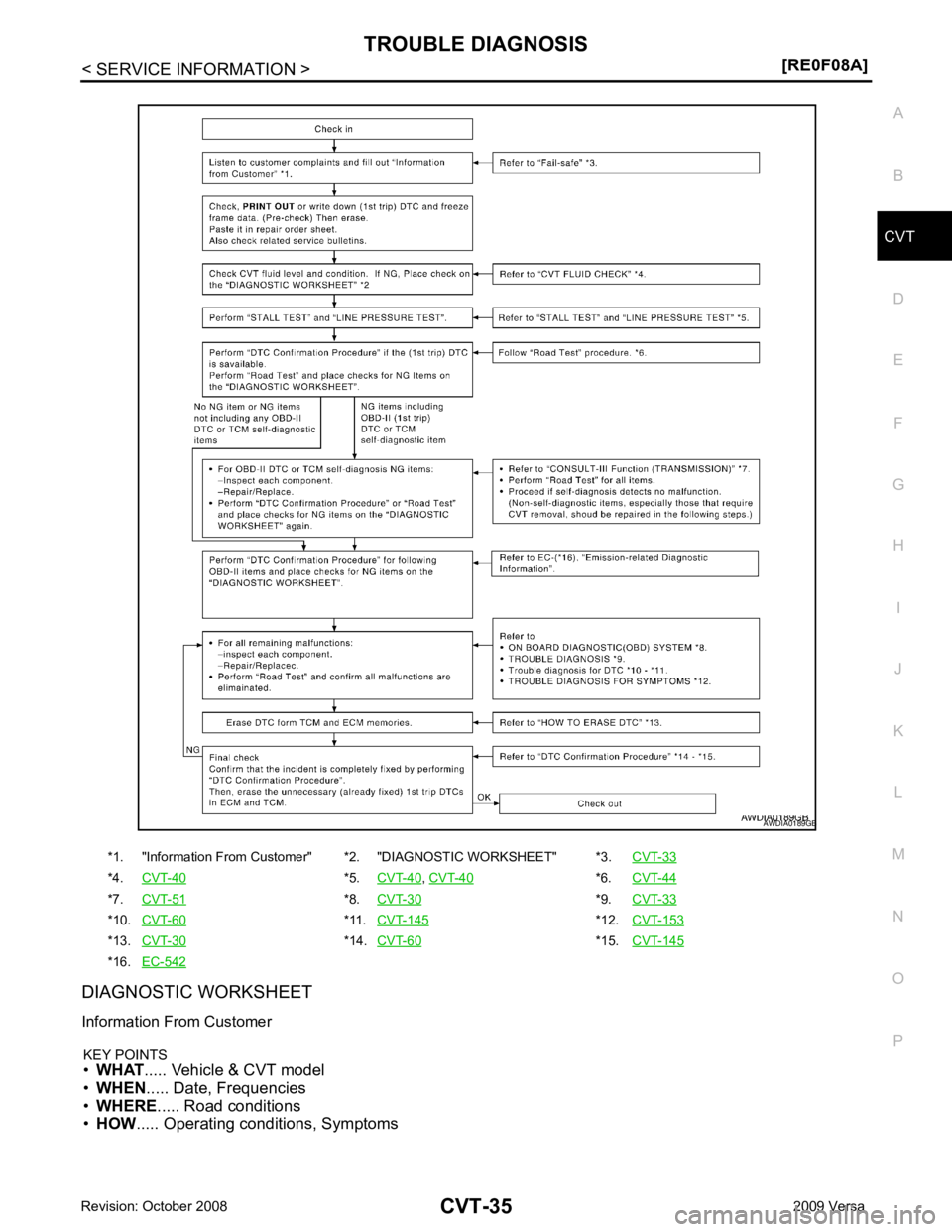

How to Perform Trouble Diagnosis for Quick and Accurate Repair INFOID:0000000004666882

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, PNP switch and provides shift control or lock-up

control via CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

CVT system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve mal-

function, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Mo st intermittent errors are caused

by poor electric connections or improper wiring. In this case, careful

checking of suspected circuits ma y help prevent the replacement of

good parts.

A visual check only may not find the cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “DIAGNOSTIC WORKSHEET” as

shown on the example (Refer to "Diagnostic Worksheet Chart" )

should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

WORK FLOW

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malf unction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Make good use of the two sheets provided, "Informati on From Customer" and "Diagnostic Worksheet Chart" ,

to perform the best troubleshooting possible.

Work Flow Chart SAT631IB

SAT632I

SEF234G

Page 979 of 4331

CVT

N

O P

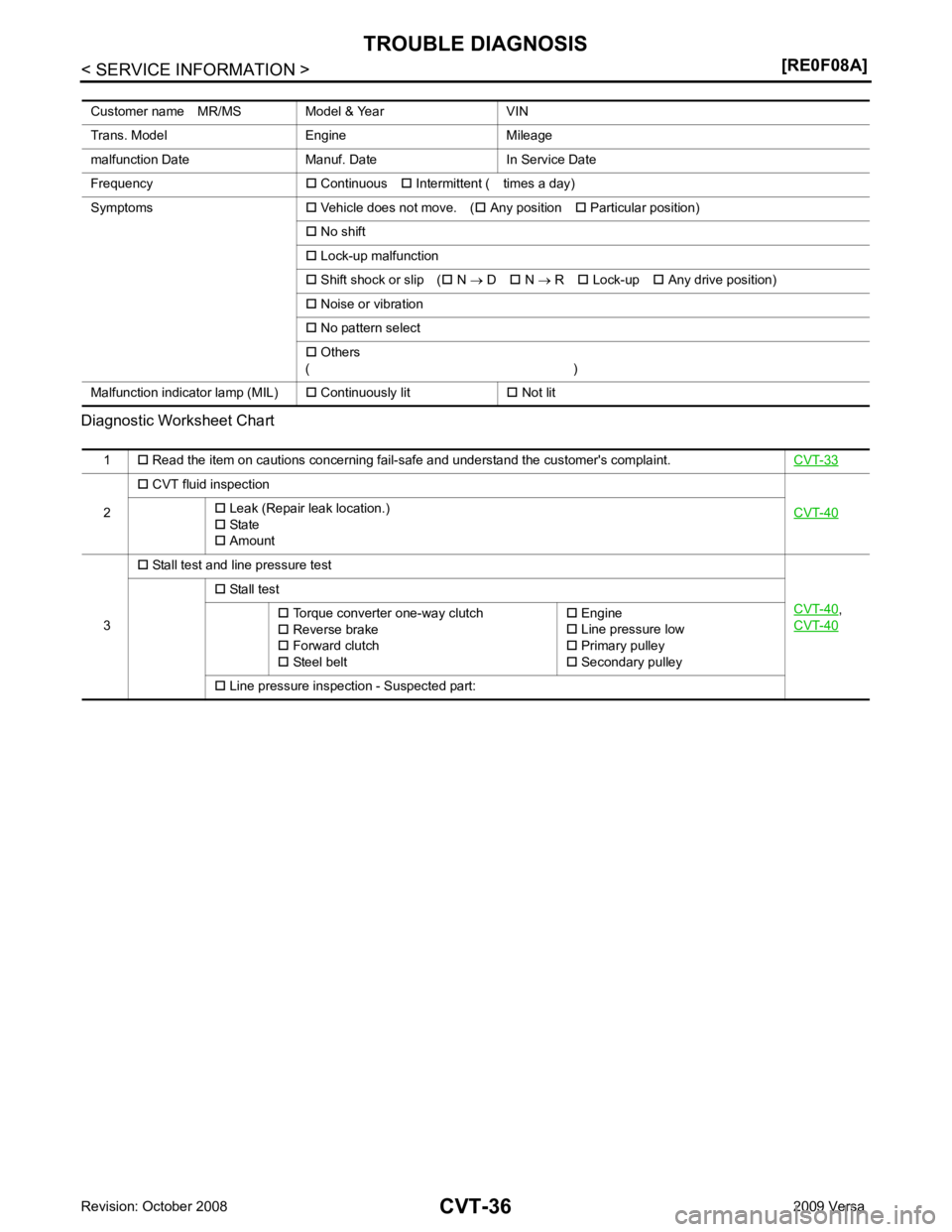

DIAGNOSTIC WORKSHEET

Information From Customer

KEY POINTS

• WHAT ..... Vehicle & CVT model

• WHEN ..... Date, Frequencies

• WHERE ..... Road conditions

• HOW ..... Operating conditions, Symptoms

*1. "Information From Customer" *2. "DIAGNOSTIC WORKSHEET" *3.

CVT-33*4.

CVT-40 *5.

CVT-40 ,

CVT-40 *6.

CVT-44 *7.

CVT-51 *8.

CVT-30 *9.

CVT-33 *10.

CVT-60 *11.

CVT-145 *12.

CVT-153 *13.

CVT-30 *14.

CVT-60 *15.

CVT-145 *16.

EC-542 B

Page 980 of 4331

1

�† Read the item on cautions concerning fail-safe and understand the customer's complaint. CVT-332

�†

CVT fluid inspection

CVT-40 ,

CVT-40